Preparation of polyethyleneimine AKD new type sizing agent

A polyethyleneimine, sizing agent technology, applied in the direction of adding water repellent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Embodiment 1: the optimal condition of PEI emulsified AKD emulsion

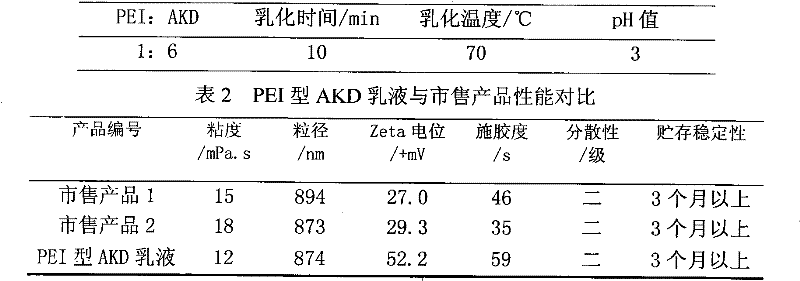

[0010] Under the optimal emulsification conditions, the particle size and Zeta potential of the emulsified AKD emulsion are 1184nm and 52.1mV respectively, and the sizing degree of hand-made tablets can reach 68s; the particle size of the pilot emulsion is 874nm, and the potential is 52.2mV. The optimum emulsification conditions are shown in Table 1.

Embodiment 2

[0011] Embodiment 2: PEI type AKD emulsion and commercially available product performance contrast

[0012] Pilot production of polyethyleneimine type AKD emulsion, the output is half a ton. The resulting product is a white emulsion, and the results are shown in Table 2. High-pressure homogenizing equipment is used in the pilot production process, so the particle size of the obtained emulsion is smaller than that of the product produced in the laboratory. The polyethyleneimine emulsified AKD sizing agent has a small particle size, and the Zeta potential of the colloidal particles is higher than that of the commercially available sizing agent, which makes it easier to stay on the fiber. This is also the reason for the fast curing rate of the PEI emulsified sizing agent The reason for the high degree of sizing.

[0013] The optimal condition of table 1 PEI emulsified AKD emulsion

[0014]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com