Titanium dioxide and graphene oxide composite nano-grade sheet material and preparation method thereof

A graphene composite, titanium dioxide technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment processing and other directions, can solve the problems of uncontrollable particle size distribution, small size, etc., to improve the photoelectric effect efficiency, continuous and controllable thickness , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

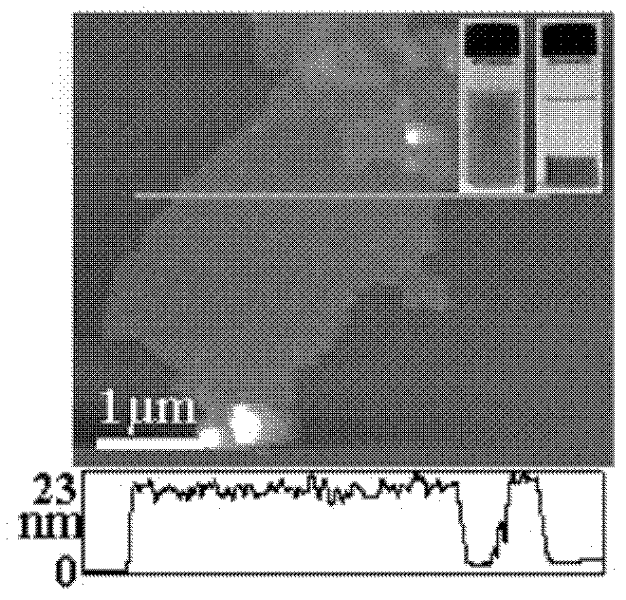

[0039] The preparation method of above-mentioned titanium dioxide and graphene oxide composite nanosheet material, its flow chart is as follows Figure 4 shown, including the following steps:

[0040] Step 1. Ultrasonic vibration of graphene oxide at room temperature to uniformly disperse it in distilled water to prepare a graphene oxide dispersion with a concentration of 6-7 mg / mL.

[0041] Step 2. Dilute the graphene oxide dispersion to 2-5 mg / mL with absolute ethanol.

[0042] Step 3. Dissolving an appropriate amount of butyl titanate in 2-5 mL of absolute ethanol to prepare a butyl titanate ethanol solution with a concentration of 4.2-84 mg / mL.

[0043] Step 4, adding different concentrations of butyl titanate ethanol solutions dropwise to the graphene oxide ethanol dilution solution at a temperature of 20-60° C. and stirring.

[0044] Step 5, reacting for 2-8 hours to obtain a dispersion of amorphous titanium dioxide and graphene oxide composite nanosheet material.

[...

Embodiment 1

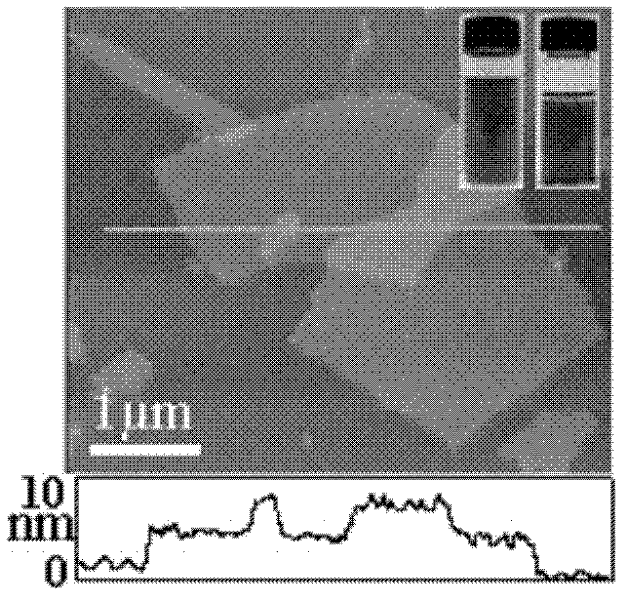

[0053] Graphene oxide was ultrasonically oscillated at room temperature to uniformly disperse it in distilled water to obtain a graphene oxide dispersion with a concentration of 7 mg / mL. Take 1.4 mL of graphene oxide dispersion and dilute it to 20 mL with absolute ethanol. After ultrasonic dispersion, transfer to 50mL flask, placed in a 20°C water bath and stirred. Weigh about 40mg of butyl titanate and dissolve it in 2mL of absolute ethanol, and then add it dropwise into a 50mL flask. Keep the reaction for 4 hours after dropping to obtain a bright brown dispersion of amorphous titanium dioxide and graphene oxide composite nanosheets. After the dispersion was left to stand for 2 months, it was divided into upper and lower layers, the transparent upper layer accounted for a very small part, and the lower layer was still brown and less viscous (see Figure 1A ).

[0054] After washing with absolute ethanol, it was vacuum-dried at room temperature to obtain a dark brown powder. ...

Embodiment 2

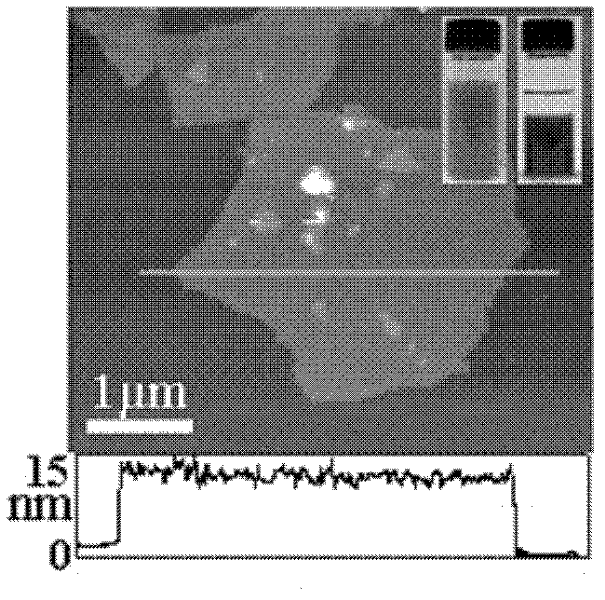

[0056] Ultrasonic vibration of graphene oxide at room temperature to uniformly disperse it in distilled water to obtain a graphene oxide dispersion with a concentration of 6.7mg / mL, take 1.5mL of graphene oxide dispersion and dilute it to 20mL with absolute ethanol, and transfer it after ultrasonic dispersion To a 50mL flask, placed in a 60°C water bath and stirred. Weigh about 210mg of butyl titanate and dissolve it in 5mL of absolute ethanol, and then add it dropwise into a 50mL flask. After dropping, the reaction was kept for 2 hours to obtain a brown dispersion of amorphous titanium dioxide and graphene oxide composite nanosheets. After the dispersion was left to stand for 2 months, it was divided into upper and lower layers, the transparent upper layer accounted for a small part, and the lower layer was still brown but with a higher viscosity (see Figure 1B ).

[0057] After washing with absolute ethanol, it was vacuum-dried at room temperature to obtain a brown powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com