Preparation method of novel nanometer micelle medicinal material

A nanomicelle, a new type of technology, applied in the field of biopolymer material synthesis, can solve the problems of inability to achieve scale and industrialization, and achieve the effect of convenient operation, strong controllability, and industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

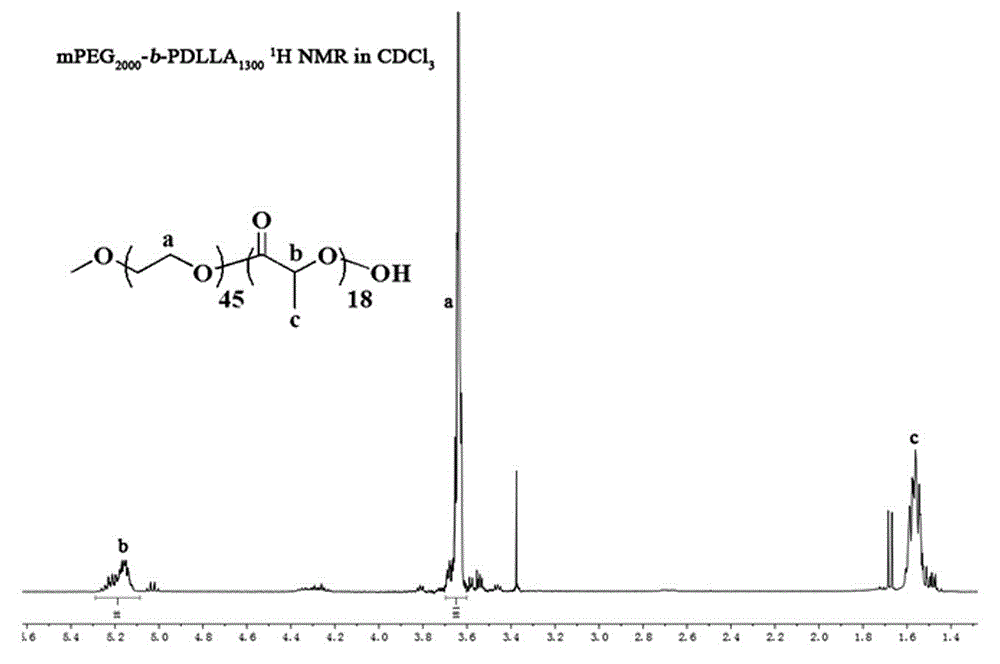

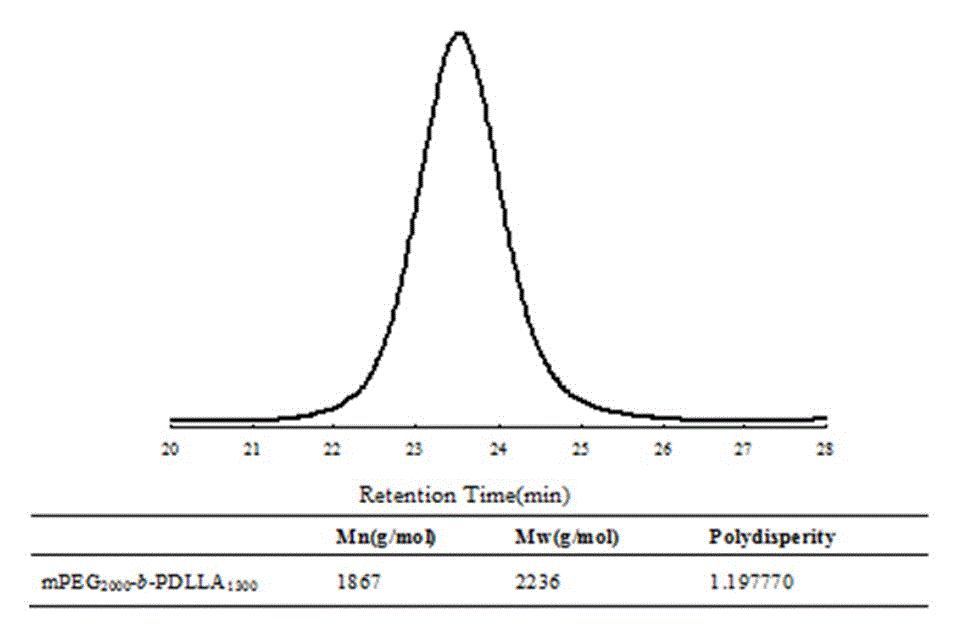

[0031] A preparation method of a novel nano-micelle medicinal material:

[0032] (1) Add 700 g of polyethylene glycol monomethyl ether (1800-2200) into a dry 2L three-neck round bottom flask (equipped with a ground three-way valve), install mechanical stirring, and seal the stirring and bottle stopper well. One end of the three-way valve is connected to a safety bottle and then connected to a vacuum pump. The safety bottle must be in liquid nitrogen, and one end is connected to nitrogen gas; then put it in an oil bath, and the boundary of the oil bath should reach 2 / 3 of the neck of the flask; turn the three-way valve to the vacuum position , 110°C to remove water under reduced pressure for 6 hours, and the pressure is lower than -0.085MPa; under the protection of nitrogen, add the catalyst stannous octoate (2.072g dissolved in 1.1ml toluene), and vacuumize for 0.5h; under the protection of nitrogen, add D, L-propane Lactide 520g, under nitrogen protection, reacted at 135°...

Embodiment 2

[0040] A preparation method of a novel nano-micelle medicinal material:

[0041] (1) Put polyethylene glycol monomethyl ether with a molecular weight of 1800-2200 in an oil bath, heat to 110°C-115°C, vacuumize for 6 hours, and then add the catalyst stannous salt compound dissolved in toluene under nitrogen protection (Dissolve 1g of stannous salt with 0.4mL of toluene), then add D, L-lactide (the weight ratio of polyethylene glycol monomethyl ether to D, L-lactide is 44:56), the The amount of stannous salt compound is reactant D, 4‰-5‰ of the weight of L-lactide, heated under nitrogen protection, the reaction temperature is 130°C-135°C, the reaction time is 14h, and cooled;

[0042] (2) Dissolve the product of step (1) in dichloromethane (the volume of dichloromethane is 1 times the weight of D, L-lactide), and slowly add it dropwise to ether (the volume of anhydrous ether is D , 10 times the weight of L-lactide), stirred, precipitated at a temperature below 10°C, and filt...

Embodiment 3

[0046] A preparation method of a novel nano-micelle medicinal material:

[0047] (1) Put polyethylene glycol monomethyl ether with a molecular weight of 1800-2200 in an oil bath, heat to 110°C-115°C, vacuumize for 8 hours, and then add the catalyst stannous salt compound dissolved in toluene under nitrogen protection (dissolve 1g of stannous salt with 0.5mL of toluene), then add D, L-lactide (the weight ratio of polyethylene glycol monomethyl ether to D, L-lactide is 58:56), the The amount of stannous salt compound is 4‰-5‰ of the weight of reactant D, L-lactide, and the reaction is carried out by heating under the protection of nitrogen. The reaction temperature is 130°C-135°C, the reaction time is 16h, and then cooled;

[0048] (2) Dissolve the product of step (1) in dichloromethane (the volume of dichloromethane is 1.2 times the weight of D, L-lactide), and slowly add it dropwise to ether (the volume of anhydrous ether is D , 15 times the weight of L-lactide), stirred, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

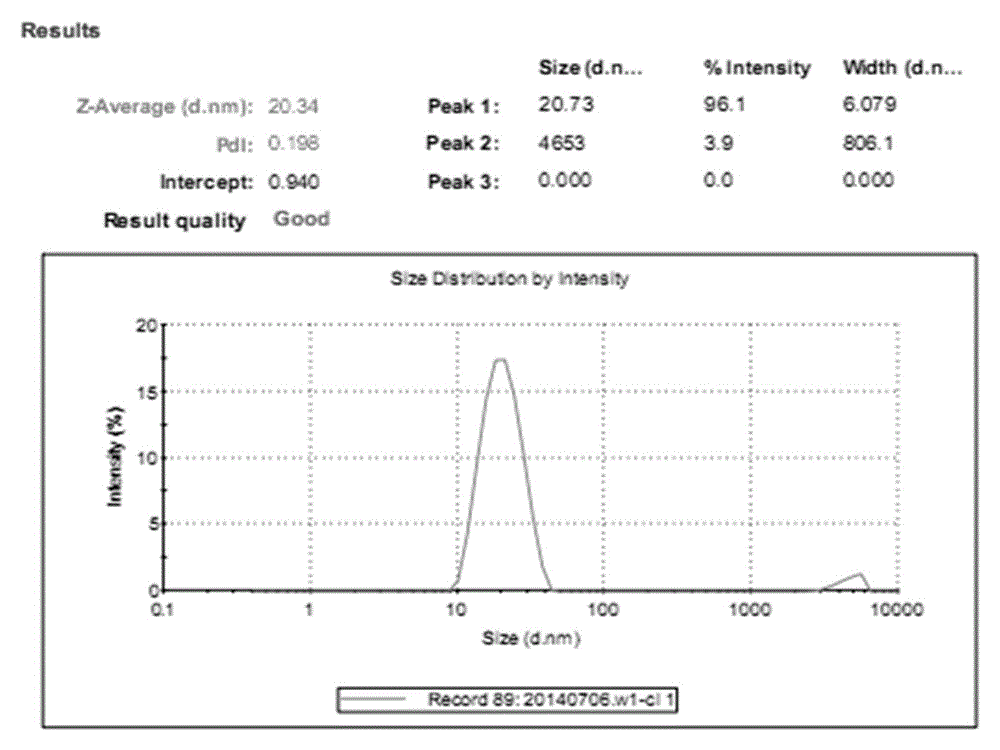

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com