Purification method of polyarylether by using water and alcohol mixed solvent

A mixed solvent and polyarylether technology, which is applied in the field of purified polyarylether materials, can solve problems such as increased product costs, easy corrosion of acidic liquids, and large equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

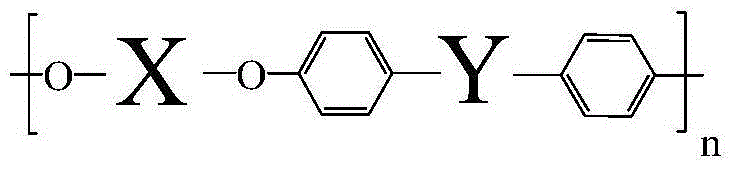

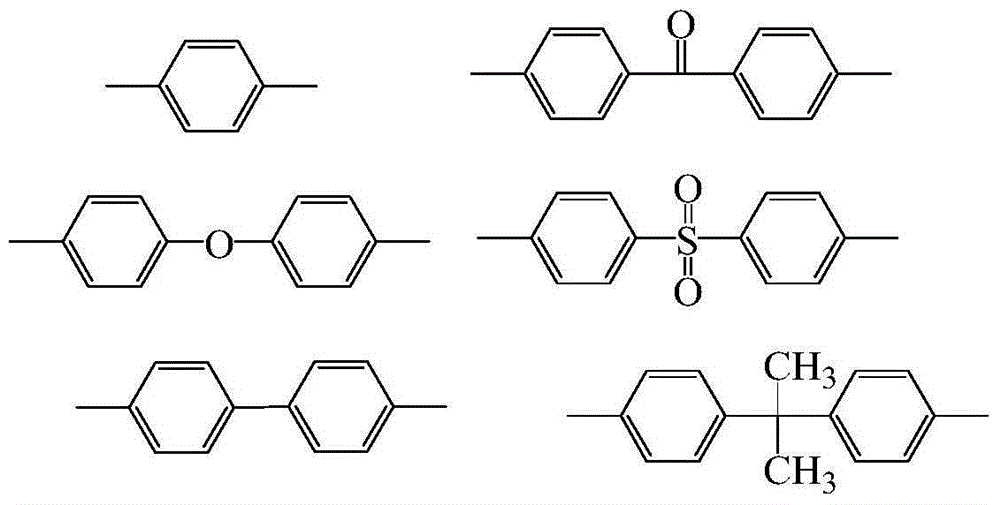

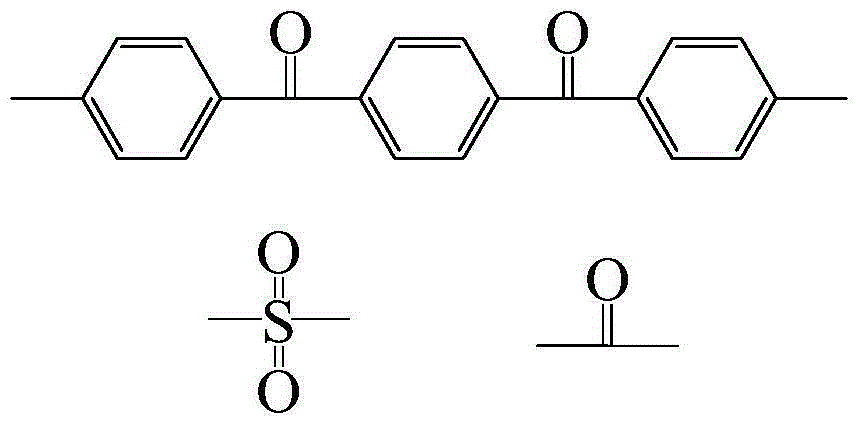

Method used

Image

Examples

Embodiment 1

[0023] PEEK 2.0 g of the powder and 50 g of isopropanol aqueous solution with a mass concentration of 1% were thoroughly mixed, put into a 100 mL hydrothermal synthesis reactor, and heated at 150° C. for 30 min. After cooling to room temperature and filtering, the polyether ether ketone powder was dried at 160° C. for 4 hours to obtain a polyether ether ketone resin with low metal ion content. The data are shown in Table 1.

[0024] Table 1: Metal ion content data before and after treatment of the product of Example 1

[0025]

Embodiment 2

[0027] PEEK 2.0 g of the powder and 50 g of n-butanol aqueous solution with a mass concentration of 1% were thoroughly mixed, put into a 100 mL hydrothermal synthesis reactor, and heated at 150° C. for 30 min. After cooling to room temperature and filtering, the polyether ether ketone powder was dried at 160° C. for 4 hours to obtain a polyether ether ketone resin with low metal ion content. The data are shown in Table 2.

[0028] Table 2: Metal ion content data before and after treatment of the product of Example 2

[0029]

Embodiment 3

[0031] PEEK 2.0g of the powder was fully mixed with 50g of isopropanol and n-butanol aqueous solution with a mass concentration of 1%, the mass ratio of isopropanol and n-butanol was 1:1, put into a 100mL hydrothermal synthesis reactor, and heated at 150°C for 30min. After cooling to room temperature and filtering, the polyetheretherketone powder was dried at 160° C. for 4 hours to obtain a polyetheretherketone resin with low metal ion content. The data are shown in Table 3.

[0032] Table 3: Metal ion content data before and after treatment of the product of Example 3

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com