Efficient coating machine with replaceable roller

A coating machine and drum technology, which is applied in the forming of food, coating of food, and devices for making medicines into special physical or taking forms, etc. and equipment waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

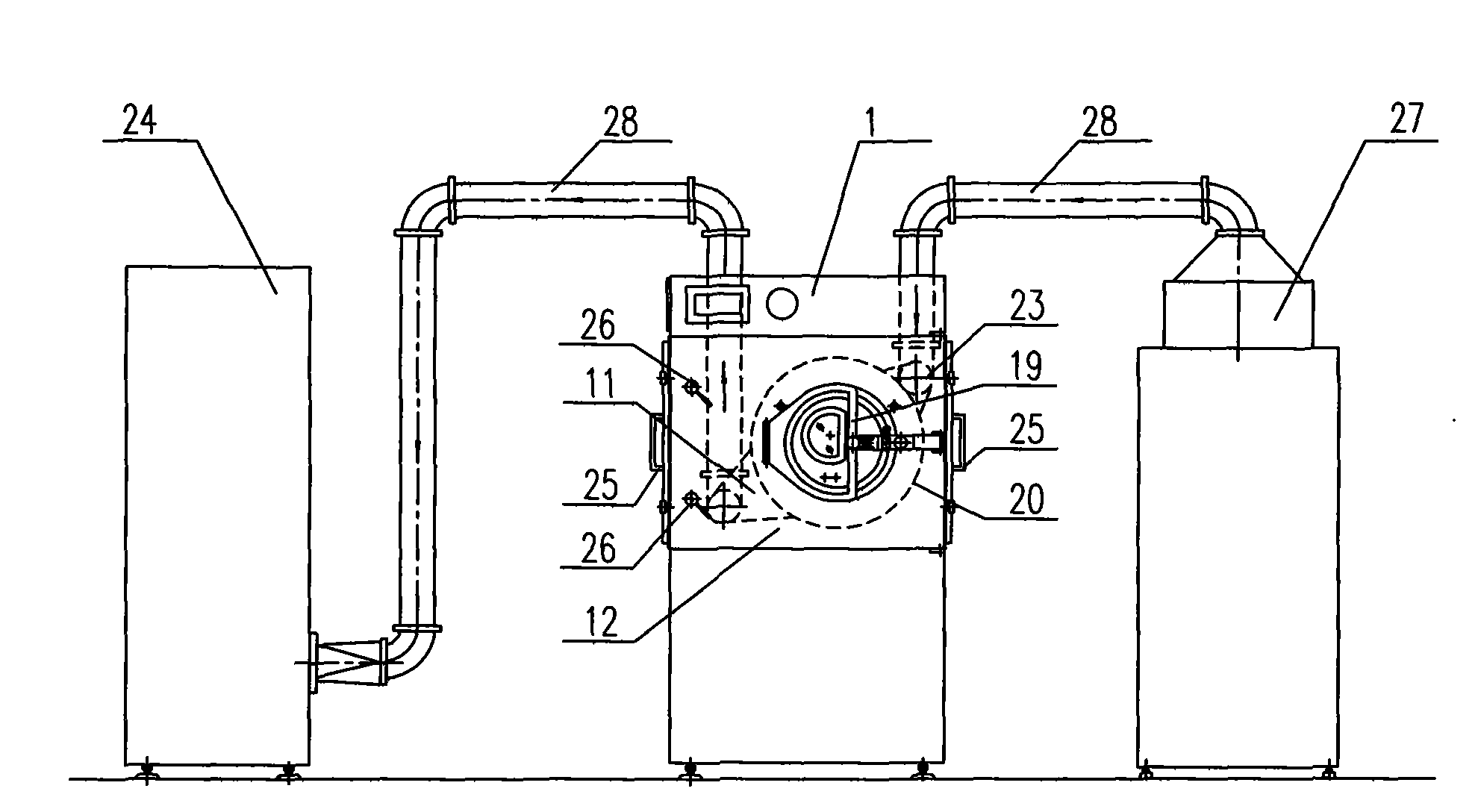

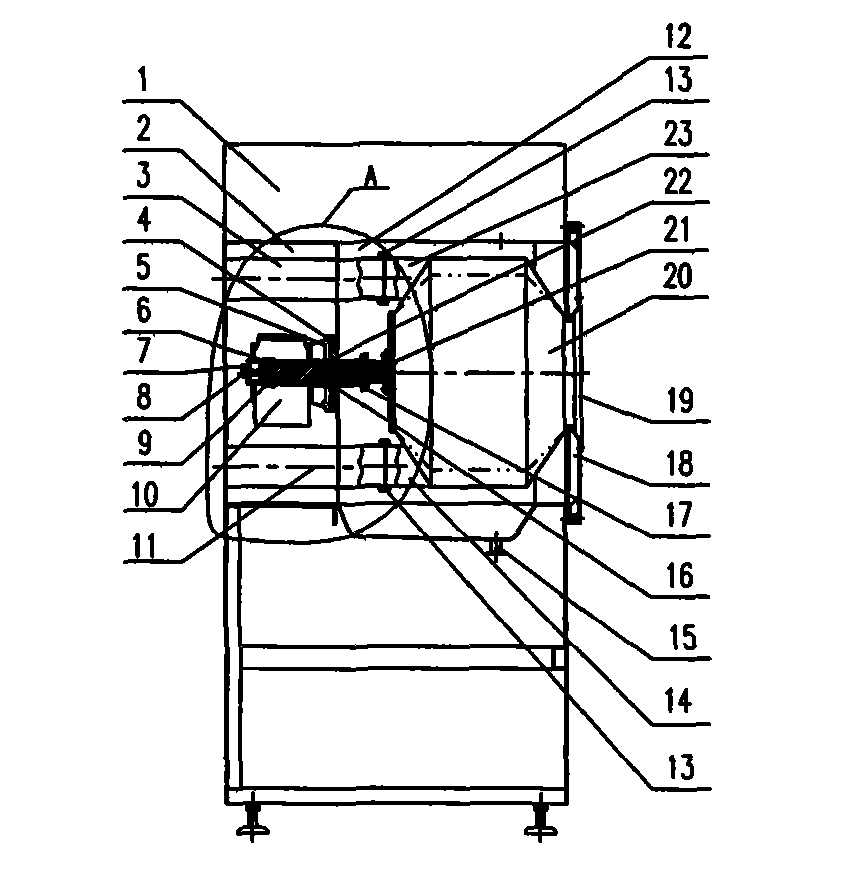

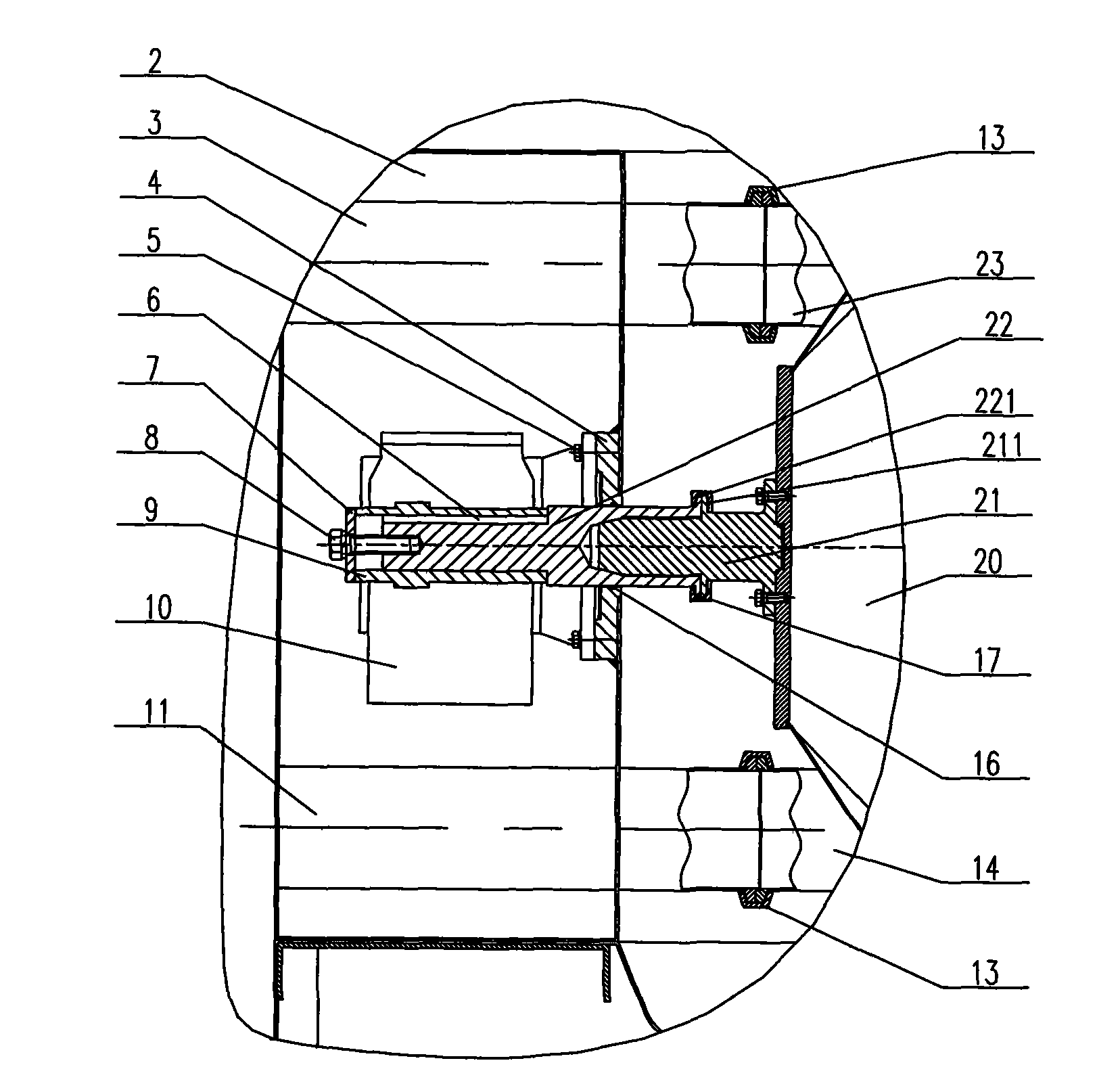

[0013] like figure 1 , figure 2 , image 3 The illustrated embodiment comprises a main frame 1, and the main frame 1 includes a front casing 12 for setting a coating drum 20 and a rear casing 2 for installing a transmission speed reducer 10 arranged in isolation from each other. The connecting shaft 22 on the hollow shaft 9 of 10 is connected with the main shaft 21 of the coating drum 20; the air inlet pipe connection port 3 and the air discharge pipe connection port 11 are also housed in the front box body 12, and the air inlet pipe connection port 3 and the exhaust pipe coupling port 11 are respectively connected with the air inlet funnel 23 and the air exhaust funnel 14 of the coating drum through the first fastener 13, and the joint end surface of the air inlet pipe coupling port 3 and the air inlet funnel 23 and the air exhaust The joint end surfaces of the pipe coupling port 11 and the air exhaust bucket 14 are all step joint surfaces, so as to improve the joint effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com