Method for positioning touch screen

A positioning method and touch screen technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of high touch screen manufacturing process, complicated driving method, and small number of touch points, and achieve good light penetration Transparency, simple driving method, effect of improved resolution and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

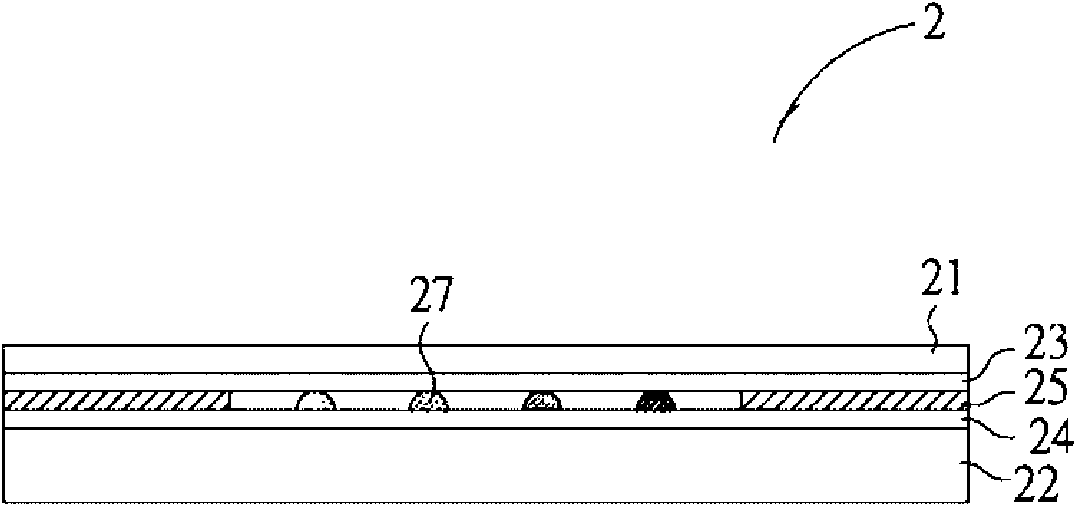

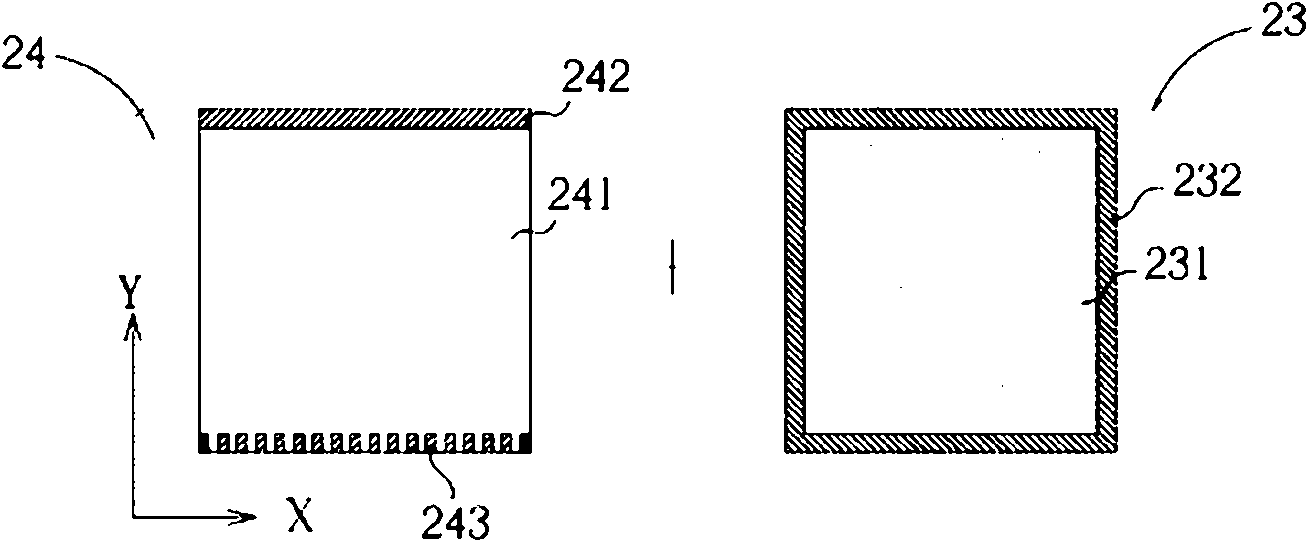

[0019] see figure 1 , which is a schematic cross-sectional structure diagram of the first embodiment of the touch screen of the present invention. The touch screen 2 includes a first substrate 21 and a second substrate 22 oppositely disposed. The first substrate 21 is generally made of elastic material, and the second substrate 22 is made of rigid material to bear a certain pressure. In this embodiment, the first substrate 21 is a polyester film, and the second substrate 22 is a glass substrate. A first conductive layer 23 is disposed on a surface of the first substrate 21 opposite to the second substrate 22 . A second conductive layer 24 is disposed on a surface of the second substrate 22 opposite to the first substrate 21 . An adhesive layer 25 is disposed at the edge between the first substrate 21 and the second substrate 22 to bond the first substrate 21 and the second substrate 22 together. The distance between the first conductive layer 23 and the second conductive l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com