Novel method for environmentally and efficiently preparing polycarbosilane

A polycarbosilane and polysilane technology, which is applied in the field of preparation of organosilicon polymer precursors, can solve the problems of long PDMS production cycle and environmental pollution, and achieve the effects of shortening post-processing time, improving recycling rate, and being easy to clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

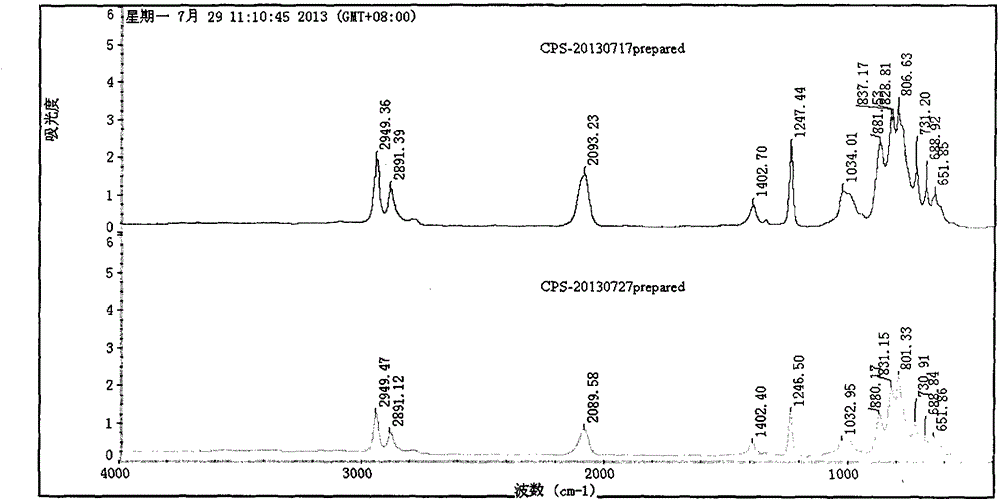

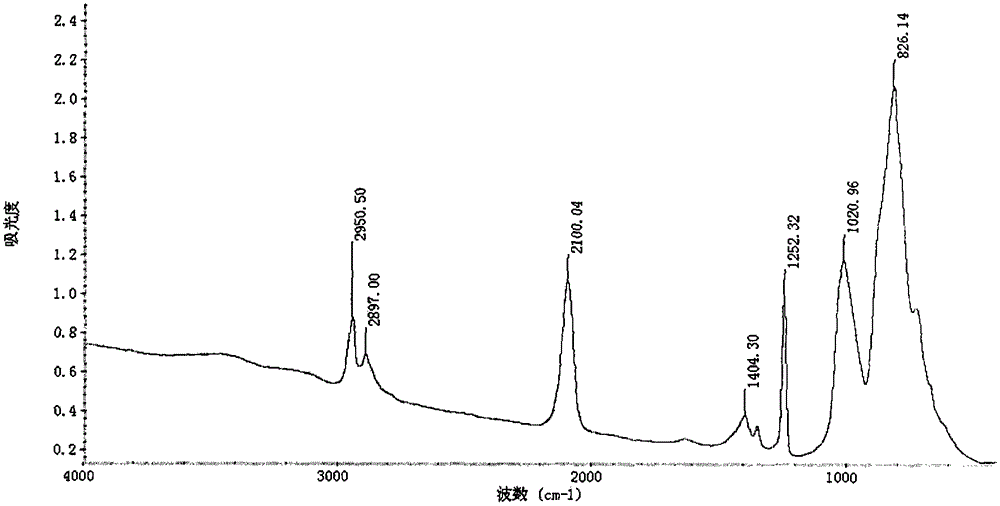

[0026] Under the protection of high-purity nitrogen, add refined and purified anhydrous xylene and metal sodium into a three-necked flask, heat until the metal sodium melts, start stirring, and then add dichlorodimethylsilane dropwise after the sodium is dispersed. The crude product of polydimethylsilane was obtained; after cooling to room temperature, the solvent xylene was removed by suction filtration, and the excess sodium was washed with ethanol;

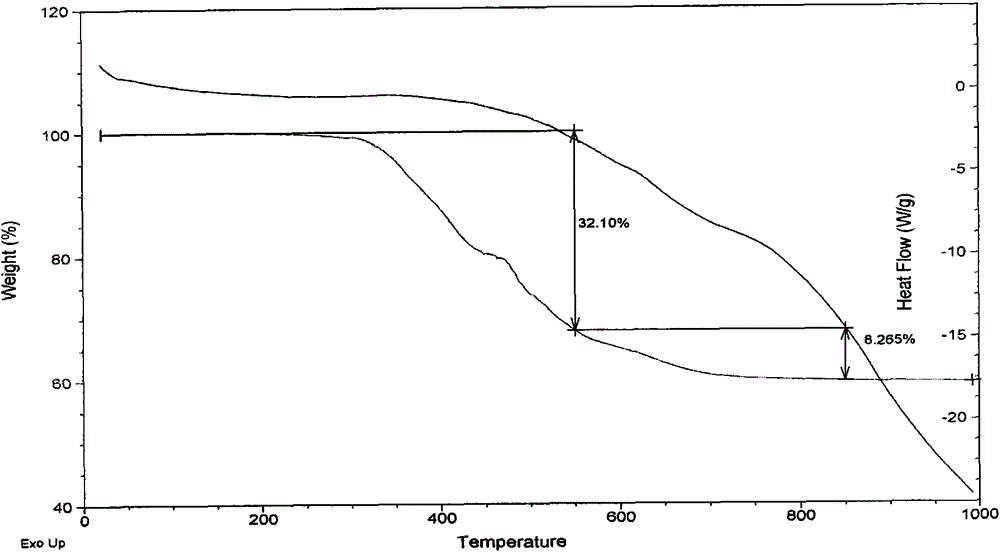

[0027] Add the crude PDMS product into a three-necked flask, pump it with high-purity nitrogen after vacuuming, start stirring and heating, and raise the temperature to different temperature ranges to collect ethanol and xylene respectively. When the temperature of the system rose to 320°C, PDMS began to break and crack, and white vapor appeared in the flask. The vapor was cooled by the condenser tube and collected in the receiving bottle. After the system temperature reaches 420°C, the white vapor decreases, and the N 2 The f...

Embodiment 2

[0030] Under the protection of high-purity argon, add refined and purified anhydrous toluene and metal sodium into the three-necked flask, heat until the metal sodium melts, start stirring, and then add dichlorodimethylsilane dropwise after the sodium is dispersed. The crude product of polydimethylsilane was obtained; after cooling to room temperature, the solvent toluene was removed by suction filtration, and excess sodium was washed with methanol;

[0031] Put the crude PDMS product into a three-necked flask, vacuumize and pass high-purity argon, start stirring and heating, and raise the temperature to different temperature ranges to collect methanol and toluene respectively. When the temperature of the system rose to 320°C, PDMS began to break and crack, and white vapor appeared in the flask. The vapor was cooled by the condenser tube and collected in the receiving bottle. After the system temperature reaches 420°C, the white vapor decreases, and the flow rate of argon gas ...

Embodiment 3

[0034] Under the protection of high-purity nitrogen, add refined and purified anhydrous xylene and metal sodium into a three-necked flask, heat until the metal sodium melts, start stirring, and then add dichlorodimethylsilane dropwise after the sodium is dispersed. The crude product of polydimethylsilane was obtained; after cooling to room temperature, the solvent xylene was removed by suction filtration, and the excess sodium was washed with ethanol;

[0035]Add the crude PDMS product into a three-necked flask, pump it with high-purity nitrogen after vacuuming, start stirring and heating, and raise the temperature to different temperature ranges to collect ethanol and xylene respectively. When the temperature of the system rose to 320°C, PDMS began to break and crack, and white vapor appeared in the flask. The vapor was cooled by the condenser tube and collected in the receiving bottle. After the system temperature reaches 420°C, the white vapor decreases, and the N 2 The fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com