Electronic device, electrode system and preparation method of germanium selenide-based solar water splitting for hydrogen production

An electronic device, germanium selenide technology, applied in chemical instruments and methods, electrical components, semiconductor devices, etc., can solve complex film components and lattice defects, difficult to further improve actual efficiency, low theoretical photoelectric conversion efficiency, etc. problem, to achieve the effect of continuous controllable film thickness, cheap and non-toxic raw materials, and less crystal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below.

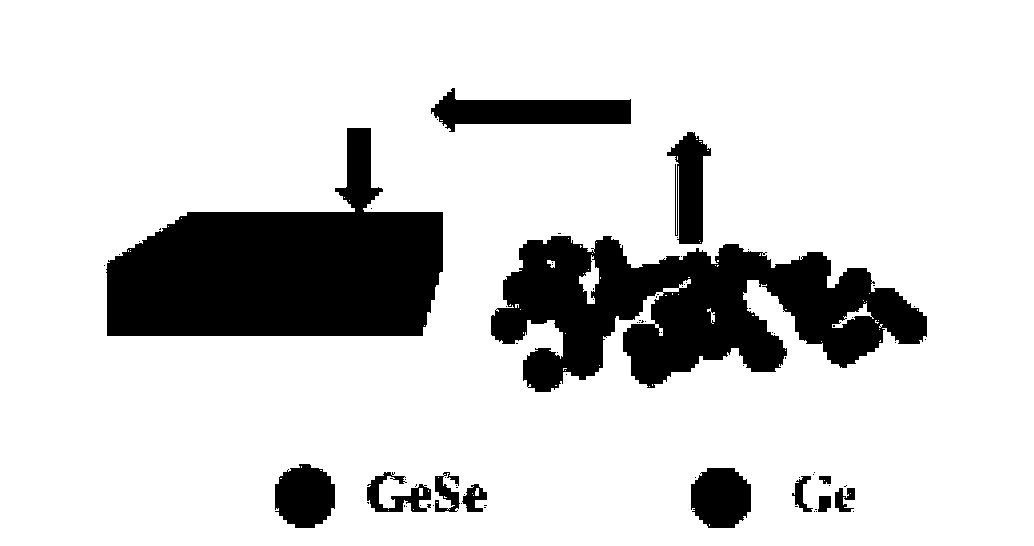

[0038] figure 1 It is a schematic diagram of the preparation principle of germanium selenide, the absorbing layer material of the present invention. As shown in the figure, the germanium selenide powder is heated and evaporated, and deposited on the substrate to form a germanium selenide film.

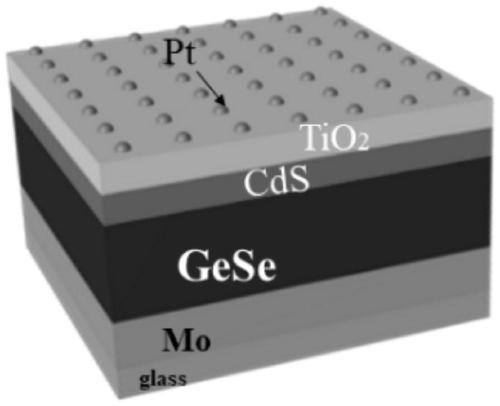

[0039] figure 2 Shown is the structure of the germanium selenide-based sunlight splitting water hydrogen production electronic device of the present invention, which includes a substrate, a back electrode layer on the substrate, a GeSe absorber layer on the back electrode layer, and a buffer on the GeSe absorber layer layer, a protective layer on the buffer layer, and a nanometer metal particle layer attached to the protective layer. Concrete, its substrate can be soda-lime glass substrate, and back electrode can be Mo electrode, FTO, ITO, AZO etc., and in this embodiment, back electrode selects Mo electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com