Patents

Literature

52results about How to "Improve shot blasting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

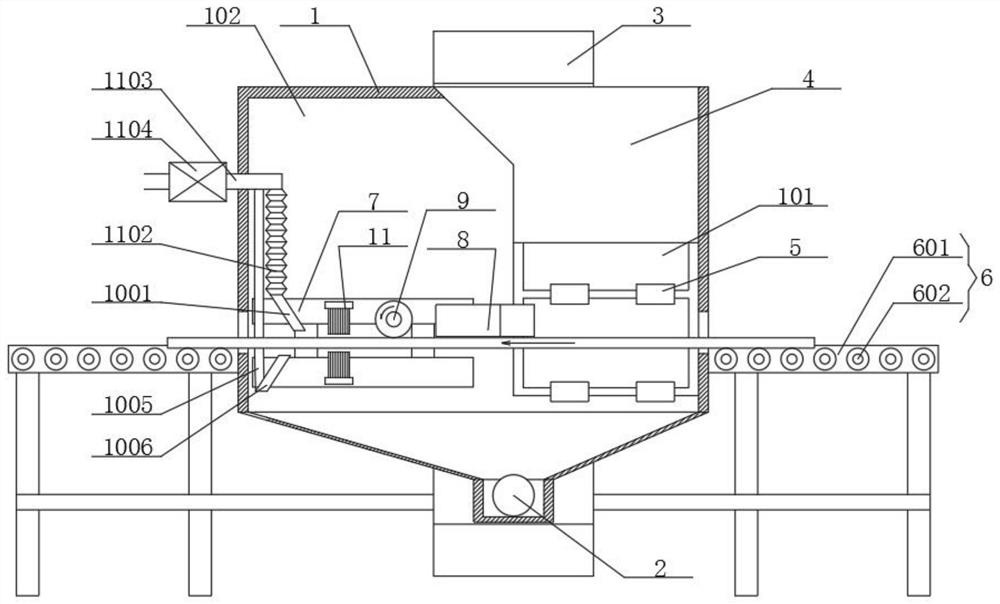

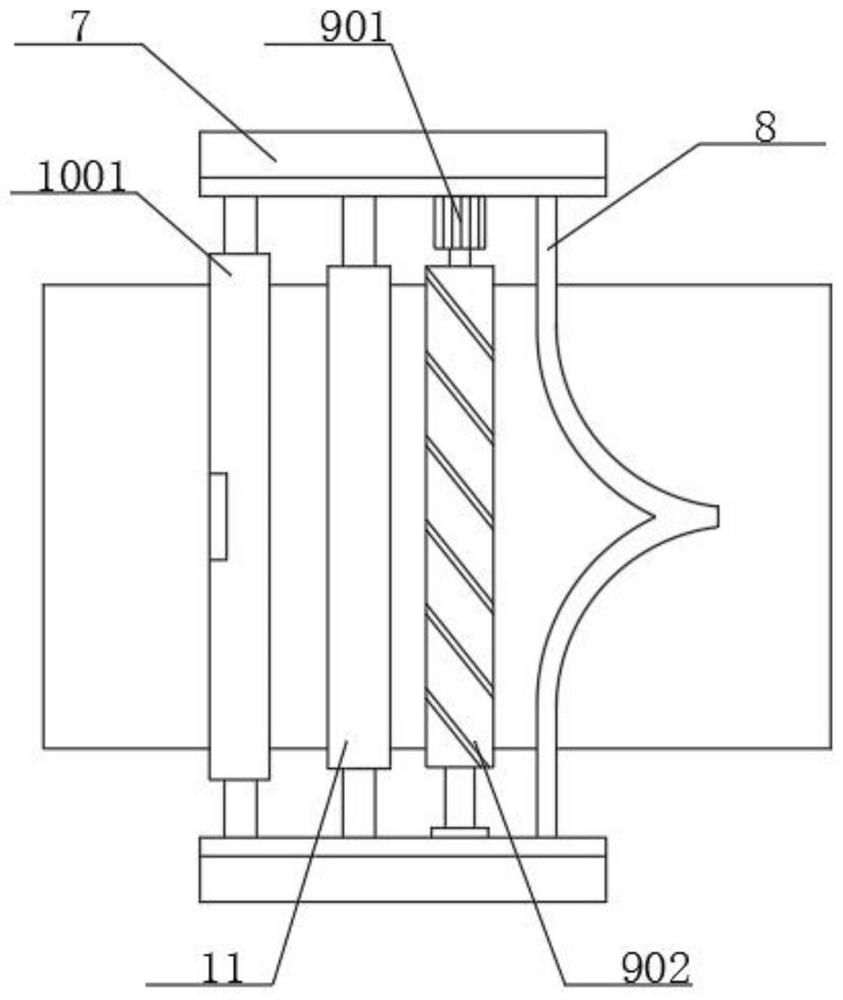

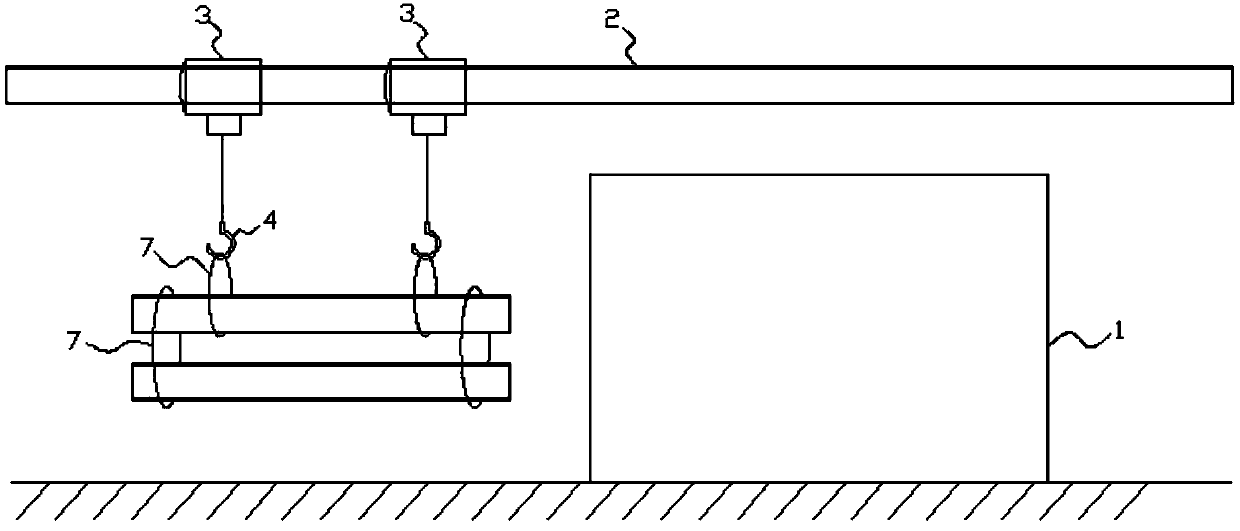

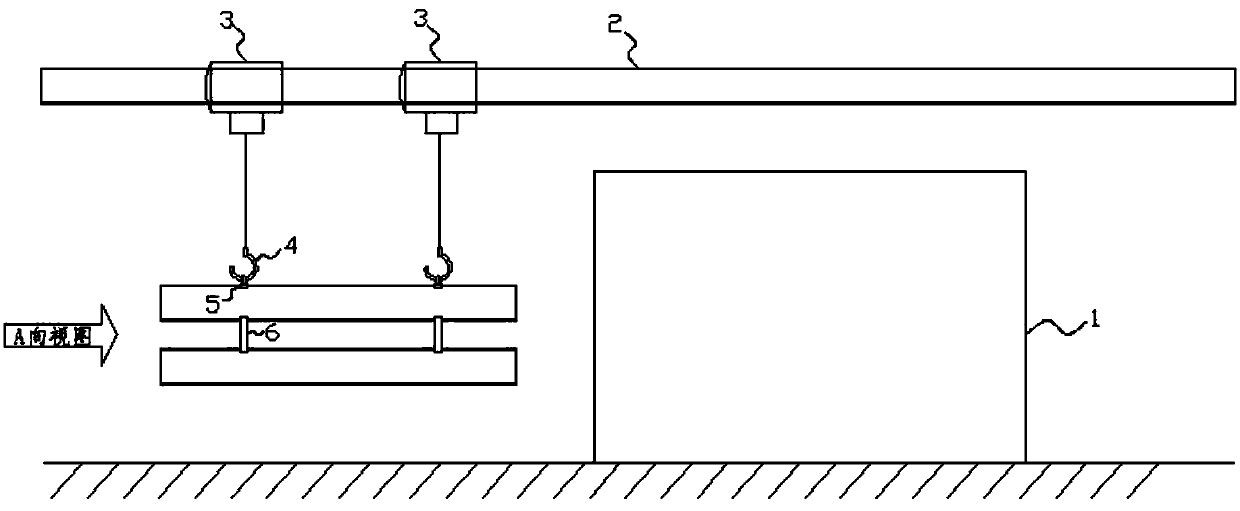

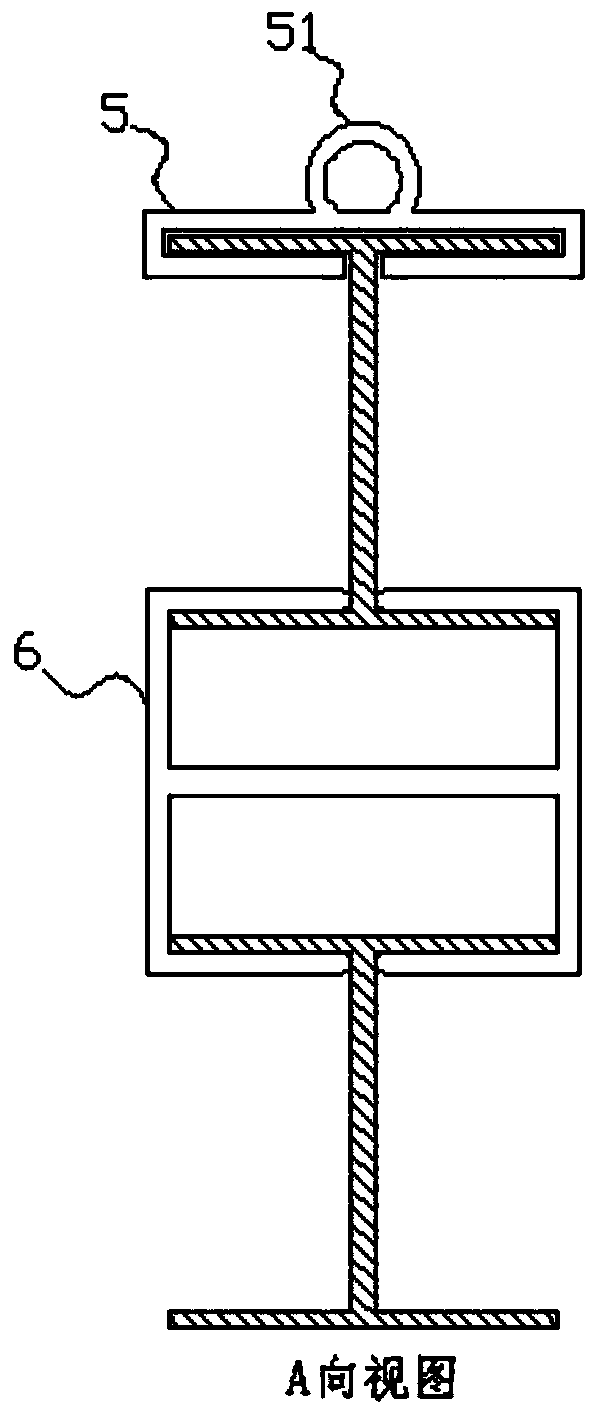

Box body type workpiece shot blasting cleaning device for upper mobile material conveying

InactiveCN104354115AEliminate the drudgery of manual laborShorten the timeAbrasive feedersAbrasive machine appurtenancesManipulatorSand separator

The invention discloses a box body type workpiece shot blasting cleaning device for upper mobile material conveying. The box body type workpiece shot blasting cleaning device comprises a shot blasting chamber, shot blasters mounted on the shot blasting chamber, a shot and sand circulating system matched with the shot blasters and a shot and sand separator, wherein a workpiece inlet is formed in one side surface of the shot blasting chamber; the shot blasting cleaning device further comprises material conveying roller ways arranged at one side of the workpiece inlet of the shot blasting chamber and material feeding manipulators; each material feeding manipulator comprises a stander; a rail and a power trolley matched with the rail are arranged on the top of the stander; the direction of the rail is perpendicular to the material conveying roller ways; a lifting hook is perpendicularly mounted on the power trolley; the lower end of the lifting hook is opposite to the workpiece inlet of the shot blasting chamber; a rotary workbench is arranged in the shot blasting chamber; a clamp is arranged on the rotary workbench. The box body type workpiece shot blasting cleaning device is used for achieving multi-orientation and high-efficiency shot blasting treatment of a box body; the possibility of cleaning dead corners is reduced to minimum; the box body type workpiece shot blasting cleaning device is low in overall manufacturing cost, easy to operate, convenient to maintain and good in use effect.

Owner:UNIV OF JINAN

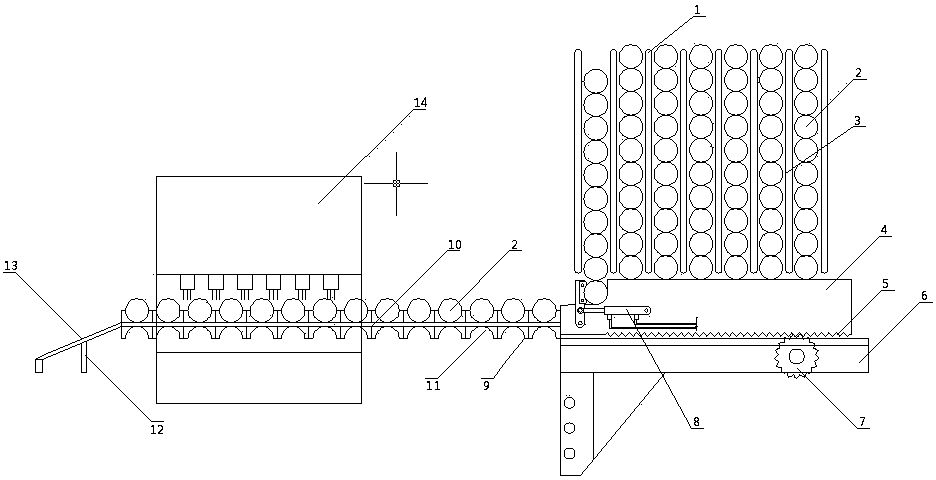

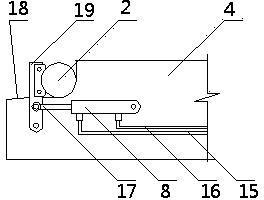

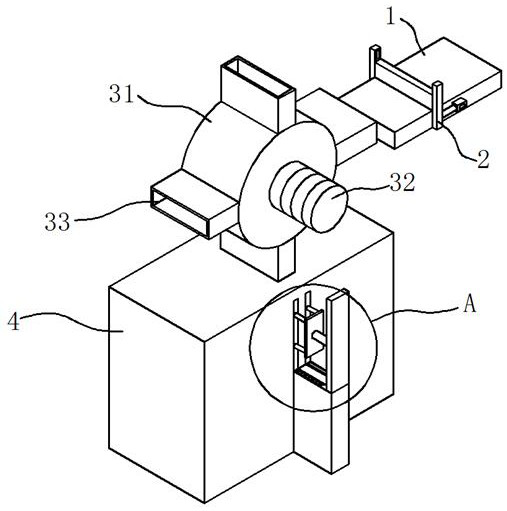

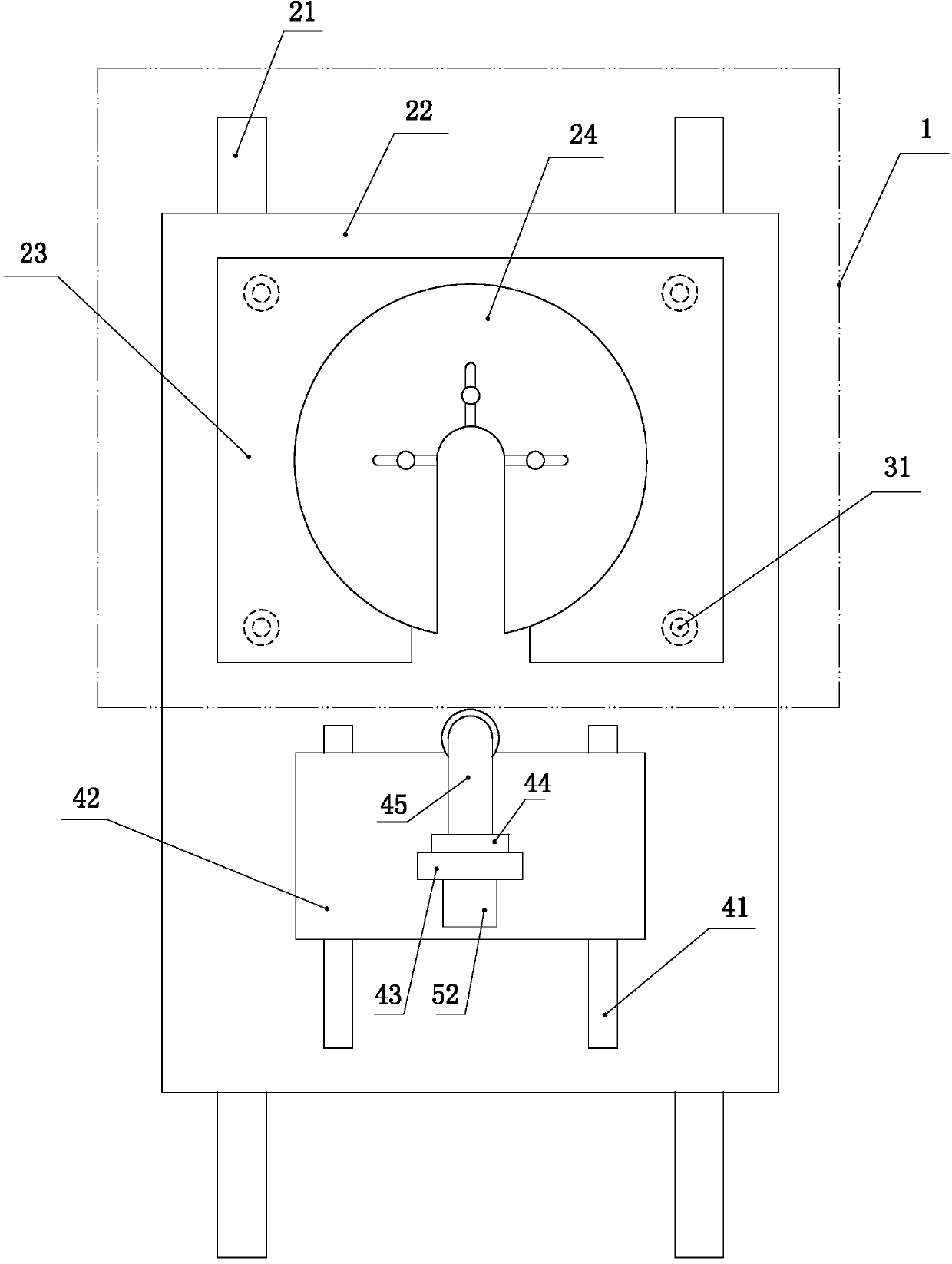

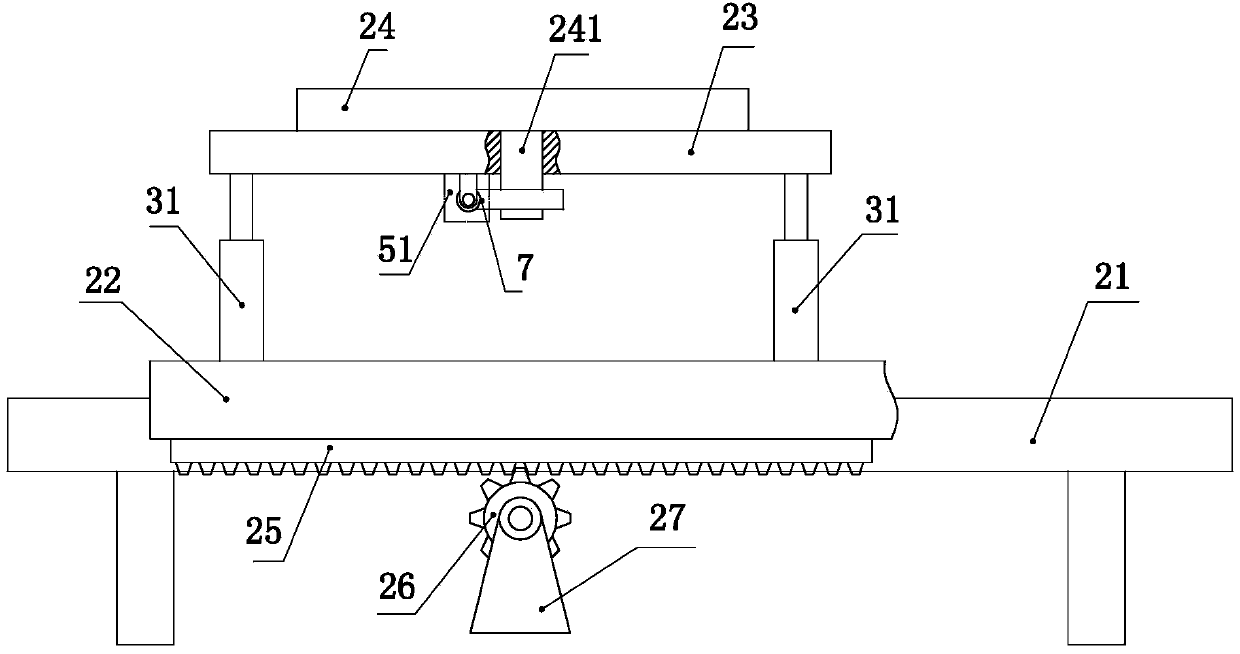

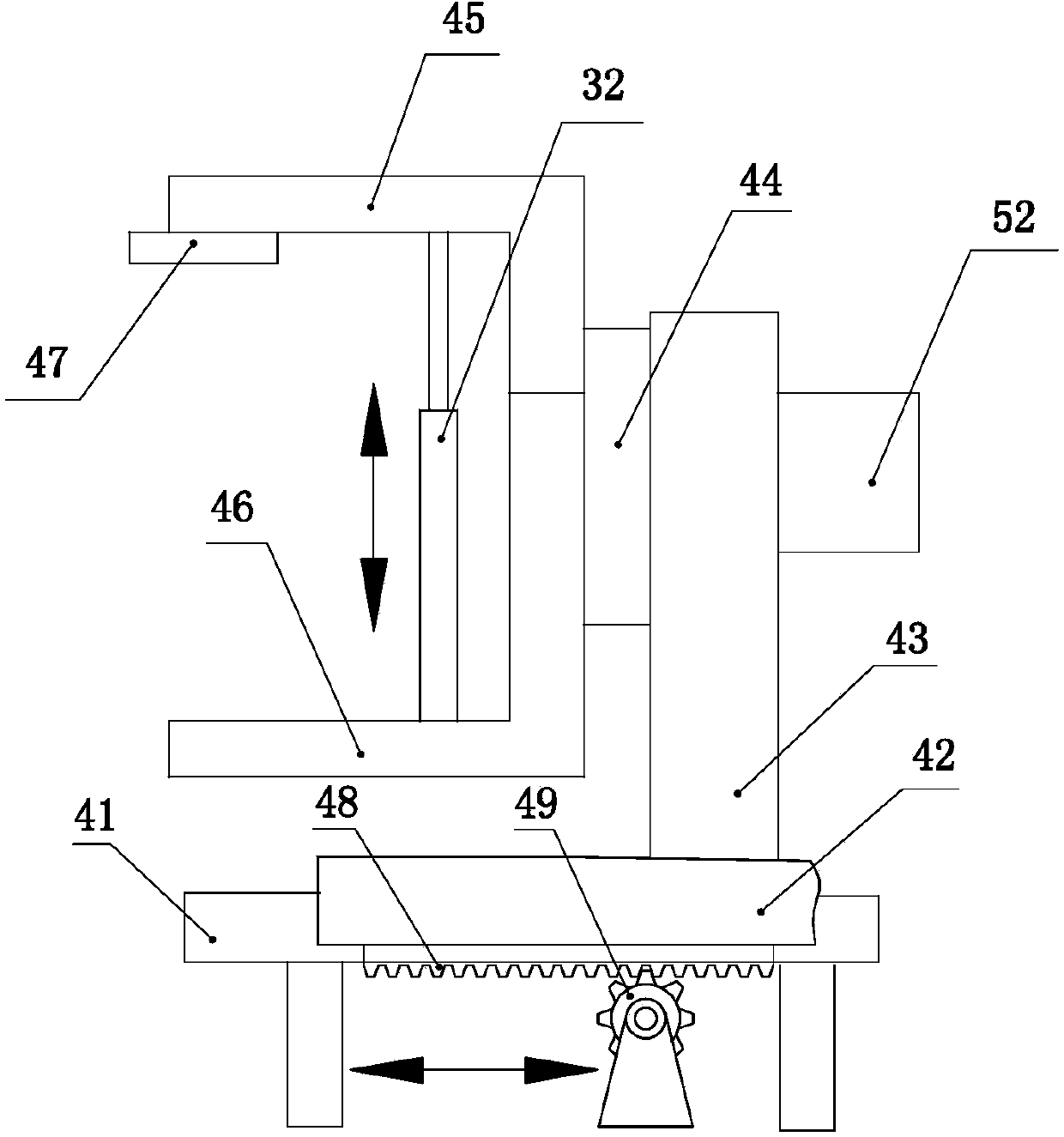

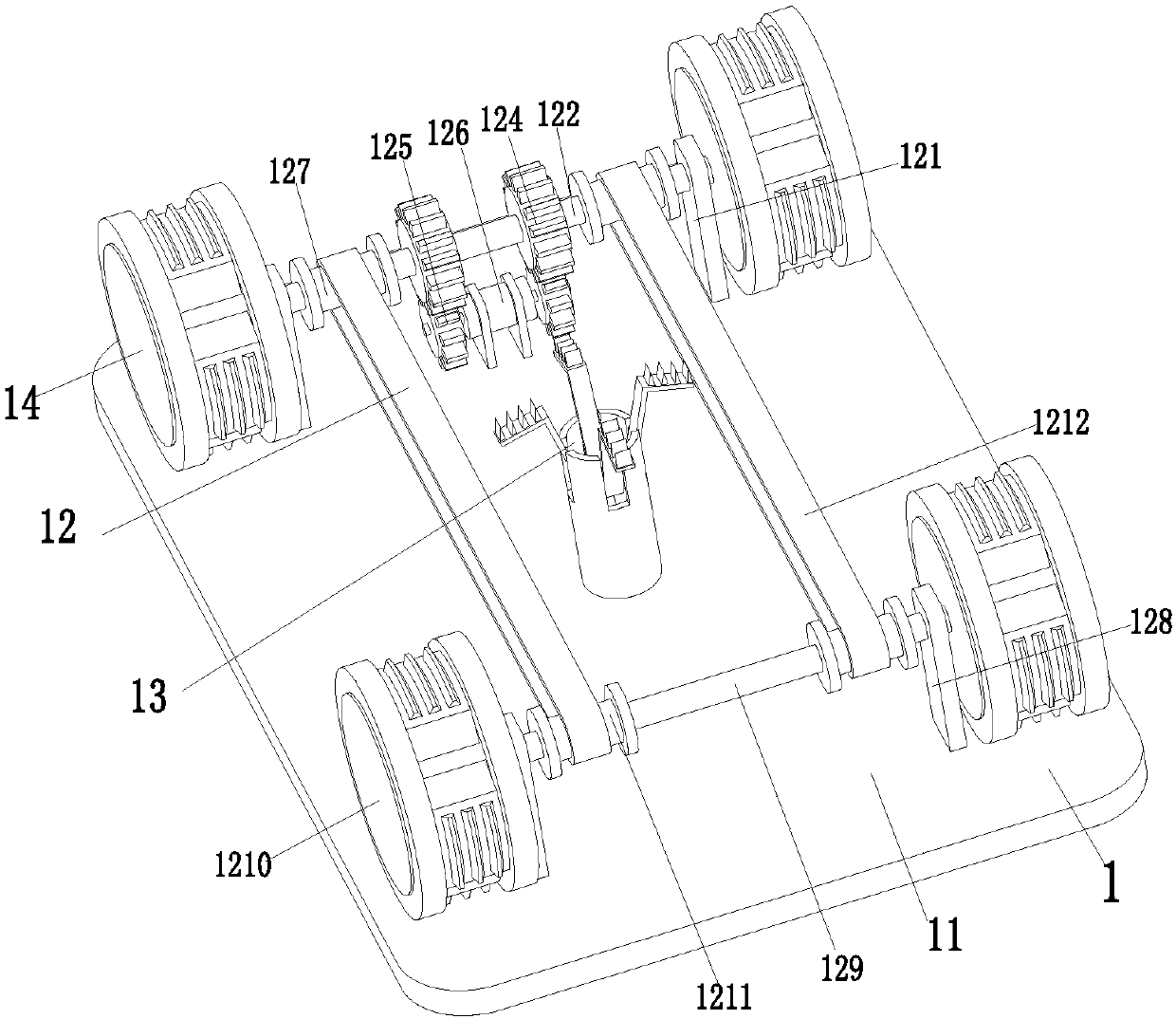

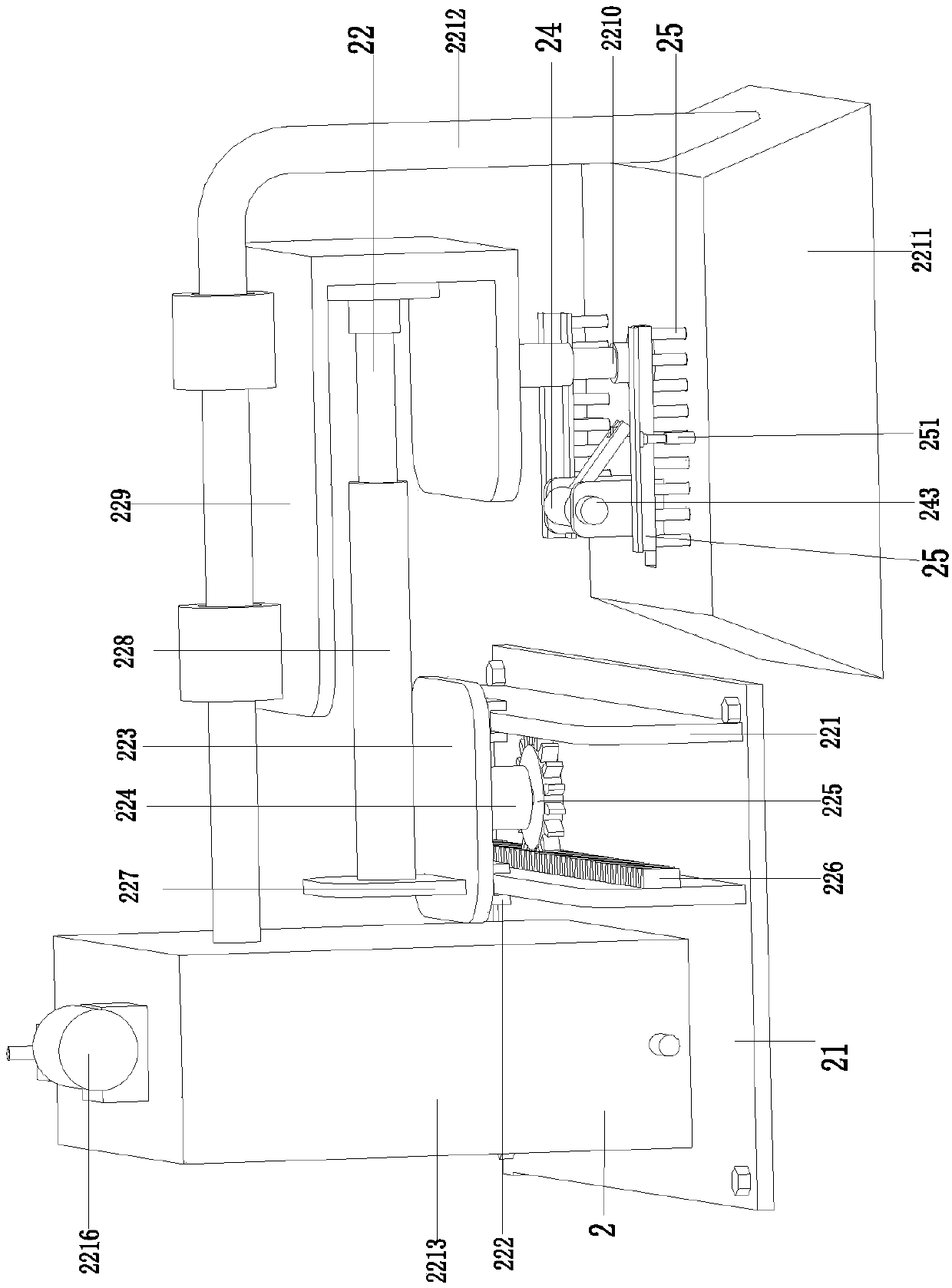

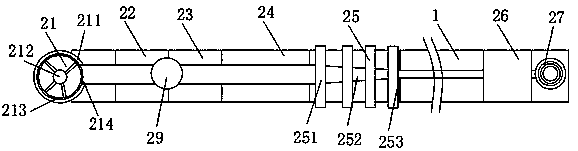

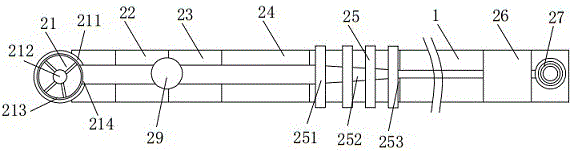

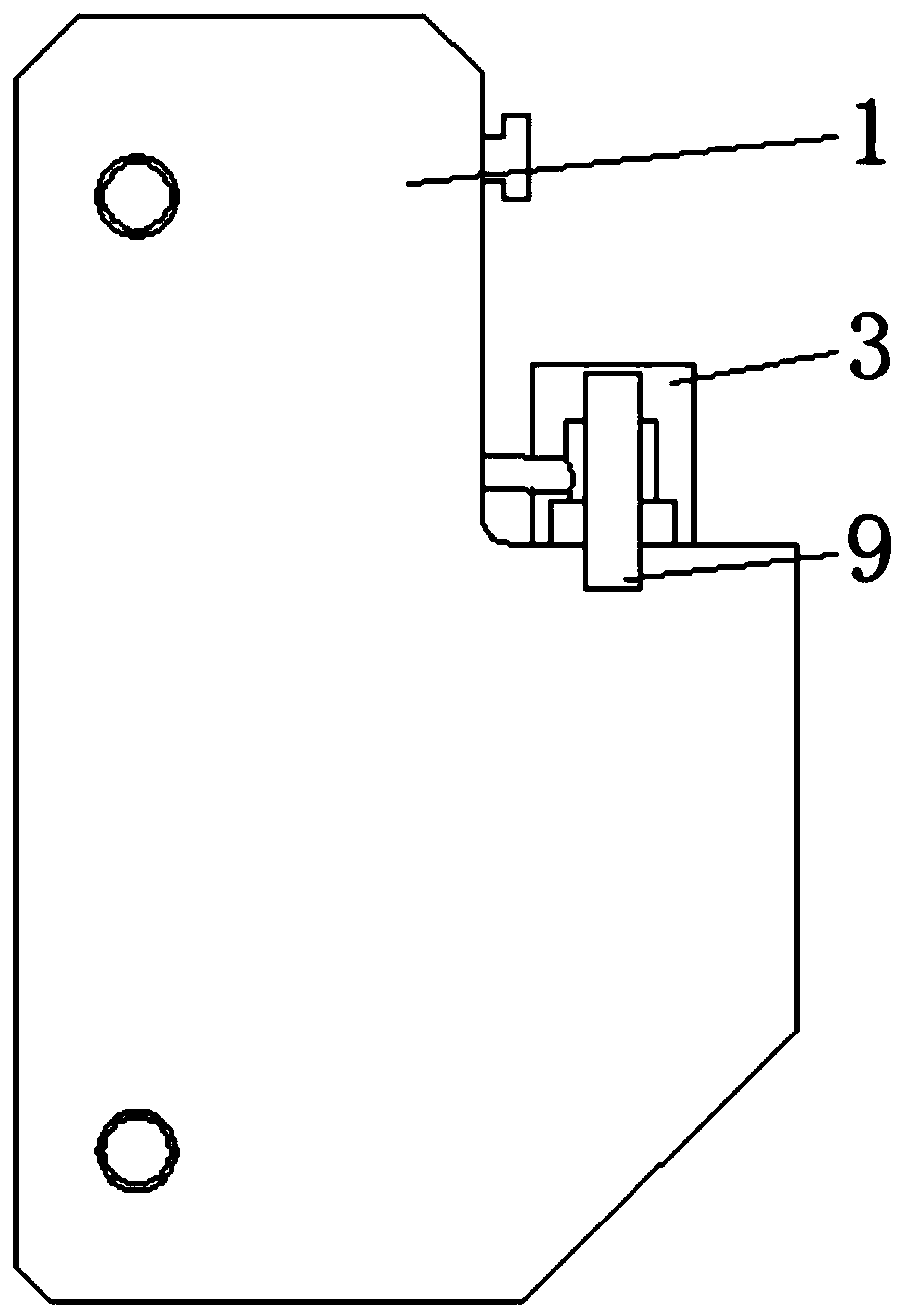

Heavy round steel automatic-feeding machine for shot blasting machine

InactiveCN103612213ASave human effortImprove shot blasting efficiencyAbrasive machine appurtenancesHydraulic cylinderGear wheel

The invention discloses a heavy round steel automatic-feeding machine for a shot blasting machine. The heavy round steel automatic-feeding machine comprises partition plates, a material shelf, a gear plate, straight teeth, a rack, a gear, a hydraulic cylinder, a conveyor line, a support frame, a slope and the shot blasting machine, and is characterized in that the gear is arranged on the rack; the gear plate is arranged above the rack; the material shelf is arranged above the gear plate; the partition plates are arranged in the material shelf at certain intervals; the conveyor line is arranged on the left part of the rack; the shot blasting machine is arranged above the conveyor line; round steel placement frames are arranged on the two sides of the conveyor line at certain intervals; the slope is arranged on the left part of the conveyor line; the support frame is arranged below the slope. The heavy round steel automatic-feeding machine has the advantages of reliable performance, labor conservation, high production efficiency and the like, and has broad market prospect.

Owner:雍自玲

Steel shot preparing method and shot blasting technology applying steel shots

InactiveCN107914020AHigh hardnessHigh strengthFurnace typesAbrasive machine appurtenancesMetallurgyMechanical engineering

The invention discloses a steel shot preparing method, and relates to the technical field. A steel shot comprises chemical components including, by mass percent, 0.65%-0.78% of C, 0.22%-0.25% of Si, 0.14%-0.16% of W, 0.55%-0.75% of Mn, 0.49%-0.58% of Ti, 0.11%-0.18% of Al, 0.02%-0.07% of Nb, and the balance Fe. The invention further discloses a shot blasting technology. The shot blasting technology comprises the following steps that S1, degreasing, washing and drying are conducted on a workpiece which is about to be subjected to shot blasting; S2, after shot blasting line equipment is debugged, steel shots are added in the shot blasting line equipment, the workpiece is arranged in a shot blasting chamber, the position of the workpiece is adjusted, a nozzle of an impeller head faces the workpiece, and then shot blasting treatment is conducted; S3, after shot blasting treatment is finished, shot particles on the surface of the workpiece are removed; and S4, the workpiece obtained after shot blasting treatment is checked. According to the steel shot preparing method and the shot blasting technology, the steel shot hardness and deformation resisting capability are effectively improved,dust is small, the service life is longer, the shot blasting technology efficiency is effectively improved, and meanwhile the cost of the shot blasting technology is reduced.

Owner:江苏飞腾铸造机械有限公司

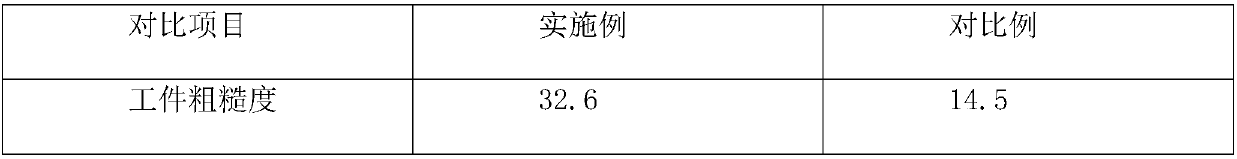

Shot blasting treatment process

InactiveCN107891374AAvoid severe deformationImprove shot blasting qualityBlast effectsMaterials science

The invention discloses a shot blasting treatment process, and relates to the field of shot blasting. The shot blasting treatment process comprises the following steps: (S1) the thickness of each partof a workpiece is measured; (S2) the workpiece is degreased, is put in clear water for water washing, and is taken out; water on the surface of the workpiece is blown away by adopting compressed air;and the workpiece is put in a drying chamber for drying; (S3) the dried workpiece is placed in a shot blasting chamber; according to the thickness of the part, towards a shot blasting machine, of theworkpiece, the rotating speed of the shot blasting machine is adjusted, and the shot blasting treatment is performed; after the shot blasting of the part is finished, the workpiece is overturned; theother part of the workpiece is towards a nozzle of the shot blasting machine; according to the thickness of the part, the rotating speed of the shot blasting machine is adjusted;the shot blasting treatment is performed; and the workpiece is overturned until the shot blasting treatmet is performed on all parts of the workpiece; (S4) shots on the surface of the workpiece are cleaned after the shotblasting is finished; and (S5) the workpiece is inspected. The shot blasting treatment process adopts different shot initial speeds on all parts, with different thicknesses, of the workpiece, so thatthe shot blasting effects of all the parts of the workpiece are basically kept consistent, and the service life of the workpiece is prolonged.

Owner:江苏飞腾铸造机械有限公司

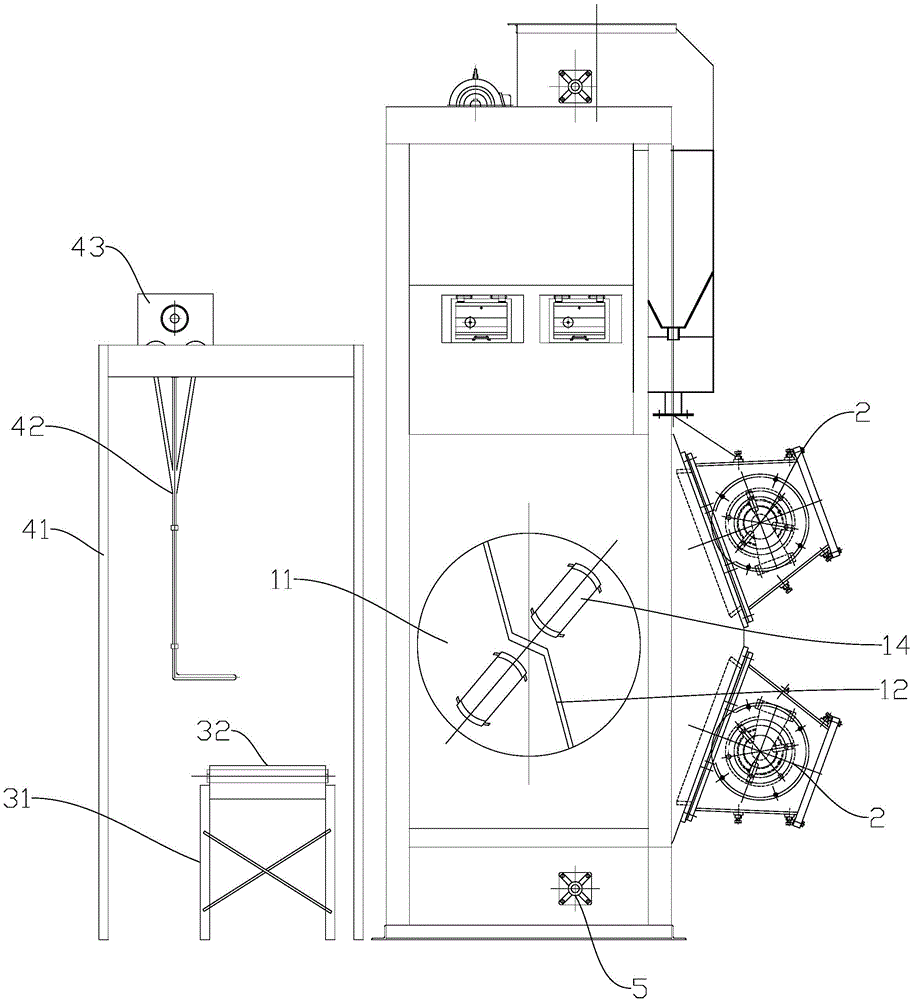

Novel shot blasting equipment and method thereof

InactiveCN111745550AImprove efficiencyHigh degree of intelligenceImpeller wheelsRotor bladesStructural engineeringMechanical engineering

Owner:莱州伟辰汽车配件有限公司

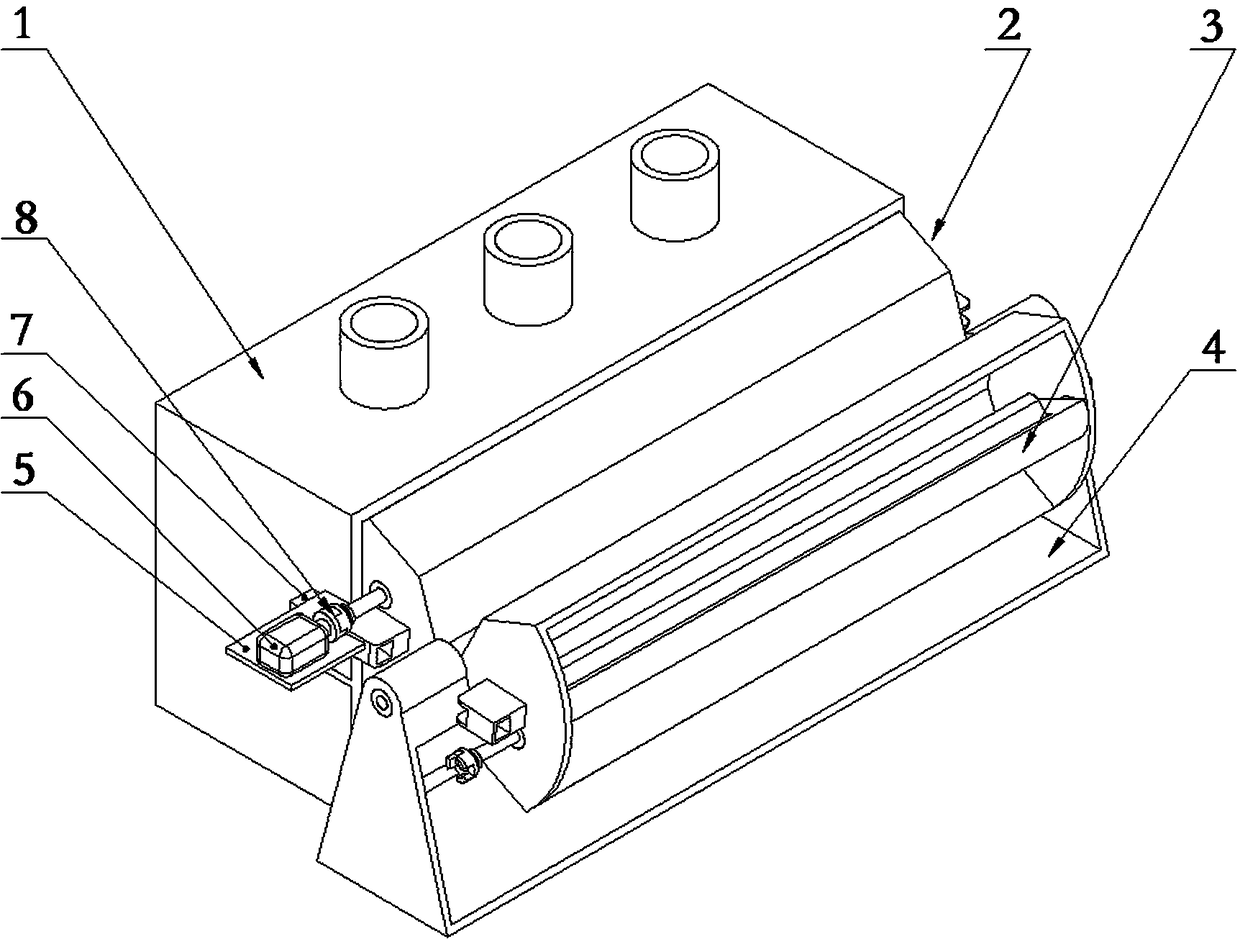

Full-automatic numerical control shot blasting machine

ActiveCN112571291ARealize cleaning and derustingIncrease the shot blasting areaImpeller wheelsRotor bladesNumerical controlChinese characters

The invention belongs to the technical field of shot blasting machines, and particularly relates to a full-automatic numerical control shot blasting machine. The full-automatic numerical control shotblasting machine comprises a shell, a roller, an arc-shaped plate and a feeding plate, wherein a feeding cylinder is arranged in the center of the upper surface of the shell; the roller is arranged under the feeding cylinder, and a first rotating shaft is arranged in the center of the roller; a rocker designed to be shaped like a Chinese character "gong" is arranged in front of the first rotatingshaft; the arc-shaped plate is arranged under the roller; a connecting rod is hinged between the left end of the arc-shaped plate and the central concave part of the rocker; a collecting plate is arranged below the arc-shaped plate; a feeding opening is formed in the middle of the roller on the left side wall of the shell, and an obliquely designed feeding plate is arranged at the feeding opening;and the cross section of the feeding plate is in a waveform design, and the wave crest of the end, close to the roller, of the feeding plate is fixedly connected with a fixing rod. Through the mutualcooperation of the feeding plate, the roller and the arc-shaped plate, automatic classification of steel bars and other workpieces is achieved, the post-processing time is saved, and resource waste is reduced.

Owner:山东盛德机械有限公司

Building steel plate dual-face shot blasting derusting machine

ActiveCN111791151AReasonable structural designImprove shot blasting efficiencyAbrasive machine appurtenancesSteel platesStructural engineering

The invention provides a building steel plate dual-face shot blasting derusting machine. The building steel plate dual-face shot blasting derusting machine comprises a conveying belt. A pushing structure is arranged at one end of the conveying belt. A steering structure is arranged on one side of the pushing structure. A shot blasting derusting machine body is arranged at the bottom of the steering structure. The structural design of the shot blasting derusting machine is reasonable, through the arranged pushing structure and steering structure, a steel plate on the conveying belt is pushed into a groove plate on the steering structure through the pushing structure, the steel plate is rotated to the vertical direction from the horizontal direction through a rotating disc, the steel plate is vertically conveyed to the shot blasting derusting machine, the two faces of the steel plate are subjected to shot blasting at the same time, and the shot blasting efficiency is improved.

Owner:芜湖天达重工有限公司

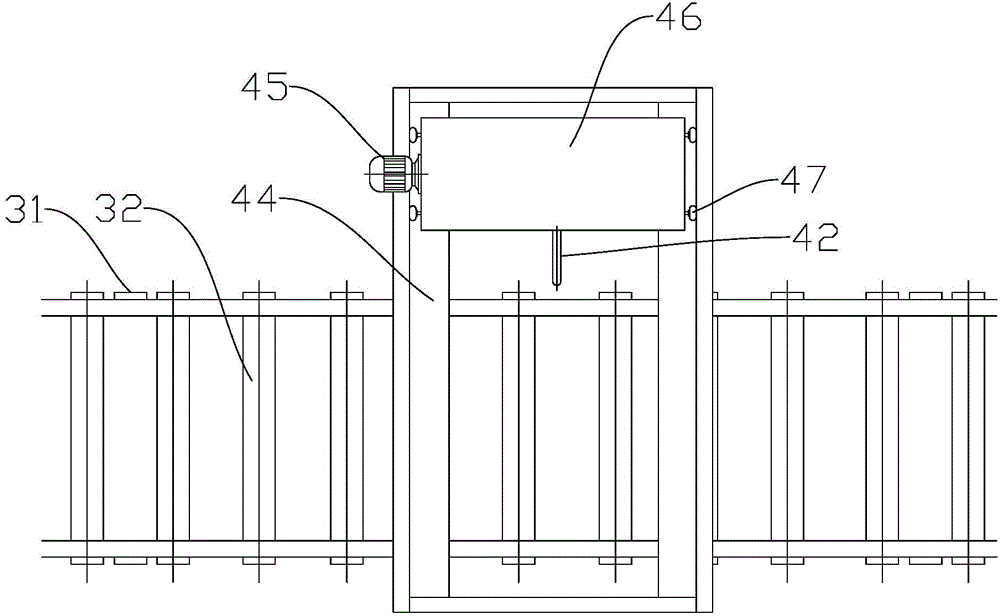

Loading and unloading alternating mechanism of roller way shot blasting machine

InactiveCN108249138AOvercome limitationsEnsure continuous and efficient operationAbrasive machine appurtenancesConveyor partsButt jointBlasting machine

The invention discloses a loading and unloading alternating mechanism of a roller way shot blasting machine. The mechanism comprises a feed roller way connected to a feed end of a shot blasting machine, a discharge roller way connected to a discharge end of the shot blasting machine, a workpiece alternating roller way parallel to the feed roller way and the discharge roller way, and two transversemoving devices, wherein one end of the workpiece alternating roller way is in butt joint with the feed roller way, and the other end is in butt joint with the discharge roller way; one of the transverse moving devices is arranged between the feed roller way and one end of the workpiece alternating roller way in butt joint; and the other one is arranged between the discharge roller way and the other end of the workpiece alternating roller way in butt joint. The mechanism has the beneficial effect of guaranteeing the equipment utilization rate.

Owner:ANHUI HEFEI AUTO FORGING

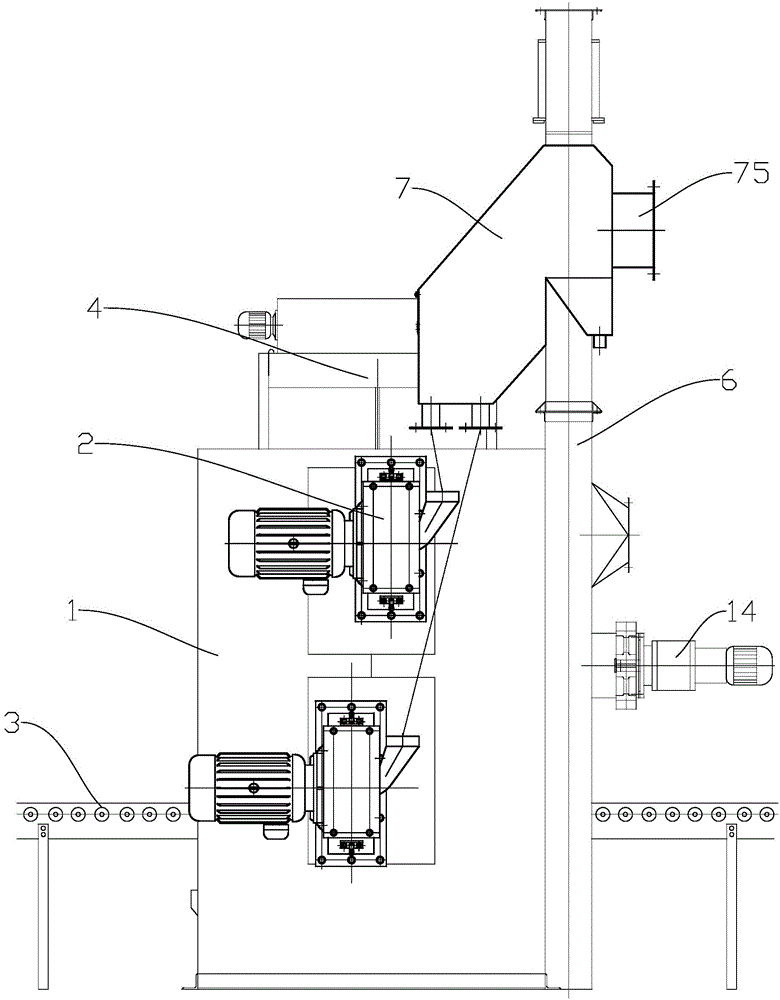

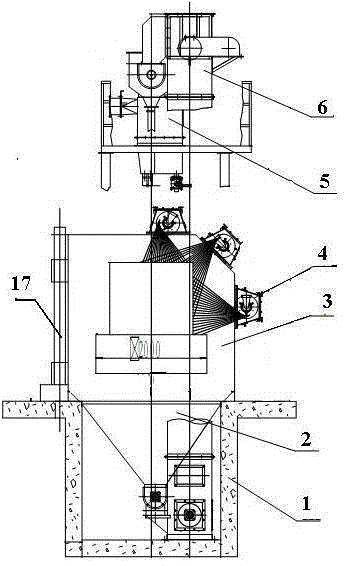

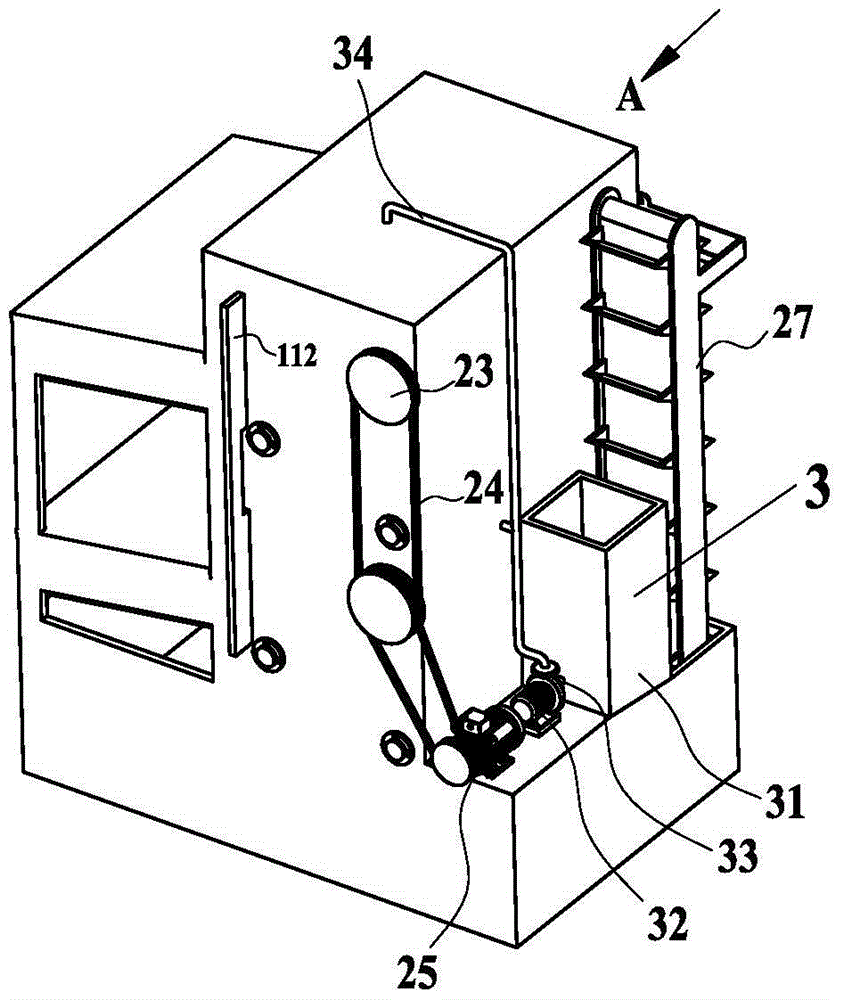

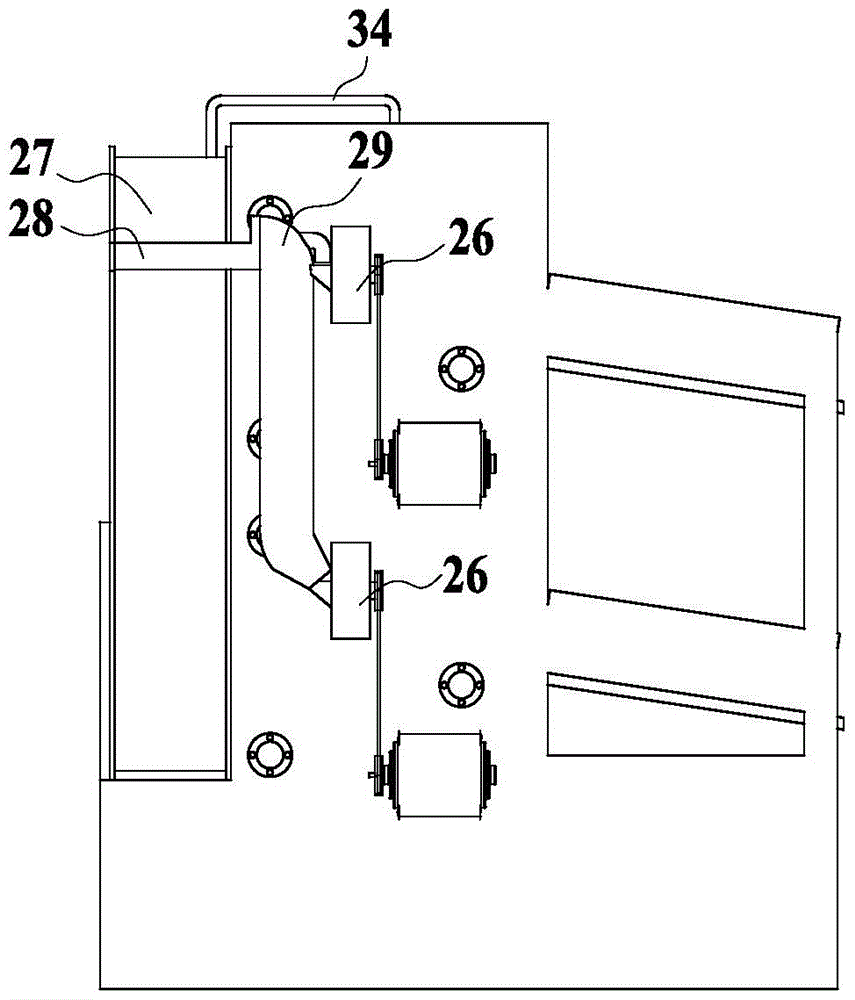

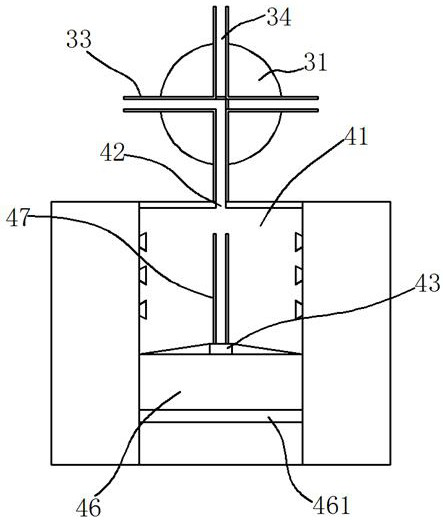

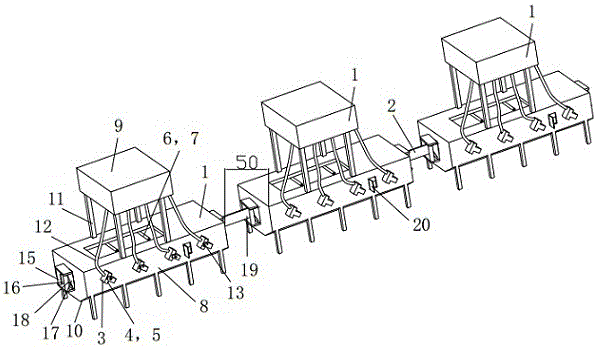

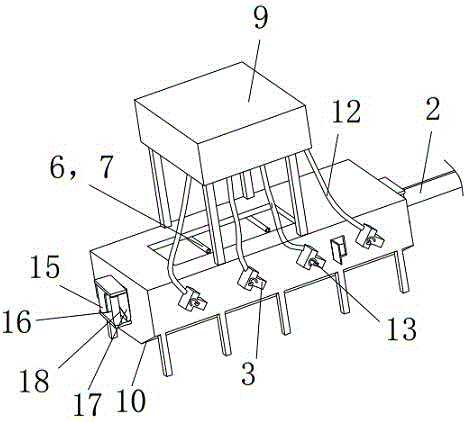

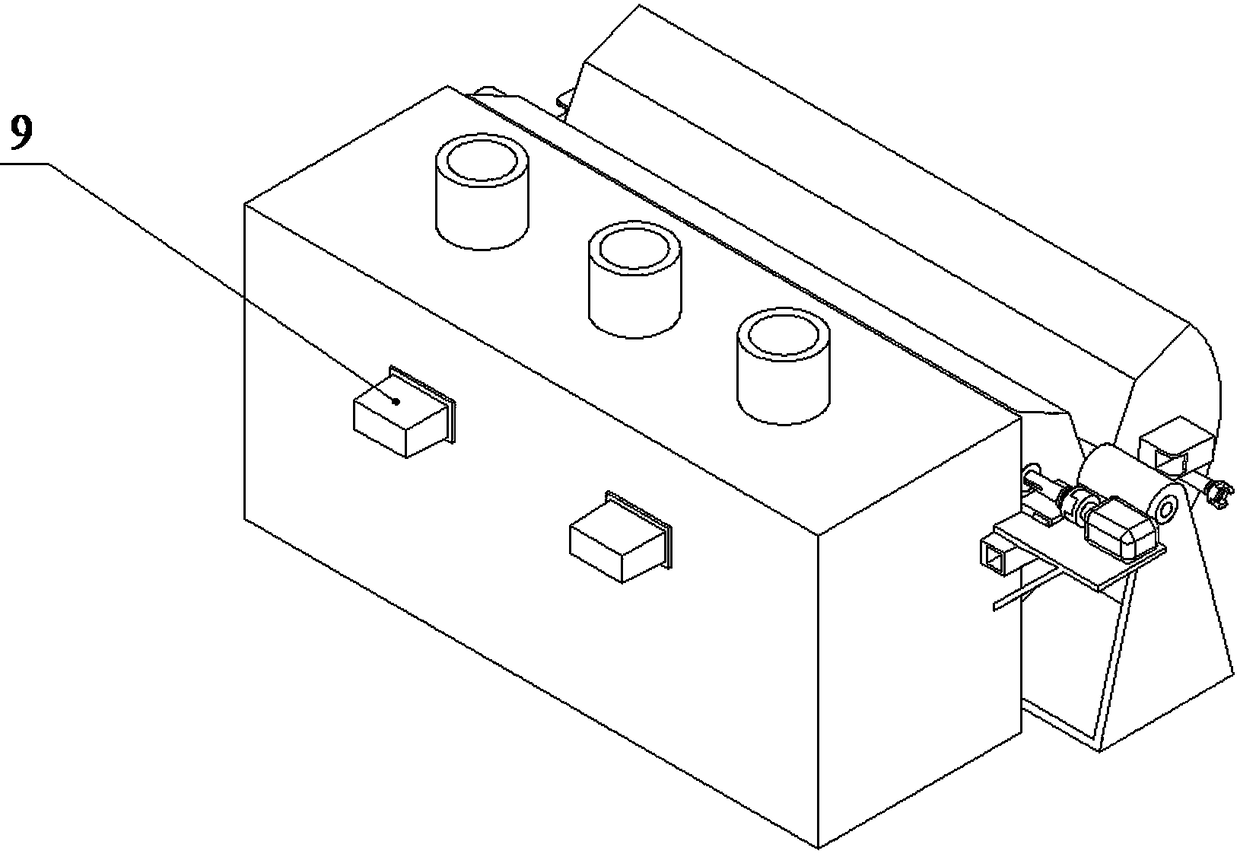

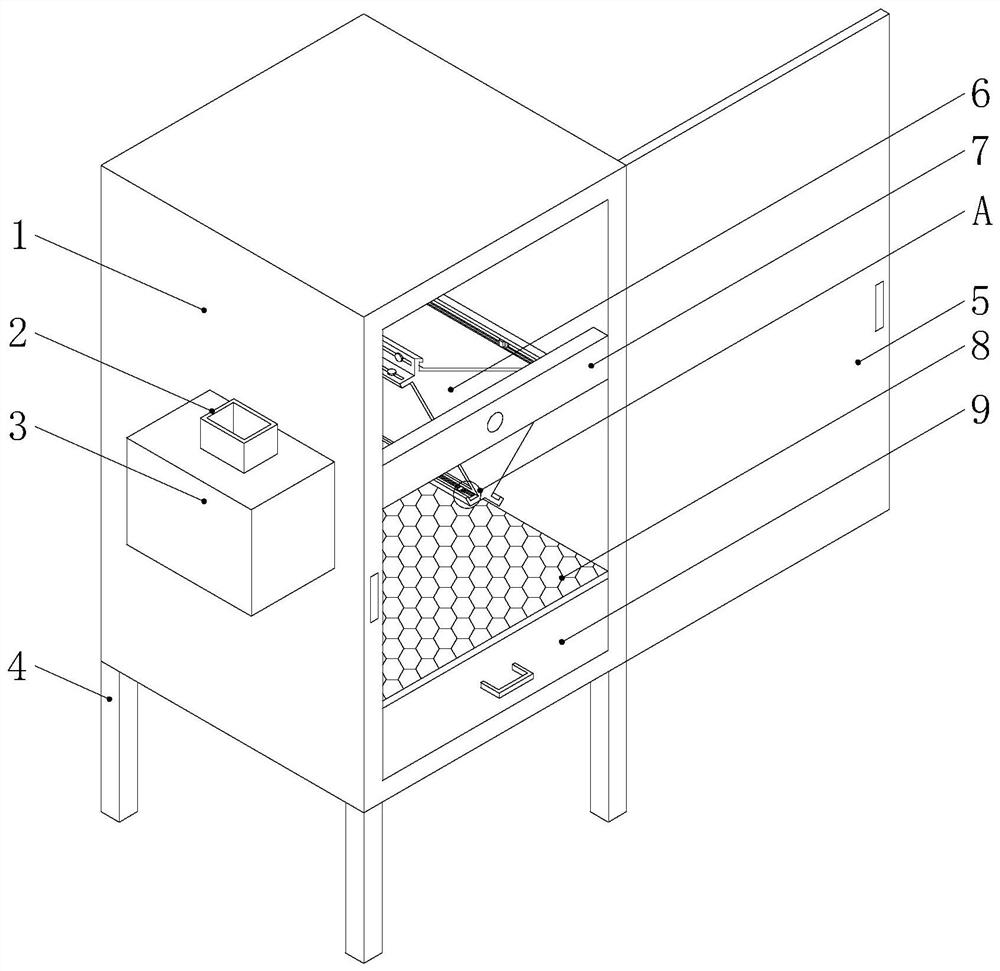

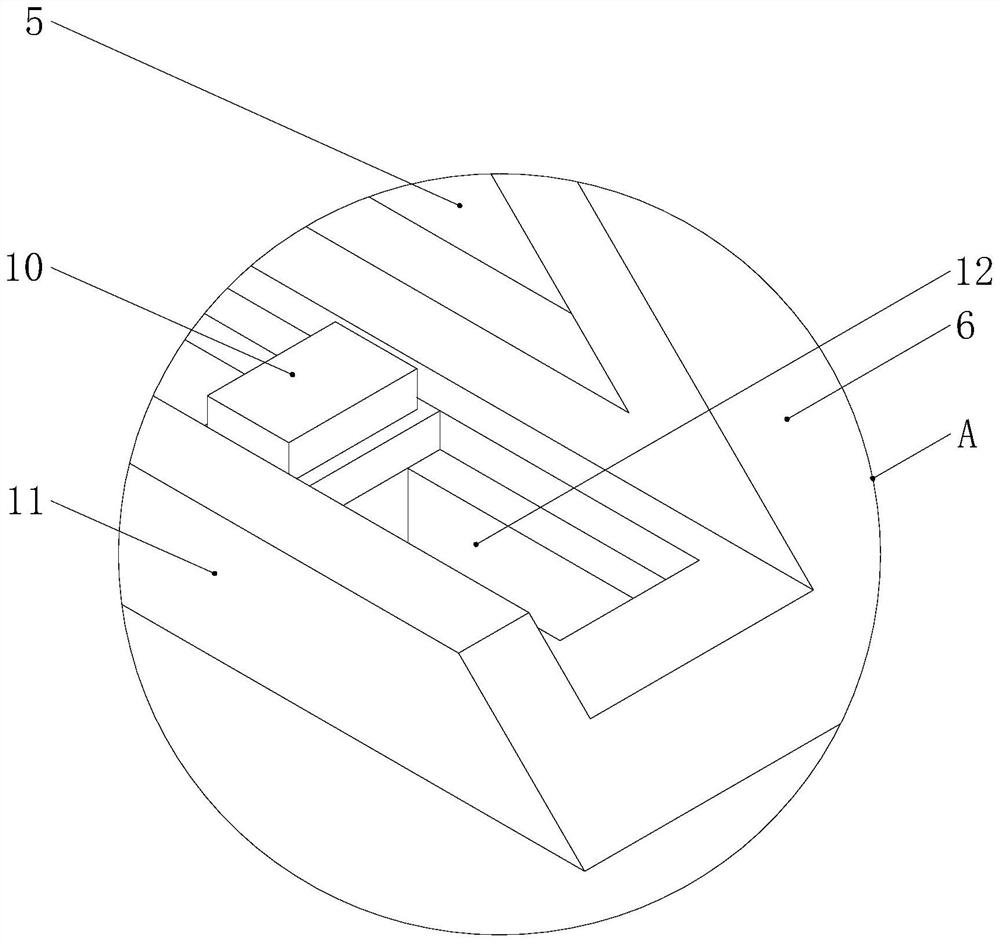

Novel shot blasting equipment

InactiveCN106737224ASolve difficult problemsIncrease productivityAbrasive machine appurtenancesAbrasive blasting machinesSmall footprintEngineering

The invention relates to novel shot blasting equipment. The novel shot blasting equipment comprises a foundation device, a shot blasting chamber, an elevator and workpiece conveying systems. The foundation device is concave, and is arranged at the bottommost part of a shot blasting machine; a shot collecting hopper is arranged in the foundation device; the shot blasting chamber is arranged above the foundation device, and is provided with shot blasting chamber assemblies inside; the shot blasting chamber is provided with gates; a separator and the elevator are arranged above the shot blasting chamber; and the workpiece conveying systems are arranged on the gates. Trolleys enter and leave from the shot blasting chamber 3 through closing and opening of the gates 17; and two gates 17 are opened and closed in turns for loading and unloading workpieces to improve the efficiency by one time. The gate trolleys 11 are fixed on the gates 17; and the equipment is delicate in structure and small in floor area, and saves the space for users.

Owner:王帅

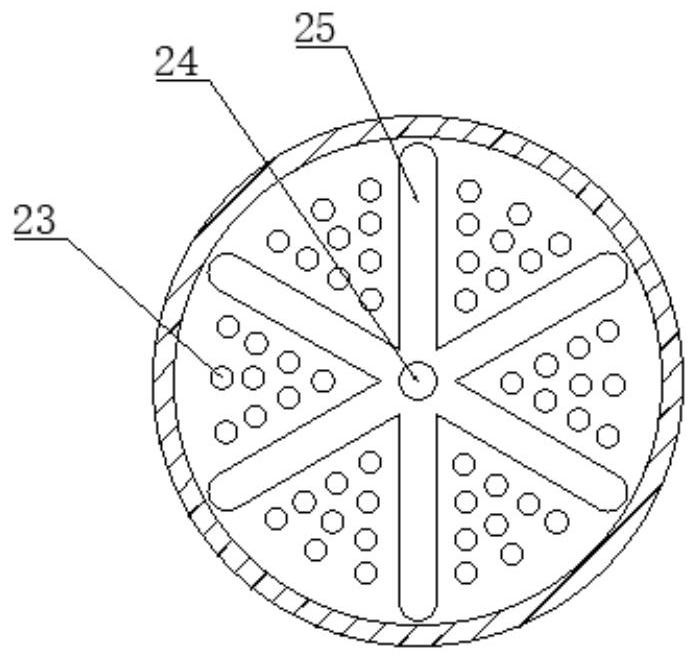

Automatic turn-over and shot blasting machine for workpiece

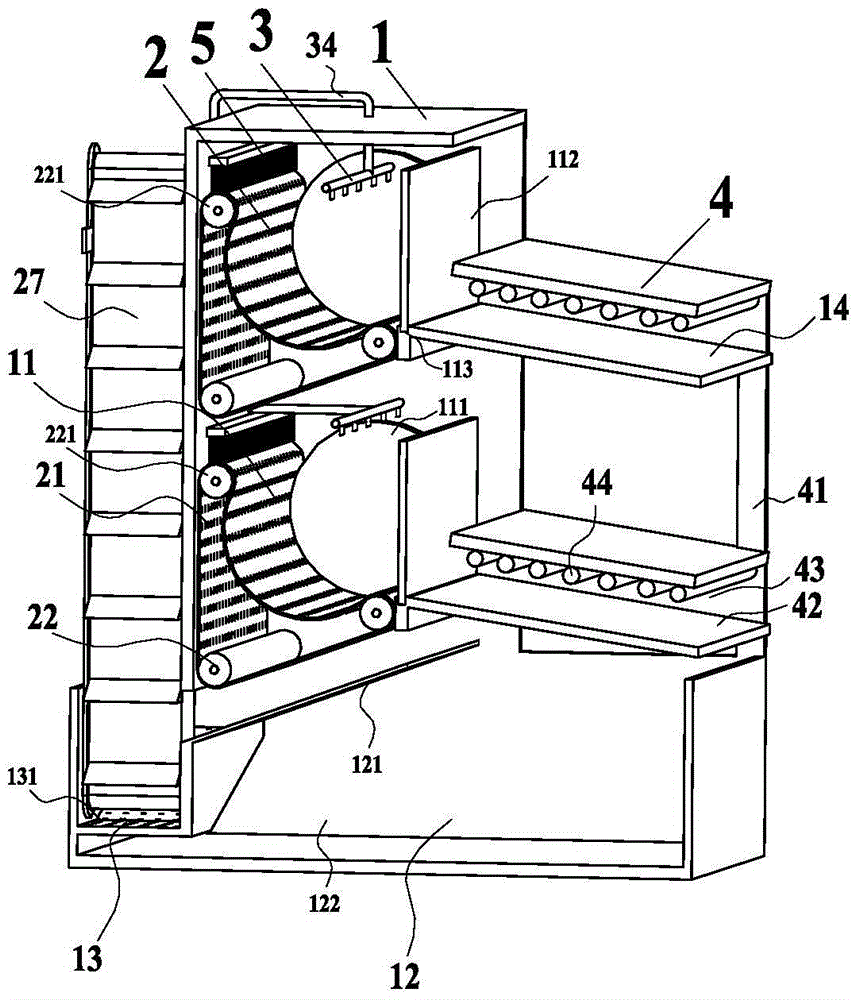

InactiveCN105563346ALabor savingReduce energy consumptionConveyorsAbrasive machine appurtenancesSurface finishingTreatment costs

The invention discloses an automatic turn-over and shot blasting machine for a workpiece. The automatic turn-over and shot blasting machine comprises a rack, a first-level conveying belt located on the front portion of the rack and a second-level conveying belt located on the rear portion of the rack. Impeller heads are arranged above the two levels of conveying belts. An inlet of the second-level conveying belt is located below the rear portion of an outlet of the first-level conveying belt. A turn-over wheel is arranged between the inlet of the second-level conveying belt and the outlet of the first-level conveying belt and comprises a wheel body and partition plates arranged in a radial shape in the circumferential direction of the wheel body. Inserting grooves for turnover of the workpiece are formed between the adjacent partition plates. The workpiece can fall into the inserting grooves from the outlet of the first-level conveying belt and enter the inlet of the second-level conveying belt after being turned over. After the structure is adopted, the aims that shot blasting of the front face and the back face of the workpiece is finished simultaneously at a time, and no manual turning over is needed are achieved, manpower is saved, energy consumption is reduced, and shot blasting efficiency is improved; and various surface finishing needs can be met, and treatment cost is greatly reduced.

Owner:JIANGSU HONGZHAN MACHINERY CO LTD

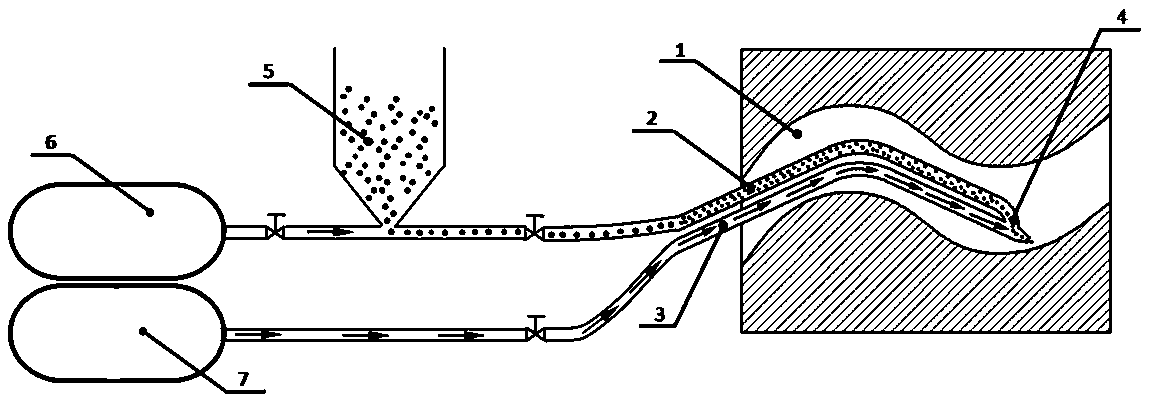

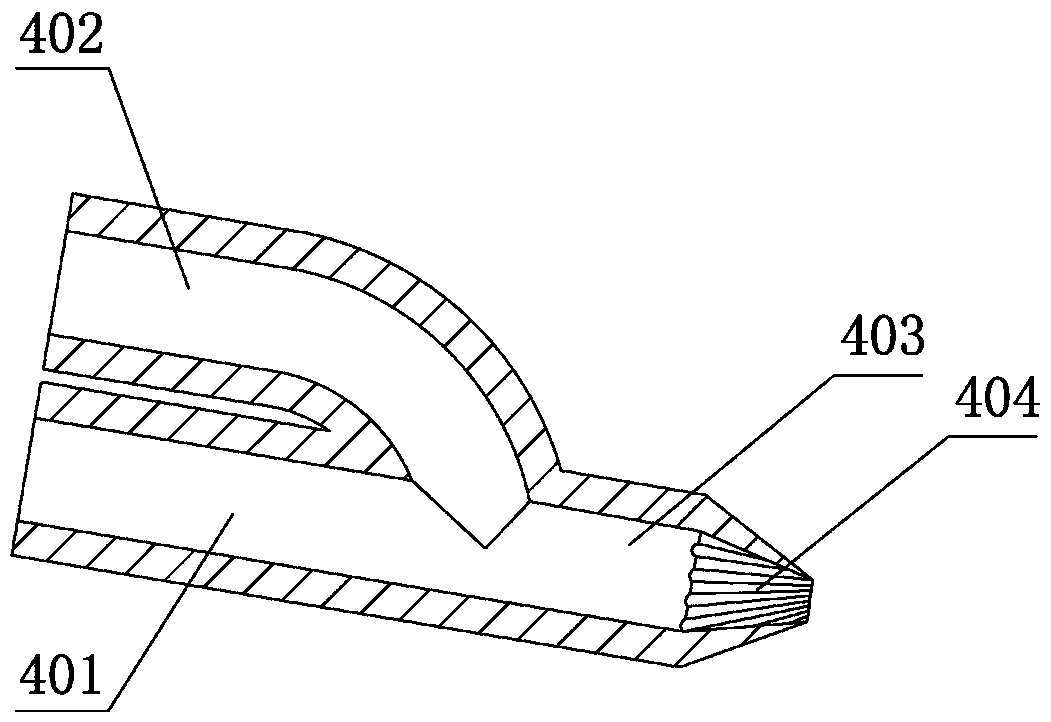

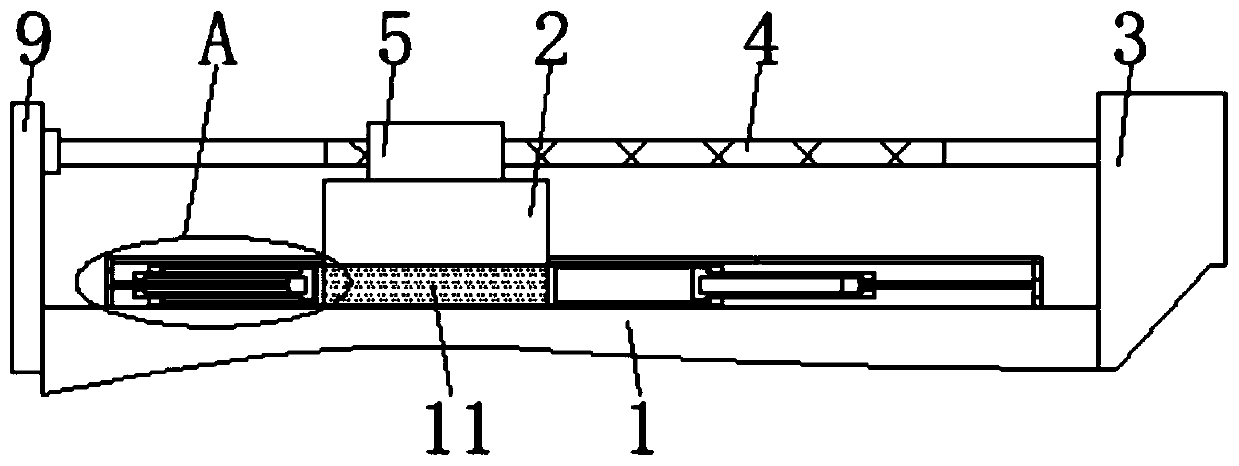

Shot blasting device for complex cavity in casting

ActiveCN110434766AAvoid wear damageIncrease shot blasting energyBlast gunsAbrasive feedersHigh energyEngineering

The invention relates to a shot blasting device for a complex cavity in a casting in the technical field of casting product surface shot blasting cleaning. The shot blasting device comprises a low-pressure feeding pipeline, a high-pressure power pipeline and a Y-shaped shot blasting joint, the Y-shaped shot blasting joint is provided with a shot blasting medium feeding port, a high-pressure air inlet and a shot blasting outlet, the low-pressure feeding pipeline is connected with the shot blasting medium feeding port, the high-pressure power pipeline is connected with the high-pressure air inlet, and the low-pressure feeding pipeline and the high-pressure power pipeline are conformal hoses. According to the shot blasting device, the shot blasting medium and the shot blasting power are separately conveyed to the position of the Y-shaped shot blasting joint to be collected and thrown out, so that the abrasion damage to the conveying pipeline in the conveying process of the high-energy shot blasting medium is avoided; and the special Y-shaped shot blasting joint and the conformalconveying hose are used for accurately jetting the parts of the complex inner cavity. Therefore, the shot blasting device is suitable for carrying out shot blasting on the complex narrow inner cavity of the casting and separately conveying the shot blasting medium and the high-pressure power, so that the abrasion damage to the conveying pipeline is avoided, the shot blasting efficiency is improved, and the maintenance cost is reduced.

Owner:KOCEL STEEL

Shot blasting machine for rust removal of steel member

InactiveCN113183041ASolve the problem of a large amount of steel shot remainingReduce labor intensityImpeller wheelsRotor bladesMetallurgyStructural engineering

The invention relates to the technical field of shot blasting machines, in particular to a shot blasting machine for rust removal of a steel member. A supporting mechanism for supporting a steel plate is arranged on the outer portion of a machine shell, the lower end of the machine shell is connected with a lower spiral conveyor in a penetrating manner, a shot blasting chamber and a cleaning chamber are arranged in the machine shell, a shot-ash separator is arranged in the shot blasting chamber, a shot blasting device is arranged below the shot-ash separator, and the shot-ash separator is connected with the shot blasting device through a steel shot conveying mechanism. A scraping plate scrapes off most of steel shots on the surface of the steel member, a rolling brush cleaning mechanism cleans away the steel shots remaining on the surface of the steel member, a secondary cleaning mechanism cleans away dust on the surface of the steel member, and a high-pressure dust blowing mechanism blows off the dust on the surface of the steel member. By means of the shot blasting machine for rust removal of the steel member, the problem that after shot blasting, a large number of steel shots remain on the steel member is solved, shots and dust remaining on the surface of the steel member are thoroughly removed, and labor intensity and operation safety risks are reduced.

Owner:TONGLING FERROUS CONSTR & INSTALLATION STEEL STRUCTURE

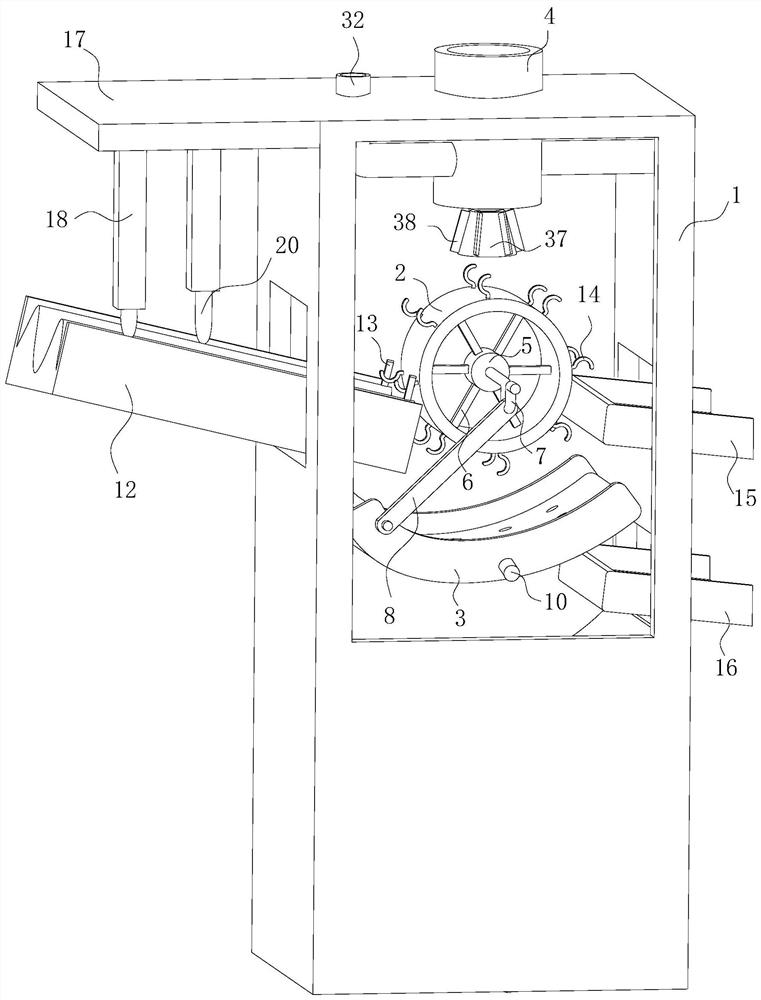

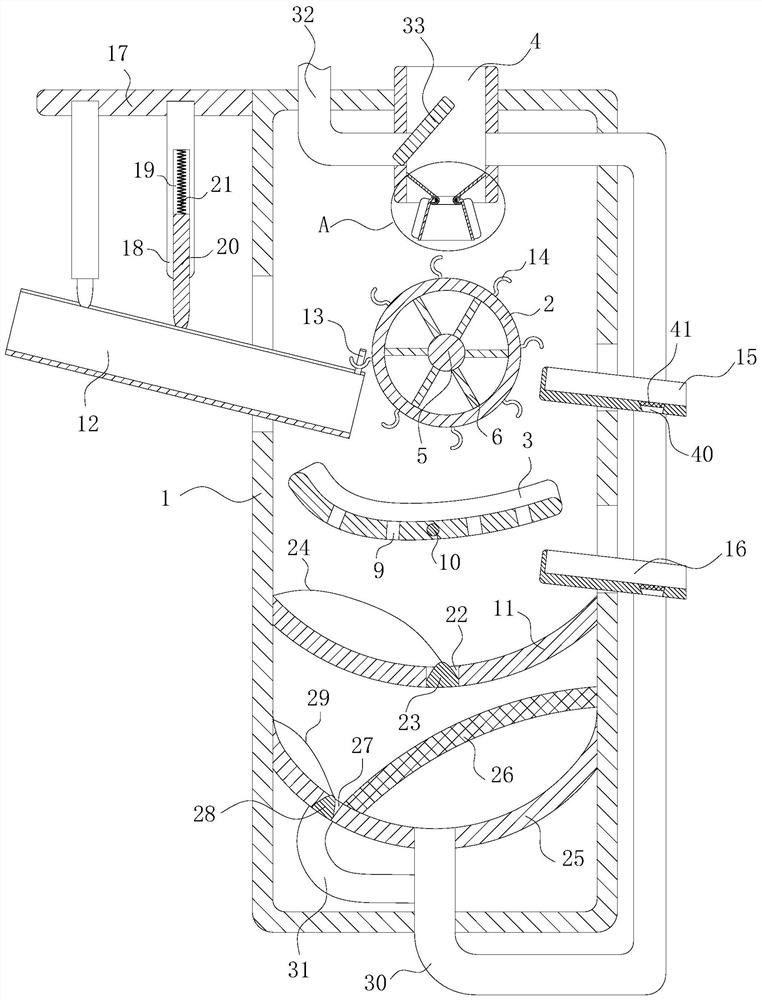

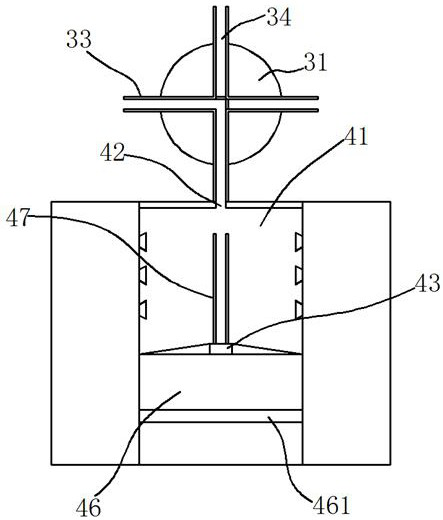

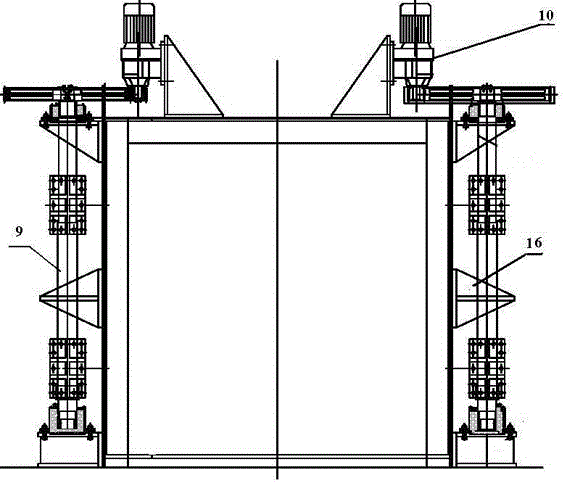

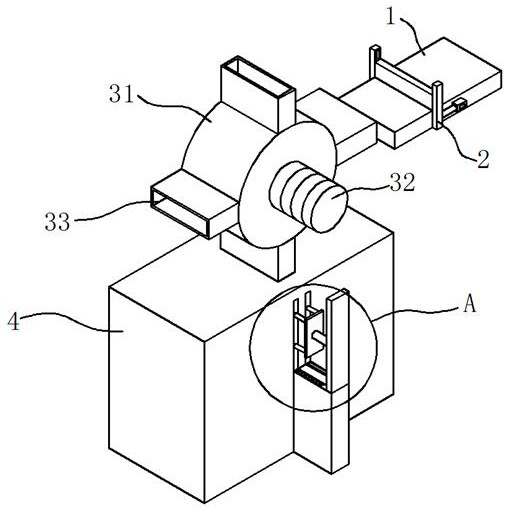

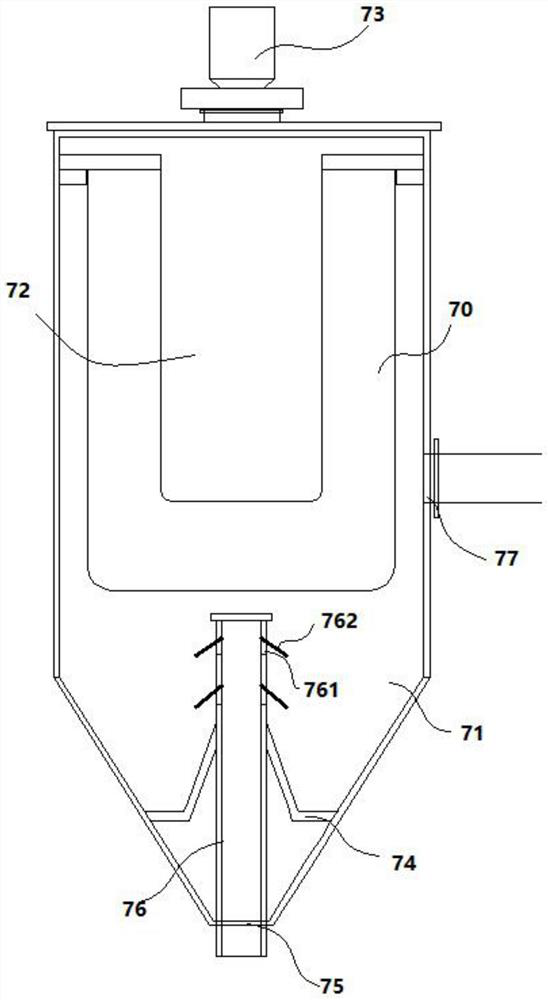

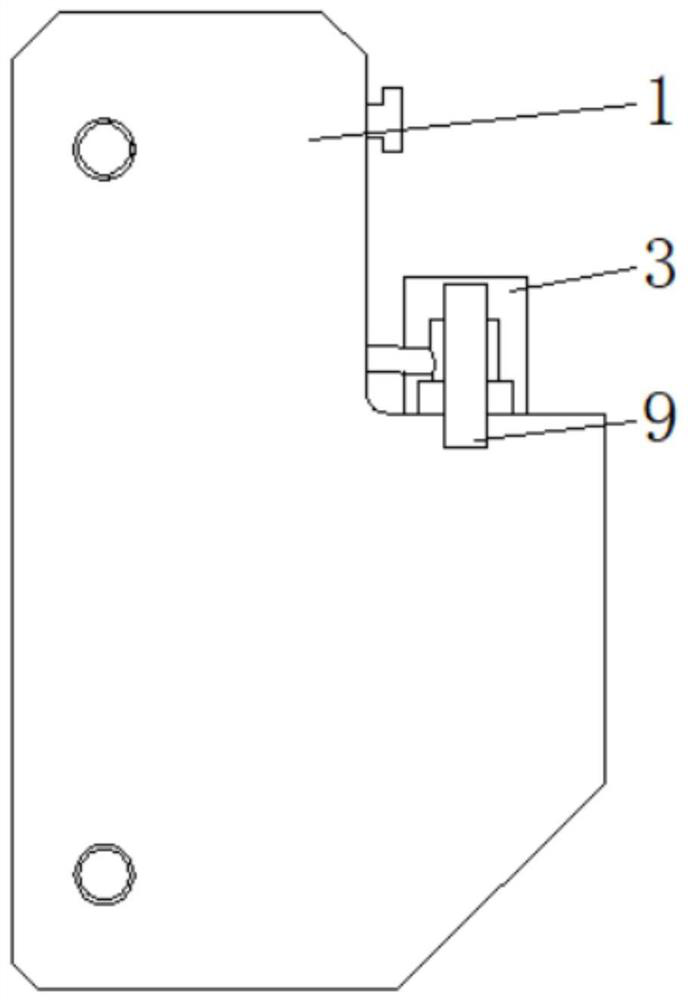

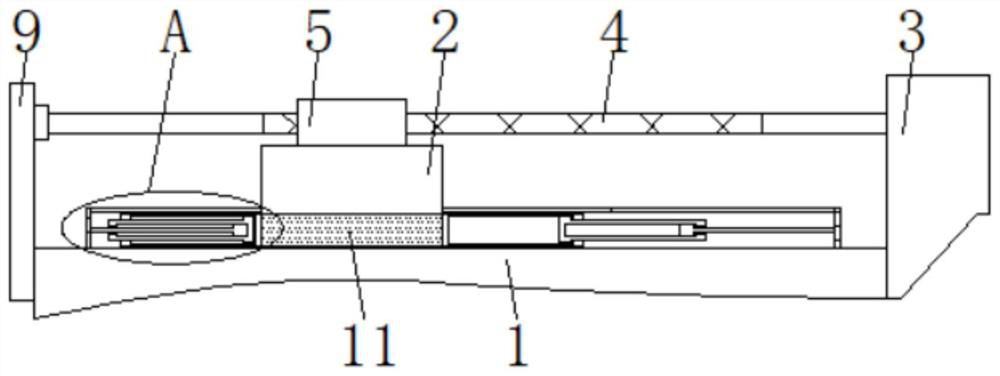

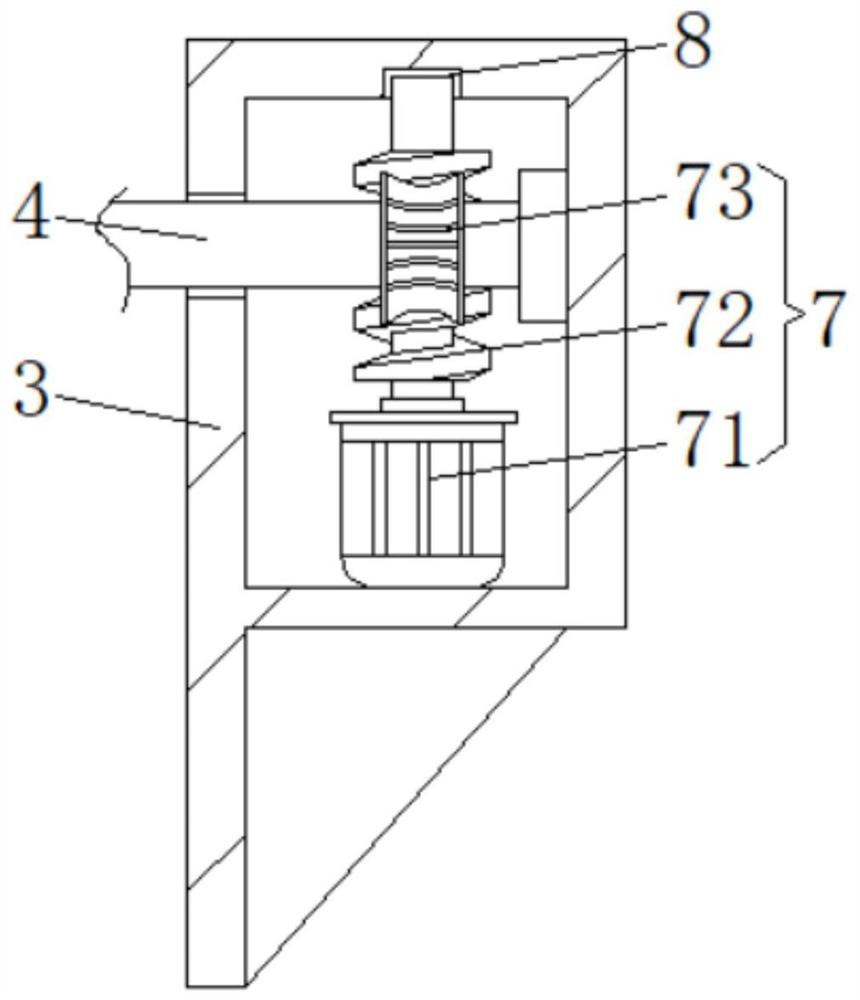

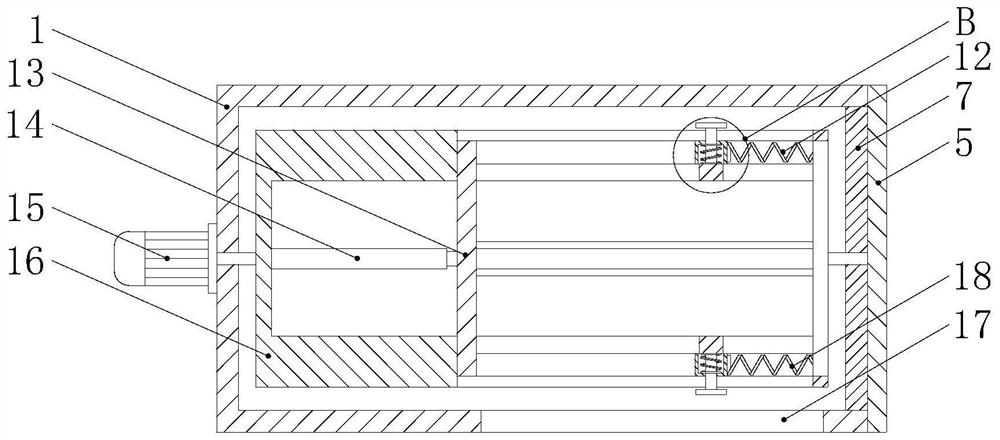

A shot blasting machine for a reel

ActiveCN104209870AAvoid stayingImprove shot blasting efficiencyAbrasive machine appurtenancesAbrasive blasting machinesMechanical engineeringMolding sand

A shot blasting machine for a reel relates to the technical field of a shot blasting machine. The reel shot blasting machine is used for solving the problem that the surface molding sand of the roller is not completely cleaned up when the present shot blasting machine performs the shot blasting operation of the roller. The shot blasting machine for a roller of the invention conveys a roller to a shot blasting chamber via a platform I, rising of a platform II and rotation of a rotating table enables each outer surface of the roller to contact with a steel shot in a friction way when the roller performs the shot blasting operation. When shot blasting is needed to be performed to the bottom surface of the roller, the roller is turned over 180 degrees by a turning assembly. The shot blasting machine avoids the scratch on the roller caused by long term lifting. Meanwhile, all-around compound motion avoids the presence of the shot blasting dead angle, so that the shot blasting efficiency is greatly improved.

Owner:SHANDONG HUIFENG CASTING TECH

A crawler shot blasting machine

ActiveCN104816252BImprove shot blasting efficiencyReduce generationDrying machines with progressive movementsAbrasive machine appurtenancesFoundryWater storage tank

The invention relates to the technical field of foundry equipment, specifically to a crawler-belt shot blasting machine. The crawler-belt shot blasting machine comprises a housing, a shot blasting device, a cleaning device, a drying device and a sweeping device. The housing comprises a shot blasting area, a wastewater collection area, a shot collection area and a material discharge drying area. The shot blasting device comprises crawler belts, rollers, belt pulleys, a belt, a shot blasting motor, a blast wheel, a bucket elevator, a spiral conveyor and a shot deliver pipe. The cleaning device comprises a water storage tank, a water pump, a first water pipe and a second water pipe. The drying device comprises a bracket, sliding plates, a discharge cover and a drying rod. The cleaning device is an elongated hairbrush which is fixedly installed above the two crawler belts inside the shot blasting area. A lower end face of the hairbrush is contacted with the crawler belts. The crawler-belt shot blasting machine has a simple structure. According to the invention, shot blasting efficiency of the shot blasting machine can be enhanced, and the problem that there is a lot of dust during shot blasting in the prior art is solved.

Owner:YANTAI XINCHAO FOUNDRY CO LTD

Automatic shot blasting construction machine for constructing municipal alphabet concrete road pavement

InactiveCN107938483AReduce labor intensityNo manual operationRoads maintainenceArchitectural engineeringRoad surface

The invention relates to an automatic shot blasting construction machine for constructing a municipal alphabet concrete road pavement. The automatic shot blasting construction machine comprises a walking rack, wherein a shot blasting device is mounted on the walking rack. The invention aims to solve the problems that a conventional moving tool is needed to manually move a shot blasting tool to implement operation in the conventional municipal road construction process, the operation is complex, serious environment pollution can be caused in manual shot blasting construction, the shot blastingoperation is not ideal because of hard sundries on a pavement, shot blasting equipment may cannot work stably in an appointed position and may cannot work normally on a complex road, and the automaticshot blasting construction machine has the function of automatic shot blasting construction of municipal roads, needs no manual operation, is free of environment pollution, and in addition has the advantages of being wide in application range, good in stability, short in time, small in working intensity, high in working efficiency, and the like.

Owner:王国超

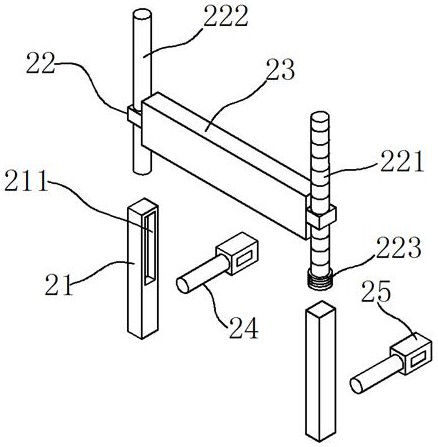

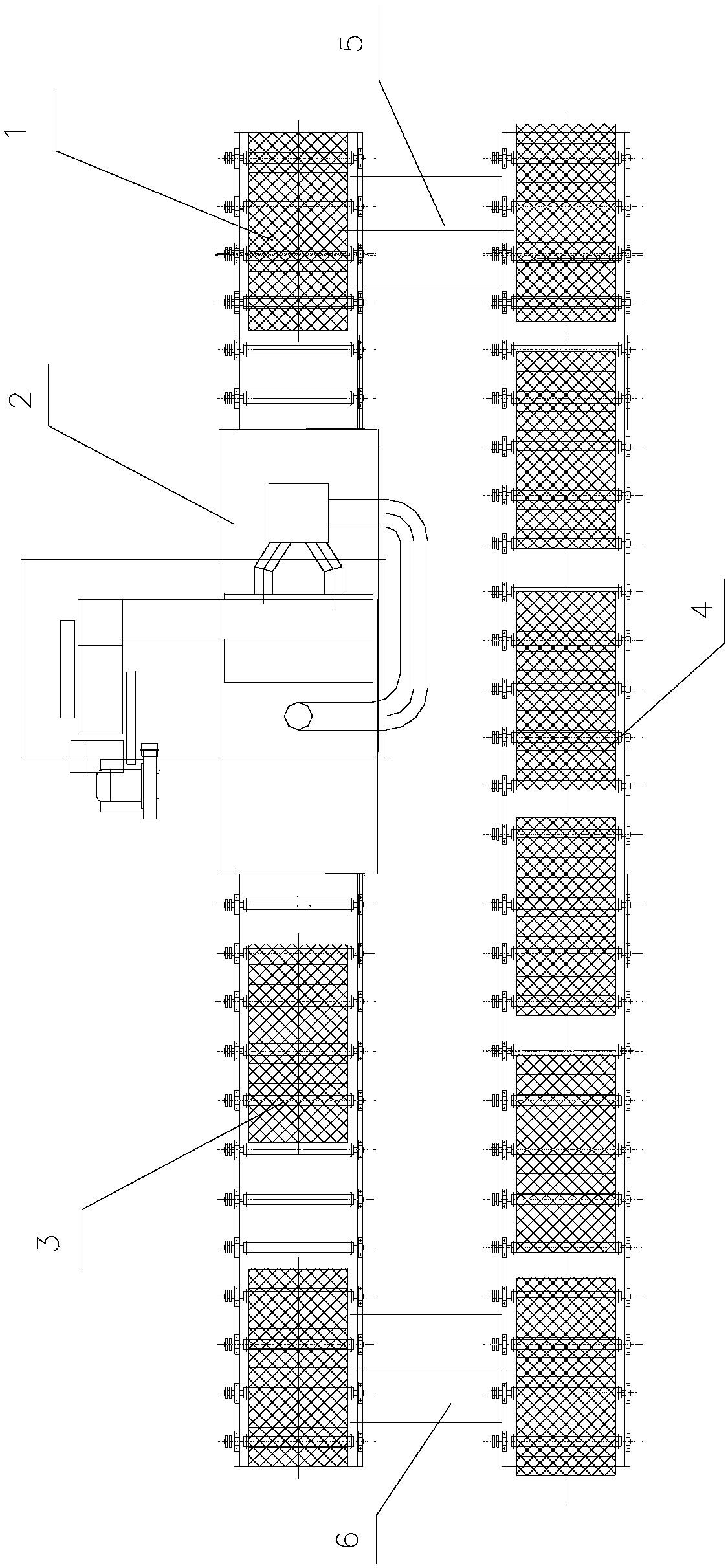

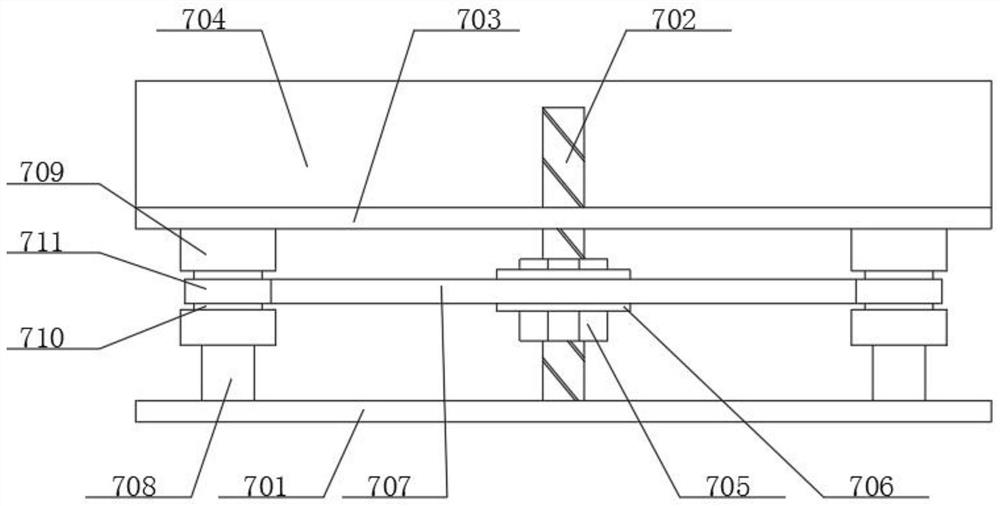

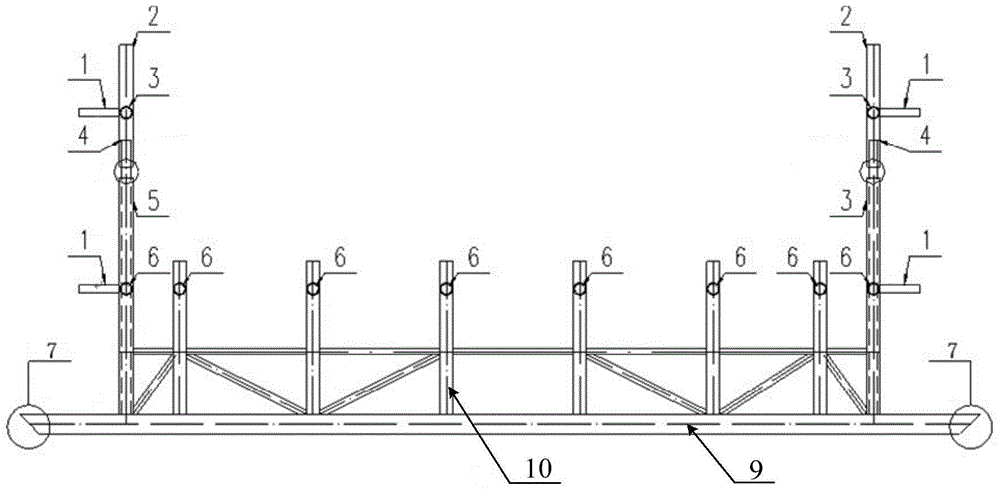

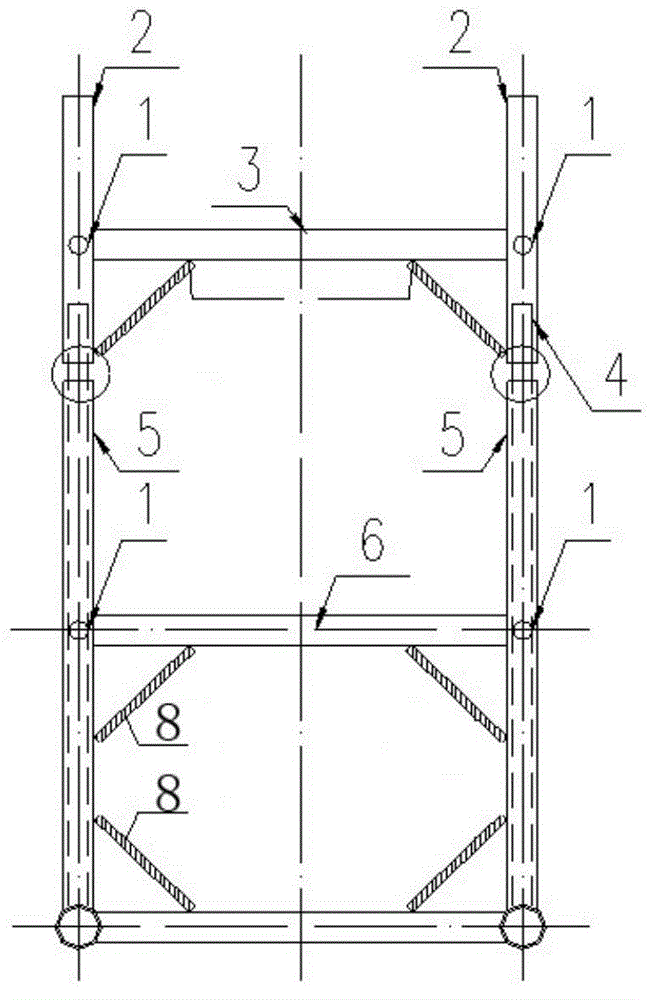

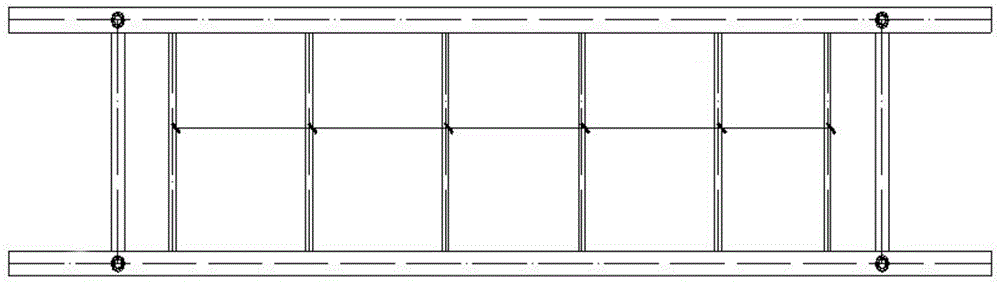

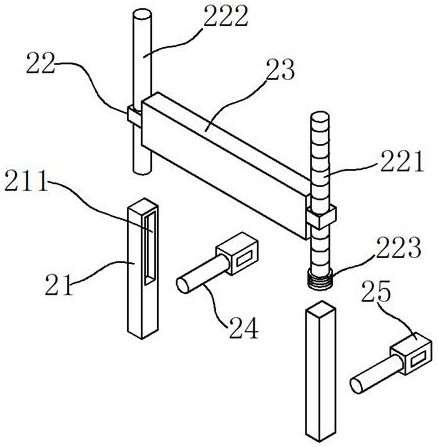

Double-layer detachable shot blasting machine roller way tool bracket

InactiveCN104476414AIncrease feed volumeImprove shot blasting efficiencyAbrasive machine appurtenancesEngineeringMechanical engineering

The invention provides a double-layer detachable shot blasting machine roller way tool bracket, which is used for improving the problem that the production efficiency is reduced caused by unnecessary downtime because a component is clamped to a round roller when being conveyed to the roller way. The double-layer detachable shot blasting machine roller way tool bracket comprises cross rods at the first layers, vertical rods at the first layers, cross rods at the second layers, vertical rods at the second layers and roller way supports; the lower ends of every two vertical rods at the first layers are respectively perpendicularly installed on the end parts at two sides of the same roller way support; the vertical rods at the first layers, installed on the end part at the same side of each roller way support, are parallel with each other, and are perpendicular to a plane, on which the roller way supports are located; the lower ends of the vertical rods at the second layers are perpendicularly connected with the upper ends of the vertical rods at the first layers in a detachable mode; the cross rods at the first layers are fixed between the vertical rods at the first layers, installed on the end parts of the same side of different roller way supports; the cross rods at the second layers are fixed between the vertical rods at the second layers, installed on the end parts at the same side of different roller way supports. The double-layer detachable shot blasting machine roller way tool bracket can be used for increasing the feed amount and improving the shot blasting efficiency, is simple in structure, is convenient to implement, and is easy to popularize and apply.

Owner:KOCEL STEEL STRUCTURE CO LTD

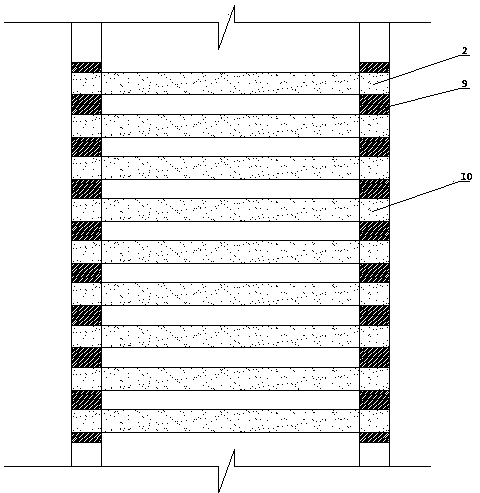

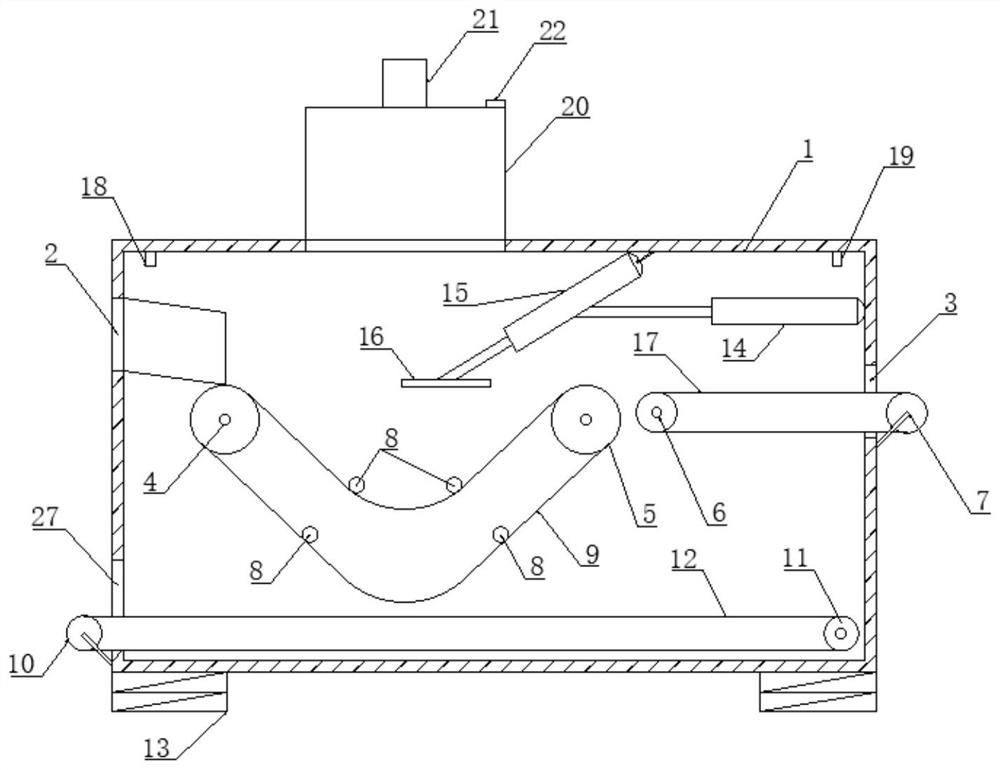

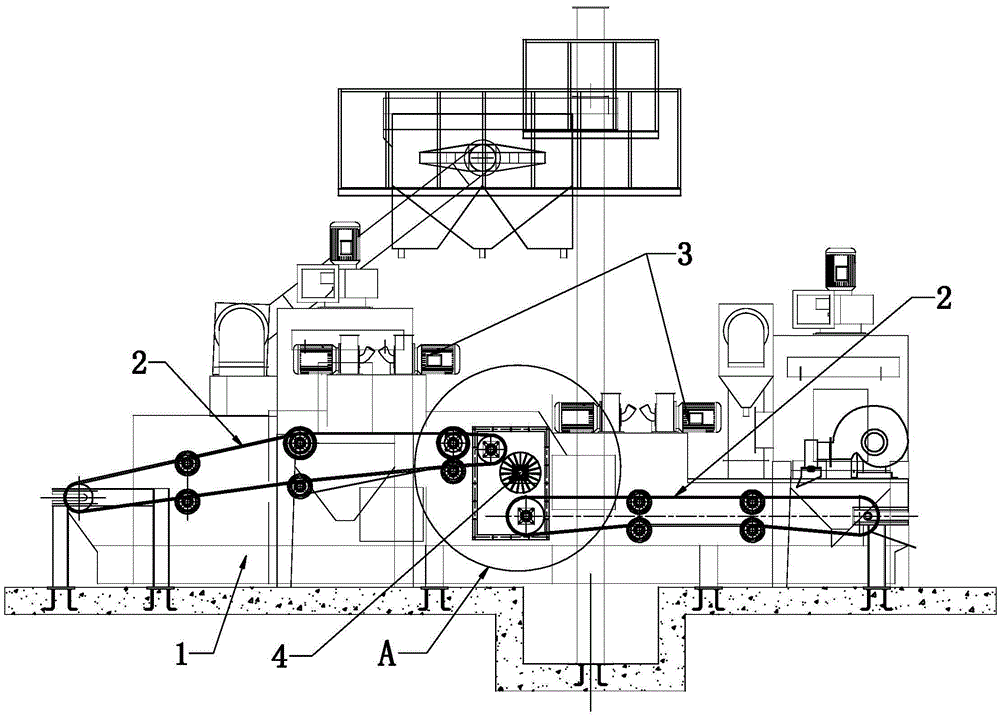

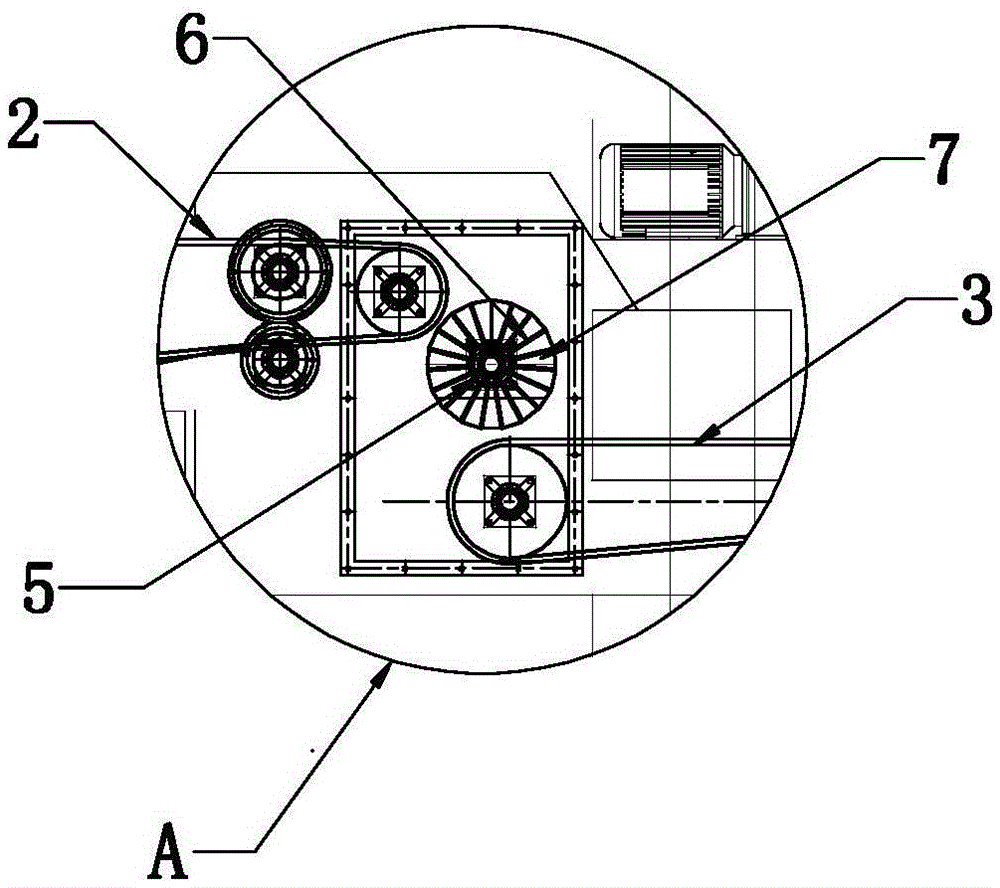

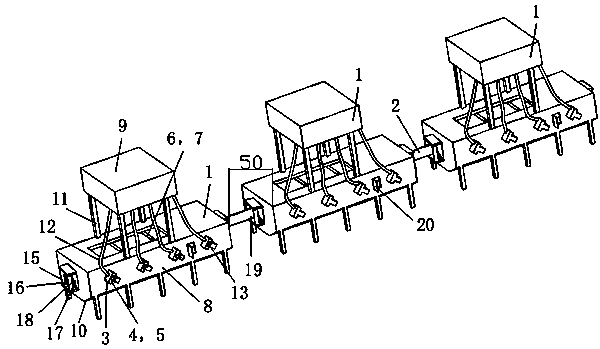

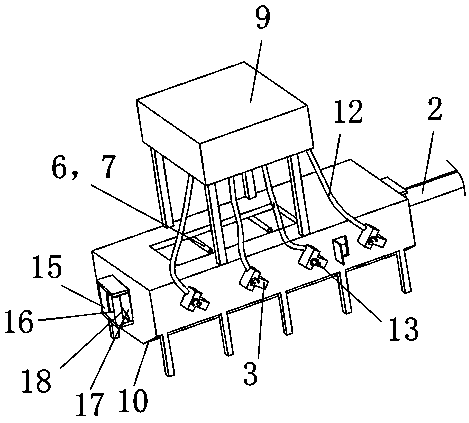

Steel strip horizontal automatic shot blasting production line

ActiveCN106239379BEasy for daily maintenanceEasy maintenanceAbrasive machine appurtenancesAbrasive blasting machinesProduction lineEngineering

The invention discloses a steel strip horizontal automatic shot blasting production line. The production line includes a steel strip unreeling device, a steel strip flattening device, a drying box, a cooling device and a rotary device, a dustproof device and a rolling device that connect several shot blasting sets. The devices achieve steel strip transfer through several driving rollers. The production line also includes at least two shot blasting sets in series connection, a gap of at least 30cm is arranged between the two shot blasting sets, and each shot blasting set consists of a closed box, a shot blasting box and a steel shot collection device. The broad side of steel strip is transferred vertically in the closed box. Several left nozzles and right nozzles are symmetrically arranged on the left side and right side of the closed box along the transmission direction of the steel strip. The shot blasting directions of the left nozzles and right nozzles in each group are opposite respectively. The steel strip shot blasting machine provided by the invention improves the efficiency and quality of steel strip shot blasting, and is convenient for timely maintenance and service in a treatment process.

Owner:江苏京生管业有限公司

Passing-type shot blasting machine

PendingCN107695891APrevent dumpingImprove shot blasting efficiencyAbrasive blasting machinesReciprocating motionStress point

The invention discloses a passing-type shot blasting machine. The passing-type shot blasting machine comprises a shot blasting chamber, a track, walkers, lifting hooks and first clamps. The shot blasting machine is used for treating H-shaped steel. The track is located above the shot blasting chamber. The walkers are installed on the track and can make reciprocating motion along the track. The lifting hooks are installed on the corresponding walkers through iron chains. The cross section of each first clamp is in a square shape, and the lower surfaces of the first clamps are provided with notches. The first clamps can be sleeved into an upper flange plate of the H-shaped steel from the two ends of the H-shaped steel. Lifting lugs are arranged on the upper surfaces of the first clamps. According to the passing-type shot blasting machine, the H-shaped steel can be overhung through the first clamps, and stressing points of the H-shaped steel are placed on the upper flange plate. Comparedwith a traditional iron chain fixation method, the toppling phenomenon possible in the moving process of the H-shaped steel is avoided fundamentally.

Owner:江苏海越铸造机械科技有限公司

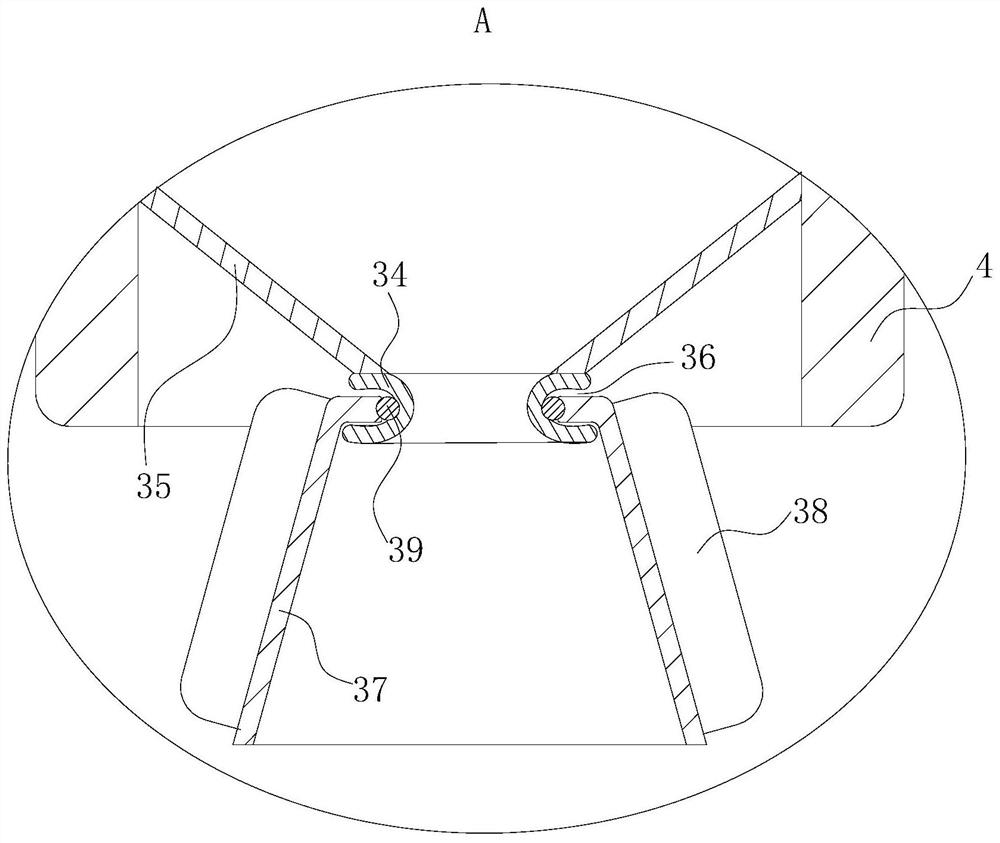

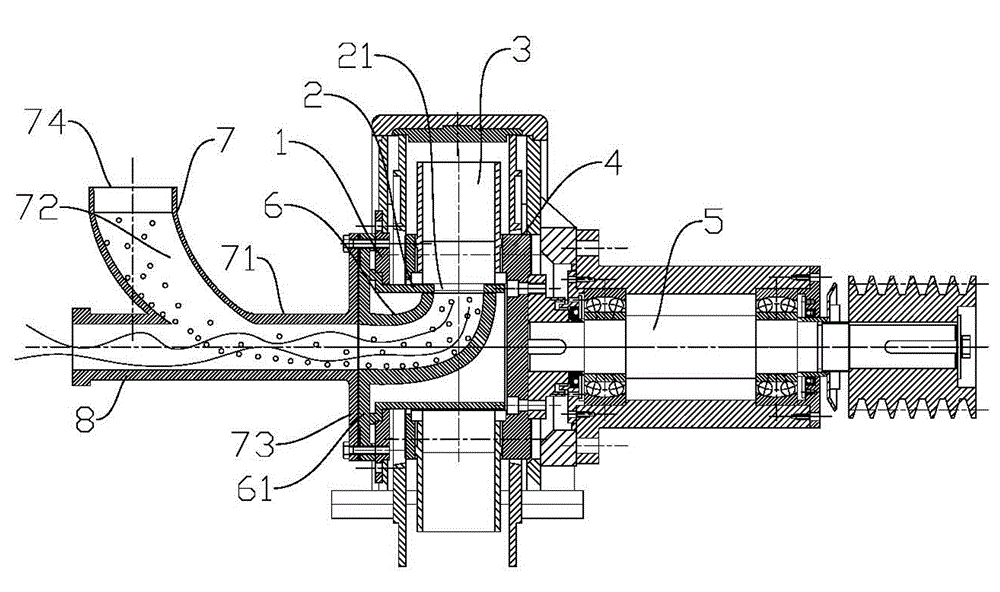

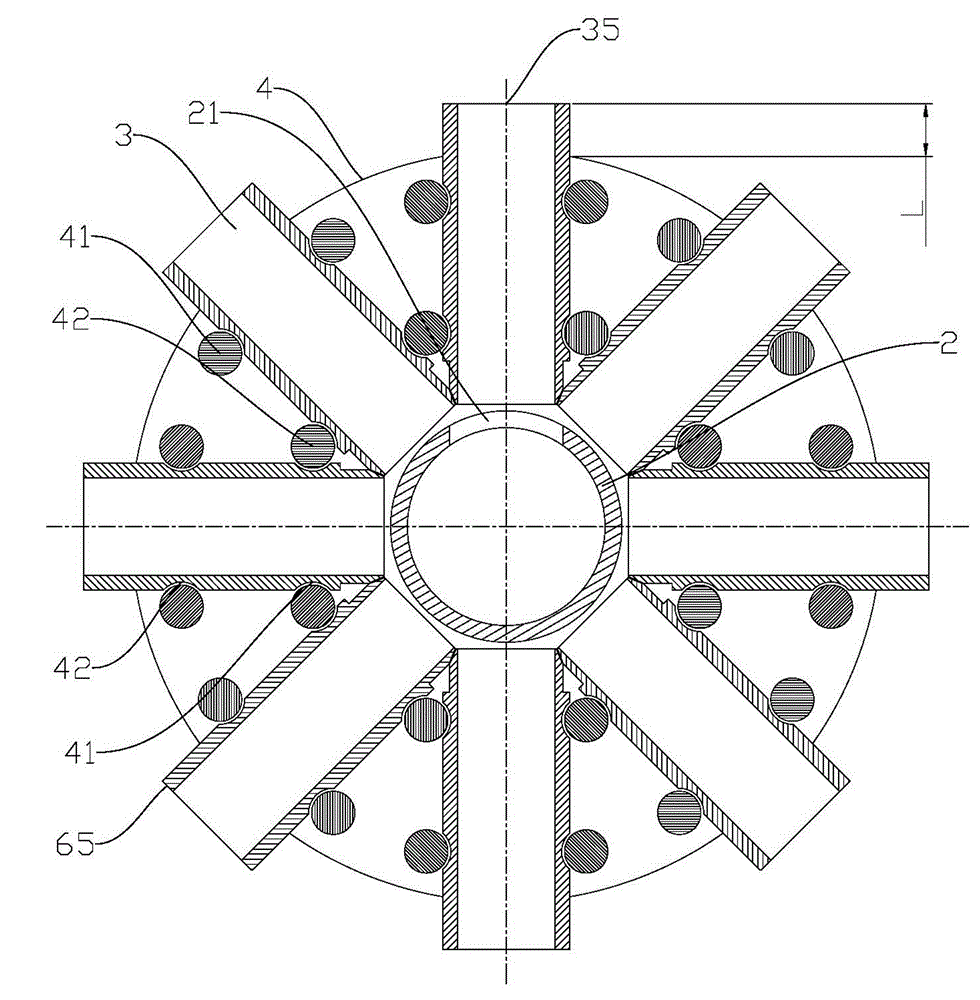

Novel impeller head capable of improving input shot quality

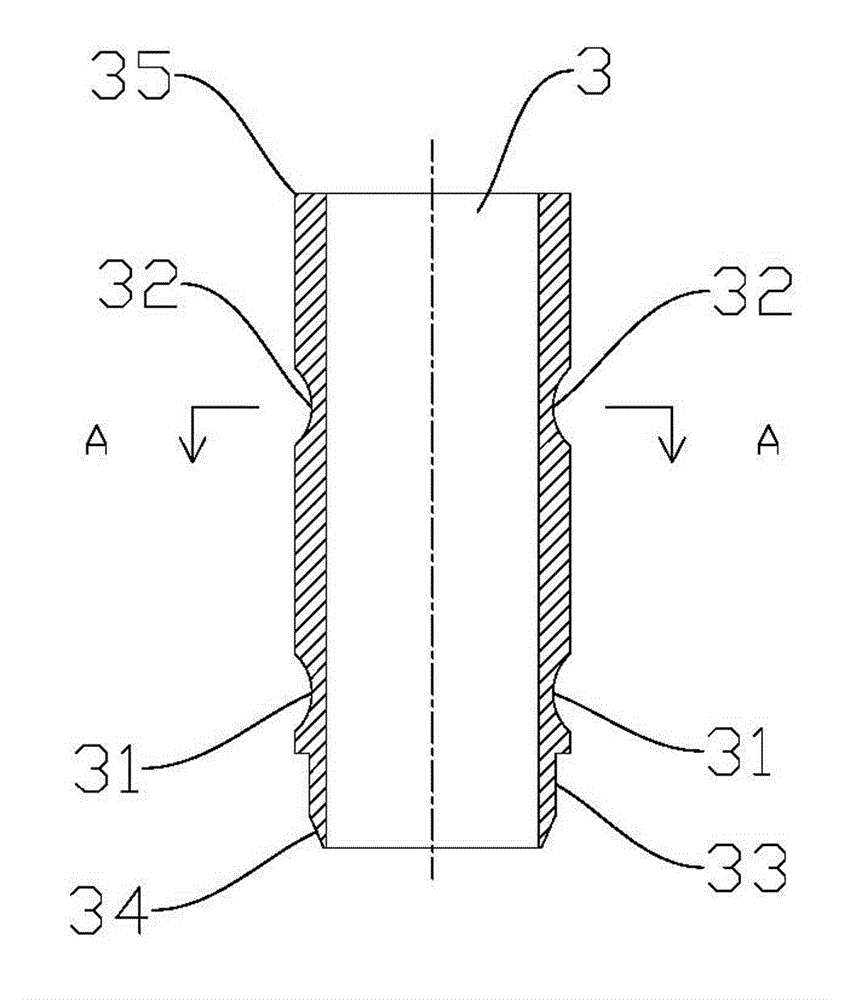

ActiveCN103506962BThe acceleration effect is obviousImprove stabilityImpeller wheelsRotor bladesCircular discImpeller

The invention discloses a novel impeller head capable of improving input shot quality. The novel impeller head comprises a housing, a shot inlet pipe, a directional sleeve, blades, an impeller body and a spindle. The novel impeller head is characterized in that the shot inlet pipe comprises an internal shot inlet pipe and an external shot inlet pipe; the shot outlet of the internal shot inlet pipe is in butt joint with the shot blasting window of the directional sleeve; the diameter of the shot outlet of the straight section of the external shot inlet pipe is equal to that of the shot inlet of the internal shot inlet pipe; the shot outlet of the straight section of the external shot inlet pipe is in butt joint with the shot inlet of the internal shot inlet pipe; the curved section of the external shot inlet pipe is connected with the end of the shot outlet of the straight section, and extends and curves upwards; the air outlet end of a compressed air input pipe is connected with the joint of the straight section and the curved section of the external shot inlet pipe; the blades are shaped like cylindrical tubes; circular arc-shaped grooves are formed in the outer surfaces of the blades; the axes of the grooves are perpendicular that of the blades; a plurality of cylindrical near impeller fixed rods and a plurality of cylindrical far impeller fixed rods are arranged between two disks of the impeller body of the impeller head, and matched with the grooves in the blades; a thin part is arranged at the end part of a near impeller; an external conical surface is arranged at the end of the thin part; the external conical surfaces of two adjacent blades are closely butted. The impeller head has the advantages that less shot materials are used, abrasion to the blades is less, and the shot blasting quality is high.

Owner:SHANDONG KAITAI SHOT BLASTING MACHINERY

Copper processing product material surface treatment method

The invention belongs to the field of surface treatment, particularly relates to a copper processing product material surface treatment method. Aiming to solve the problem that at present, the coppercasting burr treatment time is long, the following scheme is provided. The method comprises the following steps that S1, copper casting products are placed in clear water to be cleaned; S2, the cleaned copper casting products are taken out and placed on a metal net frame to be drained, and then the drained copper casting products are placed in a drying chamber to be dried; S3, the dried copper casting products are inspected through an ultrasonic flaw detector; S4, the qualified copper casting products are placed in a constant-temperature box to be stored; S5, the copper casting products in theconstant-temperature box are taken out and subjected to shot blasting treatment through a crawler-type shot blasting machine; and S6, the copper casting products subjected to shot blasting treatmentare subjected to shot removing treatment. According to the method, the copper casting products are heated through the constant-temperature box so that the copper casting products can be subjected to shot blasting treatment at a certain temperature, the shot blasting treatment time is shortened, and the actual treatment cost is reduced.

Owner:诸暨市领诚信息技术有限公司

A double-sided shot blasting derusting machine for building steel plates

ActiveCN111791151BReasonable structural designImprove shot blasting efficiencyAbrasive machine appurtenancesEngineeringStructural engineering

The invention provides a double-sided shot blasting derusting machine for building steel plates, which includes a conveyor belt. A pushing structure is provided at one end of the conveyor belt. The body of the rust machine. The structure design of the present invention is reasonable, through the provided pushing structure and steering structure, the pushing structure pushes the steel plate on the conveyor belt into the groove plate on the steering structure, uses the turntable to turn the steel plate from the horizontal direction to the vertical direction, and makes the steel plate vertical Sent to the shot blasting derusting machine, and shot blasts both sides of the steel plate at the same time, which improves the shot blasting efficiency.

Owner:芜湖天达重工有限公司

Steel strip horizontal automatic shot blasting production line

ActiveCN106239379AEasy for daily maintenanceEasy maintenanceAbrasive machine appurtenancesAbrasive blasting machinesProduction lineSpray nozzle

The invention discloses a steel strip horizontal automatic shot blasting production line. The production line includes a steel strip unreeling device, a steel strip flattening device, a drying box, a cooling device and a rotary device, a dustproof device and a rolling device that connect several shot blasting sets. The devices achieve steel strip transfer through several driving rollers. The production line also includes at least two shot blasting sets in series connection, a gap of at least 30cm is arranged between the two shot blasting sets, and each shot blasting set consists of a closed box, a shot blasting box and a steel shot collection device. The broad side of steel strip is transferred vertically in the closed box. Several left nozzles and right nozzles are symmetrically arranged on the left side and right side of the closed box along the transmission direction of the steel strip. The shot blasting directions of the left nozzles and right nozzles in each group are opposite respectively. The steel strip shot blasting machine provided by the invention improves the efficiency and quality of steel strip shot blasting, and is convenient for timely maintenance and service in a treatment process.

Owner:江苏京生管业有限公司

Automatic calling method for shot blasting speed process of shot blasting machine

PendingCN113146484AGuarantee the quality of shot blastingEliminate wear and tearAbrasive machine appurtenancesStructural engineeringMechanical engineering

The invention discloses an automatic calling method for a shot blasting speed process of a shot blasting machine, and relates to the technical field of steel production. The automatic calling method comprises the following steps that the shot blasting quality of steel plates is tracked for a long time to form a shot blasting speed process requirement; and after shot blasting steel plate information is transmitted into a secondary stage through an identification system, the secondary stage searches the shot blasting process according to the identification information and transmits the shot blasting process to a primary stage for executing the shot blasting speed. Through surface quality verification of the steel plates of different steel types and thicknesses after shot blasting, the optimal shot blasting speed is set, the production quantity of the shot blasting steel plates is improved, steel shot consumption is reduced, and buckling and the like of thin steel plates caused by long shot blasting striking time is reduced.

Owner:NANJING IRON & STEEL CO LTD

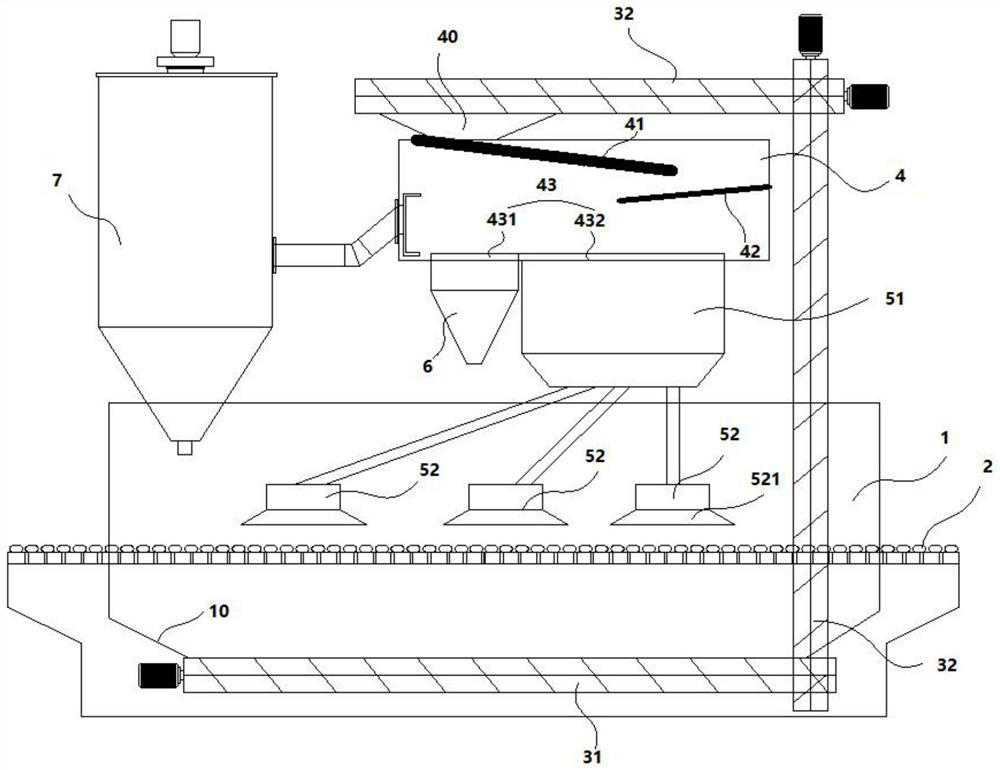

Shot blasting system of shot blasting machine

InactiveCN113305746AImprove shot blasting efficiencyProtect your healthAbrasive machine appurtenancesAbrasive blasting machinesPollutantAssembly line

The invention discloses a shot blasting system of a shot blasting machine. The shot blasting system comprises a shot blasting chamber, a material conveying belt, a circulating material conveying structure, a shot distributing box, a shot blasting structure and a filtering box. The material conveying belt is arranged to convey workpieces to be subjected to shot blasting into the shot blasting chamber for shot blasting in an assembly line mode, so that the shot blasting efficiency is high, meanwhile, the circulating material conveying structure and the shot distributing box are arranged, shot blasting shots can be rapidly recycled, manual feeding is not needed, and the shot blasting system is simple and convenient; and the filtering box is arranged, in the shot blasting process, pollutants on the workpiece to be subjected to shot blasting float in the air in a dust form and are filtered and separated through the filtering box, and the body health of operators is guaranteed.

Owner:湖北毕昌机械有限公司

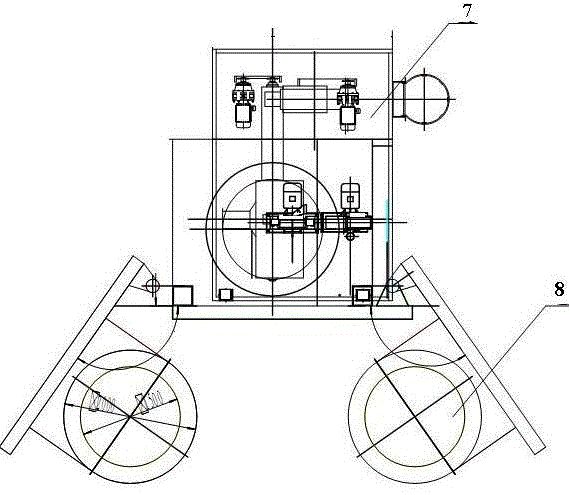

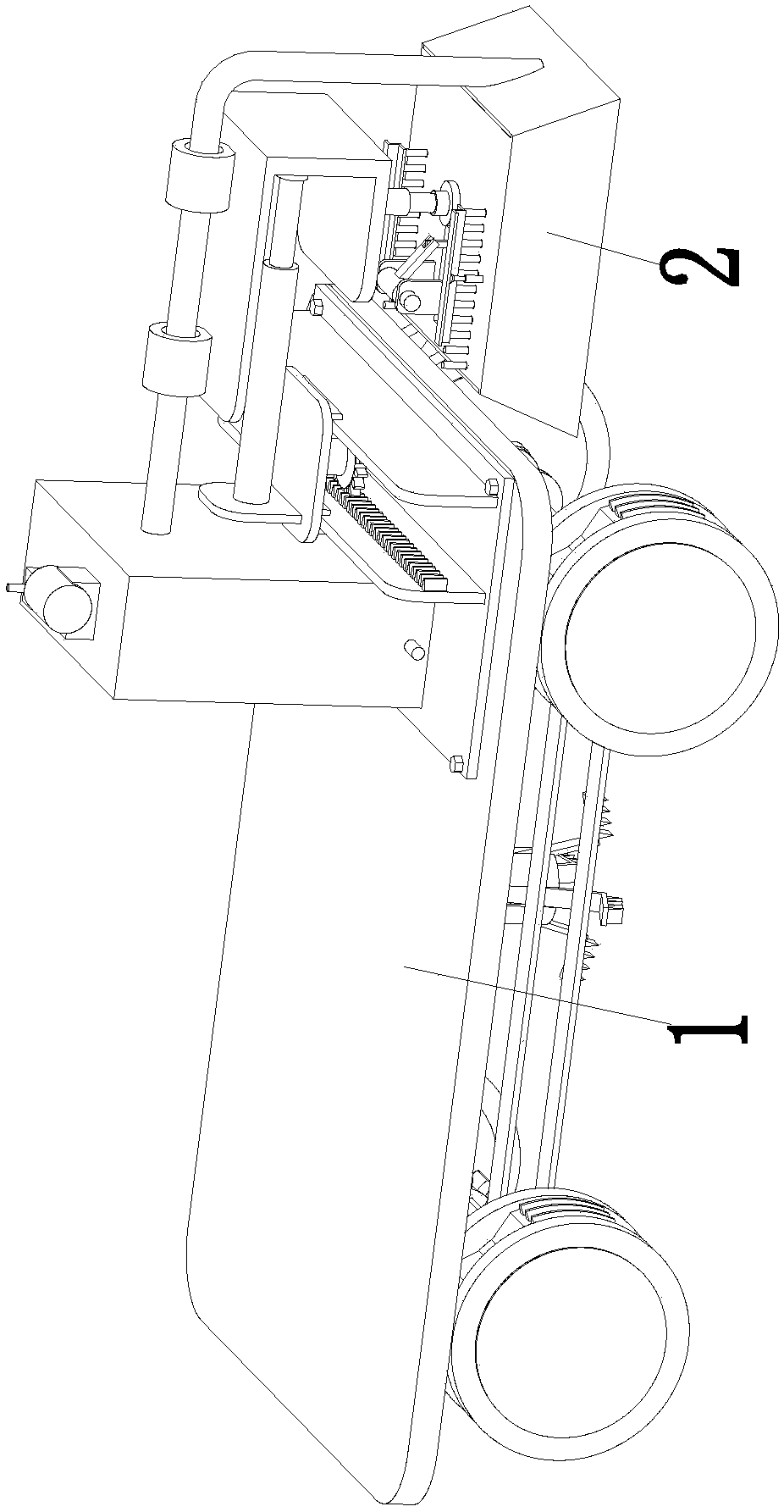

Turnover type shot blasting machine for coil wire

PendingCN108393812AImprove shot blasting efficiencyPromote sheddingAbrasive machine appurtenancesAbrasive blasting machinesCamMechanical engineering

The invention discloses a turnover type shot blasting machine for a coil wire. The turnover type shot blasting machine comprises a shot blasting chamber, a shot blasting device, a turnover device anda driving device. The turnover device is arranged on the door side of the shot blasting chamber, the turnover device is provided with a turnover shaft parallel to the reference axial direction, and aturnover frame is installed on the turnover shaft. A first hopper assembly is installed on the turnover frame and located on one side of the turnover shaft, a second hopper assembly is installed on the turnover frame and located on the other side of the turnover shaft, one of the first hopper assembly and the second hopper assembly is located inside a door, the other of the first hopper assembly and the second hopper assembly is located outside the door, and the positions of the first hopper assembly and the second hopper assembly can be interchanged based on turnover. The first hopper assembly and the second hopper assembly each is provided with a set of hanger rod assemblies, the hanger rod assemblies are provided with seat parts and cams which are installed on the seat parts, and the cams are used for hanging the coil wire. The driving device is used for driving the cams to rotate. According to the turnover type shot blasting machine for the coil wire, the coil wire is easier to disperse.

Owner:UNIV OF JINAN

A new type of crawler shot blasting equipment for uniform shot blasting

ActiveCN111469056BEven shot blastingImprove shot blasting efficiencyAbrasive machine appurtenancesAbrasive blasting machinesImpellerStructural engineering

Owner:安徽中嘉环保建材科技有限公司

A shot blasting device for the production and processing of aluminum alloy castings

ActiveCN112338815BEasy to clamp and fixImprove stabilityAbrasive machine appurtenancesAbrasive blasting machinesElectric machineryMaterials science

The invention discloses a shot blasting device for the production and processing of aluminum alloy castings, which comprises a shot blasting machine main body and a box. The shot blasting machine main body is fixed in the middle of one side of the box. The shot blasting bucket, the connection between the box body and the main body of the shot blasting machine is provided with a shot inlet, the motor is fixedly installed on the back of the box body, the front of the inner cavity of the box body is fixedly connected with a fixed plate, and the inner wall of the box body and the fixed plate are fixed. There is a connecting cylinder, three U-shaped plates and two triangular plates for rotation, and the two ends of the three U-shaped plates are respectively fixedly connected with the two triangular plates; The stability of the casting installation also improves the efficiency of the shot blasting machine for aluminum alloy castings, facilitates the disassembly of the aluminum alloy castings, so that the aluminum alloy castings to be shot can be replaced faster, and the shot blasting of the aluminum alloy castings is improved. efficiency.

Owner:江西科迪亚精密工业有限公司

Novel crawler-type shot blasting equipment capable of achieving uniform shot blasting

ActiveCN111469056AImprove shot blasting efficiencyIncrease transmission strengthAbrasive machine appurtenancesAbrasive blasting machinesStructural engineeringMechanical engineering

The invention discloses novel crawler-type shot blasting equipment capable of achieving uniform shot blasting. The novel crawler-type shot blasting equipment comprises a treatment box, a shot blastingmachine is arranged at the top of the treatment box through a corrugated pipe, a transmission box is fixedly connected to the top of the back face of the treatment box, a reciprocating screw is movably connected to the interior of the transmission box through a bearing, and the front end of the reciprocating screw penetrates to the outer side of the transmission box; and the surface of the reciprocating screw is slidably connected with a sliding sleeve through a connecting rod, and the bottom of the sliding sleeve is fixedly connected to the top of the shot blasting machine. According to thenovel crawler-type shot blasting equipment, a transmission mechanism drives the sliding sleeve to reciprocate front and back through the reciprocating screw, so that the sliding sleeve drives the shotblasting machine to move front and back to conduct uniform shot blasting on parts, the advantage of uniform shot blasting is achieved, the problems that a shot blasting device of an existing crawler-type shot blasting machine is fixedly arranged, cannot move and cannot conduct uniform shot blasting on the parts on the two sides when the shot blasting device carries out shot blasting through an impeller are solved, and the shot blasting efficiency is improved to a certain extent.

Owner:安徽中嘉环保建材科技有限公司

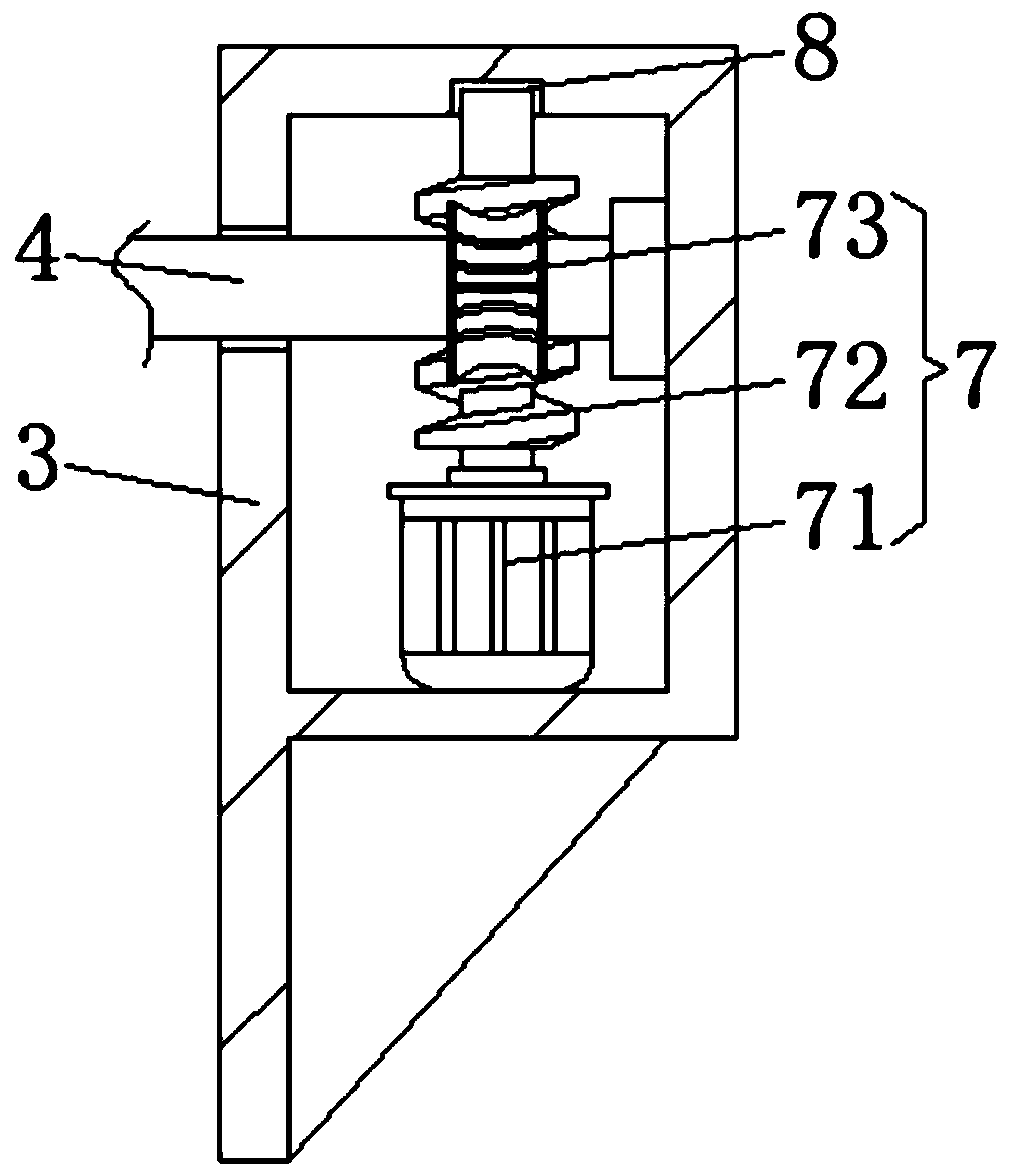

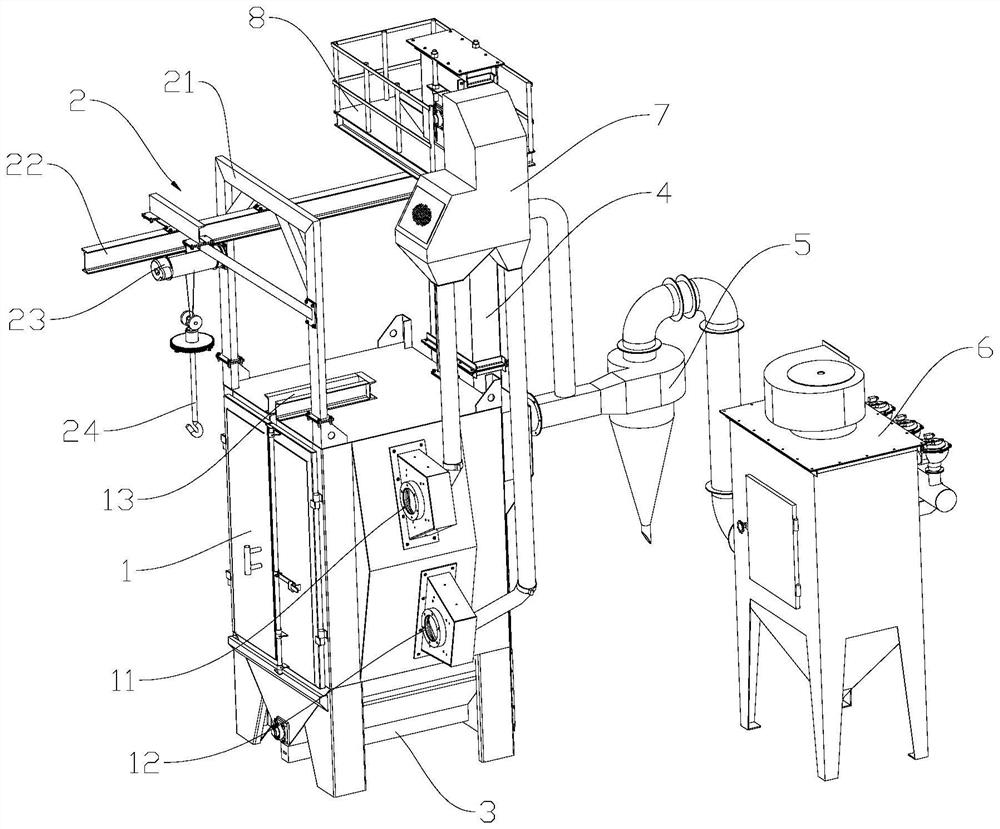

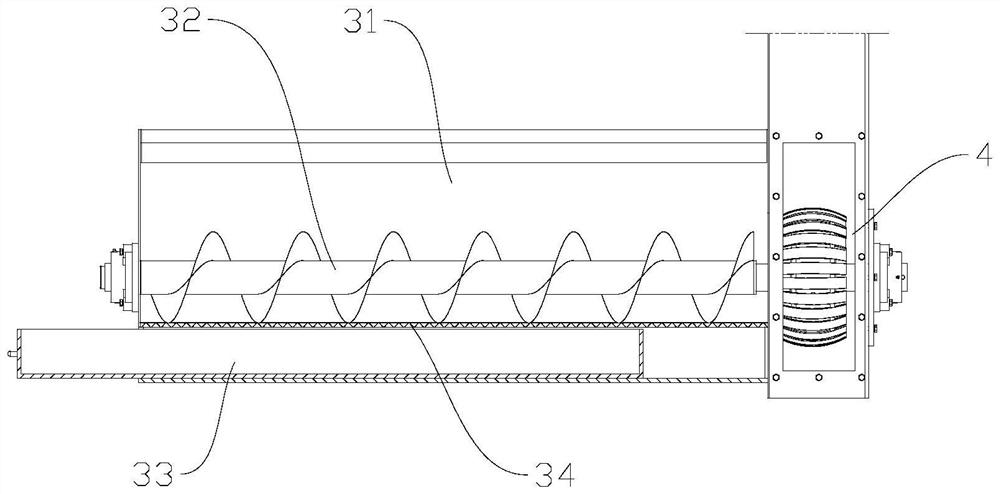

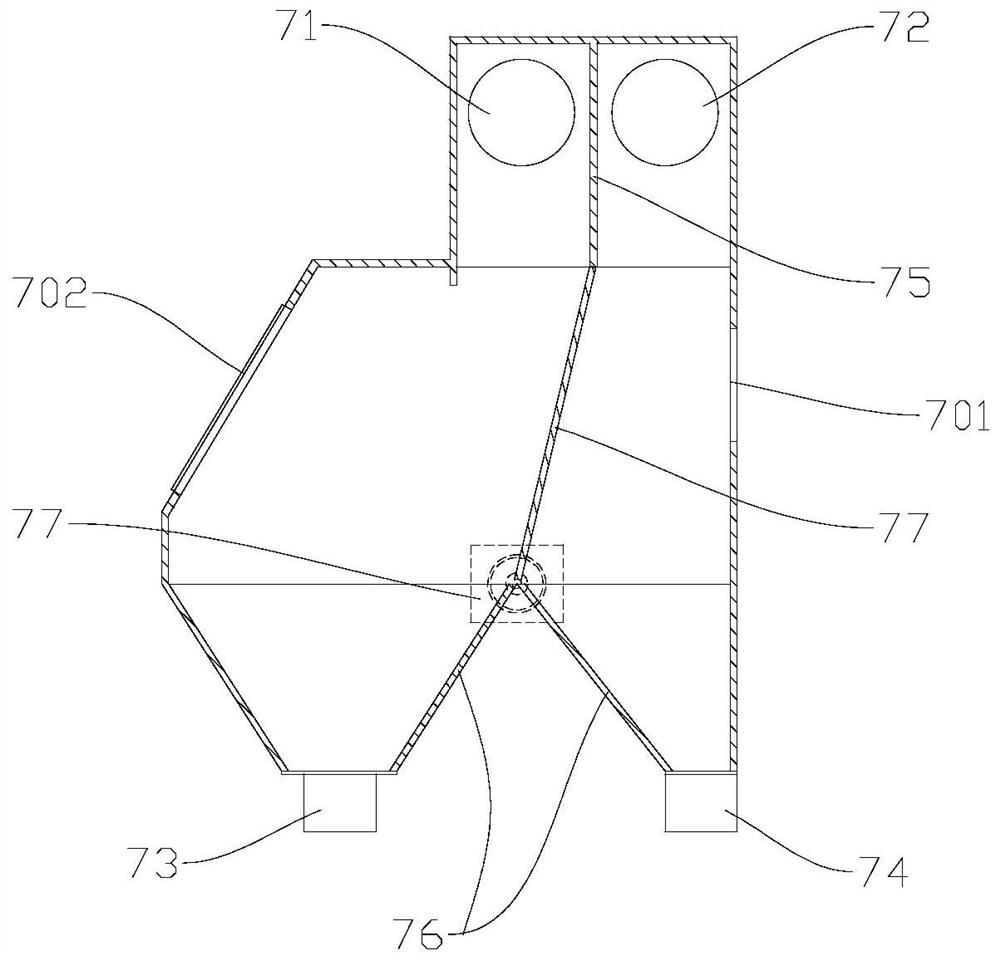

Hanging through type efficient shot blasting machine

PendingCN114346914AImprove versatilityAdapt to shot blasting needsAbrasive machine appurtenancesAbrasive blasting machinesAugerWaste collection

The invention discloses a hanging through type efficient shot blasting machine which comprises a shot blasting chamber, a hanging device, an auger device, an elevator, a cyclone dust collector and a filter cartridge dust collector, the hanging device is arranged above the shot blasting chamber, the auger device is arranged at the bottom of the shot blasting chamber, the elevator is arranged on one side of the shot blasting chamber, and the cyclone dust collector is arranged on the other side of the shot blasting chamber. The cyclone dust collector is respectively connected with the shot blasting chamber and the return box through a dust removal pipeline, the filter cartridge dust collector is connected with the cyclone dust collector through a dust removal pipeline, the auger device comprises a blanking box, an auger and a waste collection drawer, the blanking box is arranged at the bottom of the shot blasting chamber, the auger is transversely arranged in the blanking box, one end of the auger is in synchronous transmission connection with the elevator, and the other end of the auger is in synchronous transmission connection with the waste collection drawer. The waste collecting drawer is arranged at the bottom of the blanking box, and a sieve plate is arranged between the blanking box and the waste collecting drawer. Through cooperation of the auger device and the elevator, used shots can be screened and recycled and conveyed back to the shot blasting device to be reused, raw materials are saved, and the shot blasting efficiency is improved.

Owner:潍坊华星机械有限公司

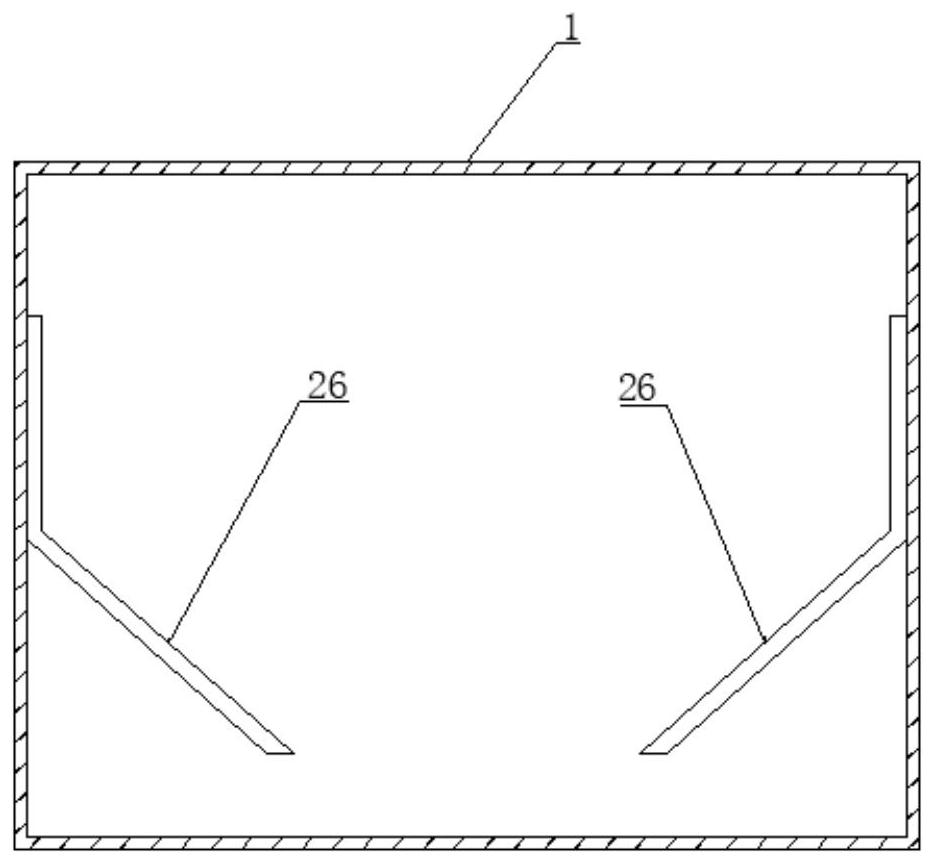

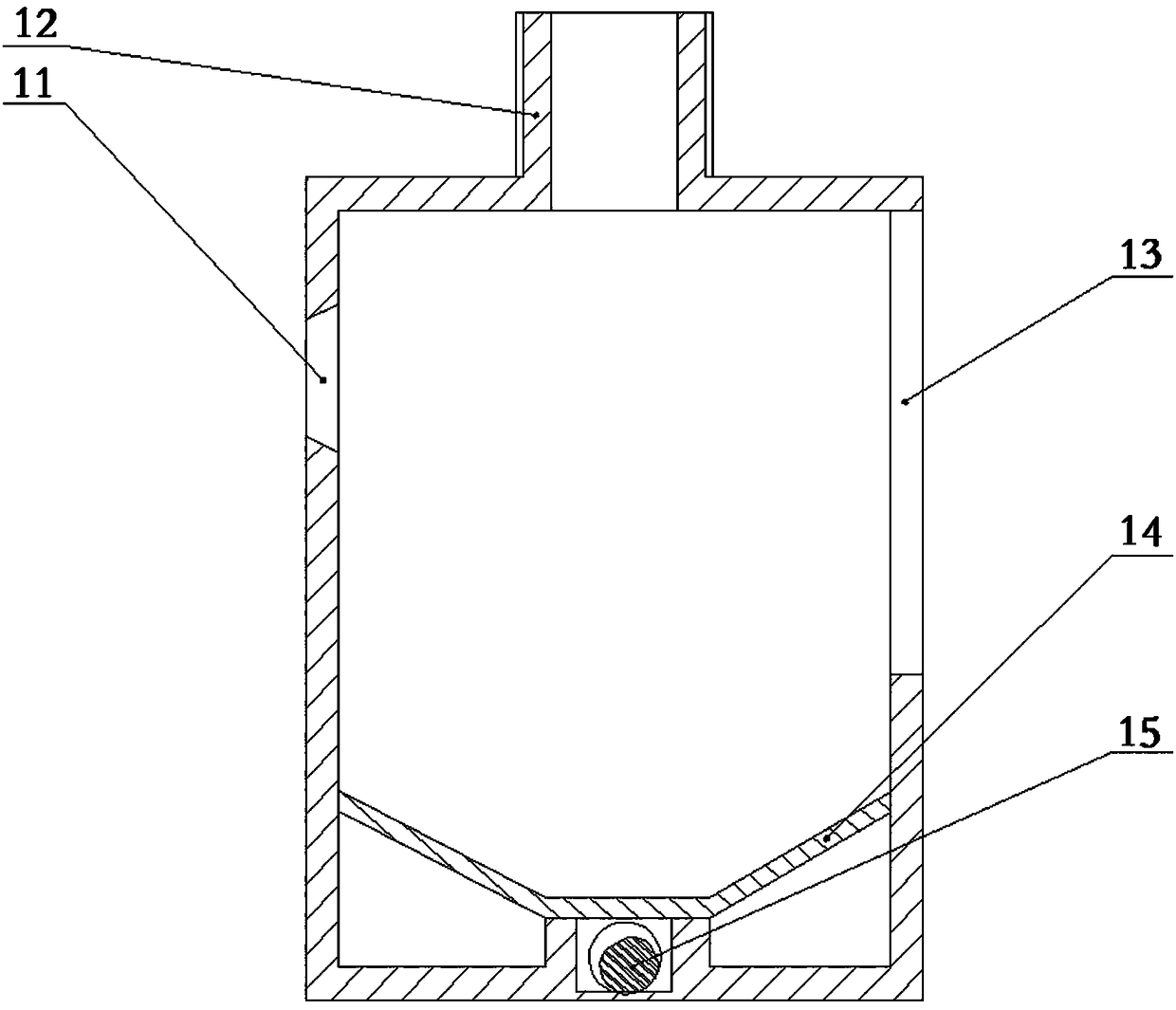

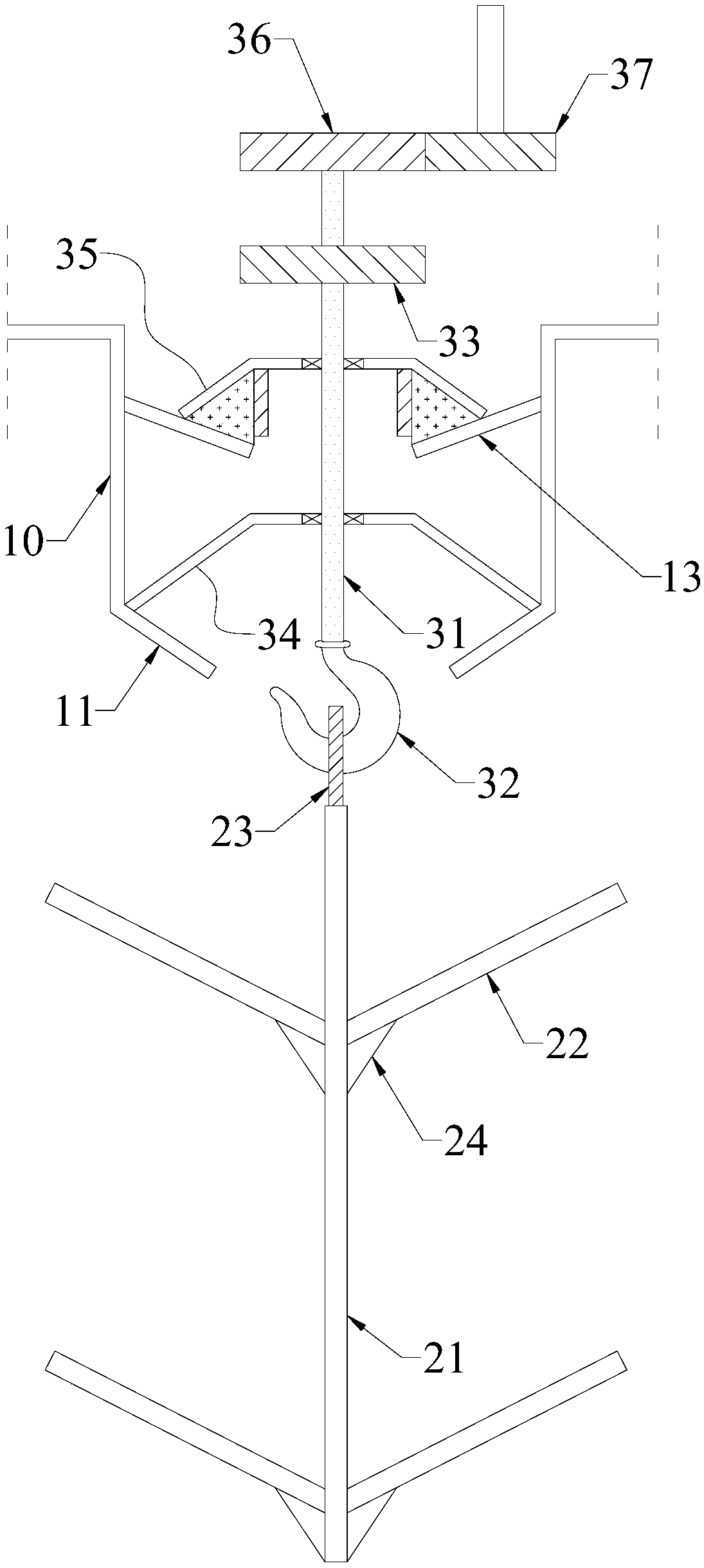

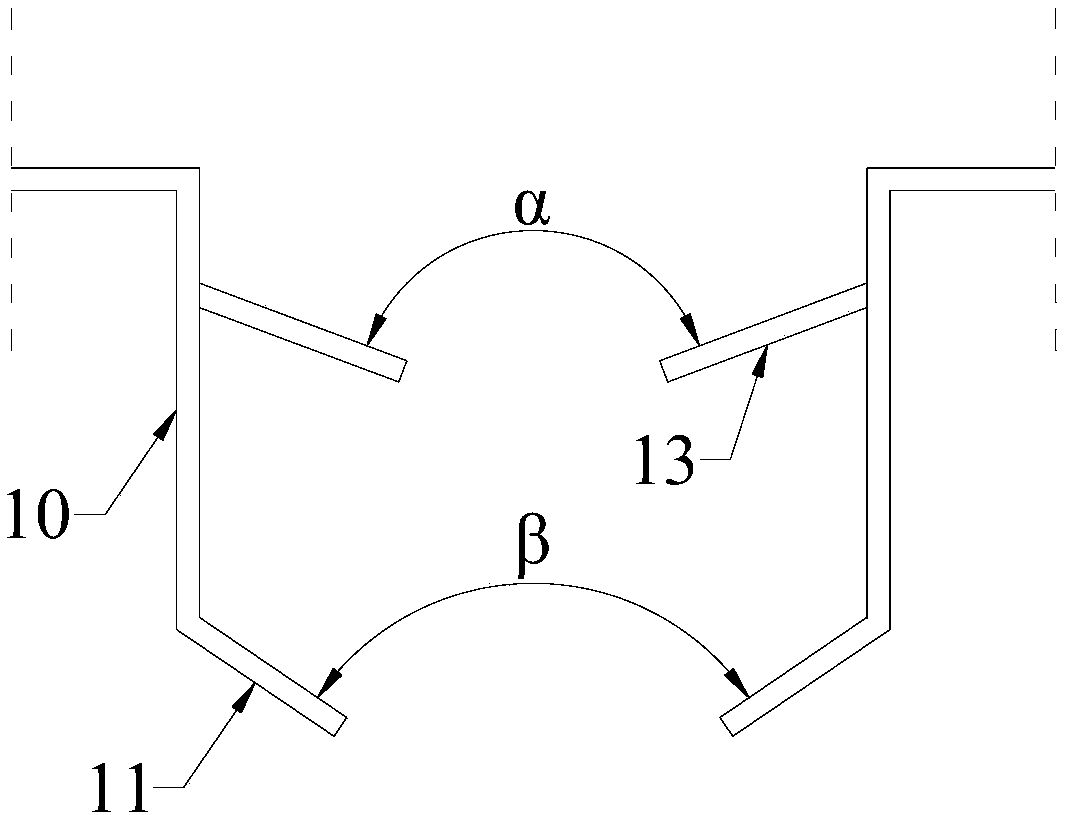

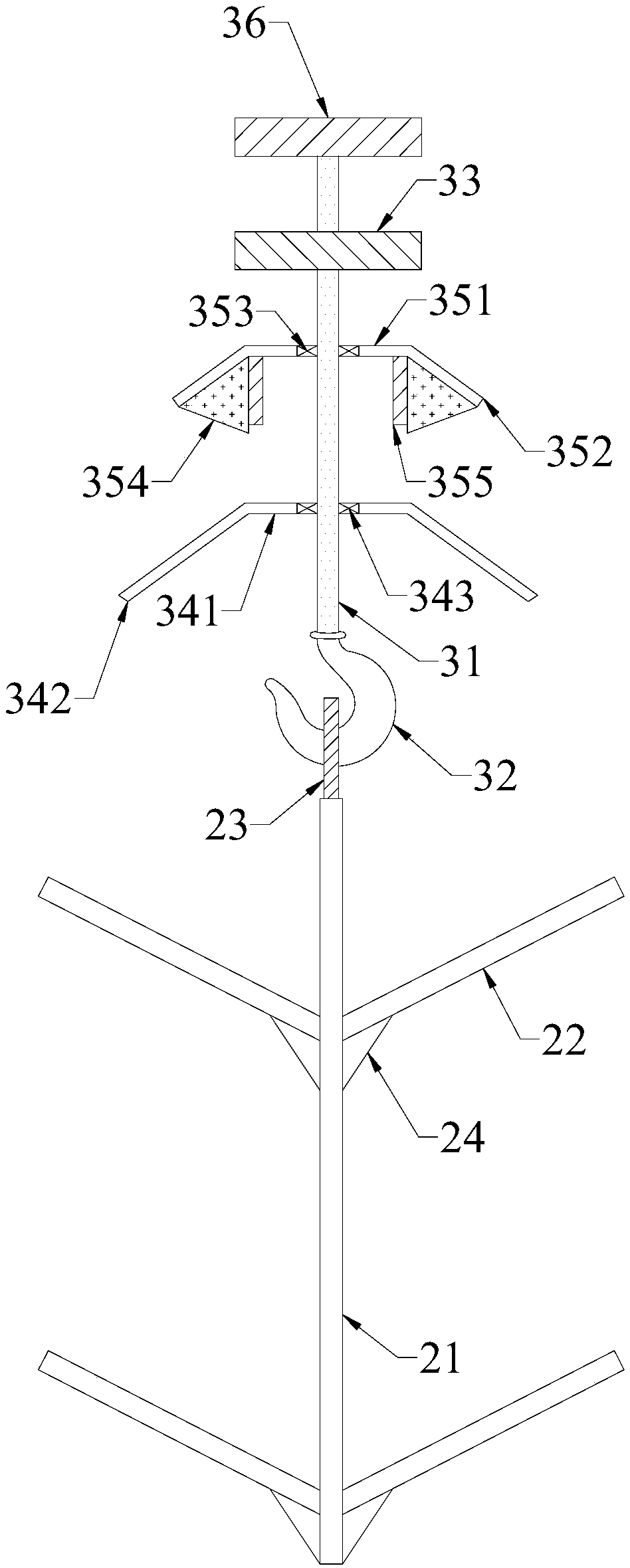

Dedicated hanging rack for shot blasting of cast cylinder block of engine

The invention relates to a dedicated hanging rack for shot blasting of a cast cylinder block of an engine. The dedicated hanging rack for shot blasting of the cast cylinder block of the engine comprises a lower hanging rod, multiple inclined rods arranged on the outer side of the lower hanging rod, a lifting lug fixedly arranged at the upper end of the lower hanging rod, a lifting hook matched with the lifting lug and an upper hanging rod. The two sides of a guide groove are provided with first inclined plates which are mutually symmetrical. The outer side of the upper hanging rod is sleeved with a first baffle. The two sides of the guide groove are further provided with second inclined plates which are mutually symmetrical. The outer side of the upper hanging rod is further sleeved with asecond baffle. Elastic rods with triangular cross sections are arranged between second inclined plate portions and the second inclined plates. The side, close to the upper hanging rod, of each elastic rod is fixedly provided with a plate-shaped electromagnet. The upper end of the upper hanging rod is fixedly provided with a driven wheel. In the shot blasting process, the cast cylinder block of the engine can rotate, a shot blasting dead angle is avoided, the shot blasting effect is good, and the shot blasting efficiency is high. The seal performance between the dedicated hanging rack and a guide groove in a shot blasting machine is good, it is avoided that shot blasting dust overflows, and the shot blasting dust is not prone to accumulating in the guide groove.

Owner:HEFEI JAC CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com