Hollow nano silica microsphere modified polyacrylate nuclear shell structure composite emulsion and thin film

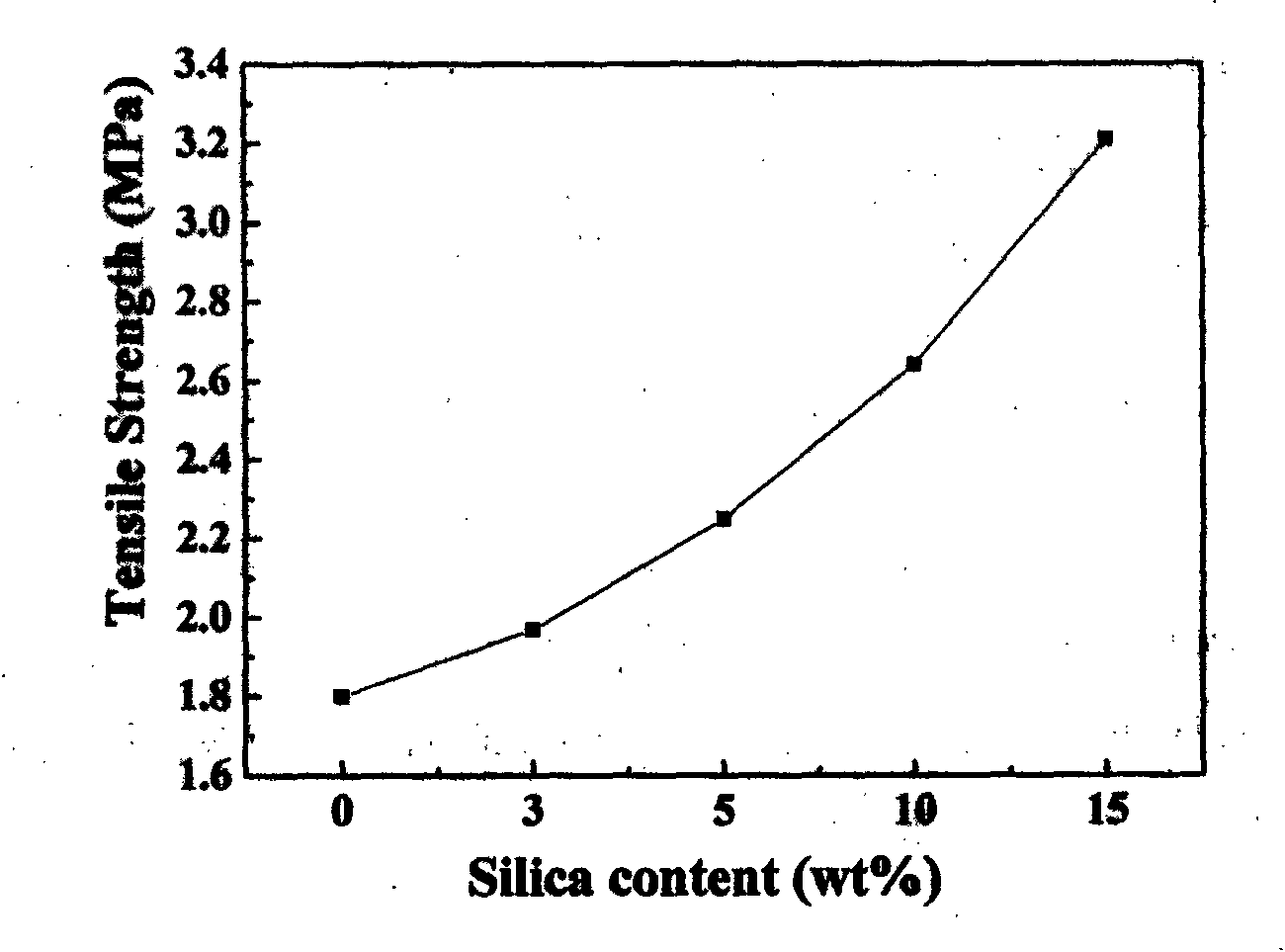

A technology of nano-silica and polyacrylate, which is applied in the field of polymer and nano-composite materials and their preparation, can solve the problems that the compatibility between nano-silica and polymer matrix cannot be achieved, and achieve easy popularization and application, good Effect of improving mechanical properties, damping properties, and dispersion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of modified polystyrene microspheres as hollow microsphere templates, the preparation method is as follows: add 0.3gSDBS, 0.1gNaHCO As a buffer and 90g distilled water, first ultrasonically disperse, then place in a three-necked flask, heat and stir . After 30 minutes, 5g-15g of styrene was added, and the temperature was raised to 70°C, and 0.1g-0.5g of ammonium persulfate in 10ml of aqueous solution was added. After 1 hour of reaction, slowly add 1g~4g of γ-methacryloxypropyltrimethoxysilane (KH-570) dropwise and add 0.02g of ammonium peroxodisulfate, and react for 2.5 hours to obtain Polystyrene seed white emulsion.

[0025] (2) TEOS hydrolysis coating: Take 3m~10ml of emulsion, 95ml of ethanol and 2.8ml of ammonia (0.4mol / L) into a three-necked flask, stir at high speed, raise the temperature to 70°C, and then drop in 7.5ml of ethanol and 3m~10ml For the mixed solution of TEOS, the dropping speed is 10ml / h~40ml / h. After the dropping is completed, th...

Embodiment 2

[0030] (1) Preparation of modified polystyrene microspheres as hollow microsphere templates, the preparation method is as follows: add 0.3gSDBS, 0.1gNaHCO As a buffer and 90g distilled water, first ultrasonically disperse, then place in a three-necked flask, heat and stir . After 30 minutes, 5g-15g of St was added, and the temperature was raised to 70°C, and 0.1g-0.5g of ammonium persulfate in 10mL of aqueous solution was added. After reacting for 1 hour, slowly add 1g-4g of KH-570 dropwise and add 0.02g of ammonium peroxodisulfate. After reacting for 2.5 hours, a polystyrene seed white emulsion with hydroxyl groups on the surface is obtained.

[0031] (2) TEOS hydrolysis coating: Take 3m~10ml of emulsion, 95ml of ethanol and 2.8ml of ammonia water (0.4mol / L) and add them into a three-necked flask, stir at high speed, and then add 7.5ml of ethanol and 3ml~10ml of TEOS drop by drop. Solution, the dropping rate is 1ml / h~10ml / h, after the dropwise addition, continue to react for...

Embodiment 3

[0036] (1) Prepare the modified polystyrene microspheres as the hollow microsphere template, and the preparation method is as follows: add 0.3gSDBS, 0.1g NaHCO as buffer and 90g distilled water, first ultrasonically disperse, then place in a three-necked flask, heat and Stir. After 30 minutes, 5g-15g of St was added, and the temperature was raised to 70°C, and 0.1g-0.5g of ammonium persulfate in 10mL of aqueous solution was added. After reacting for 1 hour, slowly add 1g-4g KH-AM (self-made coupling agent) dropwise and add 0.02g ammonium peroxodisulfate. After reacting for 2.5 hours, a polystyrene seed white emulsion with hydroxyl groups on the surface is obtained.

[0037] (2) TEOS hydrolysis coating: Take 3m~10ml of emulsion, 95ml of ethanol and 2.8ml of ammonia water (0.4mol / L) and add them into a three-necked flask, stir at high speed, raise the temperature to 70°C, and then drop in 7.5ml of ethanol and 3m~ 10ml TEOS mixed solution, the dropping rate is 10ml / h~40ml / h, aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com