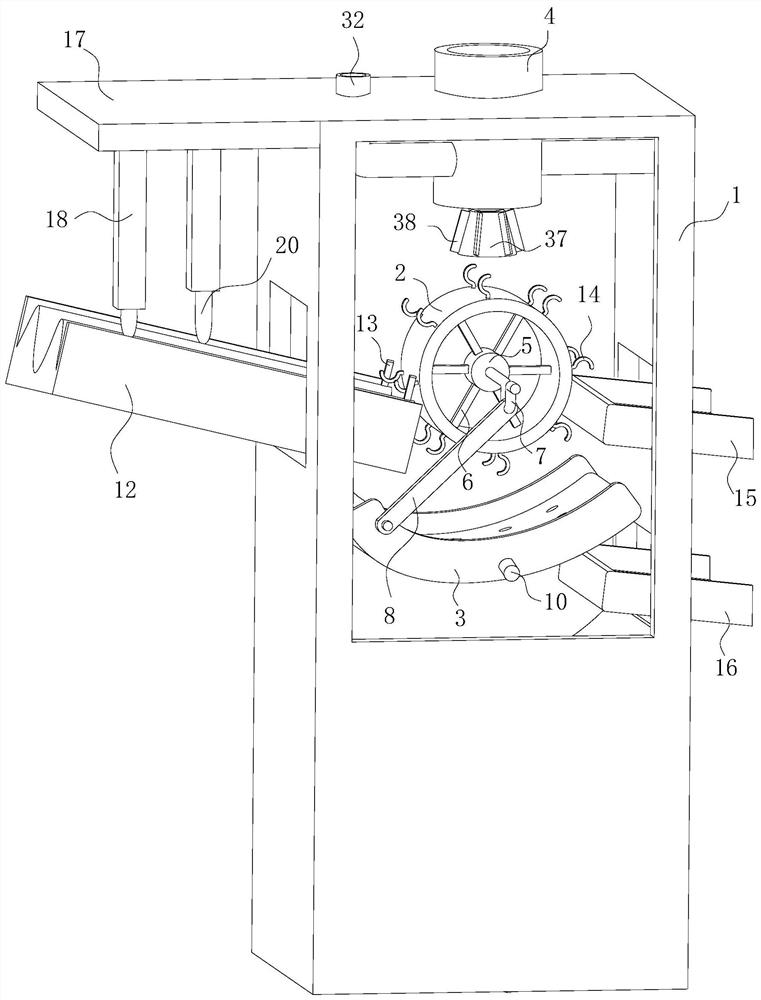

Full-automatic numerical control shot blasting machine

A kind of shot blasting machine, fully automatic technology, applied in the direction of abrasive jet machine tool, used abrasive processing device, explosion generating device, etc., can solve the problem that it takes a long time to process steel bars, increase energy consumption and production cost, and waste human resources And other problems, to achieve the effect of not easy to shoot dead angle, increase the shot blasting area, and increase the probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

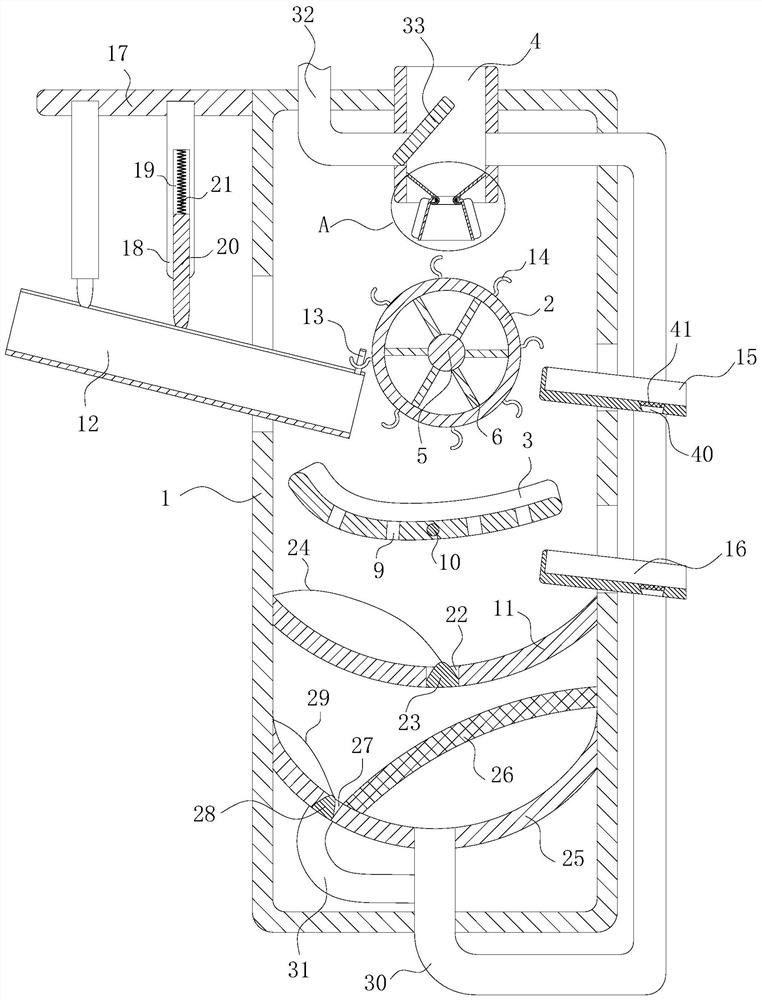

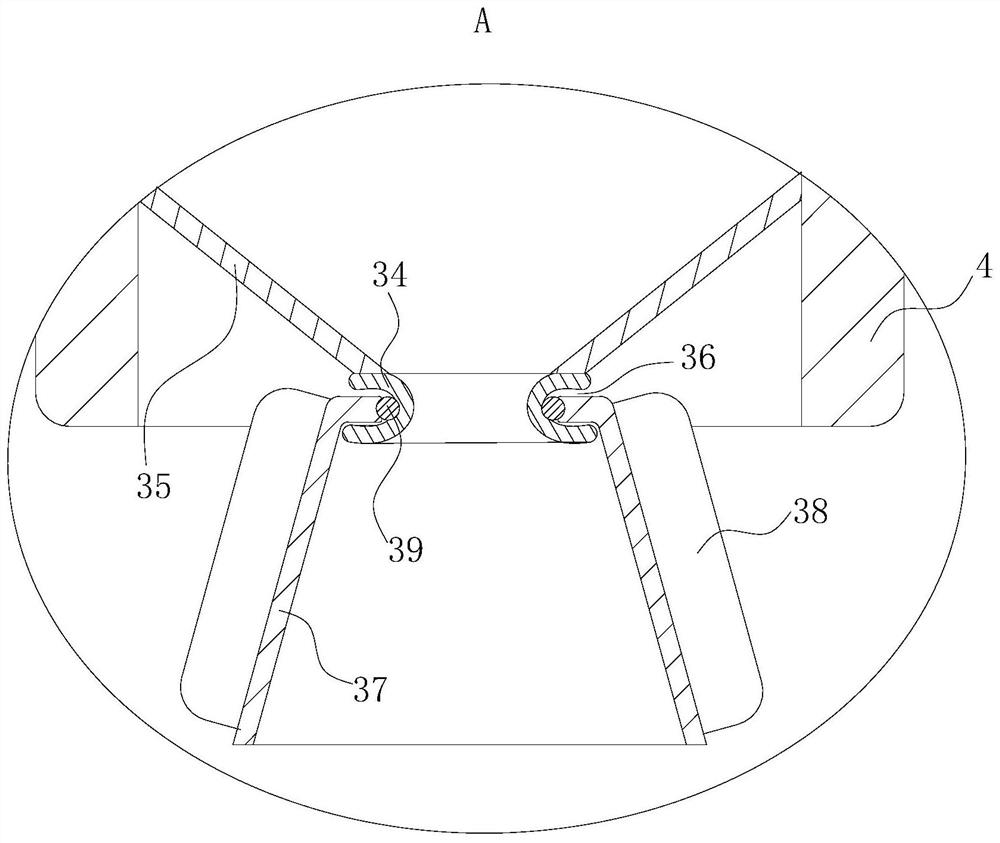

[0023] As an embodiment of the present invention, the upper left end of the housing 1 is fixedly connected with a mounting plate 17, and the lower surface of the mounting plate 17 is provided with a chute, and the number of the chute is two, and the two chute are arranged left and right. ; In the chute, slide bars 18 are slidably connected. In the initial state, two slide bars 18 are located at the front end and the rear end of the chute respectively, and the slide bars 18 are fixedly connected with the front and rear side walls of the chute respectively. There is an electric telescopic rod, which drives two sliding rods 18 to move toward each other when the electric telescopic rod moves; the inside of the lower end of the sliding rod 18 is provided with a sliding groove 19, and a sliding rod 20 is slidably connected in the sliding groove 19. The lower end of the sliding rod 20 is a tapered design, and a spring 21 is fixedly connected between the sliding rod 20 and the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com