Rotary reaction device for hydro-thermal synthesis

A reaction device, a technology for hydrothermal synthesis, applied in mixers with rotating containers, chemical/physical/physical-chemical mobile reactors, mixers, etc., can solve the problems of high maintenance cost, complex structure, poor stirring effect, etc. , to achieve the effect of accurate reaction temperature control, reduction of leakage points and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

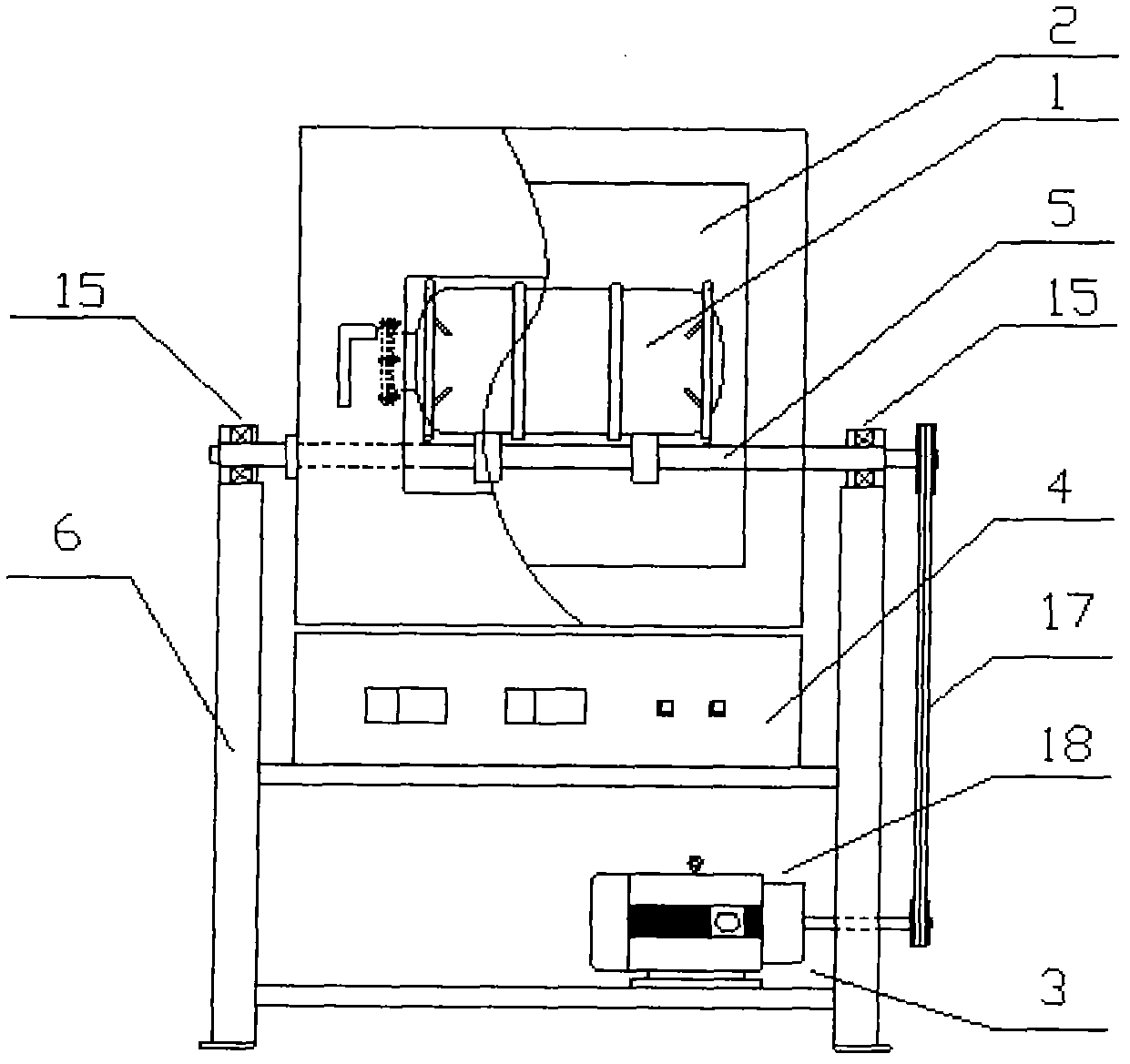

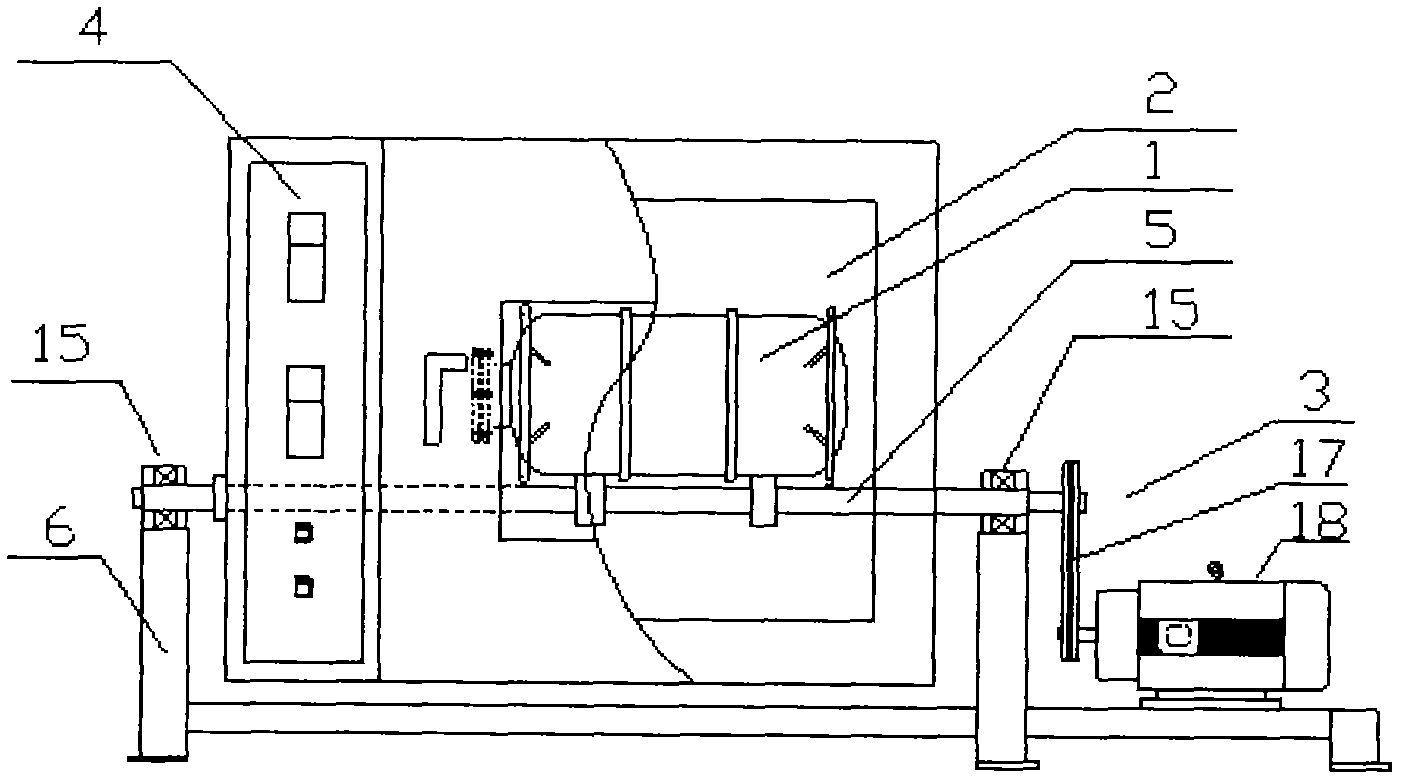

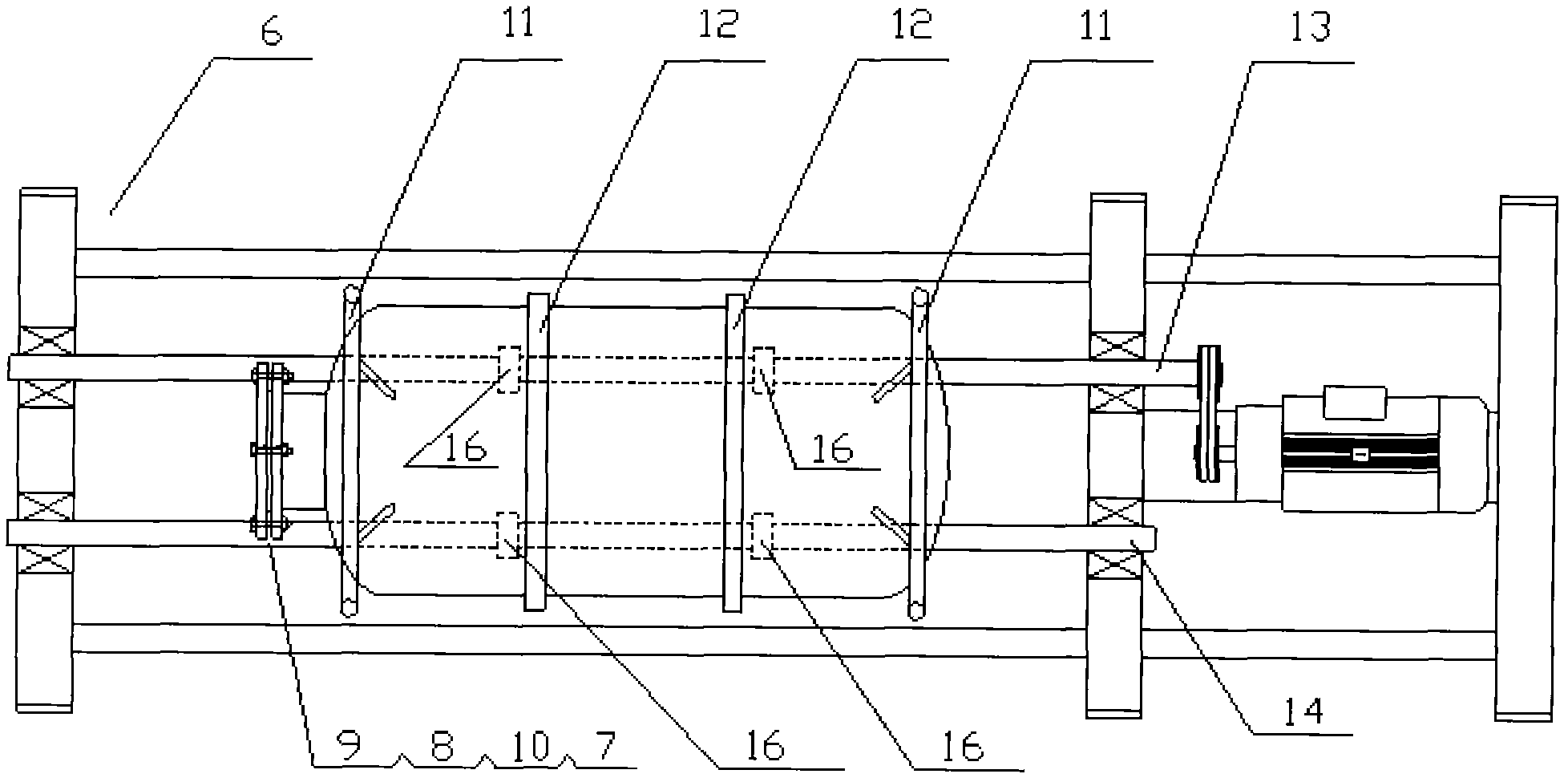

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0022] see Figure 1 to Figure 5 , A rotary reaction device for hydrothermal synthesis of molecular sieves in the present invention consists of a reaction kettle 1, an electric blower box 2, a control system 4, a supporting rotating mechanism 5 and a seat frame 6. The reaction kettle 1 is lying sideways on the supporting rotating mechanism 5 in the electric heating blower box 2 and rotates under the drive of the supporting rotating mechanism 5 . The electric heating blower box 2 is placed on the seat frame 6, and the control system 4 is provided on the side or the bottom of the electric heating blowing box, and the driving mechanism 3 supporting the rotating mechanism 5 is provided on the other side or the bottom of the electric heating blowi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com