Metallurgical bonding double-metal stainless steel cladding reinforcing steel bar and preparation process thereof

A technology of metallurgical bonding and preparation process, applied in the field of metal composite materials, can solve the problems of high cost, poor corrosion resistance, good corrosion resistance of stainless steel bars, etc., and achieve the effects of beautiful appearance, low price, and firm interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

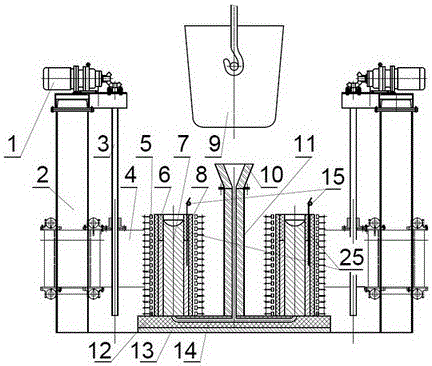

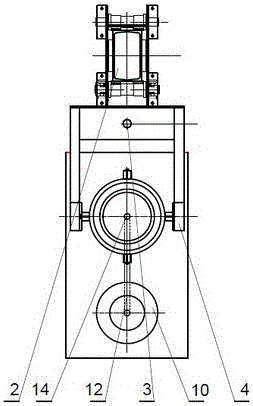

[0065] Example 1: Preparation of metallurgically bonded bimetallic stainless steel clad smooth reinforcement.

[0066] Figure 16 Among them, the metallurgically bonded bimetallic stainless steel cladding steel bar has a diameter of 5 mm to 42 mm, and it is composed of a carbon steel core metal 7 and a stainless steel cladding 6 clad along the length direction of the core metal 7, the stainless steel cladding 6 Between the carbon steel core metal 7 is a metallurgically bonded fusion interface layer formed by melting and casting.

[0067] Prepare metallurgically bonded bimetallic stainless steel clad smooth steel bars, the core 7 is carbon steel Q235, the geometry of the cross section is a circle with a diameter of 12 mm, the thickness of the stainless steel alloy layer 6 is 2 mm, and the stainless steel alloy layer 6 is made of 06Cr19Ni10 austenite Stainless steel. Figure 16 It is a schematic structural diagram of a cross-sectional view of a bimetallic smooth steel bar prov...

Embodiment 2

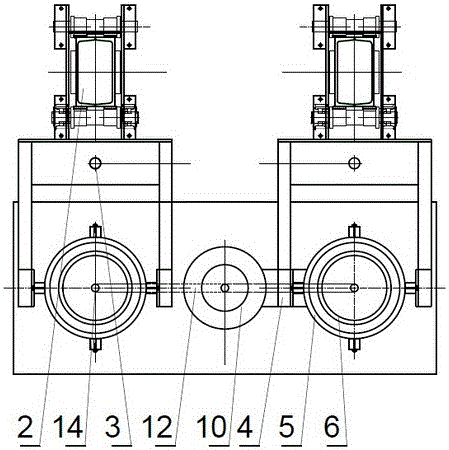

[0082] Example 2: Preparation of metallurgically bonded bimetallic stainless steel clad rebar.

[0083] Figure 17 Among them, the metallurgically bonded double-metal stainless steel clad threaded steel bar has a diameter of 5 mm to 42 mm, and it is composed of a carbon steel core metal 7 and a stainless steel cladding 6 clad along the length direction of the core metal 7. The stainless steel cladding Between 6 and the carbon steel core metal 7 is a metallurgically bonded fusion interface layer formed by melting and casting.

[0084] Prepare metallurgically bonded double-metal stainless steel clad threaded steel bars, the core 7 is carbon steel HRB335, the geometric shape of the cross section is a threaded steel bar with a diameter of 18 mm, the thickness of the stainless steel alloy layer 6 is 1 mm, and the stainless steel alloy layer 6 is selected from 304 austenitic stainless steel . Figure 17 A schematic diagram of the basic structure of a bimetallic threaded steel bar ...

Embodiment 3

[0098] Example 3: In Figure 4 in, with figure 2 The difference is that the pouring runner 14 in the casting runner brick 12 installed under the intermediate injection pipe 11 has three metal liquid outlets. The outlet flows out at the same time, and three bimetallic composite billets whose outer layer is stainless steel and inner layer is low-alloy steel can be directly poured at one time. Other process and equipment are identical with embodiment 1. slightly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com