Optical adhesive composition, optical adhesive film and optical laminate

A technology of optical glue and composition, applied in the field of optical laminates, can solve the problems of easy generation of air bubbles, inability to fit closely, height difference, etc., and achieve the effect of good light penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

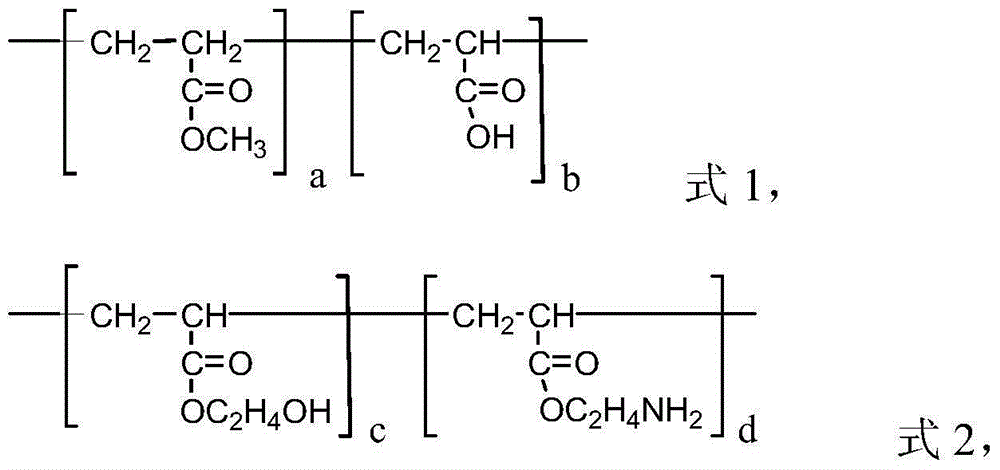

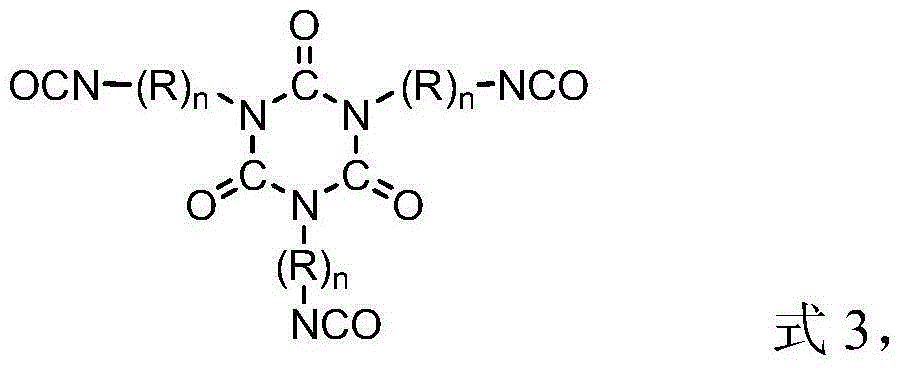

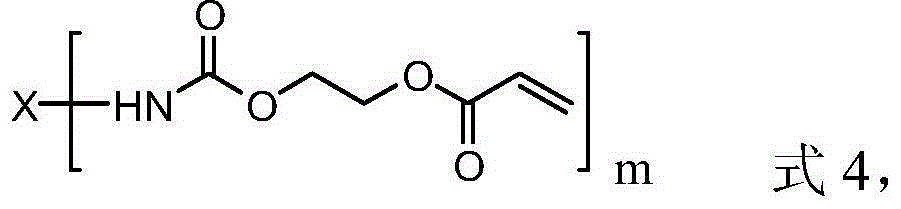

Method used

Image

Examples

Embodiment 1

[0053] Under the yellow light laboratory that cuts off ultraviolet rays, add 100 parts by weight of acrylic polymer, 0.07 parts by weight of crosslinking agent, 1 part by weight of acrylic oligomer A, and 5 parts by weight of photoinitiator , and stirred at 25° C. and 400 rpm for 30 minutes to form the optical adhesive composition of Example 1.

[0054] Next, the obtained optical adhesive composition was coated on a PET release film (Nan Ya Company, model: L150A) with a doctor blade. Subsequently, the coated PET release film was placed in an oven at 100° C. and dried for 3 minutes to obtain a PET release film having an optical adhesive film with a dry film thickness of 175 μm thereon. Then, after it was taken out, another release film (Nan Ya Company, model: H8A0A) was covered on the optical adhesive film to form the optical laminate of Example 1.

Embodiment 2~ Embodiment 4

[0056] The optical adhesive compositions and optical laminates of Examples 2 to 4 are manufactured according to the same manufacturing procedure as that of Example 1. The difference is that the addition amounts of the components used are different, and the detailed addition amounts are as follows: Table 1 shows.

Embodiment 5~ Embodiment 6

[0058] According to the same manufacturing process as in Example 1, the optical adhesive composition and optical laminate of Example 5 to Example 6 are manufactured, the difference is that the dry film thickness of the optical adhesive film is different, and its detailed thickness is shown in Table 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com