Micro-generator based on nano-film thermocouple and superlattice photoelectric structure

A micro-generator and nano-film technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of insufficient output power and easy environmental interference, and achieve the effects of improving efficiency, facilitating device interconnection, and high conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

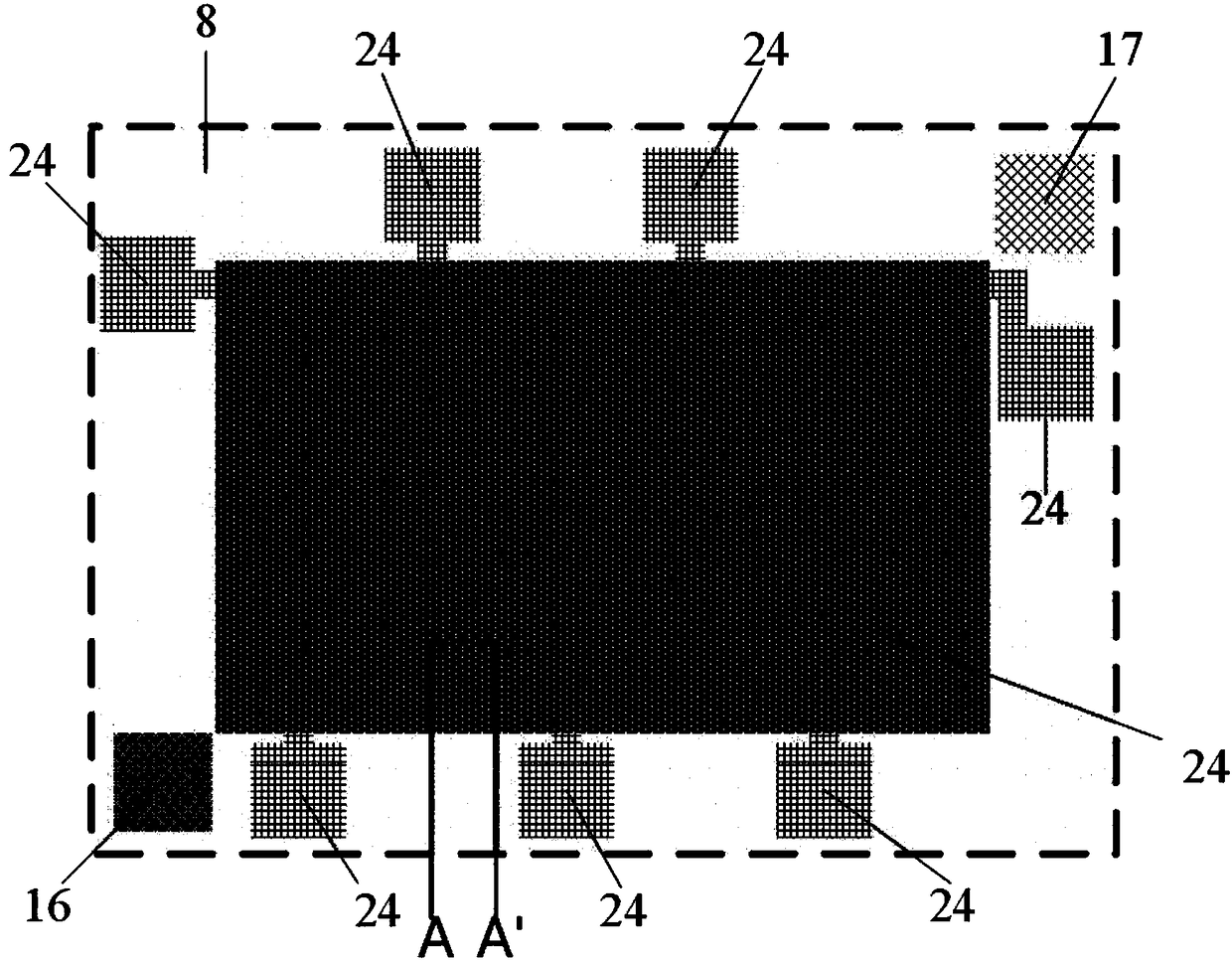

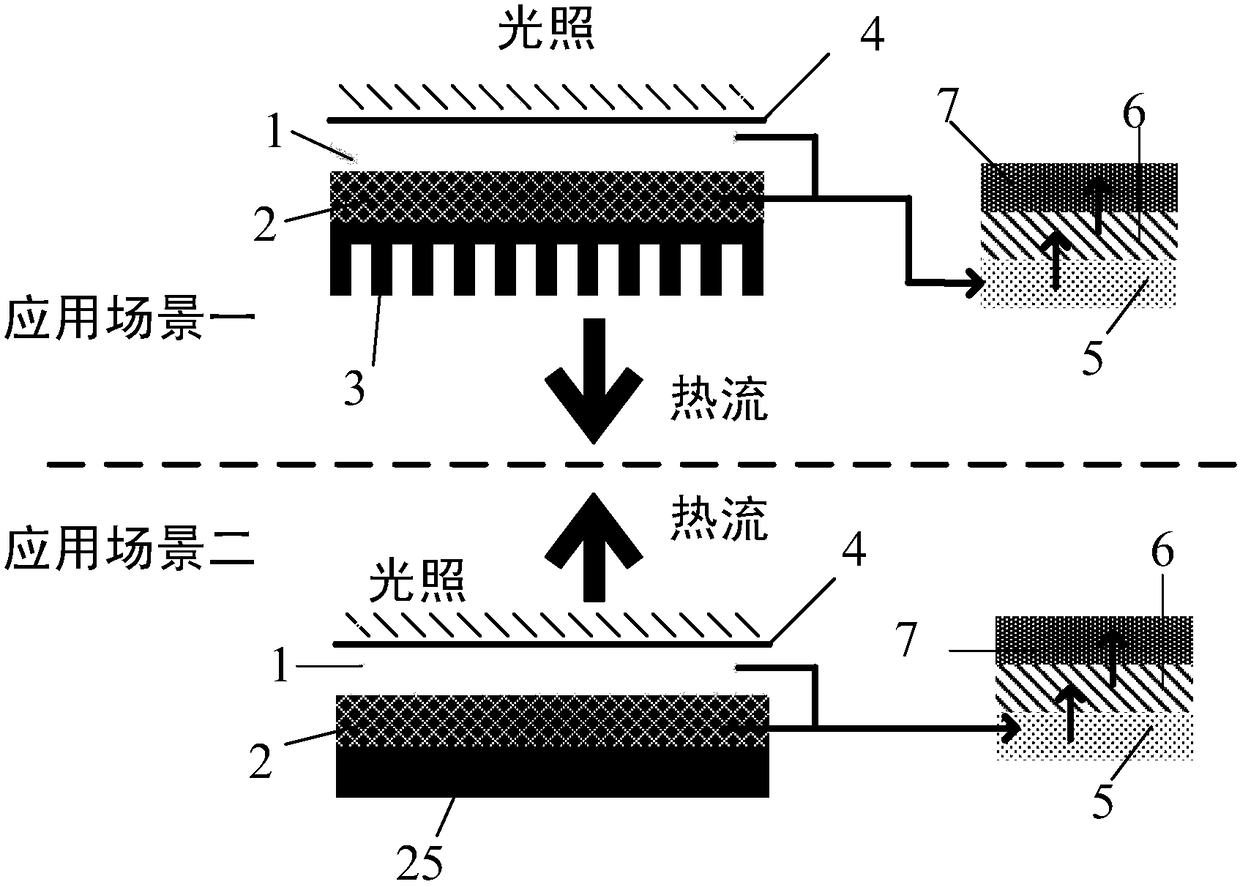

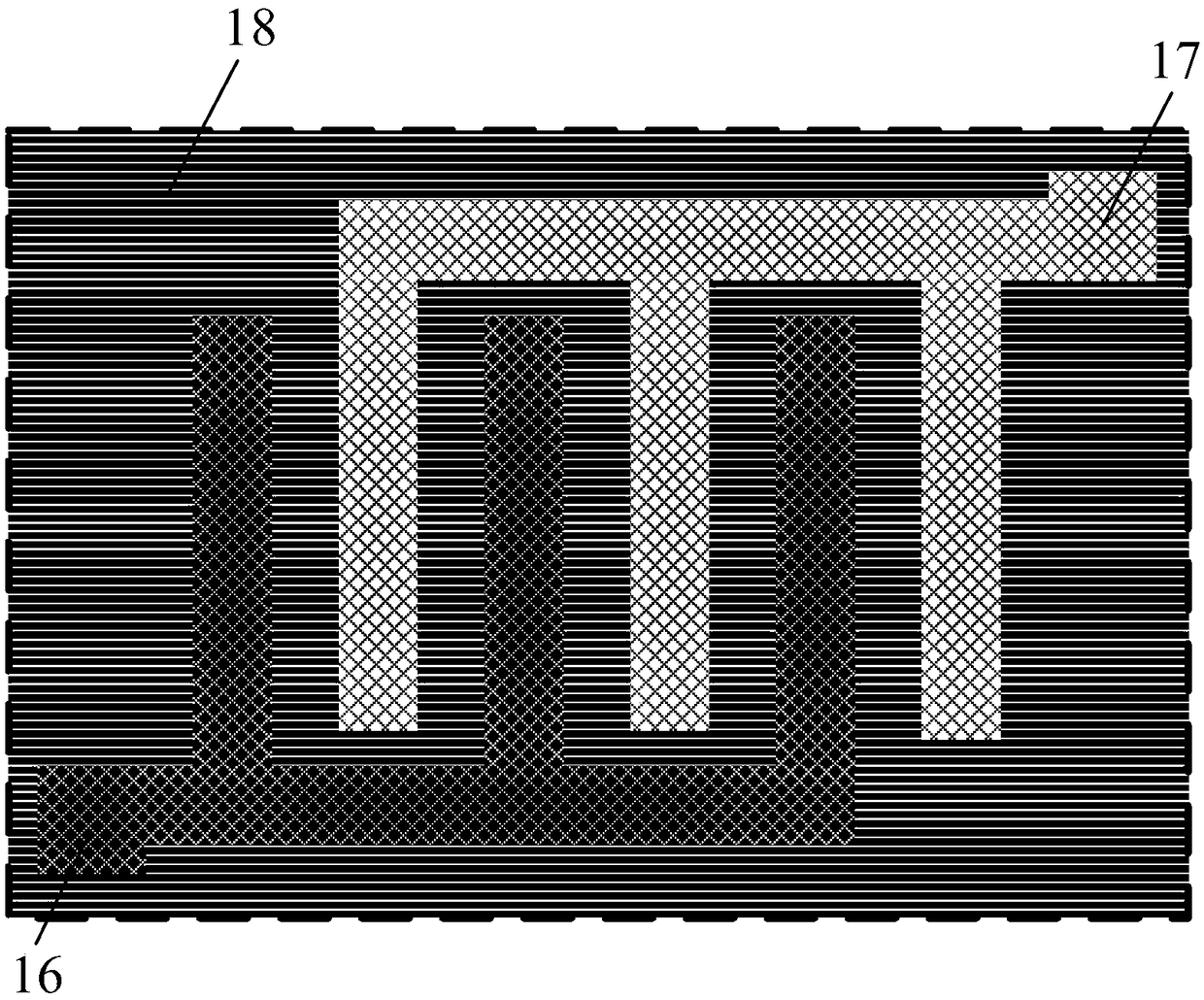

[0026] see Figure 1-5 , the present invention proposes a micro-generator based on a nano-film thermocouple and a superlattice photoelectric structure. Its structure mainly includes a photovoltaic cell 1 and a thermoelectric generator 2, the two parts are fabricated on the same silicon substrate 9, realizing the monolithic integration of thermoelectricity and photovoltaics, and the electrodes of the photovoltaic cell 1 and the thermoelectric generator 2 are located on the silicon wafer. The same side is convenient for packaging in practical applications, and the first silicon nitride film 8 is used as the insulating structure of the two parts to avoid electrical short circuit.

[0027] The substrate 9 of the photovoltaic cell is an N-type silicon chip with a long carrier life, and the light-receiving surface 4 adopts a textured inverted pyr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com