Patents

Literature

281results about How to "Improve process yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

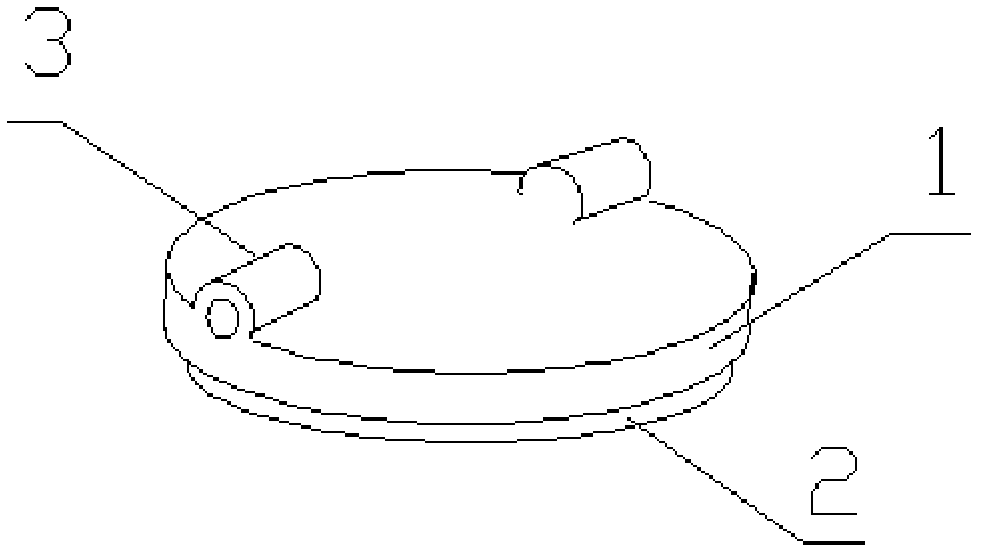

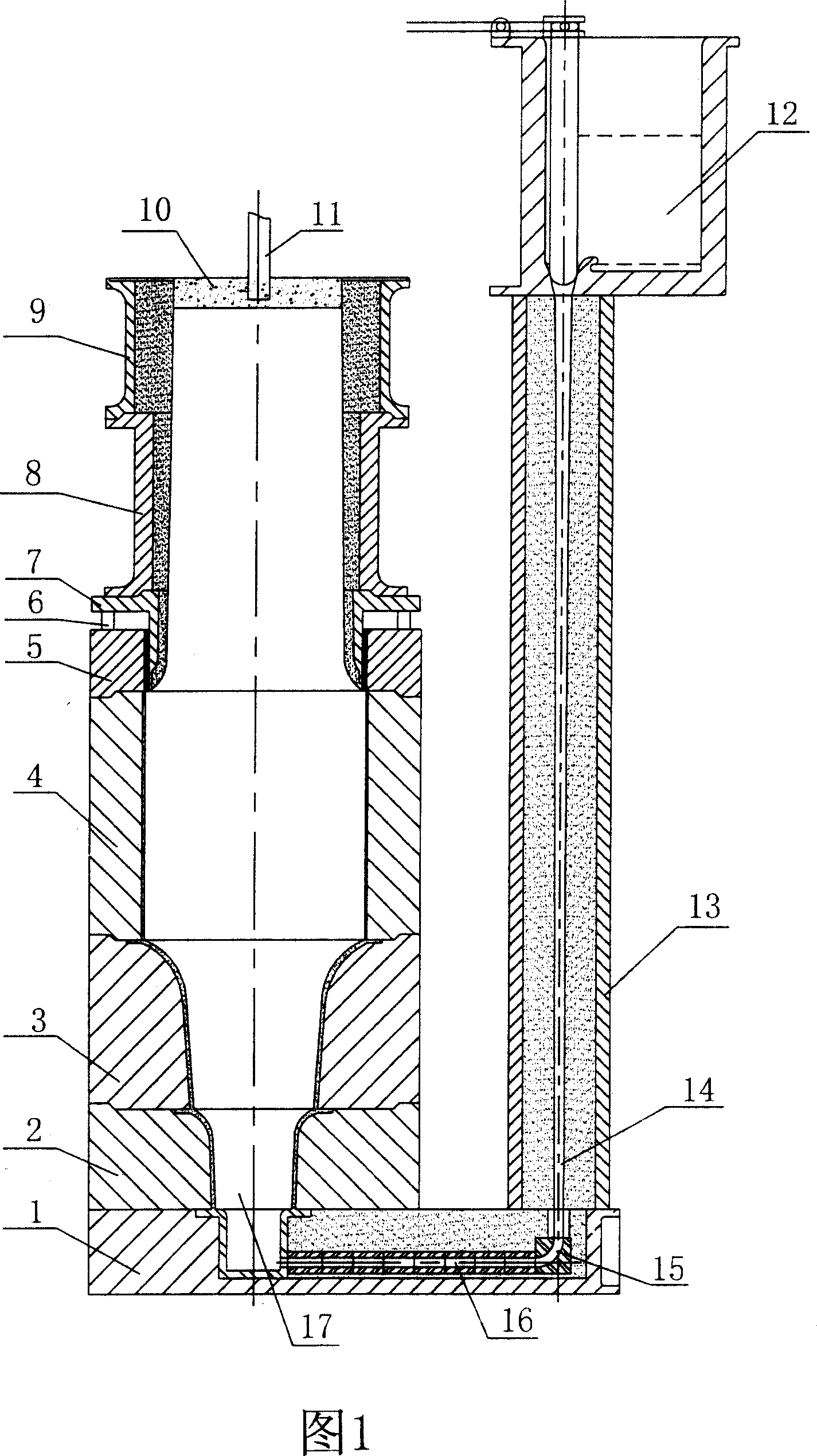

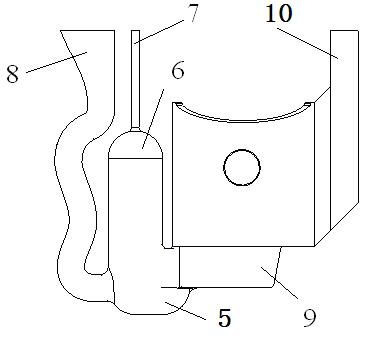

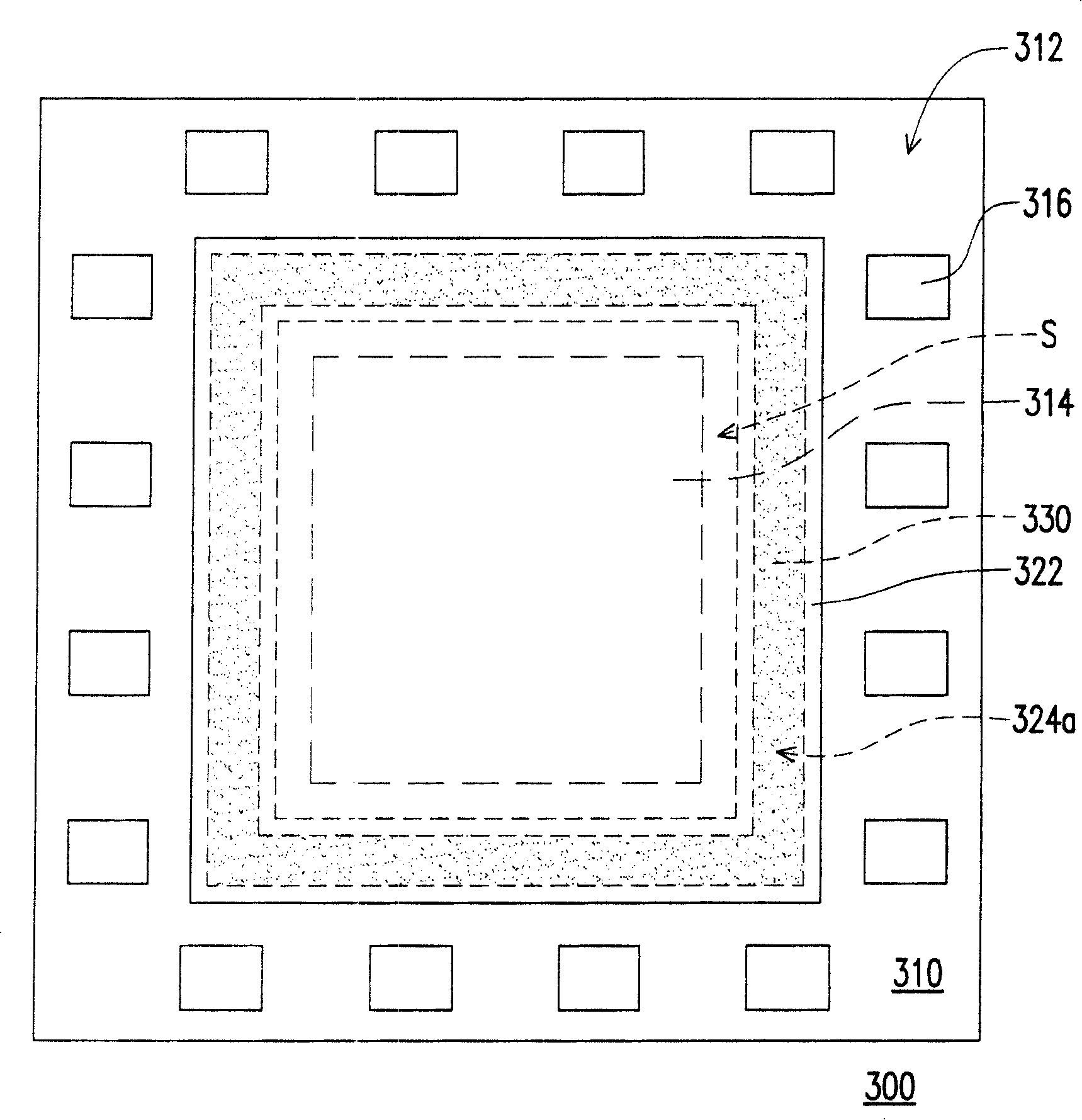

Plasma Processing Apparatus

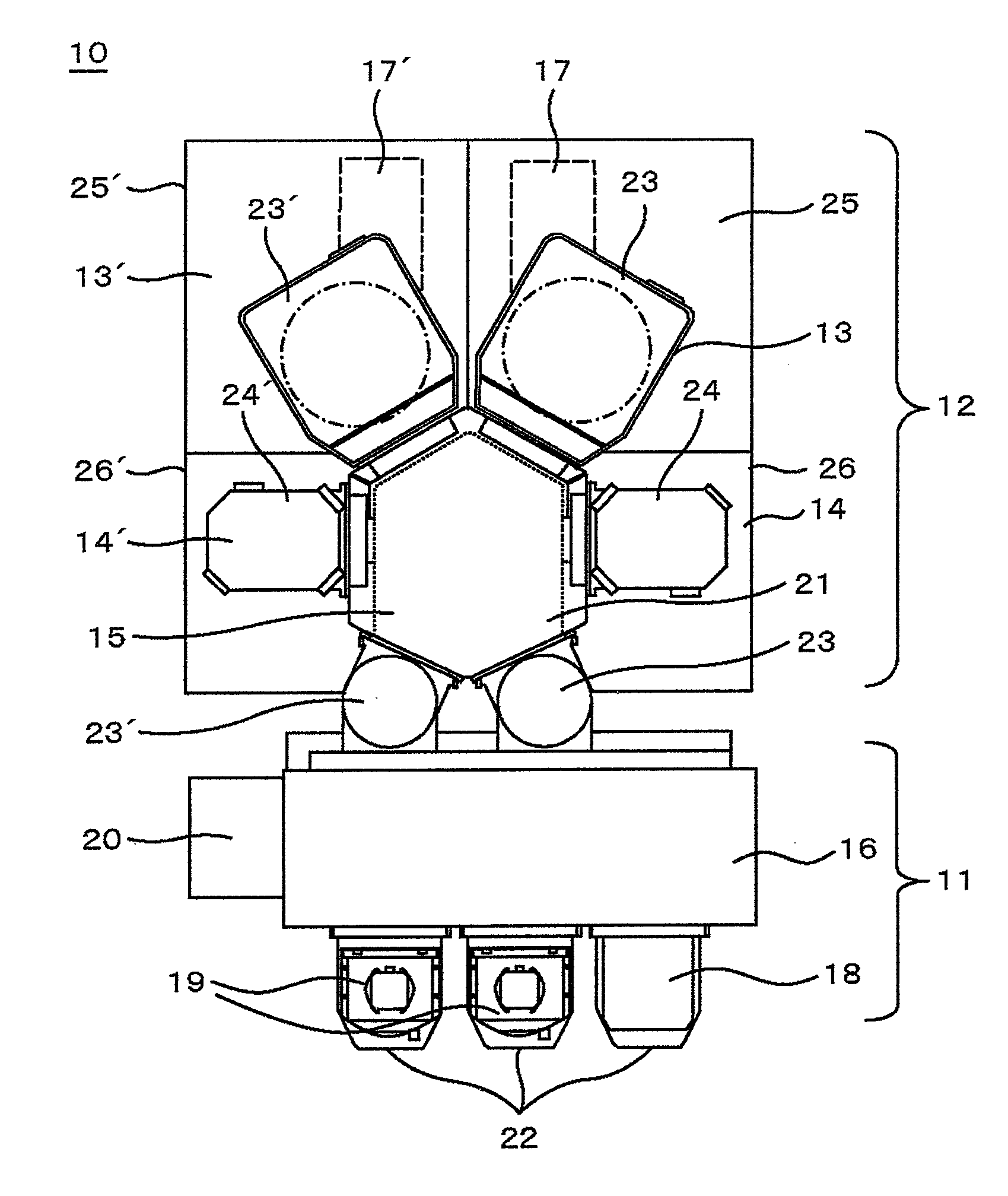

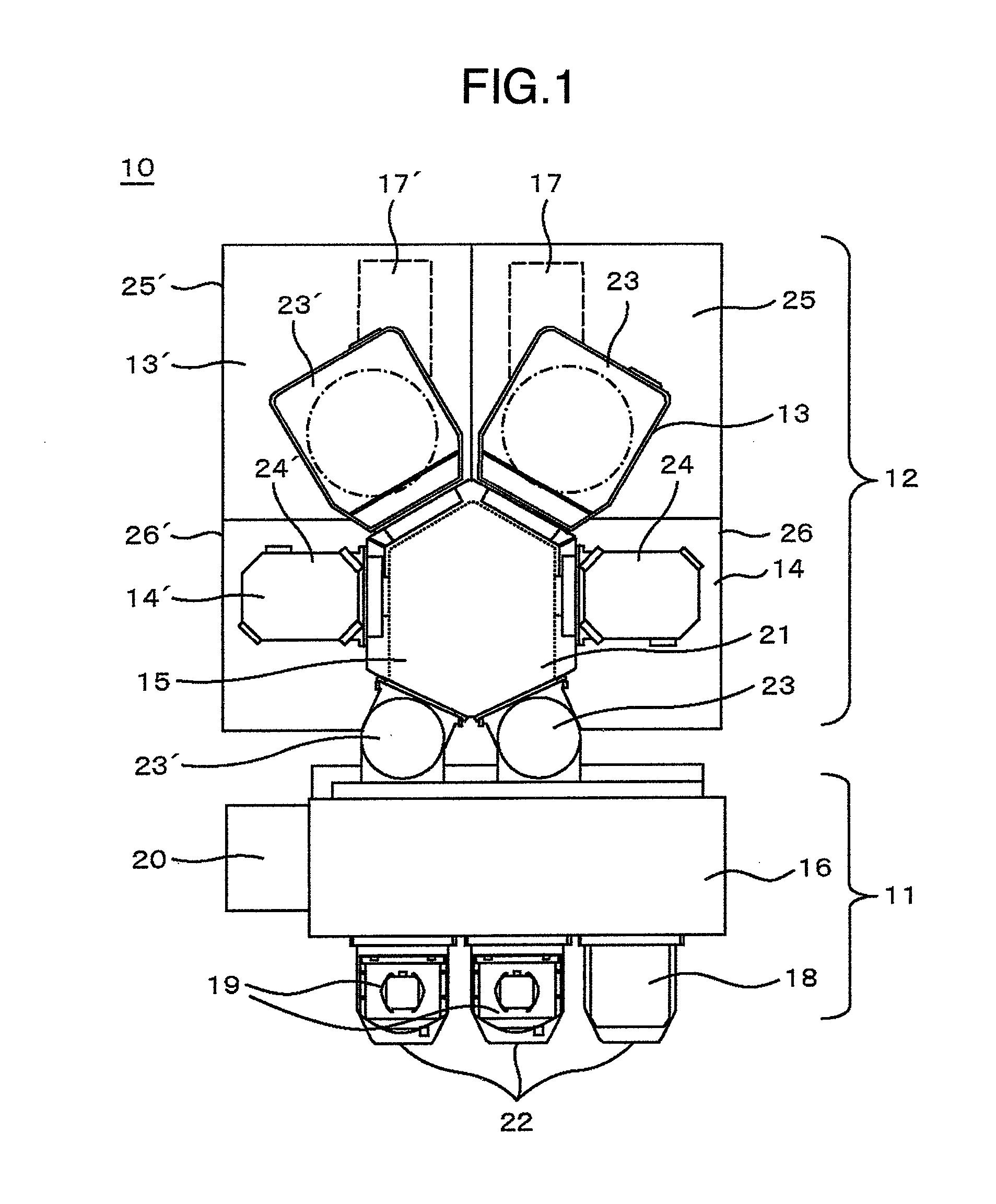

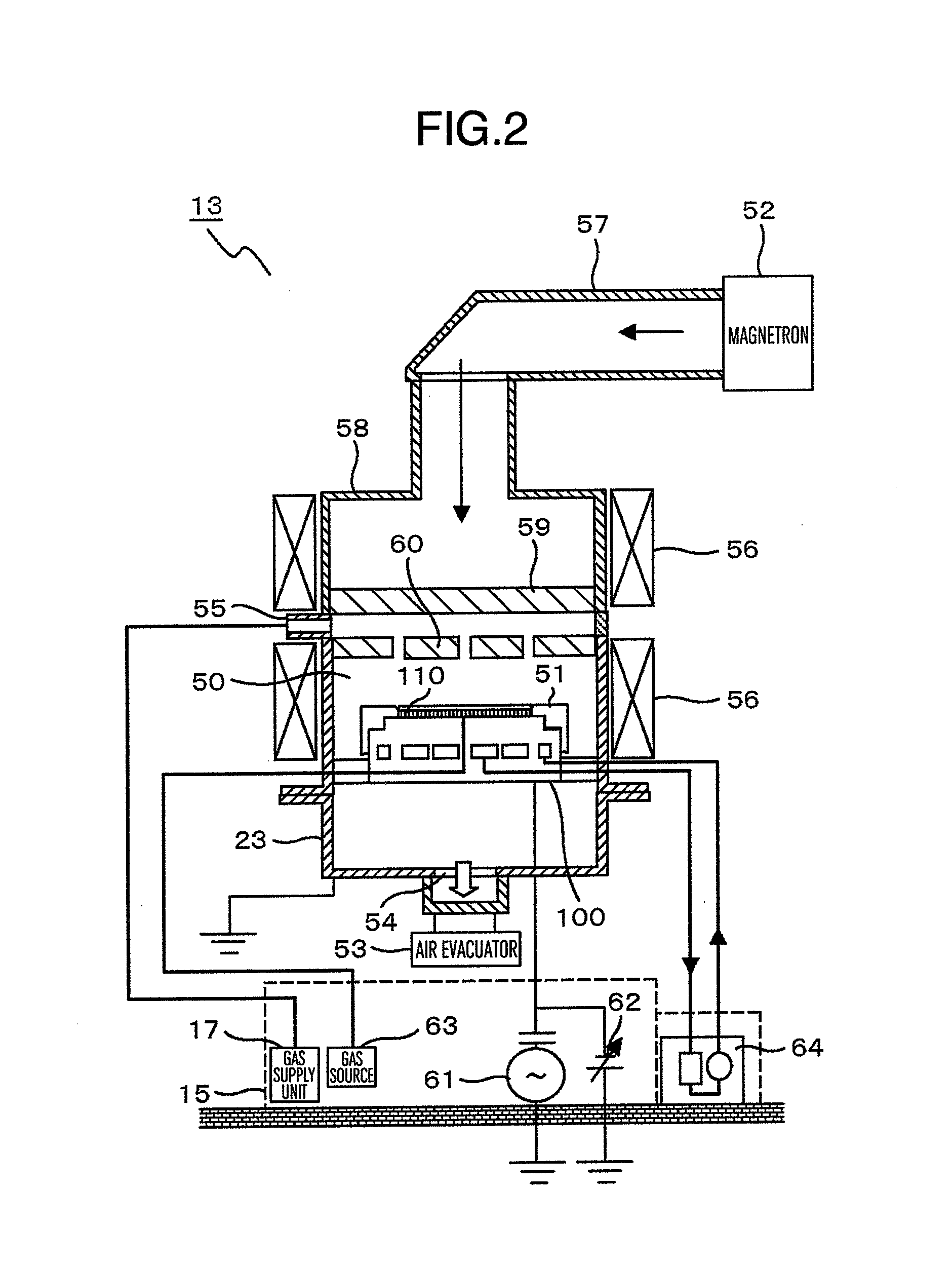

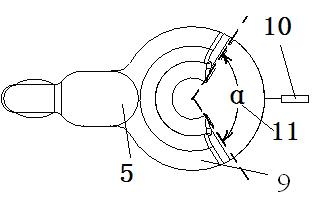

InactiveUS20080236751A1Improve process yieldUniformity of processElectric discharge tubesSemiconductor/solid-state device manufacturingCircumferential ringsPlasma processing

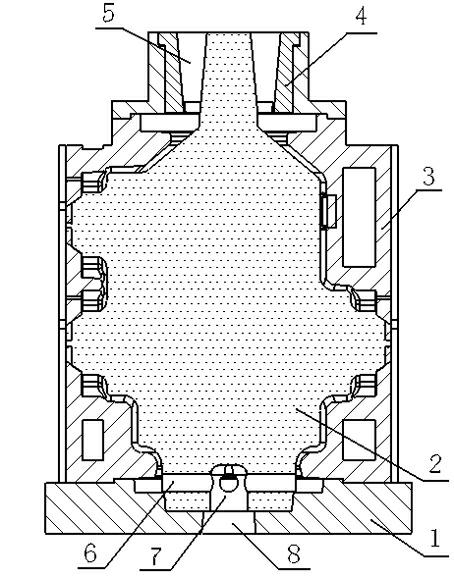

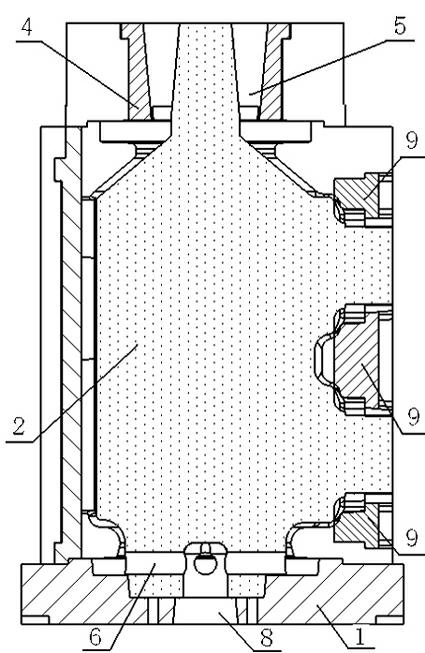

A plasma processing apparatus wherein a layer structure consisting of plural layers formed in stack one upon another on a semiconductor wafer placed on the sample holder located in the process chamber, is etched with plasma generated in the process chamber by supplying high frequency power to the electrode disposed in the sample holder, the apparatus comprising a ring-shaped electrode disposed above the electrode and around the periphery of the top portion of the sample holder, an outer circumferential ring of dielectric material disposed above the ring-shaped electrode and opposite to the plasma, and a power source for supplying power at different values to the ring-shaped electrode depending on the sorts of layers of the layer structure.

Owner:HITACHI HIGH-TECH CORP

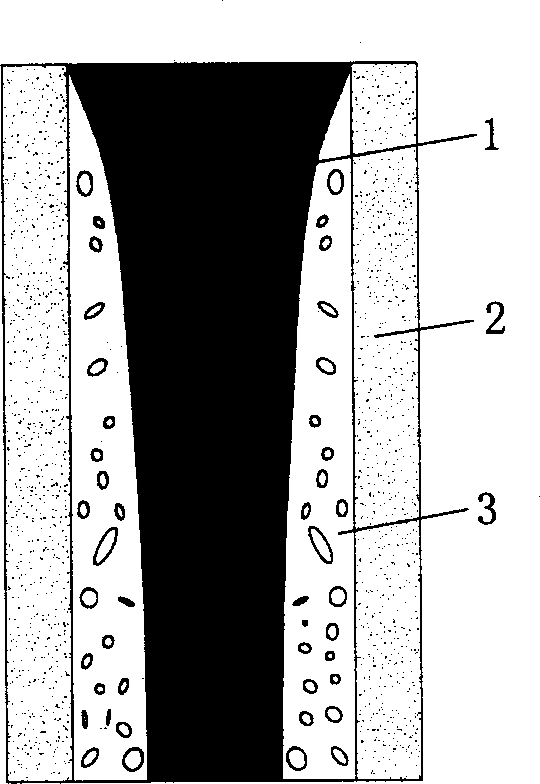

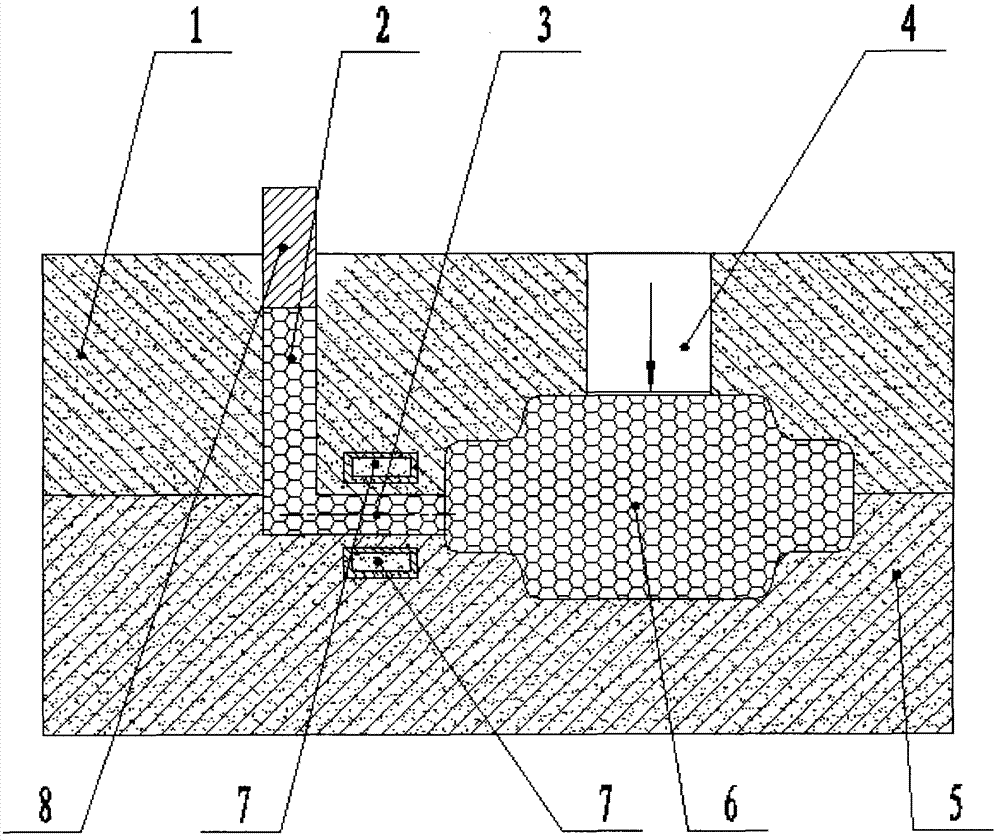

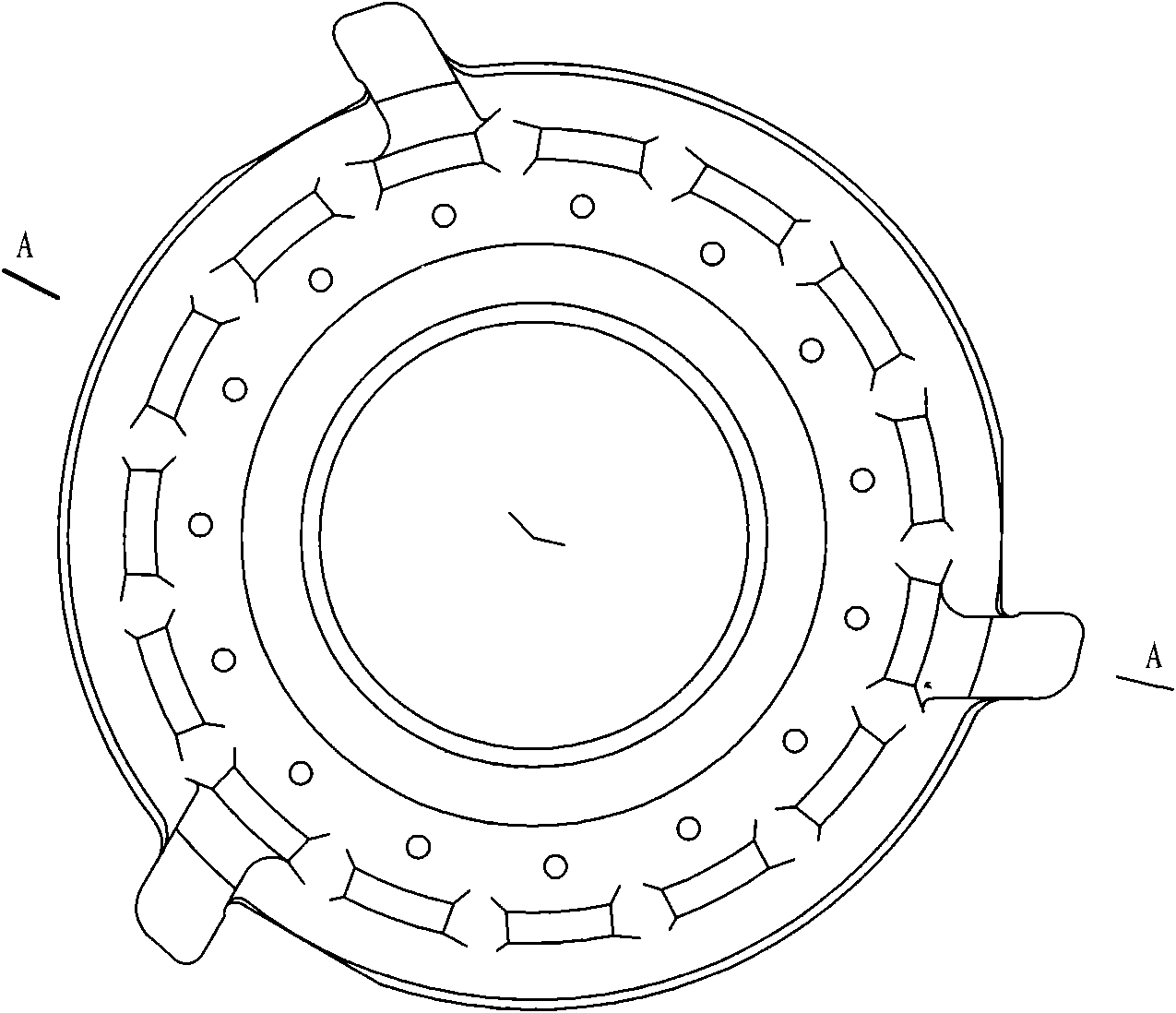

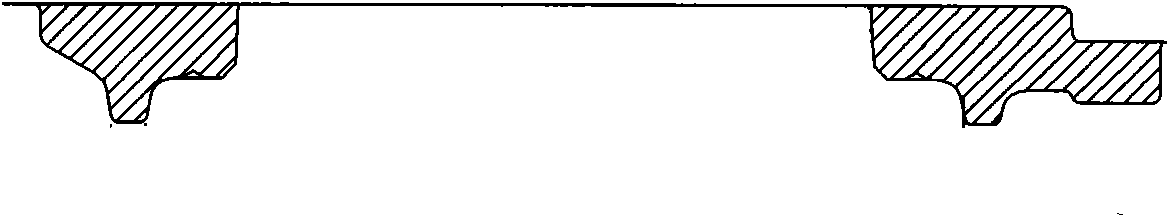

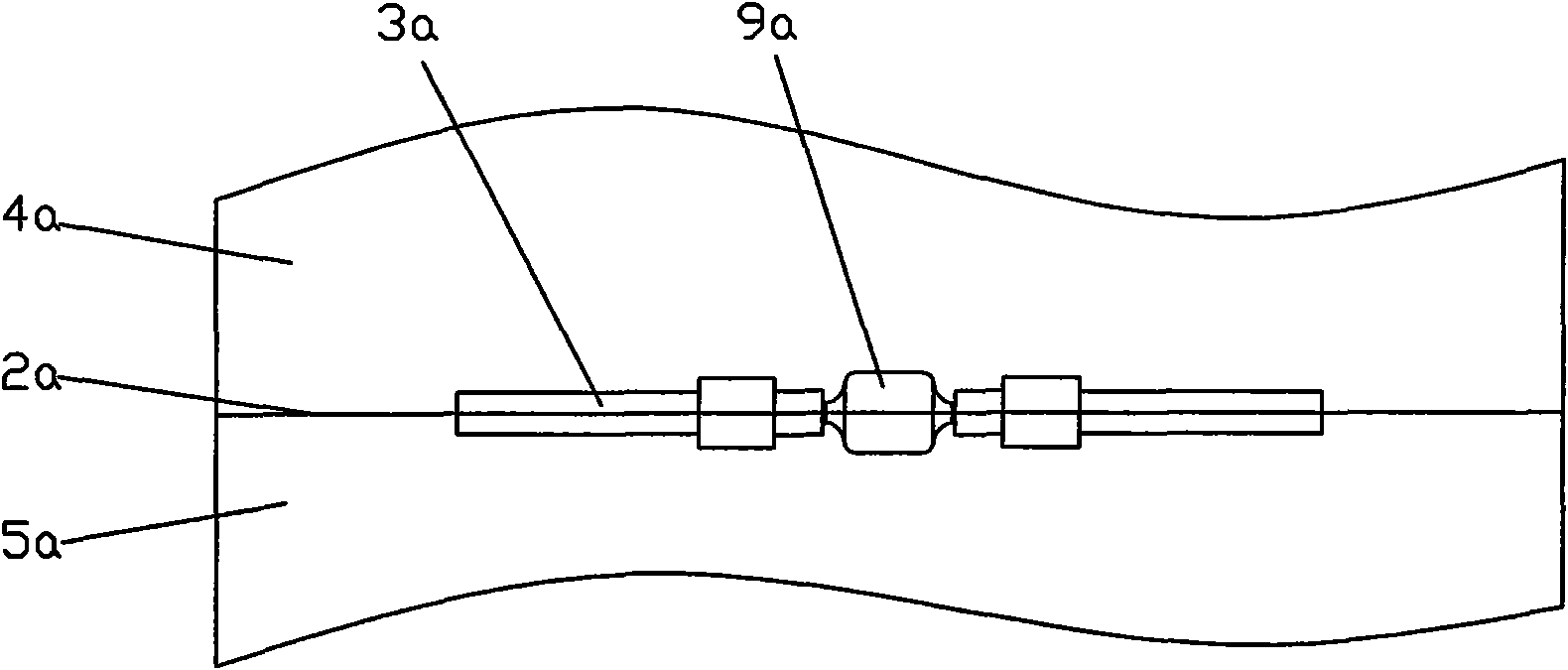

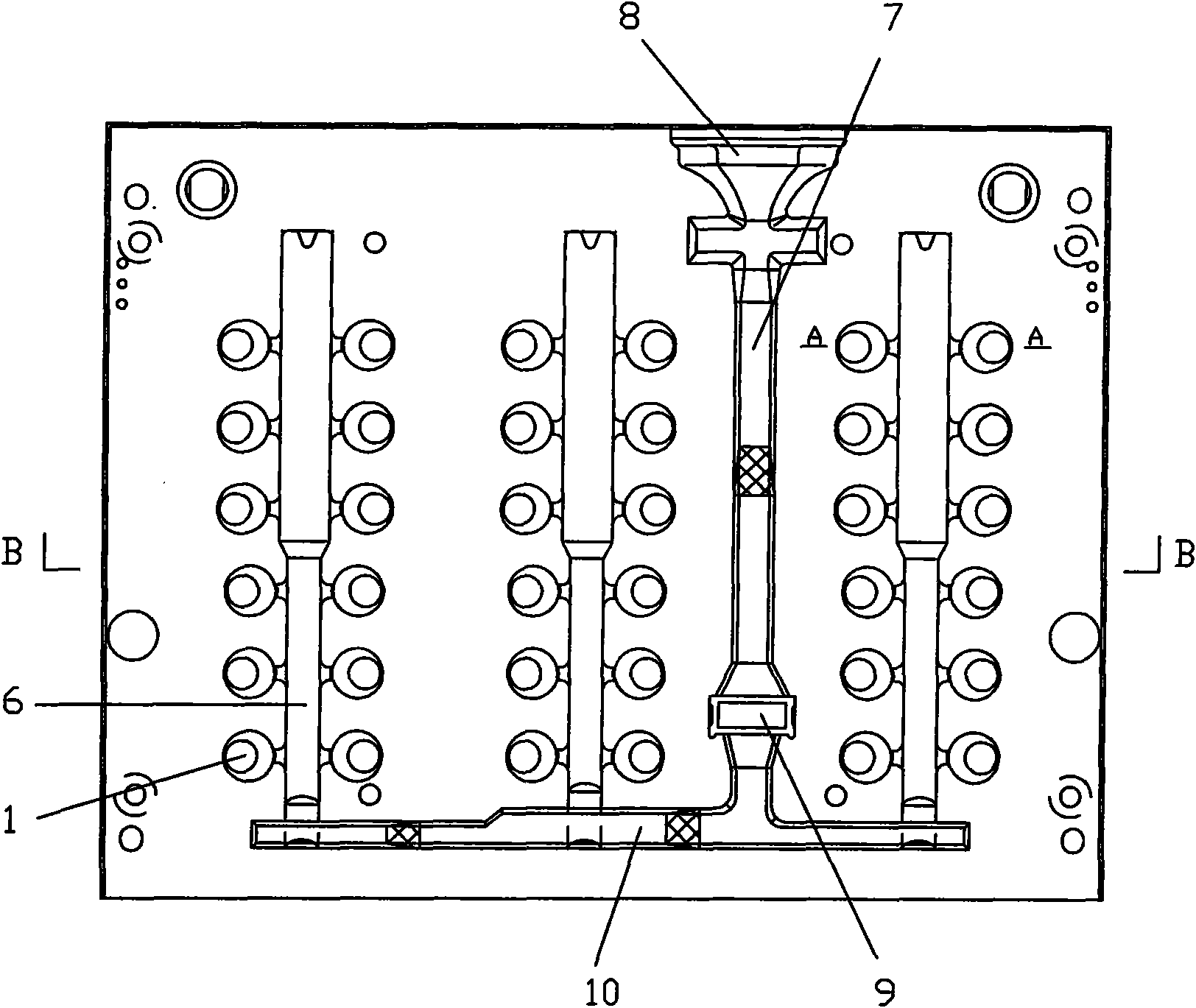

Process for casting thick and large nodular cast iron valve plate

The invention provides a process for casting a thick and large nodular cast iron valve plate. The process comprises the following steps of: (1) manufacturing a mould; (2) manufacturing a casting mould and a sand core; (3) drying and integrating; (4) smelting; (5) pouring; and (6) shaking out and cleaning. In the process, a large number of external chilling blocks and sand separation chilling blocks are used on upper and lower surfaces of a casting for chilling, appropriate placing positions and thickness are selected, and shrinkage cavity and shrinkage porosity of the casting are effectively avoided; meanwhile, a good graphite balling state is ensured by quickly chilling, a feeding head is avoided, the casting is easy to clean, 5 percent of molten iron using amount is saved, and production cost is reduced; a semi-closed casting system is adopted by a casting system, an ingate is uniformly distributed around the casting mould, and the casting mould is slightly scoured, and a good residue stopping effect is achieved; and under the action of chilling of chilling blocks, the thick and large nodular cast iron casting which is smelted by a cupola furnace is good in moulded surface, and meets production requirements, offscourings and sand are avoided, and process yield is improved by 5.9 percent.

Owner:TIJIN YIJI MACHINERY

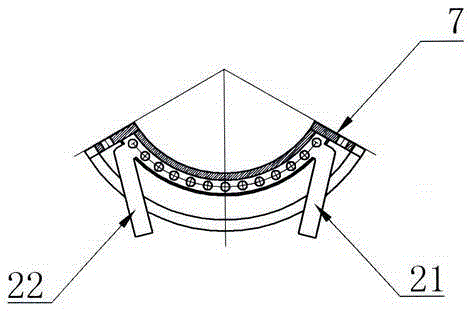

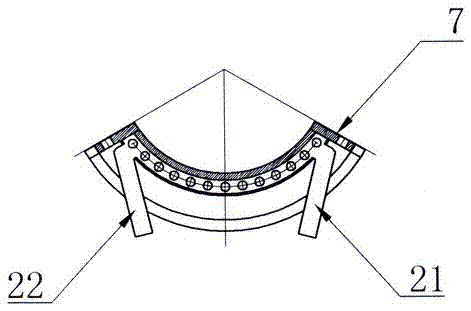

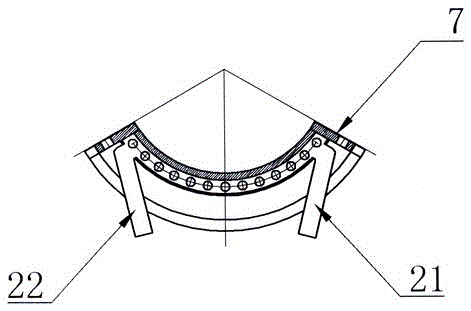

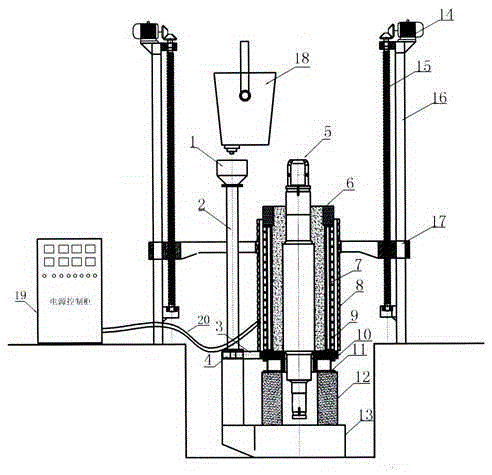

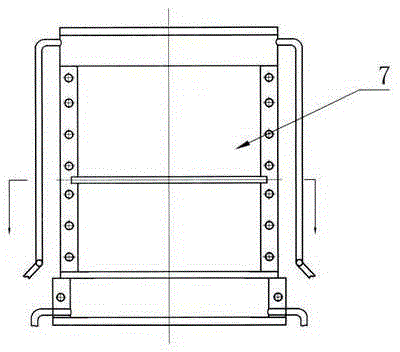

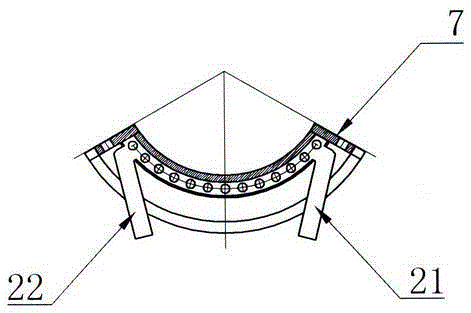

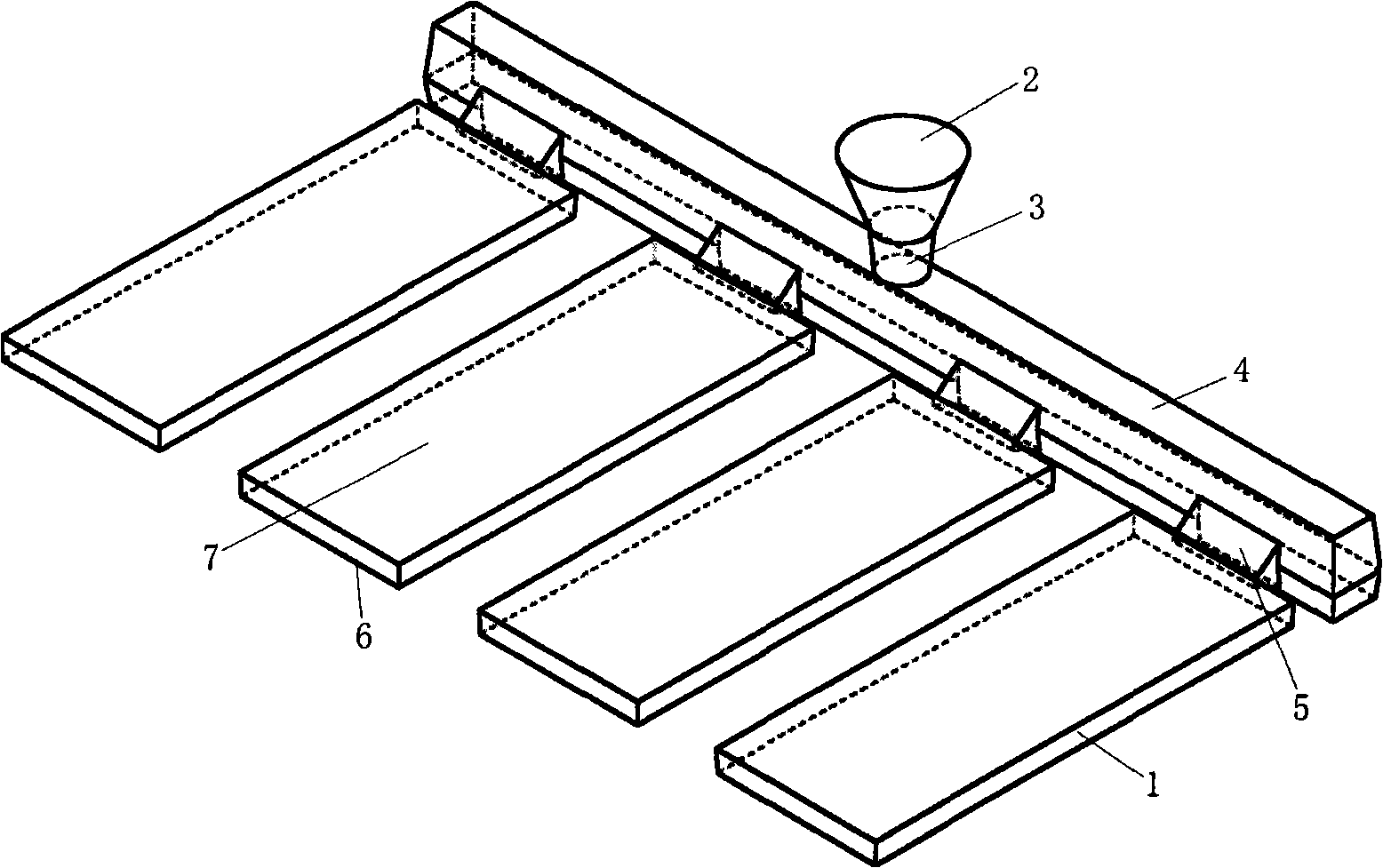

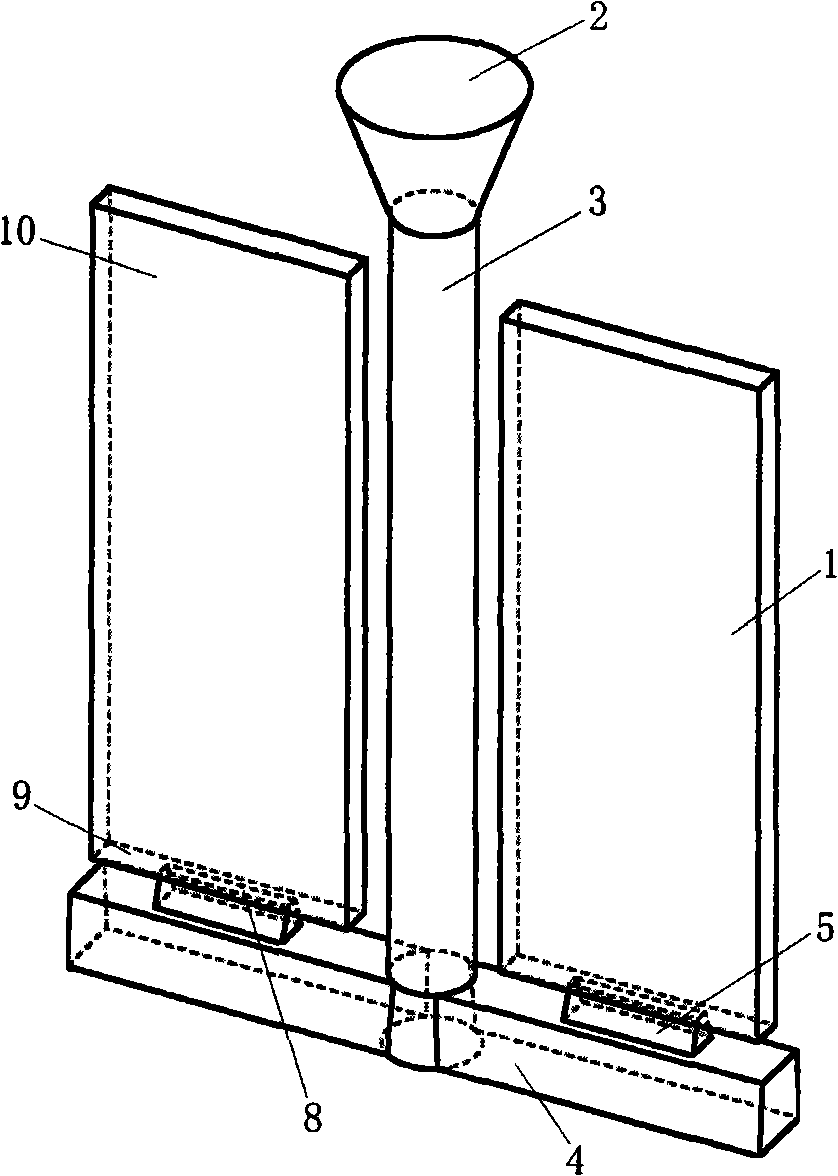

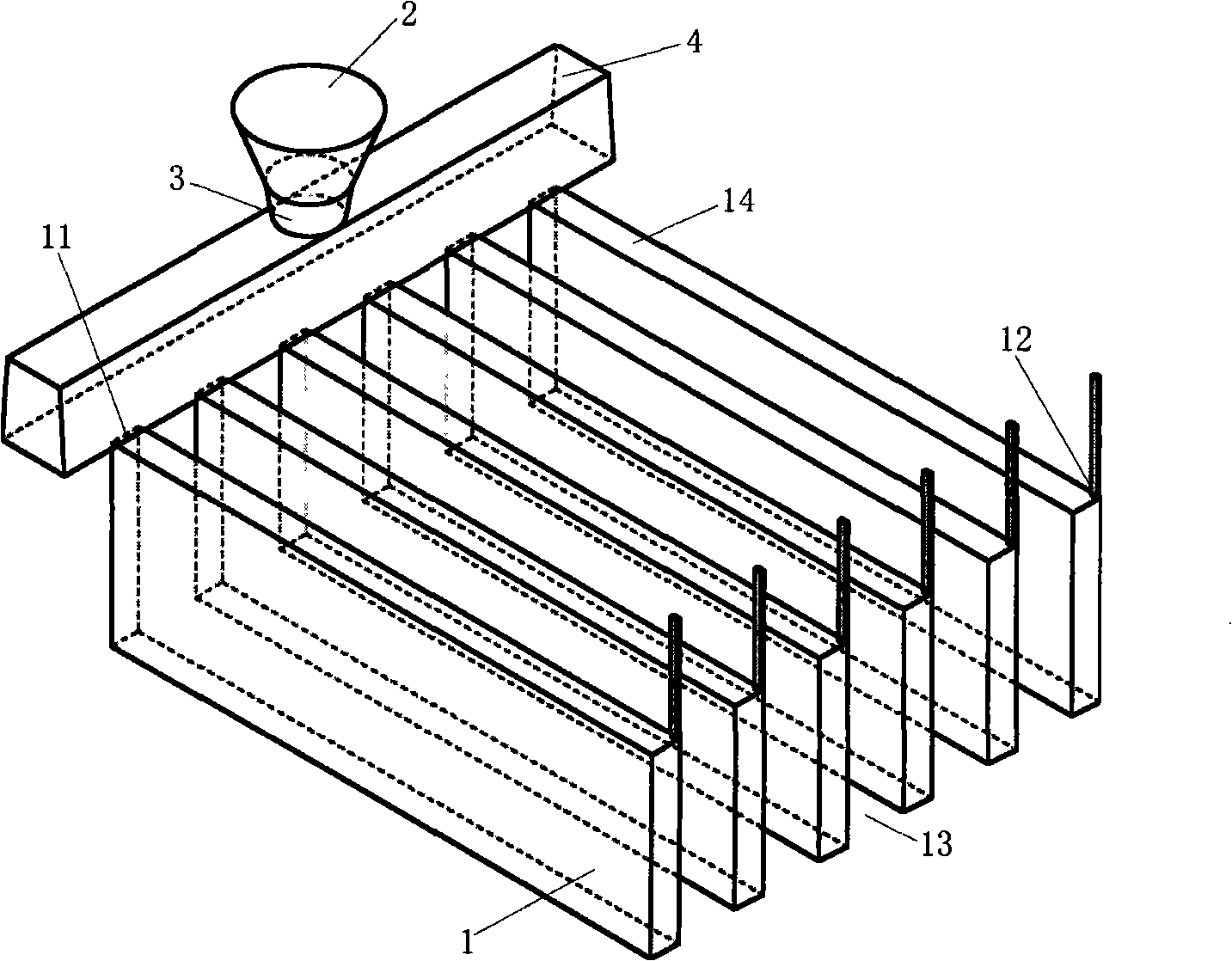

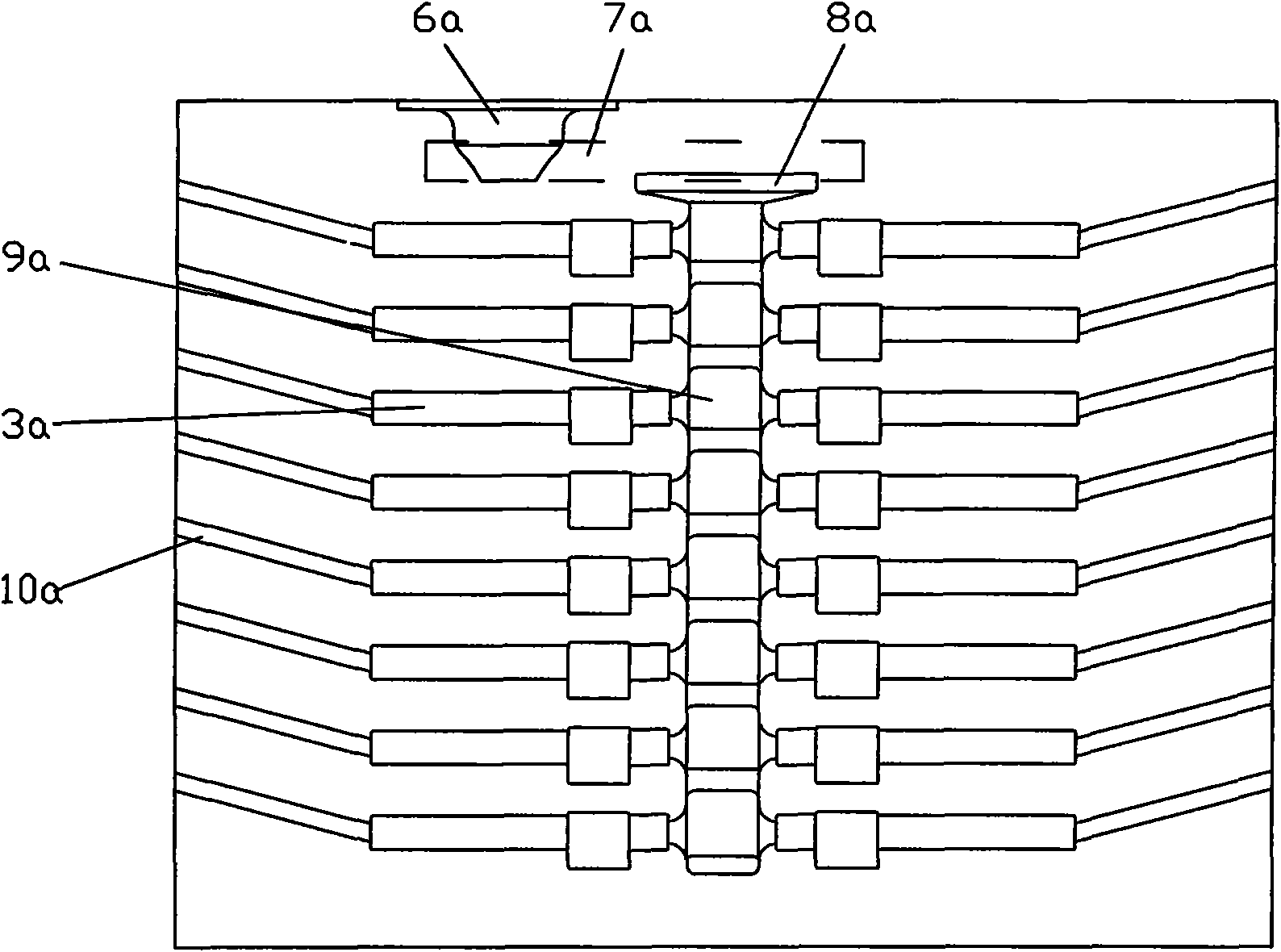

Design method and system for no air gap stable filling casting

InactiveCN1552542AReduce design sizePrevent splashFoundry mouldsFoundry coresSystems designNonferrous metal

A method for designing the non-air-gap smooth-filling casting features controlling the filling smoothness, lowering the filling speed, preventing air and oxidized film from coming in molten metal, reducing the size of pouring channel, and increasing the technological output rate. Its casting system has a pouring cup, a plug rod system connected with said pouring cup and opened when filled molten metal in the pouring cup reaches its 1 / 2-1 / 3 height, and the arc corner between vertical and horizontal pouring channels. Its pouring speed is 0.5-1.0 m / s.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

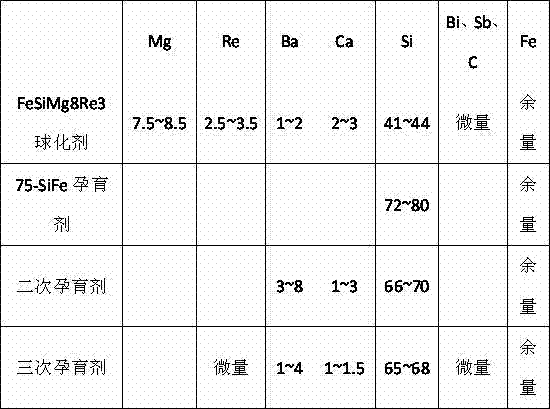

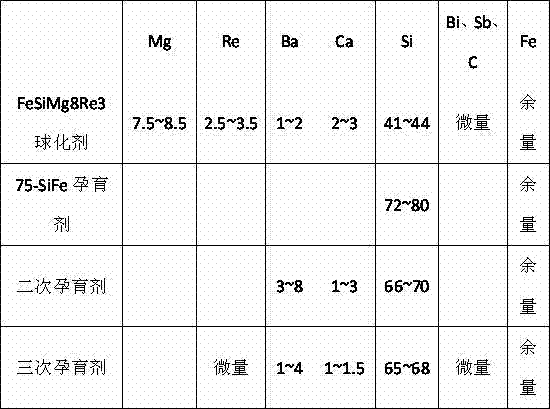

Manufacturing method of spheroidal graphite cast iron casting of wind power yaw variable-pitch device

The invention discloses a manufacturing process of a spheroidal graphite cast iron casting of a wind power yaw variable-pitch device. The process comprises the following processes of mould making, foaming and moulding, paint brushing, boxing and shaping, electric furnace smelting, tundish-covering nodulizing treatment, vacuum-assist pouring and three-time inoculation treatment, wherein the boxing and shaping process is a layered assembling process, so that the production efficiency can be improved and the process yield can be increased; cold iron is vibrated and reasonably arranged, so that the compactness of tissues in the casting can be improved and the defect of shrinkage porosity can be avoided; by virtue of the processes of electric furnace smelting and tundish-covering nodulizing treatment, the nodulizing rate of the casting can be stabilized and increased and the mechanical properties of the casting can meet the technical quality requirements of wind power castings; the spheroidal graphite cast iron casting manufactured by the process is compact and uniform in tissue, hardly has defects, has good surface quality and high size precision; the casting forming of multiple layers of castings can be realized; and the production efficiency and the process product yield are improved.

Owner:CHTC HEAVY IND

Process for preparing large cast steel support roller

The process of making cast steel supported roller is suitable for integral casting of cast steel supported roller of 5-100 ton weight. The present invention has adopts computer simulation, coating iron mold with sand, rotary cavity filling, heat insulating casting head technology, electrically casting head heating technology and sliding roller neck technology; and designs pouring system and casting mold design by means of new design principle and successive solidification principle. Adopting sliding roller neck technology and electrically casting head heating technology can avoid cracking in the cast steel supported roller.

Owner:CHANGSHU LONGTENG SPECIAL STEEL

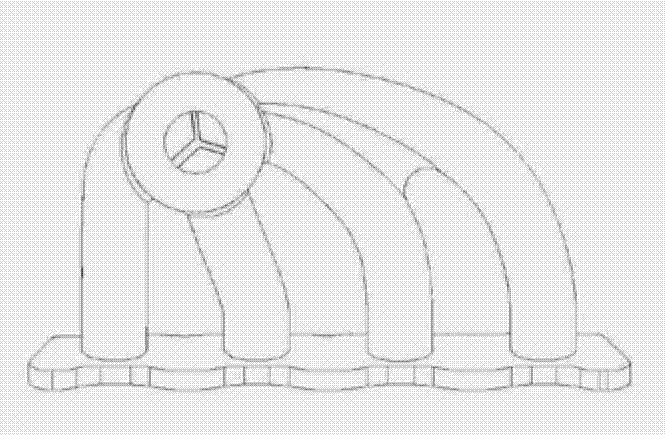

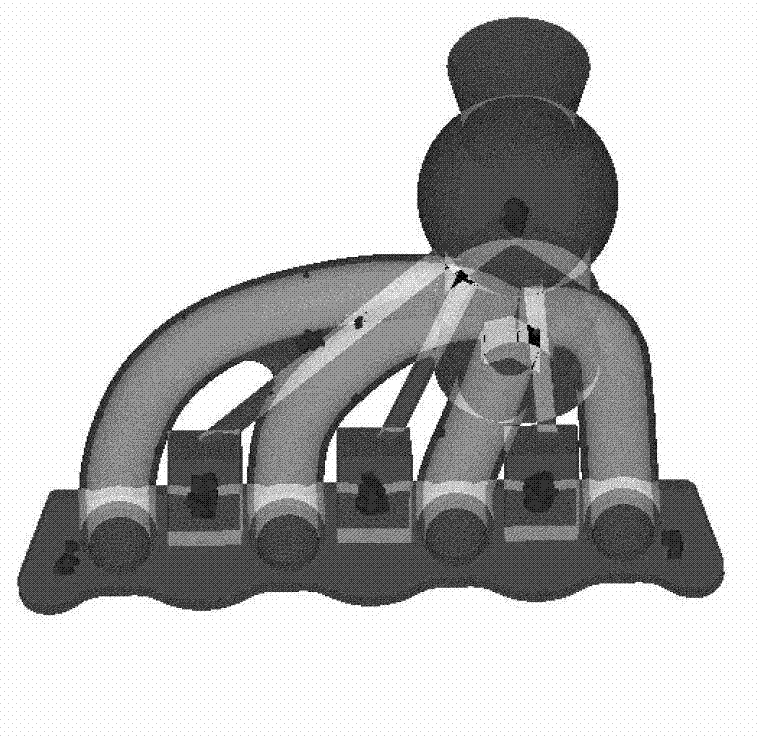

Investment casting method of heat-resistant steel exhaust manifold for automobile

InactiveCN102921890AImprove surface qualitySmall machining allowanceFoundry mouldsFoundry coresWaxInvestment casting

The invention belongs to a metal casting technology and particularly relates to an investment casting method of a heat-resistant steel exhaust manifold for an automobile. The method comprises the steps of wax mould manufacturing, shell manufacturing, alloy smelting, pouring, shakeout and cleaning. The method has the benefits that the common defects of partial shrinkage, hole shrinkage and the like of the heat-resistant steel exhaust manifold for an automobile engine can be eliminated or reduced, and the process yield is higher.

Owner:CHANGZHOU UNIV +1

Casting method for impeller made of super duplex stainless steel 5A material

ActiveCN107309405AAvoid crack defectsGuaranteed denseFoundry mouldsFurnace typesImpellerVolumetric Mass Density

The invention provides a casting method for an impeller made of a super duplex stainless steel 5A material. The method comprises the steps of preparation of a casting mould and a sand core, specifically, the casting mould and the sand core are prepared in the manner that alkaline phenolic resin is added to crude sand, the casting mould is provided with an impeller cavity for storing the sand core, and a dead head is internally provided with a ceramic foam filter; casting and pouring; and sand shakeout and heat treatment of a heat-filling furnace, and an impeller finished product is obtained. The temperature ranges of precipitation of brittle phases including Eta, Chi and Sigma can be avoided, precipitation of the brittle phases by an impeller casting structure is avoided, crack defects of an impeller casting are overcome fundamentally, density of the casting structure can also be guaranteed, and the yield rate of a casting finished product can be increased to 96% or above; and meanwhile, the casting production cost is greatly lowered as the technological yield is increased, and the heat-filling furnace process is implemented.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

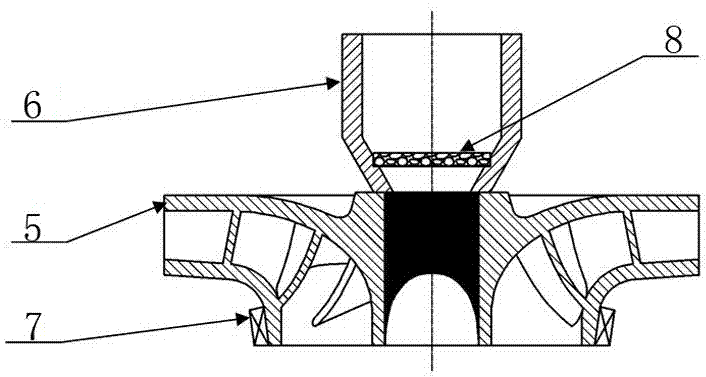

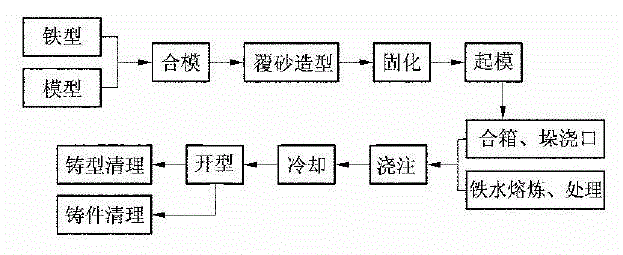

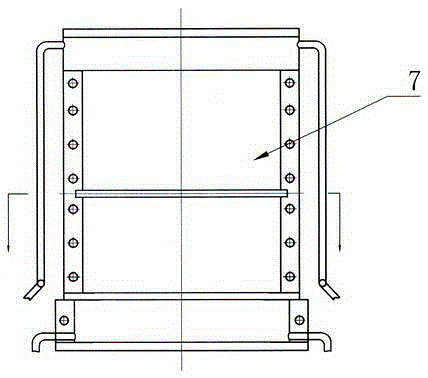

Process for casting ball iron flywheel by iron model sand covering

InactiveCN103143675ASimple processOvercome inherent weaknessesFoundry mouldsMoulding machinesFlywheelCasting

The invention discloses a process for casting a ball iron flywheel by iron model sand covering. The process is characterized by comprising the steps of die assembly for an iron model and a die, sand covering modeling, solidifying, drawing, die assembling, accumulating sprues, molten iron smelting and processing, casting, cooling, die opening, and cast and die cleaning. According to the process for casting the ball iron flywheel by the iron model sand covering, the process for clay sand is simplified, the inherent defects of the clay sand are overcome, free-dead-head production of the ball iron flywheel is achieved, process product yield is improved, and continuous volume production is achieved.

Owner:LUOYANG NEW FIRE ENERGY SAVING TECH PROMOTION

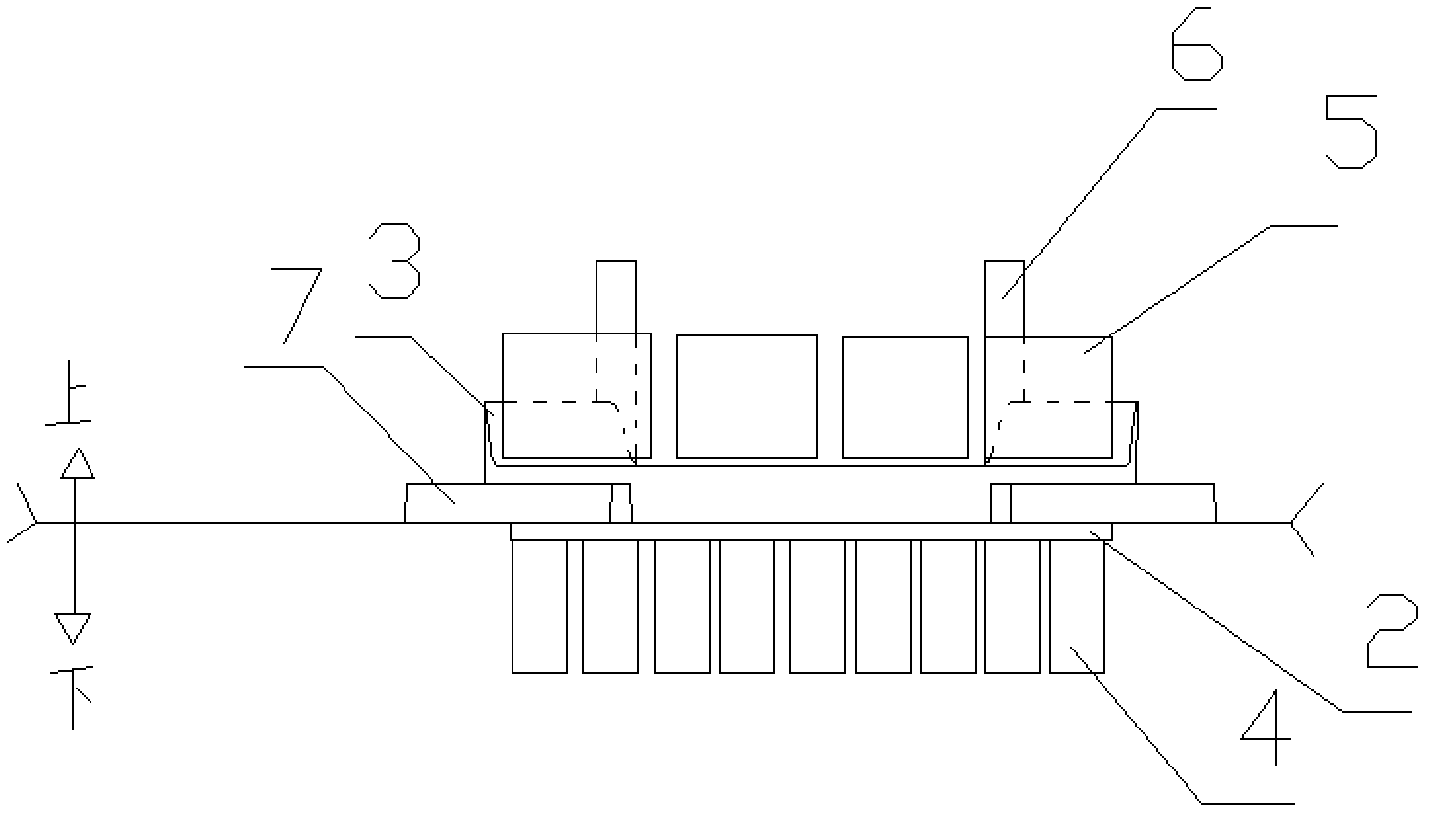

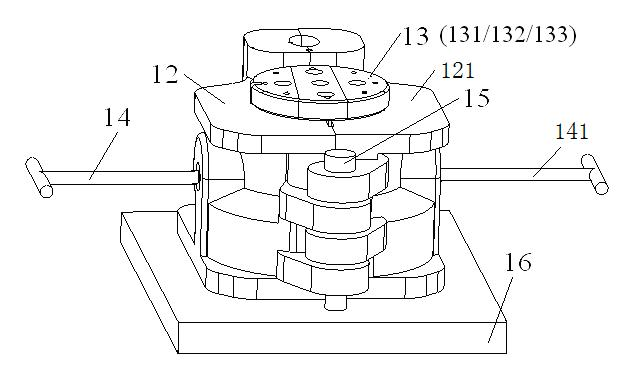

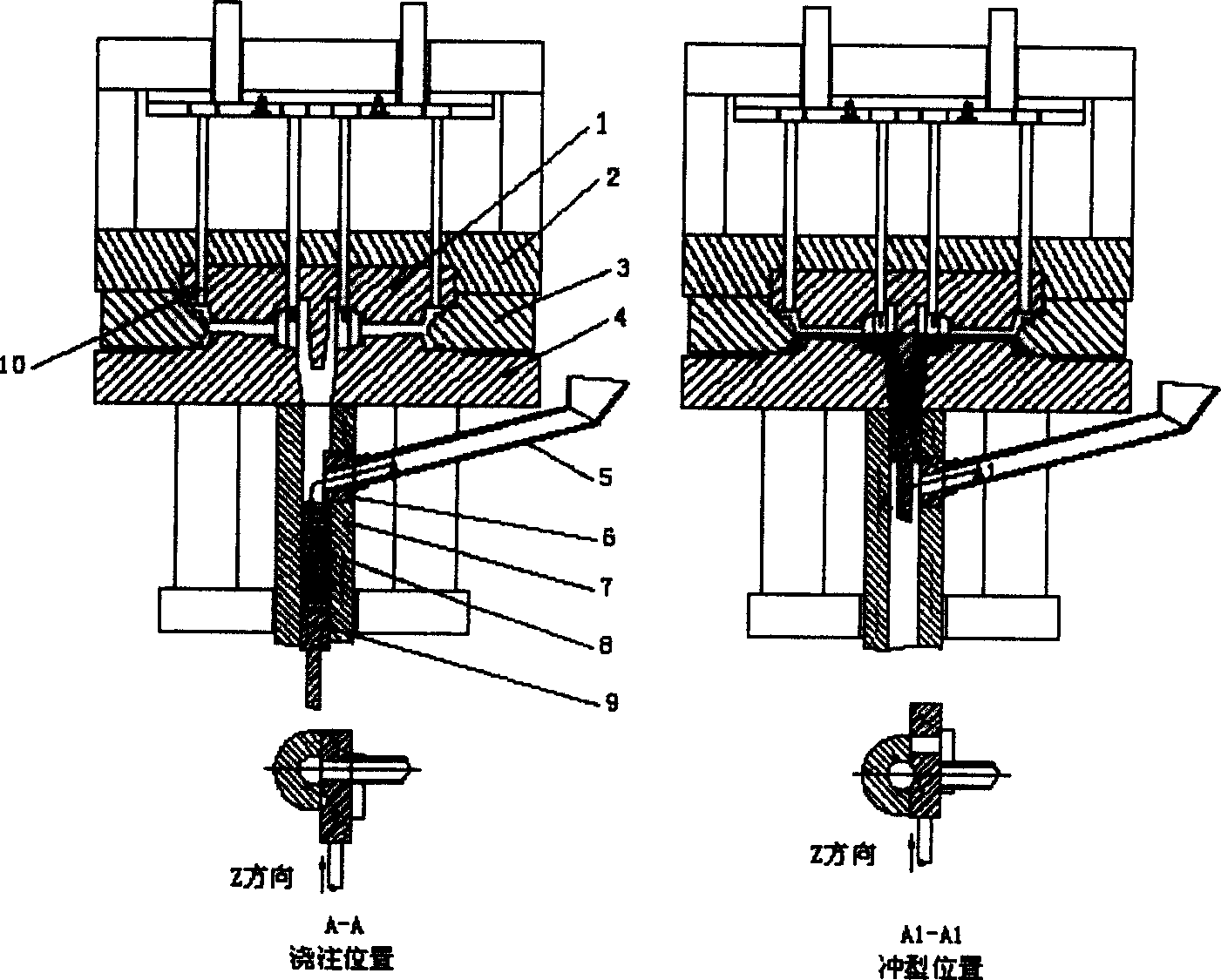

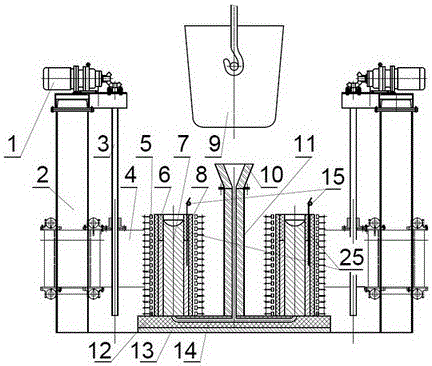

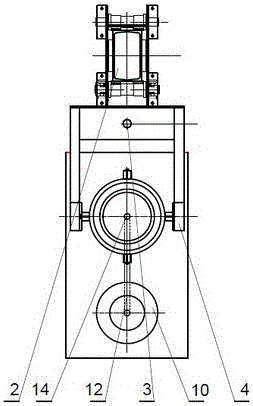

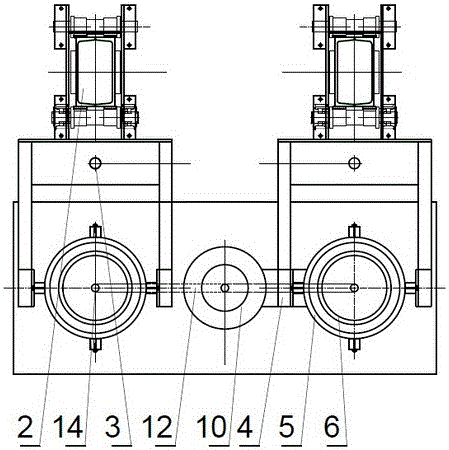

Manufacturing technology and device for improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller

ActiveCN105401059AEasy feedingOvercome the defect of prone to tissue segregationFurnace typesProcess efficiency improvementManufacturing technologyFerrosilicon

The invention discloses a manufacturing technology and device for an improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller. The roller comprises, by mass percent, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, not larger than 0.05% of P, not larger than 0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable micro elements. Yttrium base rare-earth nodulizing and Ba, Ca, and silicon iron composite inoculation are adopted, Nb, Ti, V, B and Sb are added for modification, and the mechanical performance of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved, an induction heater is adopted to carry out in-mold whole heating casting on a core stick, a water cooled crystallizer is molded, a composite layer interface can be dynamically controlled, the technology is simple, the efficiency is high, power consumption is small, the cost is low, no composition segregation exists, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

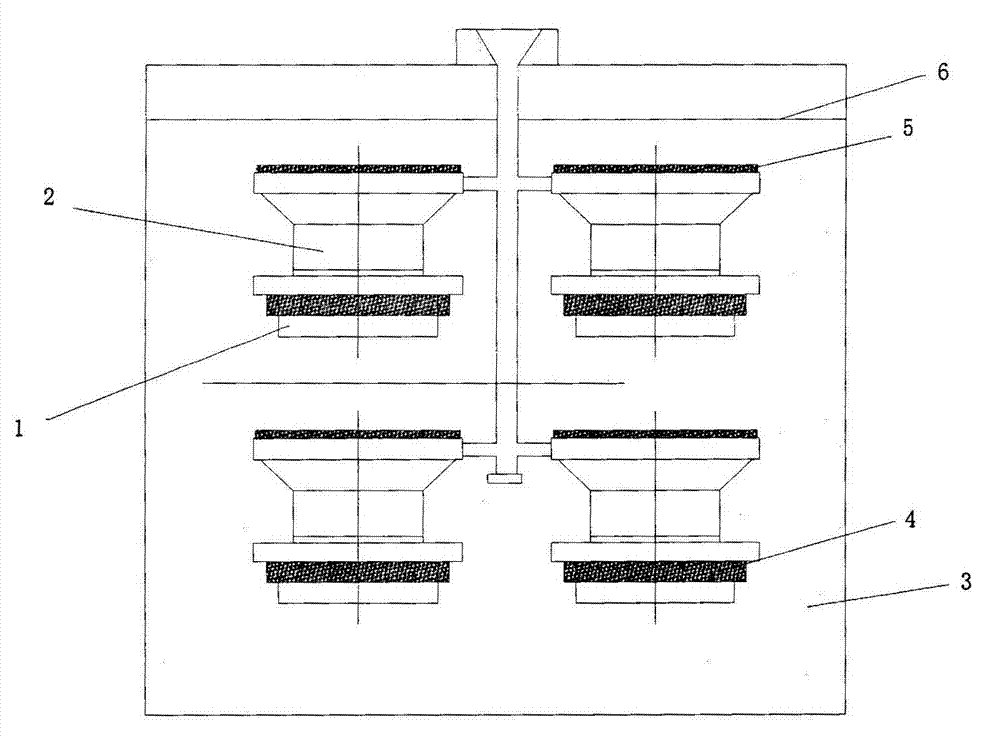

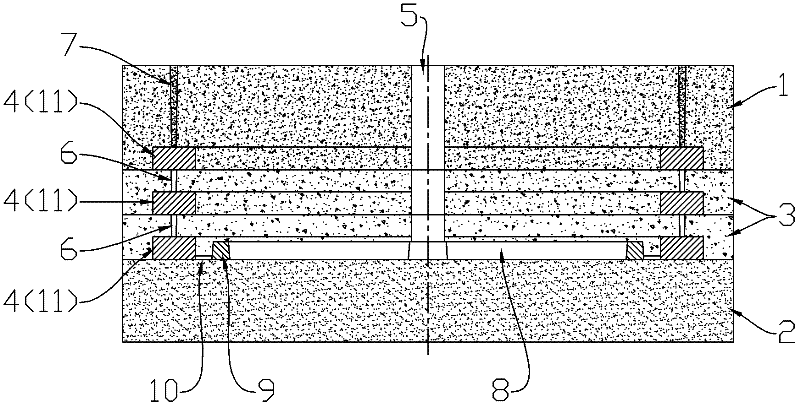

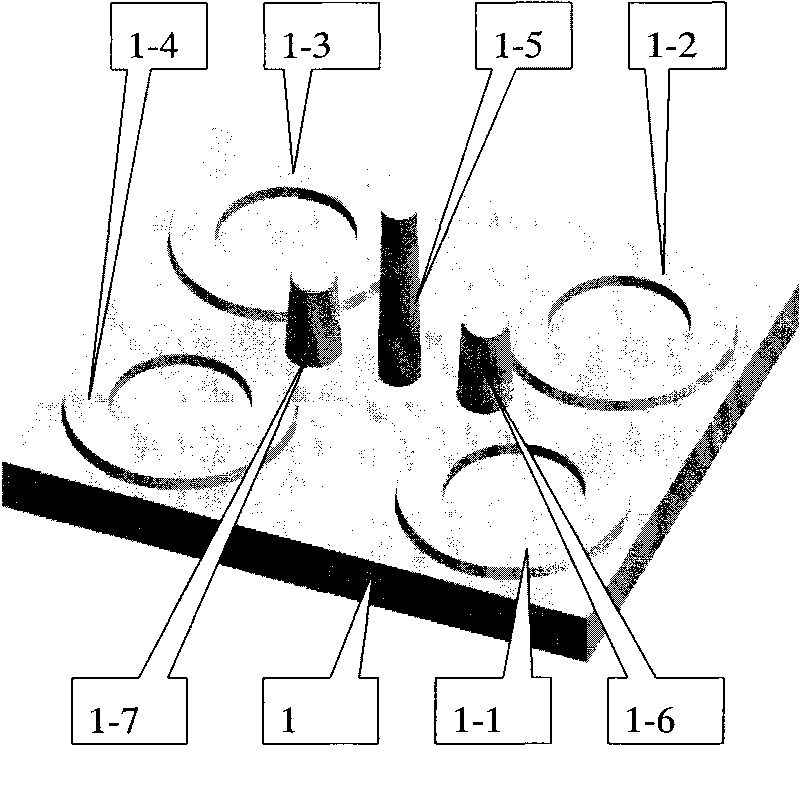

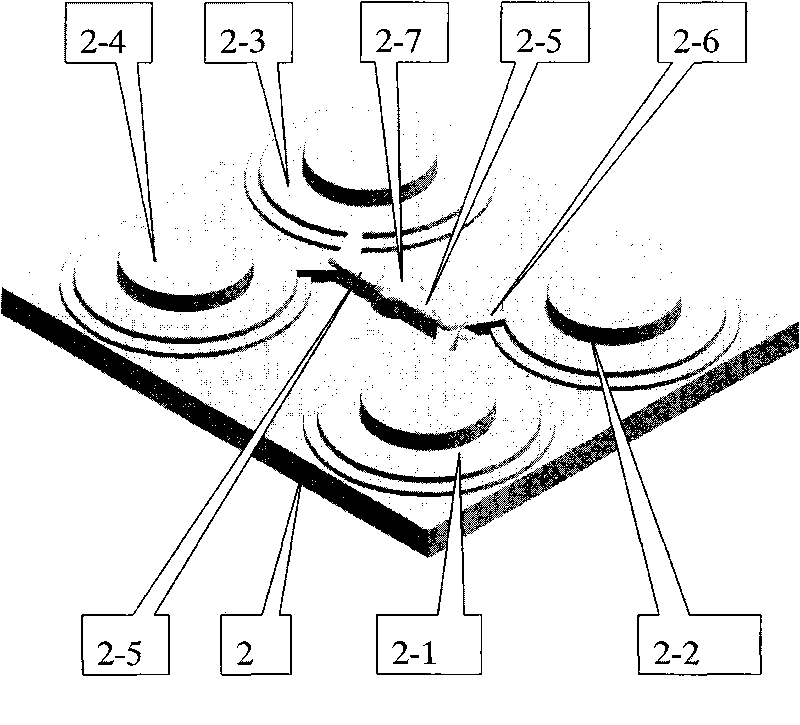

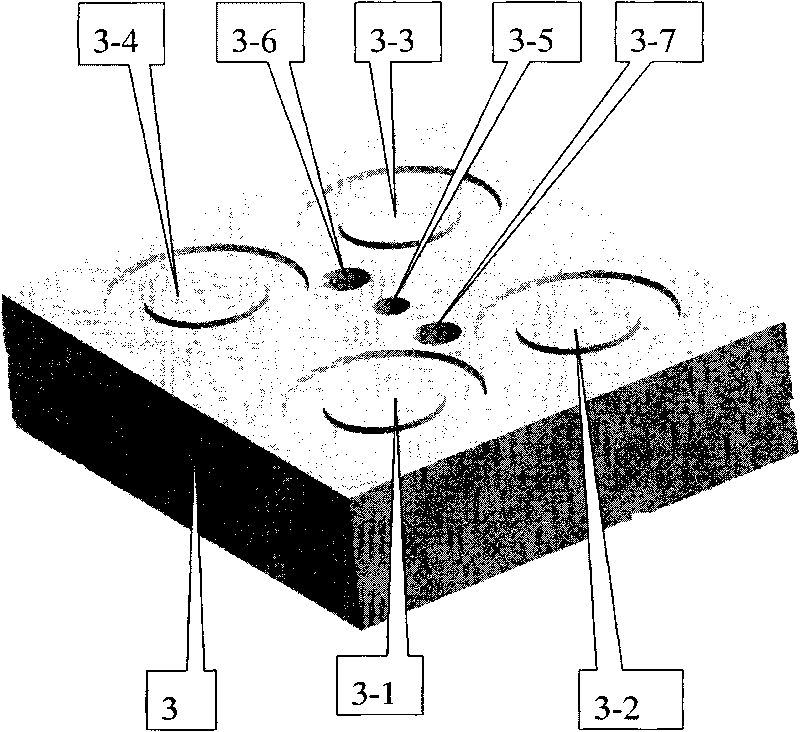

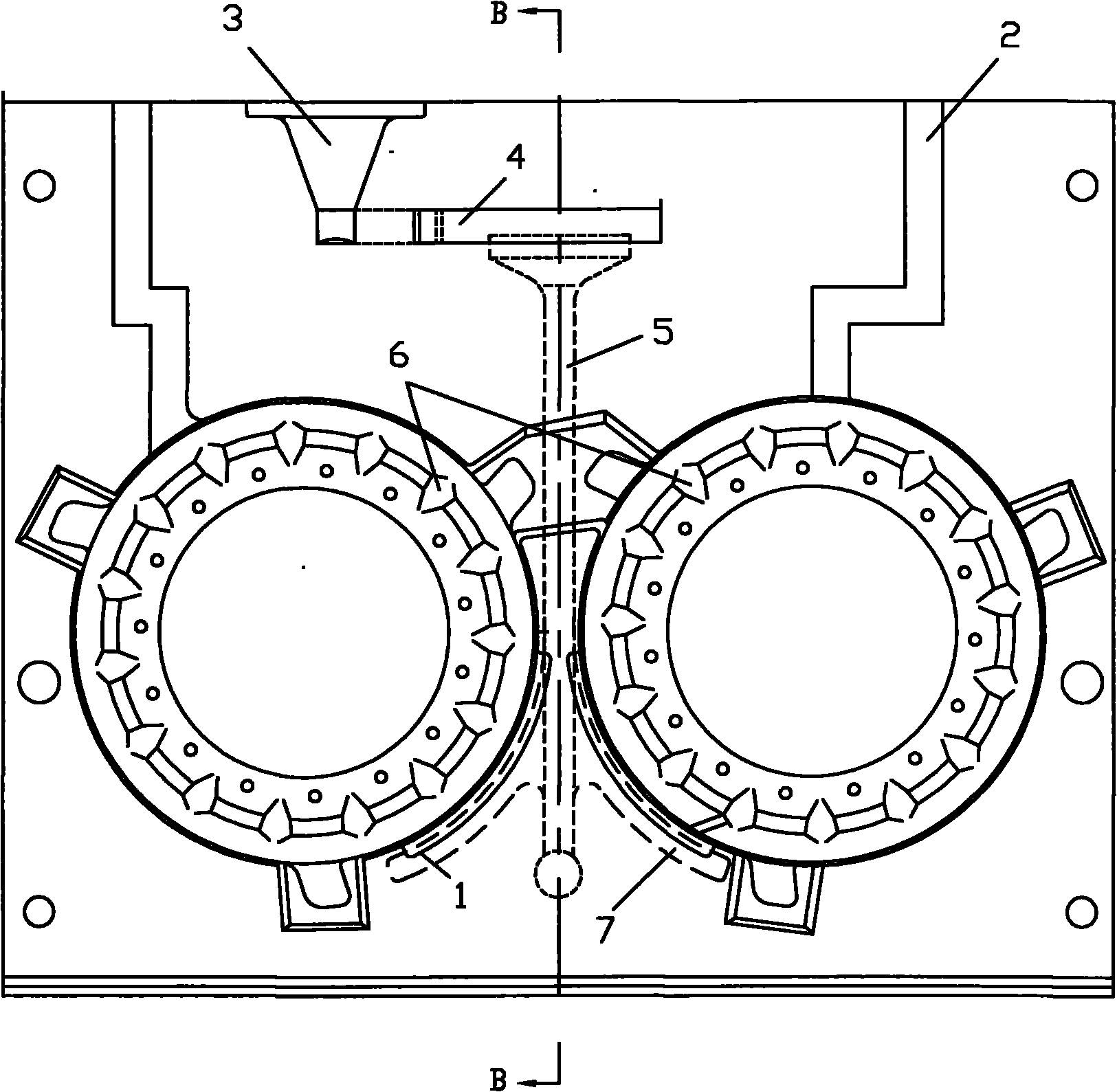

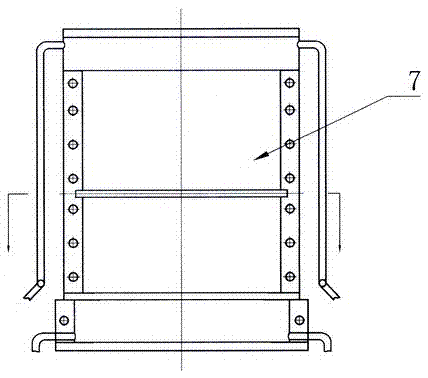

One-box multi-piece casting mold and casting method for brake disc castings

ActiveCN102416442AReduce the ratio of sand to ironReduce manufacturing costFoundry mouldsFoundry coresCasting moldMaterials science

The invention discloses a one-box multi-piece casting mold for brake disc castings, and belongs to a casting technology. The casting mold comprises an upper box, at least one middle box and a lower box which are superposed from top to bottom, wherein a round brake disc cavity and a straight pouring gate are formed in each middle box and the upper box; the straight pouring gates are vertically communicated; a plurality of upright inner pouring gates communicated with the brake disc cavities are formed in each middle box; a plurality of air outlet rods communicated with the brake disc cavities are uprightly arranged in the upper box; a transverse pouring gate, a round sub transverse pouring gate and transverse inner pouring gates are formed in the lowermost middle box; the diameter of the sub transverse pouring gate is smaller than that of the brake disc cavities; the transverse pouring gate is connected with the lower ends of the straight pouring gates and the sub transverse pouring gate; a plurality of transverse inner pouring gates are uniformly distributed circumferentially and connected with the sub transverse pouring gate and the brake disc cavities. A plurality of brake disc castings can be cast in one box, a sand-to-iron ratio is reduced, process yield is improved, production efficiency is improved, and production cost is reduced.

Owner:ZHEJIANG JIALI WIND POWER TECH

One-box four-type casting process of brake disk

ActiveCN101704069AQuick changeImprove interchangeabilityFoundry mouldsFoundry coresProduction lineHigh rate

The invention discloses a one-box four-type casting process of a brake disk. The process comprises the following technological steps: a sand processing procedure adopts a chassis rotary type rotor sand mixing machine, sand mixing is carried out according to a sand mixture ratio, the sand mixing efficiency is 120 tons / hour, and the sand mixing time is 3-5 minutes; a moulding procedure adopts a static-pressure production line with double-host wiring for moulding and a special mould of a one-box four-type brake disk, the production efficiency is 180 boxes / hour, and the moulding pressure intensity is 8-10MPa; a smelting procedure adopts a cupola and an electric furnace for double smelting, the pouring temperature is 1450-1490 DEG C, and 0.3% of degeneracy-resisting silicon-barium nucleating agent is added before the furnace; a pouring procedure adopts an automatic pouring truck for pouring, and the pouring time is 8-15 seconds; and a desanding and shot blasting procedure adopts a vibration type desanding machine for desanding, and then a stepping type suspended connection shot cleaning chamber is used for cleaning the brake disk. The production process has the characteristics of high rate of finished products, high technological casting yield, high mechanization degree, short production period, high production efficiency, small energy consumption and the like.

Owner:YANTAI WINHERE AUTO PART MFG

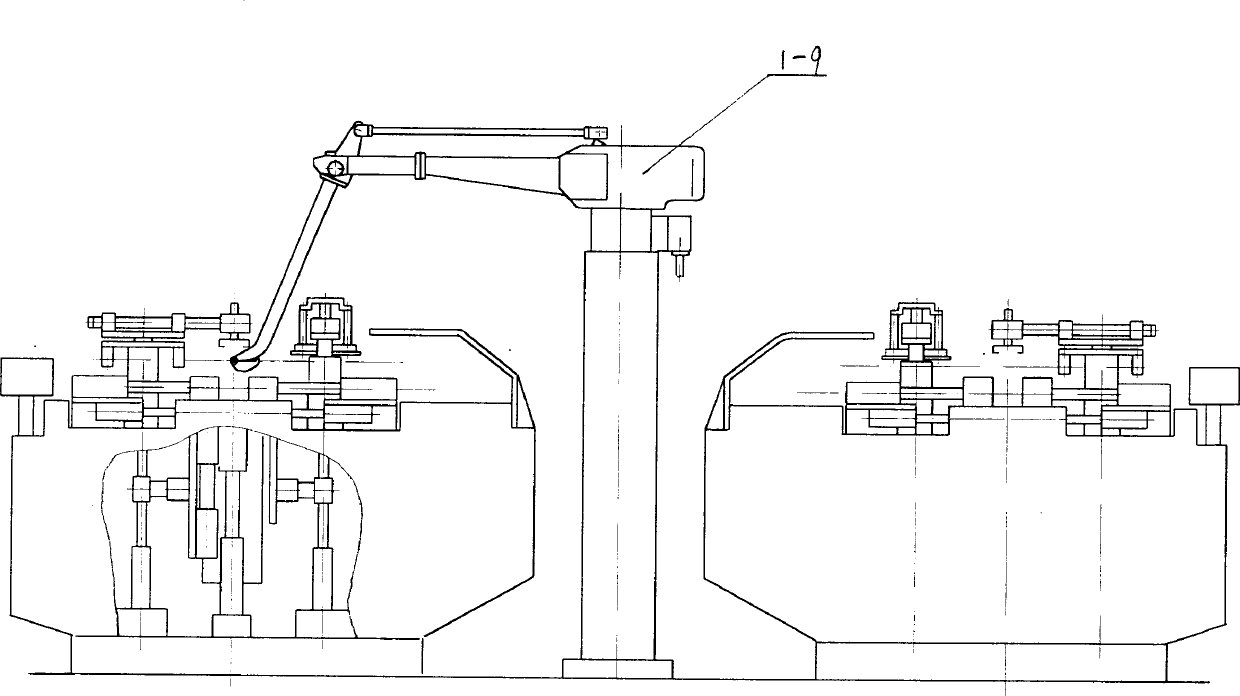

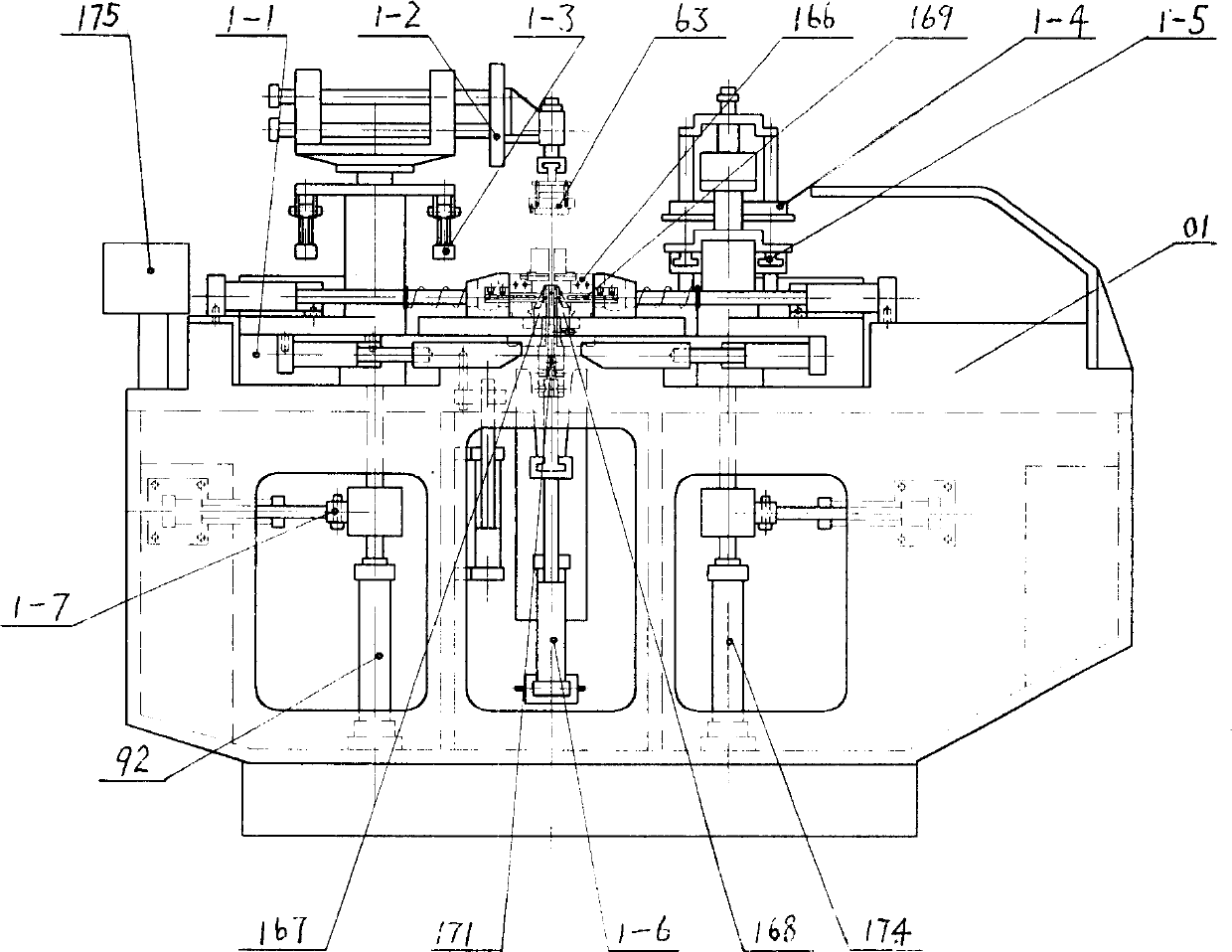

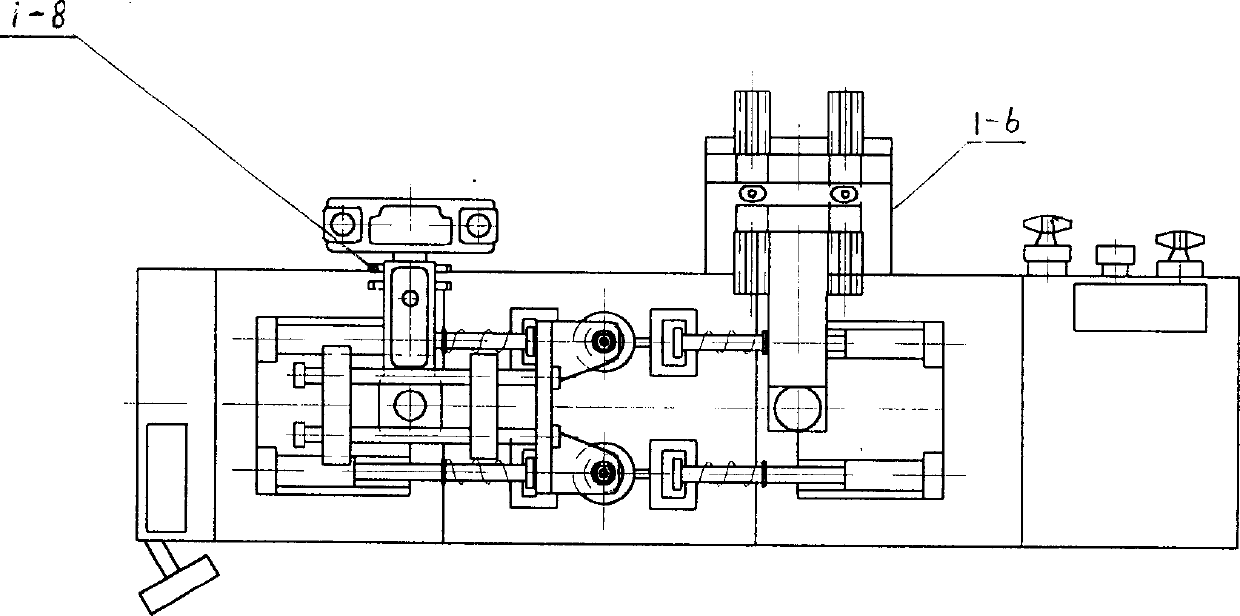

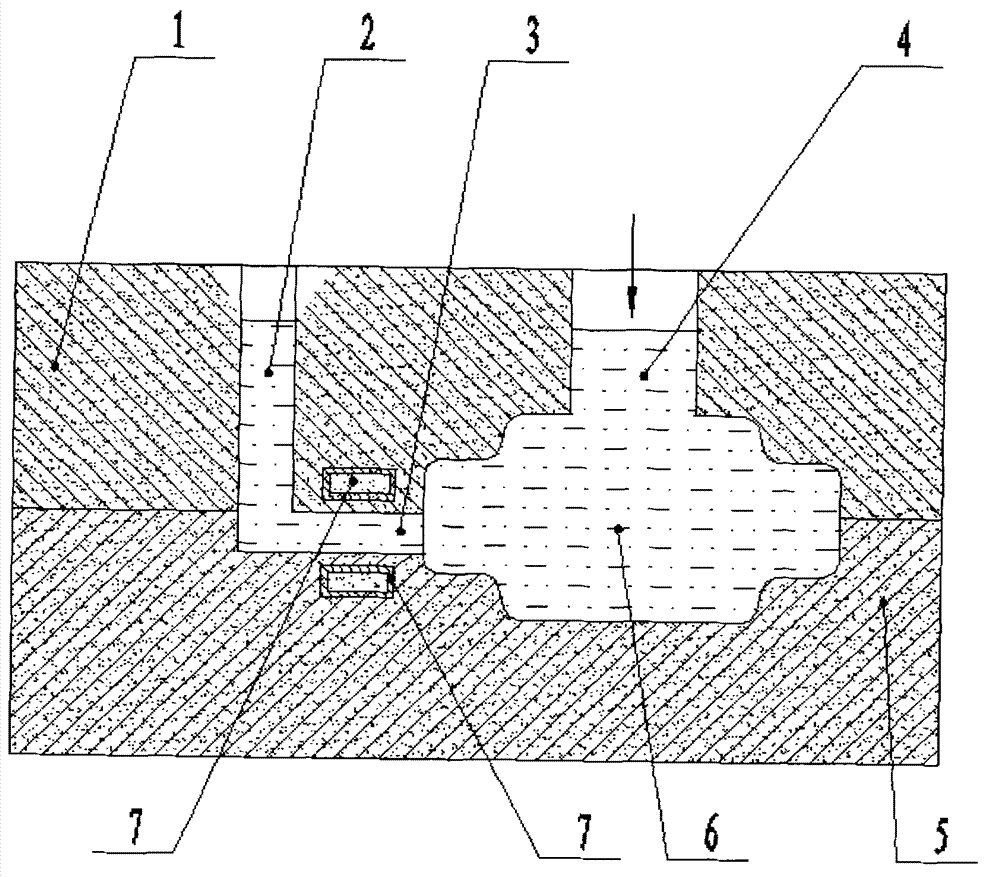

Automatic aluminium piston casting machines

InactiveCN1406690AImprove casting qualityComply with sequential solidification conditionsCasting plantsManipulatorMachining

A full-automatic casting machine for aluminium piston is composed of main body, external mould and edge core unit, mould pushing unit, manipulator for taking cast part, central core unit, rotating unit, manpulator for inlaying steel plates, steel plate chamber, filter net installing unit, and casting robot. Its advantages are high autoamtic level, productivity, and quality of castings.

Owner:SHANDONG BINZHOU BOHAI PISTON

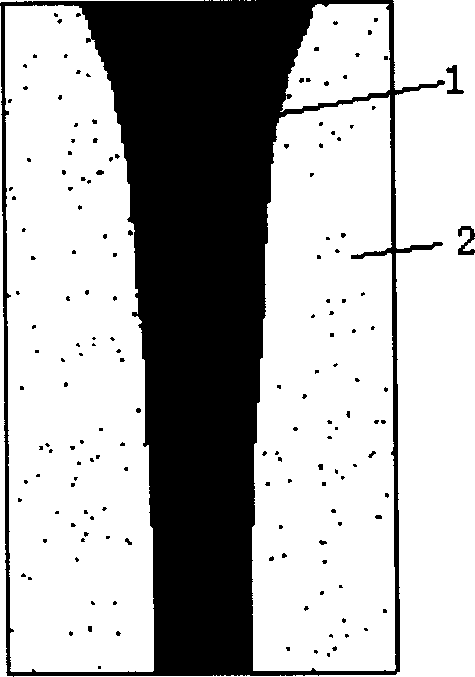

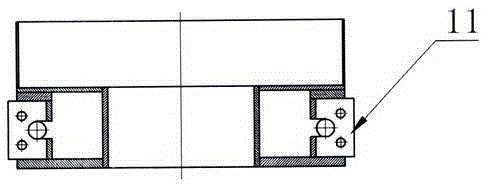

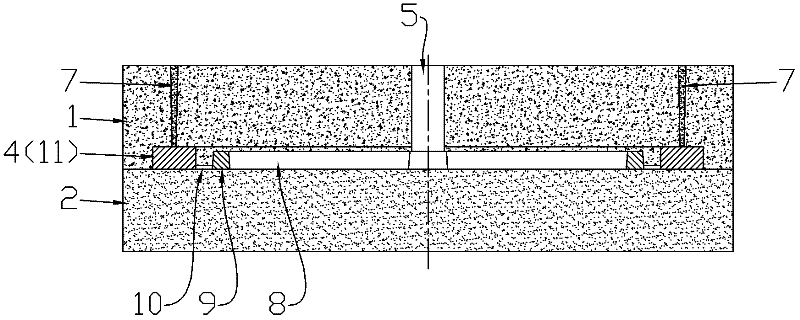

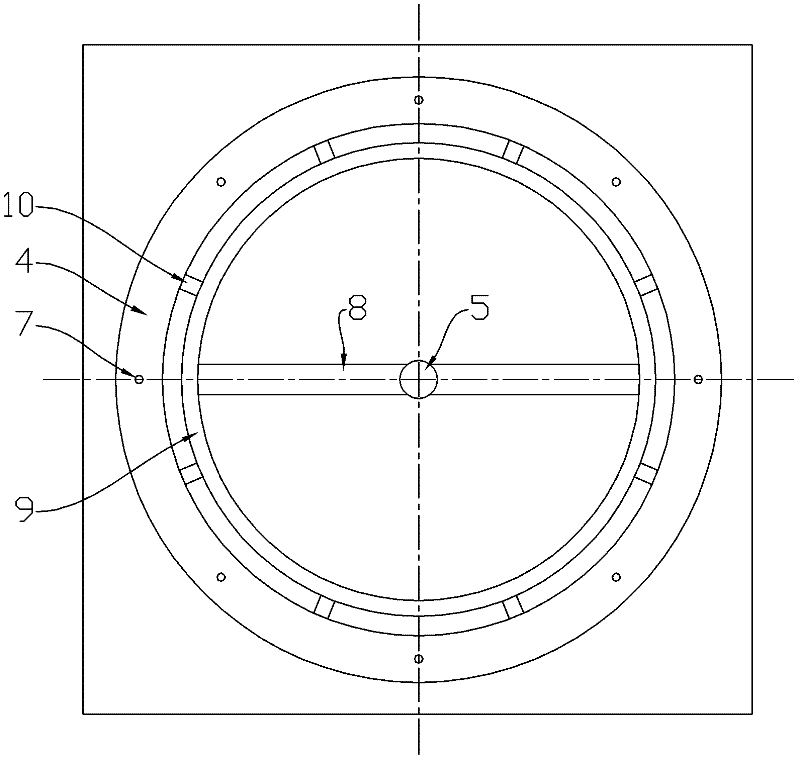

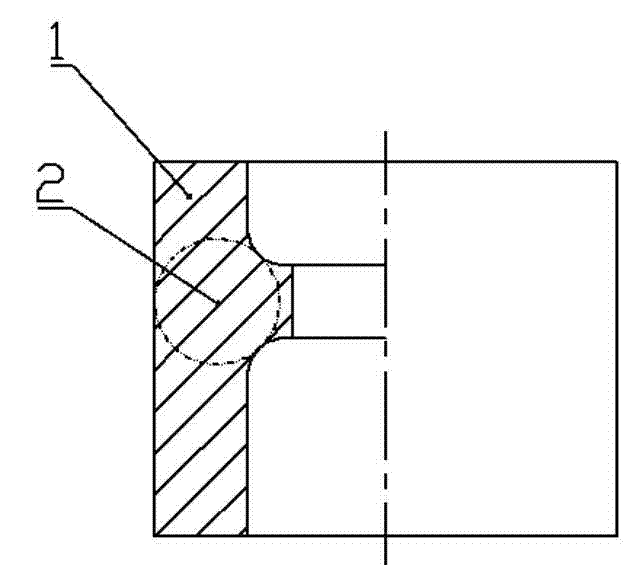

Spheroidal graphite cast iron casting mould and riser-free casting method adopting same

InactiveCN102814465AIncrease profitImprove process yieldFoundry mouldsFoundry coresDuctile ironMaterials science

The invention relates to the casting field and particularly discloses a spheroidal graphite cast iron casting mould and a riser-free casting method adopting the same. The casting mould is provided with a liquid storing cavity and a pouring gate system. The pouring gate system comprises an inner pouring gate and a straight pouring gate, wherein the inner pouring gate is communicated with a cavity, and the straight pouring gate is communicated with the inner pouring gate. Inner pouring gate coolers are arranged around the inner pouring gate. The riser-free casting method comprises the steps of combination, pouring, pouring gate cooling and forced feeding. The riser-free casting method has the advantages of being high in casting process production yield, stable in casting quality and wide in application range.

Owner:河北锐利机械科技有限公司

Process for manufacturing saloon car clutch pressure plate casting

The invention provides an optimized process for manufacturing a saloon car clutch pressure plate casting on a vertical modeling production line. The process comprises the following steps of mulling sand, modeling, melting burden, inoculating iron, pouring, cooling, opening case and clearing casting, wherein in the modeling step, two and more raw castings are horizontally and asymmetrically arranged; a pouring iron liquid enters into a straight pouring channel through a pouring cup and an upper cross channel; and the straight pouring channel enters into a lower cross channel by passing through the middle of a casting cavity and then asymmetrically enters into the cavity from the lower side of the cavity. The pressure plate casting produced by using the process of the invention has a single-cast coupon tensile strength equal to or more than 250 MPa, a casting body tensile strength equal to or more than 200 MPa and the casting body hardness from 170 to 241HBS. The product metallographic structure mainly uses the A type graphite; the length of the graphite is 4 to 6 level; the matrix contains more than 95% of small pearlites and less ferrites; and all the parts of the casting have no casting flaw and meet the technical requirements of the saloon car clutch pressure plate casting.

Owner:上海华新合金有限公司

Modified manufacturing process for high-chromium cast iron composite roll through forged steel roll neck and equipment

The invention discloses a modified manufacturing process for a high-chromium cast iron composite roll through a forged steel roll neck and equipment. The material comprises, by mass, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, 0%-0.05% of P, 0%-0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable microelements. Yttrium-based rare earth nodulizing and compound inoculating of Ba, Ca and silicon iron are adopted, and modification treatment is conducted by adding Nb, Ti, V, B, and Sb, so that the mechanical property of the roll is improved. The strength of the roll is improved through the forged steel roll neck. Overall in-mold heating and fusion casting are conducted on a core rod through an induction heater. Forming is conducted through a water cooled crystallizer. A composite layer interface can be dynamically controlled. The process is simple, the efficiency is high, power consumption is small, the cost is low, composition segregation is avoided, and the service life of the roll is long.

Owner:丹阳恒庆复合材料科技有限公司

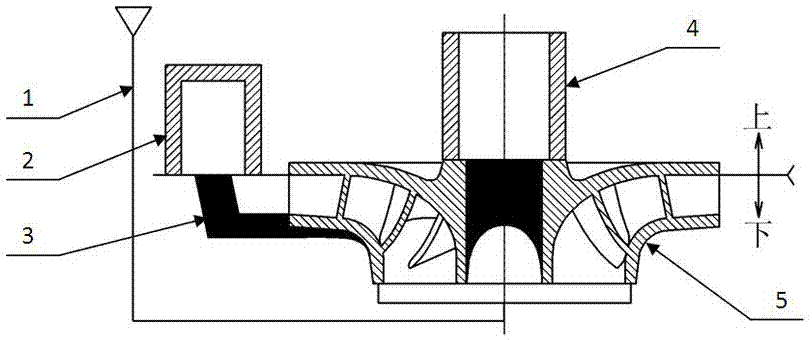

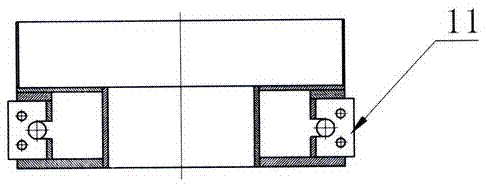

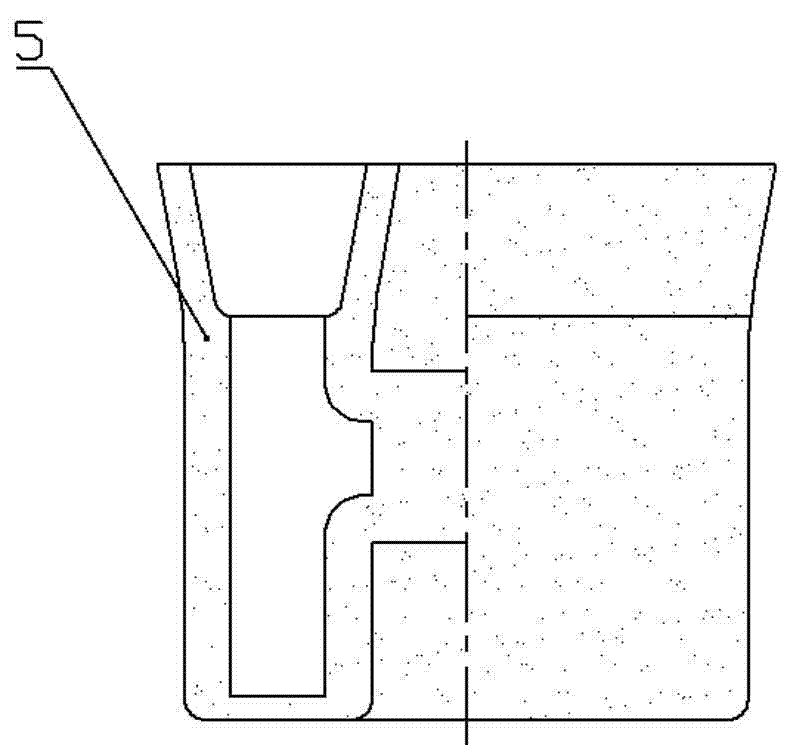

Gravity casting method and device for piston

ActiveCN102151794AAvoid formingGuaranteed unobstructedFoundry mouldsFoundry coresGasolineDiesel engine

The invention relates to the field of piston casting, in particular to a casting process for a piston, and provides a casting process and a casting device to overcome the defects of shrinkage cavity and shrinkage porosity on a ring slot part near a pin hole. The process and the device are suitable for casting of pistons in gasoline engine industry, diesel engine industry, compressor industry and other industry. In the process, an open type annular feeding passage is formed at the bottom of the piston, and an annular channel opening angle is changed by adjusting a sectorial core at the bottom of the piston, so that the full and reasonable feeding effect is achieved, and the casting yield reaches over 96 percent; and by adopting a blind riser, the process productive rate is improved. The process has the advantages of saving energy, reducing consumption, along with high yield, high process productive rate, low cost and the like.

Owner:江苏永航轨道交通科技有限公司

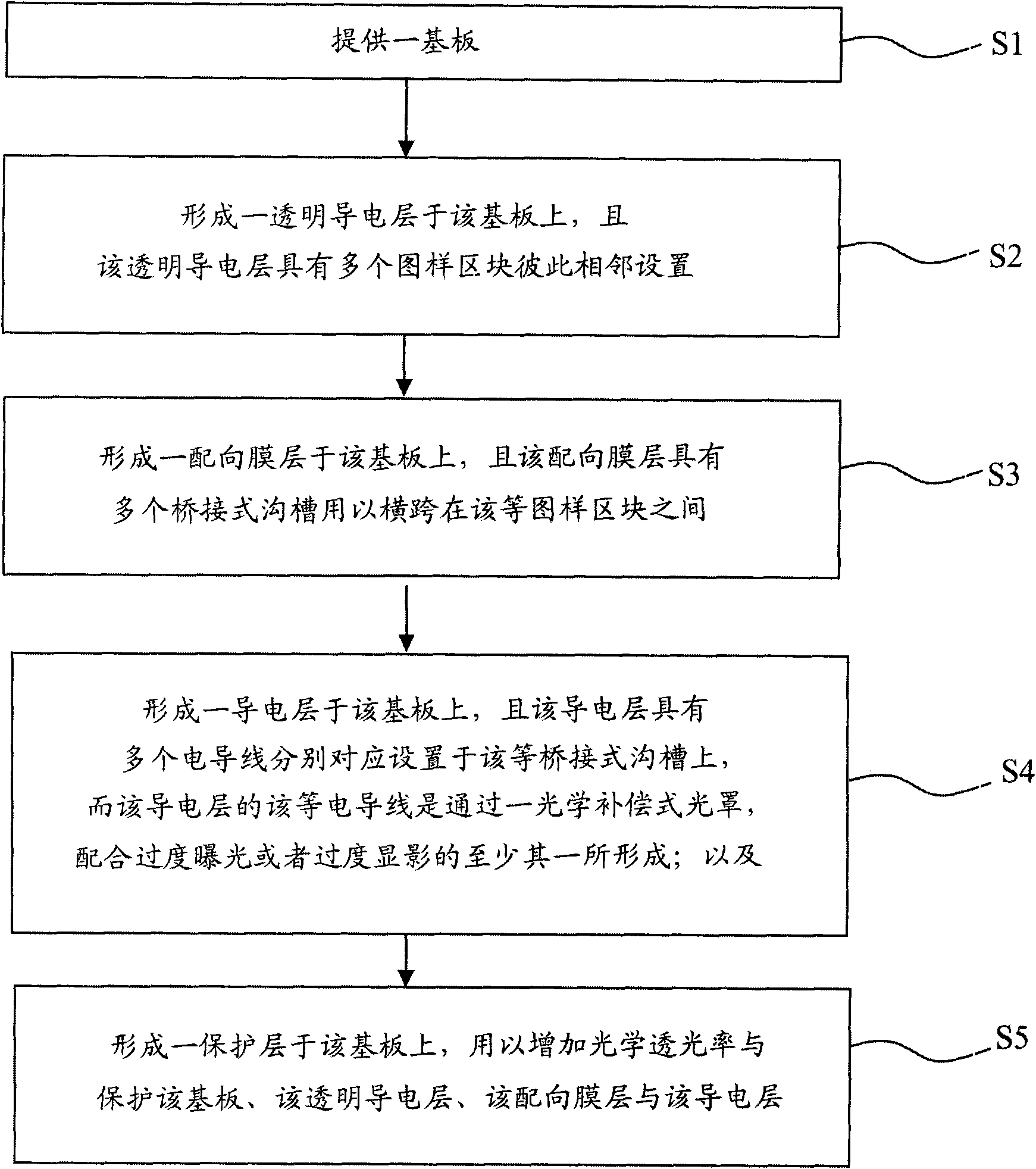

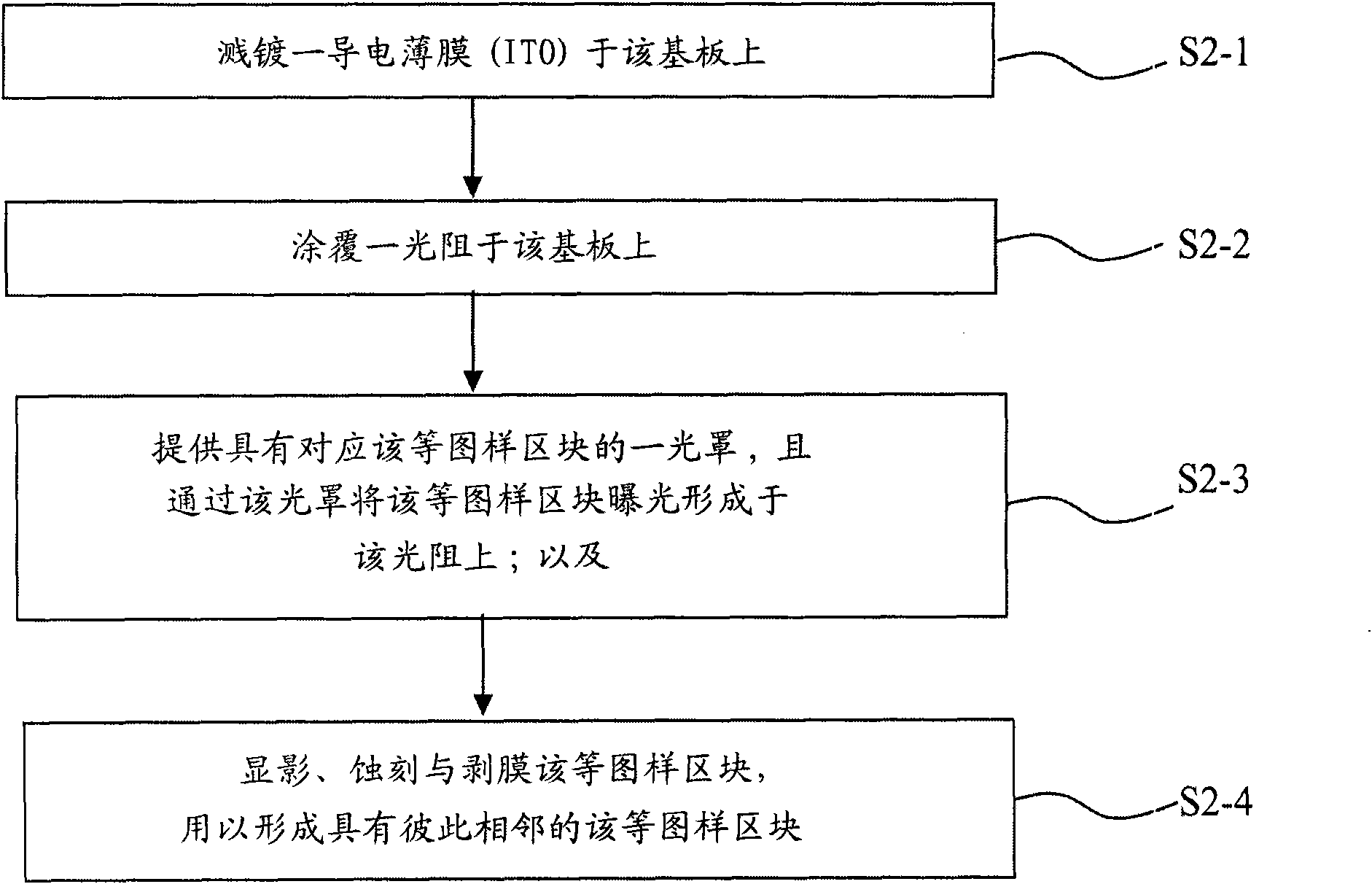

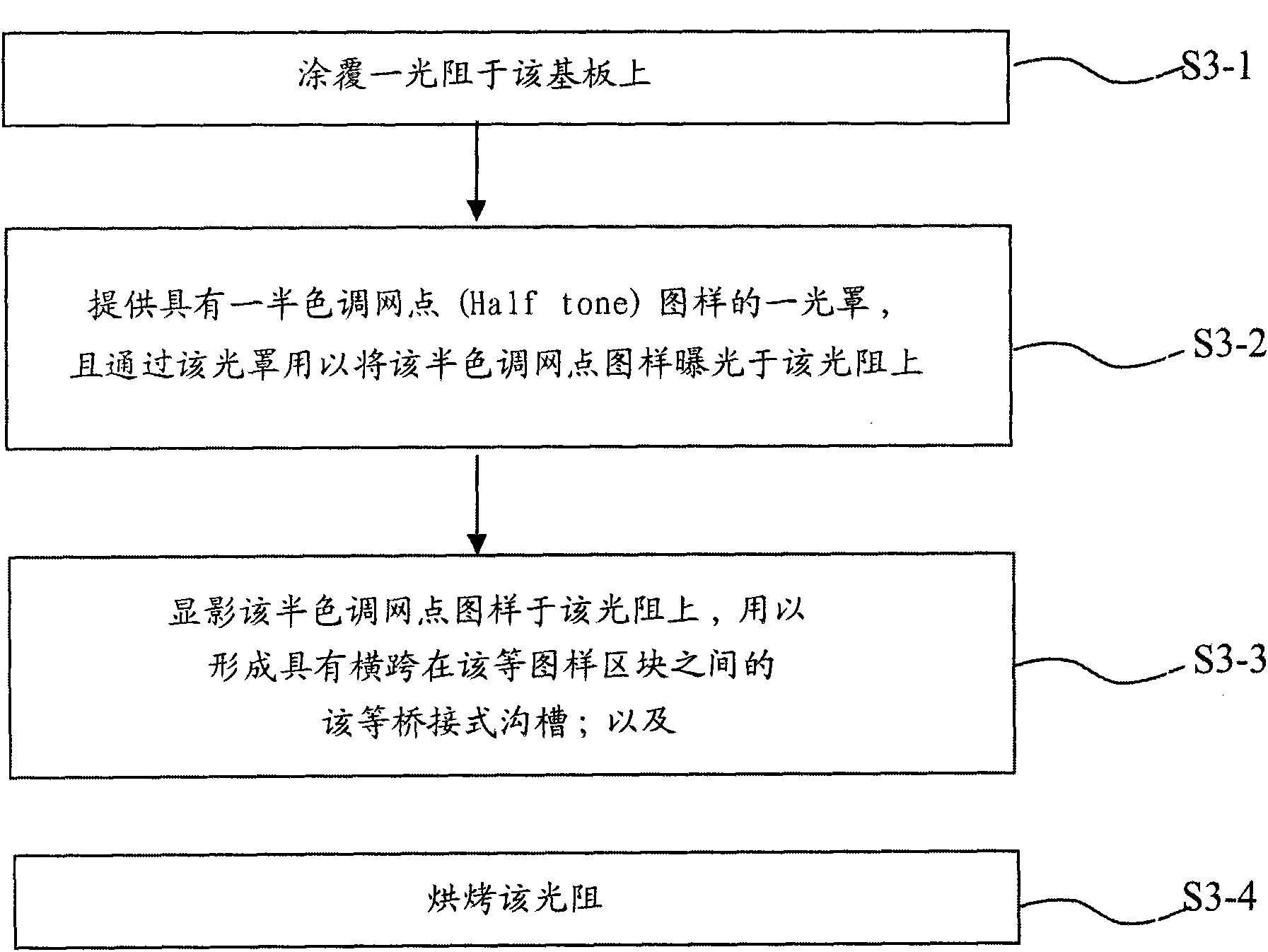

Arrangement method and structure of bridge electrode

InactiveCN102169395AImprove process yieldImprove processing yieldInput/output processes for data processingOptical transmittanceEngineering

The invention relates to an arrangement method and a structure of a bridge electrode. The arrangement method of the bridge electrode comprises the following steps of: providing a substrate; forming a transparent conductive layer on the substrate, wherein the transparent conductive layer is provided with a plurality of pattern blocks which are arranged adjacent to each other; forming an alignment film layer on the substrate, wherein the alignment film layer is provided with a plurality of bridge grooves used for crossing among the plurality of pattern blocks; forming a conductive layer on the substrate, wherein the conductive layer is provided with a plurality of electrical conductors which are respectively arranged on the plurality of bridge grooves, the plurality of electrical conductorsof the conductive layer are formed by an optical compensation photomask together with over exposure or over development; and forming a protective layer on the substrate, wherein the protective layer is used for increasing optical transmittance and protecting the substrate, the transparent conductive layer, the alignment film layer and the conductive layer.

Owner:范莉立

Pouring process for extrusion casting

InactiveCN1546257ASolve large burning lossSolve the problem of many solidification defectsAlloyCasting

The invention refers to a kind of pressing founding and casting method, which is used to produce colored alloy foundry goods. The realizing method is: the alloy fusant enters the pressure room through batch casting device and casting aperture sliding block, after the casting, the gate sliding block closes the pressure room, the indenter up runs, the alloy fusant is formed, pressure maintained, condensed under pressure. The efficiency is high, the quality is good, and the process reclaiming rate is high.

Owner:CHONGQING UNIV

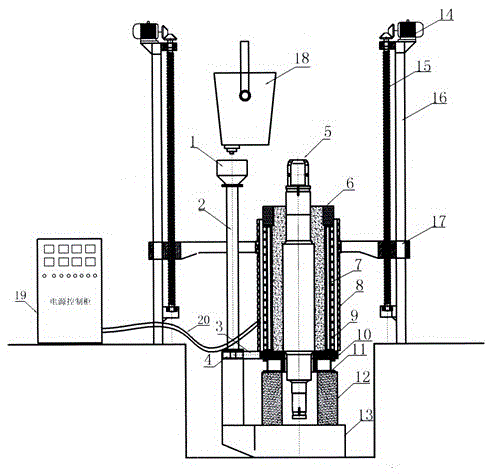

Manufacturing technique and equipment for high-performance composite roller shaft

The invention discloses a manufacturing technique and equipment for a high-performance composite roller shaft. The manufacturing technique comprises the steps that a mandril installed in a combined water-cooling crystallizer is integrally heated to 840-1100 DEG C through an induction heater; molten liquid of a working layer of the roller shaft is poured into the mandril, and then the mandril is continued to be heated for 10-50 minutes; a lifting device is stared so as to lift the heater at a certain speed for 5-15 minutes, and the heater is stopped in the position of a heat-insulating ring; and heating is continued for 10-50 minutes, feeding is conducted on a dead head, and after heating is stopped, cooling is conducted for 30 minutes to 24 hours through water. When the composite roller shaft is manufactured through the manufacturing technique, the number of controllable technological parameters is small, the interface of a composite layer is easy to control, the technique is simple, the efficiency is high, the power consumption is low, the cost is low, the composite layer is free of composition segregation, and the service life of the roller shaft is long; the defect of a centrifugation method that structure segregation is prone to occurring is overcome, and the problems of a CPC method and an ESR method that the production technique is complex, and the cost is high are solved.

Owner:丹阳恒庆复合材料科技有限公司

Casting method capable of preventing precise investment casting from generating hot-spot shrinkage holes

InactiveCN103394644AAvoid shrinkageSave metalFoundry mouldsFoundry coresInvestment castingHead position

The invention discloses a casting method capable of preventing a precise investment casting from generating hot-spot shrinkage holes. The casting method comprises the following steps that: a dead head position is determined according to a conventional method, and a dead head metal patch is replaced by a shell patch at a part, needing to be provided with the dead head metal patch, of the precise investment casting, wherein the material of the shell patch is mortar paste prepared from back layer slurry, back layer powder and back layer sand in a mass ratio of 1:1:5; the shell patch is bonded by the mortar paste, wherein before bonding, a layer of back layer slurry is brushed at a part needing to be bonded with the mortar paste at first, and then the wedge-shaped shell patch is formed according to a method that the thickness at a dead head is greater than that at a hot spot; after that, shell roasting and pouring are performed. Due to the action of the shell patch, the dead head and the hot spot keep a good feeding channel, thus realizing a mode of sequentially solidifying from the hot spot to the dead head, and then preventing the hot spot of the casting from generating the shrinkage holes. According to the method, patch metal for the casting is saved, the product yield of the process increases, and the visual quality of the casting is guaranteed.

Owner:HEBEI NORMAL UNIV

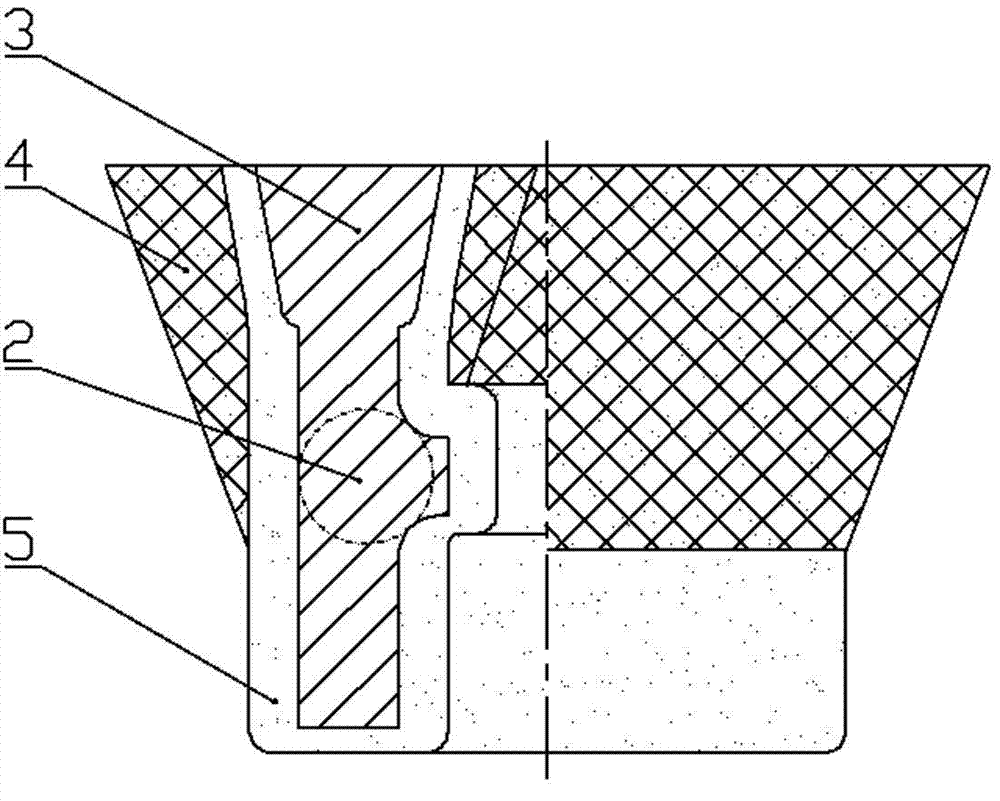

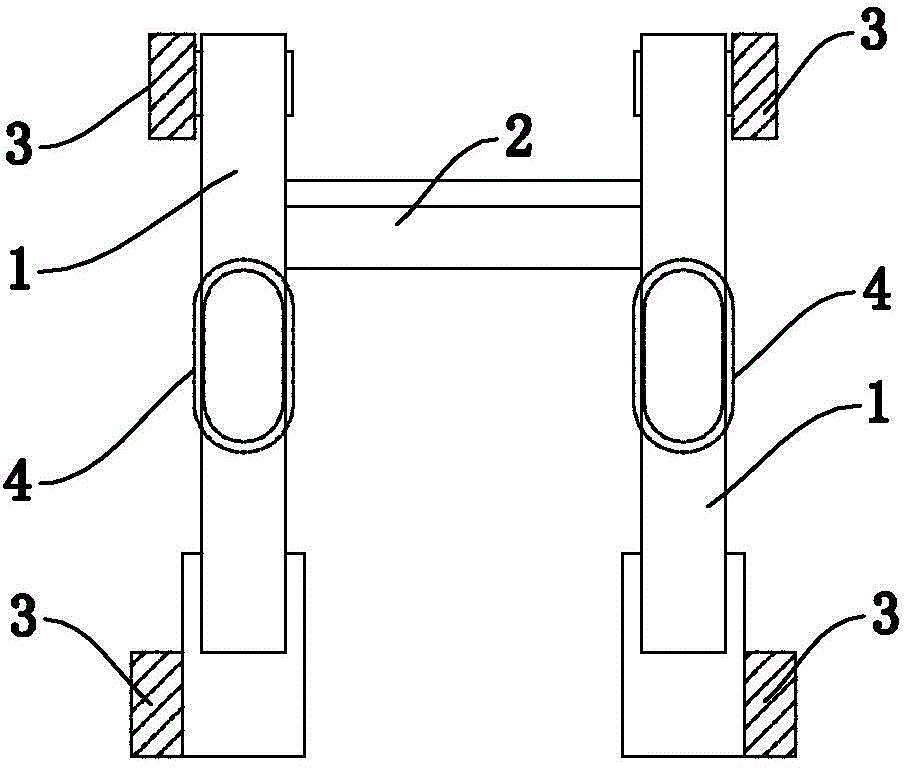

Manufacturing technology and device of forged steel roller neck alloy nodular cast iron composite roller

ActiveCN105397067AEasy feedingOvercome the defect of prone to tissue segregationManufacturing technologyFerrosilicon

The invention discloses a manufacturing technology and device of a forged steel roller neck alloy nodular cast iron composite roller. The forged steel roller neck alloy nodular cast iron composite roller comprises, by mass percent, 3.2%-3.9% of C, 1.6%-2.1% of Si, 0.4%-0.8% of Mn, not larger than 0.05% of P, not larger than 0.03% of S, 0.2%-0.5% of Cr, 0.3%-0.7% of Mo, 1.4%-2.0% of Ni, 0.04%-0.06% of Mg, 0.06%-0.2% of Nb, 0.1%-0.25% of Ti, 0.2%-0.5% of V, 1.5%-2.5% of Ba, 1%-2% of Ca, 1.0%-2.0% of RE and the balance Fe. Rare-earth nodulizing and Ba, Ca and silicon iron compound inoculation are adopted, and Nb, Ti and V are added for modification, so that the mechanical property of the roller is improved, a forged steel roller neck is adopted to improve the strength of the roller, and an induction heater is adopted to carry out in-mold whole heating casting on a forged steel or cast steel core stick; and a combined type water cooled crystallizer is molded, a lifting device lifts the heater upwards at a certain speed to form area directional solidification, a composite layer interface is dynamically controlled, the technology is simple, the efficiency is high, the electric consumption is small, the cost is low, no composition segregation exists in the composite layer, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

Metallurgical bonding double-metal stainless steel cladding reinforcing steel bar and preparation process thereof

InactiveCN106825515AHas comprehensive mechanical propertiesHigh strengthInduction heaterSS - Stainless steel

The invention discloses a metallurgical bonding double-metal stainless steel cladding reinforcing steel bar and a preparation process thereof. The metallurgical bonding double-metal stainless steel cladding reinforcing steel bar comprises a carbon steel core part and a stainless steel cladding. The composite forming process comprises the following steps: integrally heating an outer-layer stainless steel pipe to 600 to 1000 DEG C by using an induction heater, pouring into inner-layer carbon steel, performing metal liquid casting and manufacturing an interface metallurgical bonding cladding type double-metal composite blank; hot-rolling the cast double-metal blank to form cladding double-metal round steel and threaded steel. The metallurgical bonding interface of the stainless steel layer and the carbon steel core is formed by casting, and the advantages of high bonding strength, excellent processing property, dense structure, high quality, few procedures, low cost, high efficiency and the like are achieved. The integral stainless steel reinforcing steel bar is replaced by the double-metal reinforcing steel bar, so on the premise of guaranteeing the corrosion-resistant characteristic of the reinforcing steel bar, the stainless steel material is saved, the engineering cost is reduced, the strength of the reinforcing steel bar is effectively improved, waste of resource and energy and environmental pollution are reduced, and a wide application prospect is achieved.

Owner:丹阳恒庆复合材料科技有限公司

Casting method of tabular spheroidal iron piece and casting system thereof

InactiveCN101301681AReasonable structureSimple structureMolten metal conveying equipmentsCompensation effectSlag

The invention discloses a pouring method and a pouring system used for a plate-shaped ball iron casting. The method adopts a sand casting technique; the pouring system comprises a sprue cup, a sprue, a horizontal runner and a plurality of plate-shaped castings; the method adopts a type that the large plane of the plate-shaped casting is vertically arranged in parallel; the horizontal runner and the plate-shaped casting form a narrow seam edge gate so as to lead the molten steel to flow in along the wall and be stably filled from bottom to top during the pouring process. When the method and the pouring system of the invention are adopted, the molten steel is filled along the wall during the pouring process and the metal is sequentially solidified from bottom to top, thus ensuring the uniformity and consistency of the metallographic structure of the plate-shaped ball iron casting; furthermore, by the narrow seam edge gate, the pouring time is prolonged, the shrinkage compensation effect is provided during the pouring process, furthermore, the slag retaining effect is good and the defects such as slag inclusion, sand inclusion, etc. are avoided; the plate-shaped ball iron casting pouring system of the invention has reasonable and simple structure, saves the metal and has high process yield; furthermore, the pouring system is convenient to be removed; the casting adopts serial pouring, thus having small land occupying and high production efficiency.

Owner:鑫工艺(上海)材料科技有限公司

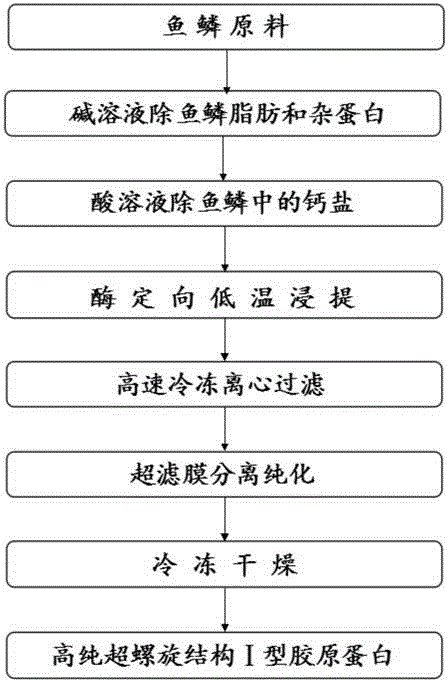

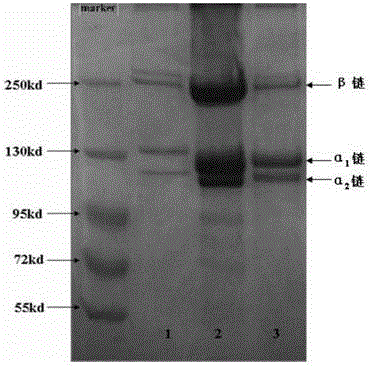

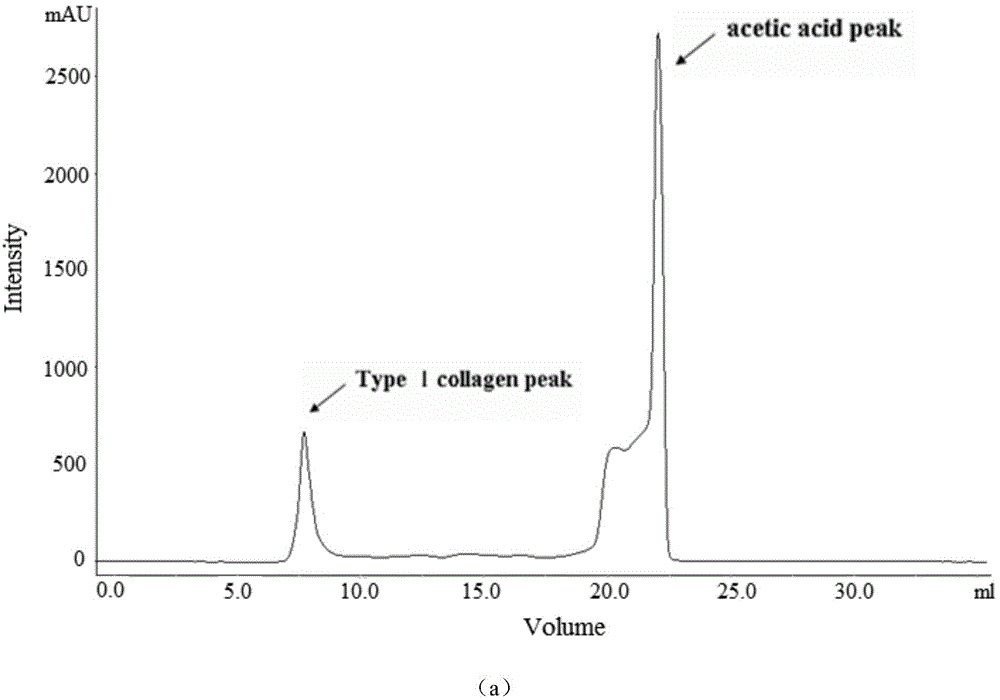

Preparation method of pepsin-soluble high-purity superhelical-structured type-I collagen

ActiveCN104152519AHigh yieldIntegrity guaranteedConnective tissue peptidesPeptide preparation methodsSeparation technologyFreeze-drying

The invention discloses a preparation method of a pepsin-soluble high-purity superhelical-structured type-I collagen, i.e. a low-antigenicity high-purity superhelical-structured type-I collagen. The preparation method is characterized by comprising the following steps: carrying out alkali treatment on scales which mainly contain the type-I collagen and serves as a raw material to remove hybrid proteins and fats, then carrying out acid treatment to remove calcium salts of the scales, adding a weak acid solution as an extraction agent, simultaneously adding pepsin, carrying out low-temperature stirring and leaching, and after the leaching is completed, carrying out refrigerated centrifugation so as to obtain crude leach liquor of the pepsin-soluble type-I collagen; purifying the crude leach liquor of the pepsin-soluble type-I collagen by using a membrane separation technology, and freeze-drying, so that the pepsin-soluble type-I collagen with a purity of not less than 90% and kept at a triple helix structure is obtained. A collagen product prepared by using the method disclosed by the invention is low in antigenicity, clear in configuration, and integral in triple helix structure; HPLC detection shows that the product is a type-I collagen with a purity of greater than or equal to 90%, and MALDI-TOF-MS detection shows that a mass spectrogram of the product has no impure peak, and the molecular weight is 288 kDa.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

Sequential solidification technology device and method used in vacuum smelting equipment

The invention discloses a sequential solidification technology device and method used in vacuum smelting equipment. An induction heating coil is placed in a dead head section of an ingot die, and the feeding capacity of metal liquid in a dead head is enhanced through an induction heating method; a bottom cooling device with the cooling area smaller than the area of the cross section, at the bottom position of the ingot die, of a casting is arranged at the bottom of an ingot die base, the solid-liquid interface angle is reduced, and the metal liquid in the ingot die after pouring can be sequentially solidified from bottom to top. The solidification process control method is applicable to production of metal bar castings in the vacuum smelting equipment. Through the sequential solidification technology device and method, macroshrinkage and shrinkage porosity in alloy bar castings can be eliminated, the casting quality and the technology yield are improved, and the production efficiency is greatly improved.

Owner:BEIHANG UNIV

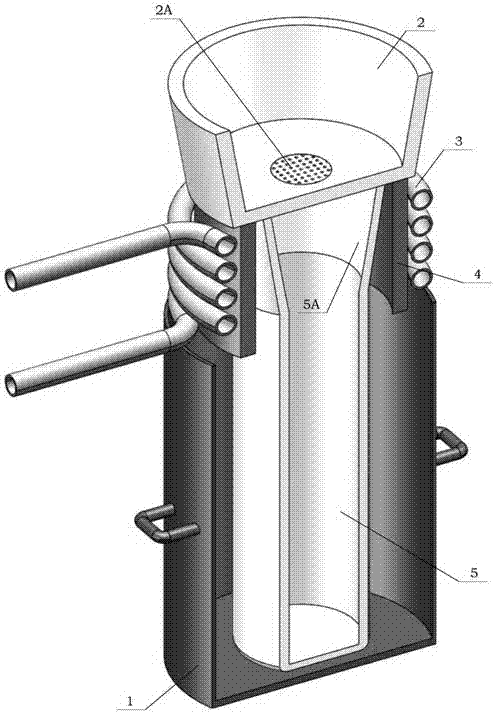

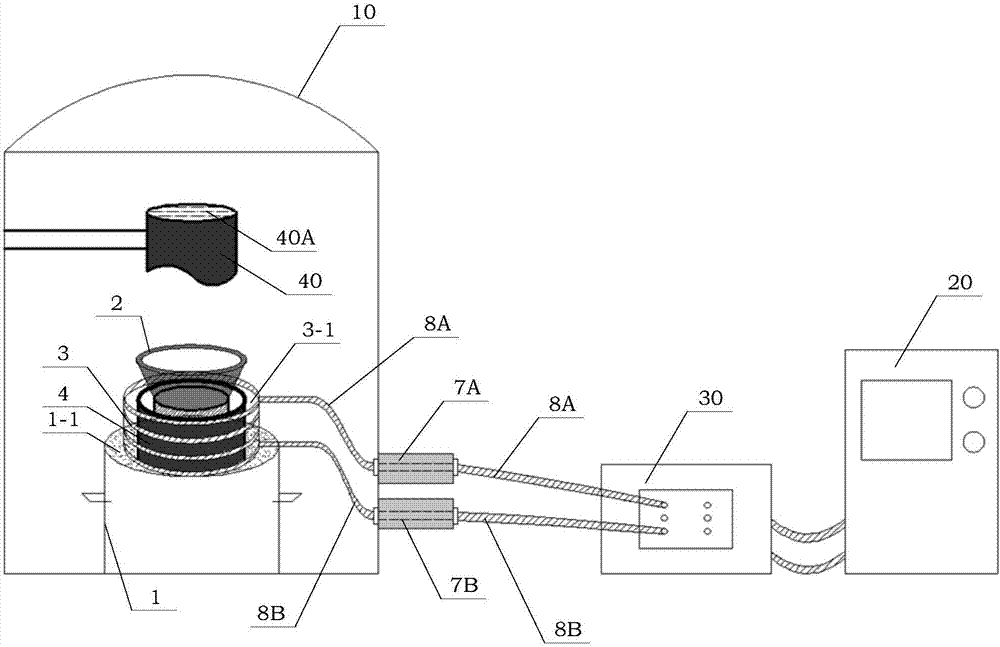

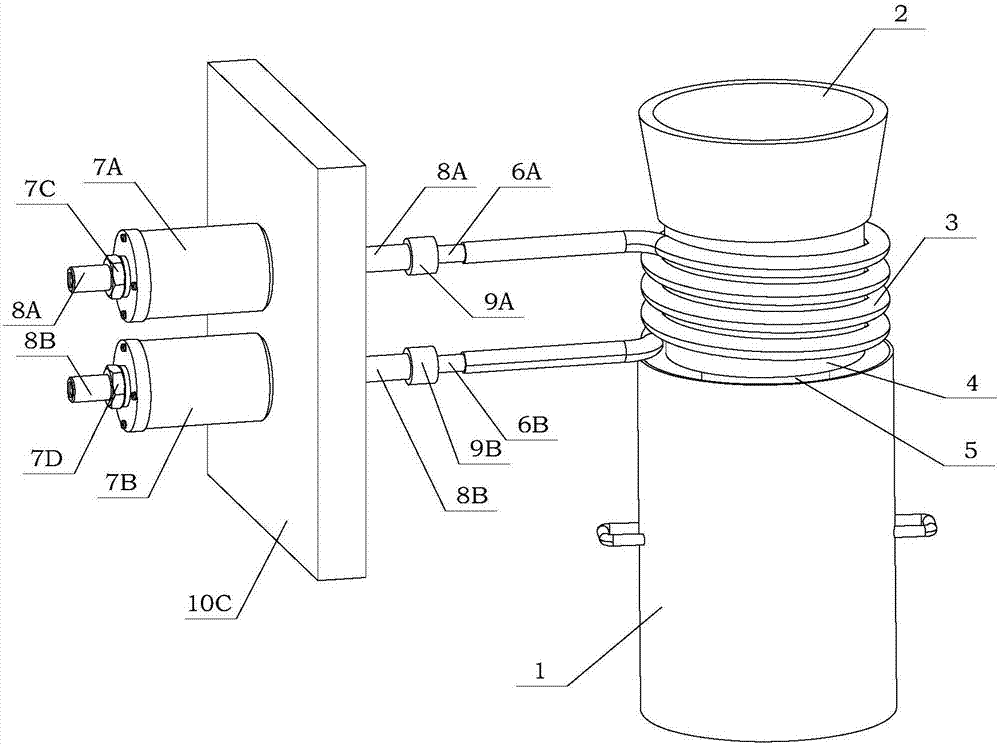

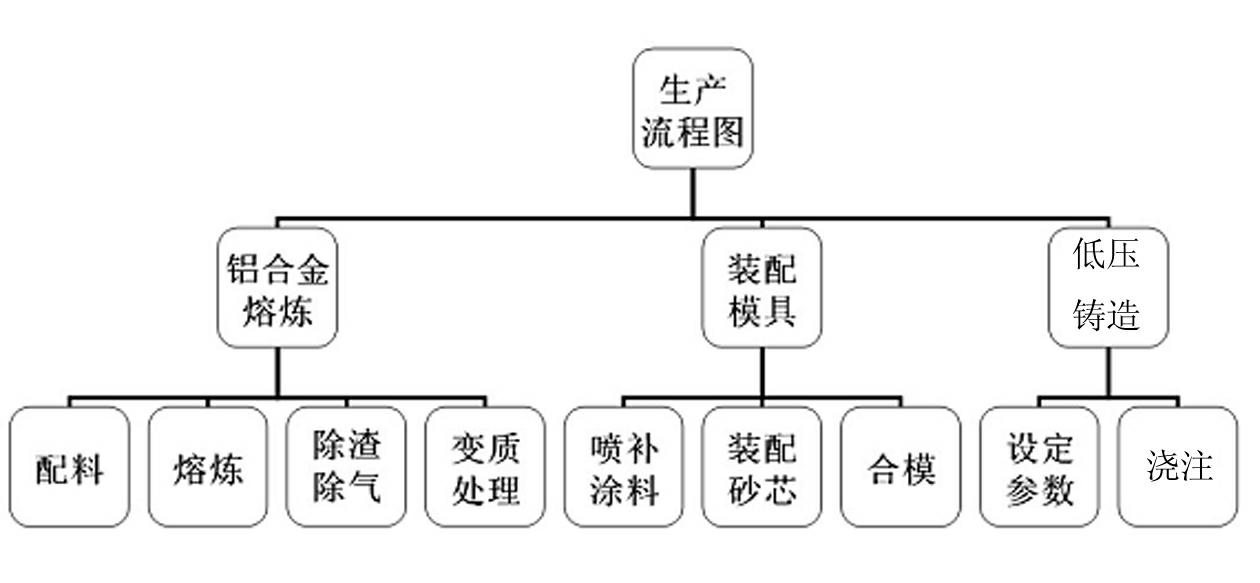

Die of cast aluminum shell for high pressure switch, and method for producing cast aluminum shell

The invention provides a die of a cast aluminum shell for a high pressure switch, and a method for producing the cast aluminum shell. The die of the cast aluminum shell for the high pressure switch comprises a metal die and a sand core; and the die is characterized in that: a lead-in port connected with a crucible liquid raising pipe is arranged on a bottom plate; a straight pouring channel at the bottom of the sand core is connected with the lead-in port; an internal pouring channel is arranged on the straight pouring channel; the metal die is wrapped at the external side of the sand core; araiser core is arranged on the top of the metal die; the inner side of the raiser core and the outer side of the upper part of the sand core form a raiser; and an embedding block is longitudinally arranged at the side of the sand core. The method comprises the following steps of: melting aluminum alloy, assembling the die, casting at low pressure, and taking out the casting component. By using the technical scheme of the invention, the method is simple in operation, easy to control, high in product surface quality, high in technique yield, high in air tightness inspecting yield, and low in production cost.

Owner:沈阳创新合金有限公司

Lost foam casting process of high-manganese steel sieve plate

InactiveCN104353782AReduce defectsShorten the timeFoundry mouldsFoundry coresHigh volume manufacturingPilot scale

The invention relates to a lost foam casting process, in particular to a lost foam casting process of a high-manganese steel sieve plate. The lost foam casting process comprises the following steps: 1, performing blank moulding; 2, preparing paint; 3, serially connecting moulds and blank moulds; 4, painting; 5, performing sand moulding; 6, smelting; 7, casting, performing shakeout and performing water toughing treatment. By the lost foam casting process, the top pouring time is shortest and the pouring speed is high, so that sand crushing can be easily prevented; the temperature fall is small, so that defects caused by insufficient pouring and a cold shut can be easily prevented; the product yield is high, and the sequential solidification and feeding effect is good; carbon defects of a cast product can be eliminated; small-batch pilot scale tests and mass production practices show that the one-time pass rate of the cast product reaches about 95%.

Owner:WUXI LEHUA AUTOMATION TECH

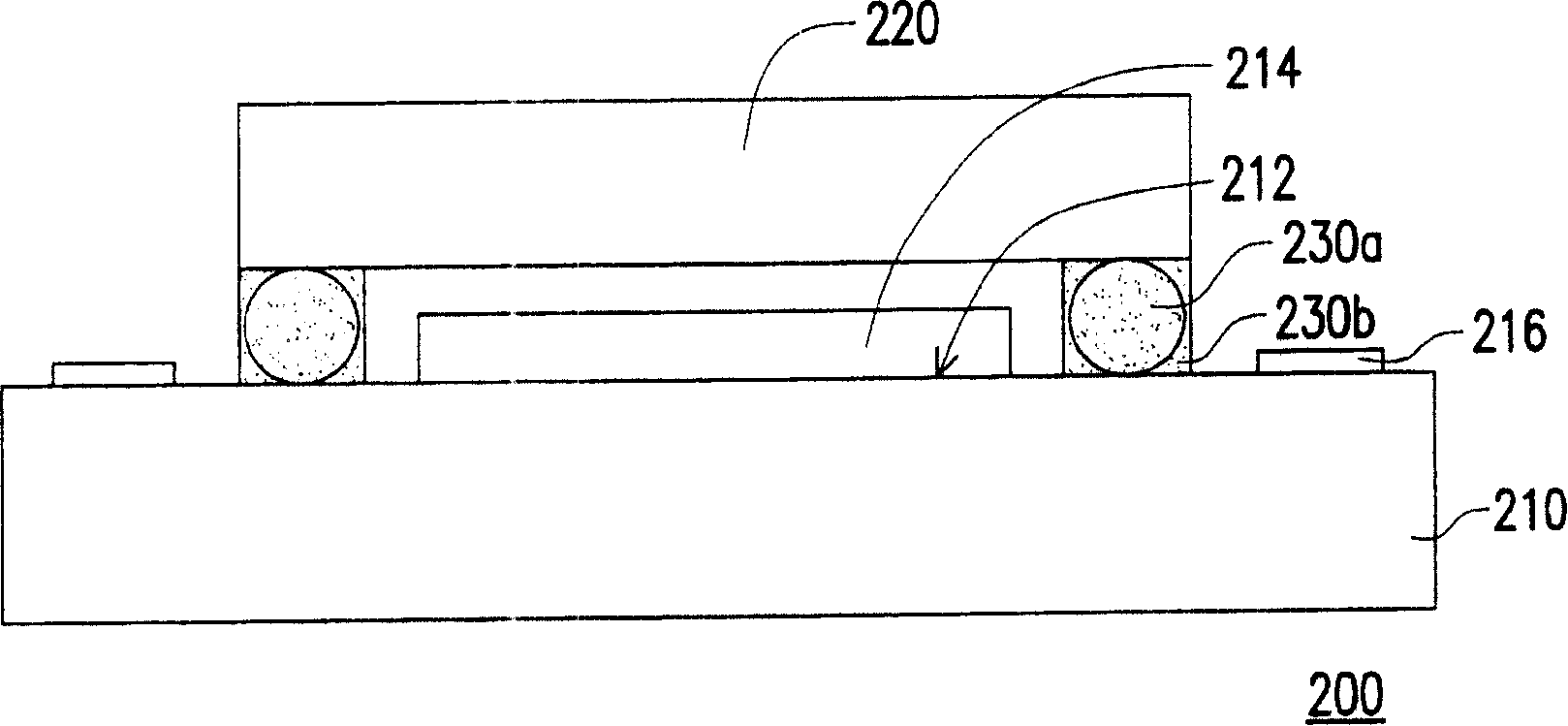

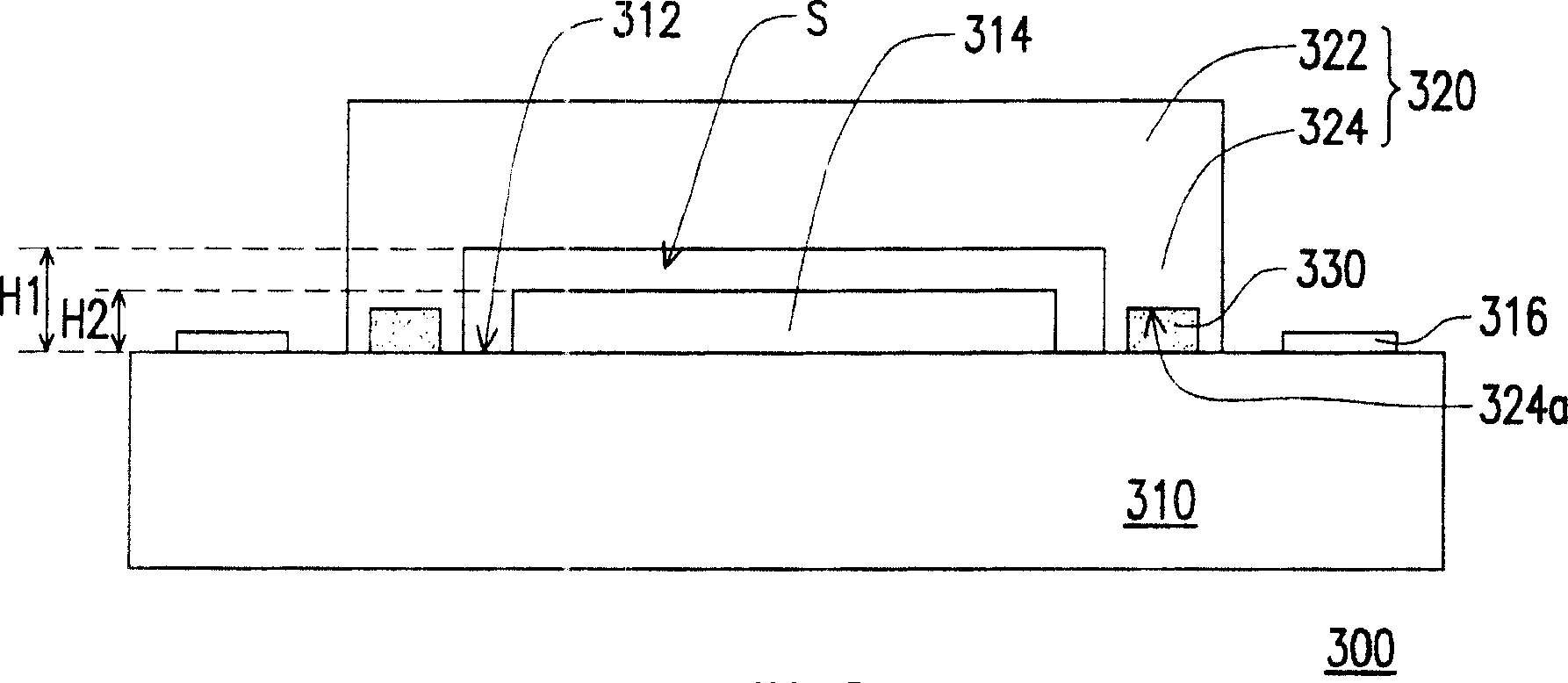

Packaging cover board, chip packaging structure and manufacturing method thereof

InactiveCN101162711AImprove process yieldGood light penetrationSemiconductor/solid-state device detailsSolid-state devicesHigh rateEngineering

A chip package structure comprises a chip, a package cover board and a bound layer, wherein, the chip is provided with a drive surface which is provided with an image sensing element and a plurality of connection cushions positioned on the periphery of the sensing element. In addition, the package cover board is arranged above the drive surface and comprises a baseplate and a support part positioned on the baseplate, wherein, a holding room is left on the baseplate by the support part, the support part contacts with the drive surface of the chip to ensure the image sensing element on the drive surface arranged in the holding room. Besides, the bound layer is arranged between the support part and the drive surface. The chip package structure of the invention has the advantages of high rate of finished products of technique, low cost of production and good optical penetrating power.

Owner:UNITED MICRODISPLAY OPTRONICS CORP

Production technology for as-cast spheroidal graphite iron casting QT600-7

The invention discloses a production technology for an as-cast spheroidal graphite iron casting QT600-7 and belongs to the technical field of casting. The production technology comprises the steps of feeding Q10 raw iron, Q235 waste steel and a foundry returns into a furnace for smelting to obtain liquid iron; putting Cu, Ni and an RE-Mg balling agent as well as a SiBaCa nucleating agent at the bottom of a foundry ladle, and pouring the smelted liquid iron into the foundry ladle for balling; adding the powdered SiBaCa nucleating agent along with the flow during ladle transferring of the balled liquid iron; pouring the nucleated liquid iron into a casting mold to obtain the as-cast spheroidal graphite iron casting QT600-7. The material intensity of the spheroidal graphite iron casting produced by the production technology is higher than or equal to 600Mpa, and the elongation rate is greater than or equal to 7 percent. The as-cast spheroidal graphite iron casting QT600-7 has comprehensive performance of high elongation rate of ferrite spheroidal graphite iron and high intensity of pearlyte spheroidal graphite iron; the pearlyte content is 35-60 percent, the balling rate is about 85 percent, and stable production that the as-cast spheroidal graphite iron casting 600-7 has standard performance is realized.

Owner:SHANDONG QIU CHEN MACHINERY MFG

Production technology of air-conditioning compressor crankshaft

ActiveCN102397993AReduce contact areaIncrease the number of placementsFoundry mouldsFoundry coresEngineeringAir conditioning

A production technology of an air-conditioning compressor crankshaft comprises the following steps of: sand mulling; modeling; melting and interrupted front treatment; casting; casting cleaning and product quality inspection. During the modeling design process, the axial direction of a die crank is perpendicular to a parting face and parting of the die crank is carried out at the eccentric part of the crankshaft. After modeling and stripping, crankshaft cavities are formed and are respectively arranged inside two adjacent sand molds. During the casting process by a bottom casting mode, a filter screen is used to filter molten iron. On the basis of meeting technological requirements of crankshaft casting, production efficiency is raised and the purpose of energy saving and emission reduction is achieved.

Owner:上海华新合金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com