Harmless treatment method for urban garbage incineration fly ash

A technology for incineration of fly ash and disposal method, which is applied in the direction of solid waste removal, etc., to achieve good economic benefits, excellent material, and the effect of being conducive to the utilization of resources and resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

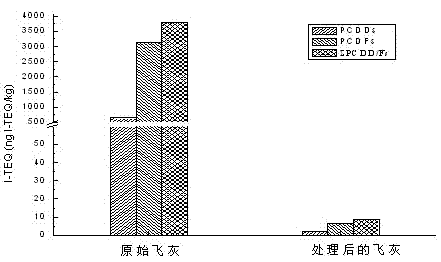

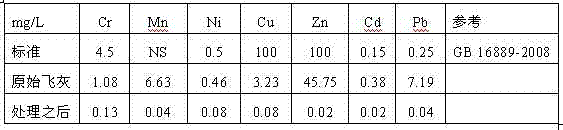

Embodiment 1

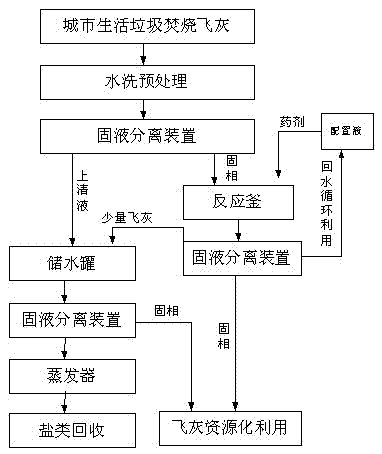

[0048] figure 2 It is the harmless disposal process of municipal waste incineration fly ash of the present invention. Incineration fly ash is collected in the bag filter of the flue gas purification system of the municipal solid waste incineration plant. First of all, according to the flow chart, the collected fly ash is washed and pretreated, and the method is as follows: According to the flow chart, the fly ash and tap water are mixed at a ratio of 1:10, and after mixing, stir with a strong paddle for 20 minutes to promote soluble salts Fully dissolve. After washing with water, the collected solid ash is about 70% of the weight of the original fly ash. After pretreatment of fly ash after washing with water, the chlorine content of the original fly ash was reduced from 3.85% to 0.032%, which was lower than the 0.06% chlorine content requirement specified in the "General Portland Cement" product standard.

[0049] Then the washed mortar is subjected to a solid-liquid separ...

Embodiment 2

[0057] The bag dust-removing fly ash obtained in Example 1 is first subjected to the water washing pretreatment of the same working condition as in Example 1. After washing with water, the fly ash and the configuration solution are mixed at a ratio of 1:10, and the NaOH concentration of the configuration solution is 1mol / L. The temperature was 300°C, and the reaction time was 10 hours. After harmless treatment, the PH value dropped from 13.7 of the original configuration solution to 12.49, the heavy metal leaching solution of the fly ash was lower than the national standard, the dioxin degradation rate was 99.99%, and the specific surface area of the fly ash after treatment was 36.3 m 2 / g, the adsorption capacity is 73.5 meq / 100g.

Embodiment 3

[0059] The bag dust-removing fly ash obtained in Example 1 is first subjected to the water washing pretreatment of the same working condition as in Example 1. After washing with water, the fly ash and the configuration solution are mixed at a ratio of 1:10, and the NaOH concentration of the configuration solution is 1mol / L. The temperature was 150°C and the reaction time was 12 hours. After harmless treatment, the PH value dropped from 13.7 in the original configuration solution to 12.95, the heavy metal leaching solution of the fly ash was lower than the national standard, the dioxin degradation rate was 40.6%, and the specific surface area of the fly ash after treatment was 50.2 m 2 / g, the adsorption capacity is 85.2 meq / 100g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com