Patents

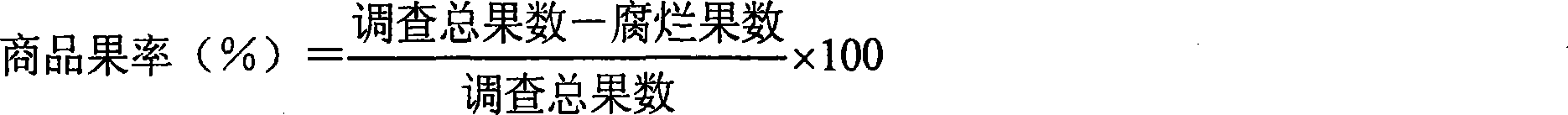

Literature

186 results about "Pilot scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pilot scale is proof of concept at a scaled up size for treating up to 50% of a total actual flow for the application. Usually these are on-site at the eventual place where full scale will be built and operated.

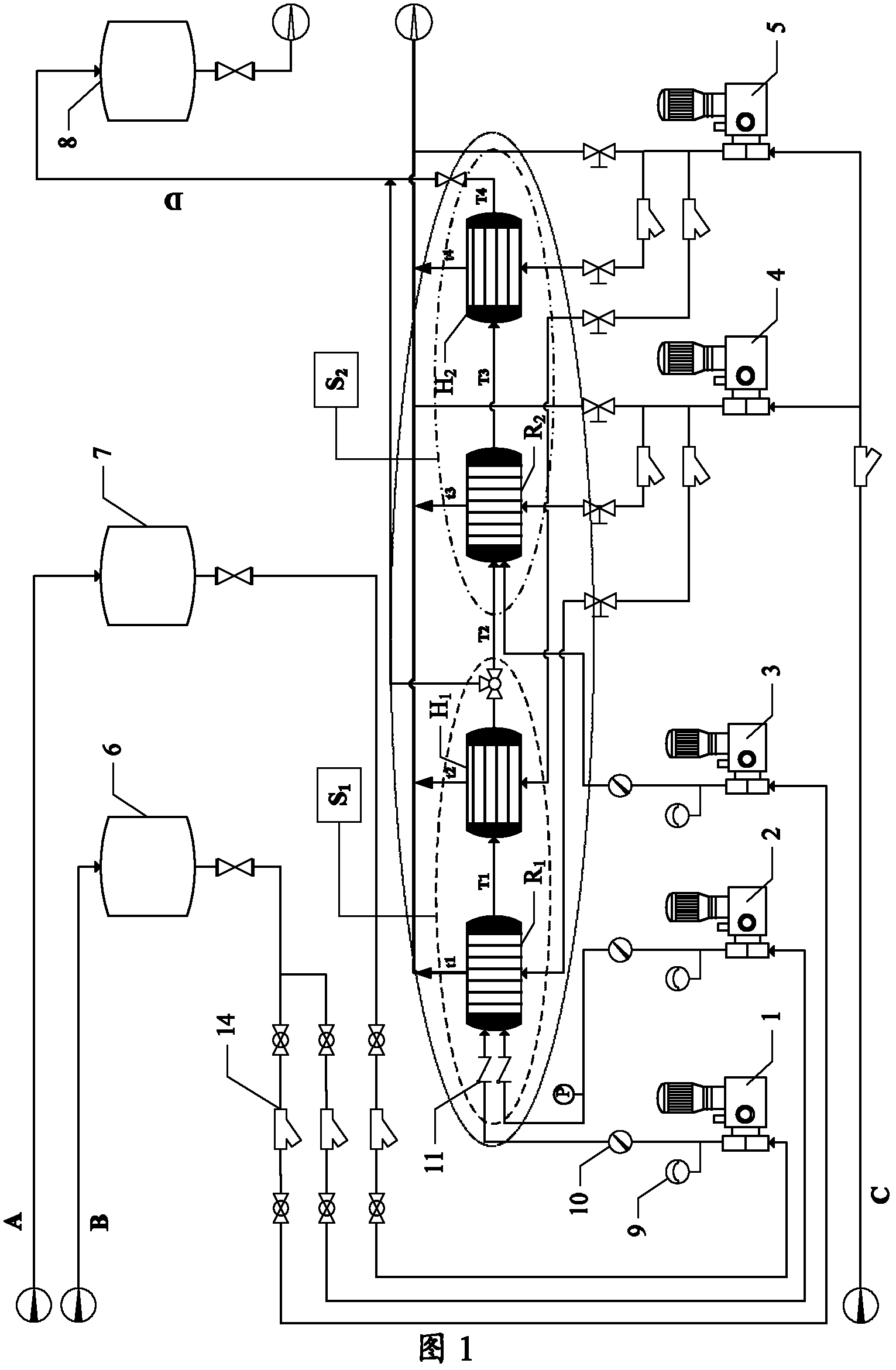

Method for preparation and activation of multimetallic zeolite catalysts, a catalyst composition and application for n2o abatement

InactiveUS20060088469A1High activityRemarkable stabilityNitrous oxide captureProductsBiological activationPilot scale

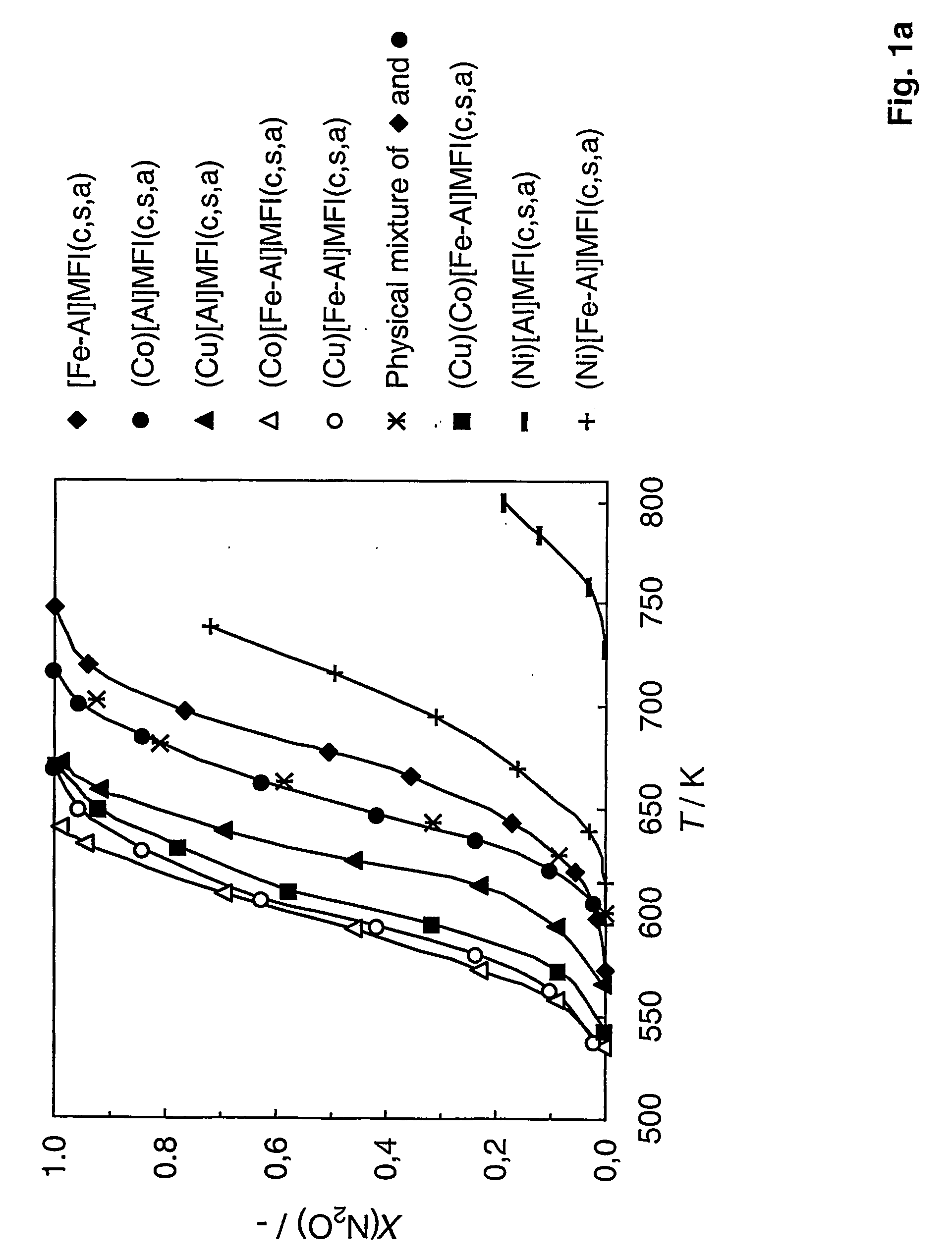

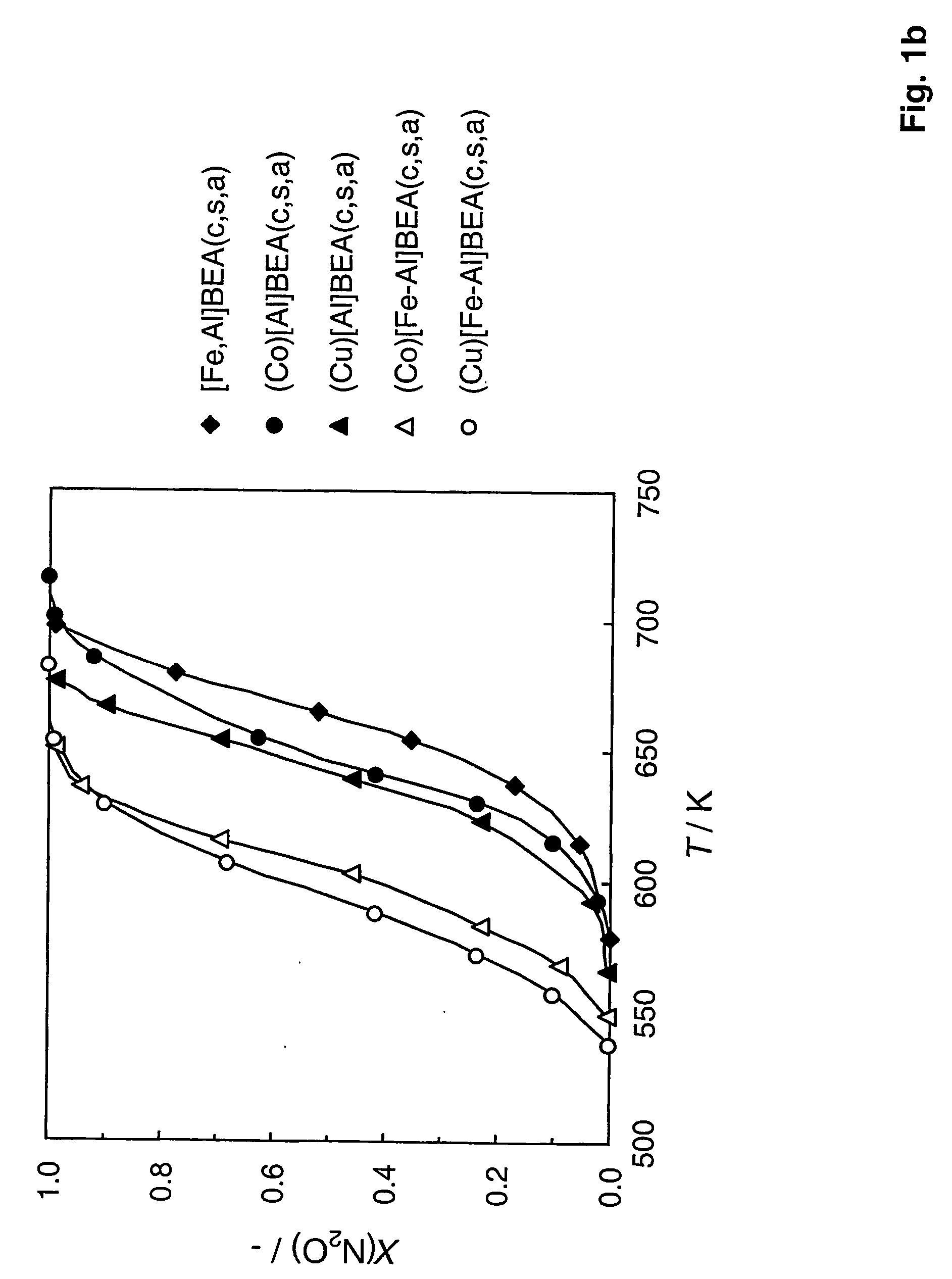

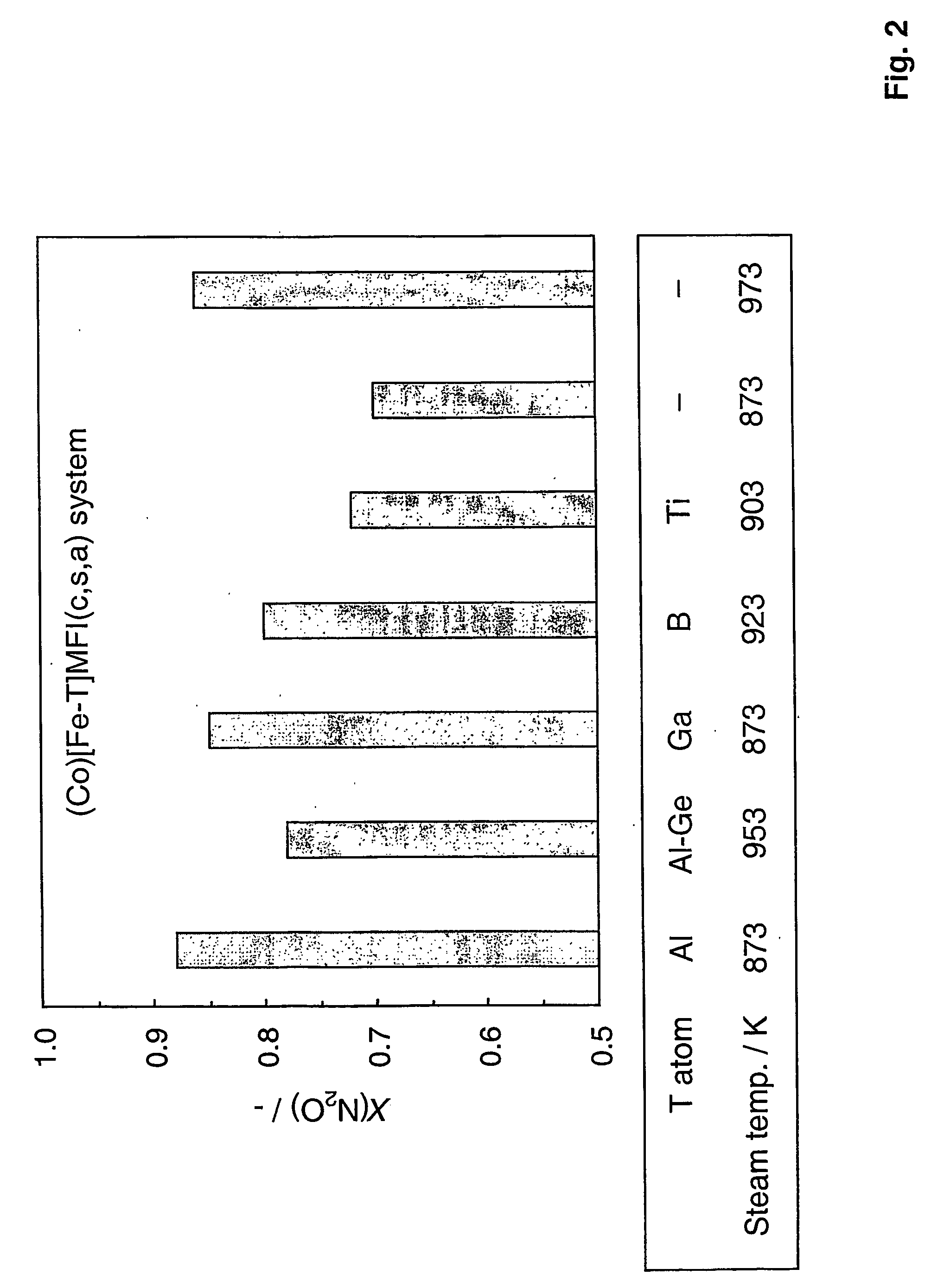

The present invention relates to the preparation and activation of multimetallic zeolites loaded with transition metals for N2O abatement in tail-gases from different sources. The N2O-containing gas is brought in contact with a catalyst comprising Fe and a second, third, or any additional transition metal (Cu, Co, Ni, Mn, Cr, V), with a total metal content ranging from 0.1-1.0 wt. %, on a zeolite support (MFI or BEA) at 523-873 K. Not 10 only the combination and loading of metals, but also the method of incorporation in the zeolite and its activation is essential to obtain active and stable catalysts. The synergy between metals was observed in Fe—Cu, Fe—Co, and Fe—Co—Cu systems, but not with combinations of iron with other transition metals. The optimal catalysts show high N2O conversions (>80%) at temperatures <623 K and stable behaviour for >2000 hours in pilot-scale tests with a zeolite-coated monolithic reactor.

Owner:YARA INT ASA

Environment-friendly type moldable aqueous transfer coating, preparation and use thereof

ActiveCN101407656AReduce contentReduce manufacturing costCoatings with pigmentsPolyurea/polyurethane coatingsSolvent basedPolyresin

The invention relates to an environment-friendly moldable waterborne transfer coating, a preparation method and an application thereof, wherein, the waterborne transfer coating takes the following components with the contents (parts by weight) as raw materials: 40 to 70 parts of waterborne resin; 10 to 20 parts of cosolvent; 18 to 40 parts of deionized water; 0.1 to 2 parts of pH value regulator; 0.1 to 0.5 part of wetting agent; 0.1 to 0.2 part of leveling agent; and 0.05 to 0.2 part of defoamer. Compared with the prior art, the environment-friendly moldable waterborne transfer coating has the following advantages of environmental protection and cost advantages, good printing adaptability, relatively wide range of suitable molding temperature during the molding, good molding effect and easy production control; furthermore, the environment-friendly moldable waterborne transfer coating can be directly used for replacing the existing solvent laser transfer coating by the pilot scale production confirmation.

Owner:SHANGHAI WEIKAI CHEM

Kiwi fresh fruit preservation technique

InactiveCN101223906ANo pollution in the processEasy to operateFruits/vegetable preservation by freezing/coolingVacuum pumpingActinidia

The invention relates to a preservative technique for fresh kiwifruit, which comprises technique processes of cold storage disinfection, precooling, bagging, air regulate case vacuum pumping, air distribution, preservation and unhouse packaging. The technique of the invention carries out laboratory study test on the storage of the fresh kiwifruit, the test shows that the kiwifruit can be preserved for more than 200 days with average fruit firmness more than or equal to 3.0kg / cm<2>, fruit firmness rate more than or equal to 90 percent, commercial fruits rate more than or equal to 95 percent, Vc keeping-rate more than or equal to 80 percent and freshness index more than or equal to 0.90. Pilot scale study was carried out in an air conditioned storehouse in Zhouzhi County Shanxi Province in 2006 by the technique of the invention to store 50 tons of Hayward kiwifruit for 215 days with commercial fruits rate of 96 percent. The invention has the advantages of simple operation, long preservation period, good preservation effect, no environmental pollution, obvious economic benefit, etc., which can be widely applied.

Owner:SHAANXI NORMAL UNIV

Production method for extracting and purifying hyaluronic acid

The invention discloses a production method for extracting and purifying hyaluronic acid, for solving the problems such as long process route, long production period, high labor intensity, more human factors influencing product quality and relatively low product yield, existing in the purification of the traditional CPC (Cetyl Pyridinium Chloride) complexing ethanol sedimentation technology. The production method comprises the following steps of: fermentation liquor inactivation, primary alcohol precipitation, rough separation, redissolution, primary filtering decontamination, secondary filtering purification, alcohol precipitation crystallization, drying and smashing. The invention provides an industrial extraction and purification method of fermentation liquor for producing the hyaluronic acid through a streptococcus zooepidemicus fermentation method. The industrial extraction and purification method provided by the invention has the characteristics of short process route and production period, high adaptability, low production cost and good effect, can be concluded into a secondary filtering and secondary alcohol precipitation extraction process and is proved to be feasible through a small-scale test and a pilot scale test in a laboratory and verification in actual production and can meet the requirement for industrialized production.

Owner:SICHUAN HENGYI TECH

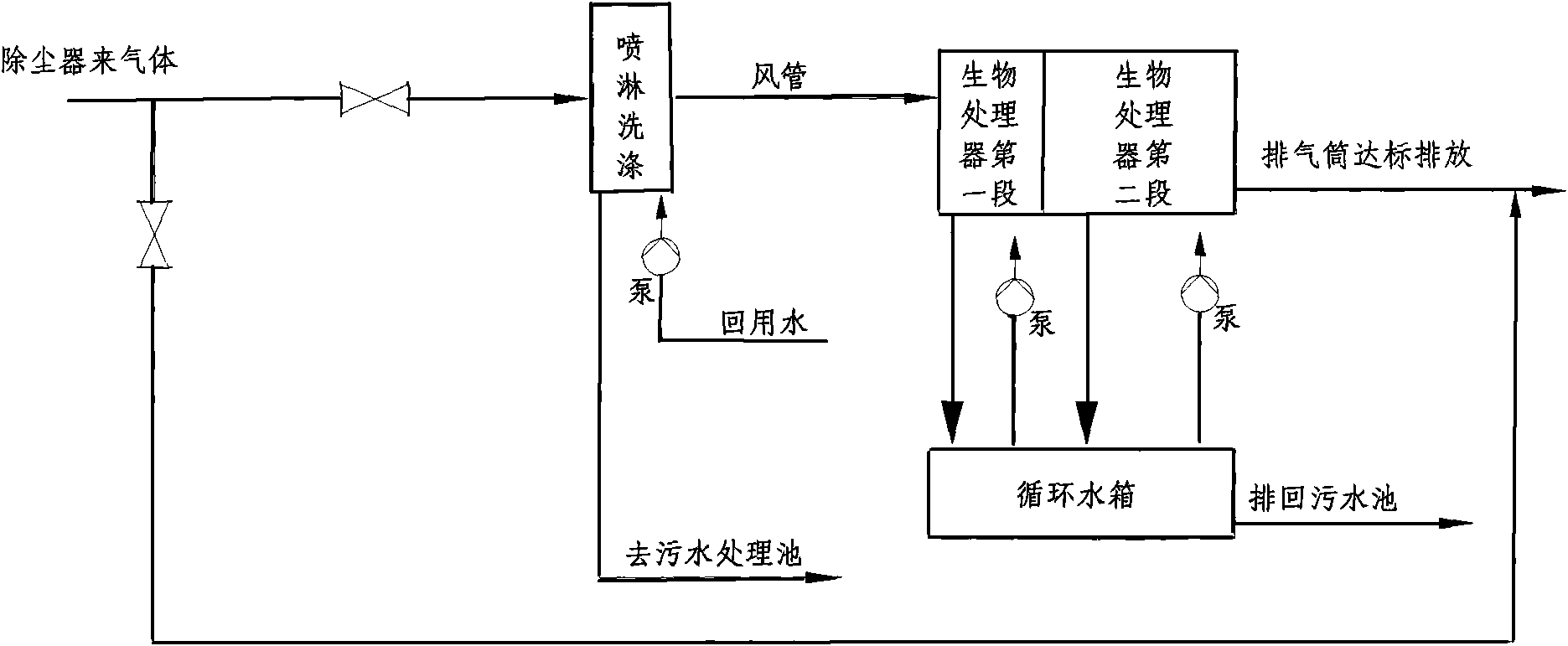

Novel process for treating fermentation waste gas of amino acid by utilizing biofilter

InactiveCN101579599AReduce contentImprove the living environmentCombination devicesUsing liquid separation agentLaboratory testLiving environment

The invention discloses a novel process for treating fermentation waste gas of amino acid by utilizing a biofilter. Waste gas of zymotic fluid is subjected to Venturi dedusting and electrostatic dedusting, then fume containing extremely high COD and condensate are removed through a gas-liquid separator, and the condensate enters a sewage treatment system; and the fume enters the biofilter when the temperature is reduced to 35 DEG C through spraying, VOC in the fume is decomposed under the action of microorganisms, and gas which reaches the standard is exhausted from an exhaust funnel. The biofiltration and deodorization of the invention can treat certain specific malodorous gas, can also flexibly treat complicated mixed odor by converting biofiltration bed fillers and microbial strains, and have simple operation and no secondary pollution. The treatment process can greatly reduce the content of pollutants in the fume, is proved that the dehumidification rate and the removal rate of the volatile organic compounds can reach over 80 percent through a laboratory test, a pilot scale test and mass production, improve the living environment of surrounding residents, greatly reduce environment protection pressure, and has remarkable social benefit and environmental protection benefit.

Owner:BAOJI FUFENG BIOTECH

Method for preparing feed from common andrographis herb dregs by virtue of fermentation

InactiveCN104782905AImprove palatabilityRemoving heat and detoxification, anti-inflammatory and pain-relievingFood processingAnimal feeding stuffMonopotassium phosphateRhizopus oryzae

The invention provides a method for preparing a feed from common andrographis herb dregs by virtue of fermentation. The method comprises the following steps: (1) pretreatment of dregs, namely drying the dregs until the moisture content is 2-5wt% and grinding until the power granularity is within the range of 2.5-10 meshes; (2) preparation of a dreg culture medium, namely mixing 50 parts of dregs with bran in the ratio of 1: 1 to 2: 1, 0.2-0.6 part of corn flour, 0.2-0.6 part of ammonium chloride and 0.1-0.3 part of monopotassium phosphate in 25-50 parts of sterile water, pouring the obtained mixed liquid into a conical flask and mixing evenly to obtain natural pH, and sterilizing at 121 DEG C under high pressure for 20 minutes; (3) dreg fermentation, namely inoculating 10-30mL of the second-level seeds of rhizopus oryzae strain or bacillus subtilis strain into each 100g of dreg culture medium, fermenting at 26-30 DEG C for 48-96 hours, and shaking the culture medium evenly every 12 hours; (4) product treatment, namely drying the culture medium obtained by fermentation, and grinding and sieving by use of a sieve of 2-4 meshes, thereby obtaining the fermented feed product. The method is simple in process, short in time, low in material consumption, advantageous for industrial pilot scale-up, and relatively high in yield.

Owner:BEIJING UNION UNIVERSITY

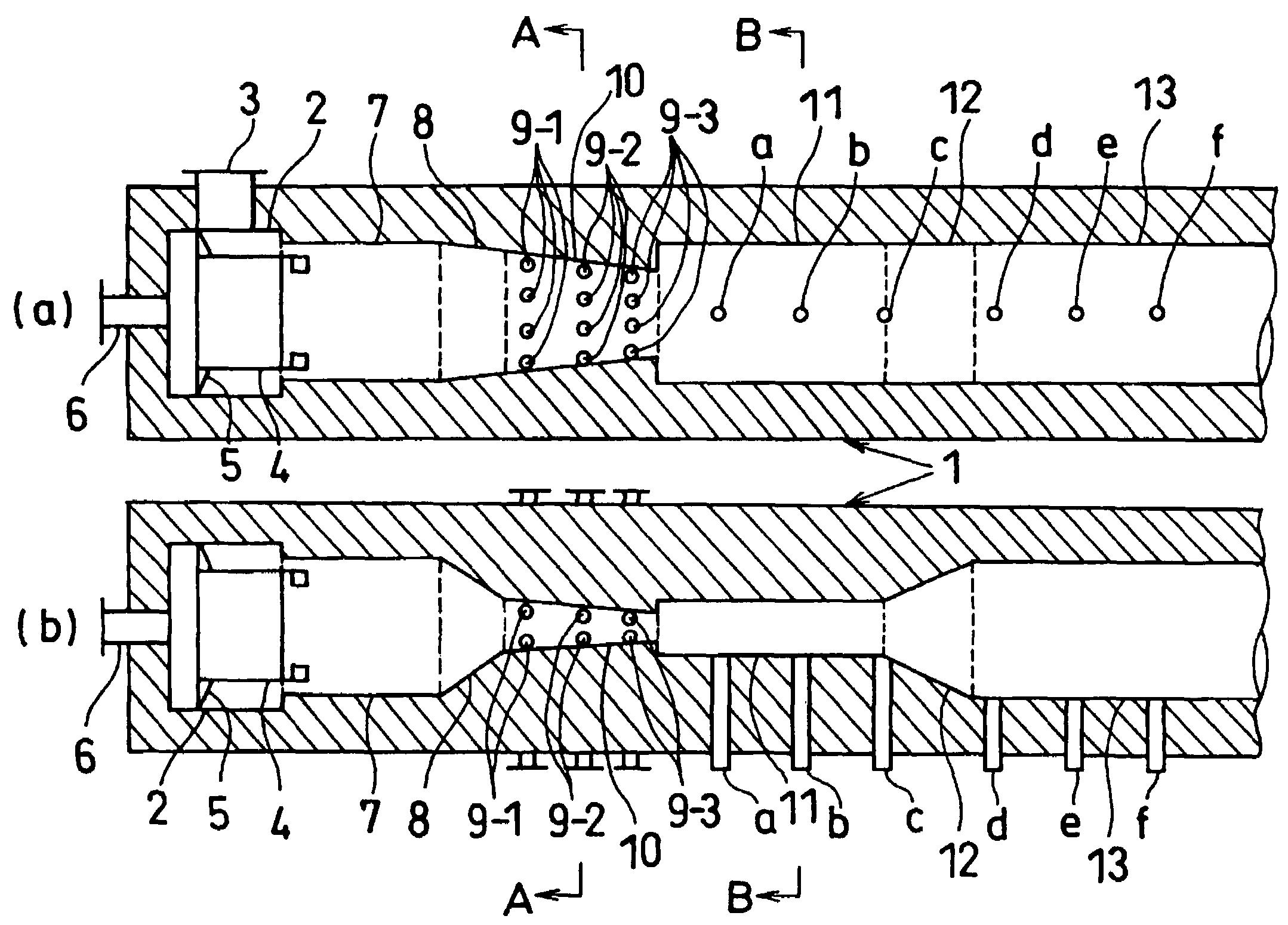

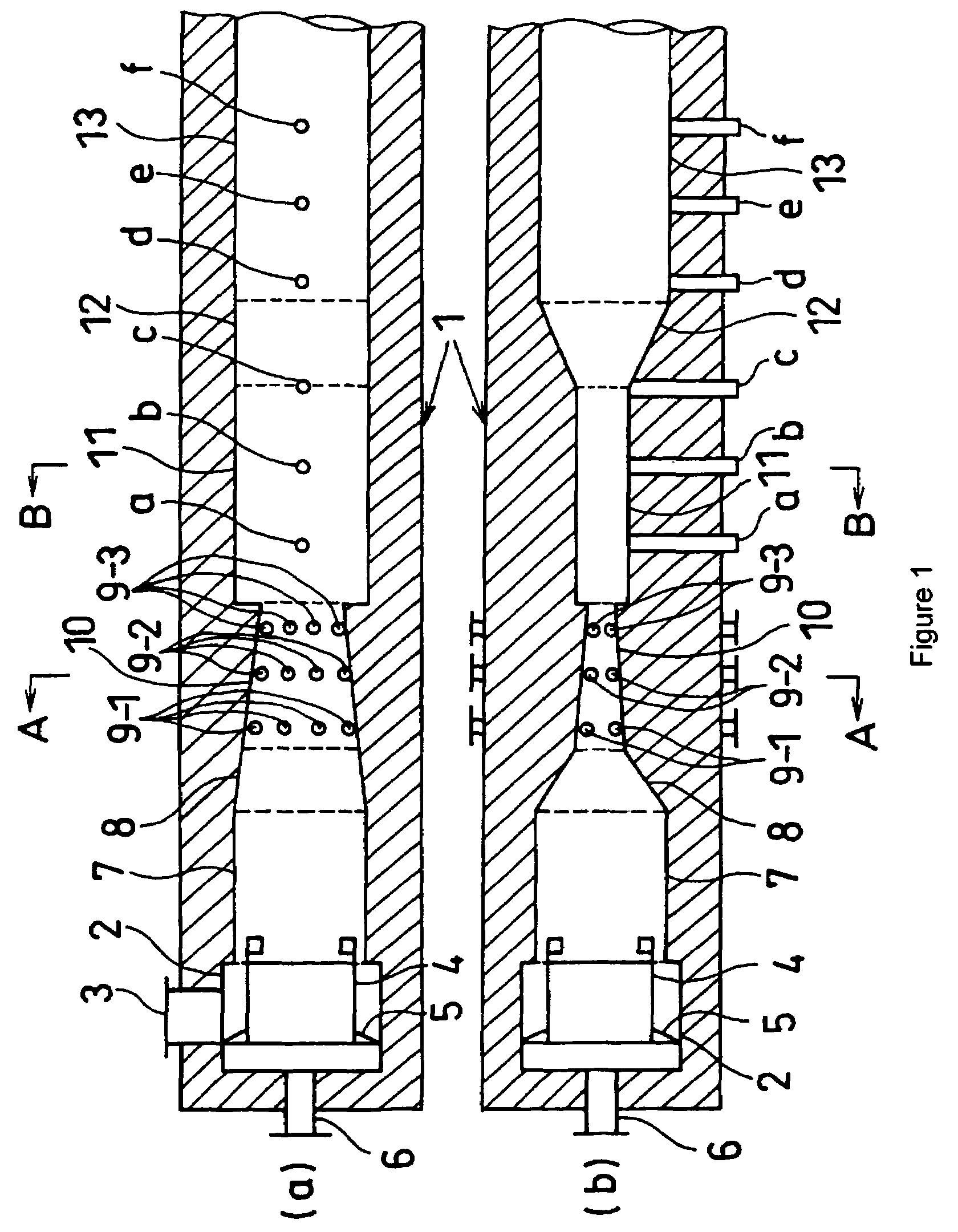

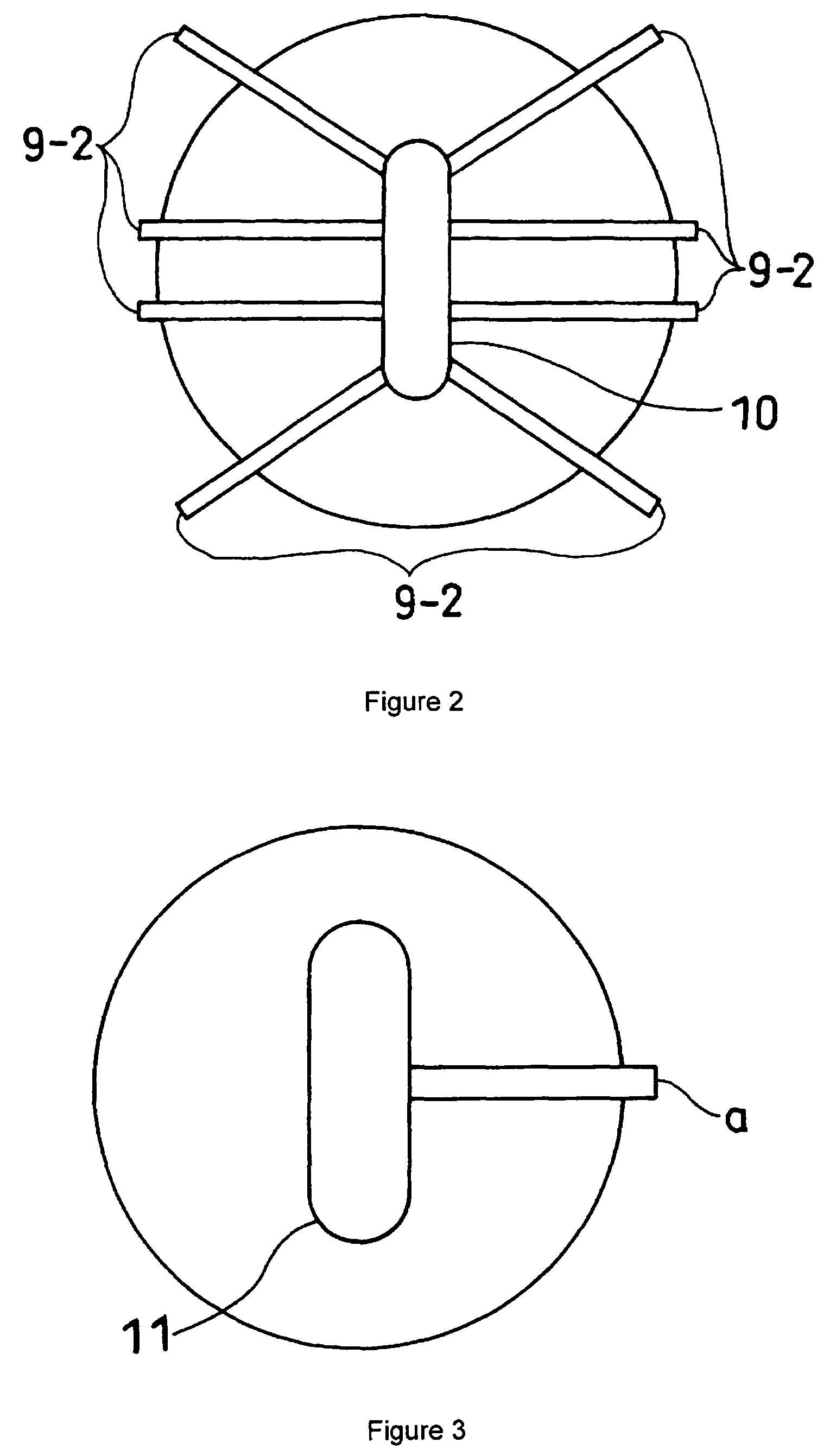

Carbon black reactor

InactiveUS7625527B2Effective contactImprove efficiencyMaterial nanotechnologyInorganic pigment treatmentCombustionReaction zone

This invention relates to a carbon black reactor comprising; a combustion zone for generating a hot combustion gas by burning a mixture of a hydrocarbon fuel and an oxygen containing gas, a reaction zone for producing a carbon black by contacting the hot combustion gas with a feedstock introduced in a plurality of divided flows to thermally decompose and / or incompletely combust the feedstock, and a quench zone for stopping a carbon black growth reaction by injection a coolant to said carbon black containing flow, and these three zones are arrayed laterally in order, wherein the cross-section shape of the feedstock introduction part in the reaction zone is not a circle nor a polygon. The carbon black reactor can produce the carbon black having same characteristics, especially the distribution of the aggregate size, as one produced by pilot-scale reactor, while its production scale is increased to the level of that of reactor actually operated.

Owner:ASAHI CARBON

Pilot scale production method for gliocladium roseum chlamydospore by liquid fermentation

The invention belongs to the technical field of microbes, and provides a pilot scale production method for gliocladium roseum chlamydospore by liquid fermentation, and the method comprises medium formula and fermentation parameter control. The liquid medium is composed of 40-50 g / L of cane sugar, 20-25 g / L of bean cake powder, 0.5-2 g / L of potassium dihydrogen phosphate, 0.2-1 g / L of magnesium sulfate and water, and the liquid medium is used for fermentation production of gliocladium roseum HLD-1 chlamydospore, wherein the inoculation amount is 0.2%-2% (volume ratio), the culture condition comprises that: pH is 4-6, the temperature is 26 DEG C-30 DEG C, the stirring speed is 180-250 r / min and the ventilatory capacity is 1:0.2-0.8. The culture time is calculated from inoculation, the spore is germinated when 8 hours pass by, and a large amount of chlamydospore is formed when the culture is 24-40 hours. When the time of liquid fermentation is 3-5 days, the concentration of chlamydospore is 1.5*108 per milliliter. The invention aims at providing a cheaper medium formula with abundant raw material source and an efficient easily-controllable liquid fermentation technology; and by using the method, the large-scale production of gliocladium roseum HLD-1 chlamydospore can be realized, and the method provides guarantee for large-area biocontrol application of gliocladium roseum HLD-1 chlamydospore.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

Medicament for in-situ repair of high-concentration polycyclic aromatic hydrocarbon polluted soil and application thereof

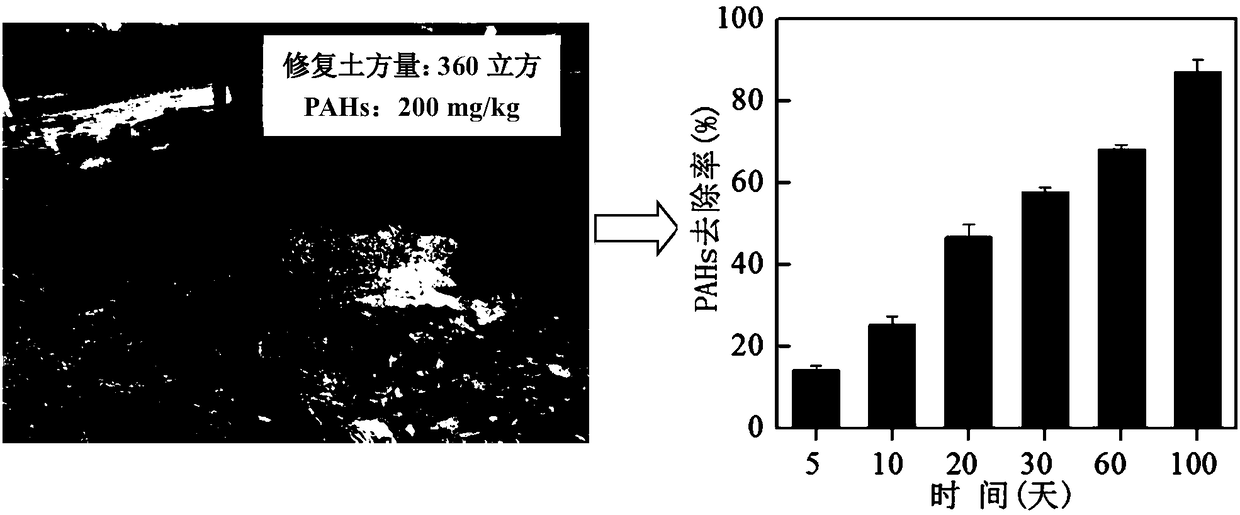

InactiveCN108213064AIncrease profitGood removal effectContaminated soil reclamationOrganic fertilisersHigh concentrationMicro nano

The invention discloses a medicament for in-situ repair of high-concentration polycyclic aromatic hydrocarbon polluted soil and application thereof; effective components are micro-nano iron sheets andsodium persulfate; and the high-activity micro-nano iron sheets are used for efficiently catalyzing sodium persulfate to generate high-oxidation free radicals so as to effectively degrade high-concentration PAHs (201.1 mg / kg) in soil. The medicament formula of the micro-nano iron sheets activating persulfate not only can efficiently degrade PAHs under laboratory underbrush conditions, but also can quickly and efficiently repair the high-concentration PAHs polluted soil in situ under the pilot scale test scale (360 cubes of soil); and the enzyme activity index of the repaired soil under environmental protection is not prominently changed. The repair medicament is suitable for in-situ field repair of the high-concentration PAHs polluted soil, is high in efficiency, convenient to operate andenvironment-friendly, and provides broad prospect for repair of the high-concentration PAHs polluted soil.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

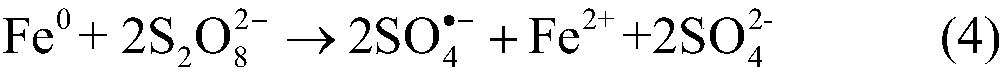

Novel method for environmentally and efficiently preparing polycarbosilane

The invention relates to a method for environmentally and efficiently preparing polycarbosilane, comprises the following steps: enabling a reactant dimethyl dichlorosilane to react with metallic sodium in an organic solvent to prepare polysilane, removing the solvent, reacting with residual metallic sodium by using alcohol, directly feeding into a cracking kettle to prepare low-molecular weight liquid state cyclic polysilane, and finally preparing polycarbosilane from the liquid state cyclic polysilane. The method has the advantages that the processes of washing and drying the polysilane for a plurality of times, which are long in time-consuming and capable of producing industrial wastewater, are avoided in an existing process route of producing the polycarbosilane; meanwhile, the solvent and the alcohol adsorbed in the polysilane can be subjected to secondary recycling in the process of preparing the liquid state polysilane. The pilot scale test data shows that compared with the prior art, the method has the advantages that the production period is saved by 30-50%, the solvent recycling rate is increased by 10-20%, the industrial wastewater containing a benzene organic solvent cannot be produced, the working environment is purified, and the reaction residue is fluffy solid residue, and can be easily cleaned from a reaction still.

Owner:宿迁澳鑫斯新材料有限公司

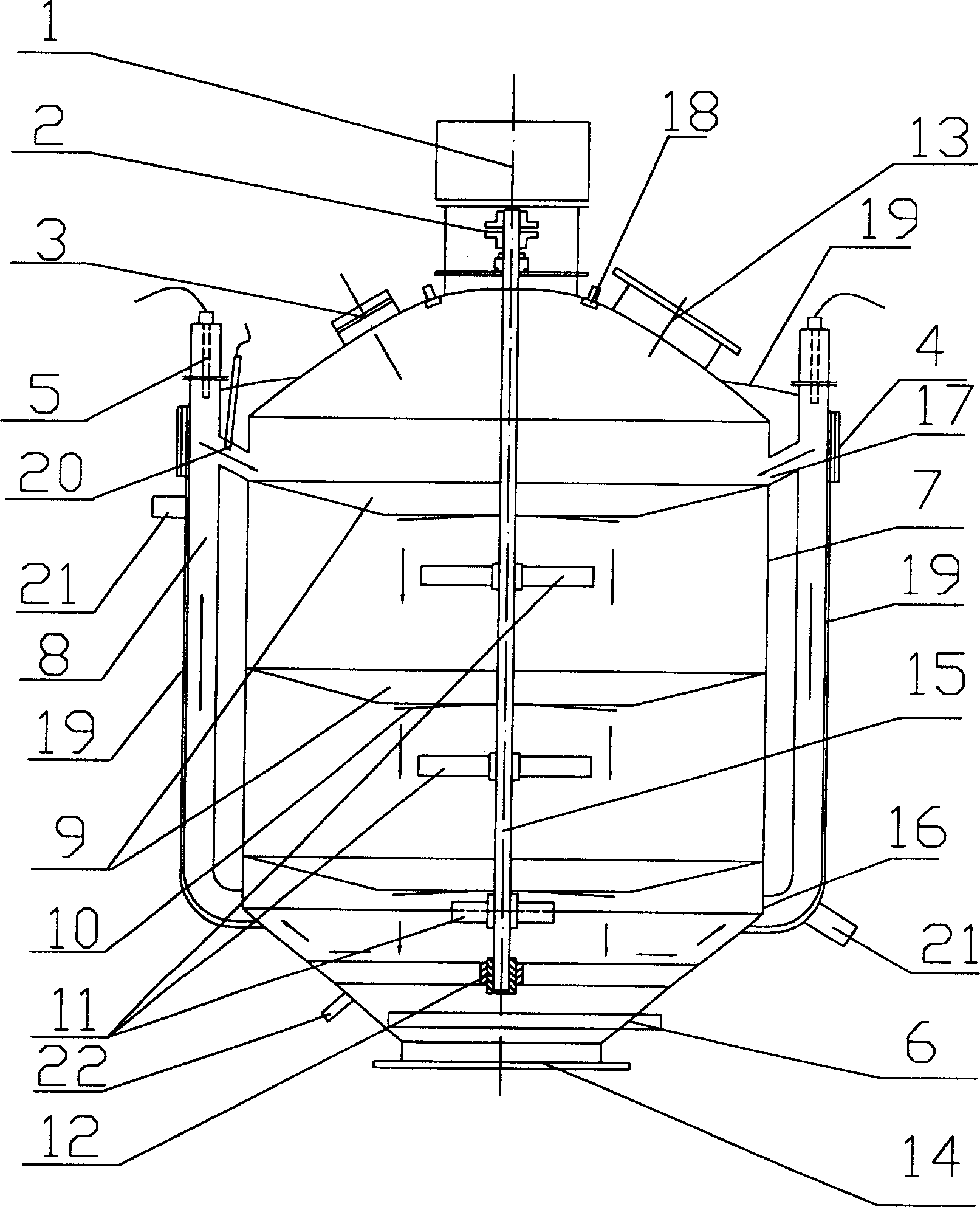

Multipurpose ultrasonic backflow circulating leaching equipment

The multipurpose ultrasonic backflow circulating leaching equipment may be used in fast extraction of various animal and plant effective components at normal temperature and low temperature as well as in ultrasonic mixing, dispersing, emulsifying and reinforcing and other uses. It includes one extracting tank with stirring shaft connected to shaft coupling and motor, guide stirring paddle and baffle; circulating connection pipes around the extracting tank and with upper ends connected to the inlets in the upper side wall of the tank and the lower ends connected to the outlets in the lower side wall; and energy accumulating ultrasonic amplitude rods inside the circulating connection pipes. Owing to the circulating connection pipes, the material inside the tank is made to pass through the ultrasonic field repeatedly, resulting in raised ultrasonic field utilization. The present invention may be used widely in various kinds of lab, pilot scale experiment and great scale production.

Owner:廊坊弘祥隆生物技术有限公司

Preparation method of novel nanometer micelle medicinal material

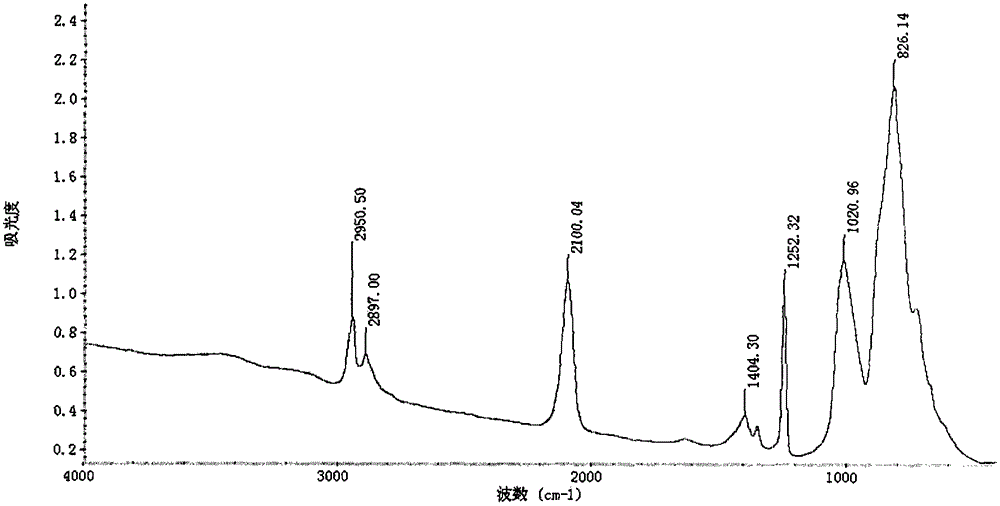

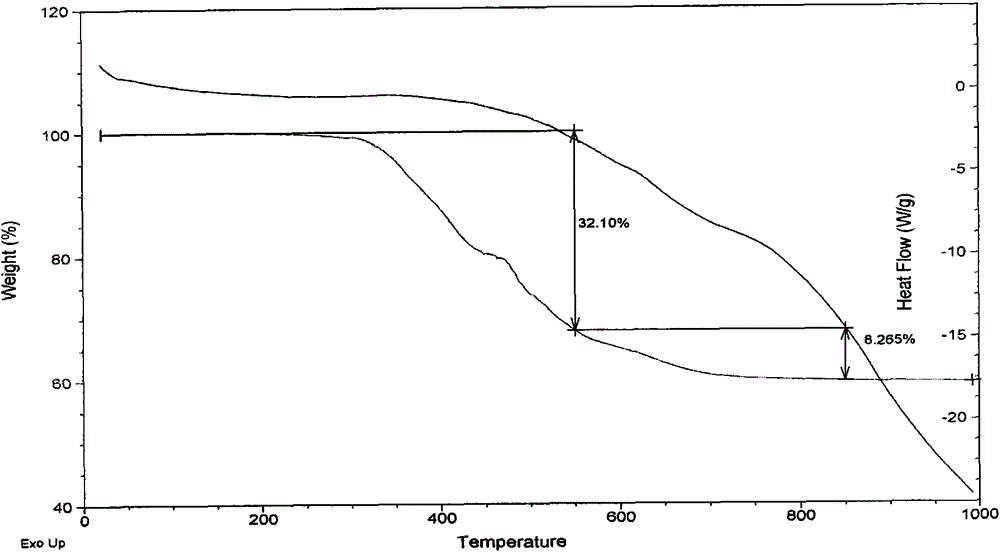

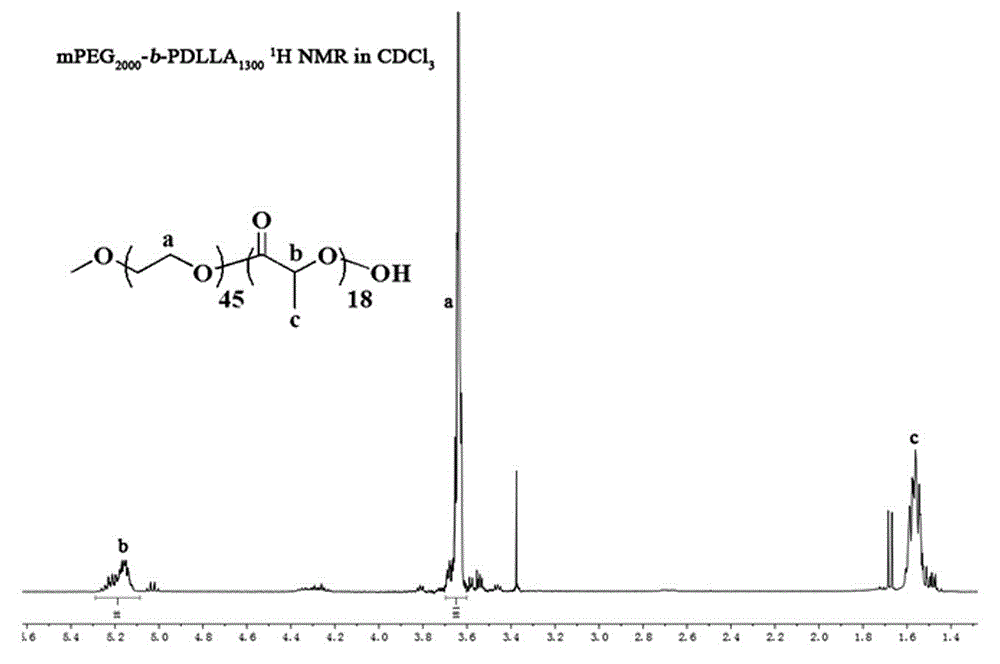

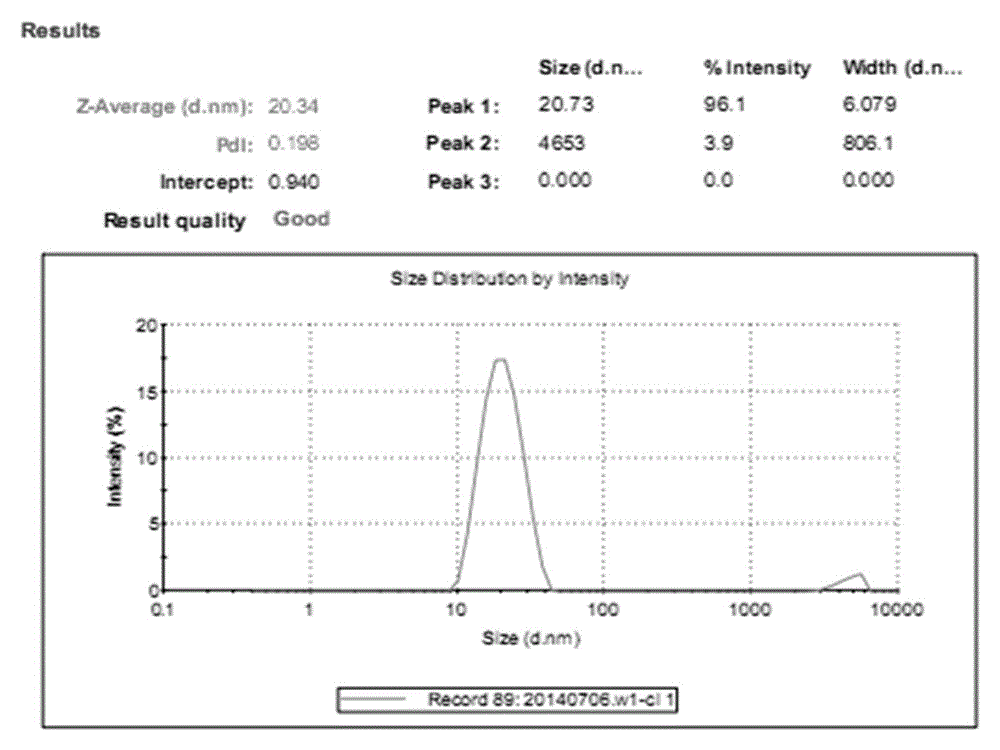

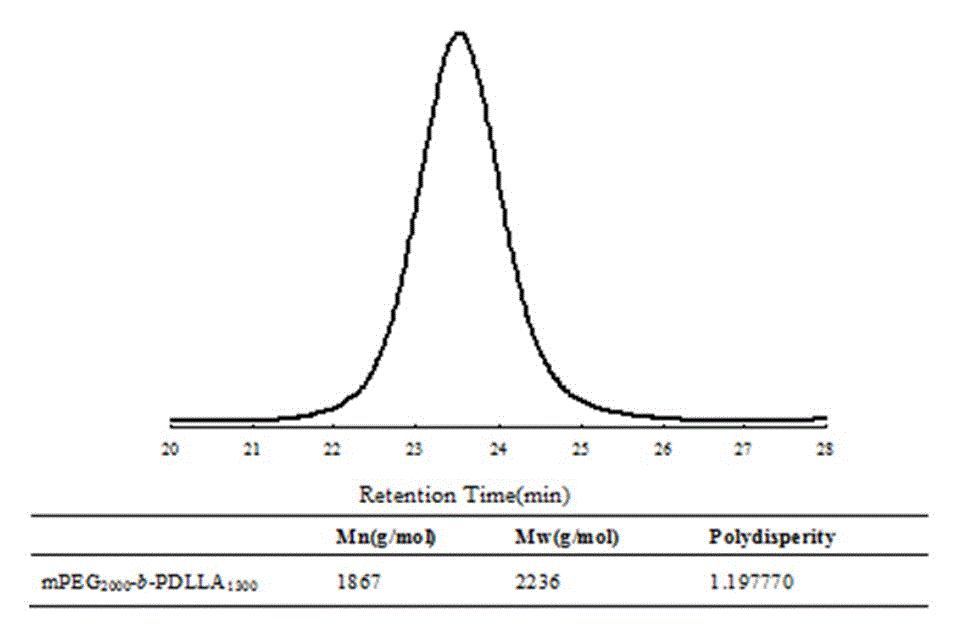

ActiveCN104961886AOvercome the disadvantages that are difficult to realize industrializationEasy to operatePharmaceutical non-active ingredientsEmulsion deliveryFiltrationPolyethylene glycol

The invention discloses a preparation method of novel nanometer micelle medicinal material, and belongs to the field of biomacromolecule material synthesis, and realizes large scale production and industrialization in preparation of polyethylene glycol-b-polylactic acid diblock copolymer micelle of small particle size and small molecular weight. The method provided by the invention comprises the following steps: (1) placing polyethylene glycol monomethyl ether whose molecular weight is between 1800 and 2200 in an oil bath, performing heating and vacuuming, adding a catalyst tin salt compound, adding D,L-lactide, carrying out a heating reaction, and performing cooling; (2) dissolving the resultants of the step (1) in dichloromethane, and slowly adding the mixture into ether, performing stirring and precipitating, carrying out a pumping filtration, obtaining a light yellow solid, and performing drying and obtaining a finished product polyethylene glycol monomethyl ether-polylactic acid mPEG-b-PDLLA diblock amphiphilic copolymer. According to the invention, routine reaction apparatuses are used for reaching to a pilot scale, thereby facilitating operation with controllability, meeting the requirements for medicinal preparation production of a large scale, and realizing industrialization.

Owner:SHANXI KANGBAO BIOLOGICAL PROD

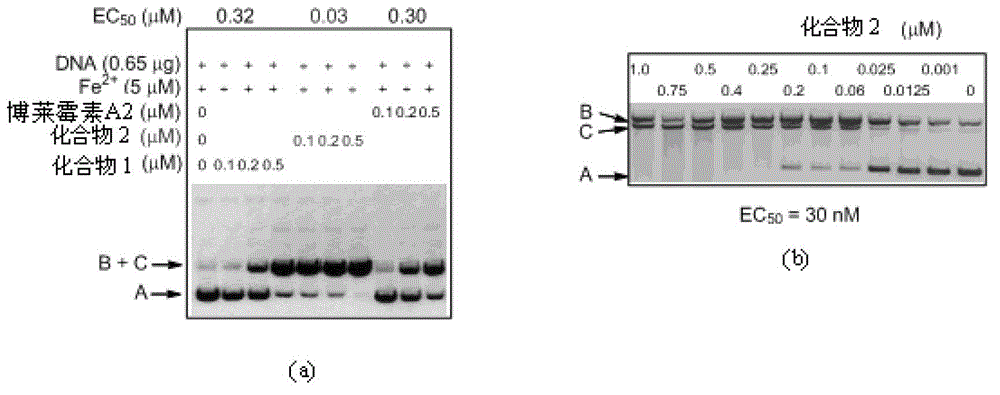

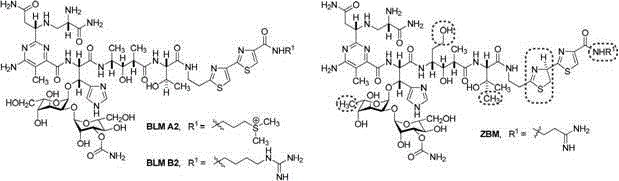

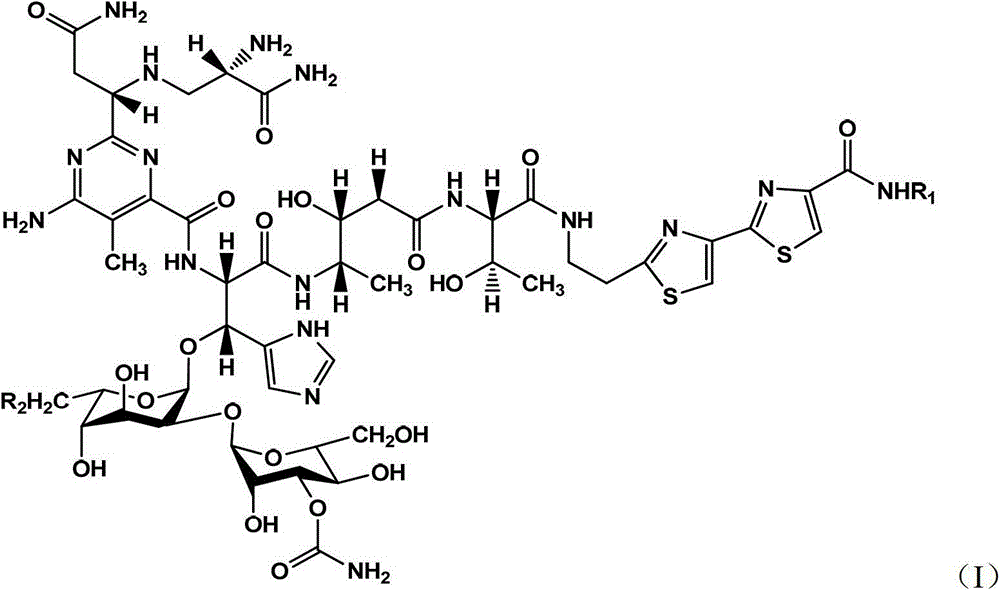

Microbial fermentation preparation method of bleomycin derivatives

ActiveCN104004804AIncrease productionShorten the fermentation preparation cycleMicroorganism based processesFermentationMicroorganismChemical structure

The invention relates to the technical field of biomedicines, and concretely relates to a microbial fermentation preparation method of bleomycin derivatives. The method is characterized in that SB9026 (with the preservation number of CCTCC M2011292) fermentation strains are cultured, an appropriate seed culturing medium, a fermentation culturing medium and culturing conditions are selected, pilot scale amplification of the above microbial fermentation preparation method is carried out in a fermentation tank, and the temperature, the rotating speed, the pH value and raw material supplementation are regulated to adjust in order to establish the large-scale microbial fermentation preparation method of novel active bleomycin derivatives 6'-dehydroxy-BLMs. The preparation method shortens the fermentation preparation period of the 6'-dehydroxy-BLMs, improves the fermentation yield of the 6'-dehydroxy-BLMs, increases the proportion of the 6'-dehydroxy-BLMs in total metabolites, and is convenient for subsequent separation and purification. The chemical structure of the bleomycin derivatives is represented by a general formula shown in the specification.

Owner:CHANGSHA CHARISM BIOSCIENCES CO LTD +2

Method for producing edible fungus rejuvenating-type strain

ActiveCN107384805AHigh growth synchronyThe tide of mushrooming is obviousFungiBiotechnologyCell separation

The invention discloses a method for rejuvenating an edible fungus strain. The method comprises strain mushroom selection, tissue isolation, single mycelium separation, transferring and rejuvenating, culture material screening, fruiting verification and pilot scale test in production. Compared with the prior art, the method fully utilizes biological characteristics of the mycelium growth of the edible fungi and utilizes combination of typical single mycelium cell separation under an optical microscope and production culture medium screening. The rejuvenated fungus strain obtained by the method has high growth synchronism, has a growth rate increased by about 10-20% than that before rejuvenating and has the mycelial volume per unit volume increased by 15 to 25% and has obvious fruiting frequency.

Owner:SHANXI AGRI UNIV

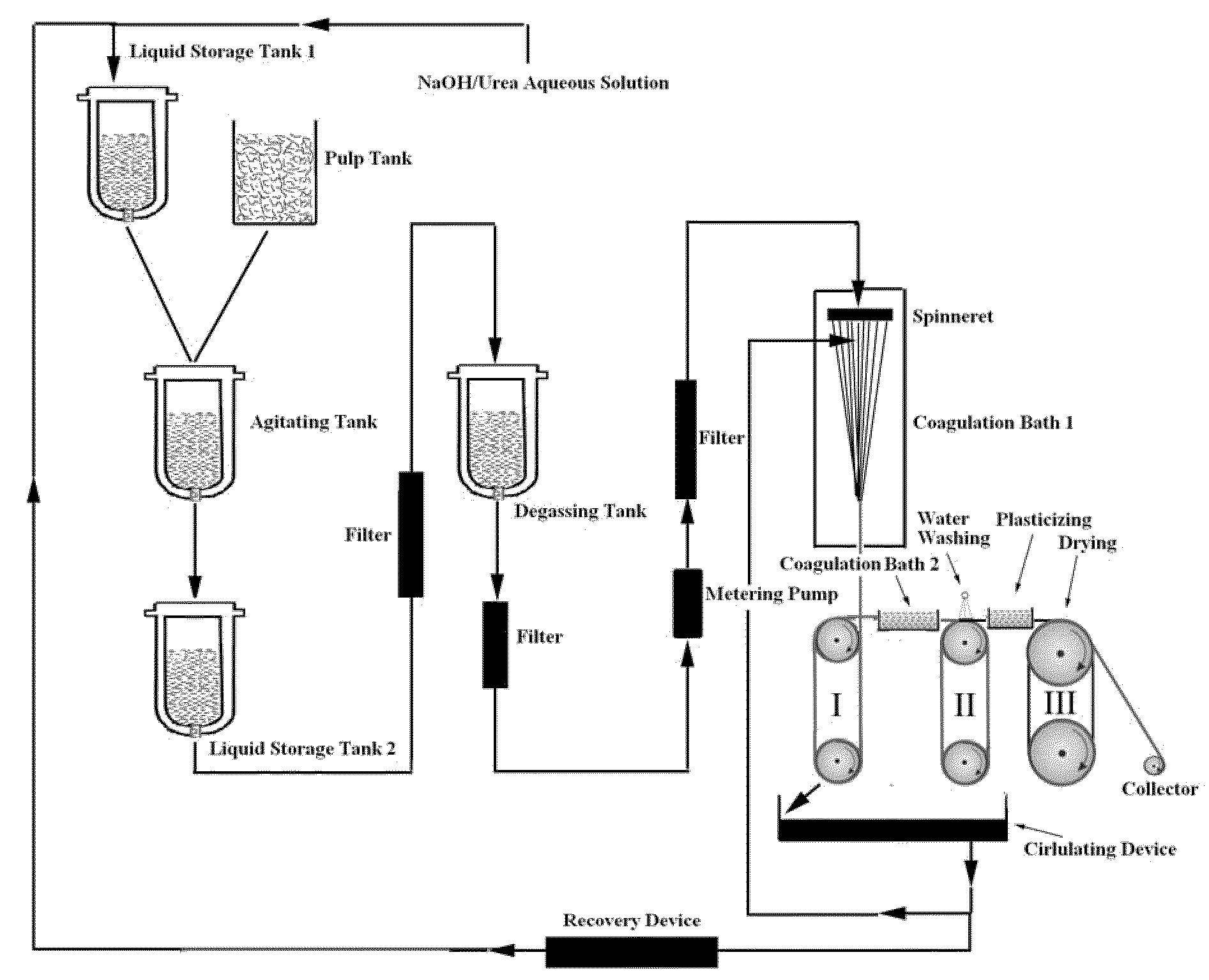

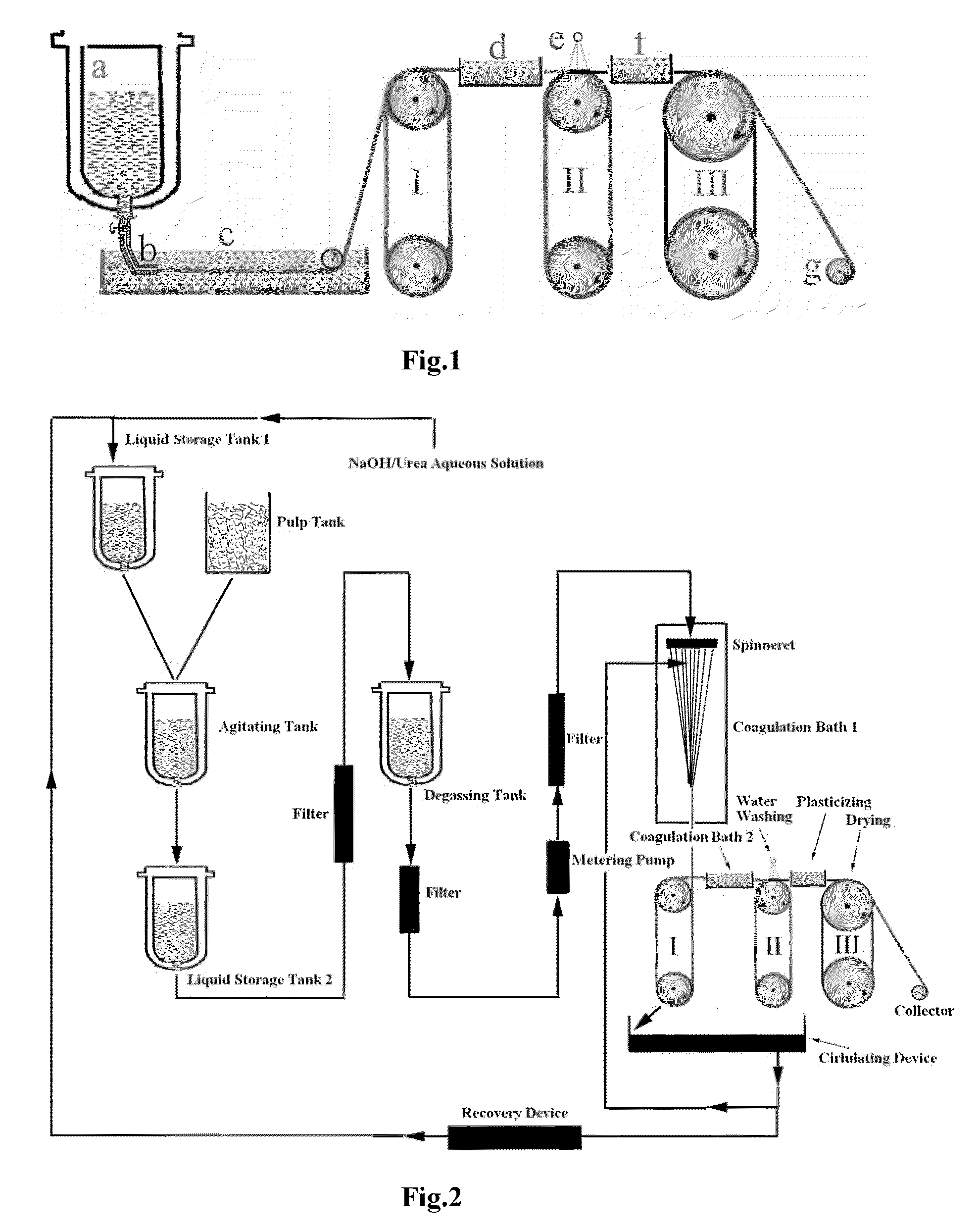

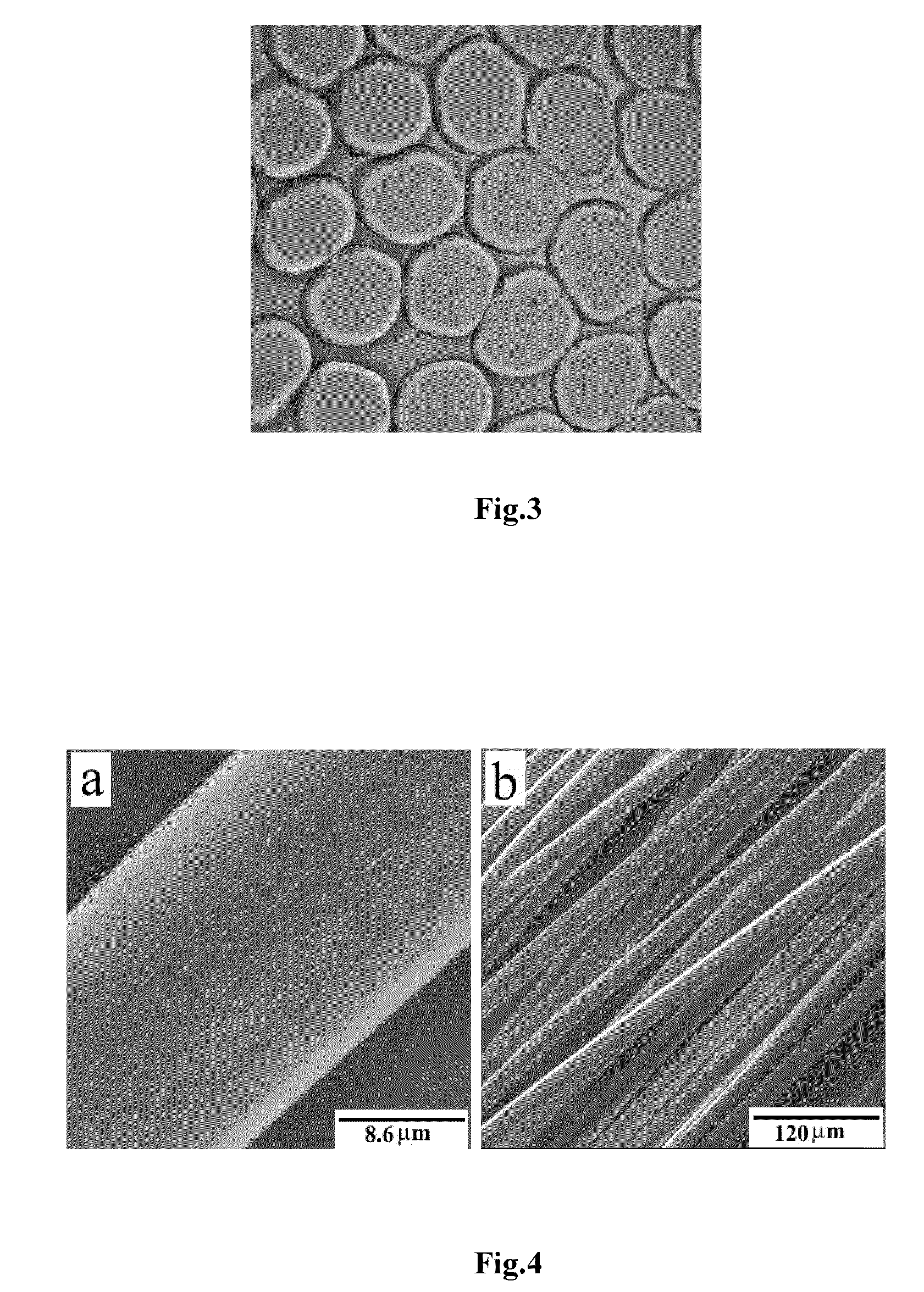

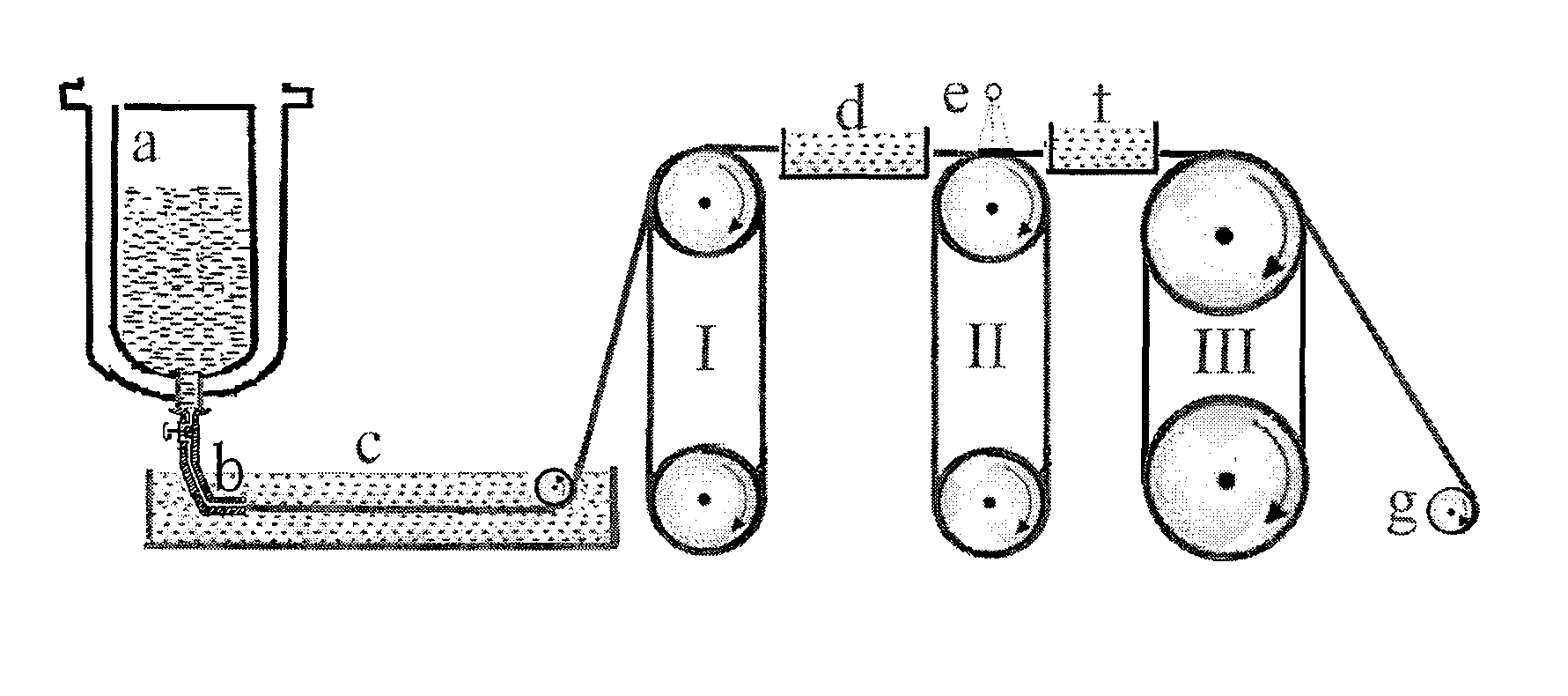

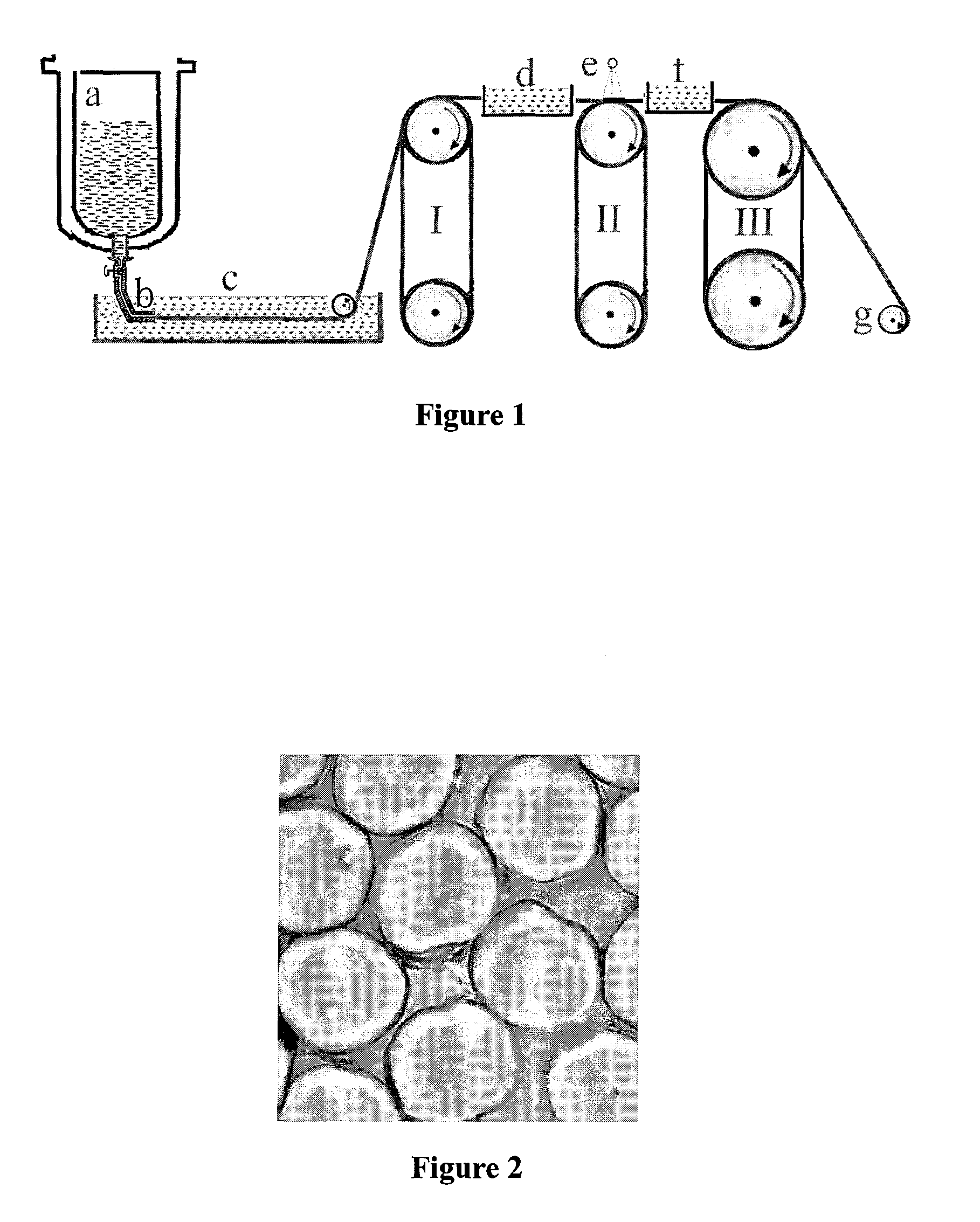

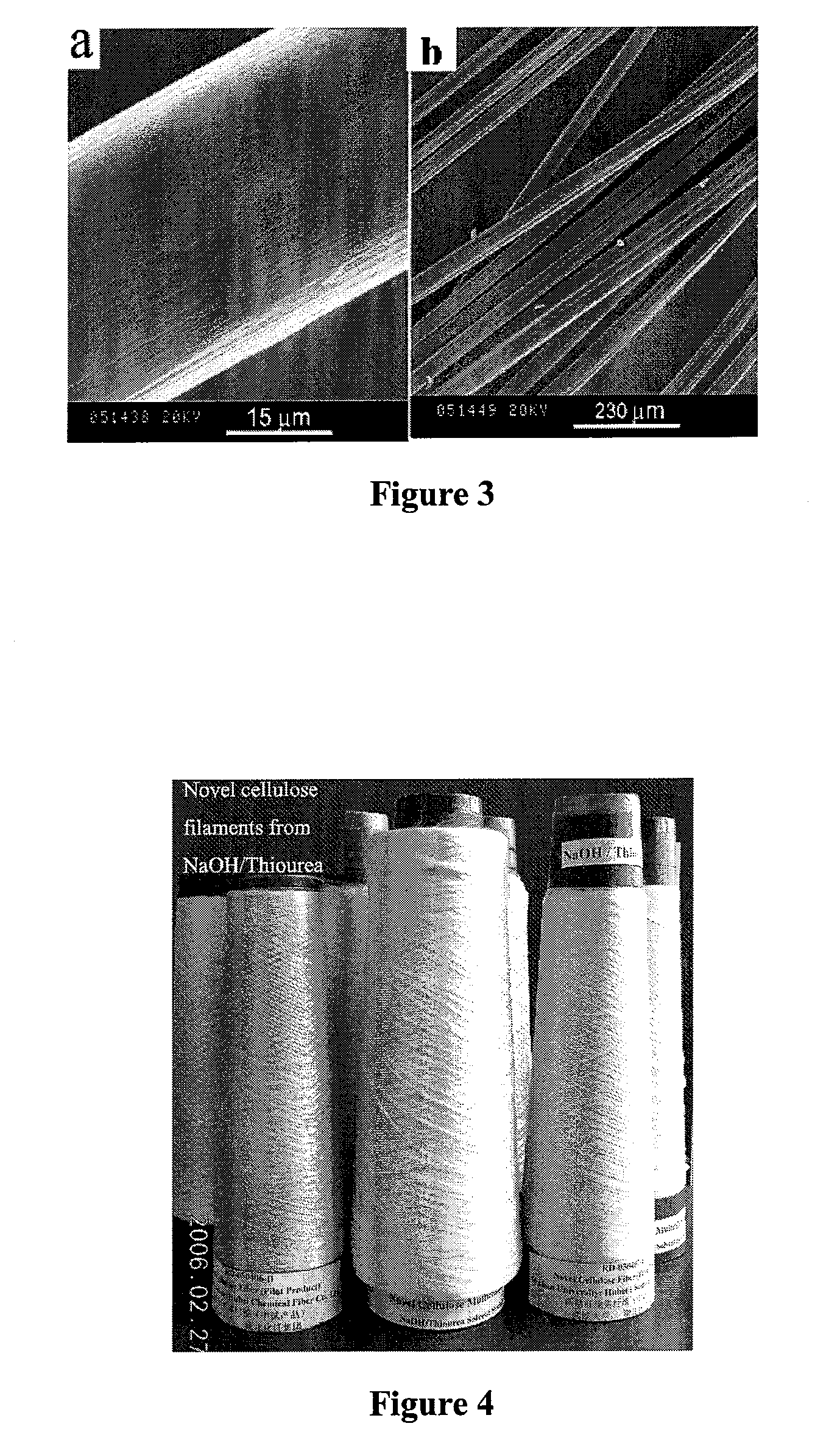

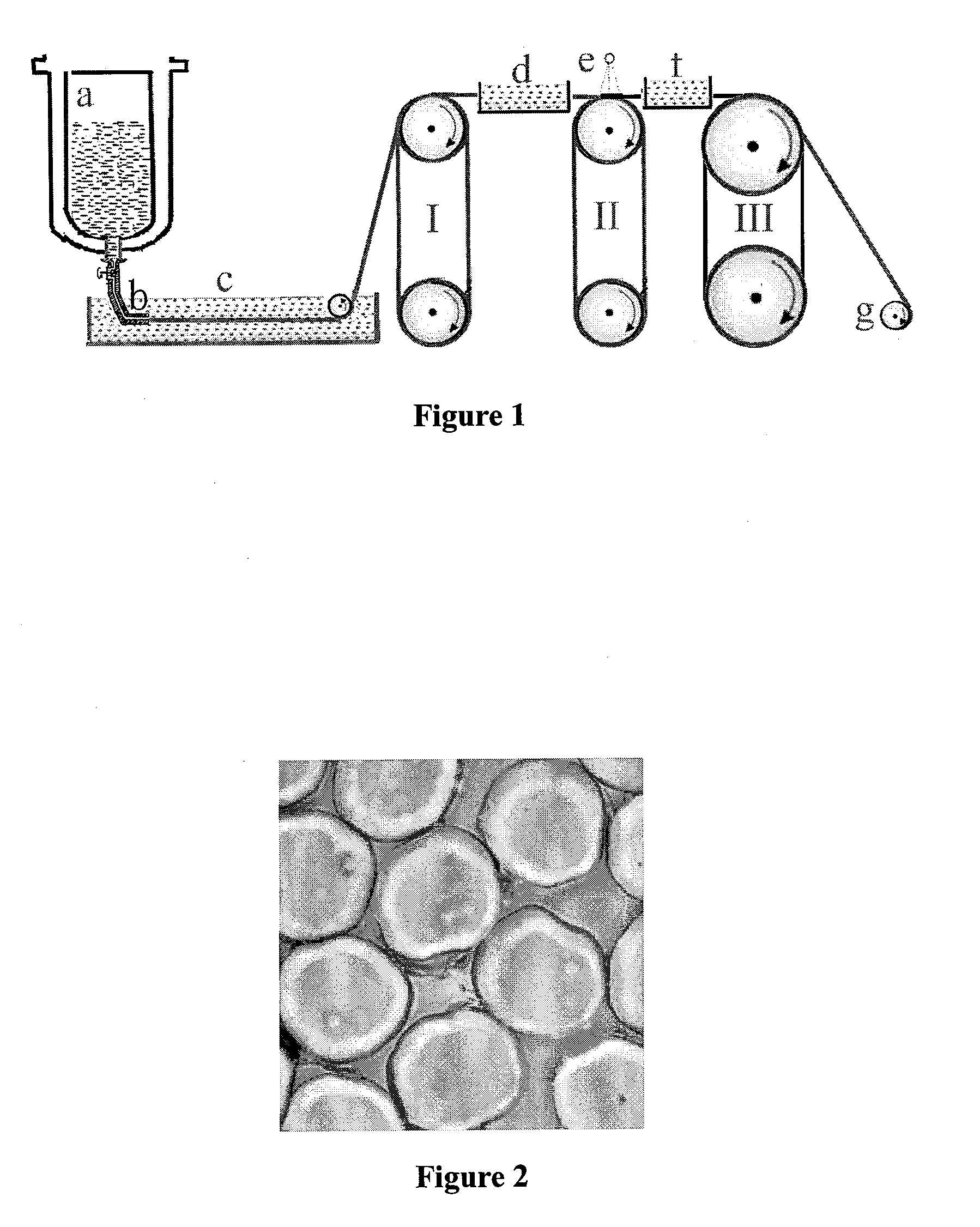

Method for Preparing Regenerated Cellulose Fiber by Two-Step Coagulating Bath Process

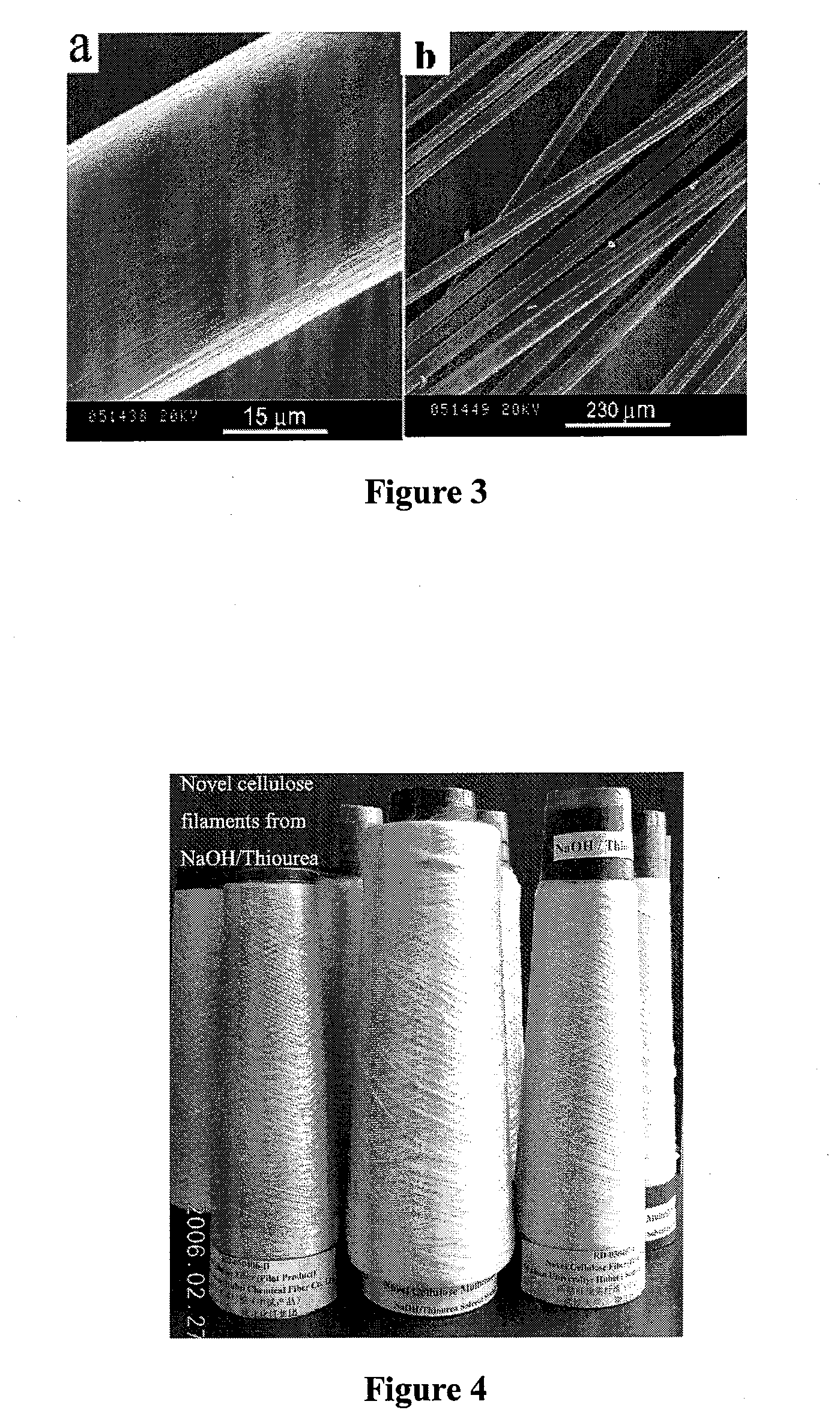

InactiveUS20080275231A1Increase added valueLess costlyArtificial filaments from cellulose solutionsWet spinning methodsAqueous sodium hydroxideCellulose fiber

The present invention relates to a non-toxic process and system for pilot-scale production of cellulose products, and particularly to a process and system for pilot-scale production of cellulose products by using aqueous sodium hydroxide / urea solution pre-colled to lower than −8° C., in which cellulose could dissolved rapidly. The said process and system can be used to produce fibers, films, chromatographic packings, or nonwovens of regenerated cellulose, as well as to produce a variety of high added-value products by adding other materials such as functional materials, nano-materials, etc.

Owner:JIANGSU LONG MA GREEN FIBERS +1

Lost foam casting process of high-manganese steel sieve plate

InactiveCN104353782AReduce defectsShorten the timeFoundry mouldsFoundry coresHigh volume manufacturingPilot scale

The invention relates to a lost foam casting process, in particular to a lost foam casting process of a high-manganese steel sieve plate. The lost foam casting process comprises the following steps: 1, performing blank moulding; 2, preparing paint; 3, serially connecting moulds and blank moulds; 4, painting; 5, performing sand moulding; 6, smelting; 7, casting, performing shakeout and performing water toughing treatment. By the lost foam casting process, the top pouring time is shortest and the pouring speed is high, so that sand crushing can be easily prevented; the temperature fall is small, so that defects caused by insufficient pouring and a cold shut can be easily prevented; the product yield is high, and the sequential solidification and feeding effect is good; carbon defects of a cast product can be eliminated; small-batch pilot scale tests and mass production practices show that the one-time pass rate of the cast product reaches about 95%.

Owner:WUXI LEHUA AUTOMATION TECH

Method of producing petroleum sulfonate by micro reaction system grading sulfonation

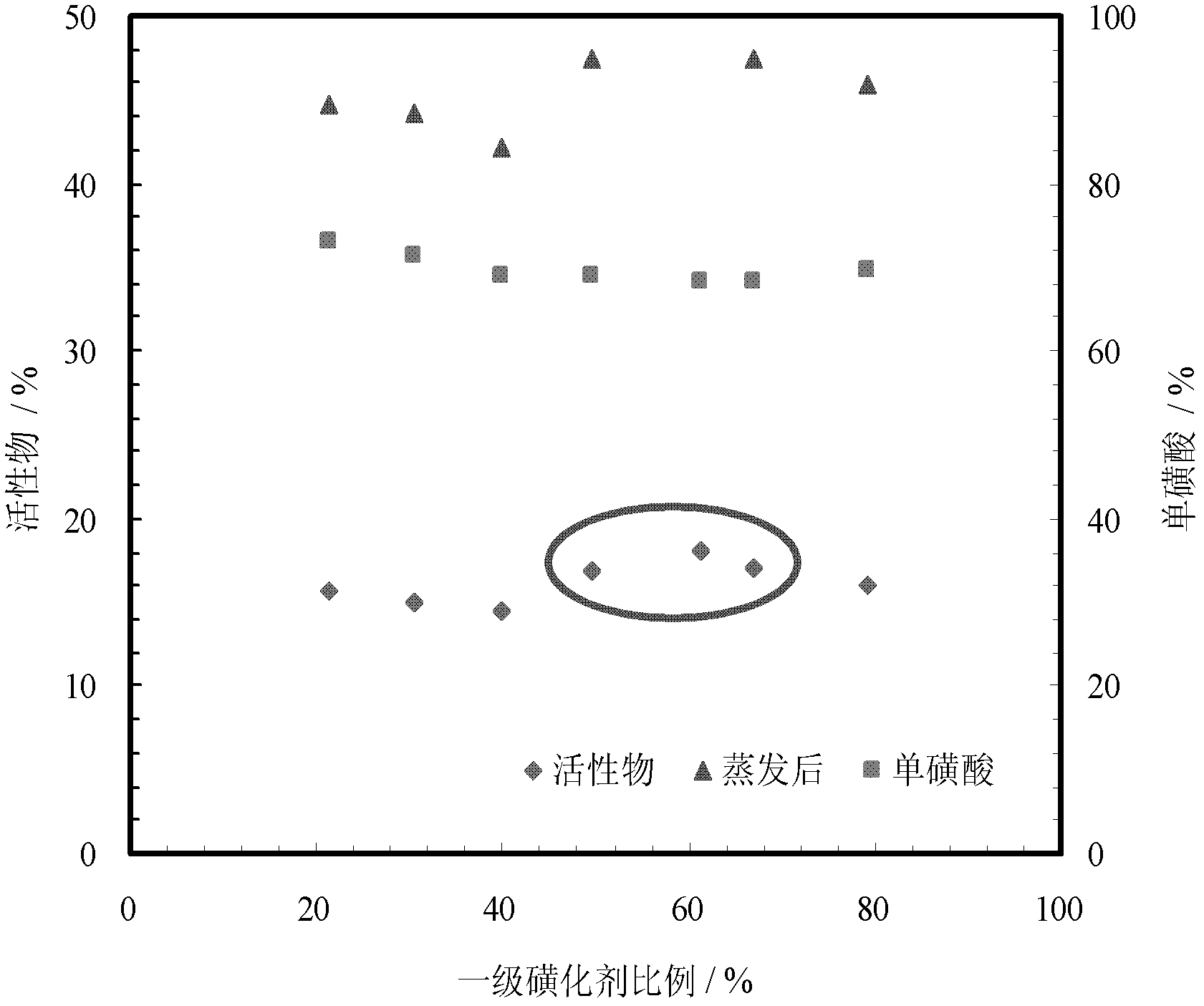

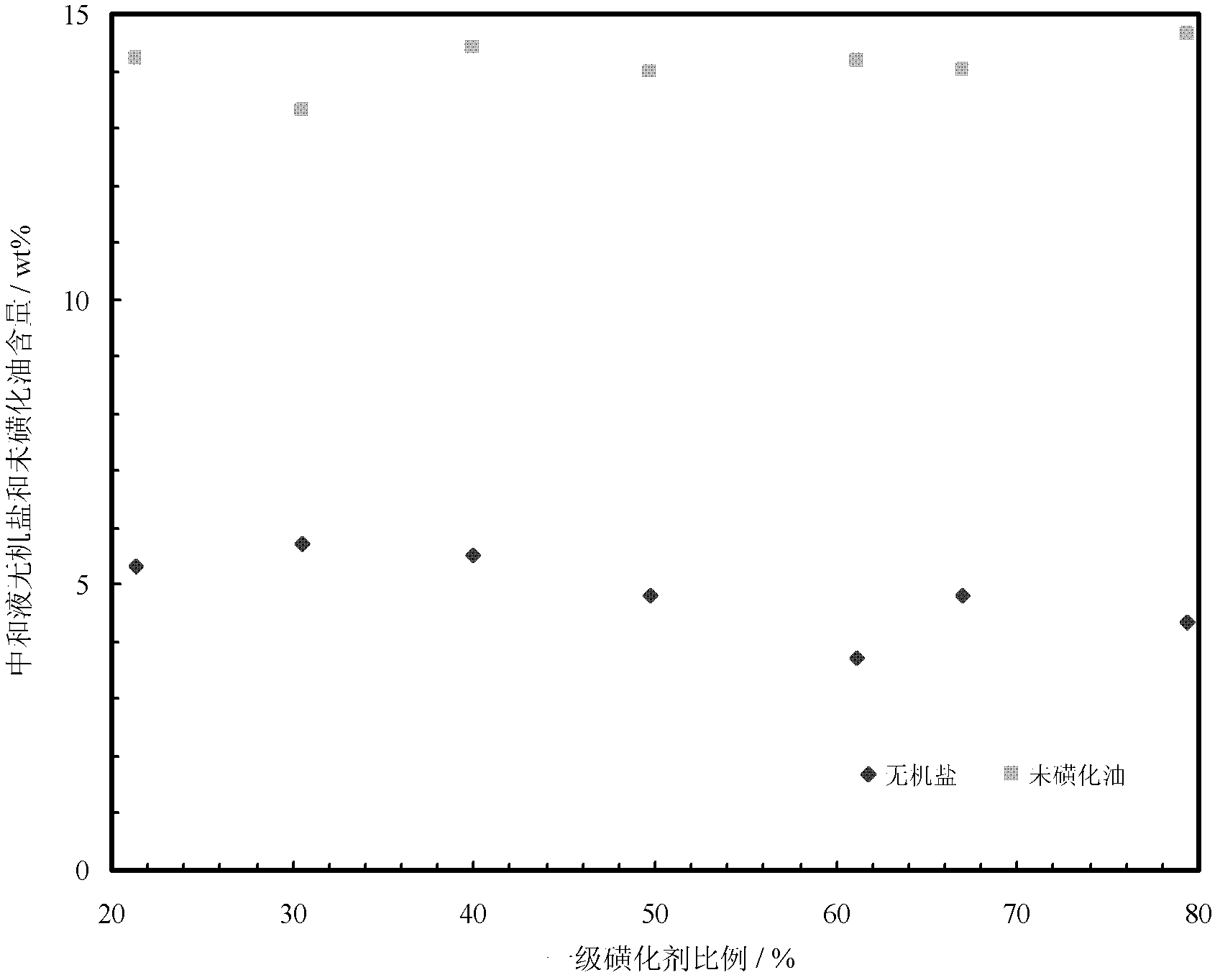

ActiveCN103130690AImprove conversion rateLow reaction temperatureSulfonic acids salts preparationChemical/physical/physico-chemical processesSingle stageReaction temperature

A method of producing petroleum sulfonate by micro reaction system grading sulfonation includes that a two-stage (or multi-stage) serial micro-channel reaction system is used as a reaction device, each stage micro-channel reaction system is composed of a micro-channel reactor and a micro-channel heat exchanger, and a micro-channel heat exchanger is integrated inside the micro-channel reactor. Petroleum fraction continuously enters from a first stage micro-channel reactor, a liquid sulfur trioxide sulfonating agent respectively enters two stages of the micro-channel reactors according to a certain percentage to react with the petroleum fraction, most reaction heat is removed through the micro-channel heat exchanger integrated inside the micro-channel reactor, two stages of reaction products are respectively and further exchanged heat through the subsequent micro-channel heat exchanger of each stage and heat transferring media all adopts normal temperature industrial circulating water. Compared with single-stage sulfonate, the method of producing the petroleum sulfonate by the micro reaction system grading sulfonation has the advantages of being lower in temperature of reaction of each stage, higher in product active matter content and single and double sulfonates proportion of active matter, capable of improving safety and efficiency of process, and further suitable for pilot scale production and industrialized production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

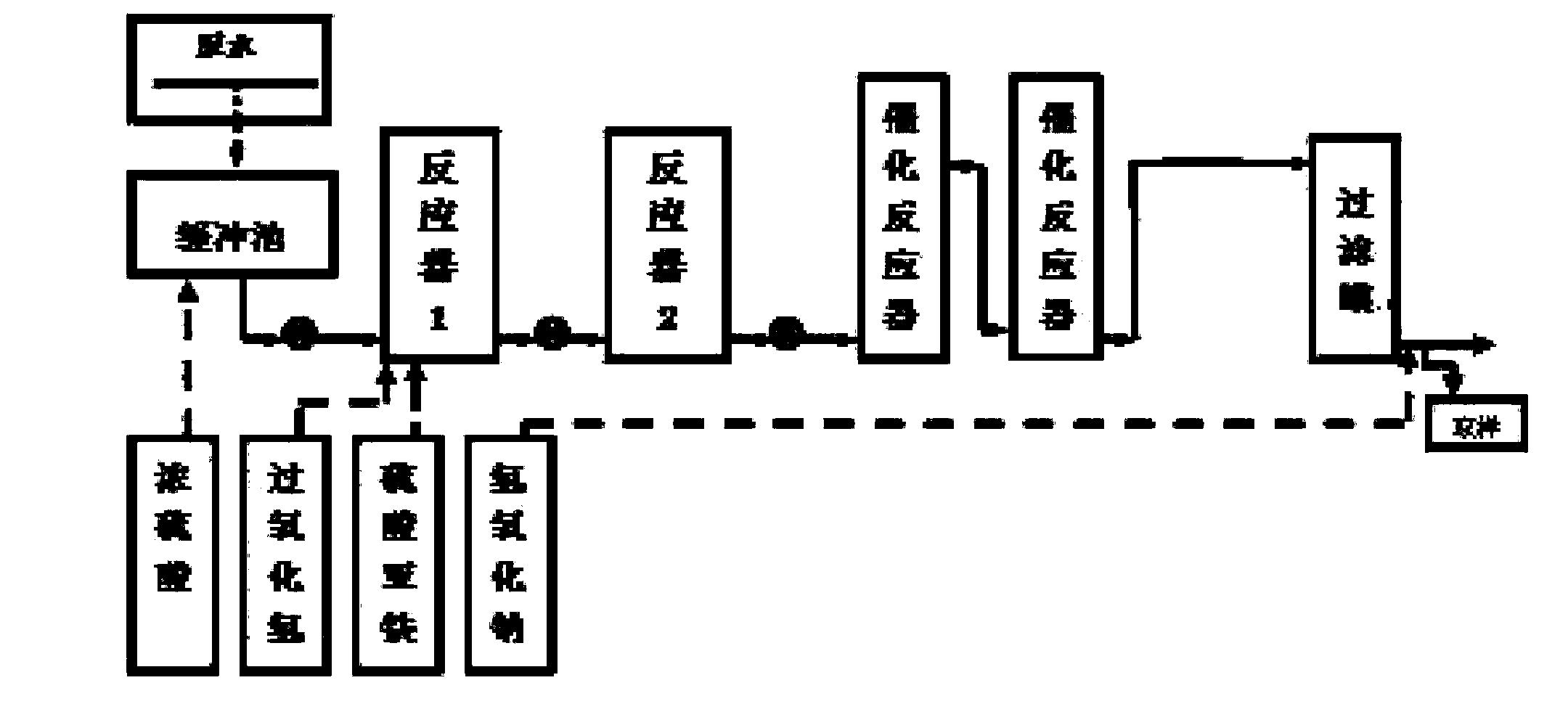

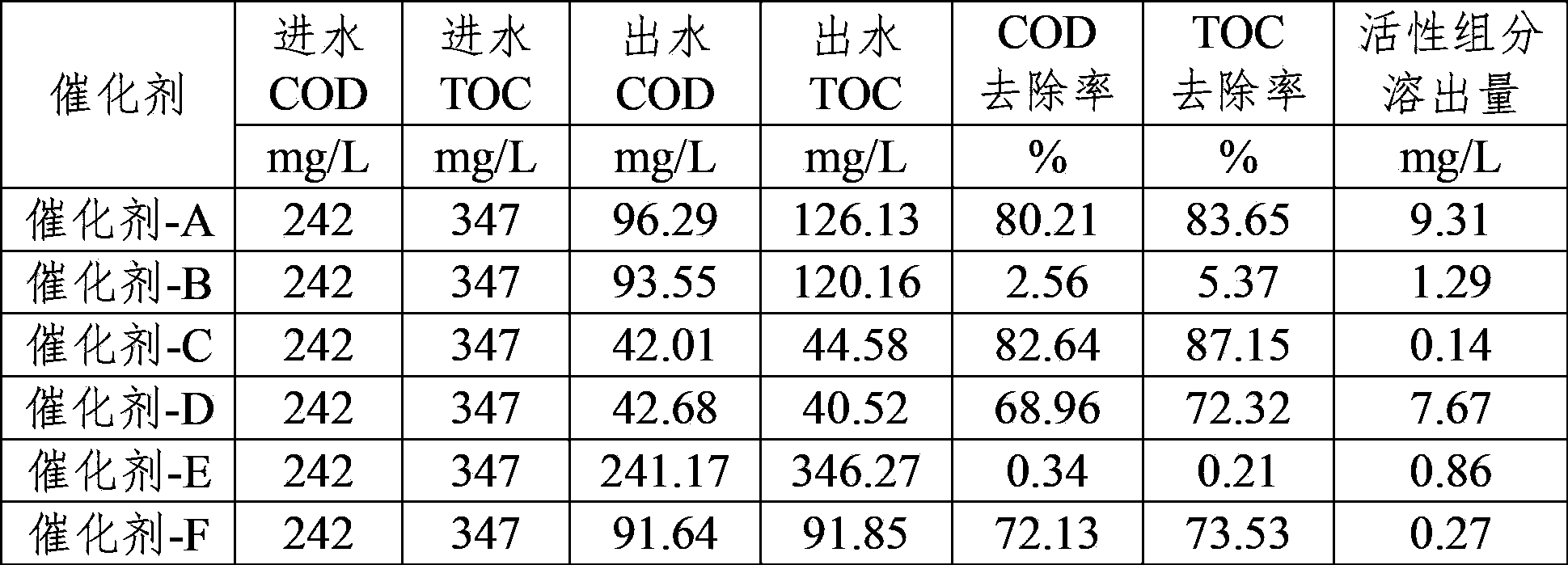

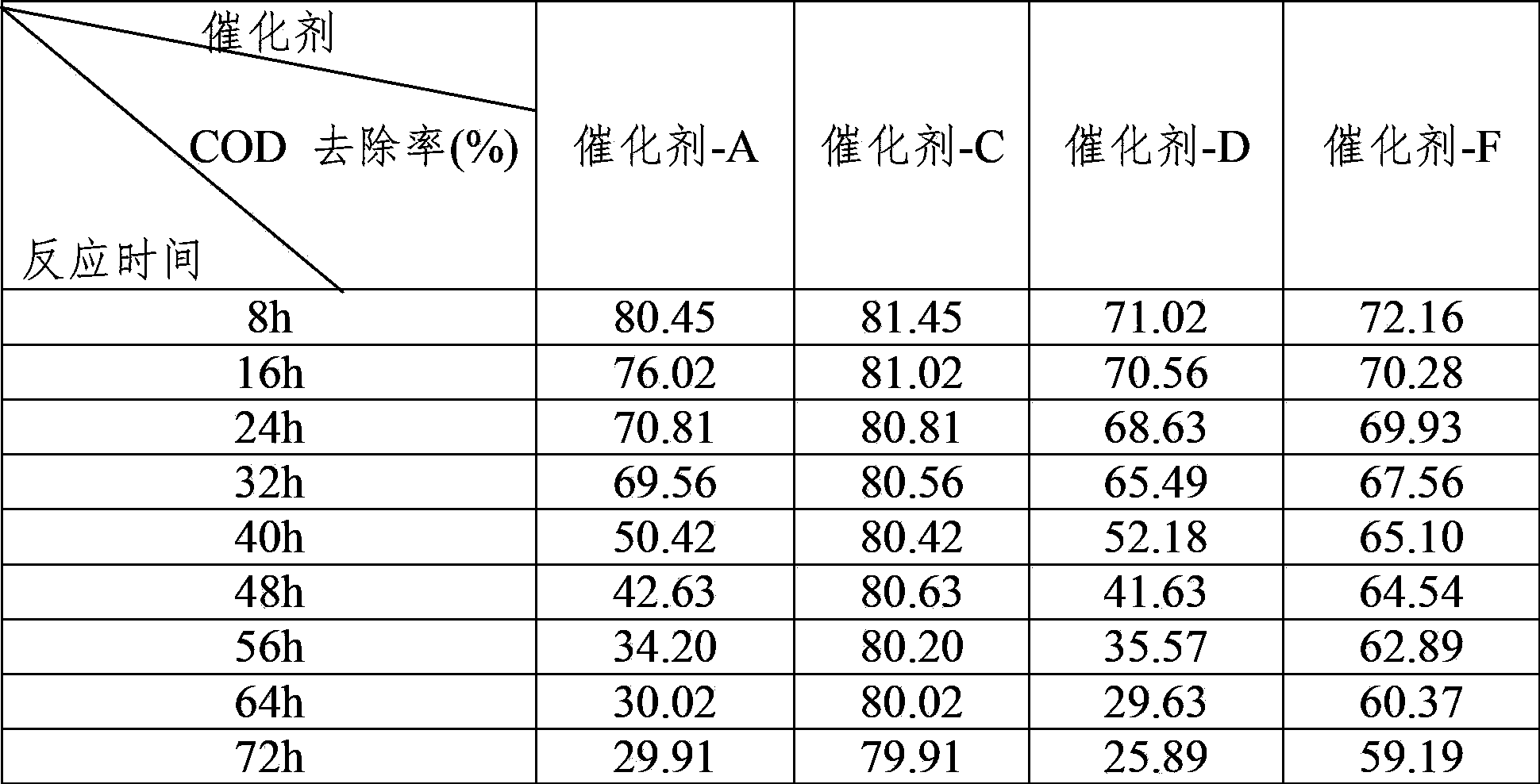

Preparation and application of catalyst for advanced treatment of printing and dyeing waste water by Fenton-like process

ActiveCN103877978AHigh catalytic activityImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationReaction temperatureComposite oxide

The invention relates to preparation and application of a catalyst for advanced treatment of printing and dyeing waste water by Fenton-like process, which belongs to the field of water treatment. The catalyst adopts transition metals of Cu, Fe, and Ni as active components, adopts zirconium aluminium composite oxide as a carrier, is prepared by an isometric impregnation roasting method, and is mainly used for treatment of printing and dyeing waste water that is difficult to degrade. The catalyst prepared in the invention can treat printing and dyeing waste water with a COD concentration of more than 240 mg / L under the reaction condition with a reaction temperature of 20 DEG C, a pH value of 2-7, a ratio of H2O2 (mg / L) to COD (mg / L) of 0.3-1.5, and residence time of 1 hour, and the effluent after treatment has a COD of less than 50 mg / L; catalytic activity of the catalyst is not changed after continuous operation for 100 hours in a pilot scale test, and the catalyst can be popularized in industrial application of advanced treatment of printing and dyeing waste water by Fenton-like process.

Owner:山东环发海若环境技术有限公司

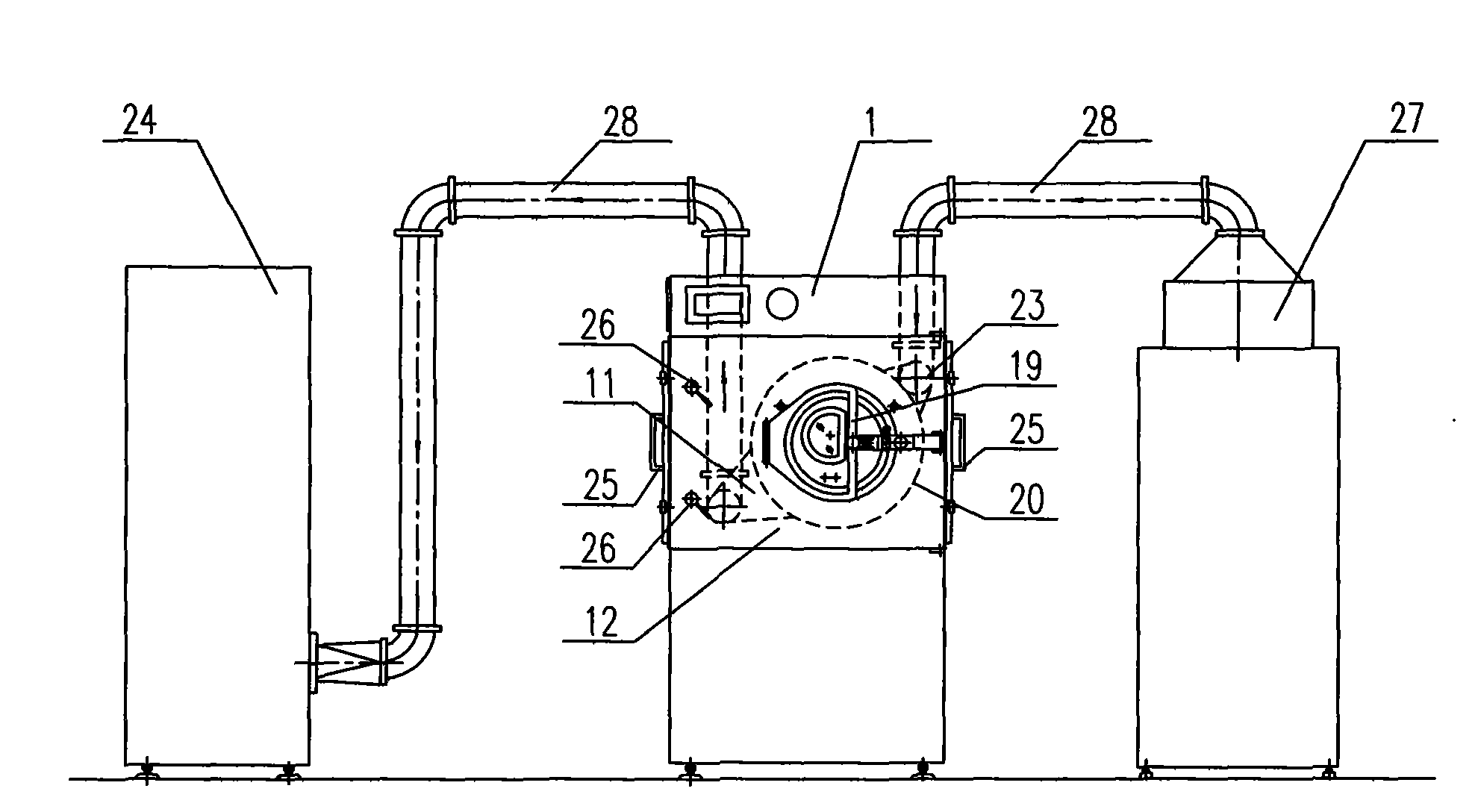

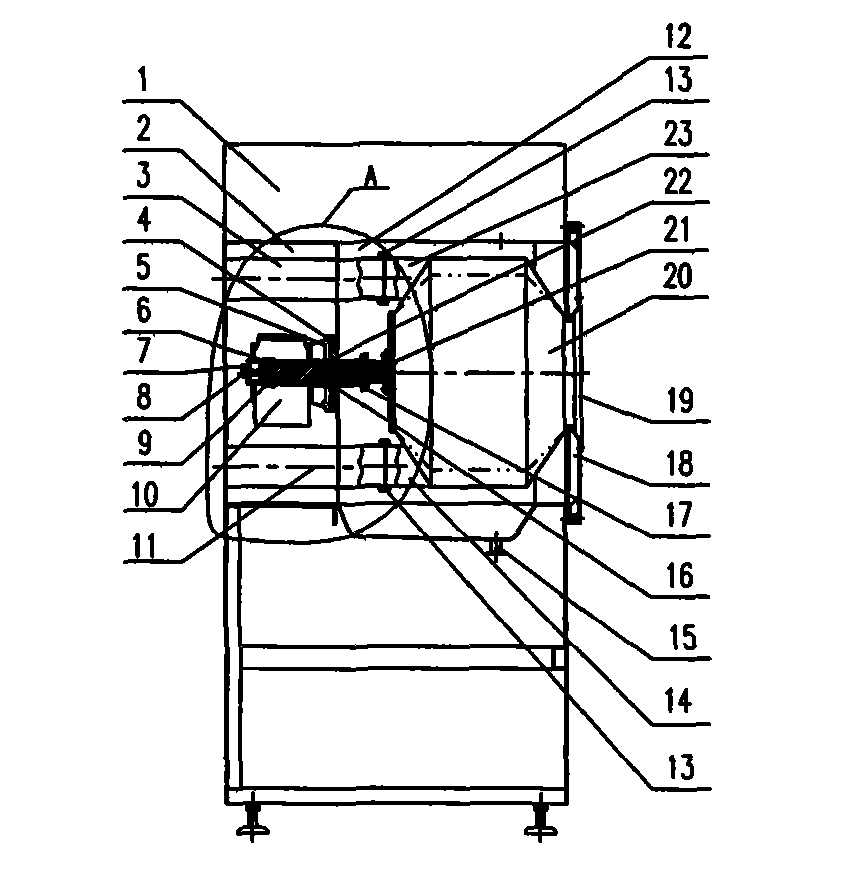

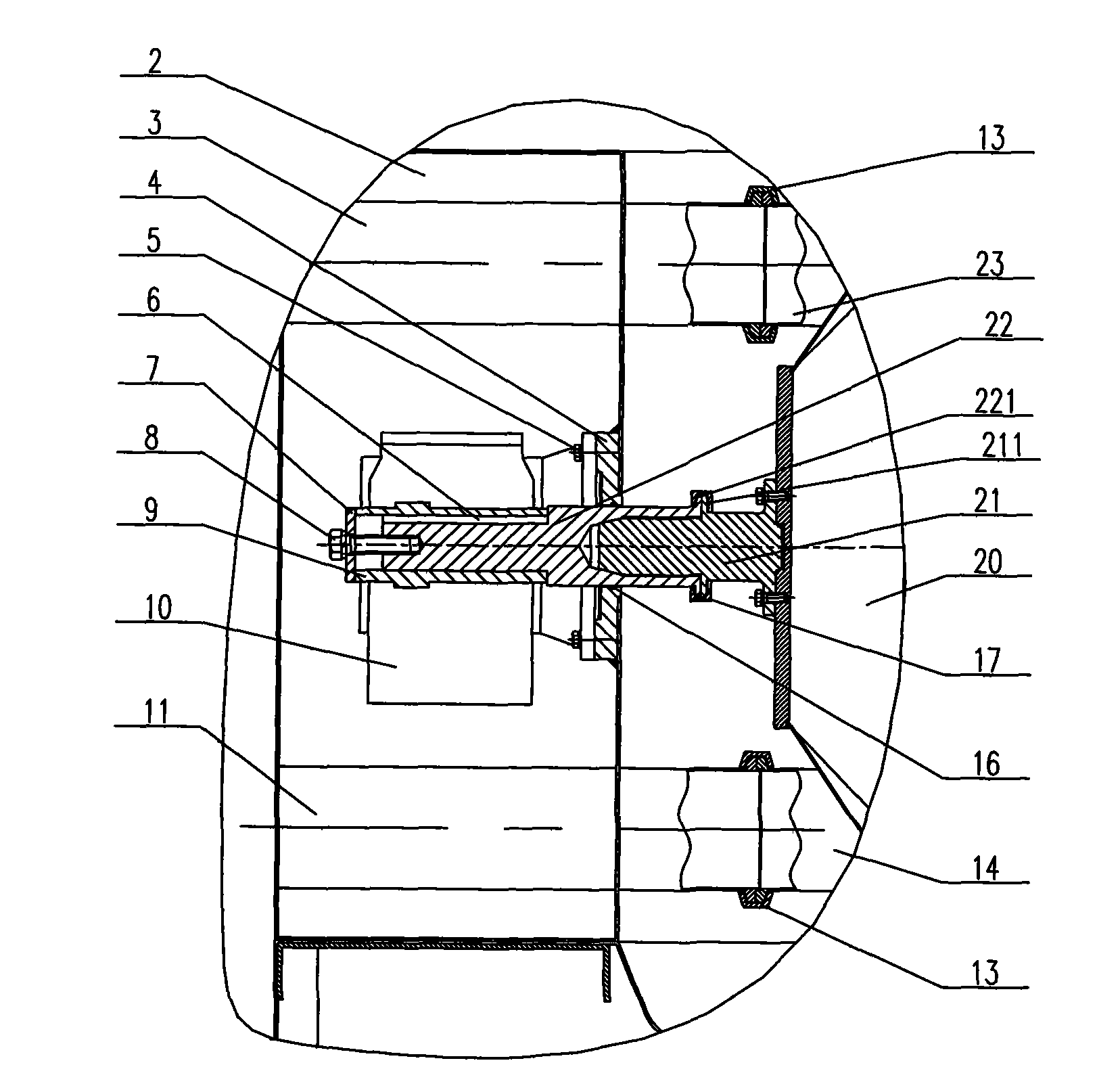

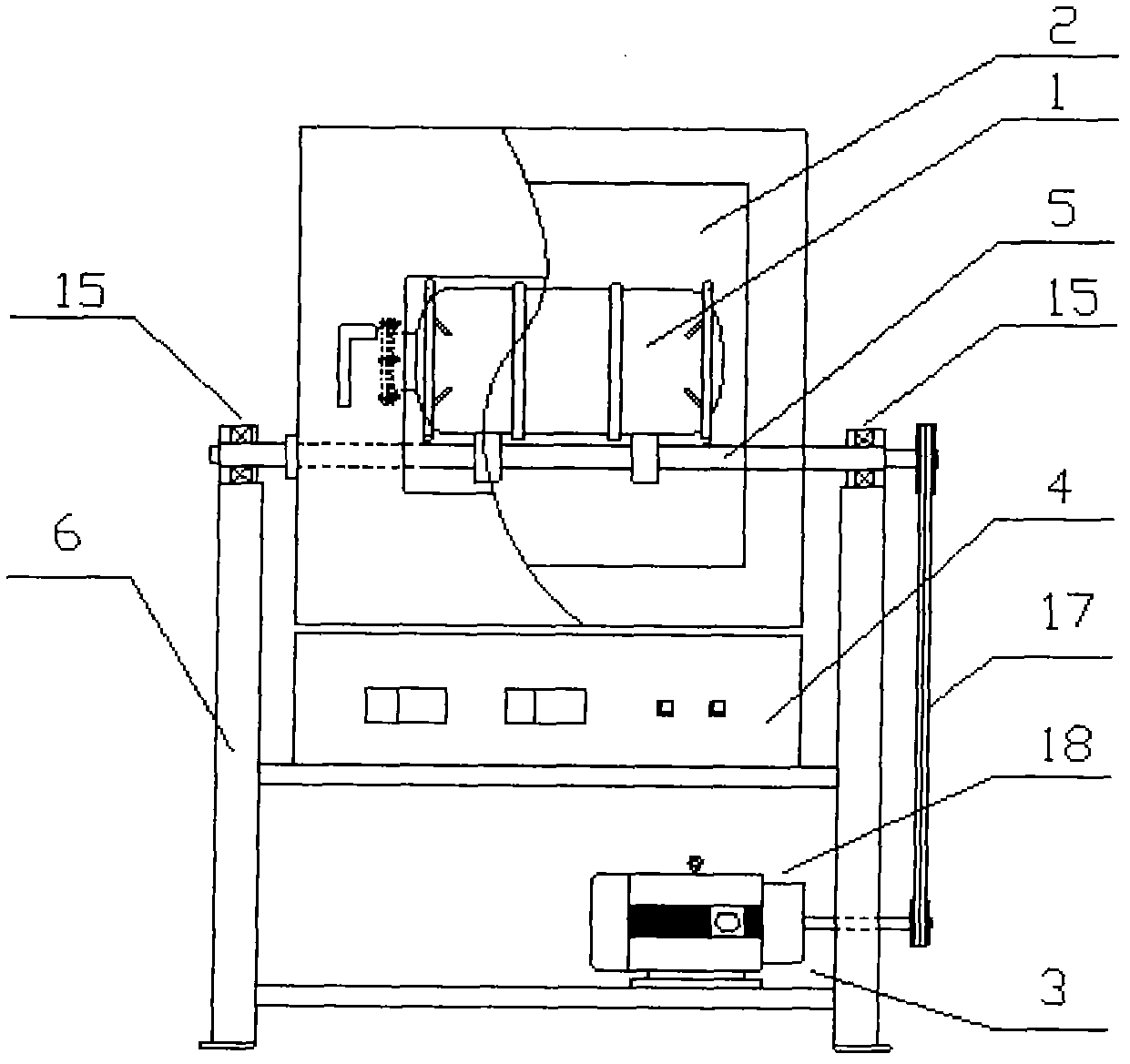

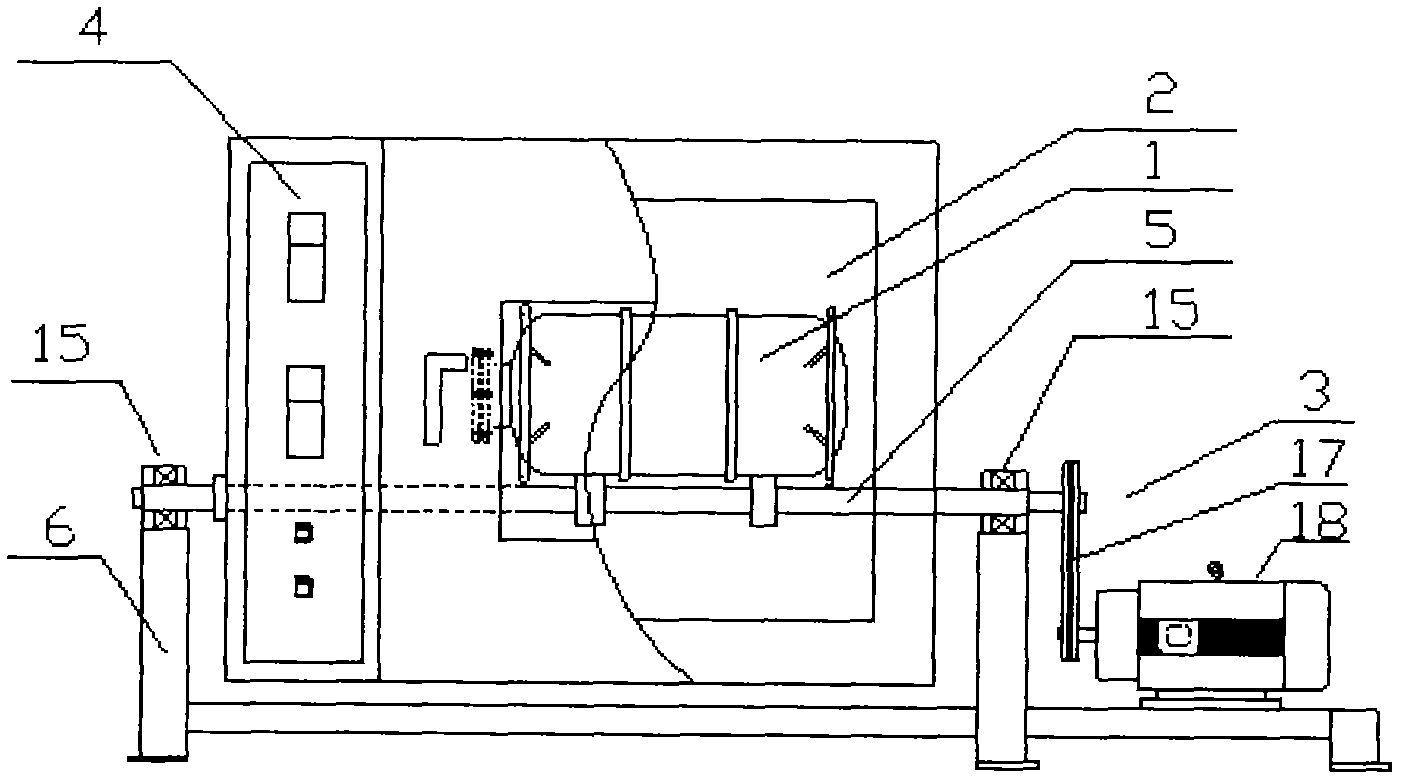

Efficient coating machine with replaceable roller

InactiveCN101953752AEasy to disassemble and useLess investmentPharmaceutical product form changeFood coatingAgricultural engineeringReducer

The invention relates to an efficient coating machine with a replaceable roller, which comprises a main machine. The main machine comprises a front box body and a back box body, wherein the front box body is mainly used for arranging a coating roller, the back box body is mainly used for installing a drive gear reducer, and the front box body and the back box body are mutually arranged at intervals. The drive gear reducer is connected with a main shaft of the coating roller through a connecting shaft installed on a hollow shaft of the drive gear reducer, an air intake pipe connecting port and an air exhaust pipe connecting port are installed in the front box body, and the air intake pipe connecting port and the air exhaust pipe connecting port are respectively connected with an air intake scoop and an air exhaust scoop of the coating roller through first fasteners. Different sizes of coating rollers and air intake scoops and air exhaust scoops which are matched with the coating rollers of the efficient coating machine can be freely replaced according to different requirements of small-scale production, pilot-scale production, large-scale production and the like by using the technical scheme, and the coating rollers, the air intake scoops and the air exhaust scoops are connected through bolts, clamps and other fasteners. The efficient coating machine has the advantages of convenient disassembly and assembly and use, multiple purposes, investment reduction and the like.

Owner:ZHEJIANG XIAOLUN INTELLIGENT MFG CO LTD

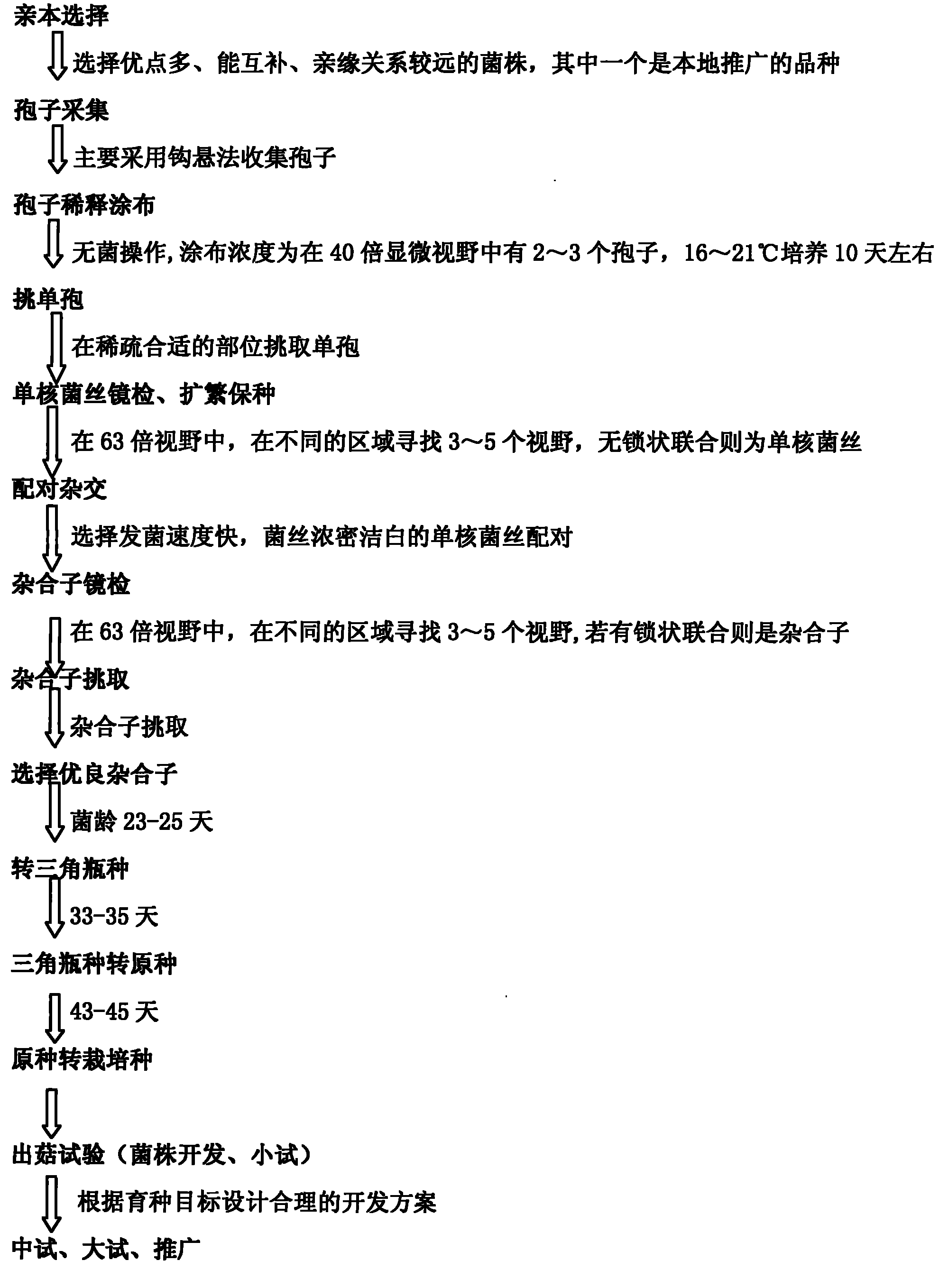

Use of aqueous NaOH/thiourea solution in pilot-scale production of cellulose products

InactiveUS7981337B2High degree of polymerizationHigh strengthArtificial filaments from cellulose solutionsOrganic non-macromolecular adhesiveAqueous sodium hydroxideThiourea

The present invention relates to the use of an aqueous sodium hydroxide / thiourea solution, specifically to the use of an aqueous sodium hydroxide / thiourea solution for pilot-scale production of cellulose products, wherein sodium hydroxide constitutes 8.1%-12.0% of the total weight of the aqueous solution, thiourea constitutes 3.0%-6.0% of the total weight of the aqueous solution, and said cellulose products include regenerated cellulose filaments, films, nonwovens, as well as composite fibers and / or functional materials of protein / cellulose, chitin / cellulose, Konjac Glucomannan / cellulose, nano-crystal particle / cellulose, etc.

Owner:JIANGSU LONG MA GREEN FIBERS +1

Transferring and compounding dual-purpose coating for waterborne polyurethane, preparation method and application thereof

InactiveCN102363708AAvoid problems such as placement stabilityQuality improvementPretreated surfacesPolyurea/polyurethane coatingsPolyesterXylylene

The invention relates to a transferring and compounding dual-purpose coating for waterborne polyurethane, a preparation method and an application thereof. The preparation method comprises the following steps: copolymerizing polyester polyol and polyether polyol with HMDI (Hexamethylene Diisocyanate), XDI (Xylylene Diisocyanate), IPDI (Isophorone Diisocyanate) and TDI (Toluene Diisocyanate); extending chains by using different chain extenders, thereby acquiring different components (components A and B); and lastly, adding a component C, stirring and milling, thereby preparing the coating. Compared with the prior art, the transferring and compounding dual-purpose coating for the waterborne polyurethane suitable for laser provided by the invention has the advantages of environmental protection and capability of enhancing anti-counterfeiting and illuminating effects and other effects, is suitable for a high-speed transferring aluminizing process, and can be applied to a compound package material, thereby realizing dual purpose of one material and meeting a demand on the packaging of products in modern society. The pilot scale production confirms that the transferring and compounding dual-purpose coating can be directly used for replacing a present related solvent-base coating.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

Use of Aqueous Naoh/Thiourea Solution in Pilot-Scale Production of Cellulose Products

InactiveUS20080284054A1Increase added valueImprove securityArtificial filaments from cellulose solutionsOrganic non-macromolecular adhesiveThioureaAqueous sodium hydroxide

The present invention relates to the use of an aqueous sodium hydroxide / thiourea solution, specifically to the use of an aqueous sodium hydroxide / thiourea solution for pilot-scale production of cellulose products, wherein sodium hydroxide constitutes 8.1%-12.0% of the total weight of the aqueous solution, thiourea constitutes 3.0%-6.0% of the total weight of the aqueous solution, and said cellulose products include regenerated cellulose filaments, films, nonwovens, as well as composite fibers and / or functional materials of protein / cellulose, chitin / cellulose, Konjac Glucomannan / cellulose, nano-crystal particle / cellulose, etc.

Owner:JIANGSU LONG MA GREEN FIBERS +1

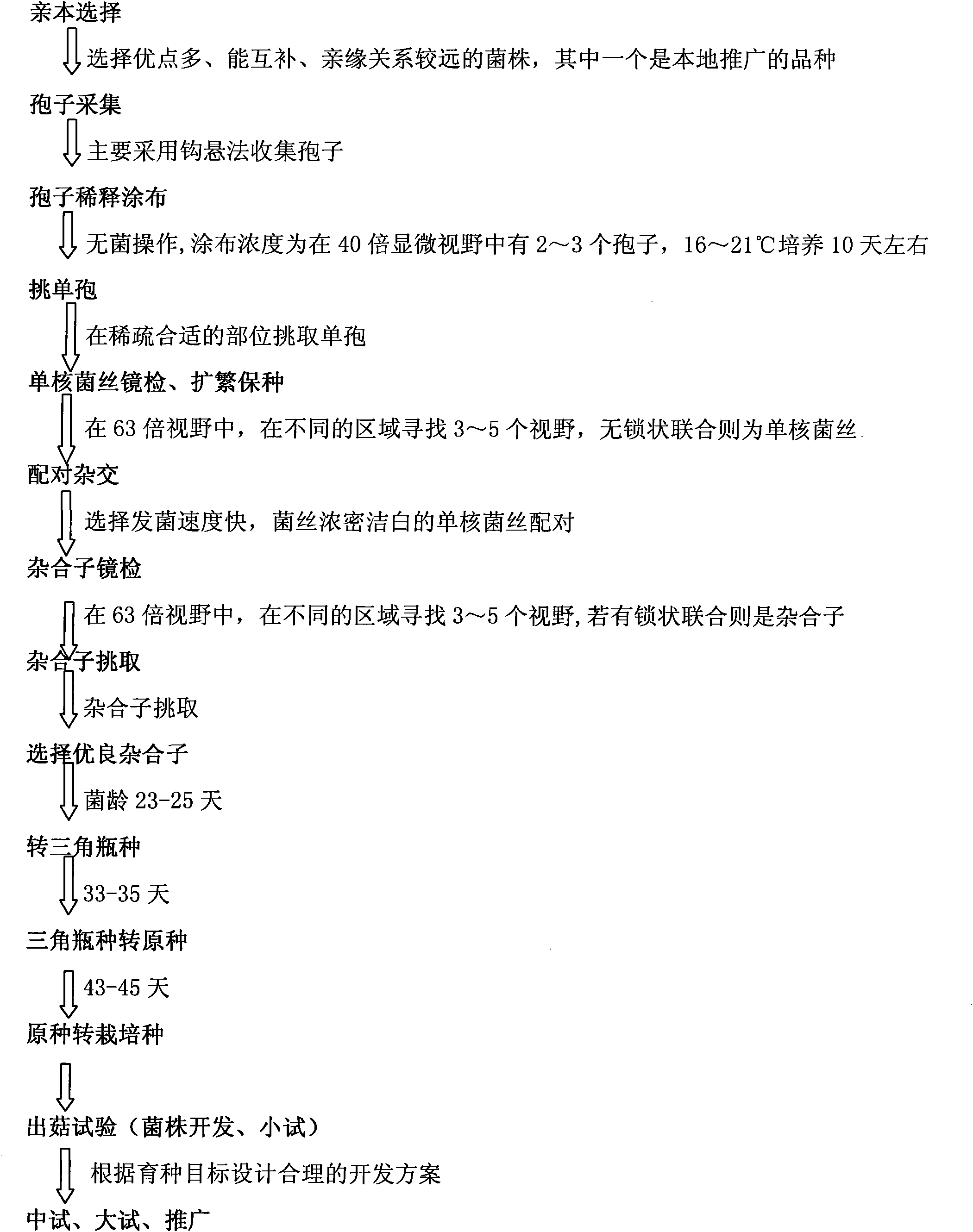

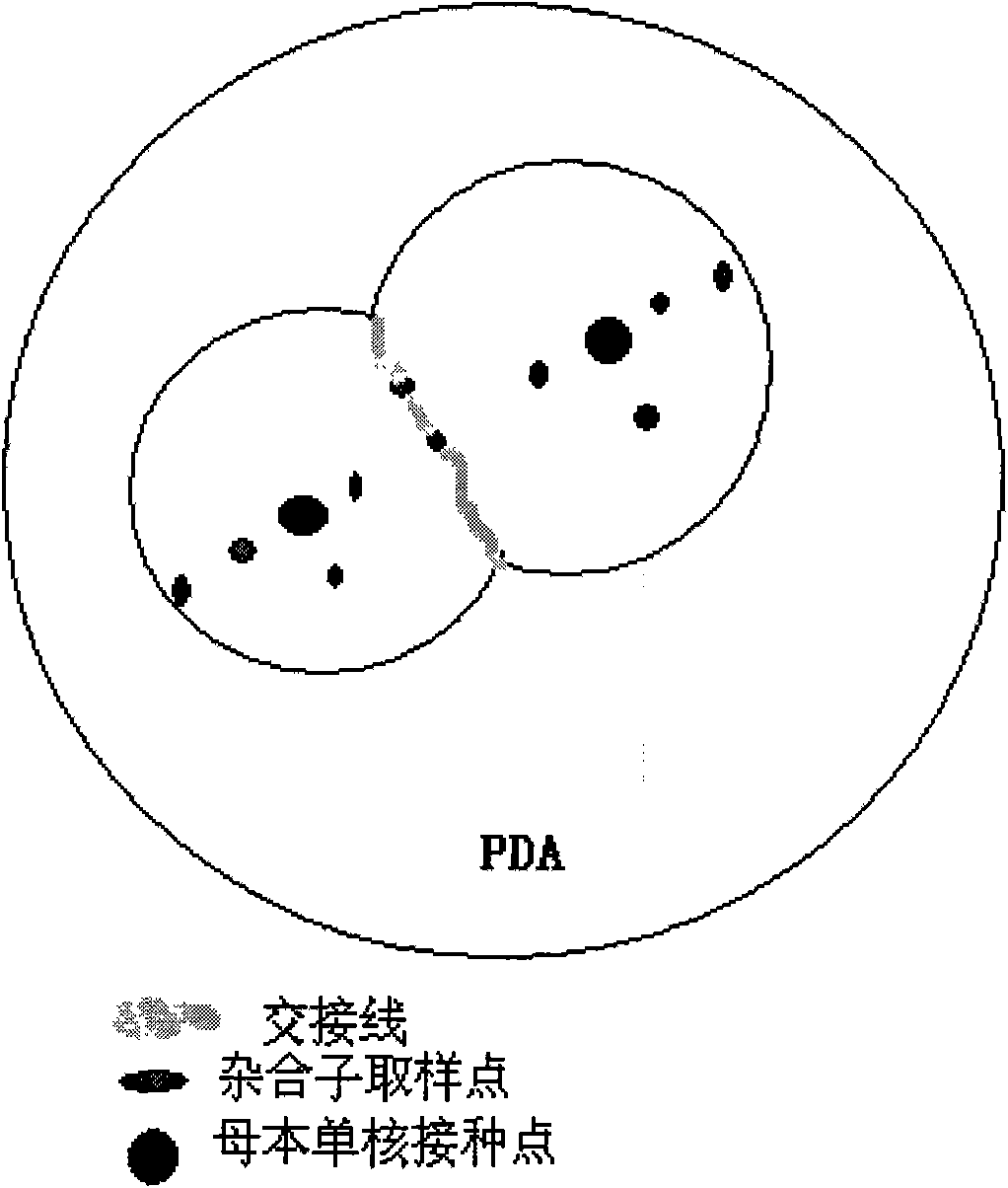

Hypsizigus marmoreus mon-mon cross-breeding method

InactiveCN102047839AStrong resilienceImprove breeding efficiencyFungi productsLichen productsSporeClamp connection

The invention relates to a hypsizigus marmoreus mon-mon cross-breeding method which comprises the steps of: selecting a parent; collecting spores, diluting and coating the spores, selecting single spores, and microscopically examining clamp connection free spores as monocaryon myceliums; diluting and coating the spores in a sterile operation manner, coating by using the concentration that 2-3 spores are in 40 times micro view, and culturing for 8-10 days at a temperature of 16-21 DEG C; selecting single spores in sparse parts; combining and hybridizing monocaryon myceliums: carrying out pairing hybridization on the parent of the monocaryon myceliums, and carrying out pairing hybridization by selecting pure white monocaryon myceliums with high spawn running speed and dense myceliums; microscopically examining monocaryon myceliums with clamp connection, and then selecting heterozygotes; microscopically examining the heterozygotes in a 63 times view, searching 3-5 views in different regions, and if the clamp connection exists, enabling the monocaryon myceliums to be heterozygotes; cultivating and fruiting; and carrying out pilot scale test and large scale test, and popularizing. In the method, the breeding time is reduced to 18 months from several years, and a plurality of bacterial strains with high yield, excellent quality and strong stress tolerance are obtained.

Owner:SHANGHAI FINC BIO TECH INC

Processing technology of Polygonatum sibiricum processed with wine

InactiveCN105434851ASpeed up exhaustionFull and even contactPlant ingredientsPolygonatum sibiricumPilot scale

A processing technology of Polygonatum sibiricum processed with wine concretely comprises the processes of cleaning, moistening, steaming and drying. Negative pressure stewing is adopted, the steaming time, the steaming temperature and other technological parameter ranges are determined through a large amount of experiment researches, and a processing end point is controlled; and moistening carried out through spraying addition of yellow rice wine is adopted, and allows auxiliary materials to be more fast and uniformly absorbed than traditional stirring moistening, and gradient heating is carried out to dry. The Polygonatum sibiricum processed with wine, produced through the technology, has stable quality; the auxiliary materials are in full contact with a medicinal material, so processing effects consistent with those of traditional technologies are reached; the technology disclosed in the invention has the advantages of processing technology simplification, production period shortening and cost saving; and pilot scale test verifies that the Polygonatum sibiricum processed with wine, produced through the processing technology, has stable quality, is uniform and effective, and adapts to industrial large-scale production.

Owner:BEIJING KANGRENTANG PHARMA

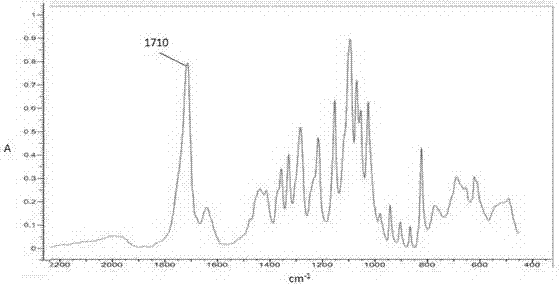

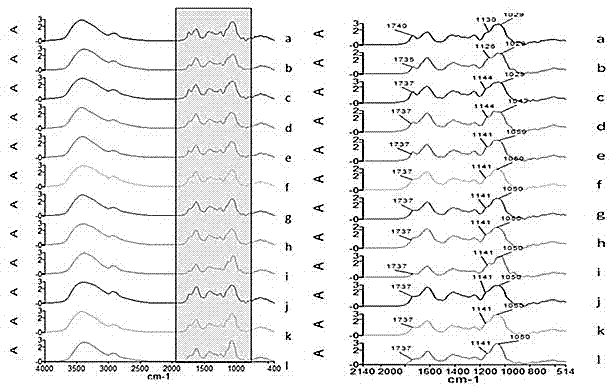

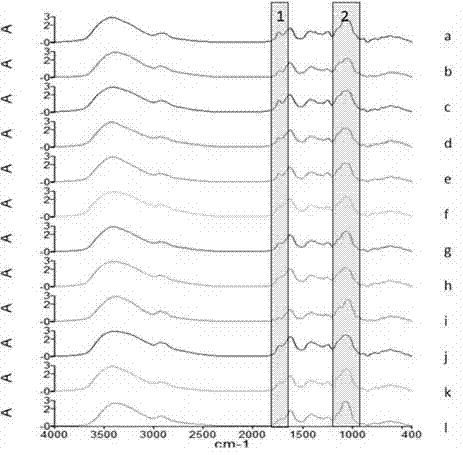

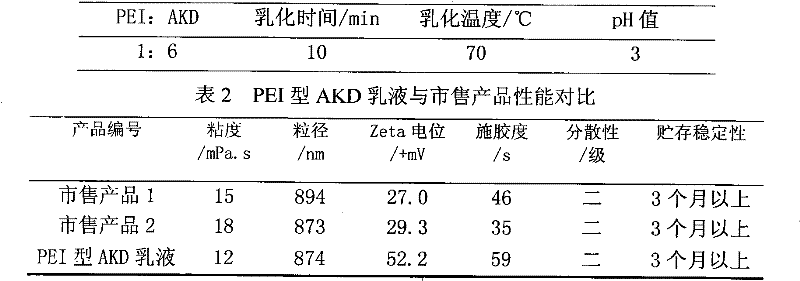

Preparation of polyethyleneimine AKD new type sizing agent

The invention relates to a PEI emulsifying type AKD sizing agent prepared by emulsifying AKD wax powder by taking polyethyleneimine as emulsifiers, the emulsifying process condition is optimized and the pilot scale test and sizing application test are carried out; experimental result expresses that when the mass ratio of the polyethyleneimine : AKD wax powder is 1:6, the pH is 3, the emulsifying temperature is 70 DEG C, the emulsifying time is 10min, and the particle size of the AKD emulsion and Zeta electric potential are 1184nm and +52.1mV respectively; when the using amount of the AKD emulsion is 0.2 percent, handsheet sizing degree can achieve 68s, the sizing curing rate is 11.87 percent and 87.43 percent respectively after natural airing and off-machine are carried out; compared with the cationic starch sizing product, the polyethyleneimine AKD new type sizing agent has the characteristics of rapid curing and high sizing degree.

Owner:QINGDAO UNIV OF SCI & TECH

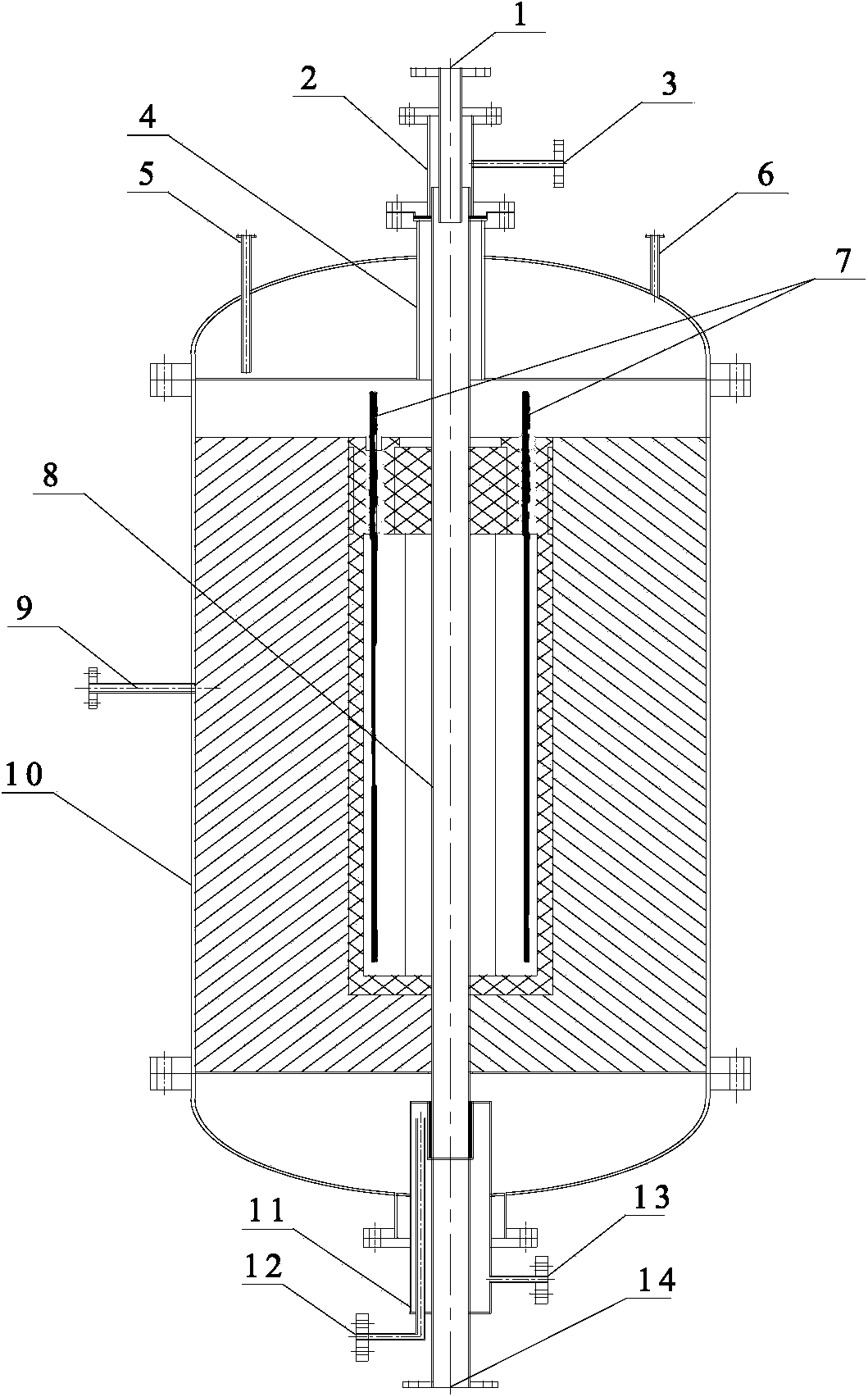

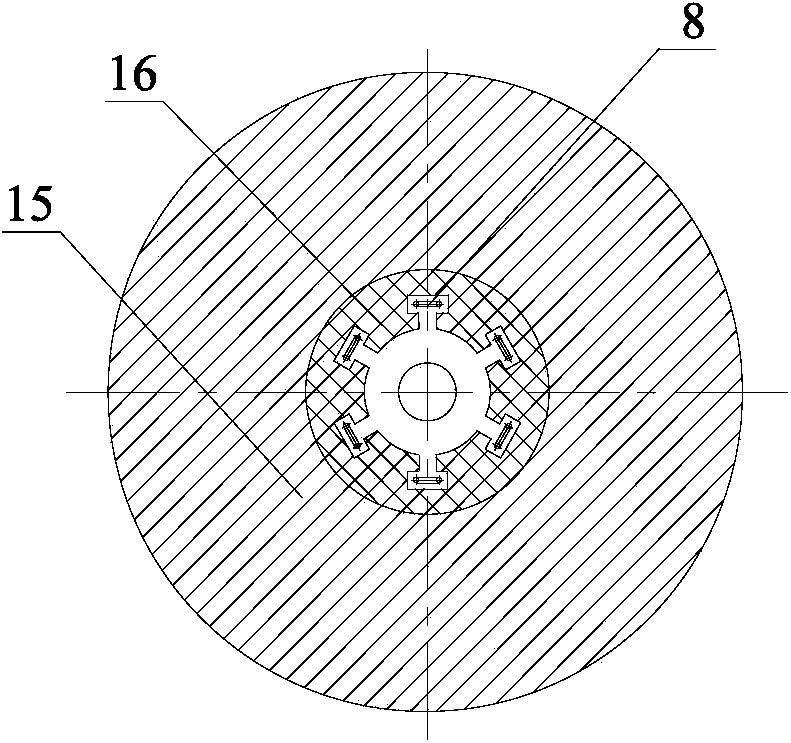

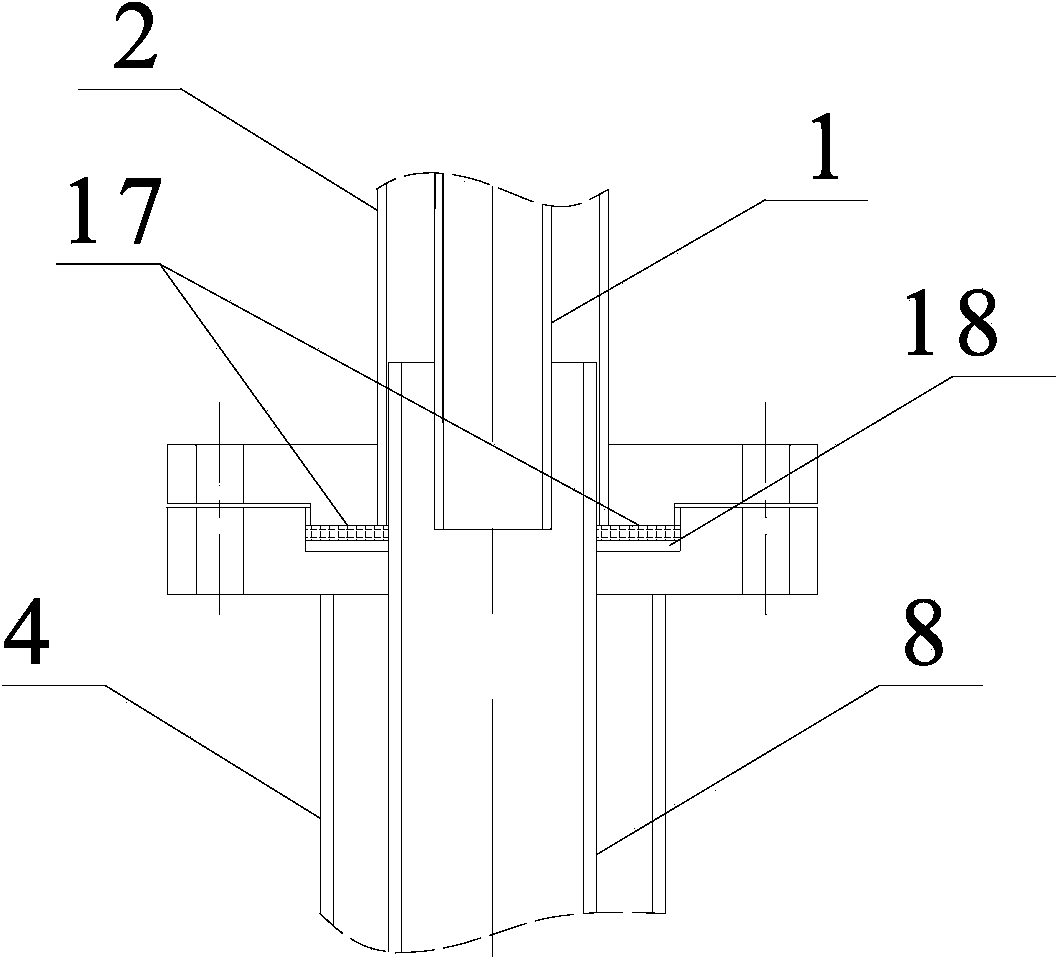

Novel high-temperature and high-pressure electric heating furnace

InactiveCN103743241AFirmly connectedContinuous and stable high temperature and high pressure environmentFurnace typesElectric heating for furnacesFiberAluminum silicate

A novel high-temperature and high-pressure electric heating furnace comprises a discharging tube, a reaction gas feeding tube, connectors, an Al2O3 ceramic reaction tube, a shell, a furnace lining gas feeding tube, silicon and molybdenum rods, aluminum silicate fiber heat-insulation cotton, a slagging tube and the like, wherein the upper end of the Al2O3 ceramic reaction tube is respectively connected with the discharging tube and the reaction gas feeding tube through the connectors, and connection positions are sealed by using graphite packing; the lower end of the Al2O3 ceramic reaction tube is connected with the slagging tube through a pipe, and a connection position is sealed by using high-temperature glue; the silicon and molybdenum rods are hung perpendicularly and are uniformly arranged around the Al2O3 ceramic reaction tube; a heat-insulation material is filled between the shell and an electric heating element; and inert gas with certain pressure is fed between the shell and the electric heating element. The Al2O3 ceramic reaction tube and the shell can bear the temperature of 1500 DEG C and the pressure of 1.5MPa, so that the novel high-temperature and high-pressure electric heating furnace is applicable to pilot-scale study on pyrolysis, gasification and combustion of solid carbonic fuels under the conditions of high temperature and high pressure, and has the advantages of quick temperature rising and stable pressurization.

Owner:SOUTHEAST UNIV

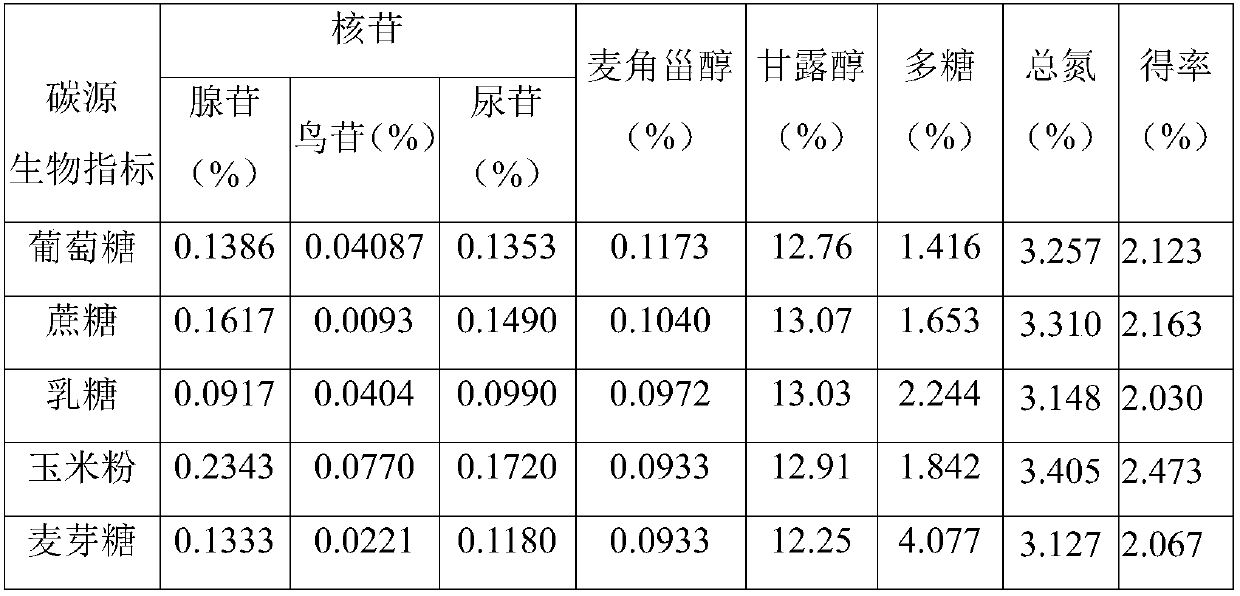

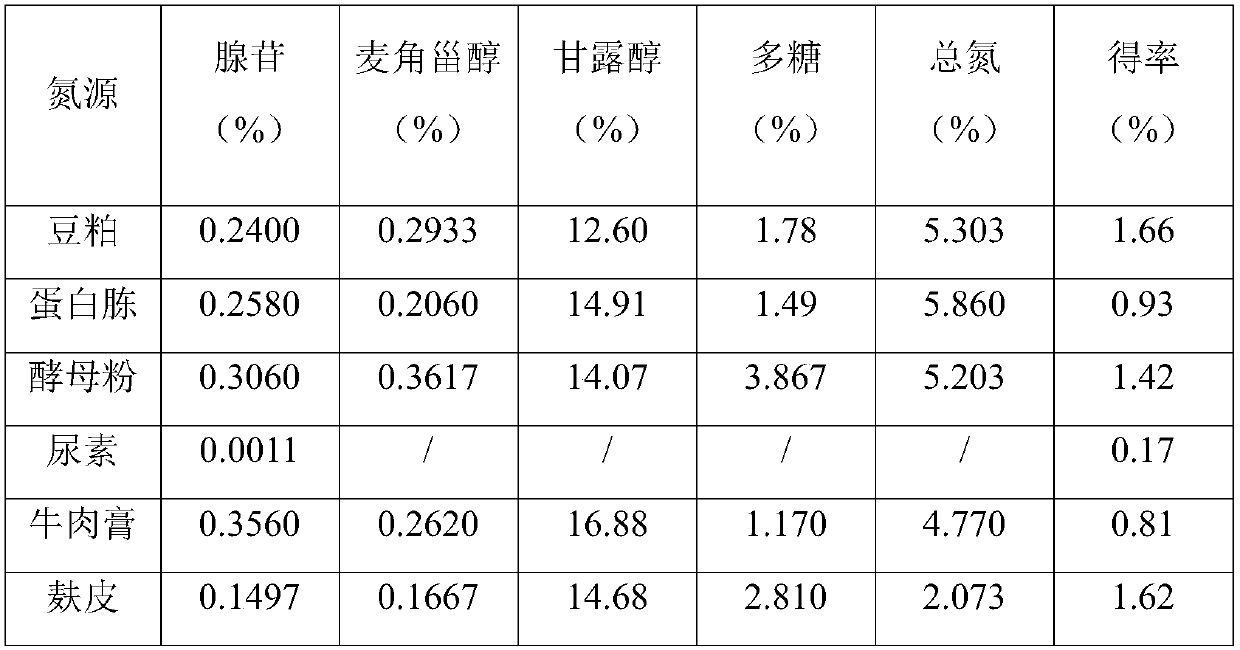

Phellinus igniarius fermentation medium

InactiveCN108676725AIncrease biomassImprove biological activityFungiMicroorganism based processesSaccharumSucrose

The invention provides a phellinus igniarius fermentation medium. The medium comprises the following components by weight: 10-15 parts of glucose, 15-20 parts of sucrose, 15-25 parts of corn powder, 10-20 parts of soybean meal, 0-10 parts of yeast powder, 5-10 parts of wheat bran powder, 0.25-1 part of MgSO4, 2 parts of Cacl2, 0.1-0.5 part of VB1, and a 4-8g / L mulberry twig aqueous extract. The medium can greatly improve the mycelial biomass and bioactivity of phellinus igniarius, the mycelial biomass is up to 3.0%, and other bioactivity indexes are as the following respectively: 0.26% for adenosine, 2.24% for polysaccharide, 0.37% for ergosterol, and 12.45% for mannitol. When the mulberry twig aqueous extract is added, the mycelial biomass can reach 3.5%. Therefore, the fermentation medium provided by the invention has the advantages of high mycelium biomass, high bioactivity, controllable quality, application to pilot scale production already and the like.

Owner:ZHEJIANG JOLLY PHARMA

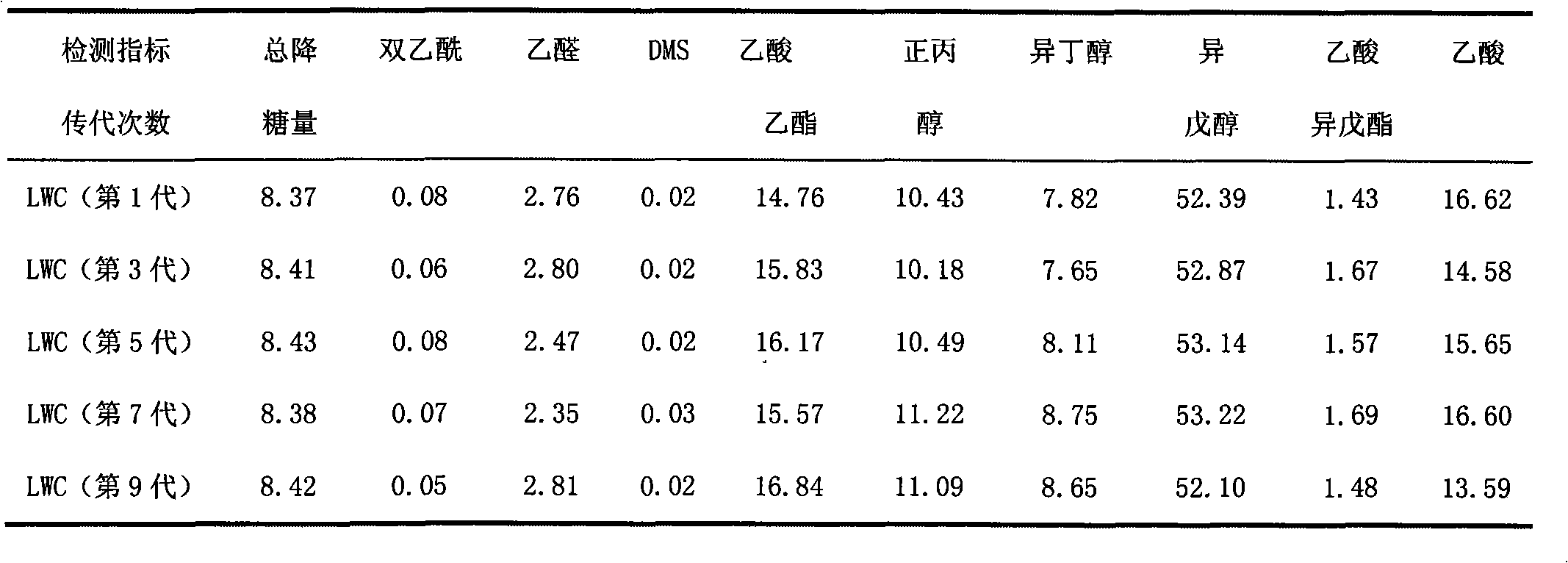

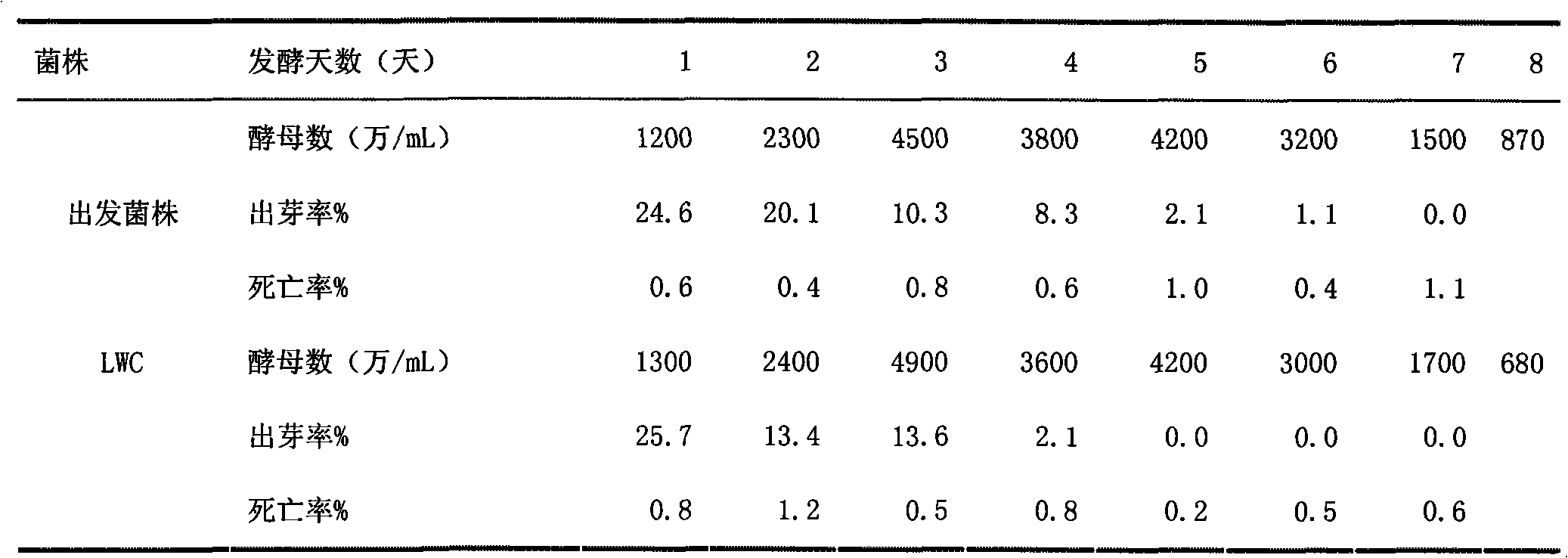

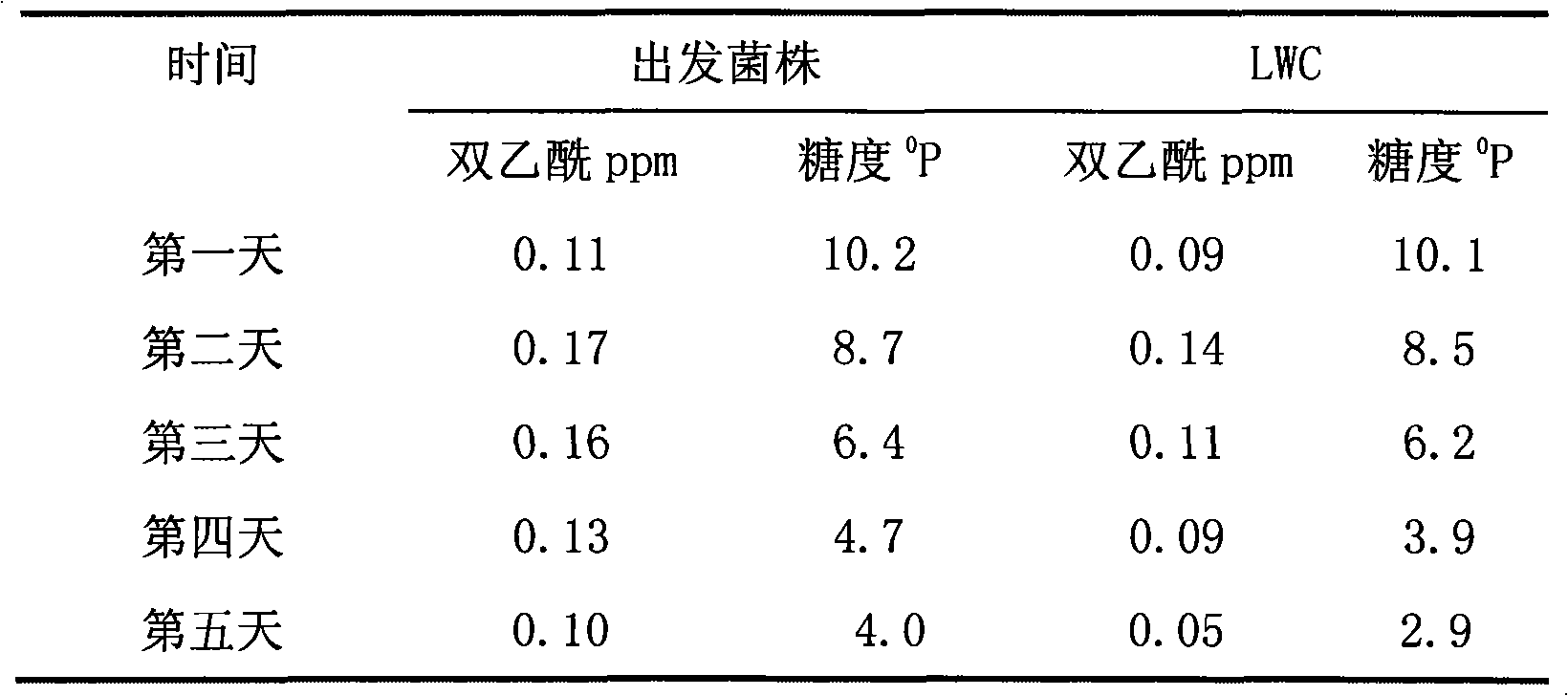

Yeast strain of beer and application thereof

InactiveCN101665772AHigh positive mutation rateIncrease mutagenic effectFungiBeer fermentationBiotechnologyMicroorganism

The invention discloses a yeast strain of beer and the application thereof in the aspect of beer fermentation. The strain of the beer-brewing yeast (saccharomyces cerevisiae) provided by the inventionis preserved in the China General Microbiological Culture Collection Center, and the preservation number is CGMCC No.3217. The selecting and breeding method of the strain comprises the following steps: activating the original starting strain, injecting ions for mutation, mutating by laser, primarily sieving by using wort and agar flat plate culturing medium, sieving again by using a fermentationbung, testing genetic stability, and performing a pilot-scale test. The yeast strain of beer is an excellent yeast strain of beer and has a potential suitable for large production of beer breweries.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

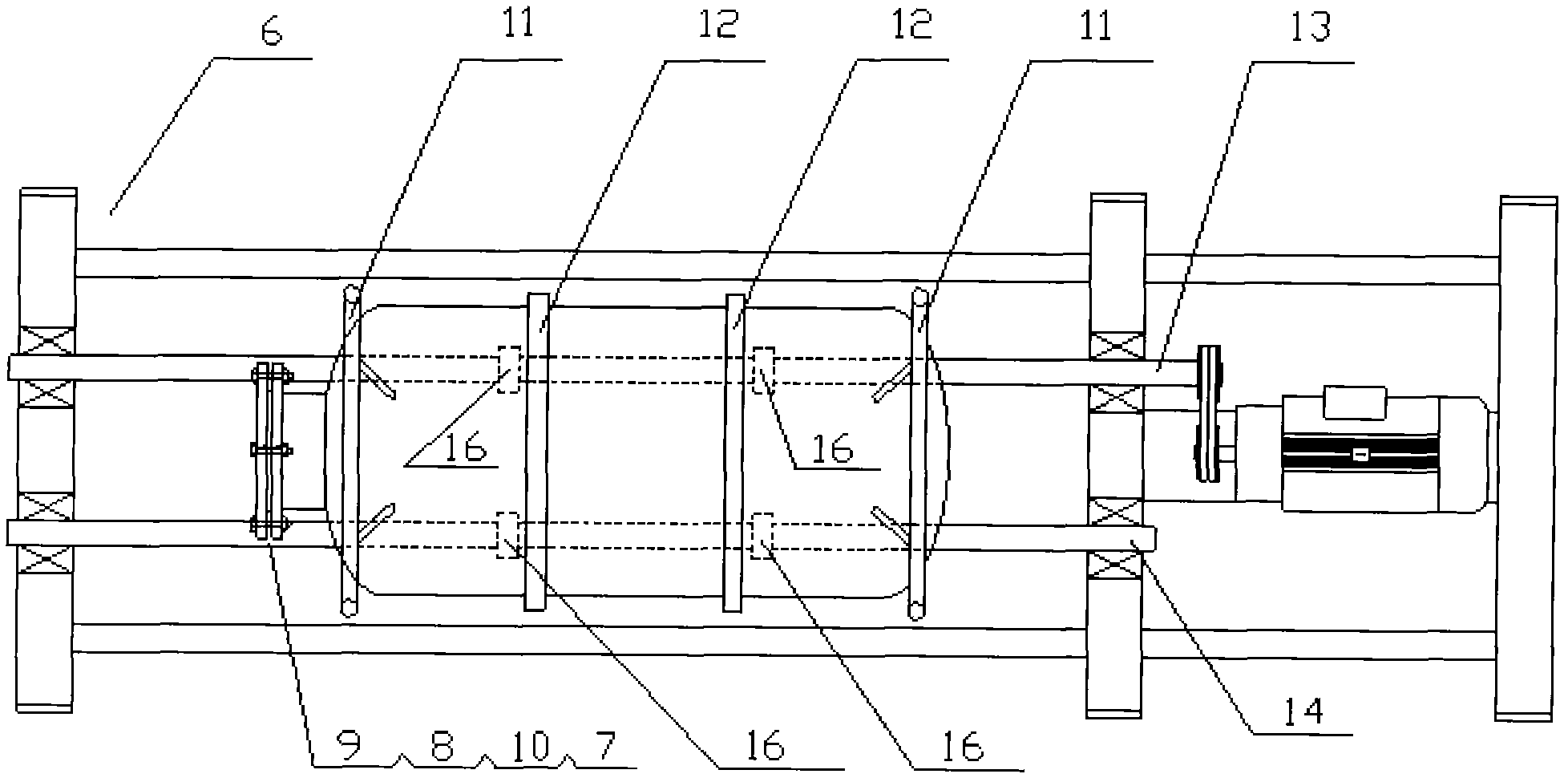

Rotary reaction device for hydro-thermal synthesis

InactiveCN102059088APromote growthStir wellRotating receptacle mixersTransportation and packagingMolecular sieveControl system

The invention discloses a rotary reaction device for a hydro-thermal synthesis molecular sieve, which comprises a control system arranged on a seat frame, an electric heating blower and a side horizontal reaction kettle arranged in the electric heating blower, wherein a support rotating mechanism is arranged under the side horizontal reaction kettle and comprises a drive mechanism and two rotating shafts parallel to the center line of the side horizontal reaction kettle, the two rotating shafts are positioned in the electric heating blower, two pairs of transmission idler wheels are arranged on the two rotating shafts, the side horizontal reaction kettle is supported on the two pairs of transmission idler wheels, and the two pairs of transmission idler wheels drive the side horizontal reaction kettle to rotate. The volume of the reaction kettle can be made into the scale of the library pilot scale test, the single-kettle output can reach the kilogram level, and the rotary reaction device is suitable for the optimization of the hydro-thermal synthesis condition in a reaction kettle amplification process and the research of a molecular size subsequent forming process. The stirring form of the reaction kettle is suitable for the growth of the molecular sieve.

Owner:CHINA TIANCHEN ENG +2

Pilot scale astragalus residue cordycepin solid state fermentation method

InactiveCN102715017AReduce pollutionIncrease added valueHorticultureFertilizer mixturesBiotechnologyPaecilomyces

The invention relates to the field of application of biotechnology and belongs to utilization of traditional Chinese medicine residues. After astragalus polyose is extracted industrially, the remaining astragalus residue can serve as a matrix of Chinese paecilomyces mycelium solid state fermentation. The invention provides a method for pilot scale amplification culture of the solid state fermentation process. The pilot scale amplification culture method for an astragalus residue cordycepin solid state fermentation process adopts a shallow tray fermentation method, wherein the outline of a shallow tray is of a rectangle; the shallow tray is 280 mm long, 180 mm wide and 120 mm high, is made of high-temperature resisting polypropylene material, and is provided with a sterile vent. The method is characterized in that during fermentation, leavening can be placed in the shallow tray, the shallow tray is placed in a plastic bag made of polypropylene material, a cotton tampon is used to seal the vent, and then sterilization and inoculation can be carried out. With increase of manual labor, the method can fully amplify culture scale, can make cyclic culture possible, and finally makes industrial production possible; and astragalus residue cordycepin baking powder with stable property can be obtained.

Owner:TIANJIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com