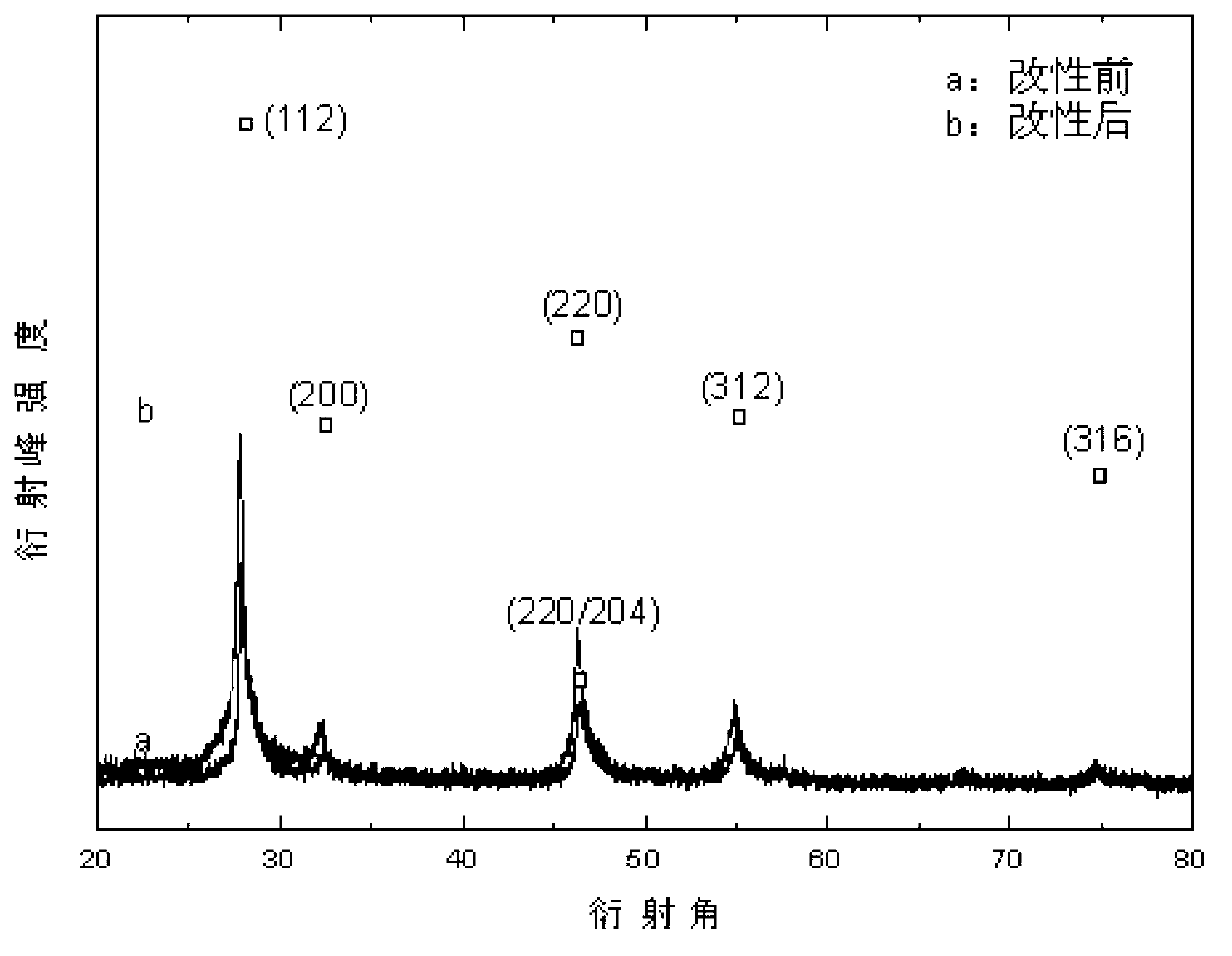

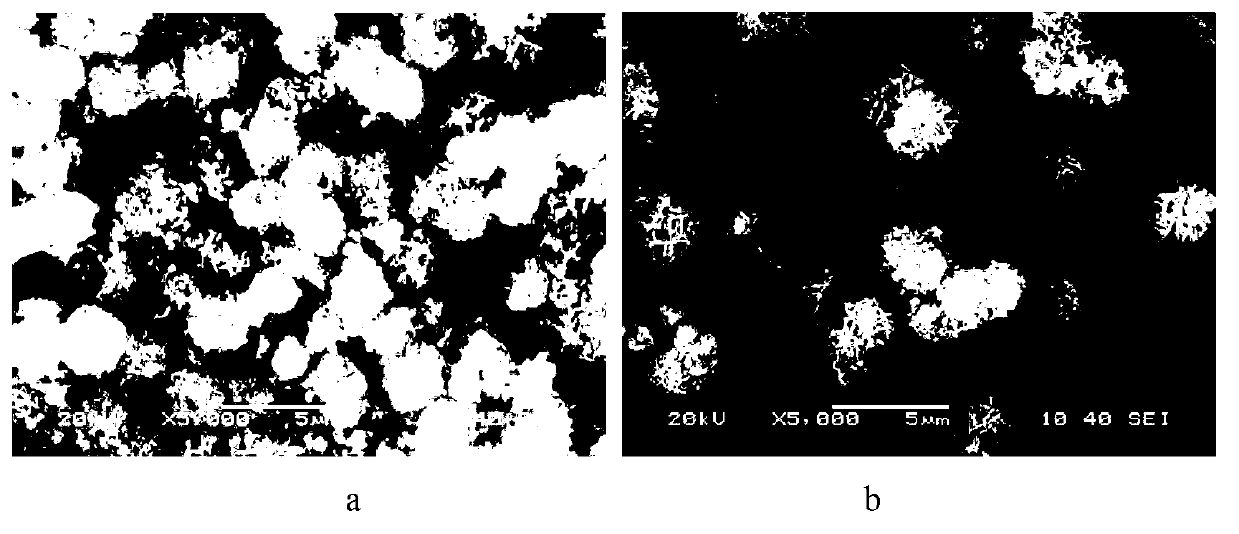

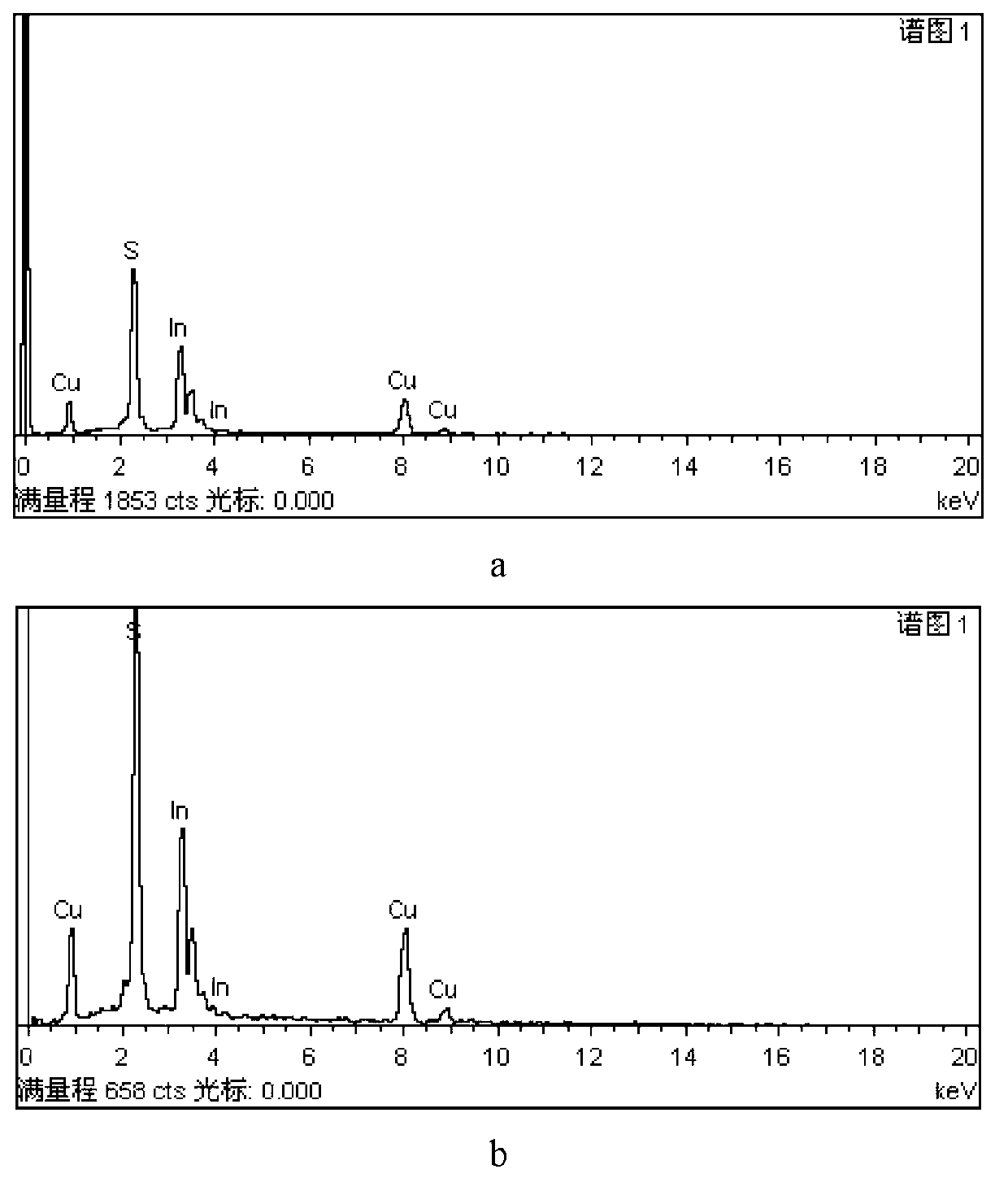

Preparation method of surfactant-modified CuInS2 nanocrystal

A technology of surfactants and nanocrystals, applied in nanotechnology, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of difficult control of CuInS2, achieve high relative solid yield, relatively light absorption performance, and improve agglomeration phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Weigh 0.4651g CuCl with an analytical balance 2 2H 2 O, 0.8000g InCl 3 4H 2 O, 0.5192g CH 4 N 2 S, placed in 40ml N, N-dimethylformamide in turn, stirred to fully dissolve it, and a yellow clear solution was obtained. where n(CuCl 2 2H 2 O):n(InCl 3 4H 2 O):n(CH 4 N 2 S)=1︰1︰2.5.

[0030] 2) Measure 40ml of ethylene glycol and slowly pour it into the solution in step 1), stir to disperse it evenly, and obtain a colorless and clear solution.

[0031] 3) Add 0.01% KH550 of the total mass of the mixed solution to the step 2).

[0032] 4) The solution in step 3) was transferred into a polytetrafluoroethylene-lined autoclave with a volume of 100 mL and then sealed. After reacting at 190°C for 12 hours, it was naturally cooled to room temperature.

[0033] 5) Centrifuge the reaction feed solution in step 4) in an electric centrifuge for 15 minutes at a speed of 3000 r / min, then pour out the upper clear layer, and wash several times with absolute ethanol and de...

Embodiment 2

[0035] 1) Weigh 0.4651g CuCl with an analytical balance 2 2H 2 O, 0.8000g InCl 3 4H 2 O, 0.5192g CH 4 N 2 S, placed in 40ml N, N-dimethylformamide in turn, stirred to fully dissolve it, and a yellow clear solution was obtained. where n(CuCl 2 2H 2 O):n(InCl 3 4H 2 O):n(CH 4 N 2 S)=1︰1︰2.5.

[0036] 2) Measure 40ml of ethylene glycol and slowly pour it into the solution in step 1), stir to disperse it evenly, and obtain a colorless and clear solution.

[0037] 3) Add 0.1% KH550 of the total mass of the mixed solution to the step 2).

[0038] 4) The solution in step 3) was transferred into a polytetrafluoroethylene-lined autoclave with a volume of 100 mL and then sealed. After reacting at 190° C. for 12 hours, it was naturally cooled to room temperature.

[0039]5) Centrifuge the reaction feed solution in step 4) in an electric centrifuge for 15 minutes at a speed of 3000 r / min, then pour out the upper clear layer, and wash several times with absolute ethanol and de...

Embodiment 3

[0041] 1) Weigh 0.4651g CuCl with an analytical balance 2 2H 2 O, 0.8000g InCl 3 4H 2 O, 0.5192g CH 4 N 2 S, placed in 40ml N, N-dimethylformamide in turn, stirred to fully dissolve it, and a yellow clear solution was obtained. where n(CuCl 2 2H 2 O):n(InCl 3 4H 2 O):n(CH 4 N 2 S)=1︰1︰2.5.

[0042] 2) Measure 40ml of ethylene glycol and slowly pour it into the solution in step 1), stir to disperse it evenly, and obtain a colorless and clear solution.

[0043] 3) Add 1% KH550 of the total mass of the mixed solution to the step 2).

[0044] 4) The solution in step 3) was transferred into a polytetrafluoroethylene-lined autoclave with a volume of 100 mL and then sealed. After reacting at 190°C for 12 hours, it was naturally cooled to room temperature.

[0045] 5) Centrifuge the reaction feed solution in step 4) in an electric centrifuge for 15 minutes at a speed of 3000 r / min, then pour out the upper clear layer, and wash several times with absolute ethanol and deion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com