Spheroidal graphite cast iron casting mould and riser-free casting method adopting same

A technology of ductile cast iron and casting molds, which is applied in the direction of casting molds, casting mold components, casting molding equipment, etc., can solve the problems of failure to achieve riser-free casting, difficult problems, etc., and achieve stable feeding effect, simple operation, and convenience Applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

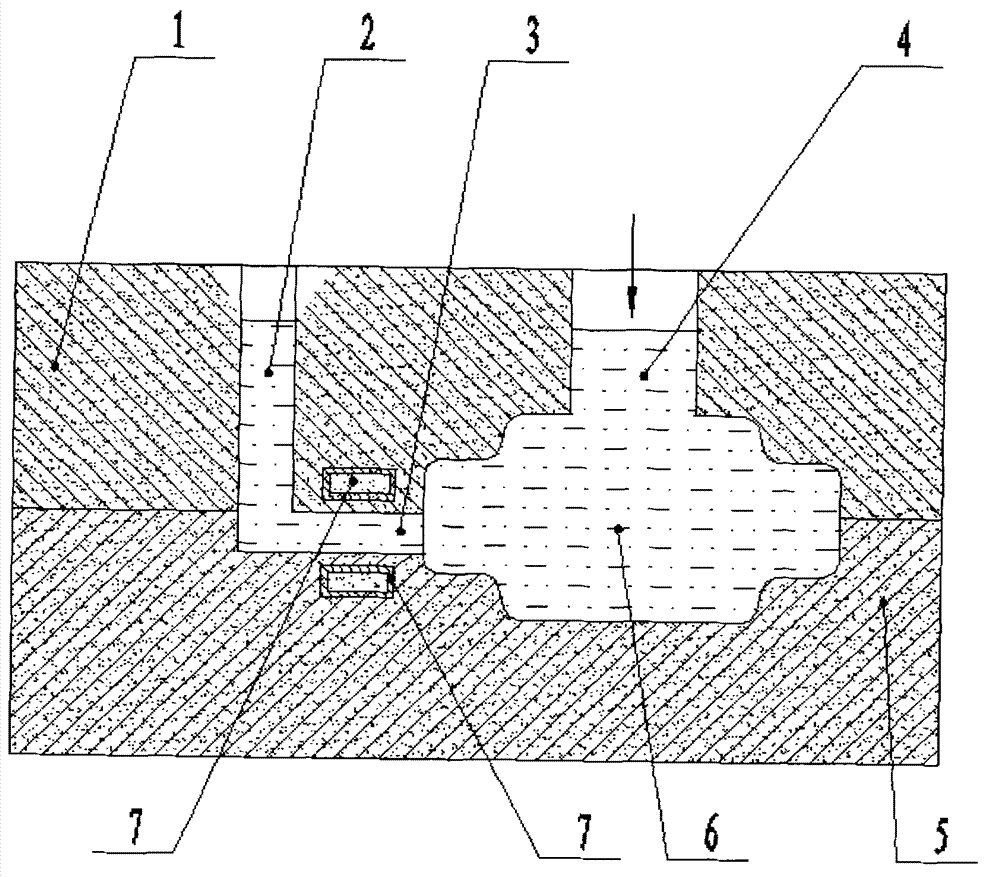

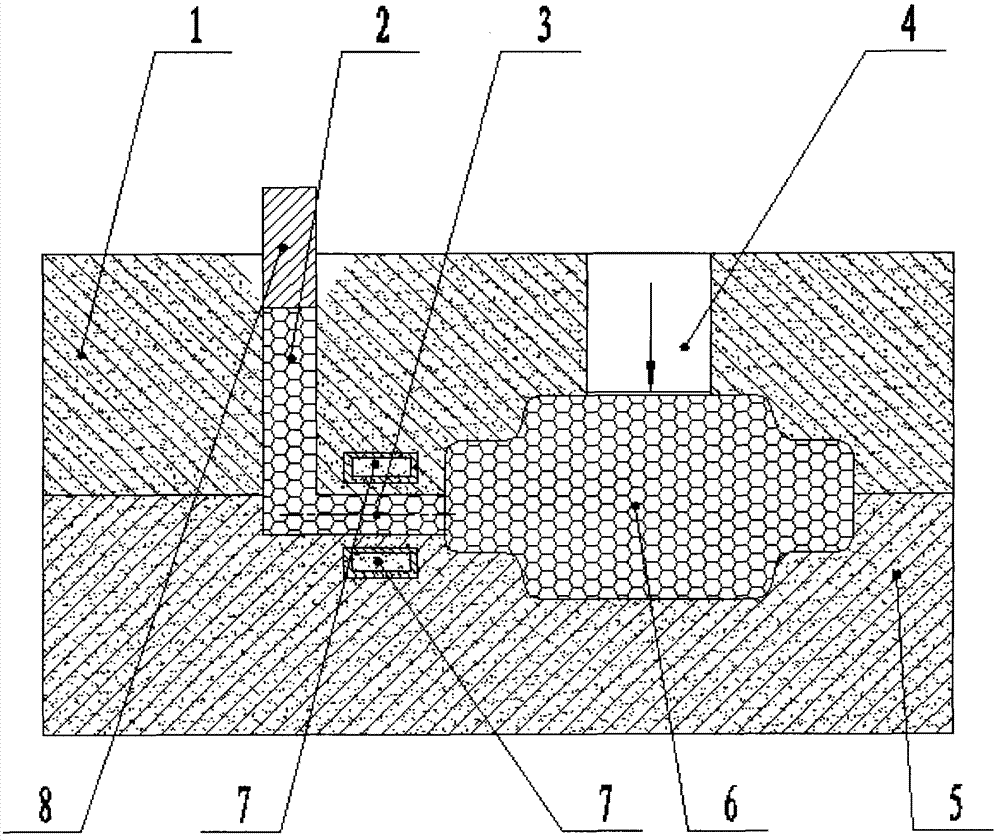

[0036] The castings produced in this embodiment are ductile iron shaft sleeve parts, with a minimum wall thickness of 25mm, a maximum wall thickness of 50mm, a thermal pitch circle diameter of 60mm, a single piece weight of 260kg, and a volume of 34dm 3 . Its riserless casting method comprises the following steps:

[0037] Step 1: Close the mold and press it tightly. Compression force (N) = 15 x cavity horizontal projected area (mm 2 ).

[0038] Step 2 pouring: pour the nodular cast iron liquid with a temperature of 1230°C through the pouring system, and pour it into the mold cavity until the liquid level in the sprue and the liquid storage chamber reaches the set position.

[0039] Step 3 Cooling the inrunner: Quickly open the cooling medium of the inrunner cooler to cool and solidify the inrunner.

[0040] Step 4 Pressurization and feeding: within 5 seconds after the ingate is solidified, directly apply a mechanical pressure of 20 MPa on the liquid surface of the ductile i...

Embodiment 2

[0046] The casting in this embodiment is a ductile iron box body, with a minimum wall thickness of 20mm, a maximum wall thickness of 30mm, a thermal pitch circle diameter of 35mm, a single piece weight of 105kg, and a volume of 13.7dm 3 . Its riserless casting method comprises the following steps:

[0047] Step 1: Close the mold and press it tightly. Compression force (N) = 20 × cavity horizontal projected area (mm 2 ).

[0048] Step 2 pouring: pour the nodular cast iron liquid with a temperature of 1280°C through the pouring system, and pour it into the mold cavity until the liquid level in the sprue and the liquid storage chamber reaches the set position.

[0049] Step 3 Cooling the inrunner: Quickly open the cooling medium of the inrunner cooler to cool and solidify the inrunner.

[0050] Step 4 Pressurization and feeding: within 7 seconds after the ingate is solidified, directly apply a mechanical pressure of 12MPa on the liquid surface of the ductile iron in the liqui...

Embodiment 3

[0055] The casting in this embodiment is a nodular cast iron wheel, with a minimum wall thickness of 5mm, a maximum wall thickness of 10mm, a thermal pitch circle diameter of 12mm, a single piece weight of 15kg, and a volume of 2dm 3 . Its riserless casting method comprises the following steps:

[0056] Step 1: Close the mold and press it tightly. Compression force (N) = 30 × cavity horizontal projected area (mm 2 ).

[0057] Step 2 pouring: pour the nodular cast iron liquid with a temperature of 1380°C through the pouring system, and pour it into the mold cavity until the liquid level in the sprue and the liquid storage chamber reaches the set position.

[0058] Step 3 Cooling the inrunner: Quickly open the cooling medium of the inrunner cooler to cool and solidify the inrunner.

[0059] Step 4 Pressurization and feeding: Within 10 seconds after the ingate is solidified, directly apply a mechanical pressure of 1 MPa on the liquid surface of the ductile iron in the liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com