Shot blasting machine for rust removal of steel member

A technology of steel components and shot blasting machines, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, explosion generating devices, etc., which can solve the problems of increased labor intensity and operational safety risks, inability to remove, cleaning equipment selection and arrangement Unreasonable and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

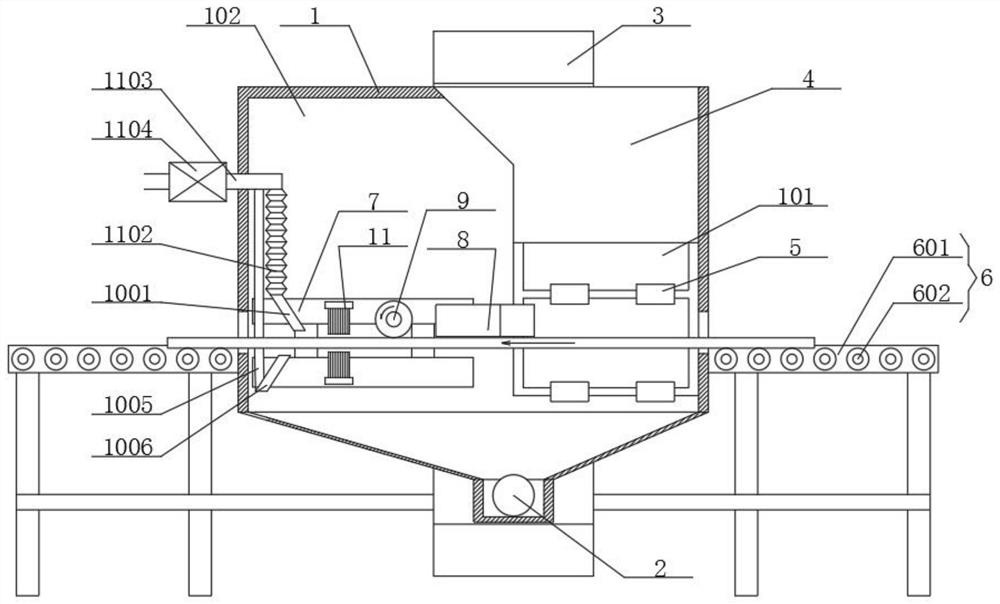

[0033] Such as figure 1 As shown, the shot blasting machine for derusting steel components includes a casing 1 and a hoist 3. A support mechanism 6 for supporting steel plates is provided outside the casing 1. A lower screw conveyor 2 is connected through the lower end of the casing 1. The interior of the shell 1 is provided with a shot blasting chamber 101 and a cleaning chamber 102. The interior of the shot blasting chamber 101 is provided with a pellet ash separator 4, and a shot blasting device 5 is provided below the pellet ash separator 4. The shot conveying mechanism is connected with the shot blasting device 5, the upper end of the hoist 3 is located above the shot ash separator 4, and the lower end of the hoist 3 is located below the lower screw conveyor 2;

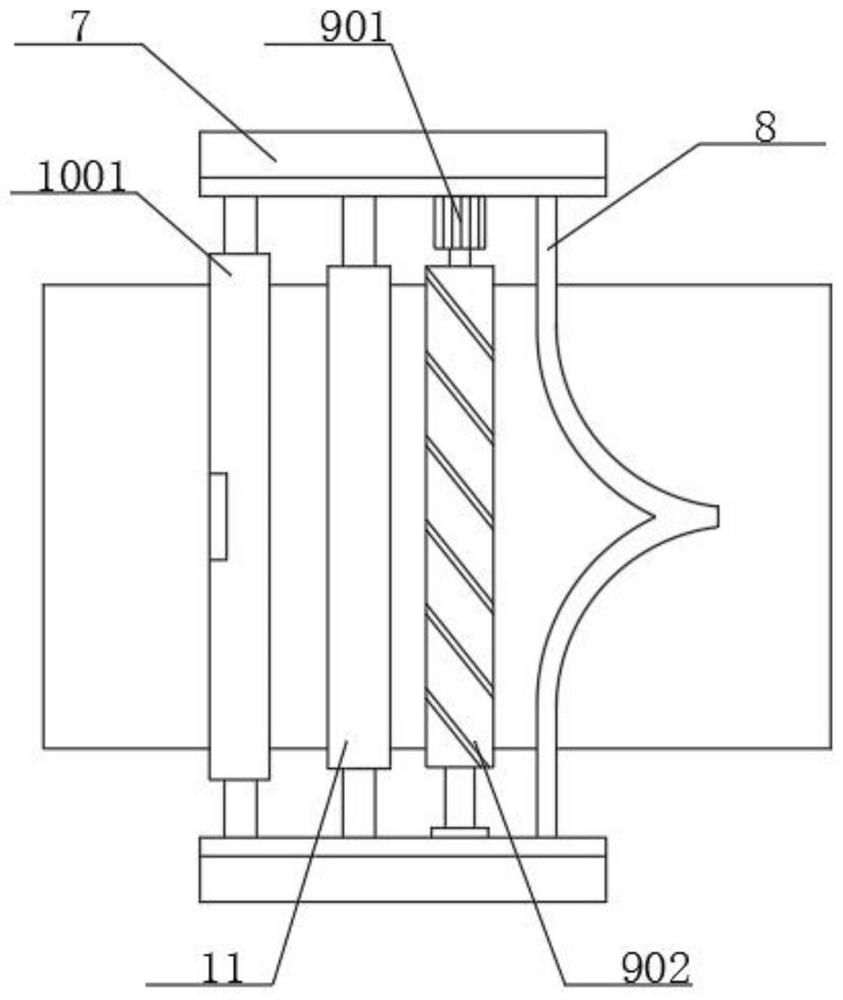

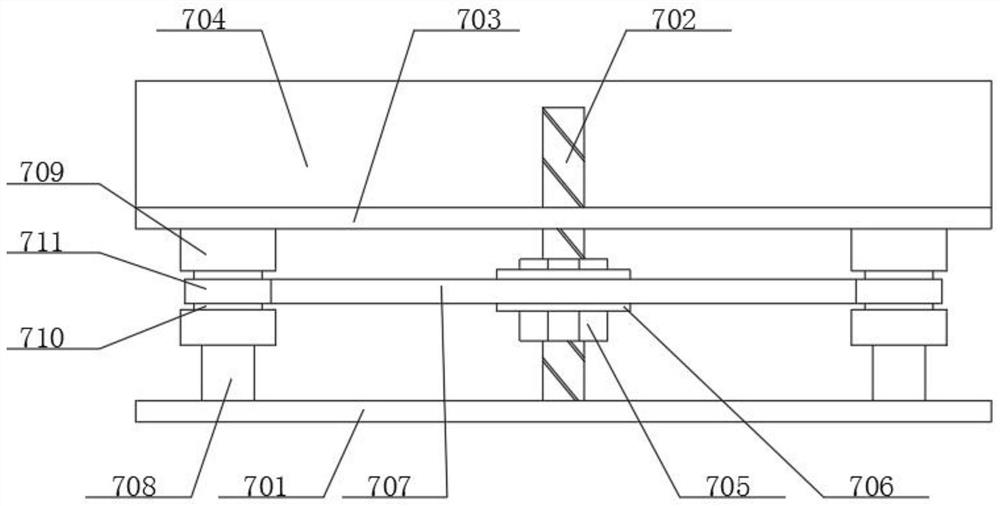

[0034] The inner wall of the cleaning chamber 102 is connected with a receiving mechanism 7, and the receiving mechanism 7 is connected with a scraper 8, a rolling brush cleaning mechanism 9, a secondary cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com