Method of producing petroleum sulfonate by micro reaction system grading sulfonation

A petroleum sulfonate and micro-reaction technology, which is applied in the fields of sulfonate preparation, chemical instruments and methods, organic chemistry, etc., can solve the problem of low ratio of monosulfonate and double sulfonate, insufficient heat transfer capacity of single-stage micro-reaction system, single The problem of high temperature of the outlet material of the micro-reactor is eliminated, and the effect of low temperature, high process efficiency and safety is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

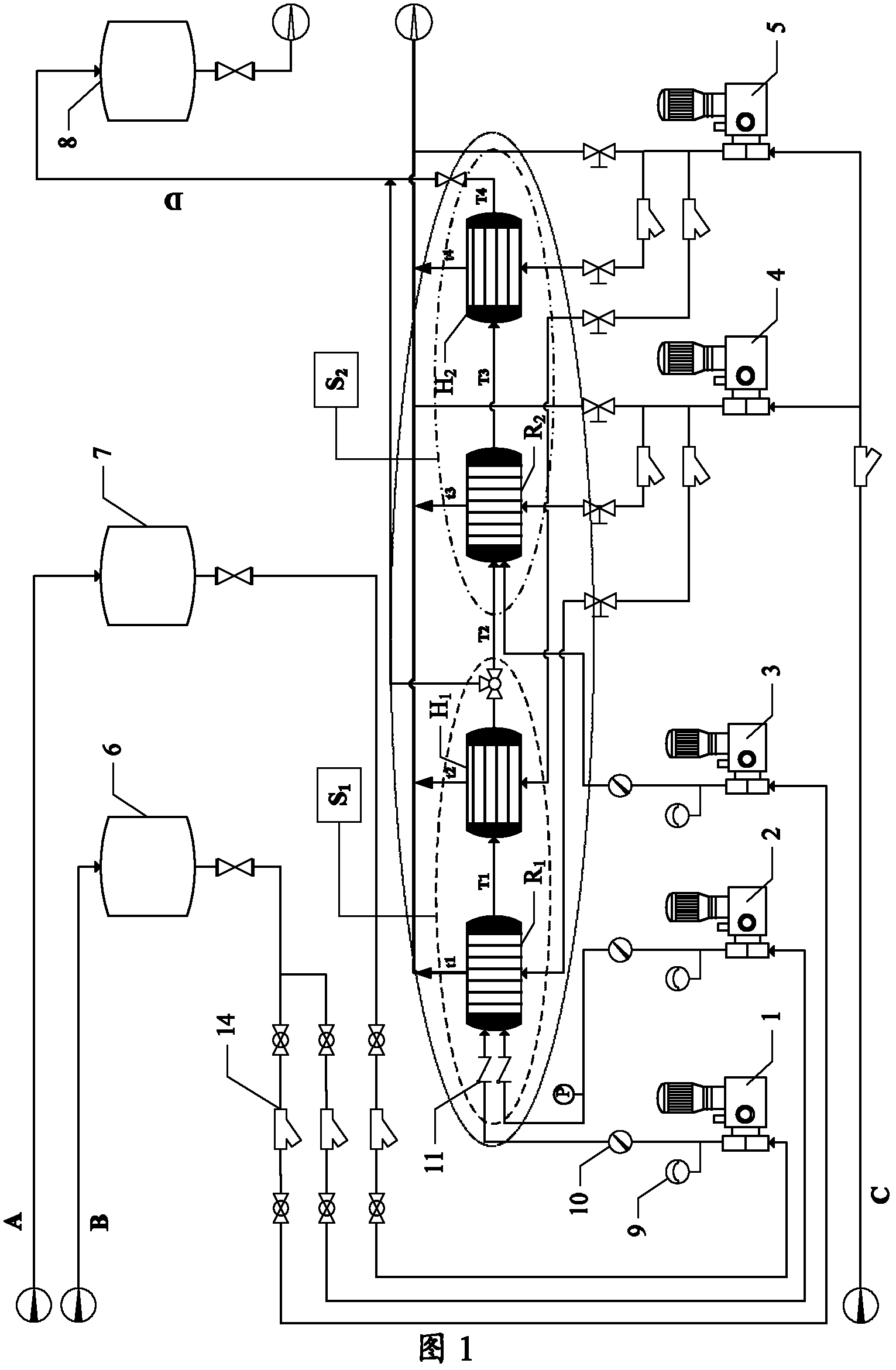

Method used

Image

Examples

Embodiment 1

[0027] 25wt.% of sulfonating agent SO 3 About 200kg of the solution is poured into the storage tank 8 for subsequent use; the light distillate oil with a boiling range of 200-450°C and the heavy distillate oil with a boiling range of 260-580°C and dichloroethane solvent are in a mass ratio of 1: 3: The ratio of 4, that is, about 300kg of sulfonated oil with a concentration of 50wt.% is put into the storage tank 6 for subsequent use. The sulfonated oil is continuously delivered to the first-stage microchannel reactor R at a flow rate of 90-95L / h through the metering pump 1 1 In this process, a part of the sulfonating agent is continuously delivered to the first-stage microchannel reactor R through the metering pump 2 at a flow rate of 12.4-32.1L / h 1 In the process, it is mixed with sulfonated oil and undergoes a primary sulfonation reaction, that is, the acid-oil ratio of the primary reaction is 0.085-0.225, and the liquid hourly space velocity in the primary reactor is 35000-...

Embodiment 2

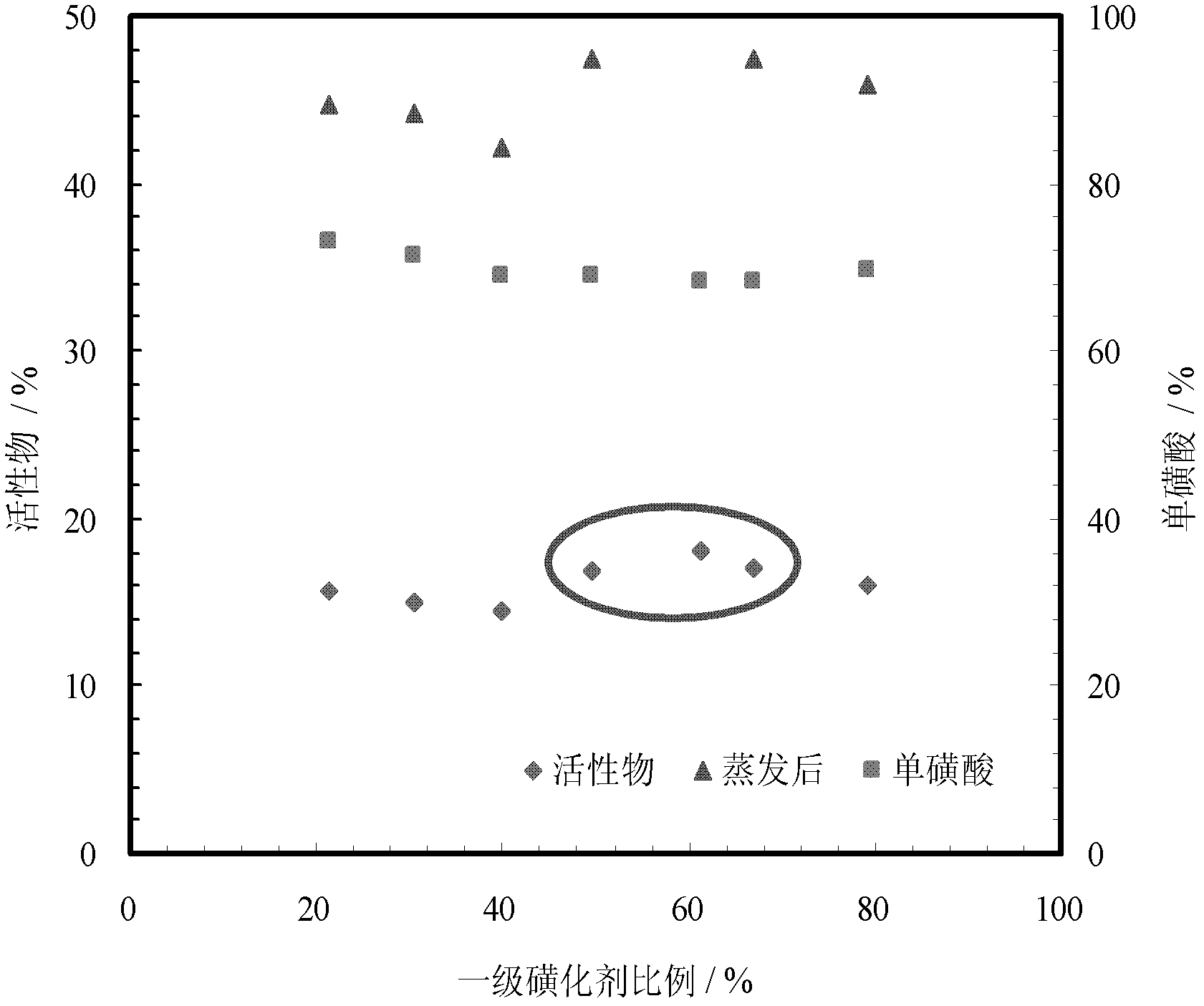

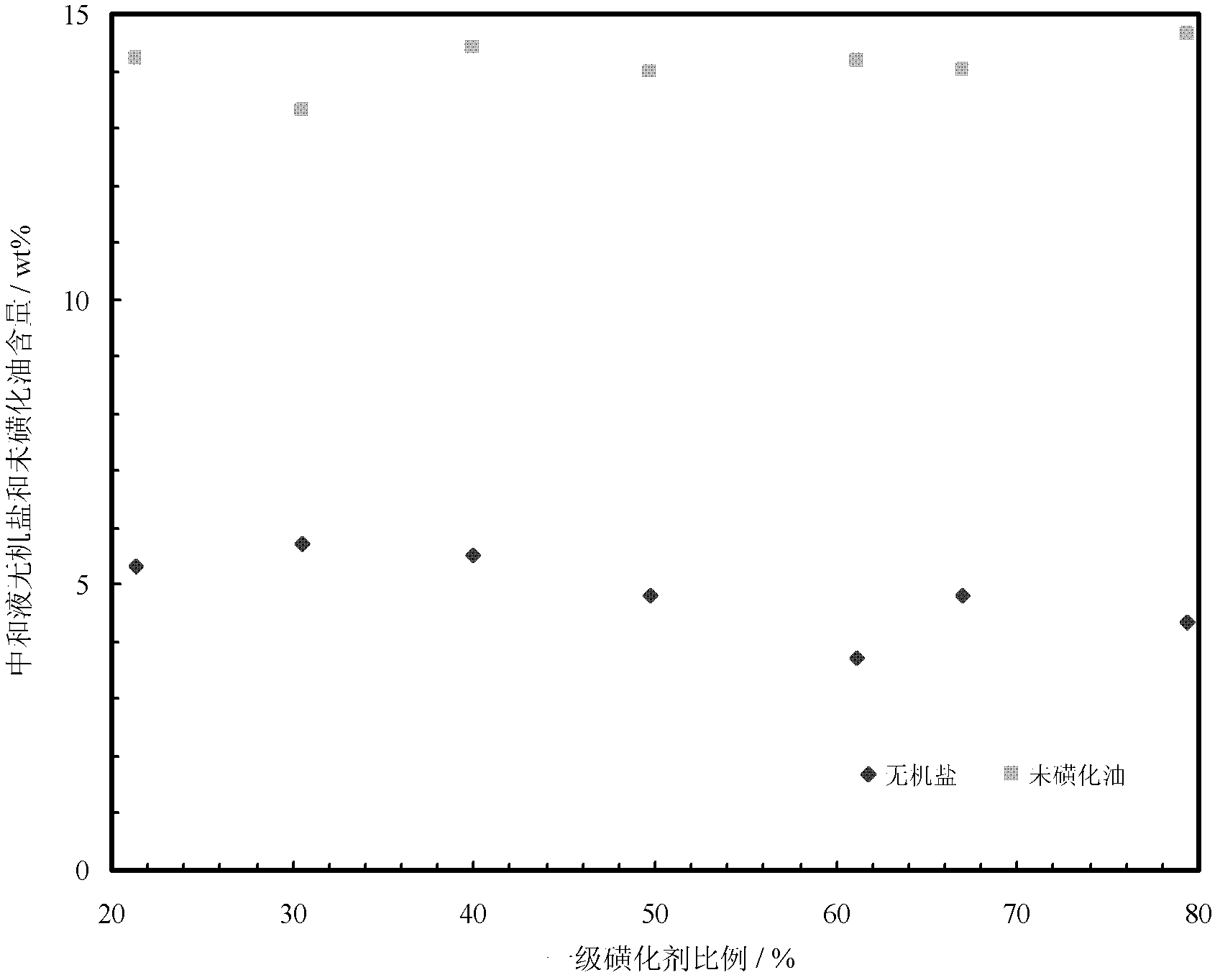

[0032] The reaction process flow is the same as in Example 1. The feed flow rate of the sulfonated oil is fixed, and the total flow rate of the sulfonating agent is changed to 37L / h and 45L / h respectively, that is, the total acid-oil ratio is 0.25 and 0.31, and the liquid sulfur trioxide sulfonating agent is in two stages. Under the distribution ratio of 50:50, 60:40 and 70:30 in the microchannel reactor, two-stage sulfonation was carried out to produce petroleum sulfonic acid.

[0033] Two different total acid-oil ratios are combined with the acid-oil ratio of 0.28 in Example 1, and the product components obtained under the three total ratios include active matter, monosulfonate, inorganic salt and unsulfonated oil and each group The sub-concentration is described by charts 4 and 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com