Patents

Literature

32results about How to "Good light penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

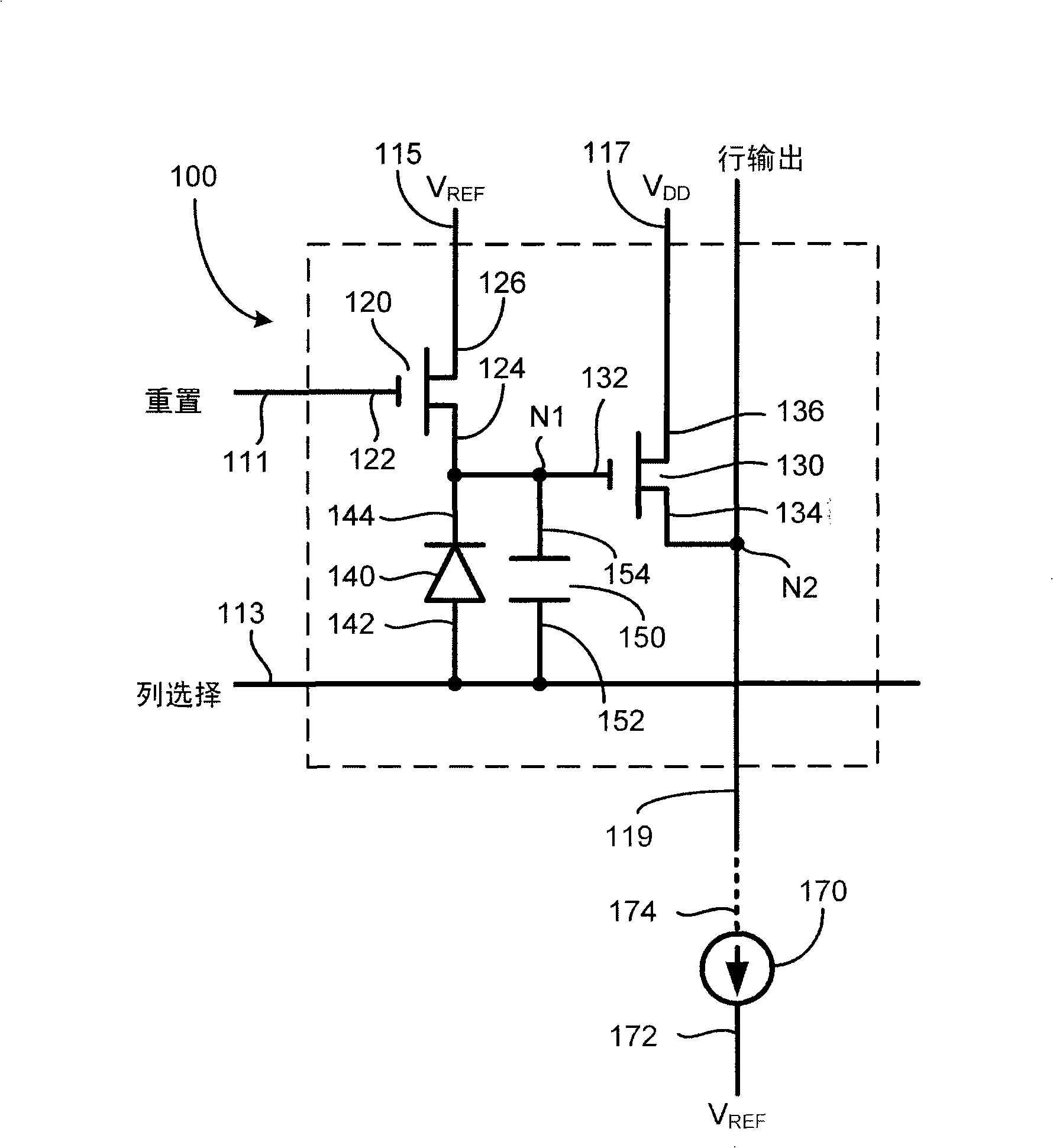

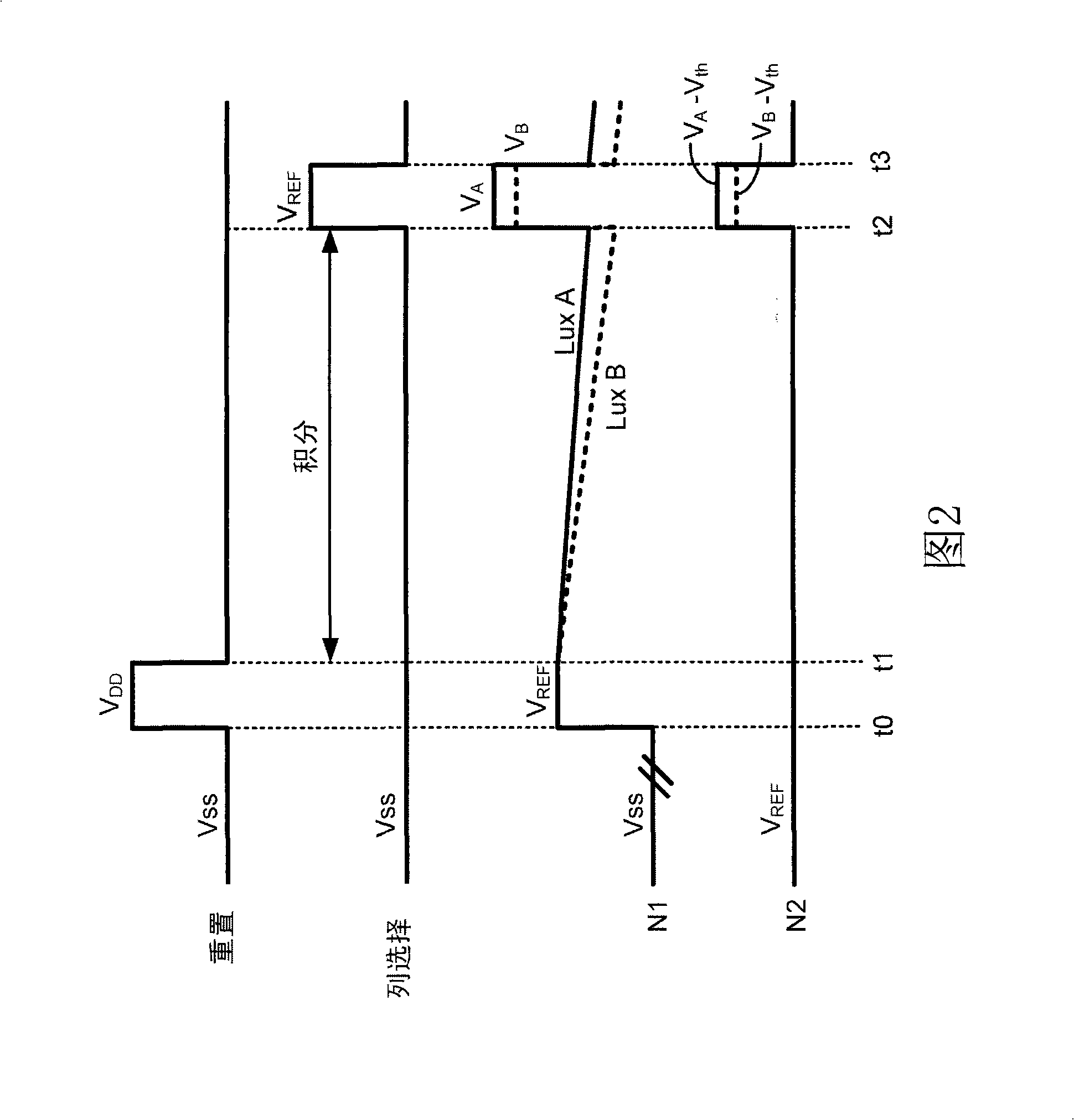

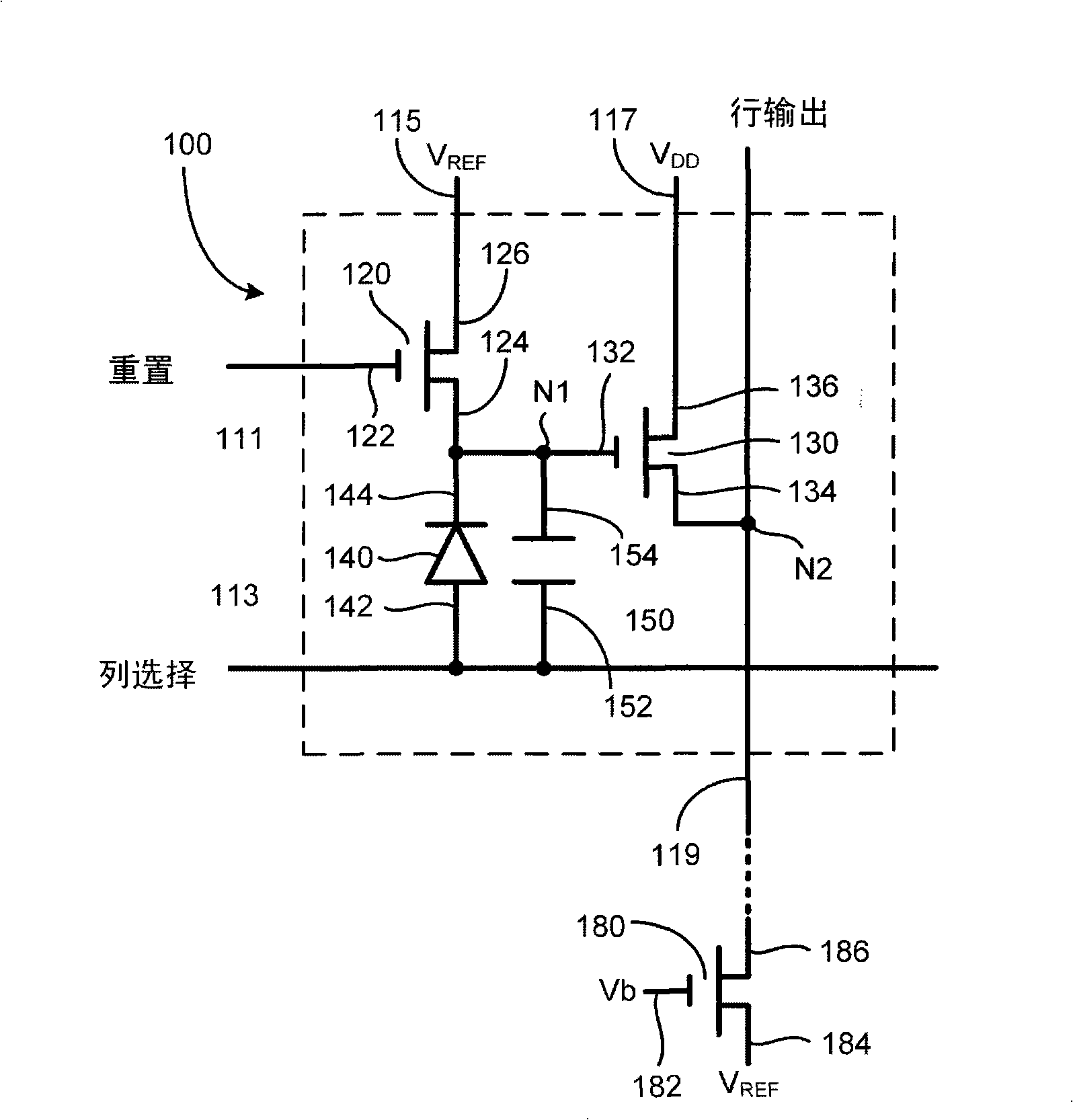

Active type pixel sensor circuit and its operation method

ActiveCN101515594AGood light penetrationReduce power consumptionTelevision system detailsTelevision system scanning detailsSiliconTransistor

The invention relates to an active type pixel sensor circuit and its operation method. The active type pixel sensor circuit comprises reset transistor, highly oxidized silicon optical sensor and read-out transistor. The reset transistor has grid, source and drain; the highly oxidized silicon optical sensor has anode and cathode and the anode and cathode are electrically coupled to source of reset transistor; the read-out transistor has source, drain and grid which is electrically coupled to cathode of high oxidized silicon optical sensor.

Owner:AU OPTRONICS CORP

Touch screen and driving method thereof

ActiveCN101937279ASimple structureWith multi-touch operationConductive layers on insulating-supportsNanoinformaticsOptoelectronicsPhysics

Owner:INNOCOM TECH (SHENZHEN) CO LTD +1

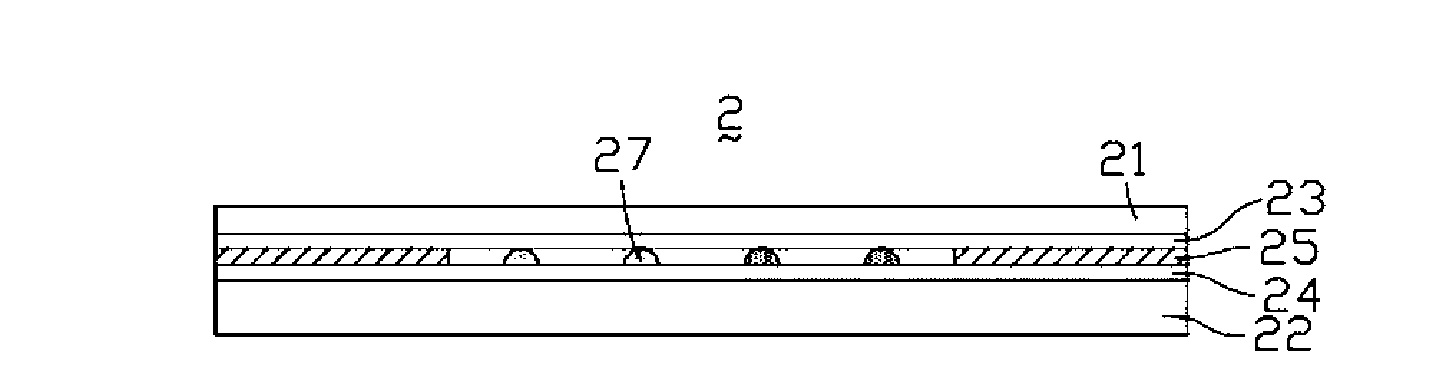

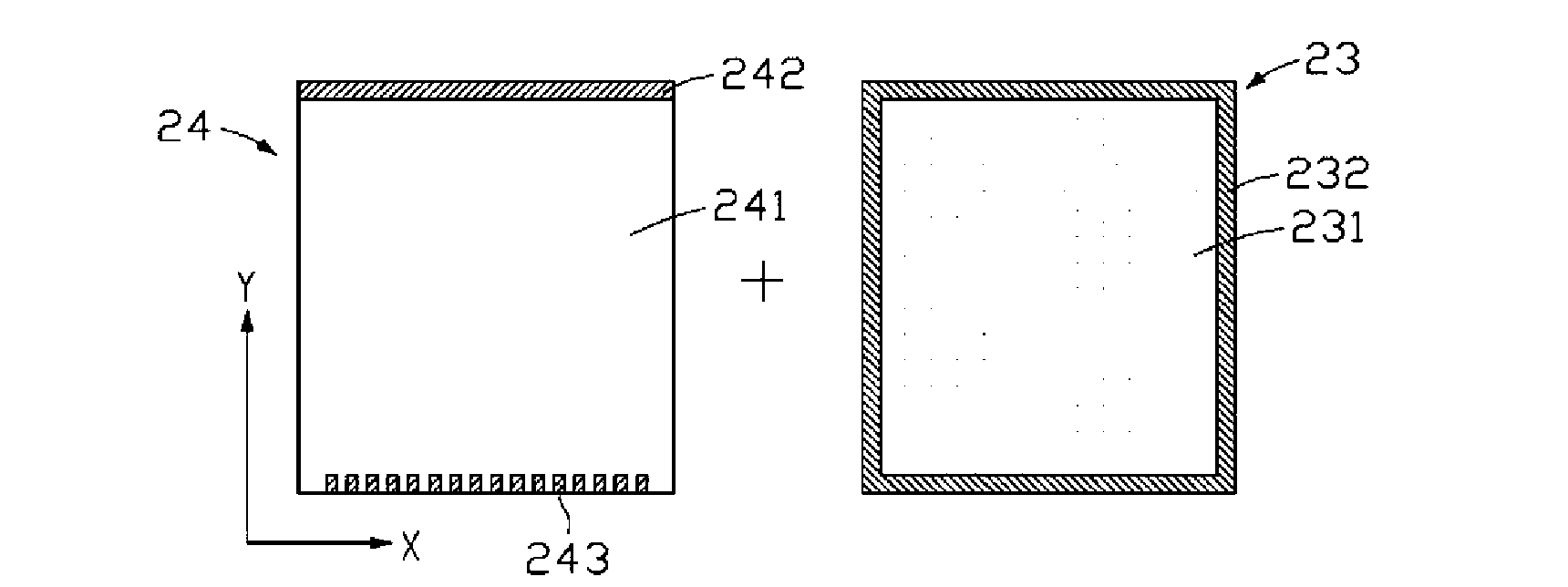

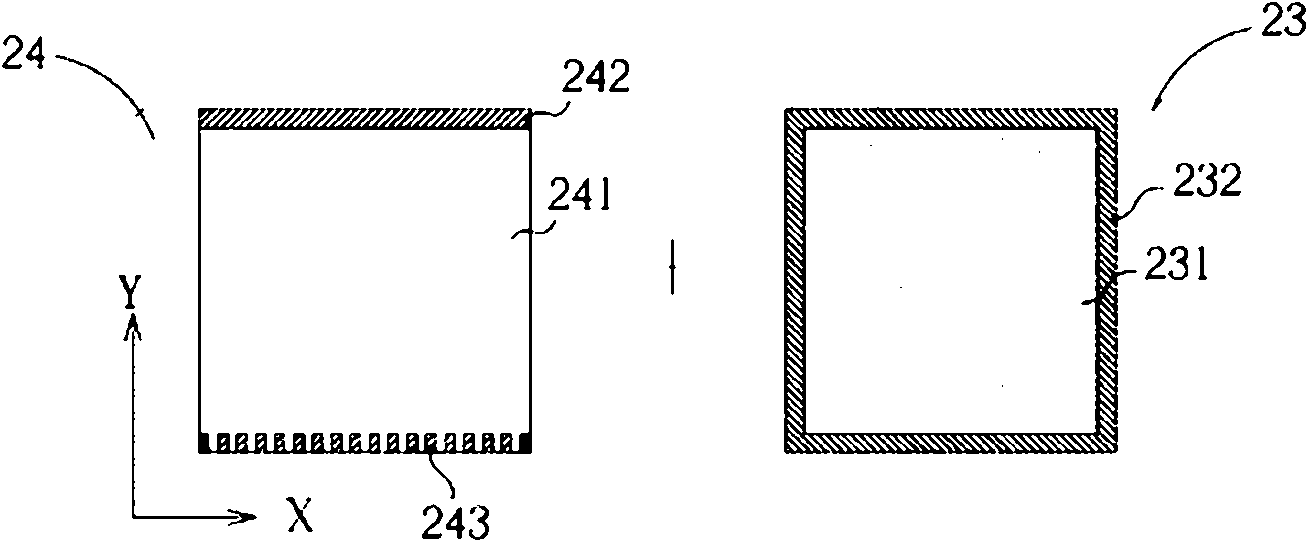

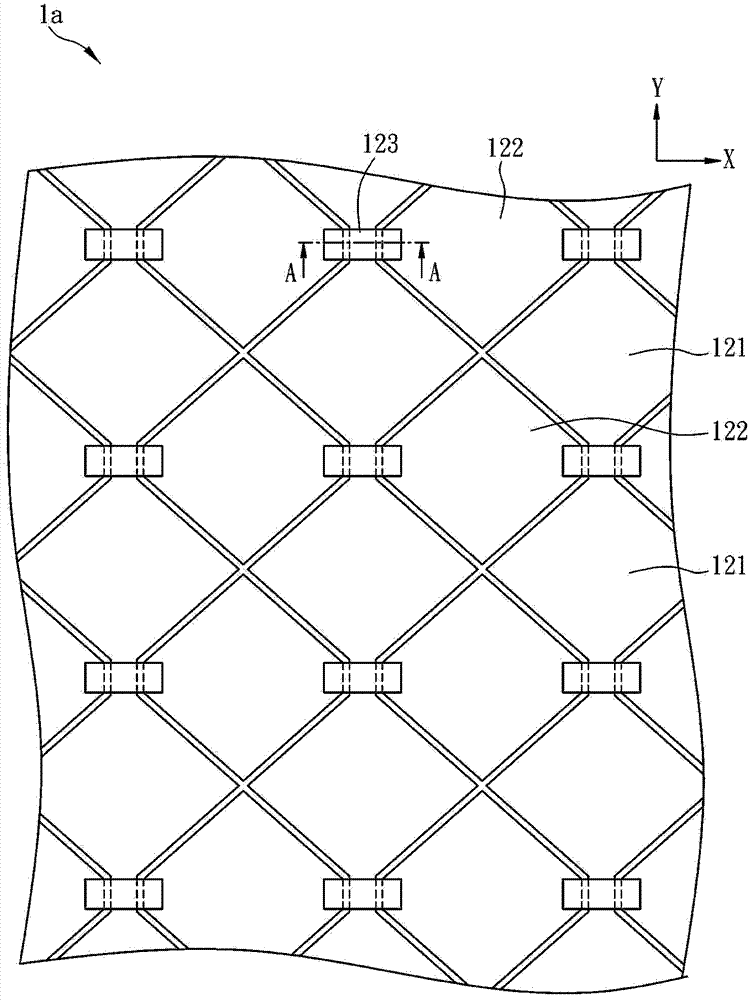

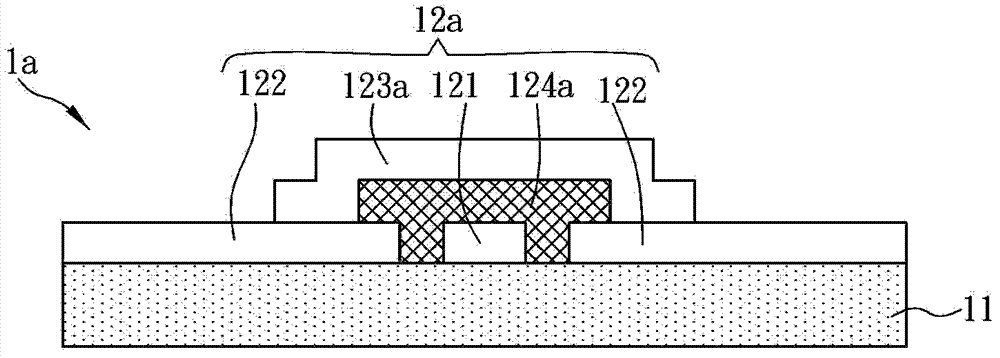

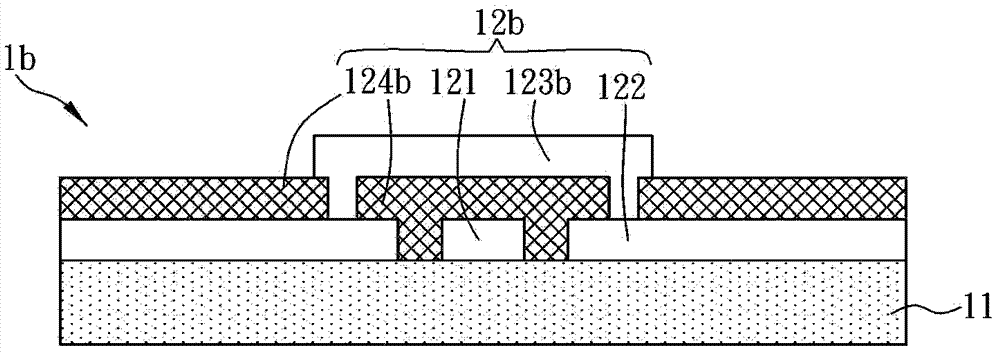

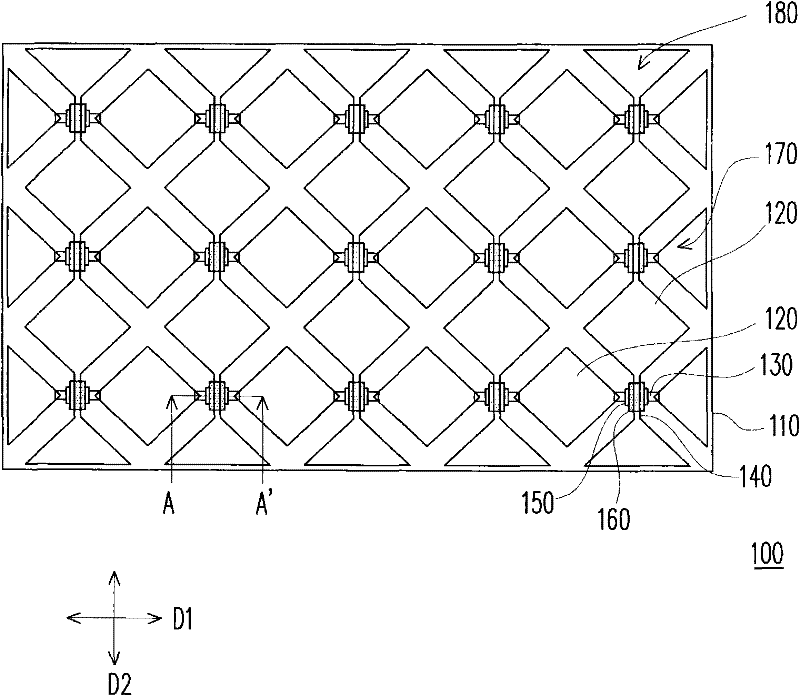

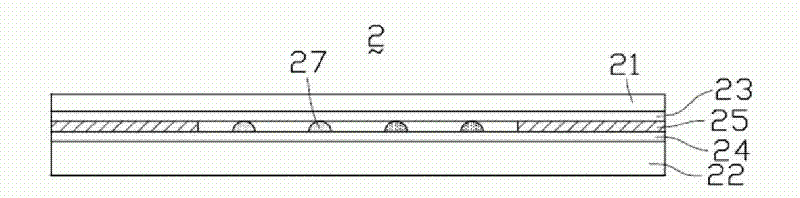

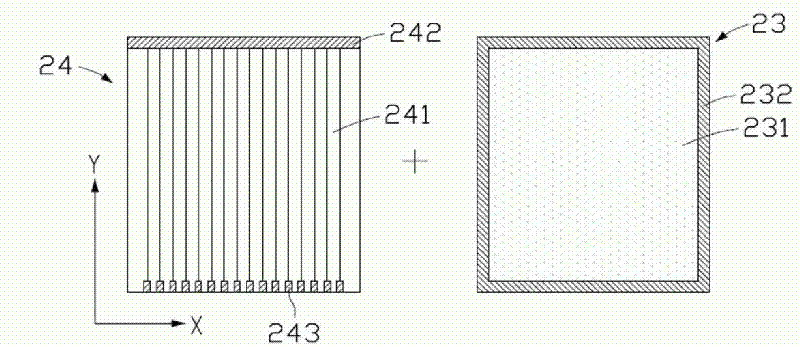

Touch panel and manufacturing method thereof

InactiveCN101699378AImprove optical qualityGood light penetrationInput/output processes for data processingTouch panelElectrical and Electronics engineering

The invention provides a touch panel, which comprises a substrate, a plurality of sensing pads, a plurality of first bridge connectors, a plurality of second bridge connectors, a plurality of first insulation patterns and a plurality of second insulation patterns. The sensing pads are arranged on the substrate. The first bridge connectors are electrically connected in series with a part of sensing pads to form a plurality of first sensing series, and extend along a first direction. The second bridge connectors are electrically connected in series with other sensing pads to form a plurality of second sensing series. The first bridge connectors are positioned between the second bridge connectors and the substrate, and each second bridge connector extends along a second direction, wherein the first direction is not parallel with the second direction. The first insulation patterns are arranged between the first bridge connectors and the second bridge connectors and expose the sensing pads. The second insulation patterns cover the second bridge connectors and expose the sensing pads.

Owner:CENTURY DISPLAY (SHENZHEN) CO LTD

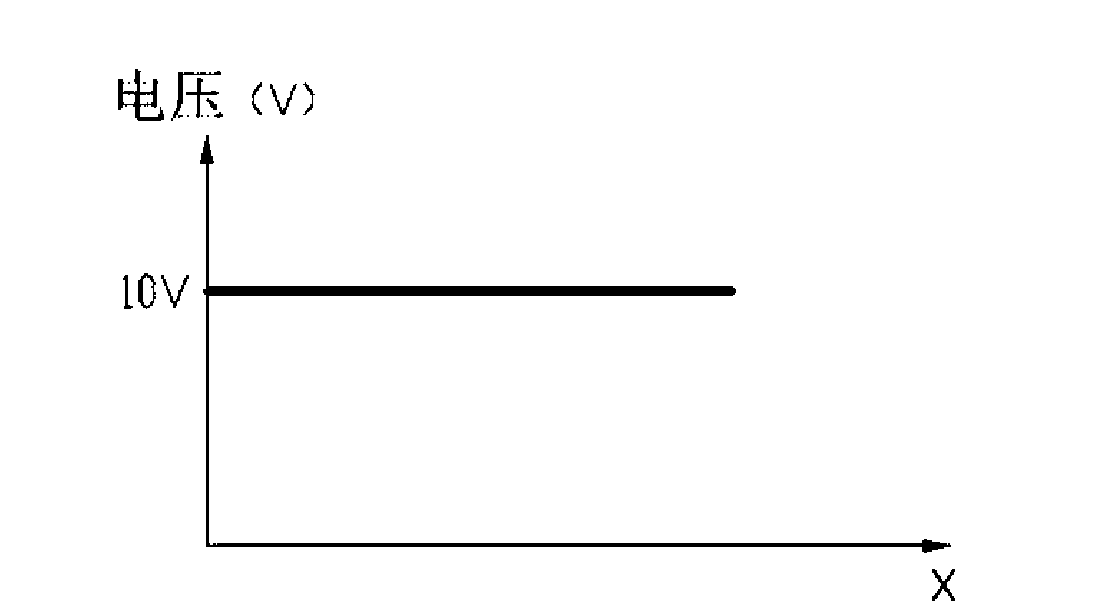

Method for positioning touch screen

ActiveCN101943967ASimple structureIncreased durabilityInput/output processes for data processingTouchscreenComputer science

The invention relates to a method for positioning a touch screen. The method comprises the following steps of: providing a touch screen comprising a conducting layer with impedance anisotropy and a plurality of spaced exploring electrodes arranged at one side edge of the conducting layer; providing a first voltage for the conducting layer; when the touch screen is contacted, providing a second voltage for the conducting layer, wherein the application point of the second voltage is defined to be a touch point; sequentially measuring the voltage of the plurality of exploring electrodes and finding out relative extreme voltage and the voltage of an exploring electrode nearest to the extreme voltage; and determining a position coordinate of the touch point on the conducting layer according to the measured extreme voltage and the exploring electrode position with the nearest exploring voltage. The manufacture process and the driving method of the touch screen are both simpler, and operations of a plurality of touch points can be simultaneously carried out.

Owner:INNOCOM TECH (SHENZHEN) CO LTD +1

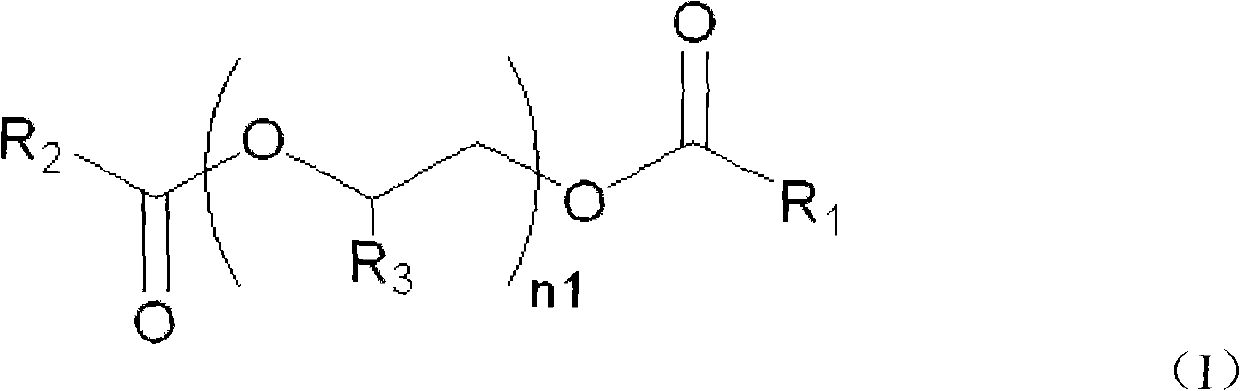

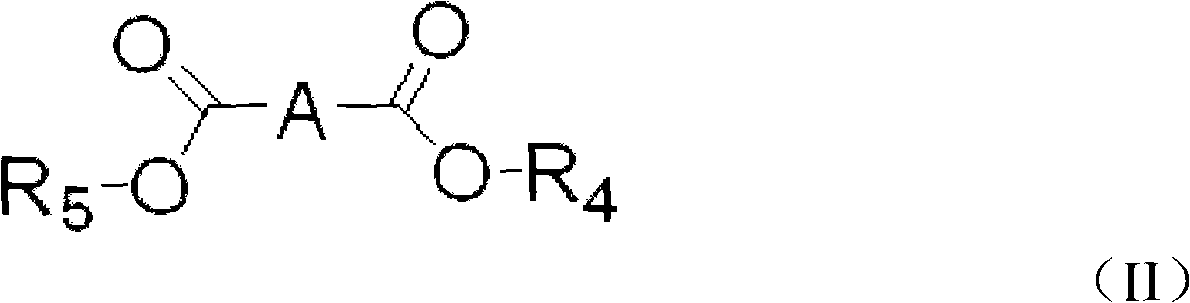

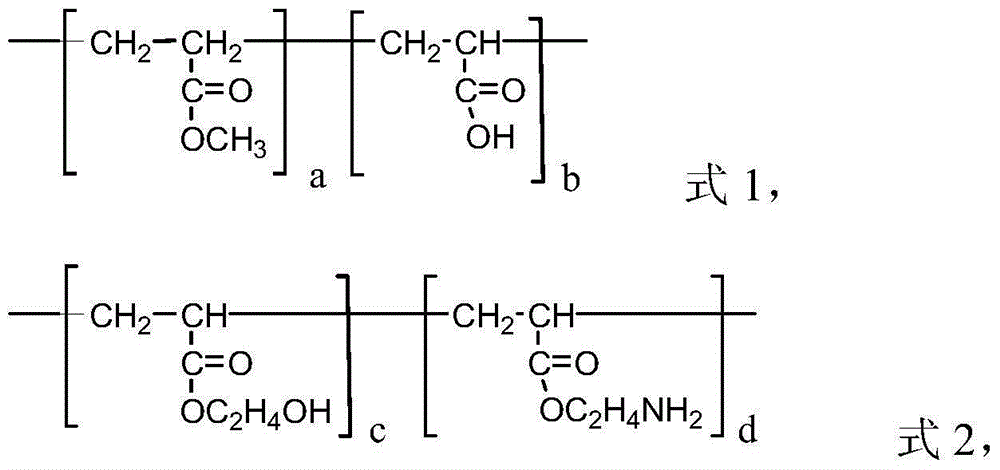

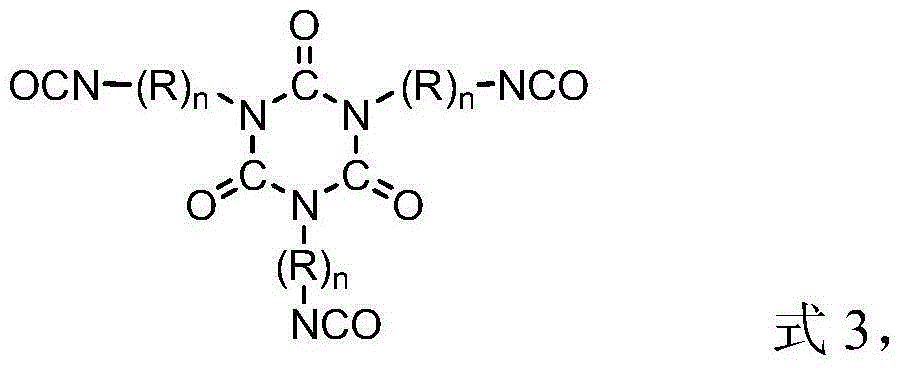

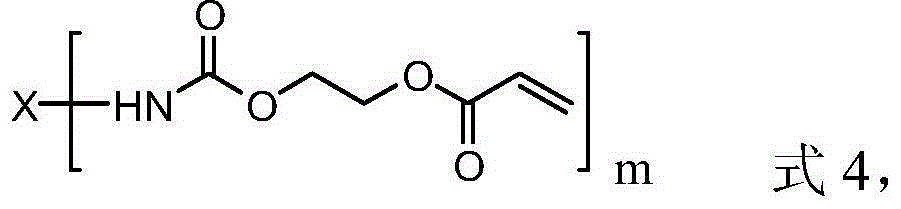

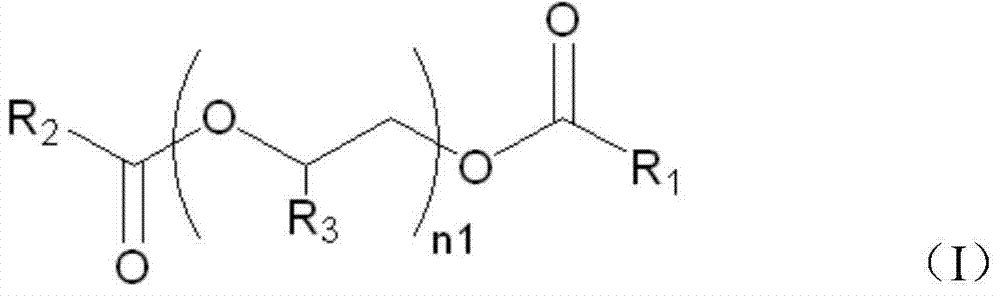

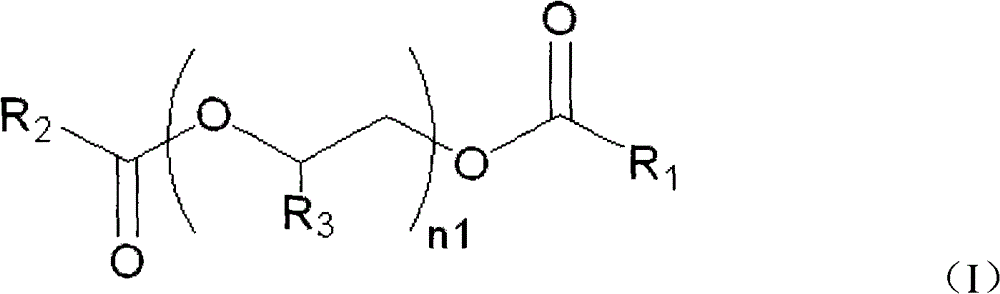

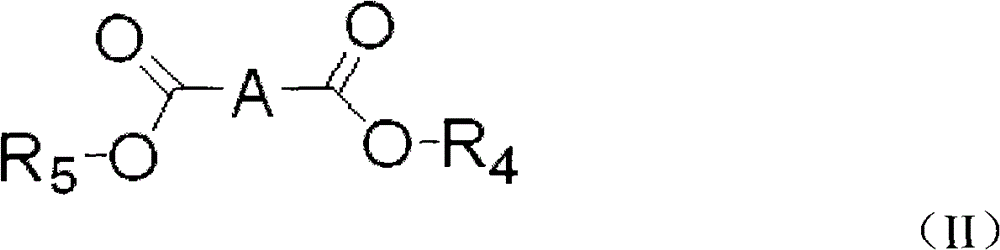

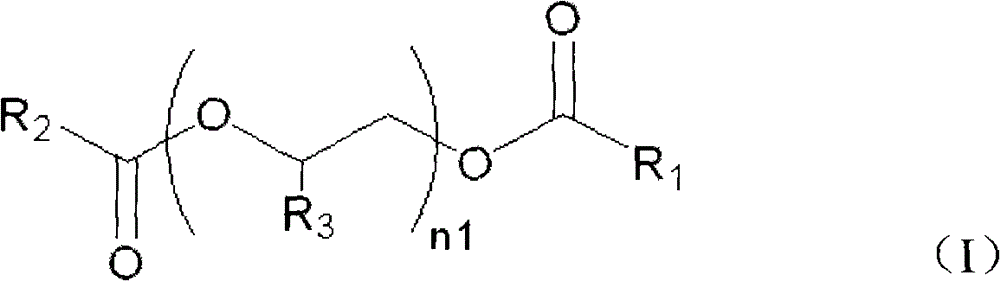

Acrylic acid series adhesive component and uses thereof

ActiveCN102417795AGood light penetrationChange propertiesNon-macromolecular adhesive additivesStatic indicating devicesPolymer scienceOligomer

The invention relates to an acrylic acid series adhesive component and the uses thereof. The component includes: (a) at least one acrylic acid series oligomer containing unsaturated group, acrylic acid series polymer containing one, two, or three kinds of hydroxyl group, amido group, and carboxylic acid group, or a mixture of acrylic acid series oligomer and acrylic acid series polymer; (b) optical monomer; (c) optical initiator; (d) plasticizer which includes compounds in formula (I) or (II). The component can be used as the adhesive of the optical laminated board, can effectively reduce the sectional difference and avoid bubble generation. The component has excellent heavy industrial performance and light penetrability, and is especially suitable for the production of optical laminated board of touch panel display or 3D display.

Owner:ETERNAL MATERIALS CO LTD

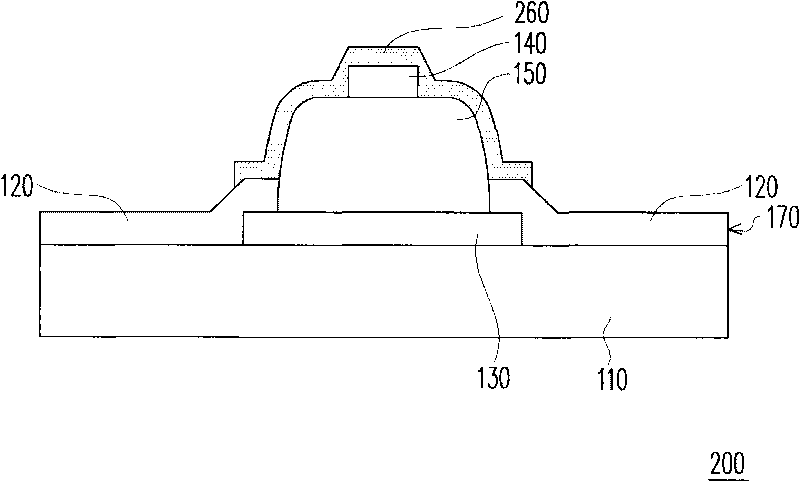

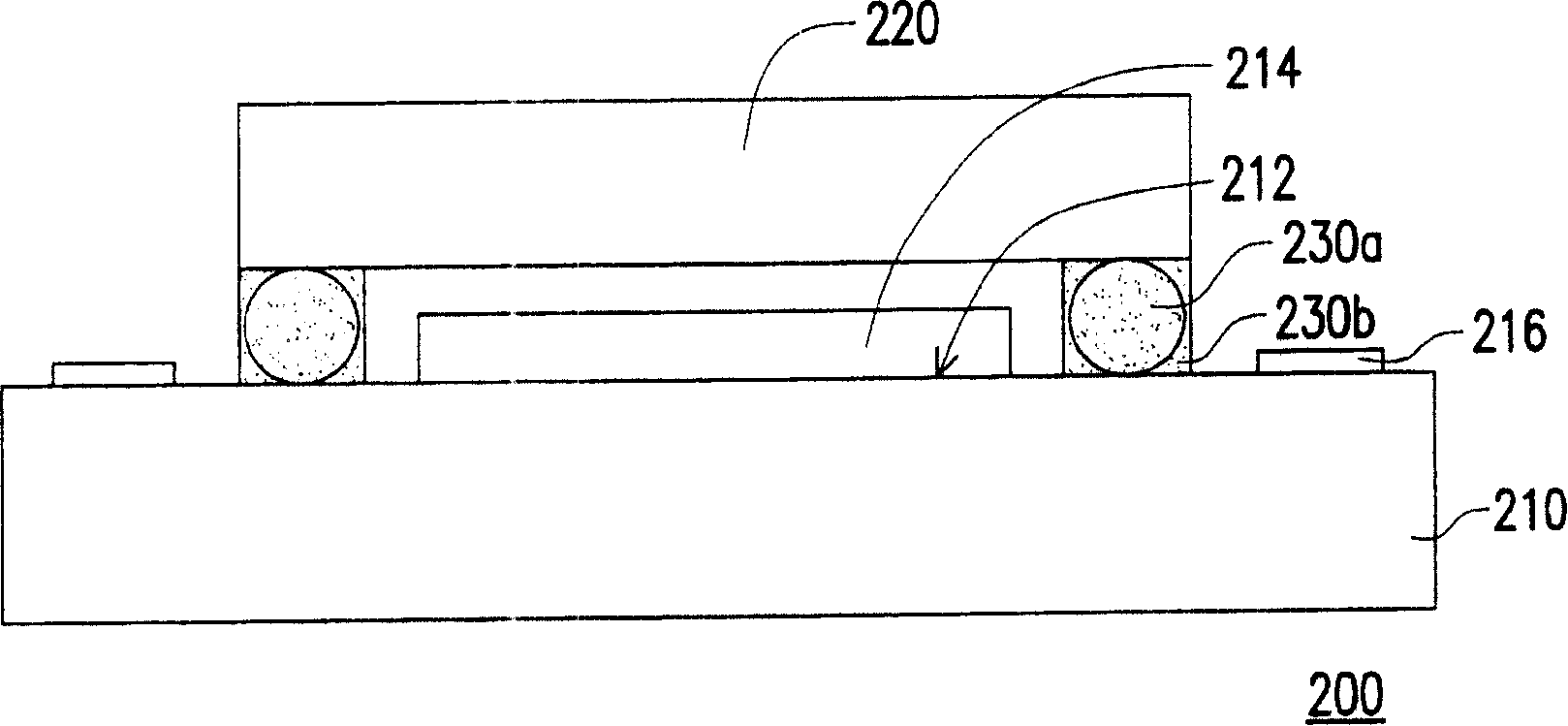

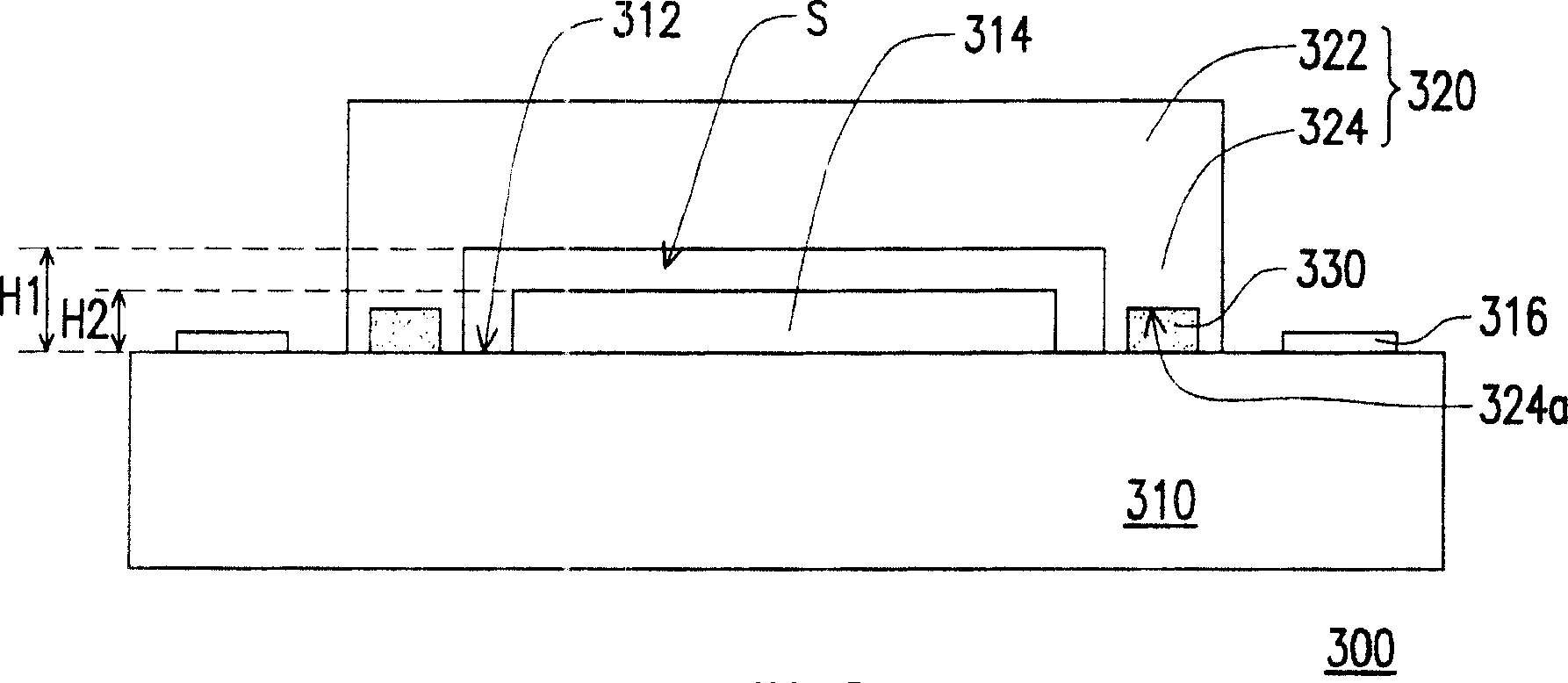

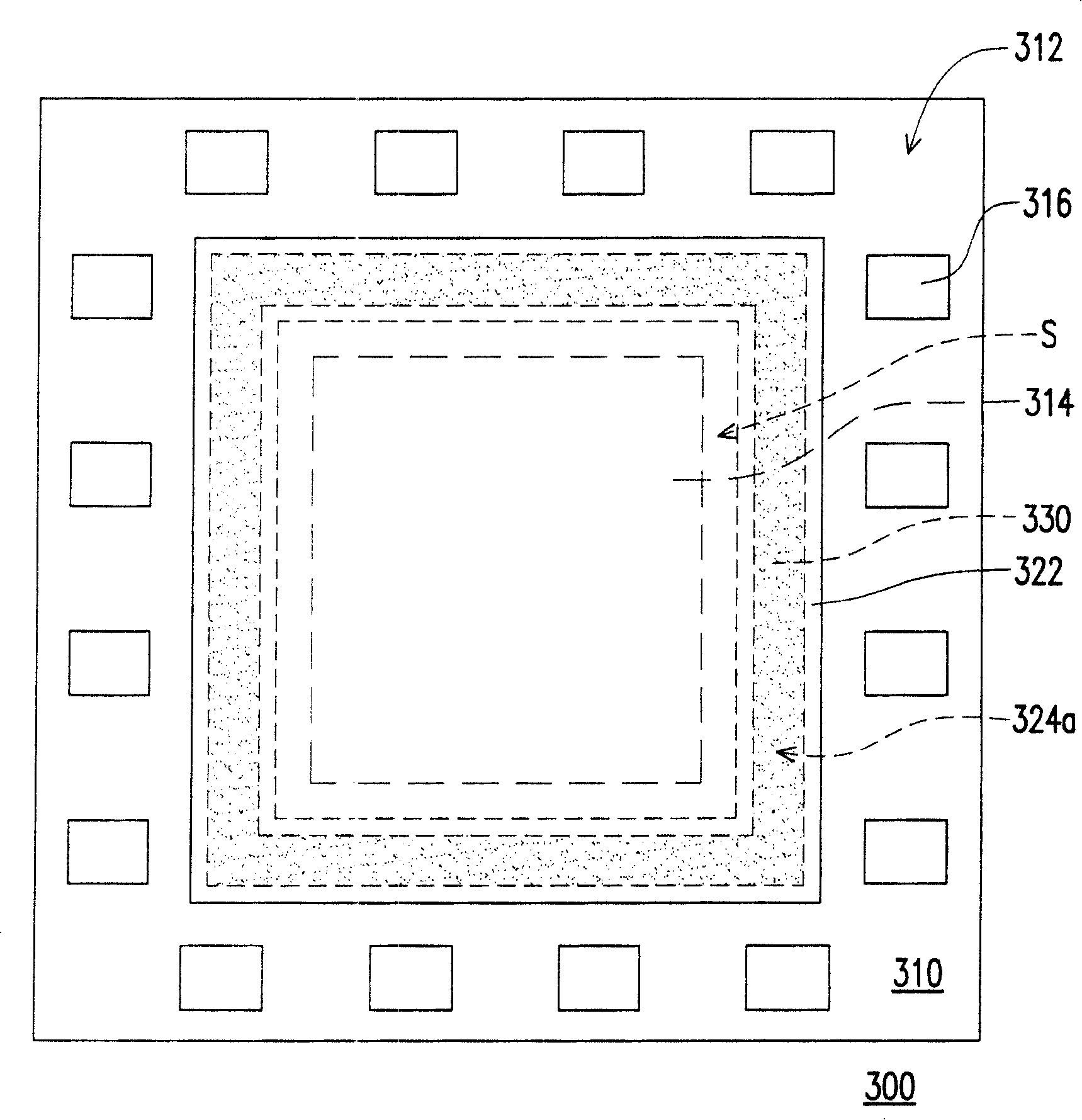

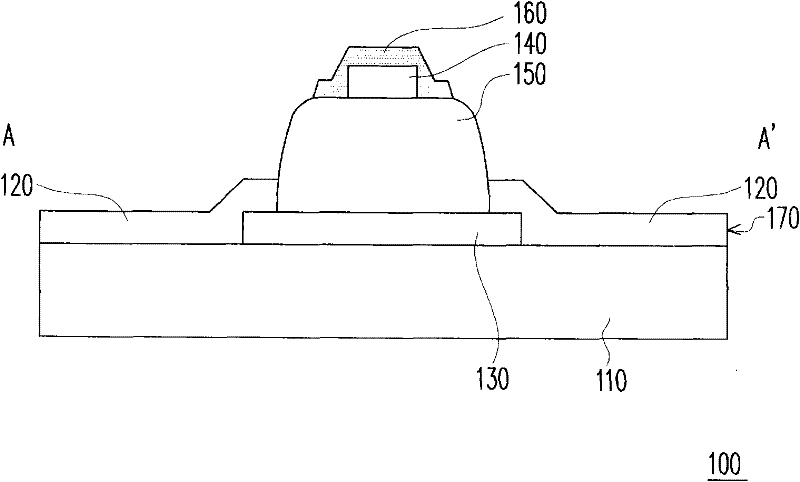

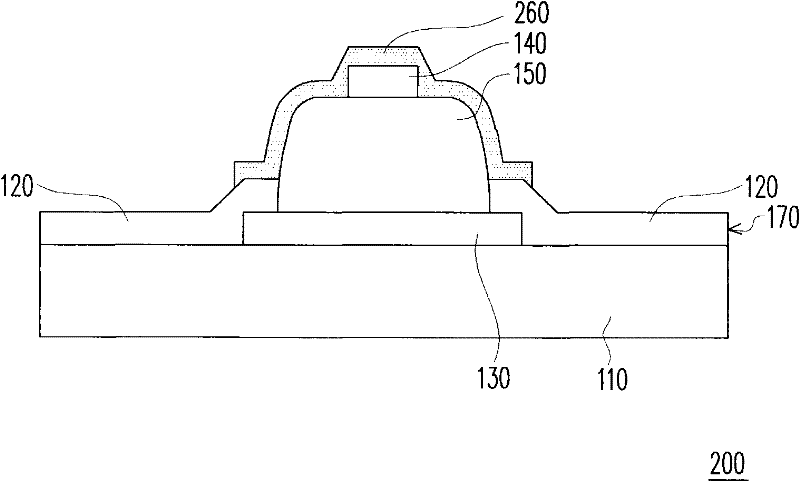

Packaging cover board, chip packaging structure and manufacturing method thereof

InactiveCN101162711AImprove process yieldGood light penetrationSemiconductor/solid-state device detailsSolid-state devicesHigh rateEngineering

A chip package structure comprises a chip, a package cover board and a bound layer, wherein, the chip is provided with a drive surface which is provided with an image sensing element and a plurality of connection cushions positioned on the periphery of the sensing element. In addition, the package cover board is arranged above the drive surface and comprises a baseplate and a support part positioned on the baseplate, wherein, a holding room is left on the baseplate by the support part, the support part contacts with the drive surface of the chip to ensure the image sensing element on the drive surface arranged in the holding room. Besides, the bound layer is arranged between the support part and the drive surface. The chip package structure of the invention has the advantages of high rate of finished products of technique, low cost of production and good optical penetrating power.

Owner:UNITED MICRODISPLAY OPTRONICS CORP

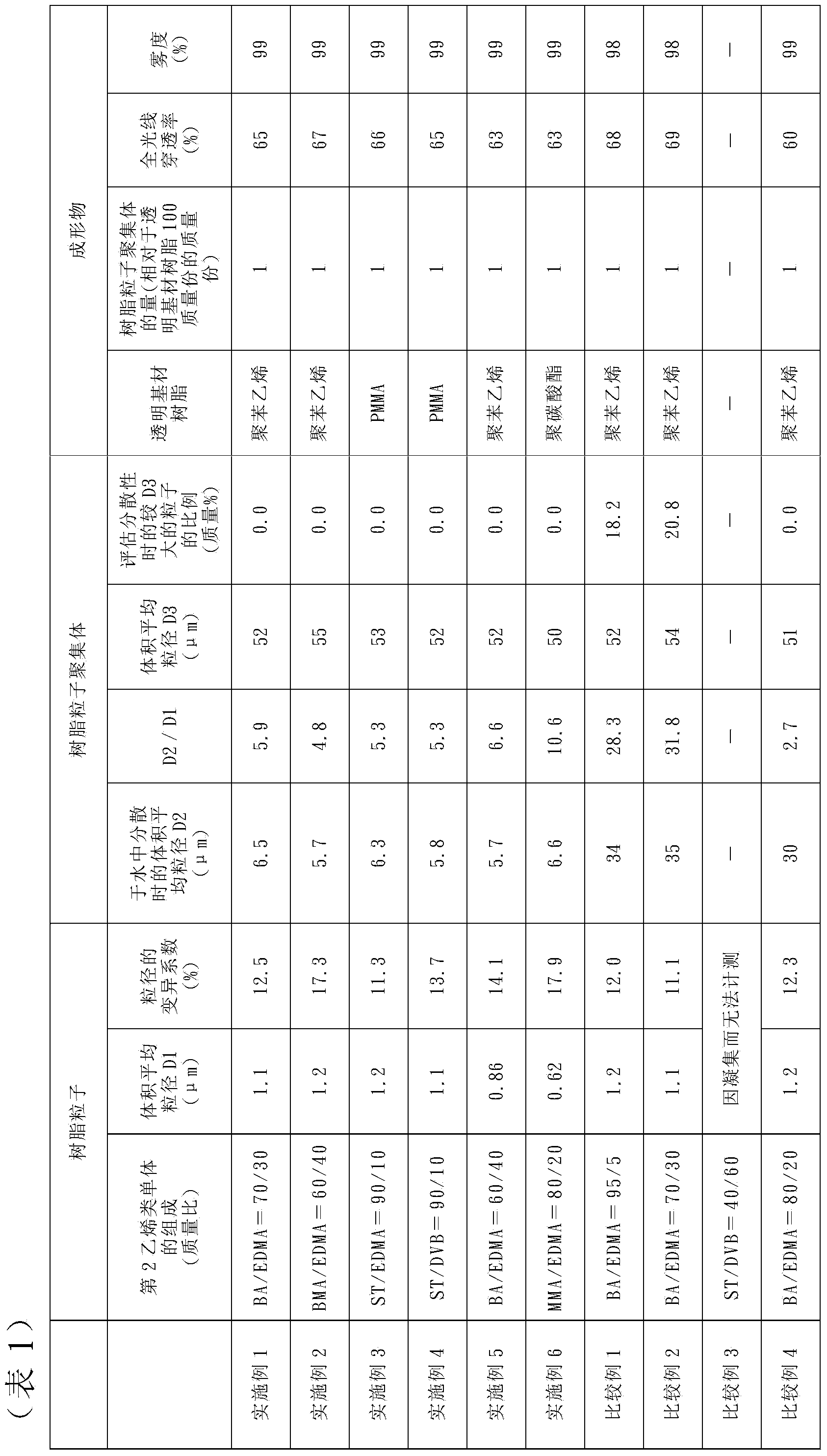

Resin particle aggregate, method for manufacturing same and application of same

ActiveCN103781843AGood light diffusion effectGood light penetrationCoatingsPolymer scienceActive agent

The present invention relates to a resin particle aggregate which is formed by a plurality of resin particles formed of vinyl monomer polymers. The present invention contains 100 parts by mass of the resin particle, and 1 to 5 parts by mass of a surfactant. The resin particle is cross-linked by a cross-linkable monomer of 10 to 50 wt% with respect to all mass of the resin particle. The content of an inorganic component in the resin particle aggregate is 0.5 wt% or less, and a ratio (D2 / D1) of a volume average particle diameter (D2) of a particle which is contained in a dispersive liquid, which is the resin particle aggregate dispersed in water, to a volume average particle diameter (D1) of the resin particle is 15 or less.

Owner:SEKISUI PLASTICS CO LTD

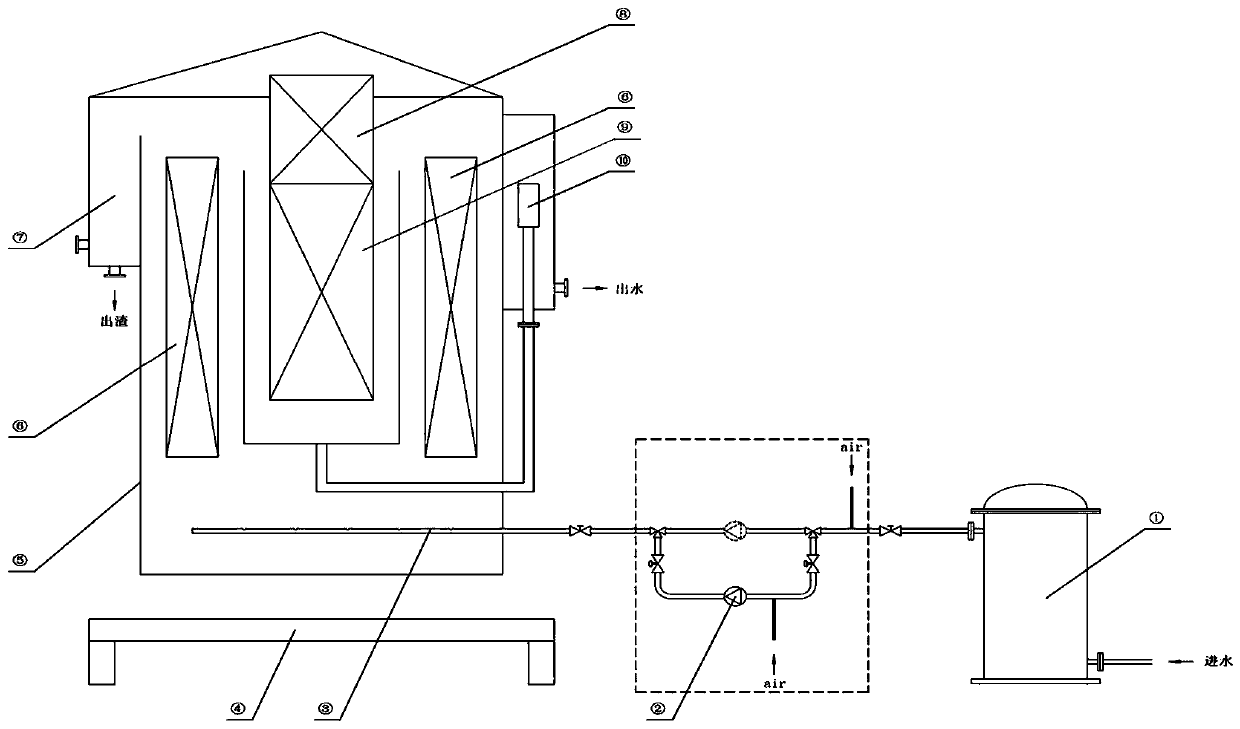

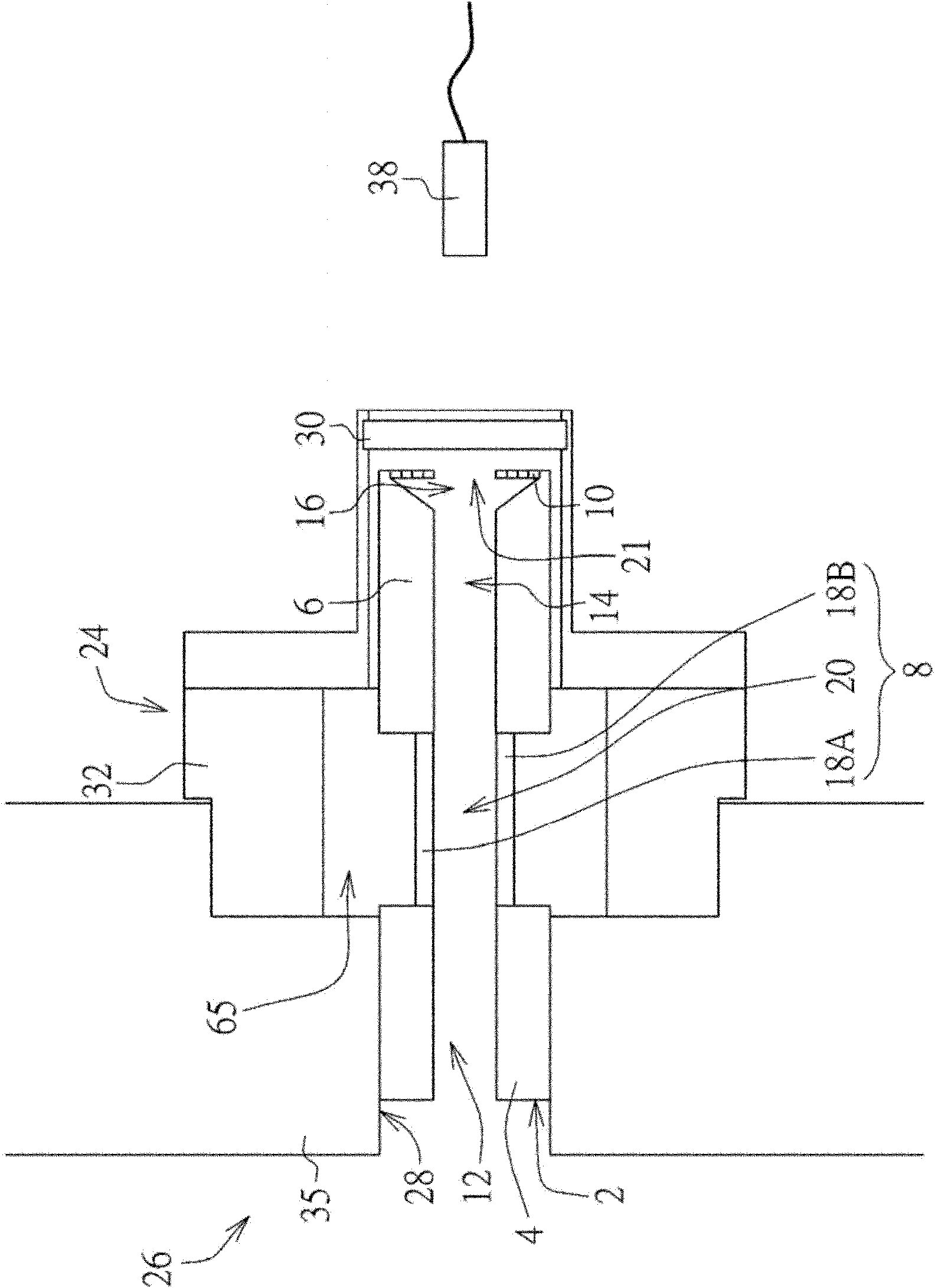

Medical wastewater disinfection and sterilization treatment method

InactiveCN110255791AImprove effective utilizationAddressing Variations in Particulate Matter LevelsWater/sewage treatment by irradiationWater treatment compoundsHydroxyl radicalHydrogen peroxide

The invention relates to a medical wastewater disinfection and sterilization treatment method. The medical wastewater disinfection and sterilization treatment method is based on a novel disinfection and sterilization treatment device. The medical wastewater disinfection and sterilization treatment method comprises the following steps of (1) decreasing an SS value of the water quality of medical wastewater source effluent; (2) improving a dissolved oxygen concentration of water; (3) making a micro-nano bubble release and aeration unit generate micro-nano bubbles with an average diameter of 24 [mu]m, wherein the dense scattered micro-nano bubbles buoy up particles in the water to a liquid level, the particles are removed by a particle collection and discharging unit, and meanwhile, dissolved oxygen in the water gains electrons in a cathode unit of a cathode cavity, and is subjected to a reduction reaction to generate H2O2 hydrogen peroxide; and (4) irradiating an anode unit with ultraviolet light, wherein electrons of a photocatalyst TiO2 semiconductor on an anode are excited for transition to form holes, while the electrons are transferred to the cathode unit under the action of an electric field, microorganisms lose electrons and are oxidized when adsorbing the holes or the anode and in contact with the holes or the anode, and water molecules are reacted with the holes or the anode to form .OH hydroxyl radicals, so that disinfection and sterilization treatment of medical wastewater is completed.

Owner:浙江森井生物技术股份有限公司

Optical adhesive composition, optical adhesive film and optical laminate

InactiveCN106189939AGood light penetrationNon-macromolecular adhesive additivesFilm/foil adhesivesOligomerCarboxylic acid

Owner:KOATECH TECH CORP

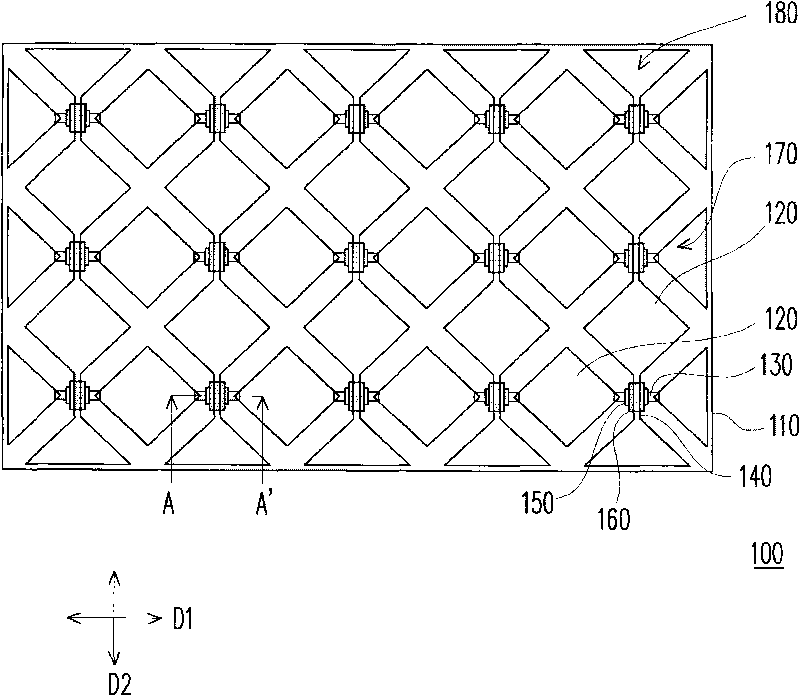

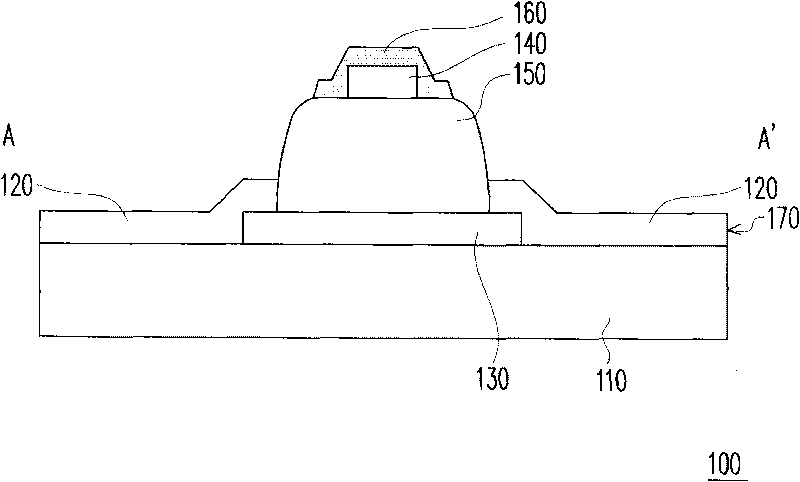

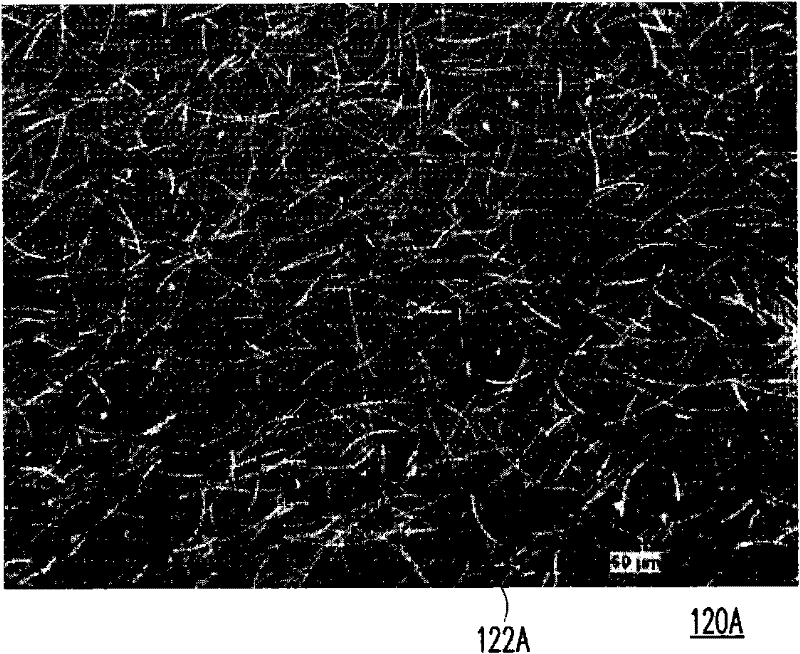

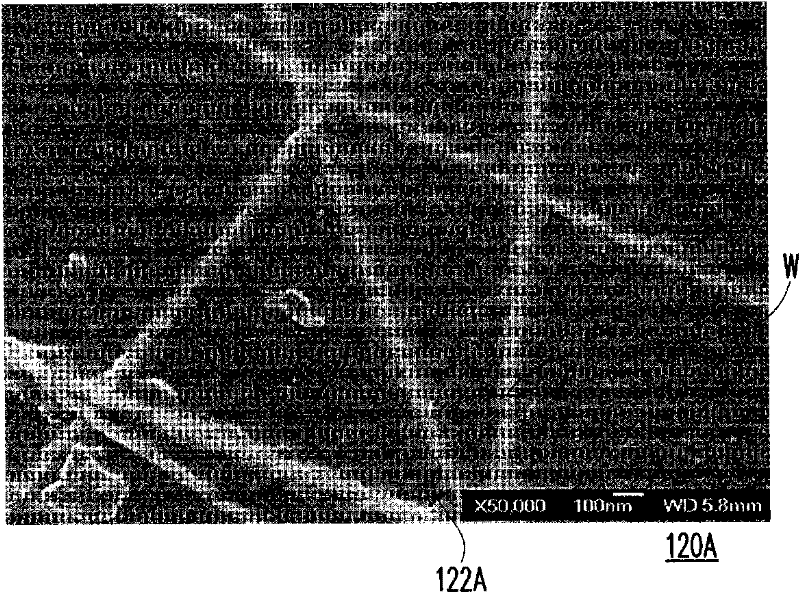

touch panel

InactiveCN102298459AImprove light penetrationReduce surface resistanceInput/output processes for data processingFine structureTransmittance

The invention relates to a touch panel, which includes a flexible substrate and a conductive film. The conductive film is disposed on the flexible substrate, wherein the area resistance of the conductive film is between 10-4 ohm / square (Ω / □) and 200 ohm / square, and the light transmittance of the conductive film is at least 87%. The conductive film may include a plurality of metal wire segments, and may also include a metal mesh. The metal material with a fine structure is used as the conductive film so that the conductive film has high light transmittance, low surface resistance and good flexibility, so that the flexibility of the touch panel is greatly improved.

Owner:DONGGUAN MASSTOP LIQUID CRYSTAL DISPLAY +1

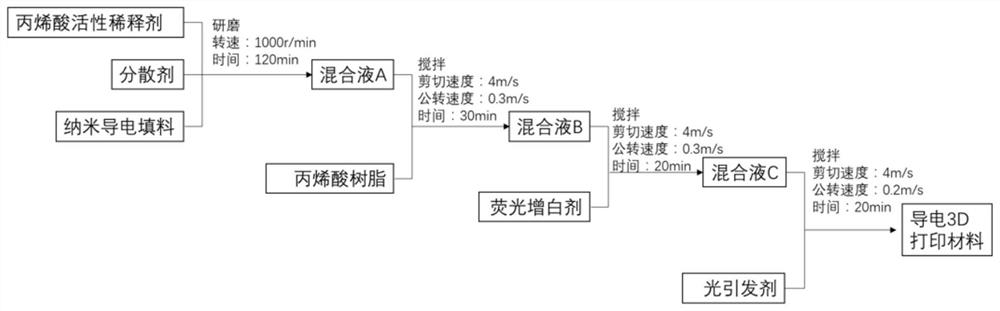

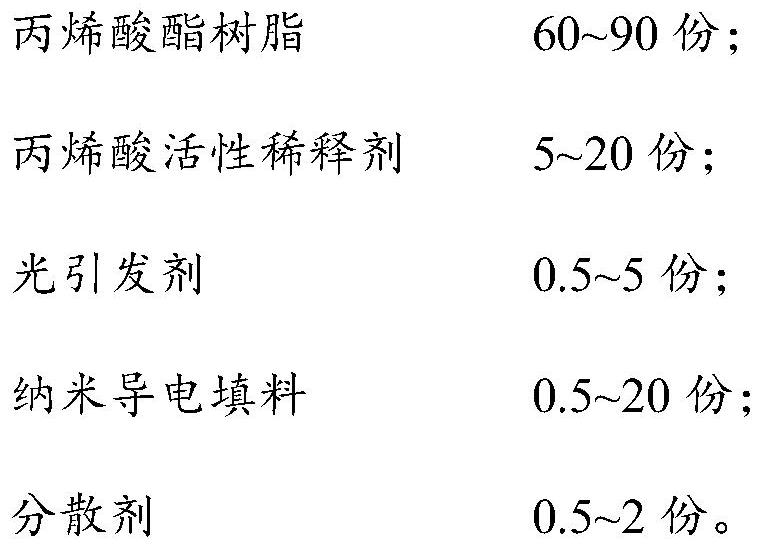

Conductive 3D printing material, and preparation method and application thereof

ActiveCN113105737AReduce settlementLight transmittance has little effectAdditive manufacturing apparatusIncreasing energy efficiencyWhitening AgentsPhotopigment

The invention provides a conductive 3D printing material, and a preparation method and application thereof. The conductive 3D printing material is prepared from the following components in parts by mass: 60 to 90 parts of acrylate resin, 5 to 20 parts of an acrylic reactive diluent, 0.5 to 5 parts of a photoinitiator, 0.5 to 20 parts of a nanometer conductive filler and 0.5 to 2 parts of a dispersing agent. As needed, the conductive 3D printing material may also comprises 0-0.2 part of a fluorescent whitening agent and 0-2 parts of a pigment and other second fillers. The conductive filler adopted by the conductive 3D printing material is nano-sized, so the problem of sedimentation of the conductive filler in the storage and application processes of the conductive 3D printing material is relieved, and the problem of low light transmittance of a 3D part printed by the conductive 3D printing material is also relieved. The conductive filler is in a rod shape, a point shape, a sheet shape and the like, so a net-shaped conductive system with high conductivity can be formed, cost is finally reduced, conductivity is improved, and the sedimentation problem of the conductive filler is relieved.

Owner:湖南创瑾技术研究院有限公司

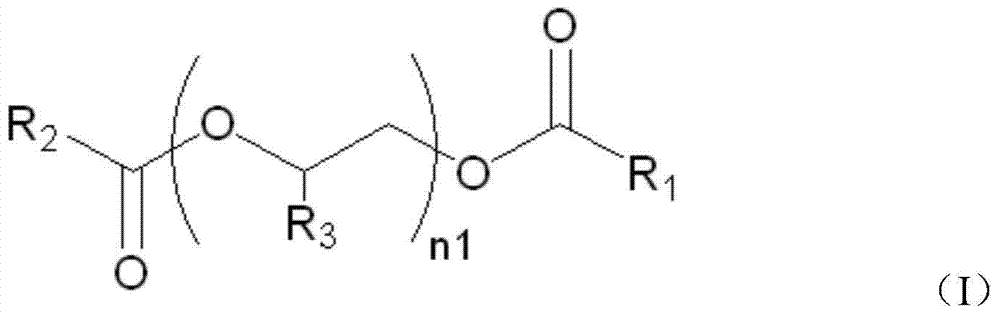

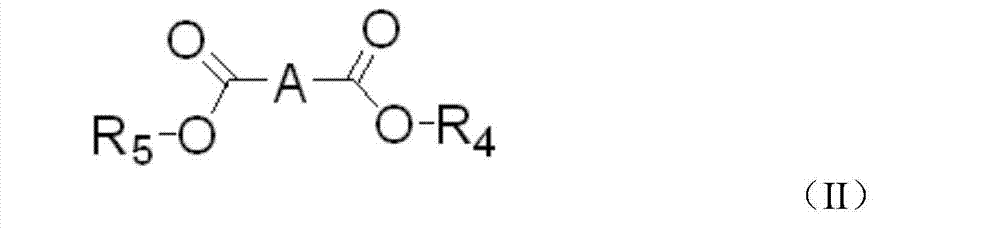

Acrylic based adhesive composition and applications thereof

ActiveCN103788879AGood light penetrationChange propertiesNon-macromolecular adhesive additivesStatic indicating devicesOligomerAdhesive

The invention relates to an acrylic based adhesive composition and applications thereof. The composition comprises: (a) an acrylic based oligomer having at least one unsaturated group, an acrylic based polymer having a group selected from a group consisting of hydroxyl, amino, carboxylic acid group and combinations thereof, or mixtures of the acrylic based oligomer and acrylic based polymer; (b) a photopolymerizable monomer; (c) a photo initiator; (d) a plasticizer comprising a compound of formula (I), a compound of formula (II), or mixtures thereof: wherein, R1 to R5, n1, and A are as defined in the specification. The composition can be used as an adhesive for an optical laminated board, can significantly reduce segment difference, prevents bubbles from generation, has good heavy industrial performance, has good light penetration rate, and is particularly suitable for manufacturing optical laminated boards of touch panel display or 3D display.

Owner:ETERNAL MATERIALS CO LTD

Touch panel and electronic device using same

InactiveCN103197806AAvoid breakingExtended service lifeInput/output processes for data processingConductive materialsEngineering

The invention provides a touch panel and an electronic device using the same. The touch panel comprises a first flexible substrate and a sensing structure, wherein the sensing structure is arranged on the first flexible substrate and comprises at least one first sensing electrode, at least two second sensing electrodes, at least one connection structure and at least one insulation structure; the second sensing electrodes are arranged on the two sides of the first sensing electrode respectively and not directly connected; the connection structure is electrically connected with the two second sensing electrodes and not electrically connected with the first sensing electrode; the connection structure is made of nonmetal conductive materials or compounds; and the insulation structure is at least partially arranged among the connection structure, the two second sensing electrodes and the first sensing electrode. As the touch panel comprises the flexible substrate and the sensing structure, the touch panel is not easy to break or rupture.

Owner:DELTA ELECTRONICS INC

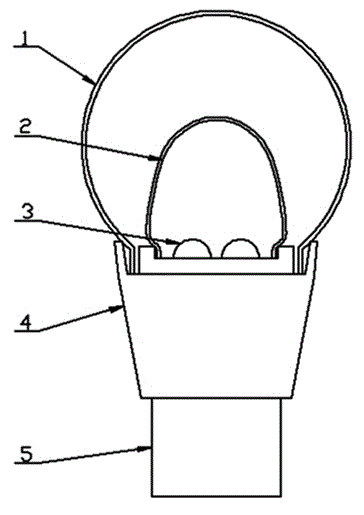

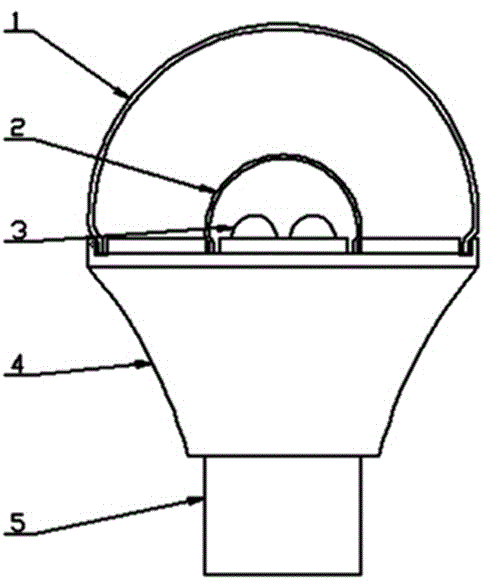

LED (Light Emitting Diode) lamp with glass lampshade with internally-coated remote fluorescent powder and process

InactiveCN104595763AGood light penetrationImprove luminous efficiencyPoint-like light sourceLuminescent paintsLight penetrationLight head

The invention discloses an LED (Light Emitting Diode) lamp with a glass lampshade with internally-coated remote fluorescent powder and a process. The LED lamp comprises a lamp adapter, a heat dissipater and light emitting chips, wherein one end of the heat dissipater is connected with the lamp adapter, and the light emitting chips are mounted at the other end of the heat dissipater. The LED lamp is characterized in that the glass lampshade with fluorescent powder is mounted outside the light emitting chips and is fixedly arranged at the end, where the light emitting chips are mounted, of the heat dissipater; the internal wall of the glass lampshade with the fluorescent powder is coated with a remote fluorescent powder coating. The invention further discloses a method for coating the fluorescent powder coating. The LED lamp mainly has the following positive effects that the light penetration performance is good, and the light emitting efficiency is higher; the product design is simple, and the lighting range is wider; the consumption of the fluorescent powder is lower; the heat dissipating performance is better, and the LED lamp is safer.

Owner:赵宁

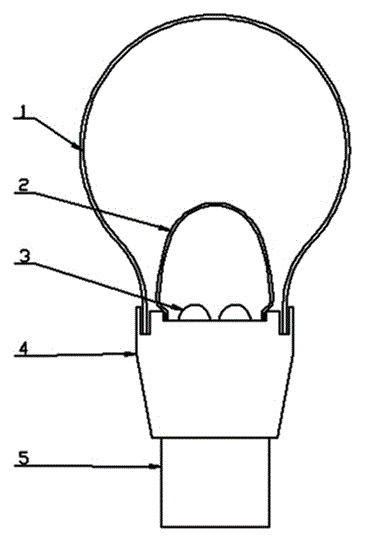

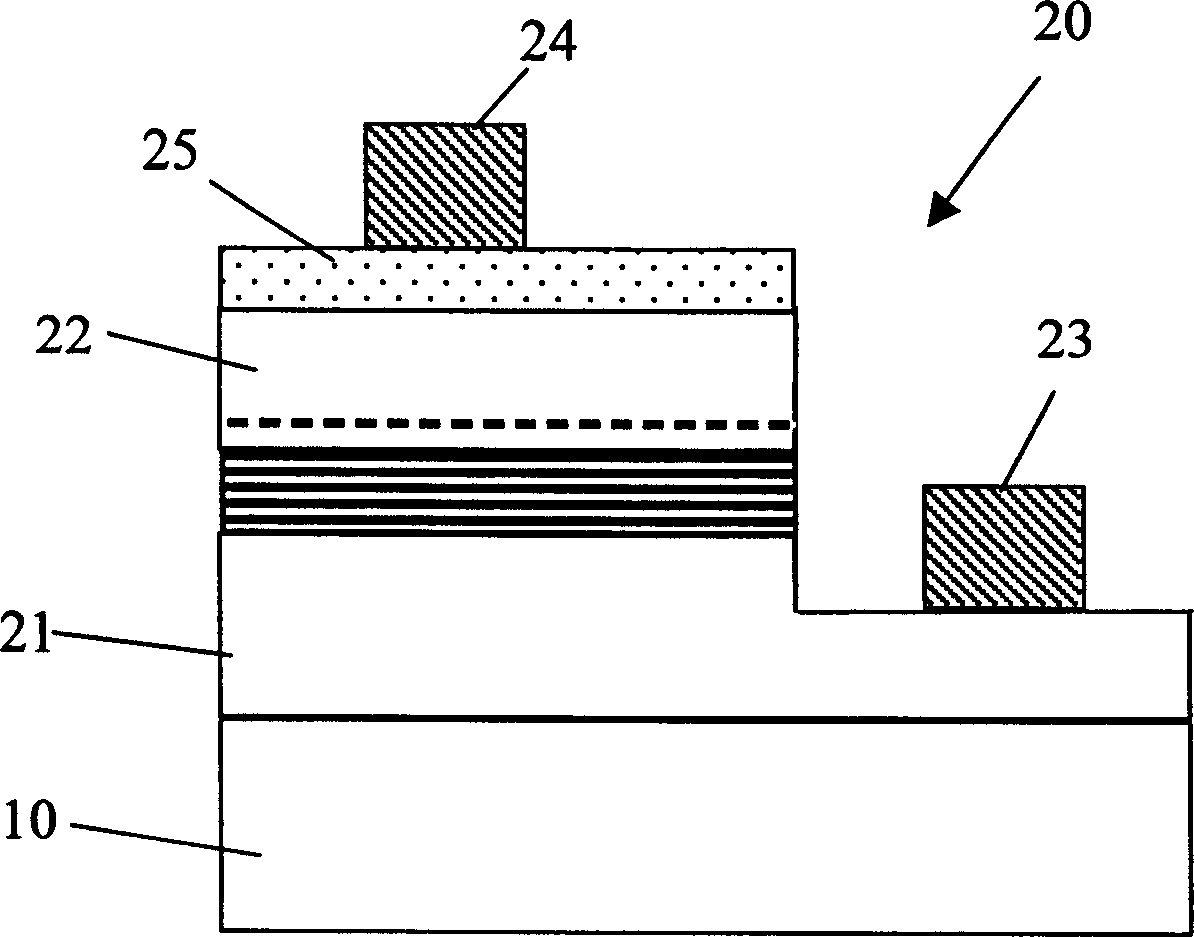

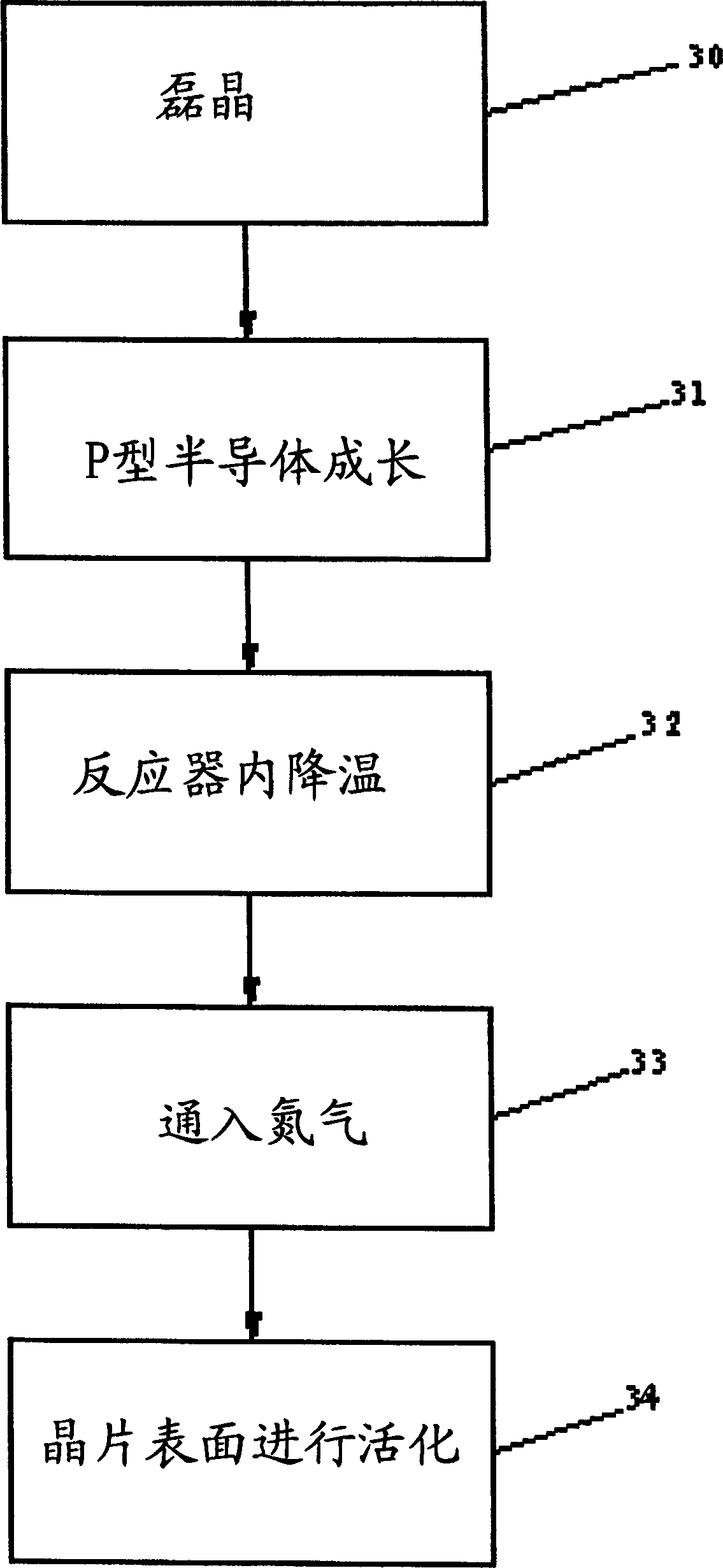

LED with electric conductive layer of metal oxide

InactiveCN1855560AImprove reliabilityGood light penetrationSemiconductor devicesElectrical conductorNitrogen gas

A light emitting diode having a metal oxide conducting layer comprises: a transparent baseboard; a semiconductor stack layer formed on said transparent layer; and an n-type gallium nitride semiconductor layer and a p-type gallium nitride semiconductor layer formed on said semiconductor stack layer. Said semiconductor stack layer has an exposed n-electrode metal pad and an exposed p-type metal pad separately coupled to said n-type gallium nitride layer and said P-type gallium nitride layer. A metal oxide conducting layer is formed between said p-type gallium nitride semiconductor layer and said p-electrode pad. After the growth of p-type gallium nitride semiconductor layer is implemented, the temperature in reactor is reduced from 900DEG C to 400DEG C, while the nitride is passed through to active the surface of chip in order to form a good electrical contact between said p-type gallium nitride semiconductor layer and said metal oxide conducting layer.

Owner:NAN YA PHOTONICS INC

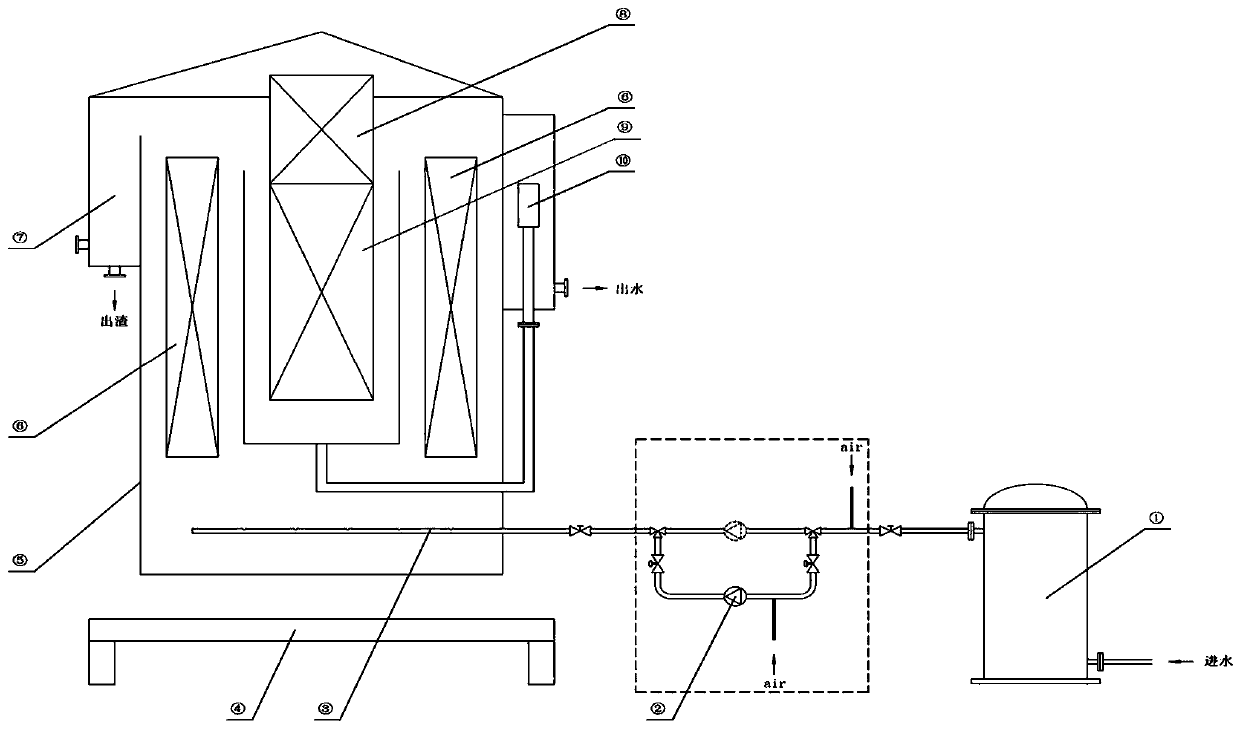

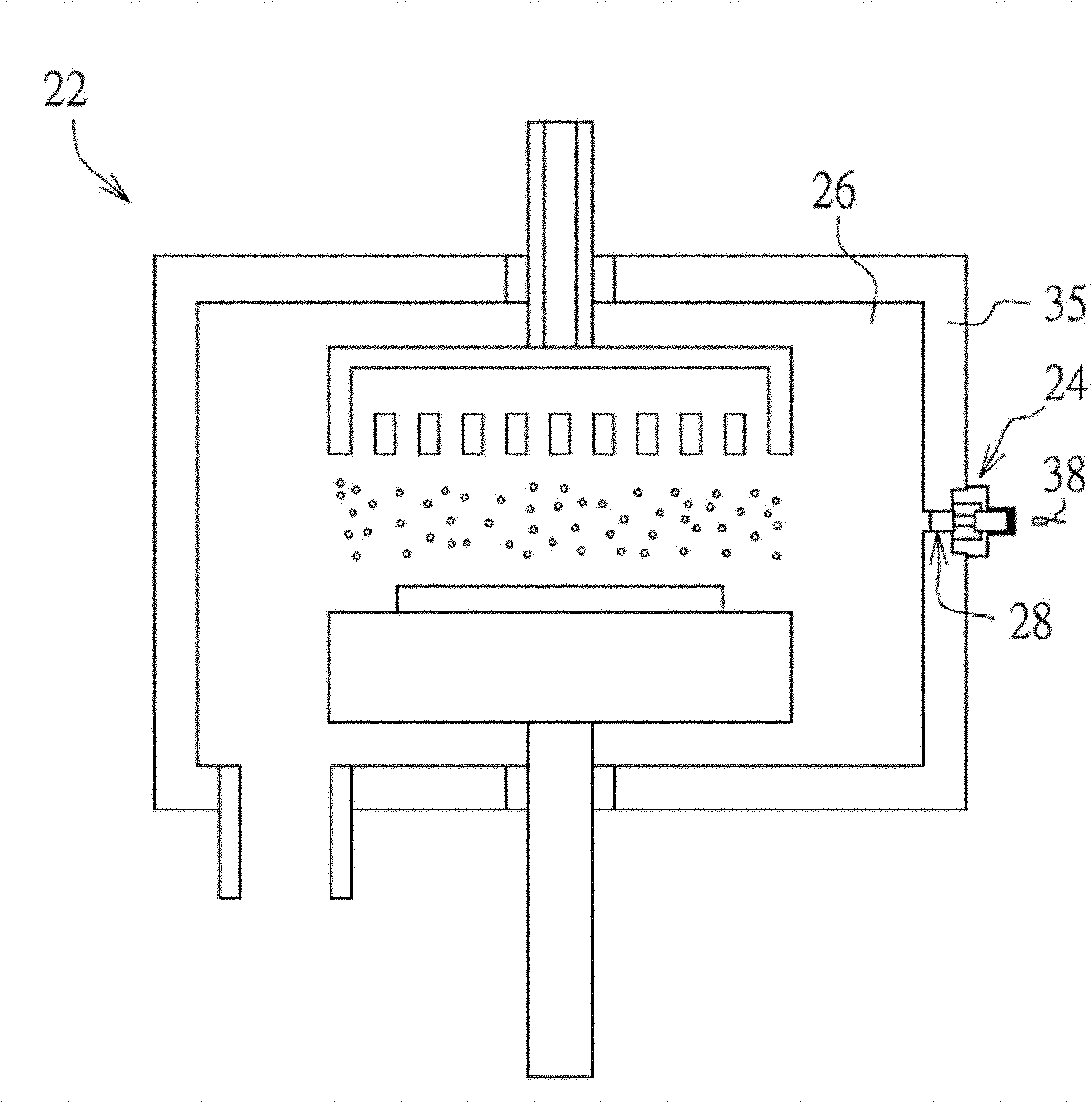

Medical wastewater disinfection and sterilization device

PendingCN110240334AImprove effective utilizationAddressing Variations in Particulate Matter LevelsWater/sewage treatment by irradiationWater treatment compoundsGenerating unitMechanical filter

The invention relates to a medical wastewater disinfection and sterilization device. The device comprises the following units: a mechanical filtering unit and a dissolved air generating unit, wherein the dissolved air generating unit is arranged at the downstream of the mechanical filtering unit and is used for dissolving air to promote dissolved oxygen in wastewater; a reactor unit and a micro-nano bubble releasing and aerating unit, wherein the micro-nano bubble releasing and aerating unit is arranged at the downstream of a dissolved gas generating unit, and the outlet end of the micro-nano bubble releasing and aerating unit extends into a reactor shell, the shell is provided with at least one water outlet channel and at least one particle collecting and discharging channel, a cathode unit and an anode unit are fixedly arranged in the shell, and an ultraviolet lamp unit is fixedly arranged in the anode unit in a staggered manner; and a liquid level adjusting unit arranged in the shell, and the mechanical filtering unit, the dissolved air generating unit, the cathode unit, the anode unit, the ultraviolet lamp unit electric control component, the liquid level adjusting unit electric control component and a sensor for acquiring the operating parameters are electrically connected with an electric cabinet unit. Through the serial use of two technologies of filtering and micro-nano bubble floating, the change of the particle contents in the water is solved, and the turbidity is improved.

Owner:浙江森井生物技术股份有限公司

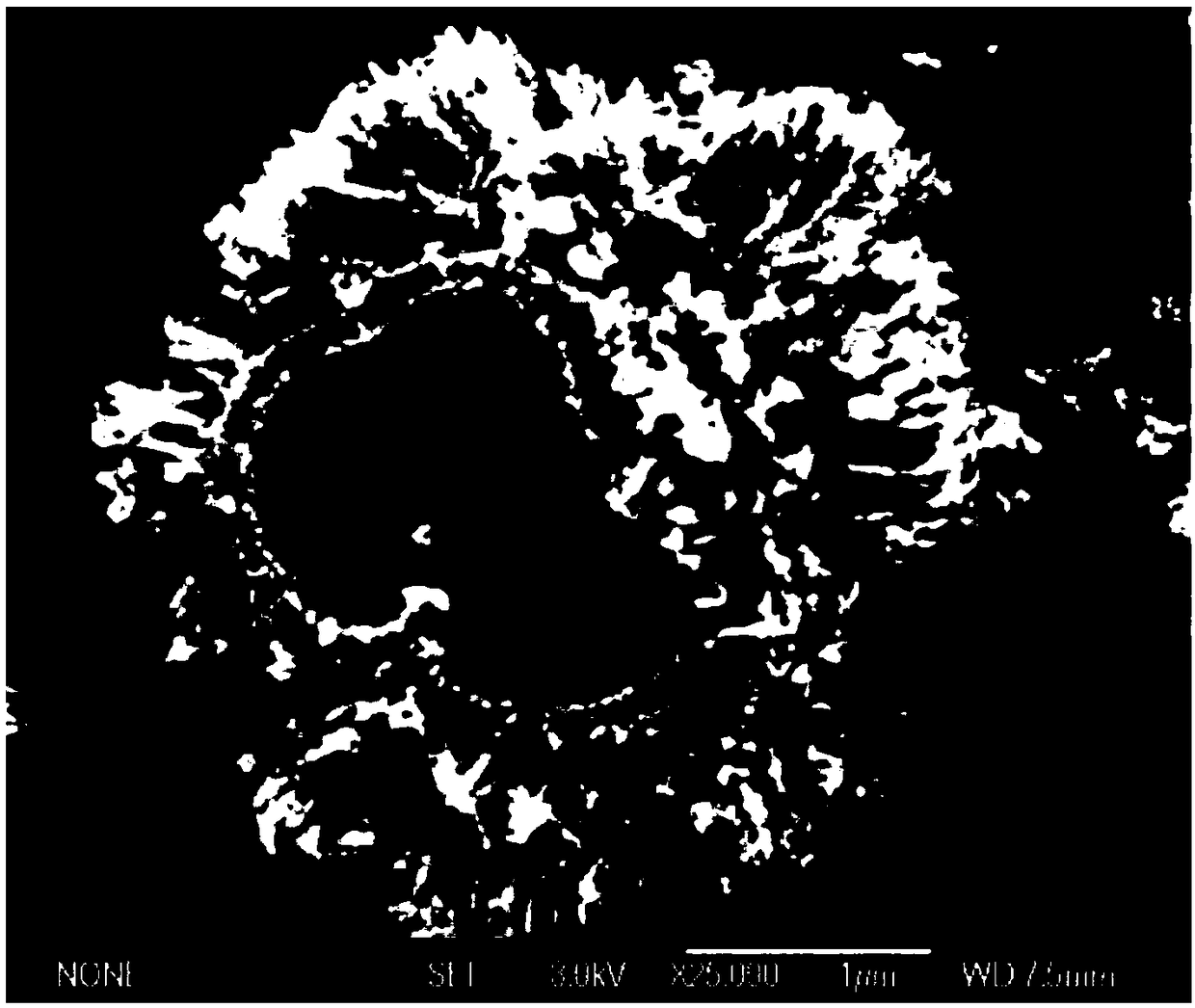

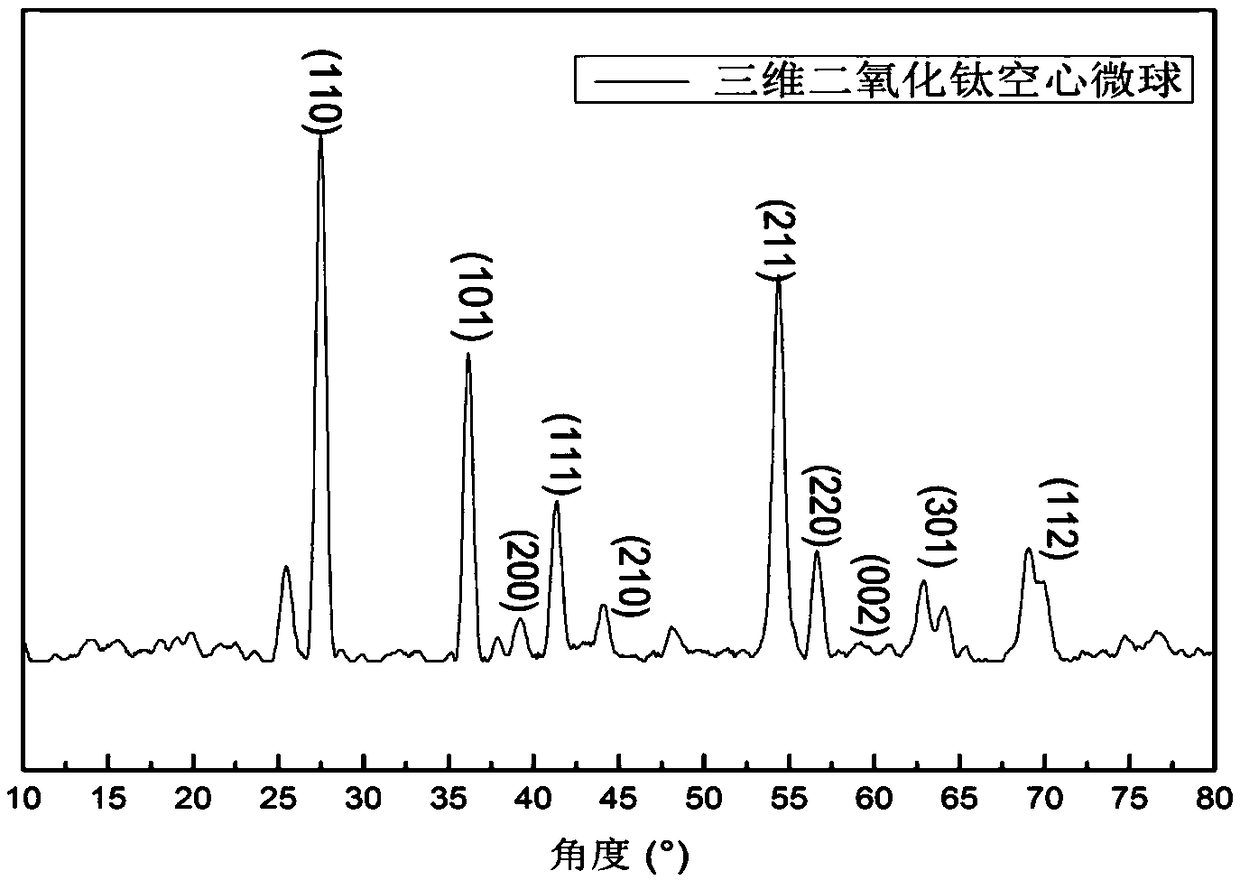

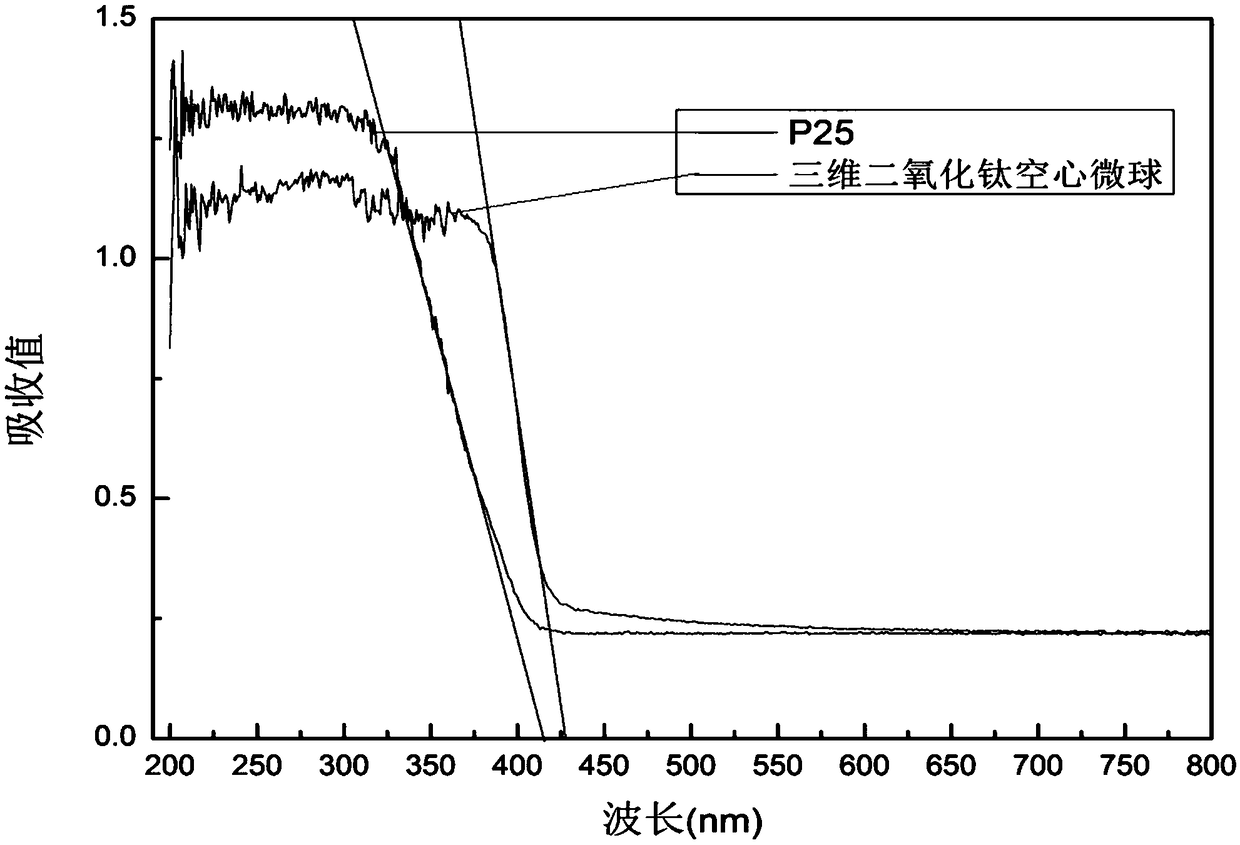

A preparation method for self-assembly of one-dimensional nanorods to form chestnut shell-like three-dimensional titanium dioxide hollow microspheres with hierarchical structure

ActiveCN106268733BLow densityImprove the utilization rate of sunlightPhysical/chemical process catalystsWater/sewage treatment by irradiationMicrosphereSolvent

Owner:SHANDONG UNIV

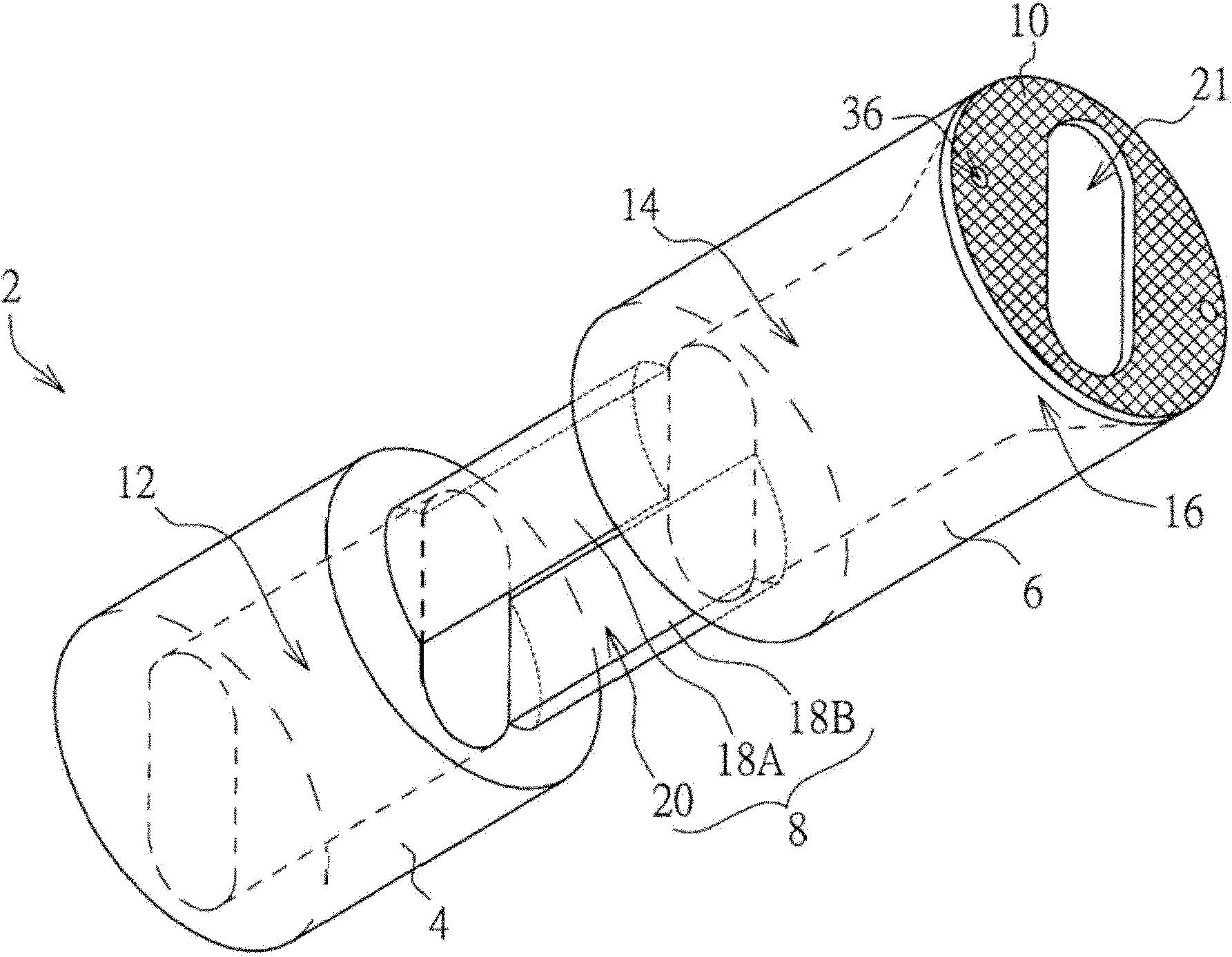

View port device for plasma process and process observation device of plasma apparatus

InactiveCN102465278ASimple structureEasy to prepareElectric discharge tubesChemical vapor deposition coatingEngineering

A view port device for a plasma process and a process observation device of a plasma apparatus are provided. The view port device for a plasma process comprises a first substrate portion, a second substrate portion, and a connecting portion. The first substrate portion has a first through hole. The second substrate portion has a second through hole and a second diffusion space. A cross-sectional area of the second diffusion space is larger than that of the second through hole. The connecting portion is disposed between the first substrate portion and the second substrate portion.

Owner:IND TECH RES INST

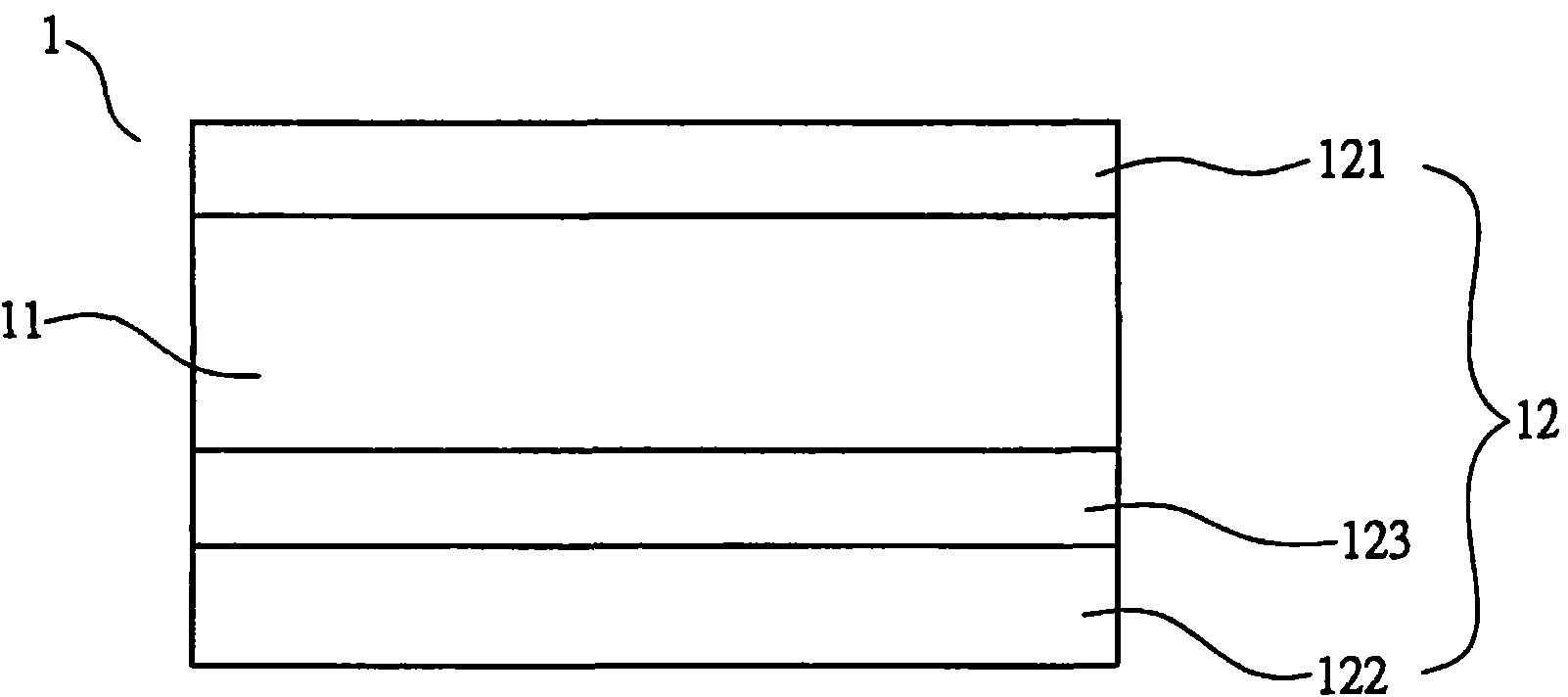

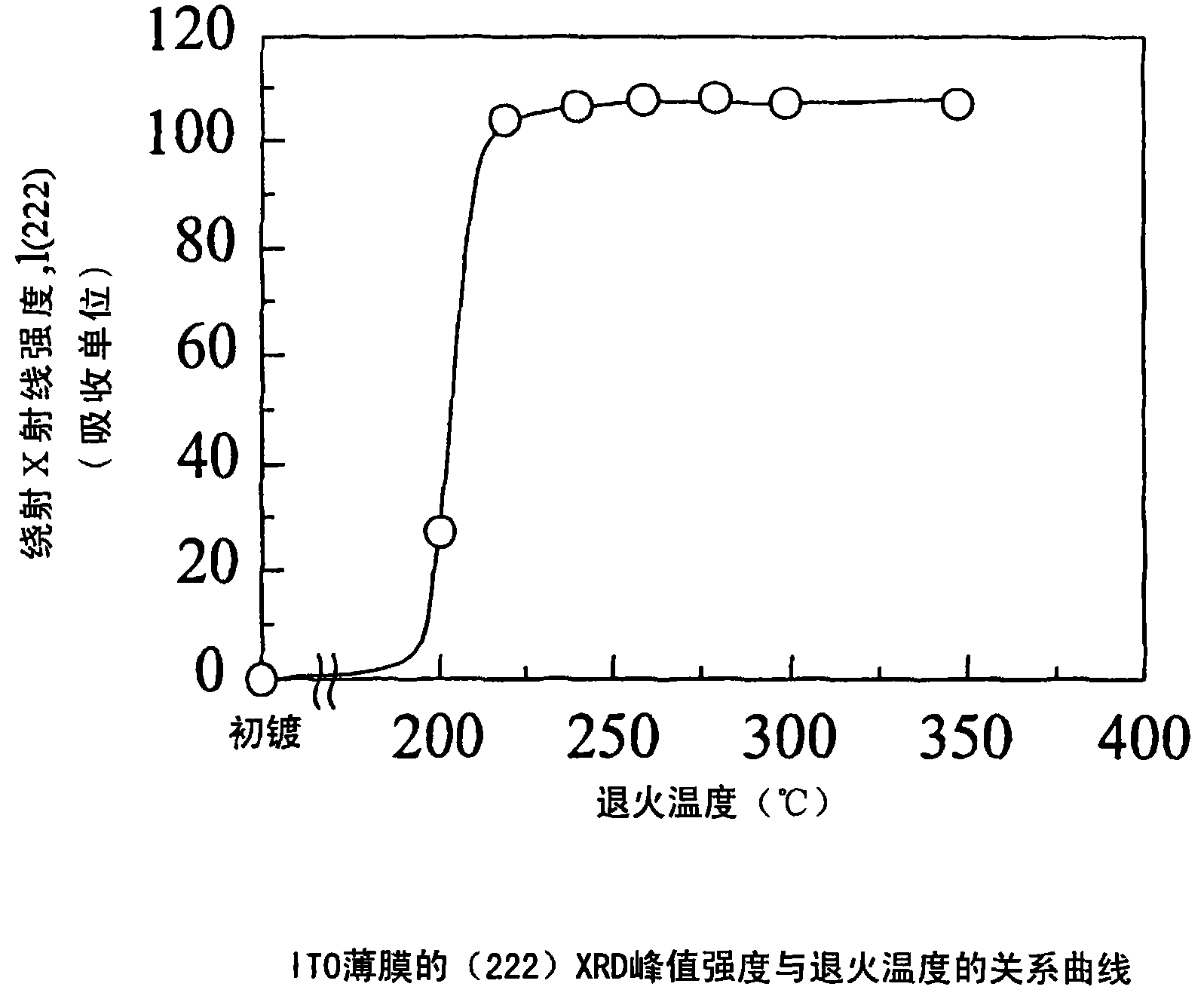

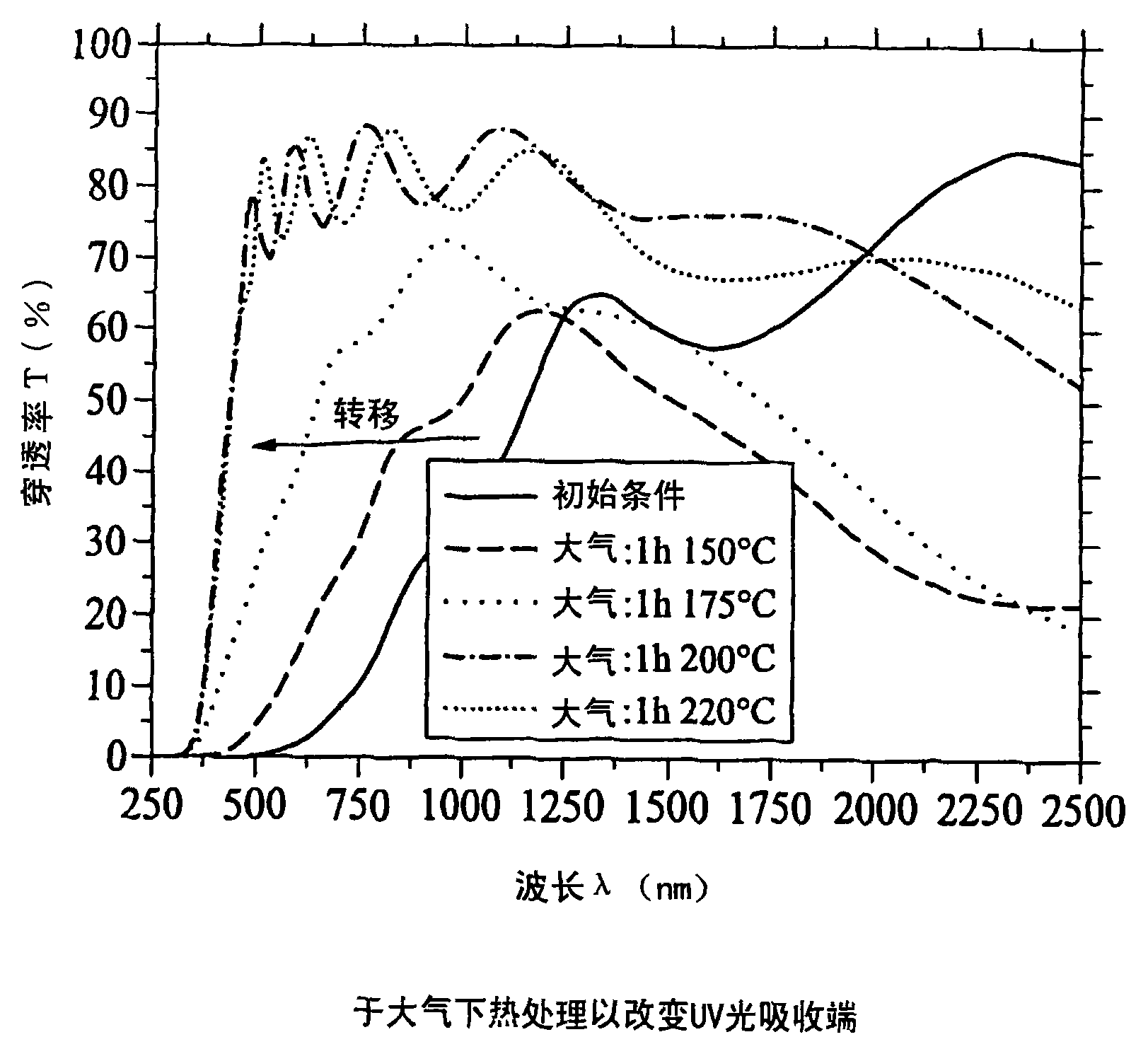

Method for manufacturing transparent conductive lamination body

InactiveCN101996713AGood light penetrationLow resistivityConductive layers on insulating-supportsCable/conductor manufactureTransparent conducting filmBroadband

The invention relates to a method for manufacturing a transparent conductive lamination body and particularly provides a method for manufacturing a conductive lamination body in a transparent conductive film. In the method, a light source with a single-wavelength or specific broadband spectrum is adopted to irradiate a transparent conductive film to crystallize a conductive layer on the surface of the transparent conductive film and improve the performance of the optical and electrical characteristics of the transparent conductive film, and thus, the reliability of the transparent conductive film is realized and improved.

Owner:GAMMA OPTICAL +1

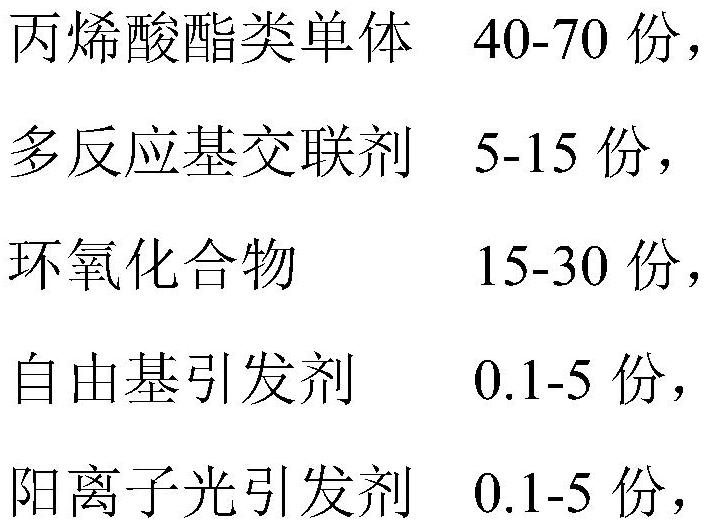

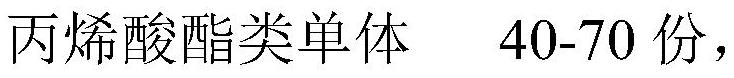

A kind of photocurable resin composition and optical device prepared therefrom

ActiveCN109293851BProcess environmental protectionIncrease productivityOptical elementsPolymer scienceRefractive index

The invention belongs to the technical field of resin optical device preparation, and in particular relates to a photocurable resin composition and an optical device prepared therefrom. The composition includes the following components in parts by weight: 40-70 parts of acrylate monomers, 5-15 parts of multi-reaction group crosslinking agents, 15-30 parts of epoxy compounds, 0.1-5 parts of free radical initiators, 0.1-5 parts of cationic photoinitiator. Using the resin composition provided by the present invention to carry out the photocuring step to prepare optical devices not only has a simple process, is environmentally friendly, has high production efficiency, can reduce process costs, and greatly shortens the process time and the amount of molds required. The prepared optical device (lens) not only has high hardness, impact resistance and chemical resistance, but also has better light penetration, high brightness, high refractive index, and low stress lines, and can be applied to lenses, optical components, etc.

Owner:长兴特殊材料(苏州)有限公司

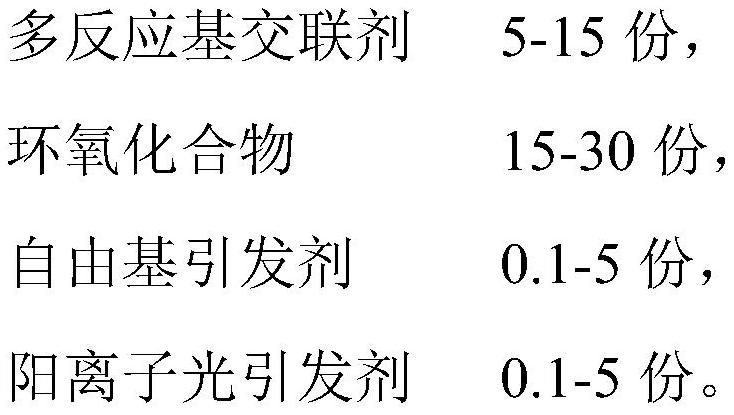

A liquid photosensitive dark solder resist material and its preparation method

ActiveCN104516205BImprove solder resistanceImprove performancePhotomechanical apparatusResistHeat resistance

The invention discloses a liquid photosensitive solder resisting material. The solder resisting material comprises the components of photosensitive resin, acrylic acid monomer, hot solidification resin, paint, a filling material, a photoinitiator, an additive and a solvent, and is characterized by comprising the following materials in parts by weight: 30-50 parts of photosensitive resin, 10-20 parts of an acrylic acid monomer, 3-20 parts of hot solidification resin, 2-5 parts of paint, 20-35 parts of a filling material, 3-8 parts of a photoinitiator, 0.3-5 parts of an additive, and 25-40 parts of a solvent. The obtained liquid photosensitive solder resisting material has superior heat resistance, and excellent flexibility, improves bridge protecting performance to 2.5 mil through a resin synthesis reaction, solves the problem that the bridge protecting performance of original photosensitive resin is low, and is simple in technology, reasonable in formula and good in performance.

Owner:江门市阪桥电子材料有限公司

Solid hydrogel and preparation method thereof

The invention provides solid hydrogel and a preparation method thereof. The preparation method comprises the following steps: a) mixing a monomer, a photoinitiator, a crosslinking agent, a preservative, an anti-freezing agent and water and stirring uniformly to prepare aqueous solution; b) injecting the aqueous solution into a plastic bag body manufactured by high cycle heal seal; c) exhausting and sealing the plastic bag body with the aqueous solution; and d) placing the plastic bag body treated in the step c behind a lampstand and turning on a lamp to irradiate the lamp. According to the preparation method for the solid hydrogel provided by the invention, the photoinitiator is triggered through irradiation, and the monomer molecule is initiated and activated by irradiation to be radical to perform crosslinking polymerization, so the light penetrability is high, polymerization is uniform and the edge, the inner layer of colloid maintain consistent, residues of an oxidation-reduction system is avoided, the using amount of the crosslinking agent is reduced, and the polymer colloid is low in crosslinking and high in strength. In addition, polymerization is triggered through irradiation, so implosion is avoided and morphologic change in the polymerization process is avoided.

Owner:HANGZHOU PHASE CHANGE TECH

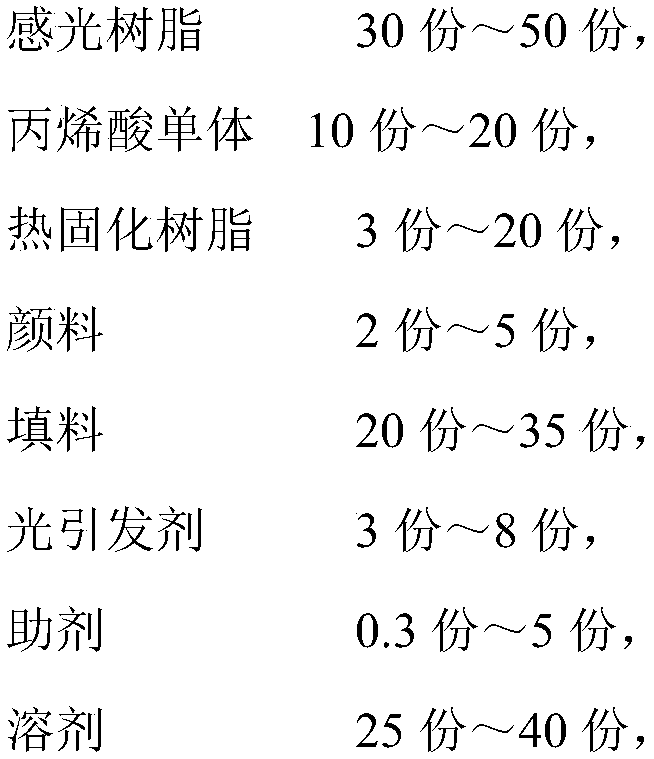

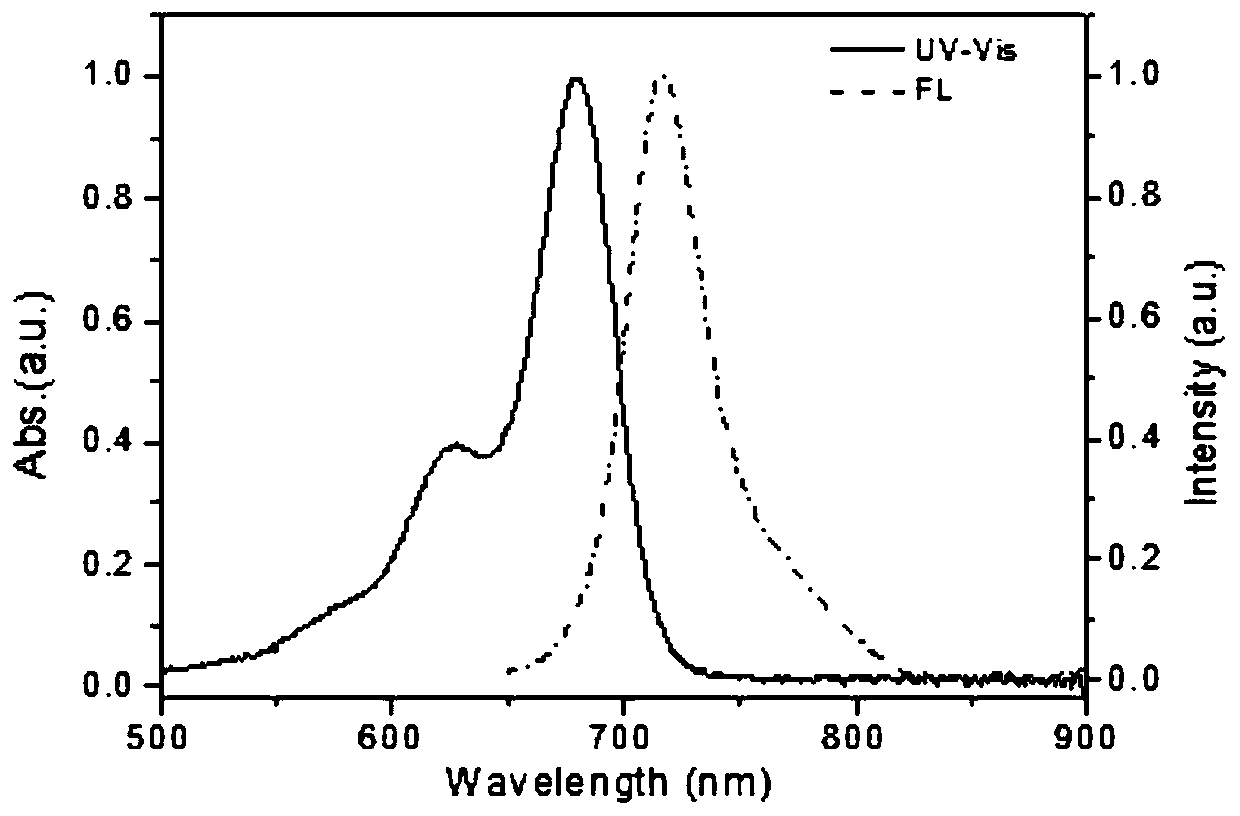

Application of a near-infrared xanthene fluorescent dye in fluorescent labeling of Schistosoma japonicum adults

ActiveCN108344722BGood light penetrationImprove signal-to-noise ratioFluorescence/phosphorescenceAdult wormFluorescent imaging

The invention provides application of near infrared xanthene fluorescent dye in fluorescent labeling of adult schistosoma. The near infrared xanthene fluorescent dye has the structure shown in formulaI. In the application, the near infrared xanthene fluorescent dye (NIR-RB) with the structure of the formula I has an emission peak located in a near infrared region and has good light transmittancein living body fluorescence imaging. The NIR-RB can perform fluorescent labeling imaging on the adult schistosomiasis; meanwhile, the fluorescence intensity of the adult schistosoma is quantitativelyanalyzed, the signal-to-noise ratio (S / N) of a fluorescent signal in a worm body region and a background region is 10, which indicates that the NIR-RB used for the fluorescence imaging of the adult schistosoma has a high signal-to-noise ratio.

Owner:GANNAN NORMAL UNIV

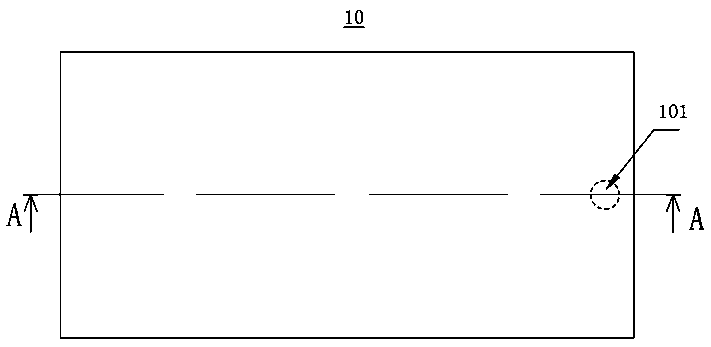

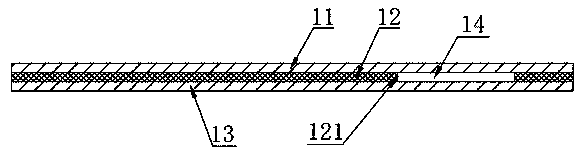

Polarizer and its manufacturing process

ActiveCN109733034BGood light penetrationAvoid interferenceLamination ancillary operationsSynthetic resin layered productsPolymer scienceManufacturing technology

The invention discloses a polaroid applied to a full-screen display panel. The polaroid comprises three films, namely, a lower-layer TAC film, a PVA film and an upper-layer TAC film, which are overlapped in turn; a through hole is formed on the PVA film; a transparent optical cement is filled in the through hole. The invention discloses a manufacturing technology of the polaroid. The manufacturingtechnology comprises the following steps: (1) using a pressing broach for pressing and punching the through hole in required size on the PVA film; (2) attaching the lower-layer TAC film to the PVA film with the punched through hole; (3) dispensing glue on the through hole in the manner of dispensing glue along annular spiral track points from outer to inner after attaching the lower-layer TAC film; (4) attaching the upper-layer TAC film to the PVA film. In the polaroid disclosed by the invention, a light-transmitting area is formed in the area corresponding to the through hole and a camera under the full-screen display panel; later irregular punching for the polaroid is avoided; when the polaroid is glued with a display panel and a cover plate in later period, the traditional technology can be adopted for directly gluing.

Owner:TRULY OPTO ELECTRONICS

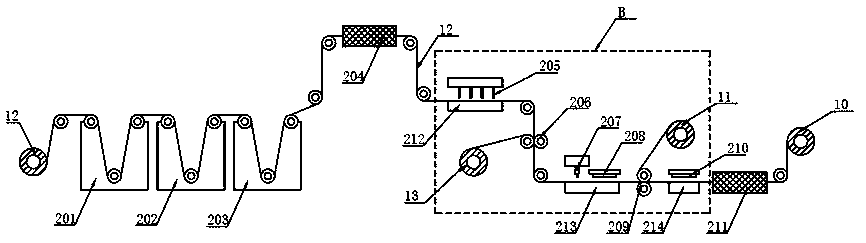

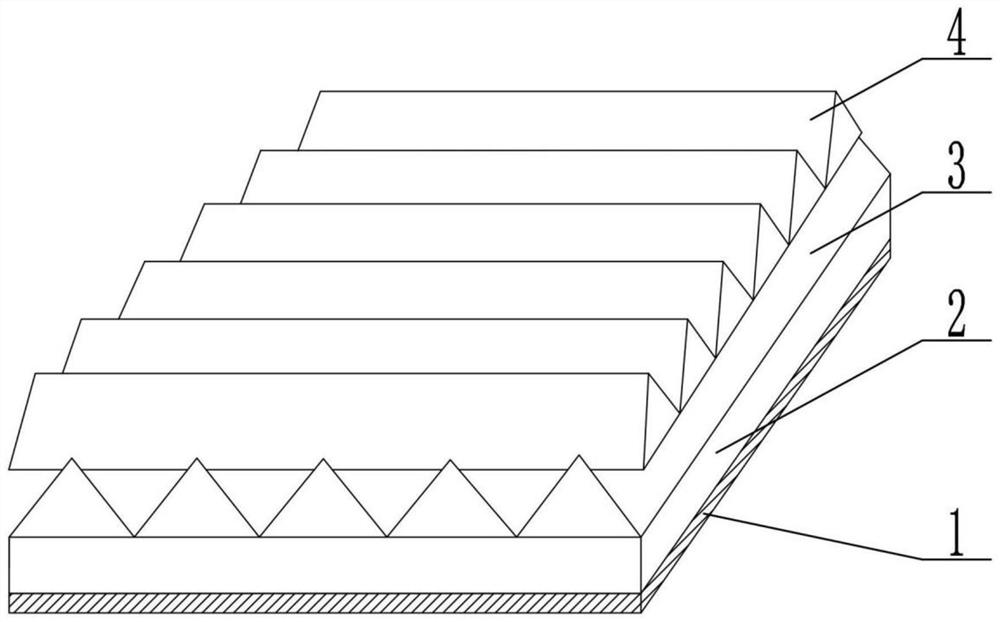

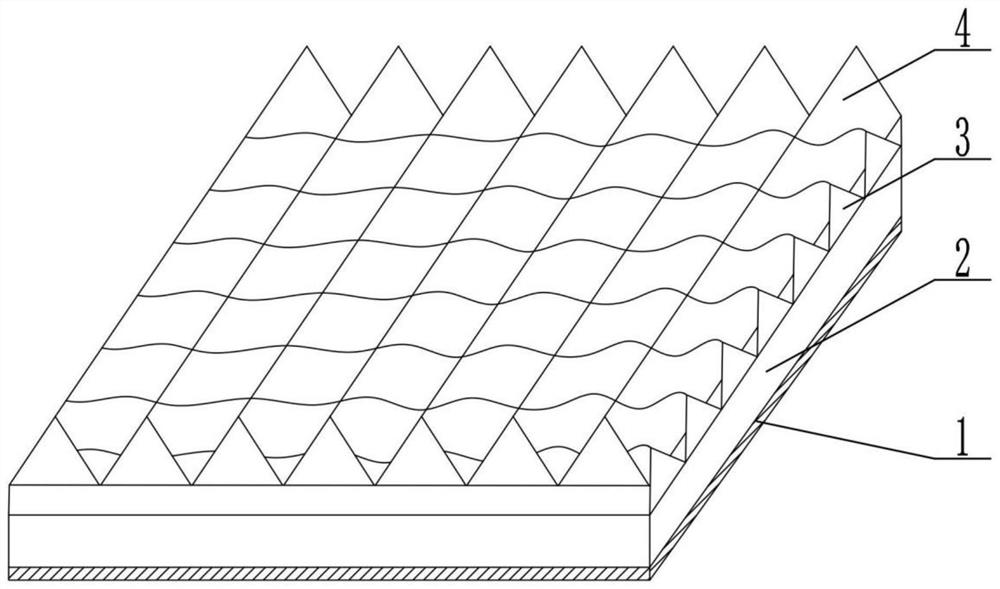

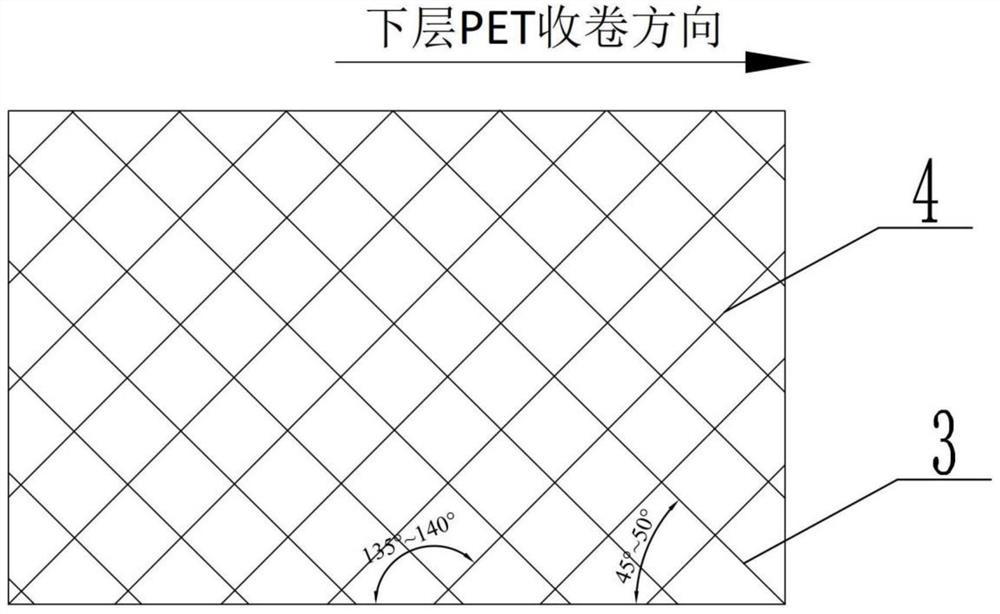

A kind of high-brightness prism bonding film and preparation method thereof

The invention discloses a high-brightness prism laminating film and a preparation method thereof, which successively comprise a back coating layer, a PET layer, a first prism layer, a second prism layer, a first prism layer and a second prism layer from bottom to top The upper array is provided with prisms, the apex angles of the prisms of the first prism layer are inserted into the lower surface of the second prism layer, the longitudinal extension direction of the prisms of the first prism layer and the longitudinal extension direction of the prisms of the second prism layer are at an angle of 90°, The prism height of the first prism layer is 20-44 μm, the height difference of each prism apex of the first prism layer is 0.5-2 μm, the prism height of the second prism layer is 20-44 μm, and each prism of the second prism layer is arranged at the same height , The haze of the back coat is 2-10%. The invention simplifies the double-layer PET layer structure in the prior art, reduces the light interference phenomenon in the whole module, thereby reduces the light loss, significantly improves the brightness of the prism bonding film, simplifies the preparation process and assembly process, and saves cost.

Owner:CHANGZHOU HUAWEI ADVANCED MATERIAL

Touch panel and manufacturing method thereof

InactiveCN101699378BImprove optical qualityGood light penetrationInput/output processes for data processingEngineeringTouch panel

The invention provides a touch panel, which comprises a substrate, a plurality of sensing pads, a plurality of first bridge connectors, a plurality of second bridge connectors, a plurality of first insulation patterns and a plurality of second insulation patterns. The sensing pads are arranged on the substrate. The first bridge connectors are electrically connected in series with a part of sensing pads to form a plurality of first sensing series, and extend along a first direction. The second bridge connectors are electrically connected in series with other sensing pads to form a plurality ofsecond sensing series. The first bridge connectors are positioned between the second bridge connectors and the substrate, and each second bridge connector extends along a second direction, wherein the first direction is not parallel with the second direction. The first insulation patterns are arranged between the first bridge connectors and the second bridge connectors and expose the sensing pads. The second insulation patterns cover the second bridge connectors and expose the sensing pads.

Owner:CENTURY DISPLAY (SHENZHEN) CO LTD

Acrylic acid series adhesive component and uses thereof

ActiveCN102417795BGood light penetrationChange propertiesNon-macromolecular adhesive additivesStatic indicating devicesPolymer scienceOligomer

Owner:ETERNAL MATERIALS CO LTD

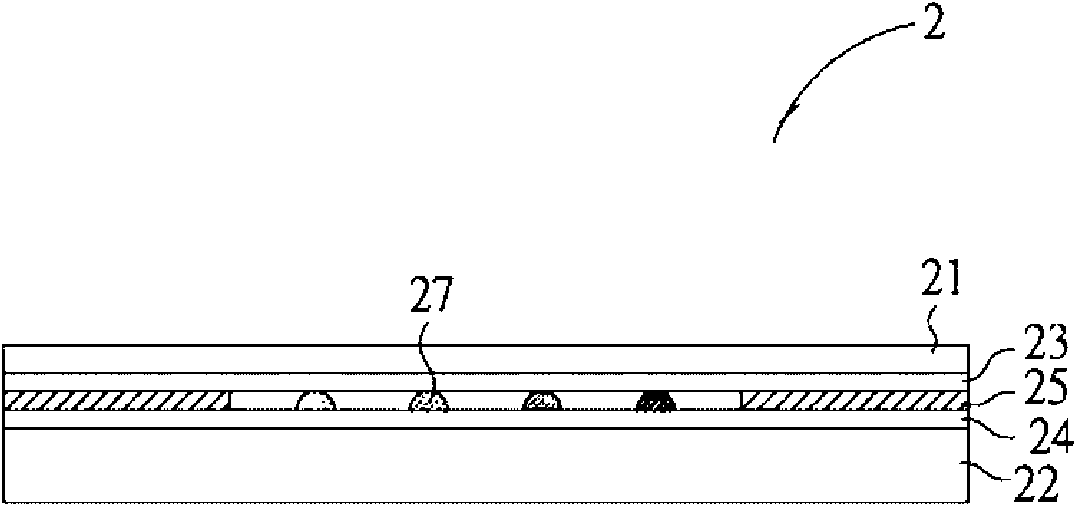

Multipoint touch screen and driving method thereof

ActiveCN101901069BSimple structureIncreased durabilityInput/output processes for data processingCarbon nanotubeEngineering

The invention provides a multipoint touch screen which comprises a first baseplate, a second baseplate, a first transparent conducting layer and a second transparent conducting layer, wherein the first baseplate and the second baseplate are oppositely arranged, the first transparent conducting layer is arranged on the inner surface of the first baseplate, and the second transparent conducting layer is arranged on the inner surface of the second baseplate. The resistivity of the second transparent conducting layer along a first direction is larger than the resistivity thereof along a second direction. The second transparent conducting layer is a carbon nanotube film, furthermore, carbon nanotubes in the carbon nanotube film are preferentially oriented and arranged along a single direction,and the single direction is parallel to the second direction of the second transparent conducting layer. The invention also provides a driving method of the multipoint touch screen.

Owner:INNOCOM TECH (SHENZHEN) CO LTD +1

Adhering coating process of photocatalyst and fixed bed base material

InactiveCN110328128AGigantic nanosize effectLarge specific surface areaPretreated surfacesSpecial surfacesWater basedElectron hole

Owner:浙江森井生物技术股份有限公司

Liquid photosensitivedark dark-color solder resisting material and preparation method thereof

ActiveCN104516205AImprove solder resistanceImprove performancePhotomechanical apparatusLiquid stateHeat resistance

The invention discloses a liquid photosensitive solder resisting material. The solder resisting material comprises the components of photosensitive resin, acrylic acid monomer, hot solidification resin, paint, a filling material, a photoinitiator, an additive and a solvent, and is characterized by comprising the following materials in parts by weight: 30-50 parts of photosensitive resin, 10-20 parts of an acrylic acid monomer, 3-20 parts of hot solidification resin, 2-5 parts of paint, 20-35 parts of a filling material, 3-8 parts of a photoinitiator, 0.3-5 parts of an additive, and 25-40 parts of a solvent. The obtained liquid photosensitive solder resisting material has superior heat resistance, and excellent flexibility, improves bridge protecting performance to 2.5 mil through a resin synthesis reaction, solves the problem that the bridge protecting performance of original photosensitive resin is low, and is simple in technology, reasonable in formula and good in performance.

Owner:江门市阪桥电子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com