A kind of photocurable resin composition and optical device prepared therefrom

A resin composition and light-curing technology, applied in optical components, optics, instruments, etc., can solve problems such as easy deformation and stress streaks, and achieve the effects of good toughness, reduced stress streaks, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

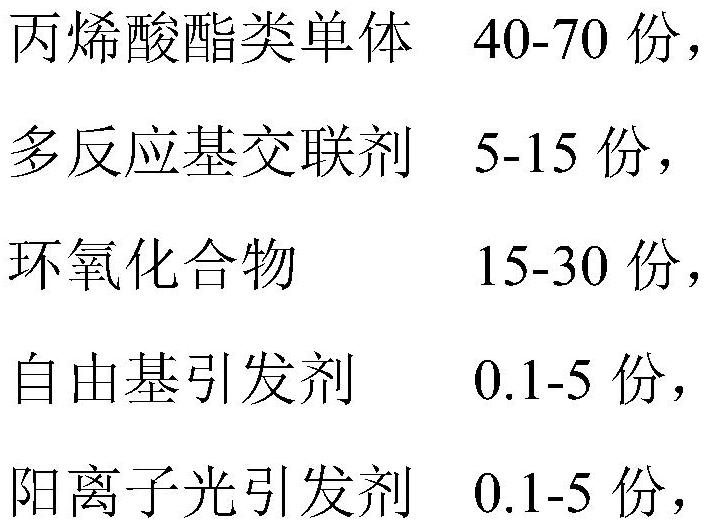

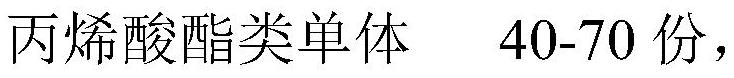

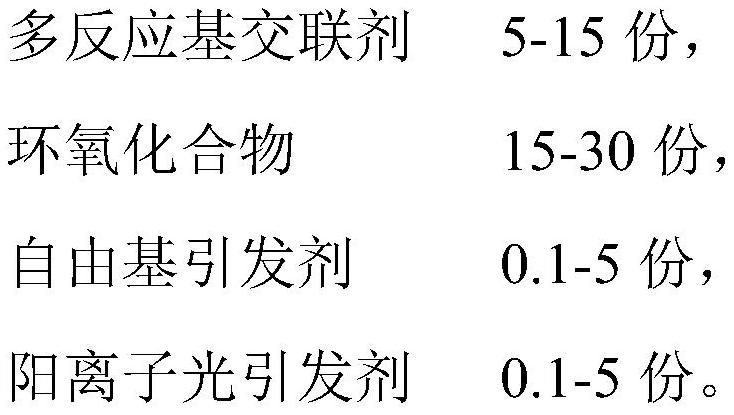

Method used

Image

Examples

Embodiment 1

[0090] This example provides a UV-curable resin composition and the lens prepared therefrom. For the composition of the UV-curable resin composition, refer to Example 1 in Table 1. Mix the reagent and its listed weight parts evenly Finally, the resulting glue was first tested for glue performance, and the results are shown in Table 3.

[0091] Afterwards, the photocurable lens is prepared, and the specific implementation steps are as follows:

[0092] (1) Put the photocurable composition above into a vacuum oven at room temperature for vacuum defoaming (30min, <0.1torr).

[0093] (2) After the defoaming of the composition is completed, inject it into a transparent mold, close the mold with an apron or adhesive tape to form a mold body, and use ultraviolet light to perform an energy on the mold body in the transparent mold. A radiation curing step of 3 minutes allowed the mold to form a photocurable lens. After that, the manual punching machine was used to remove the mold, an...

Embodiment 2-5

[0095] The UV-curable resin composition provided by Examples 2-5 and the lens prepared thereof, the composition of the UV-curable resin composition is as shown in Example 2-5 in Table 1, using the same After mixing evenly and performing the performance test of the glue solution, the mold body was formed by injection molding, and the lens was cured to obtain the lens, and the following lens evaluation items were carried out, and the results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com