Patents

Literature

56results about How to "Reasonable distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

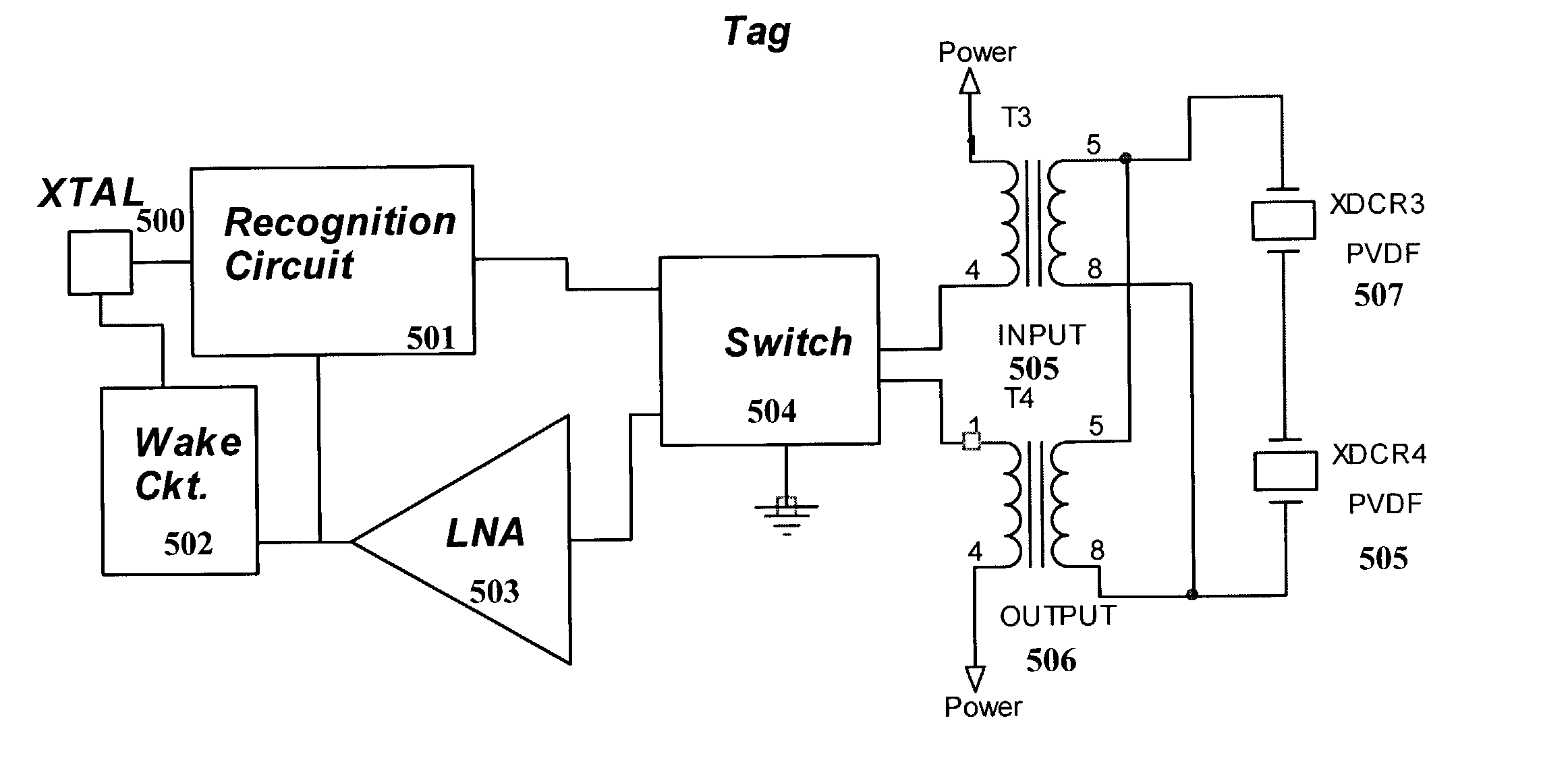

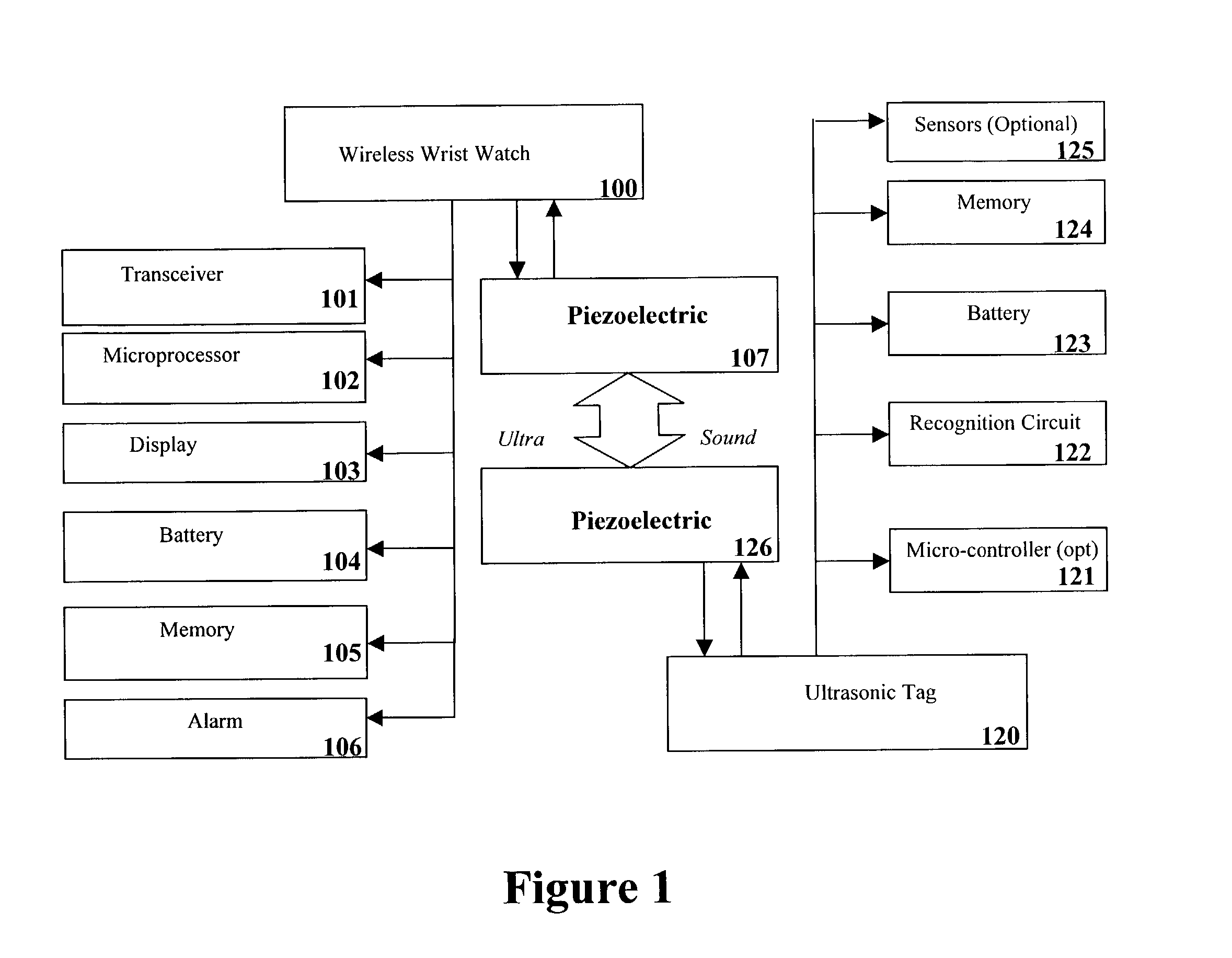

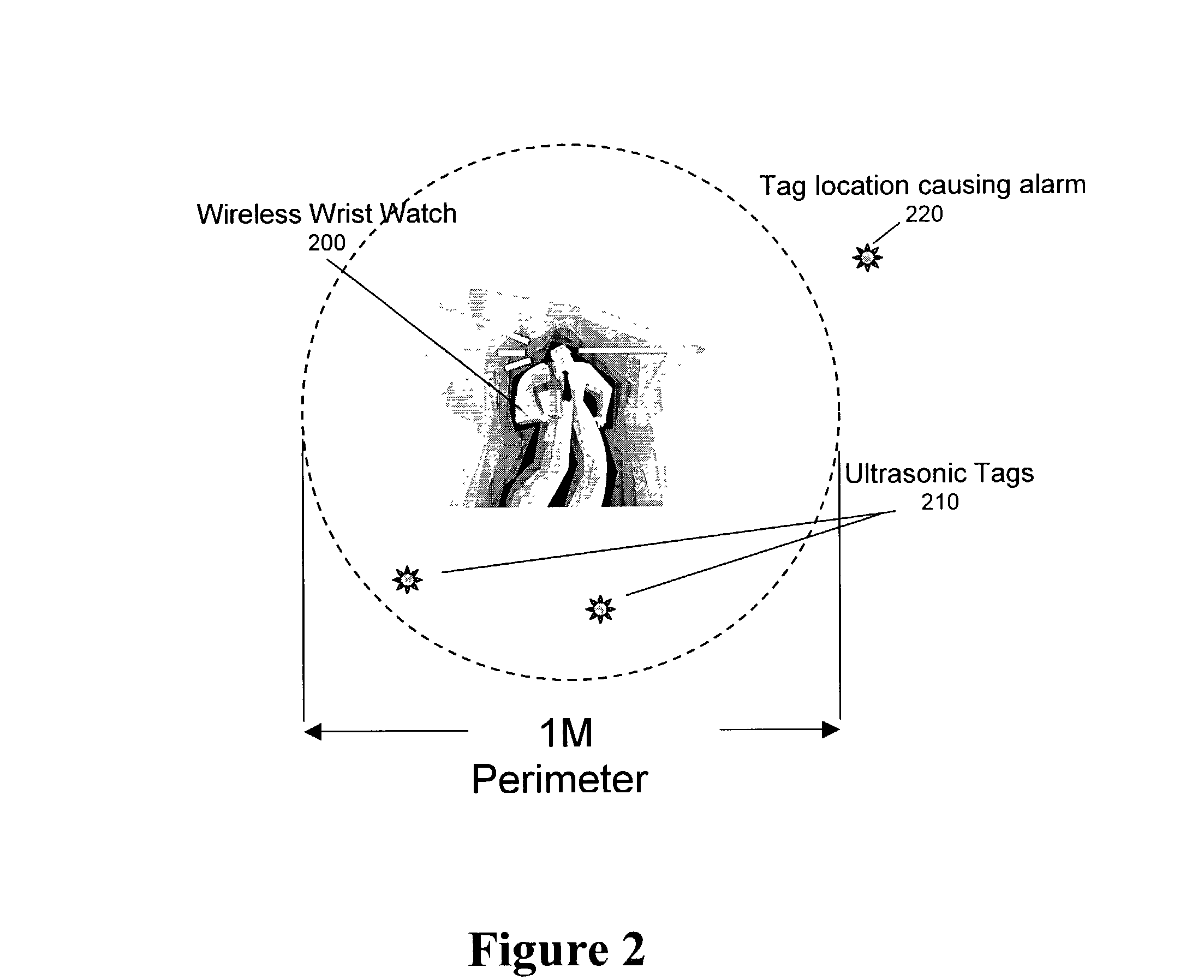

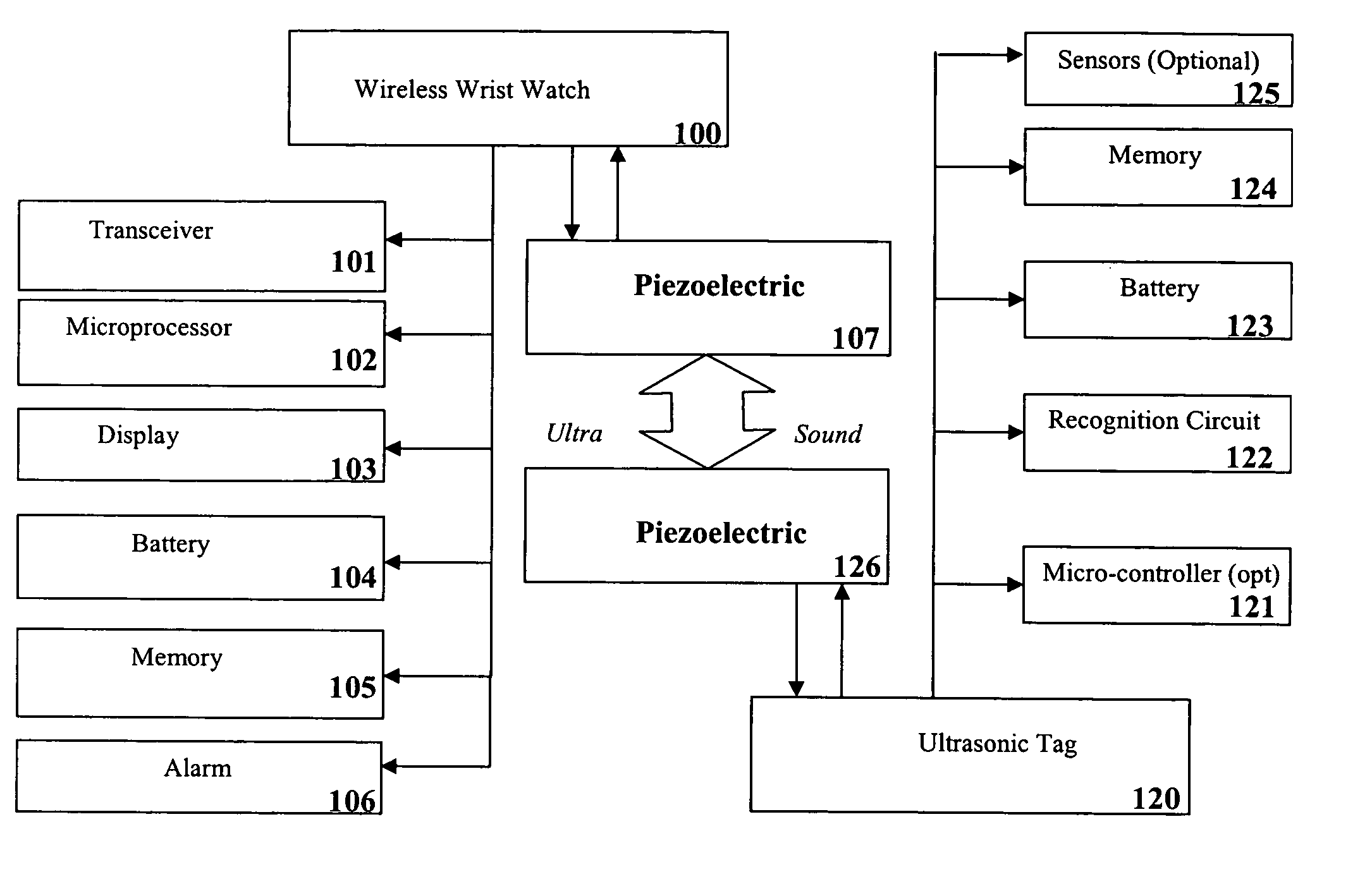

Ultrasonic transmitter and receiver systems and products using the same

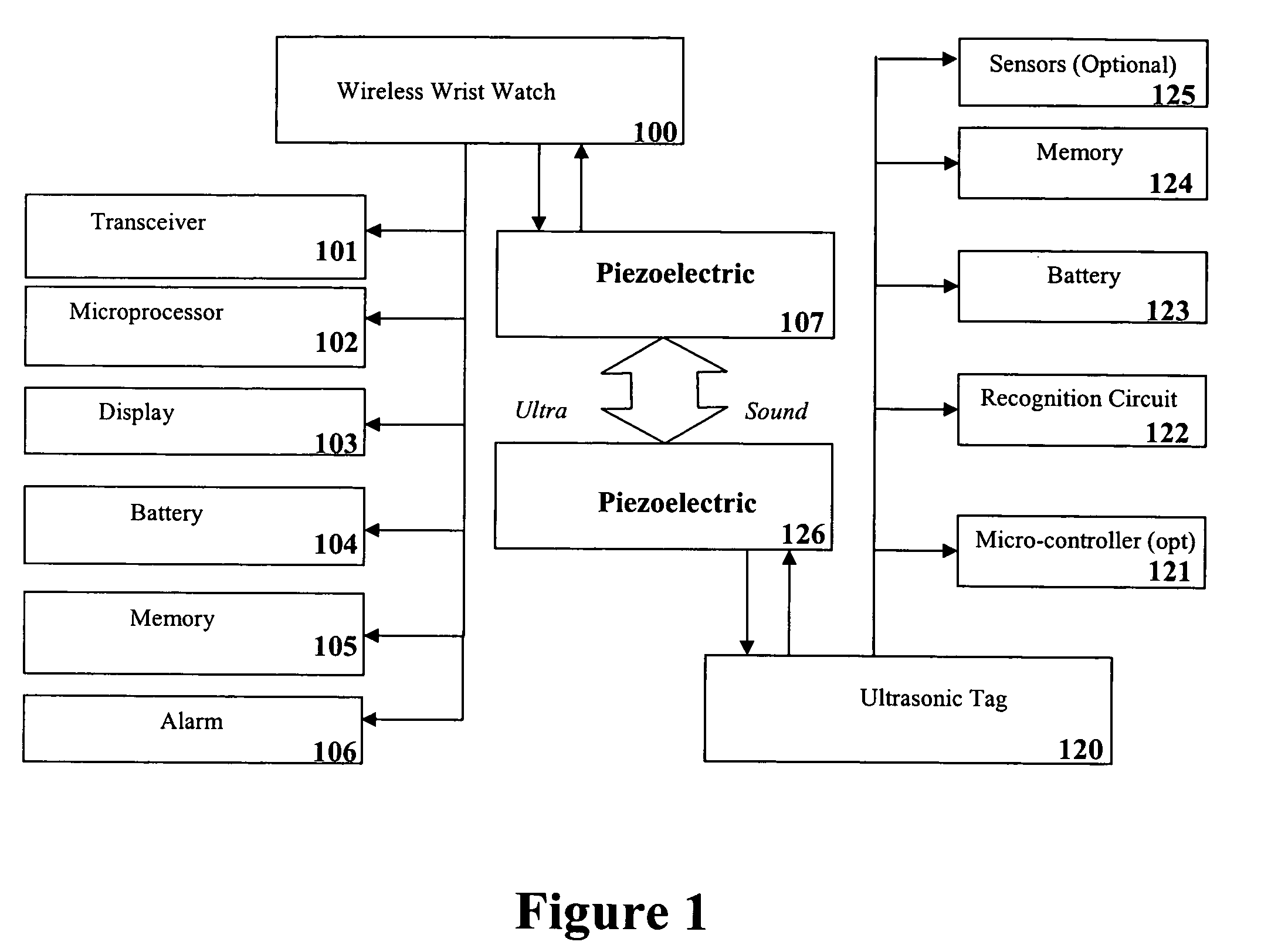

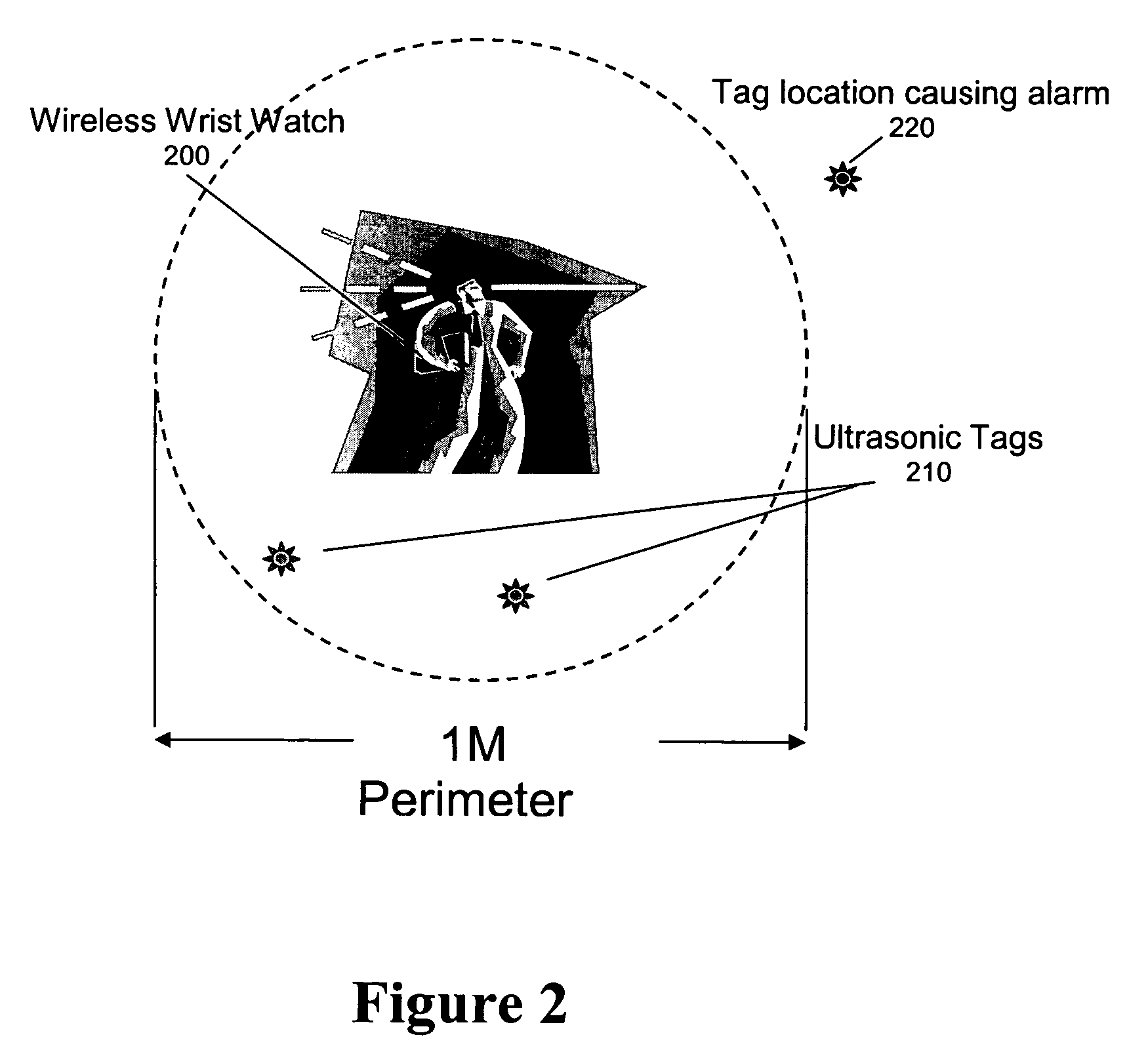

InactiveUS7061381B2Improve rangeReasonable distanceSonic/ultrasonic/infrasonic transmissionRecord carriers used with machinesRadio frequencyTransceiver

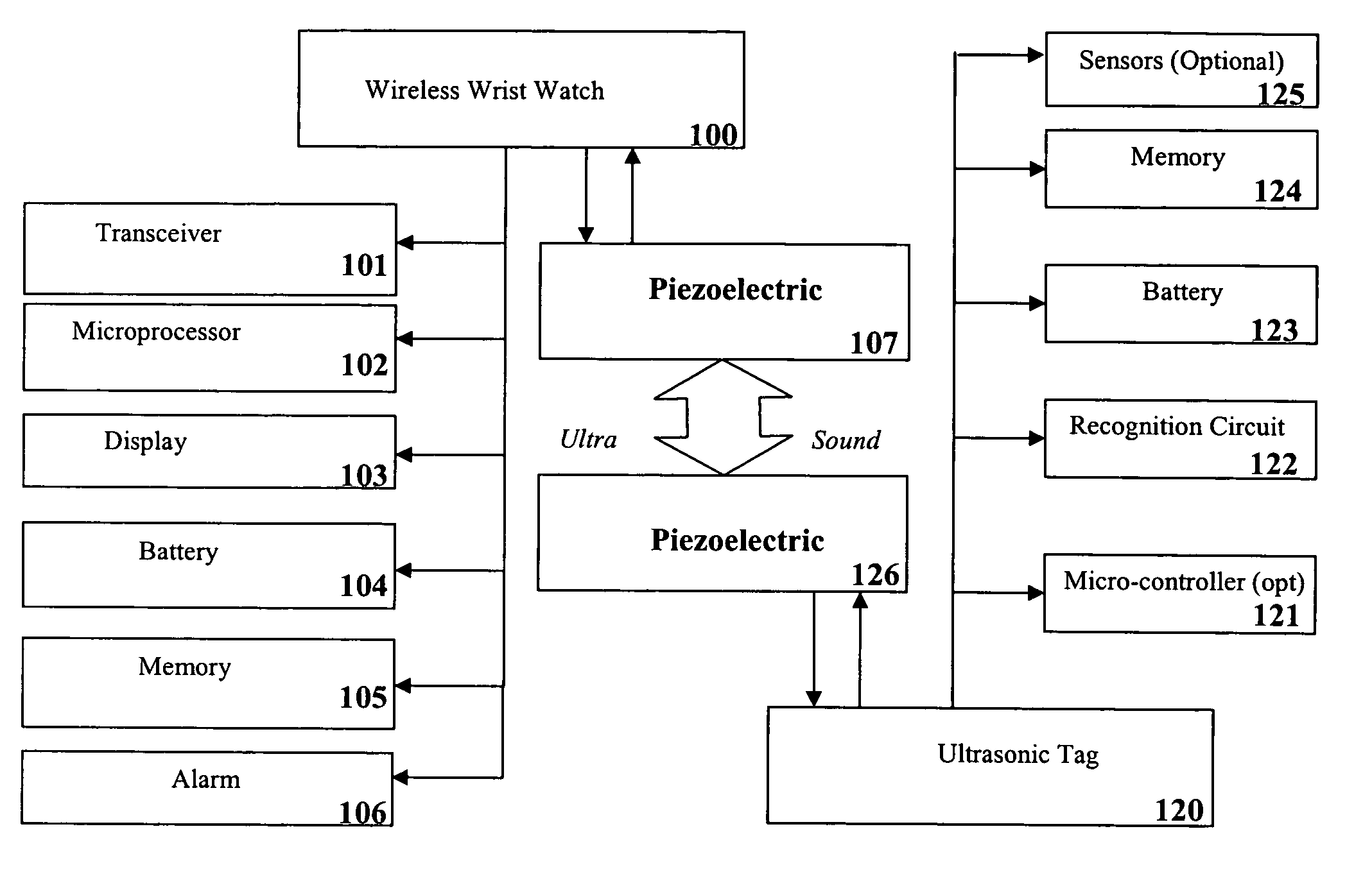

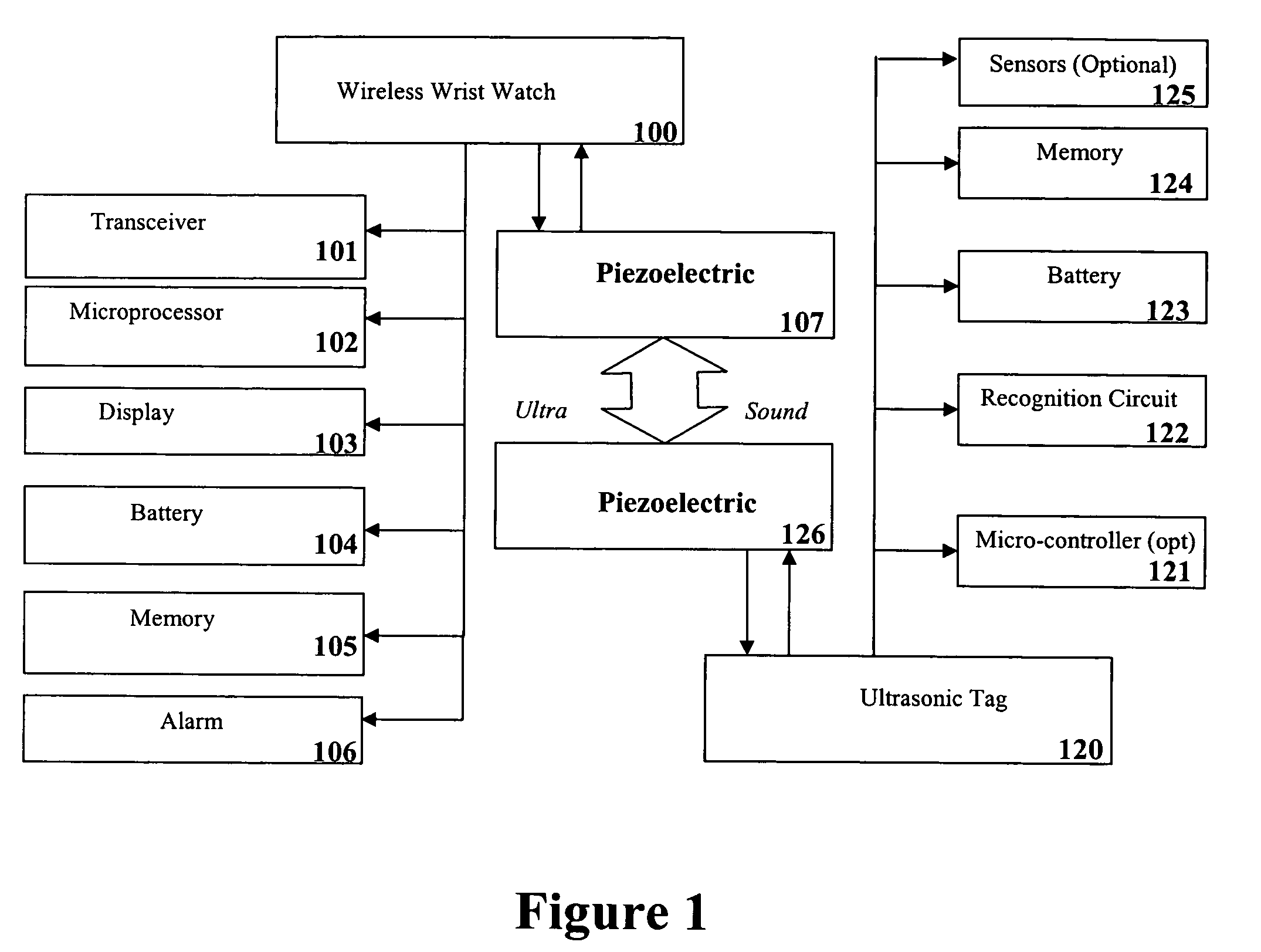

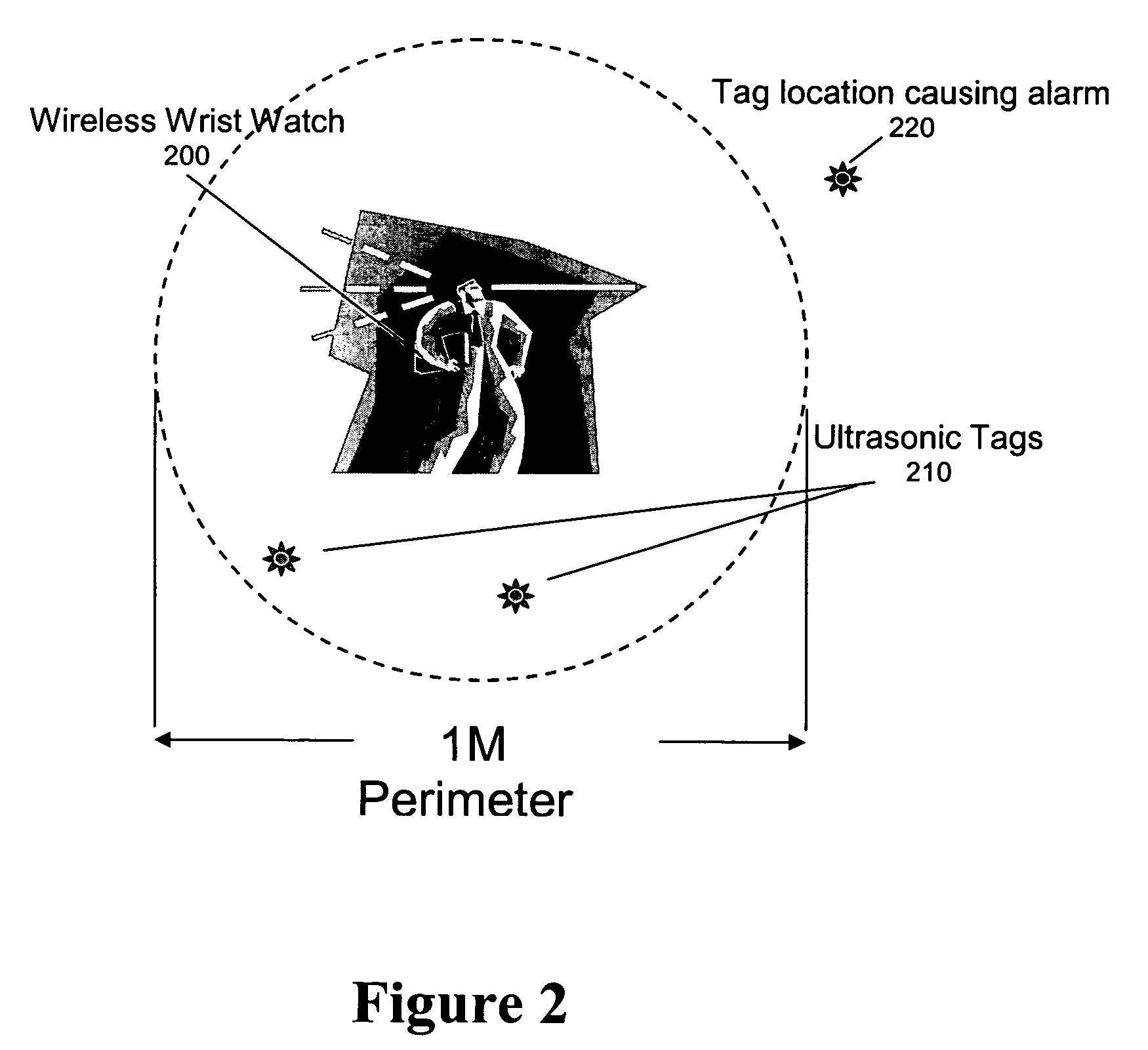

A transceiver preferably embedded within a wearable security watch, PDA, or other device which achieves a variety of wireless ultrasonic and / or radio-frequency based functions, including digital identification and proximity and sensation monitoring of assets, individuals, pets, and the like. The portable or wearable device realizes these functions by periodically polling and receiving information tags within the transmitting distance of the device. The invention can help reduce the likelihood of the theft, loss, or misplacement by detecting that a tag associated with or attached to an entity has left an individual's proximity and sounding an alarm. The device can also assist individuals with sensory impairments, including persons who are deaf, diabetic, and the like, by detecting a tagged entity as it enters the space around an individual, or by detecting environmental stimuli, such as excessive heat in an individual's proximity or vital sign changes, and sounding an alarm.

Owner:BEEZERBUG

Ultrasonic transmitter and receiver systems and products using the same

InactiveUS20060181421A1Reasonable distanceIncrease rangeSonic/ultrasonic/infrasonic transmissionPiezoelectric/electrostrictive transducersTransceiverEngineering

A transceiver preferably embedded within a wearable security watch, PDA, or other device which achieves a variety of wireless ultrasonic and / or radio-frequency based functions, including digital identification and proximity and sensation monitoring of assets, individuals, pets, and the like. The portable or wearable device realizes these functions by periodically polling and receiving information tags within the transmitting distance of the device. The invention can help reduce the likelihood of the theft, loss, or misplacement by detecting that a tag associated with or attached to an entity has left an individual's proximity and sounding an alarm. The device can also assist individuals with sensory impairments, including persons who are deaf, diabetic, and the like, by detecting a tagged entity as it enters the space around an individual, or by detecting environmental stimuli, such as excessive heat in an individual's proximity or vital sign changes, and sounding an alarm.

Owner:BEEZERBUG

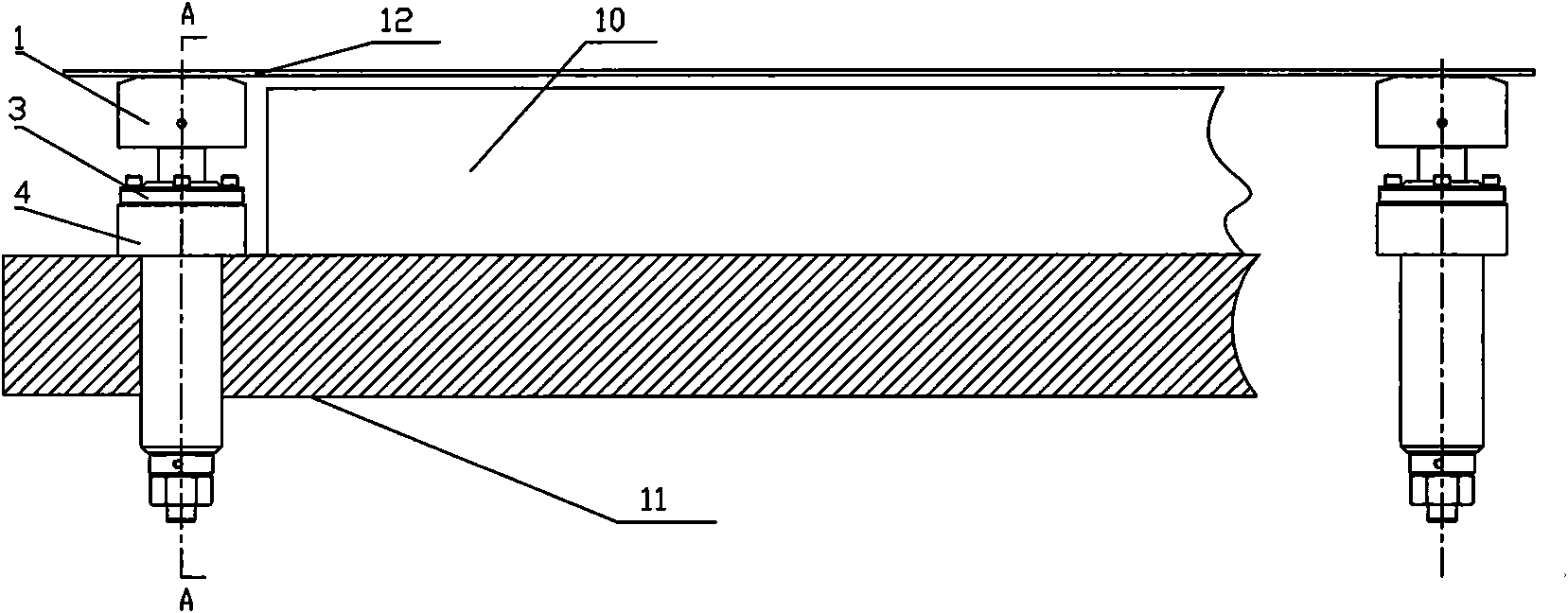

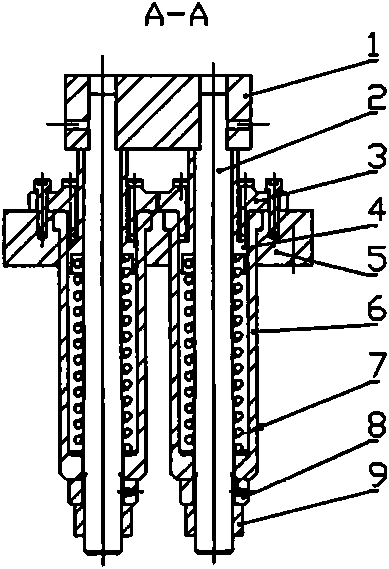

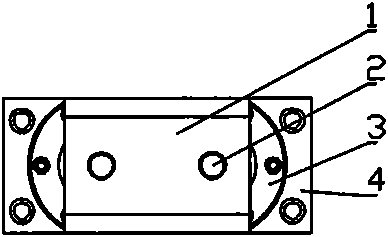

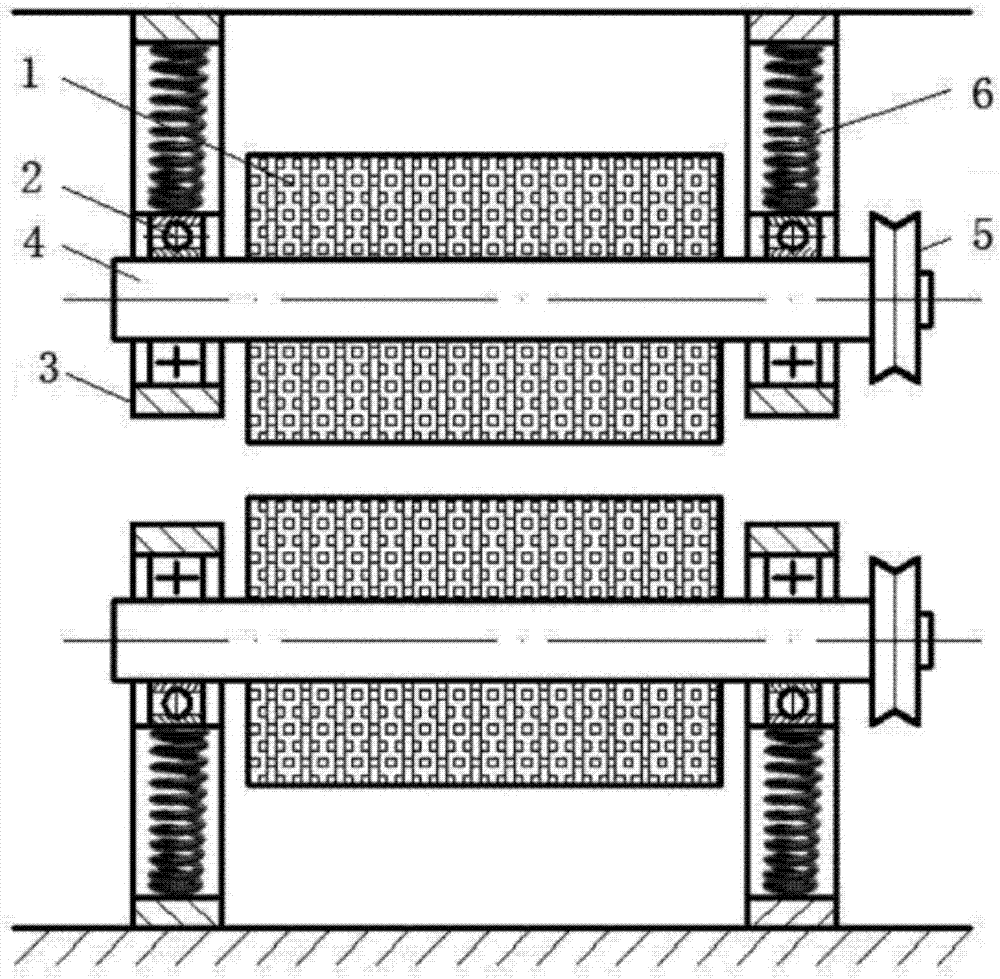

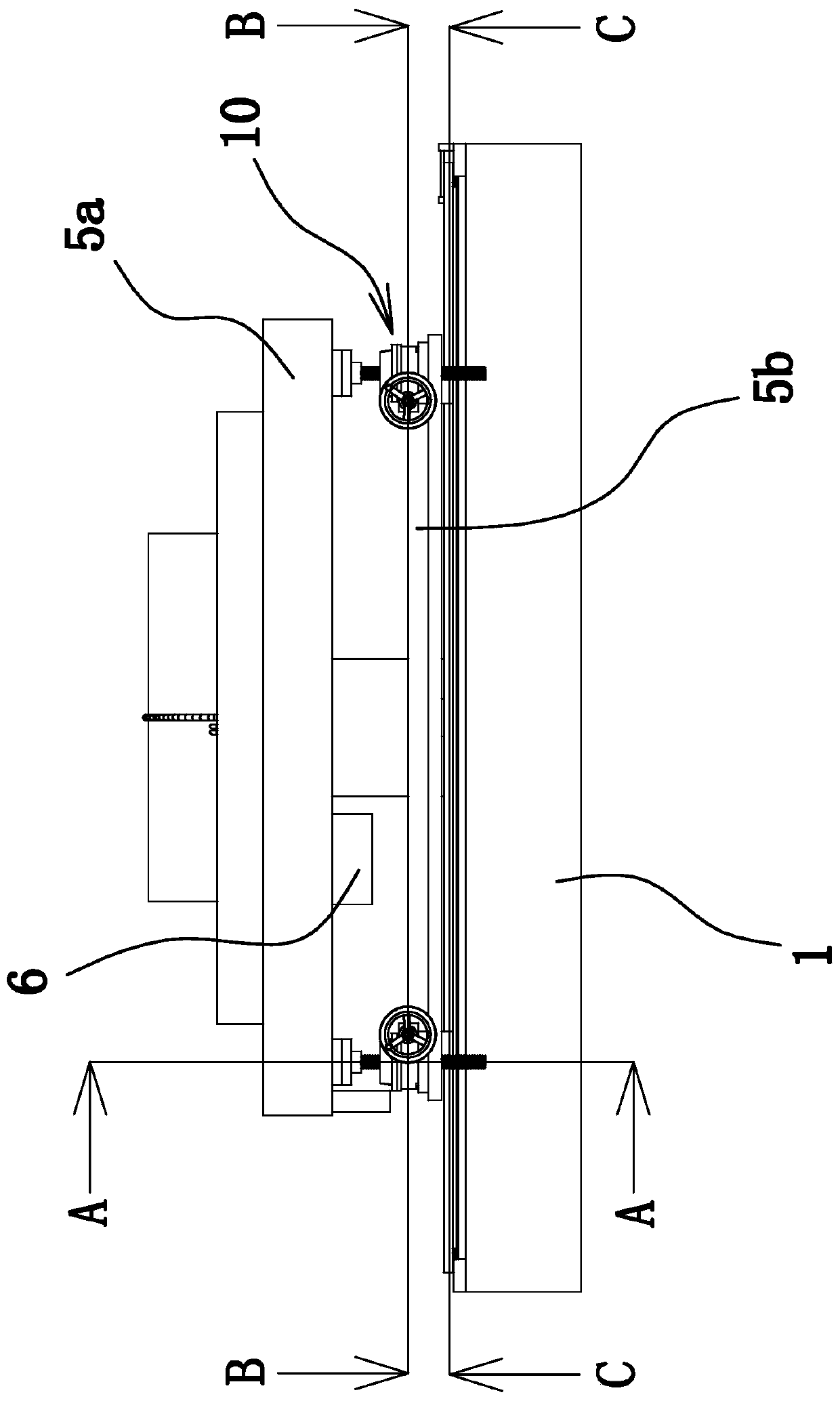

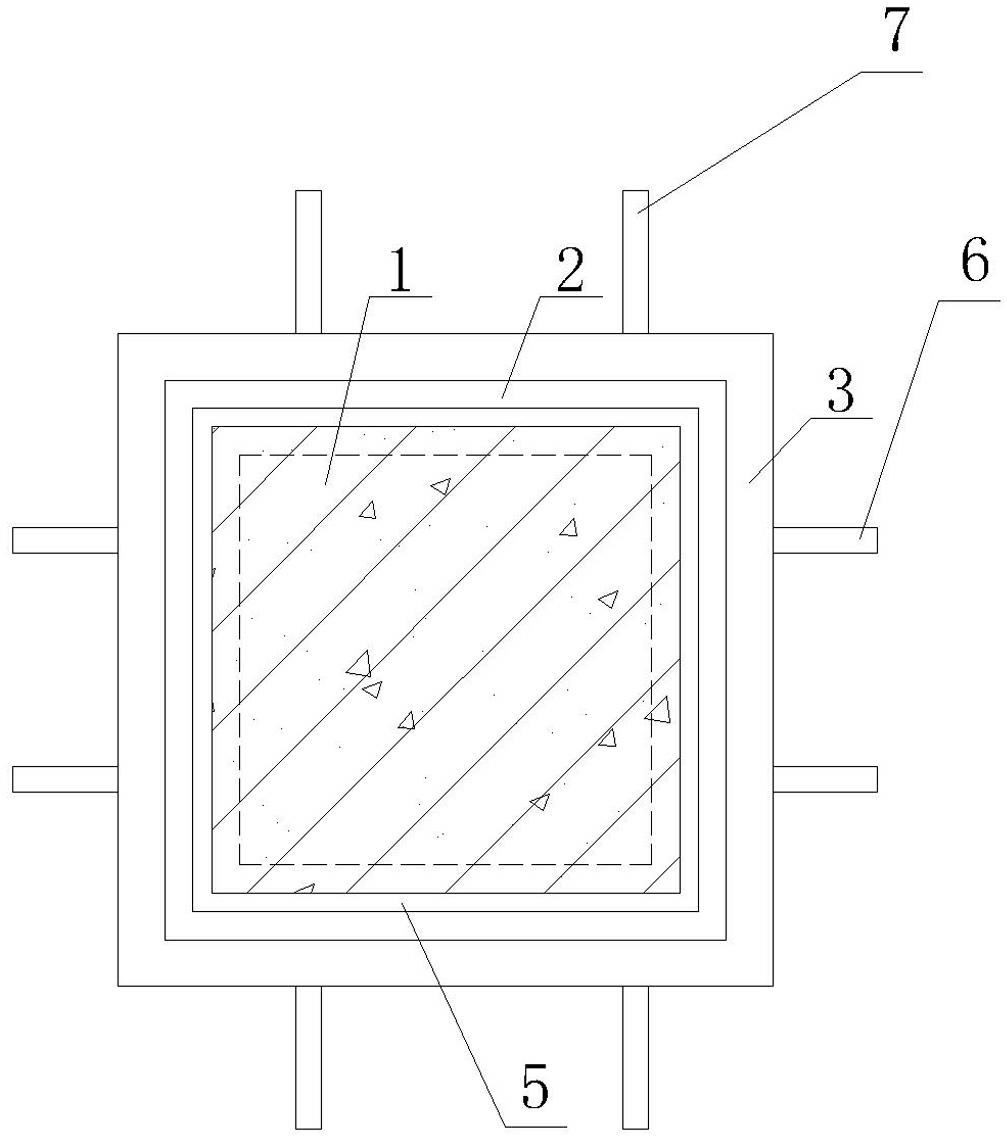

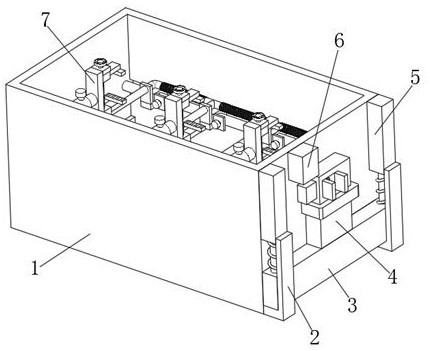

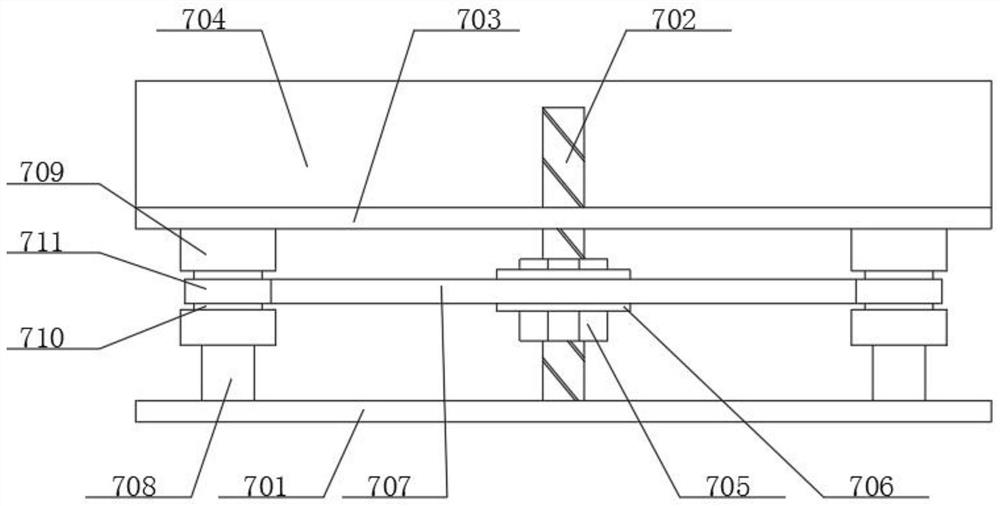

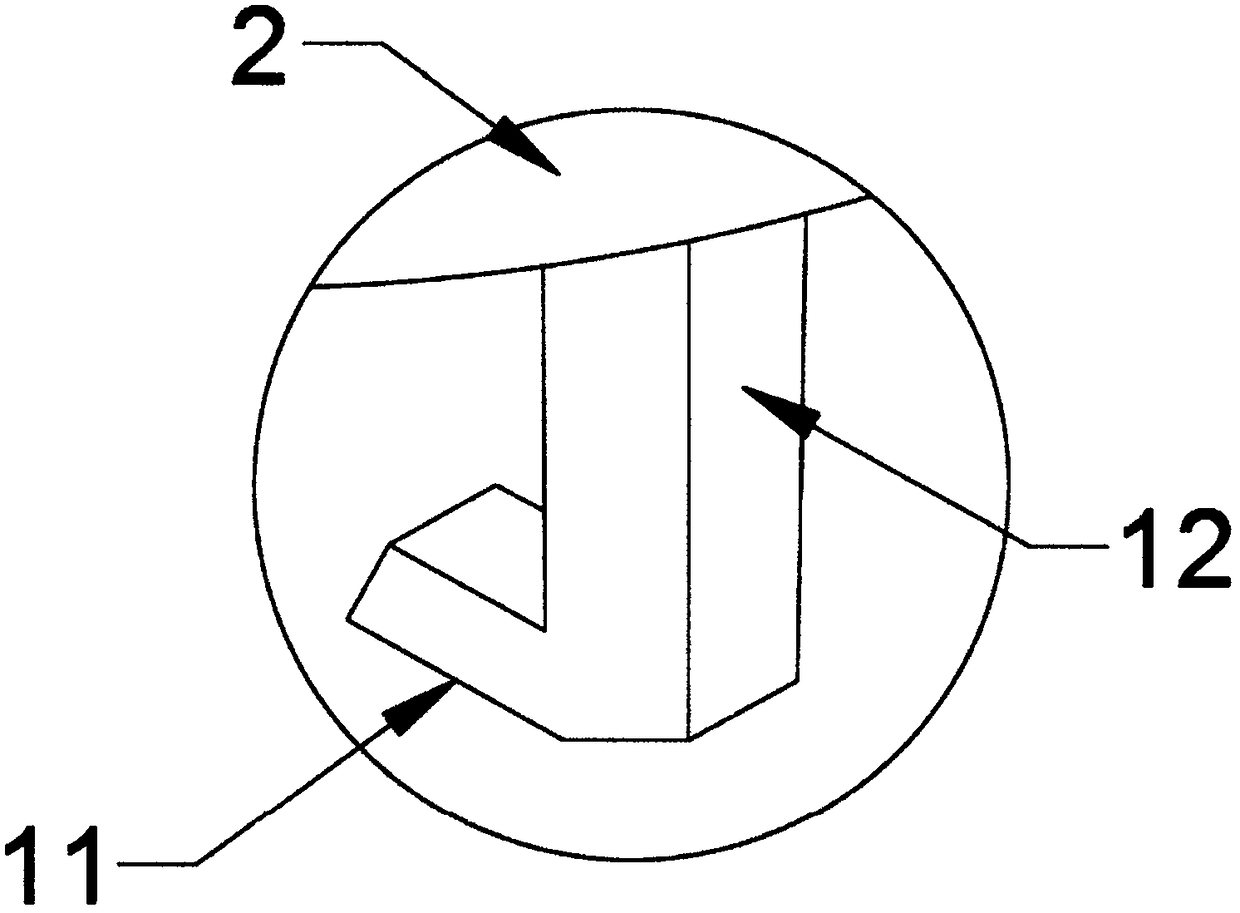

Floating plate supporting device

ActiveCN101844186AExtended service lifeAvoid direct frictionMetal-working feeding devicesPositioning devicesEngineeringMachine tool

The invention relates to a plate supporting device on plate processing equipment, which comprises a retainer block, a mounting seat and an elastic supporting mechanism of the retainer block, wherein the mounting seat is fixedly connected with a lower mold on a machine body worktable, and the retainer block is connected with the mounting seat through the elastic supporting mechanism; and the top surface of the retainer block is slightly higher than the top surface of the lower mold. The existing machine tool has not the device, so that the larger friction between the plate and the lower mold when the plate moves in the production process can damage the surface of the lower mold and the surface of the plate. The devices of the invention are arranged at the two ends of the lower mold on the travel path of the plate, and the retainer blocks at the two ends can support the plate so as to prevent the direct friction between the plate and the lower mold. In order to prevent too large or unequal distance between the plate and the lower mold from causing processing errors, the supporting device is also provided with the elastic supporting mechanism which can adjust the height of the retainer block and has adjusting function, and the reasonable distance can be kept. The invention reduces the friction between the plate and the lower mold and prolongs the service life of the lower mold.

Owner:扬州恒运建设发展有限公司

Ultrasonic transmitter and receiver systems and products using the same

InactiveUS7498946B2Reasonable distanceIncrease rangeSonic/ultrasonic/infrasonic transmissionPiezoelectric/electrostrictive transducersTransceiverSonification

A transceiver preferably embedded within a wearable security watch, PDA, or other device which achieves a variety of wireless ultrasonic and / or radio-frequency based functions, including digital identification and proximity and sensation monitoring of assets, individuals, pets, and the like. The portable or wearable device realizes these functions by periodically polling and receiving information tags within the transmitting distance of the device. The invention can help reduce the likelihood of the theft, loss, or misplacement by detecting that a tag associated with or attached to an entity has left an individual's proximity and sounding an alarm. The device can also assist individuals with sensory impairments, including persons who are deaf, diabetic, and the like, by detecting a tagged entity as it enters the space around an individual, or by detecting environmental stimuli, such as excessive heat in an individual's proximity or vital sign changes, and sounding an alarm.

Owner:BEEZERBUG

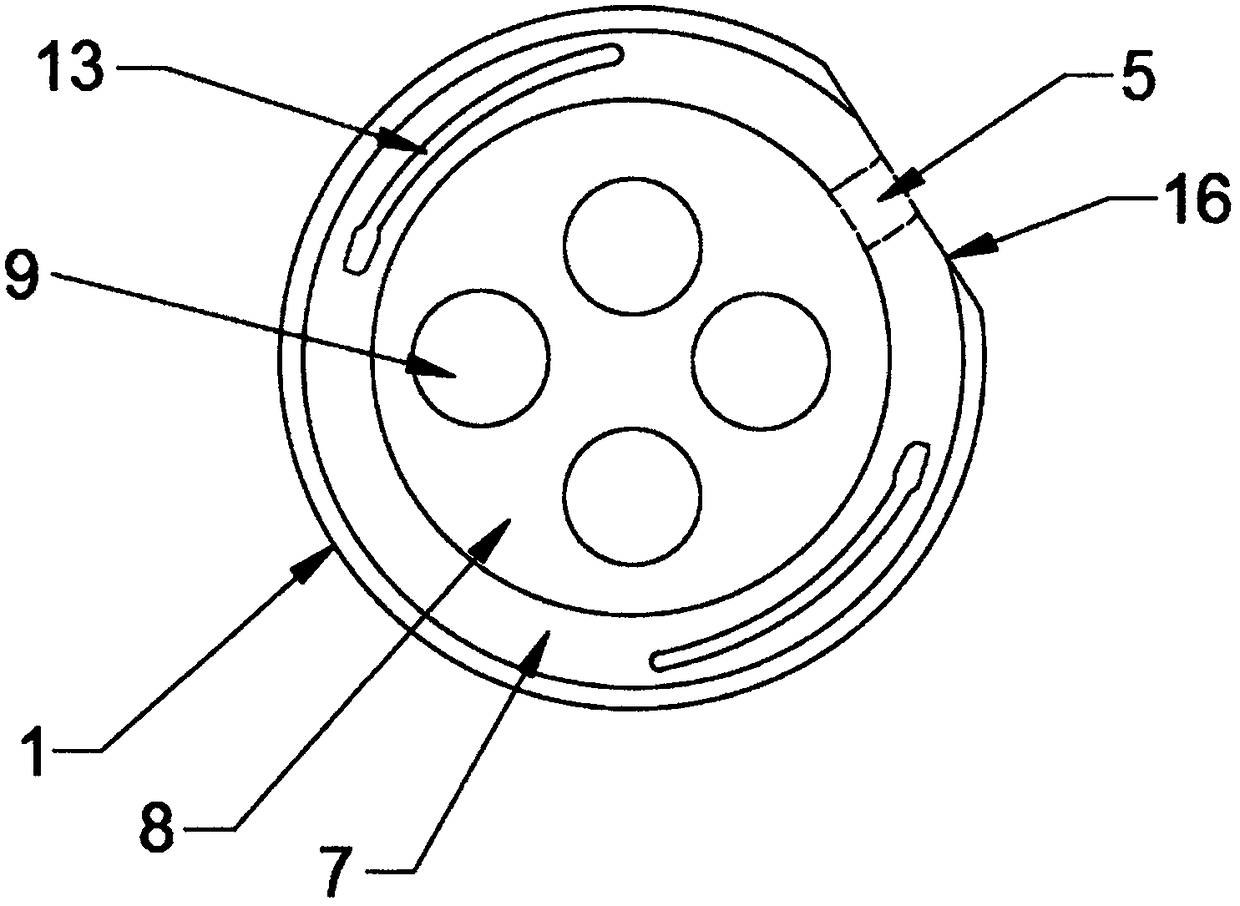

Protective cover, fan component and air conditioner outdoor unit

The invention discloses a protective cover, a fan component and an air conditioner outdoor unit. The protective cover comprises a grid; the grid comprises multiple circumferential grid strips and multiple radial grid strips; the circumferential grid strips are ring structures different in radius and are arranged around the central shaft of the protective cover sequentially from inside to outside; multiple radial grid strips are used for fixedly connecting multiple circumferential grid strips; and the circumferential grid strips on the protective cover shift toward one side of the protective cover gradually from inside to outside. According to the invention, the protective cover is composed of circumferential grid strips and radial grid strips; the circumferential grid strips are designed in a ball arch shape, and each circumferential grid strip shifts toward an impeller gradually from inside to outside, and the diameter is increased at an equal ratio; and the strength of the grid can be sufficiently guaranteed while improving the airflow efficiency, increasing the air quantity and reducing the noise.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

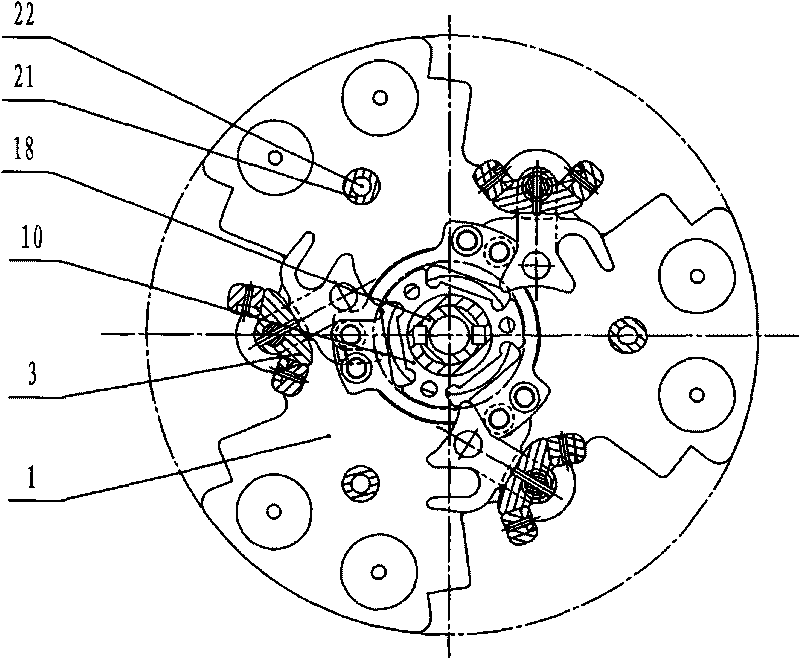

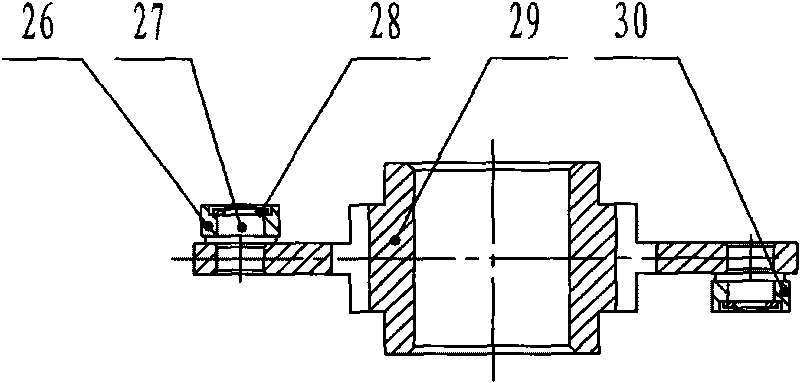

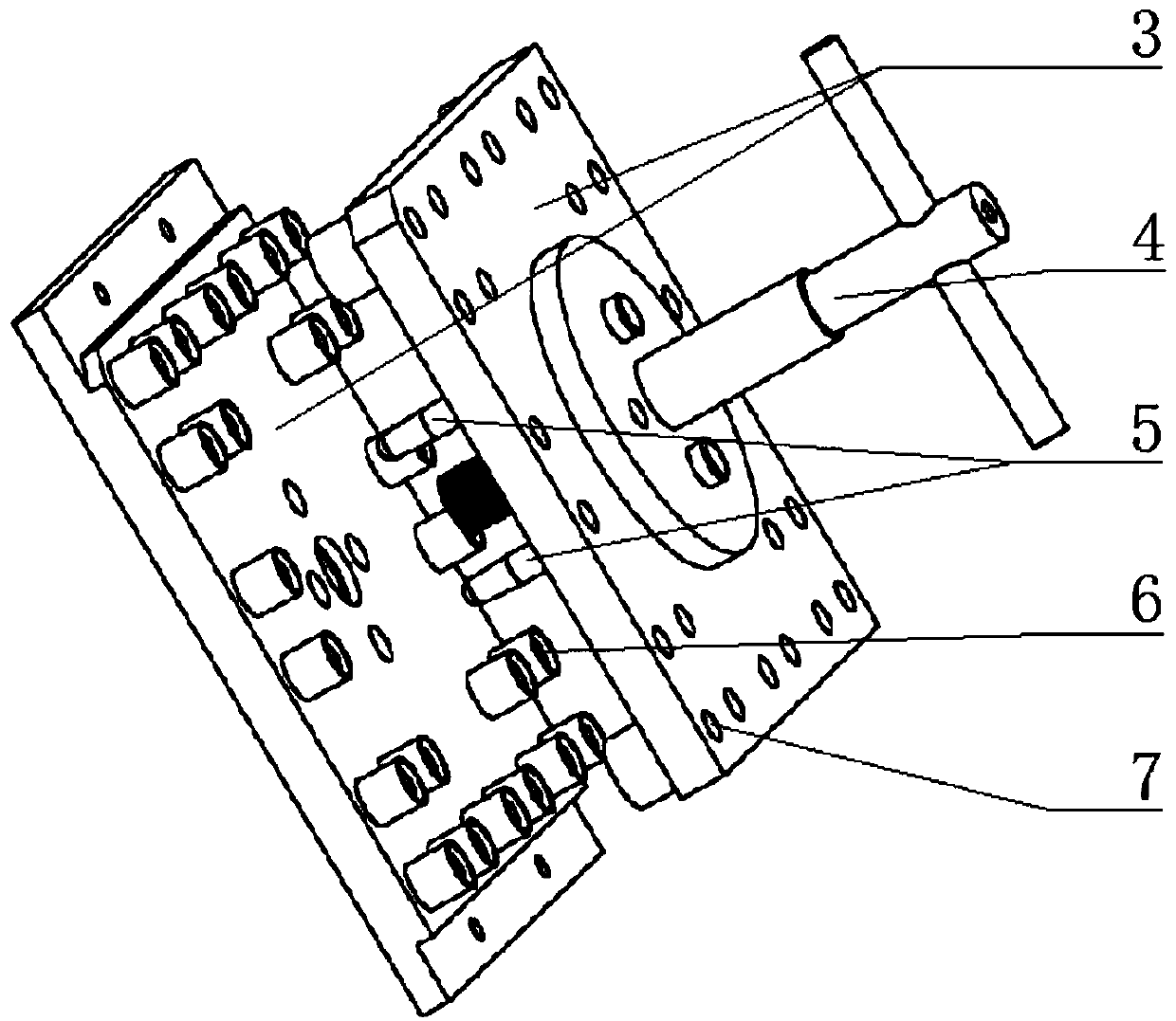

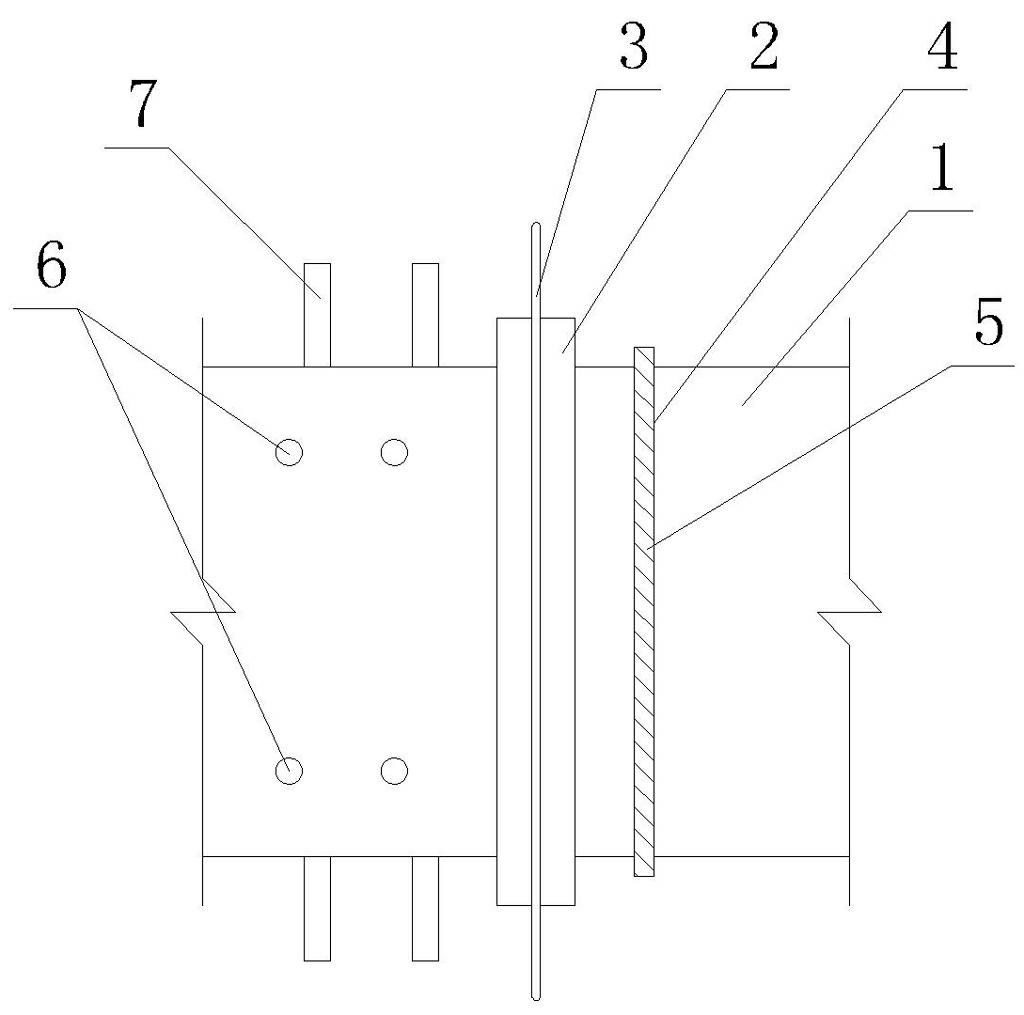

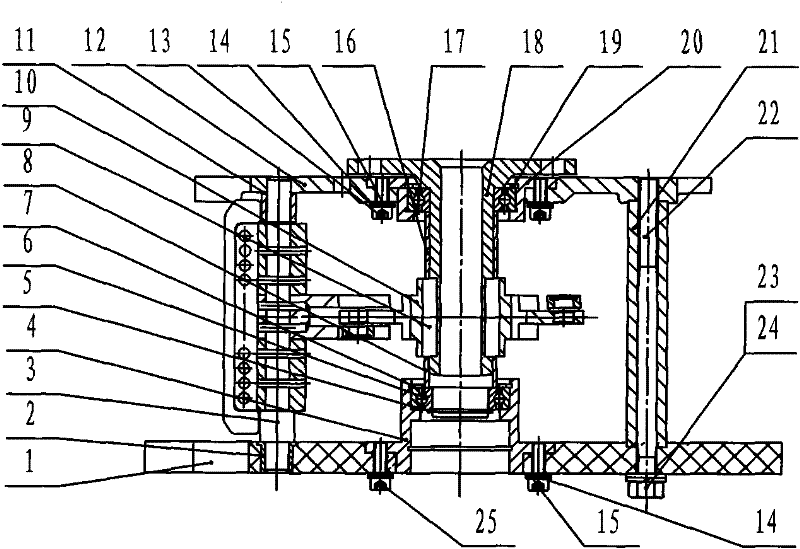

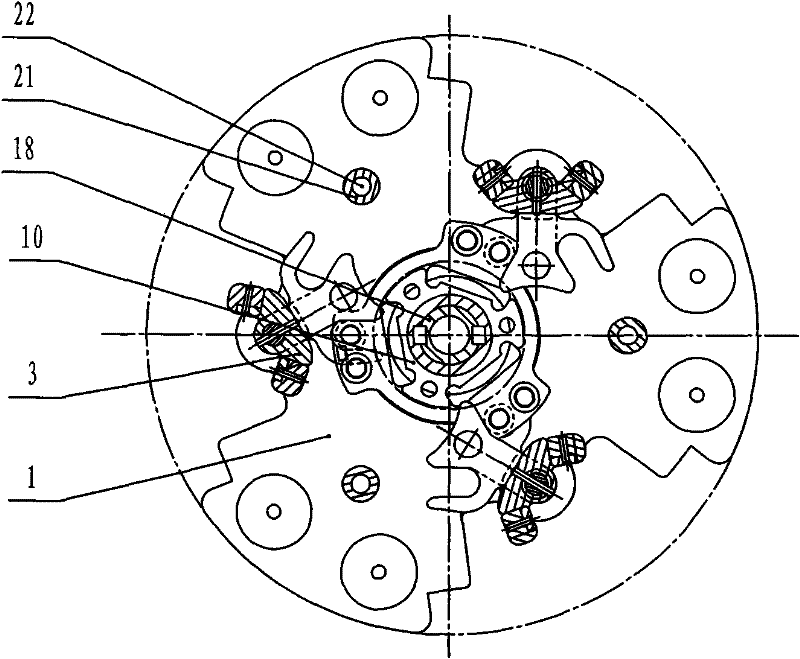

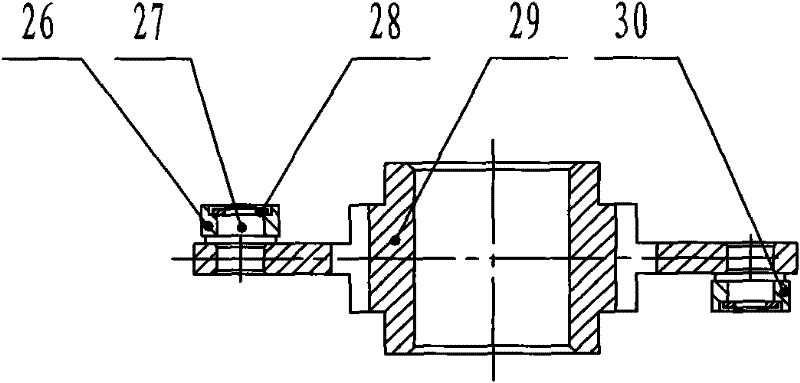

Main current carrying contact system

ActiveCN101699592ASimple structureGuaranteed uptimeVariable inductancesVariable transformersEngineeringTap changer

The invention discloses a main current carrying contact system comprising an upper mounting plate, a lower mounting plate, a first bearing bracket, a second bearing bracket, a rotating shaft, a driver disk and a main contact, wherein the lower mounting plate is connected with the upper mounting plate via a first lining; the first bearing bracket is fixed on the lower mounting plate, and a first bearing is arranged in the first bearing bracket; the second bearing bracket is fixed on the upper mounting plate, and a second bearing is arranged in the second bearing bracket; the rotating shaft is connected with the first bearing and the second bearing; the driver disk is connected with the spindle by keys; and the main contact is connected with the driver disk. The main current carrying contact system of the invention has simple structure, can be matched with the program requirements of on-load tap-changers to operate in a larger range; in the process of operating, tripping-off and switching-on occupy smaller corner under the premise of satisfying preset over travel, and electrode separation in the middle process of tripping-off and switching-on is reasonable; and meanwhile, a lock circle structure is set to effectively guarantee the reliable operation of the mechanism.

Owner:贵州长征电气有限公司

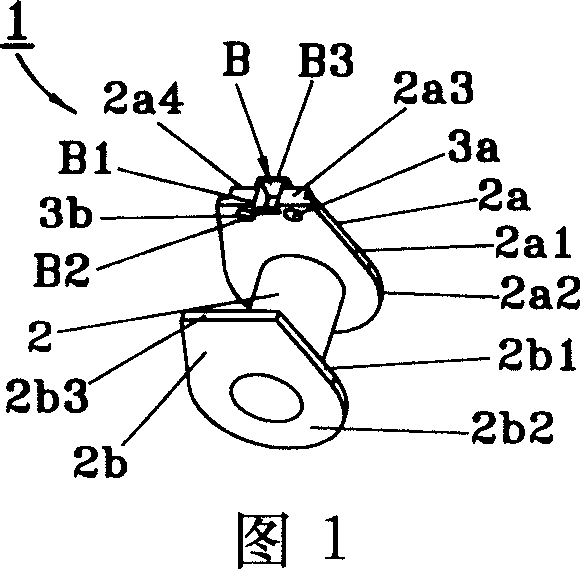

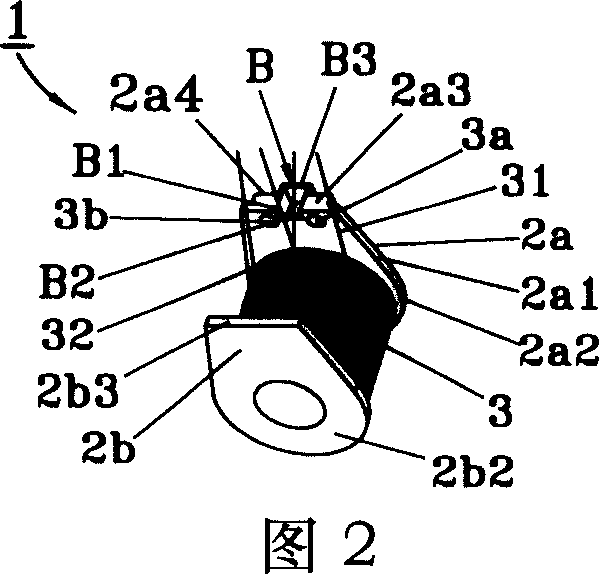

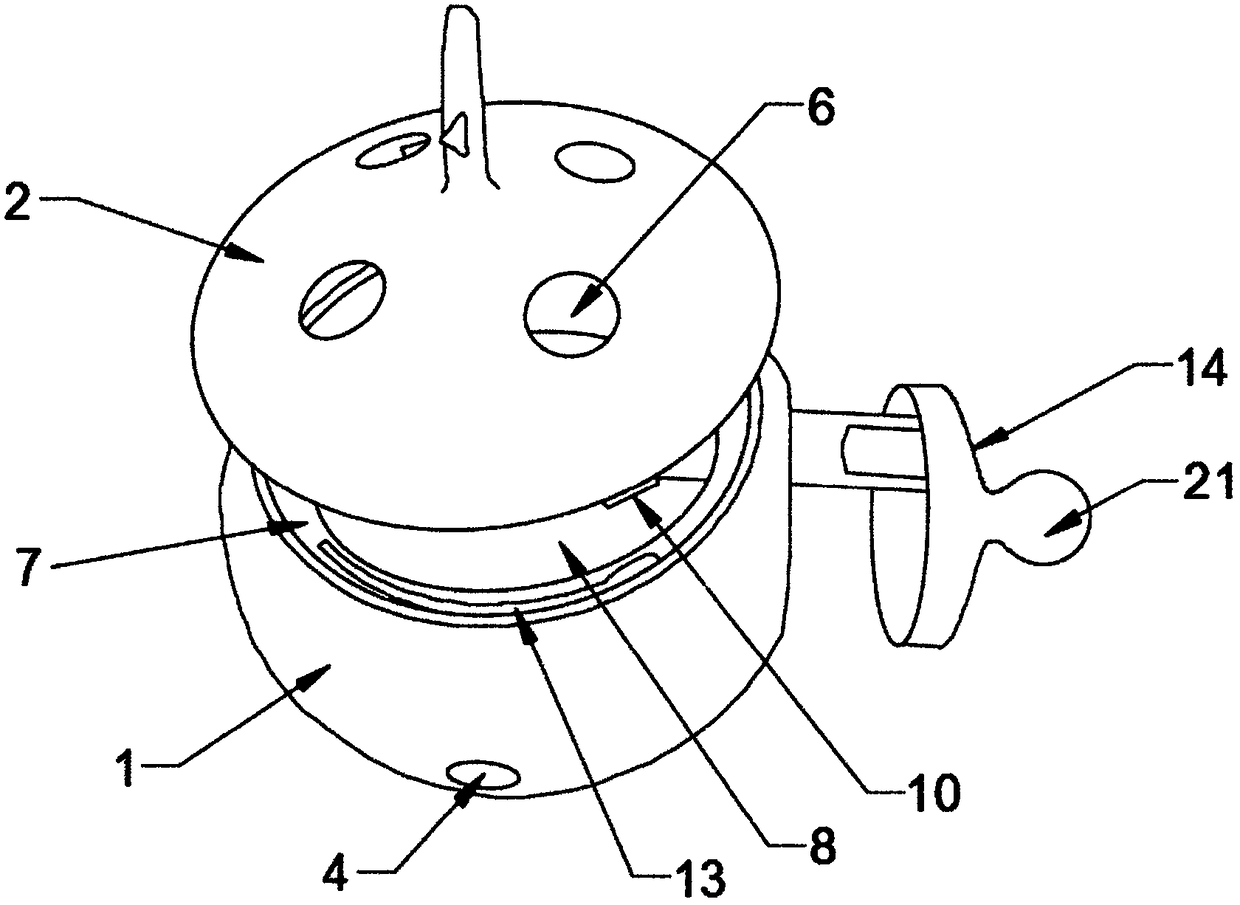

Electromagnetic coil

ActiveCN101038809APrevent movementImprove sealingOperating means/releasing devices for valvesElectromagnetsSynthetic resinConductor Coil

An electromagnetic coil includes a winding core and a pair of jaw-like portions which are arrange at two ends of the winding core and are in parallel, thereby a winding portion of a winding is formed between the jaw-like portions, a lead is connected to the winding, the winding is envelopped by a synthetic resin which at least envelops the lead portion; the coil is characterised in that each jaw-like portion includes an arc-like portion and projecting portions extending from the arc-like portion to a side, wherein one projecting portion is provided with a positioning structure for positioning the lead. In the electromagnetic coil with this structure, when the lead is contacted with electrical members such as the winding and the like, movement of the lead when sealing the synthetic resin can be effectively prevented because the lead can be positioned by the positioning structure provided on the projecting portion, the winding and an inner end of the lead can be reliably sealed and fixed, and an electromagnetic coil with electrical members provided compactly can be obtained.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

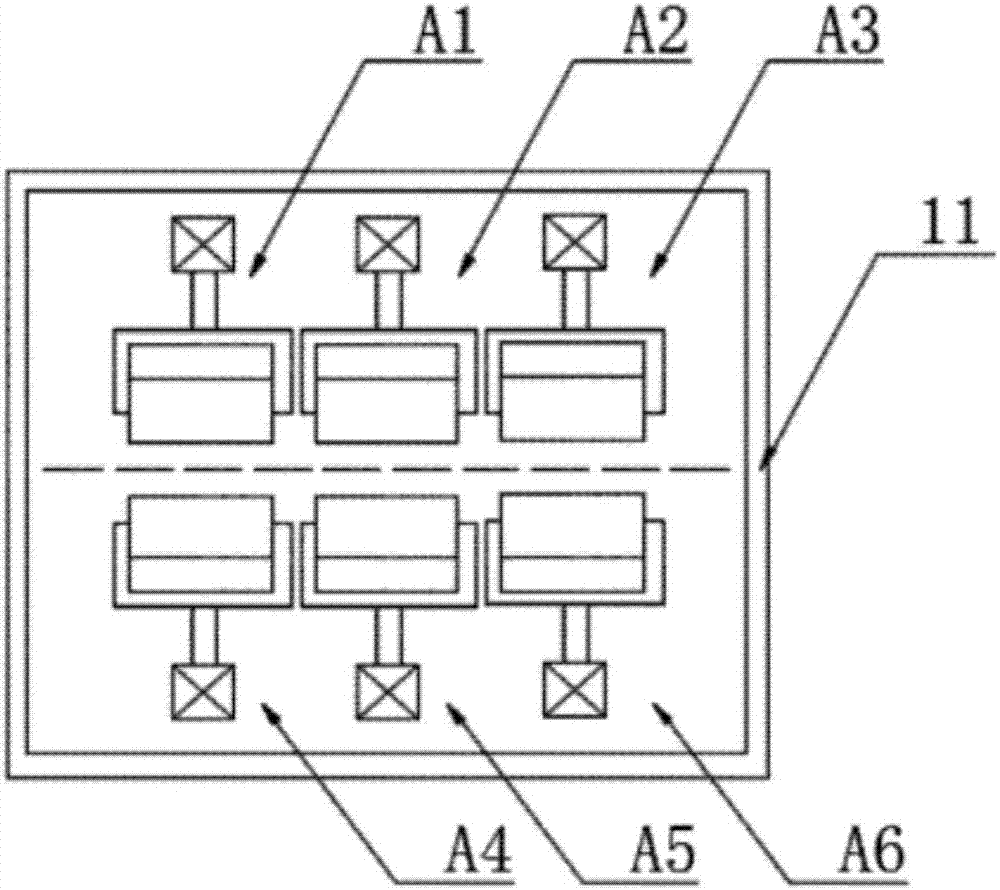

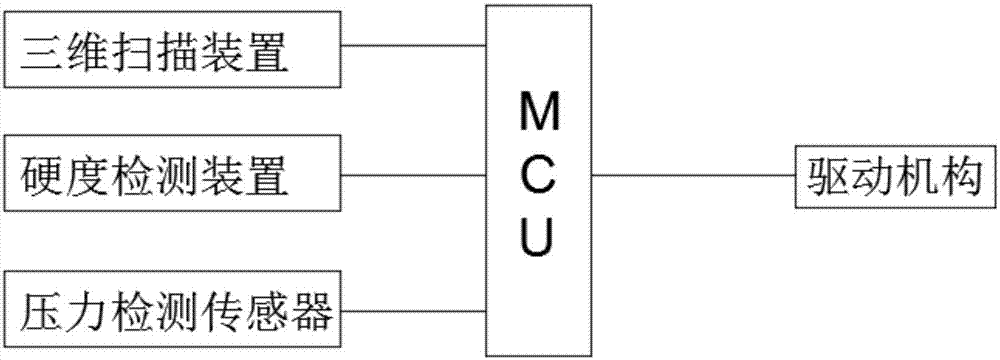

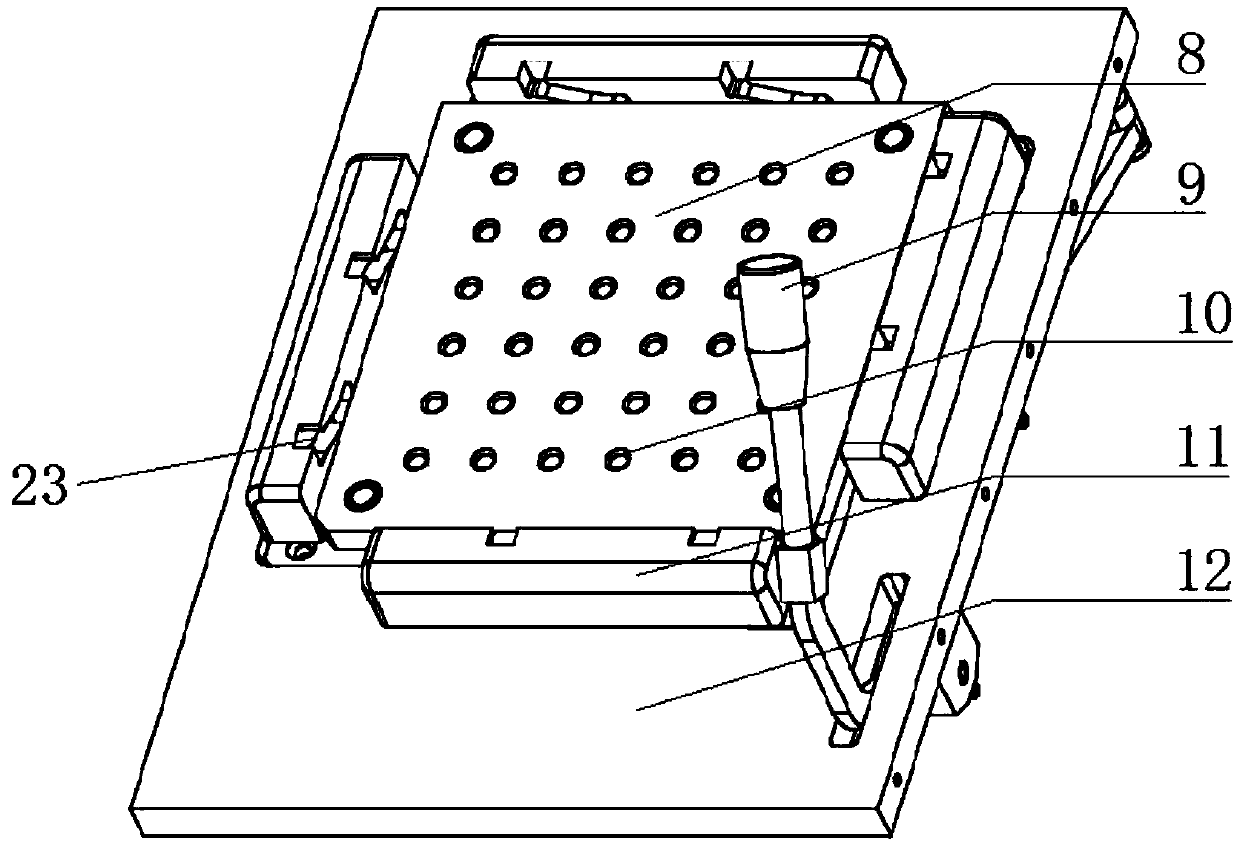

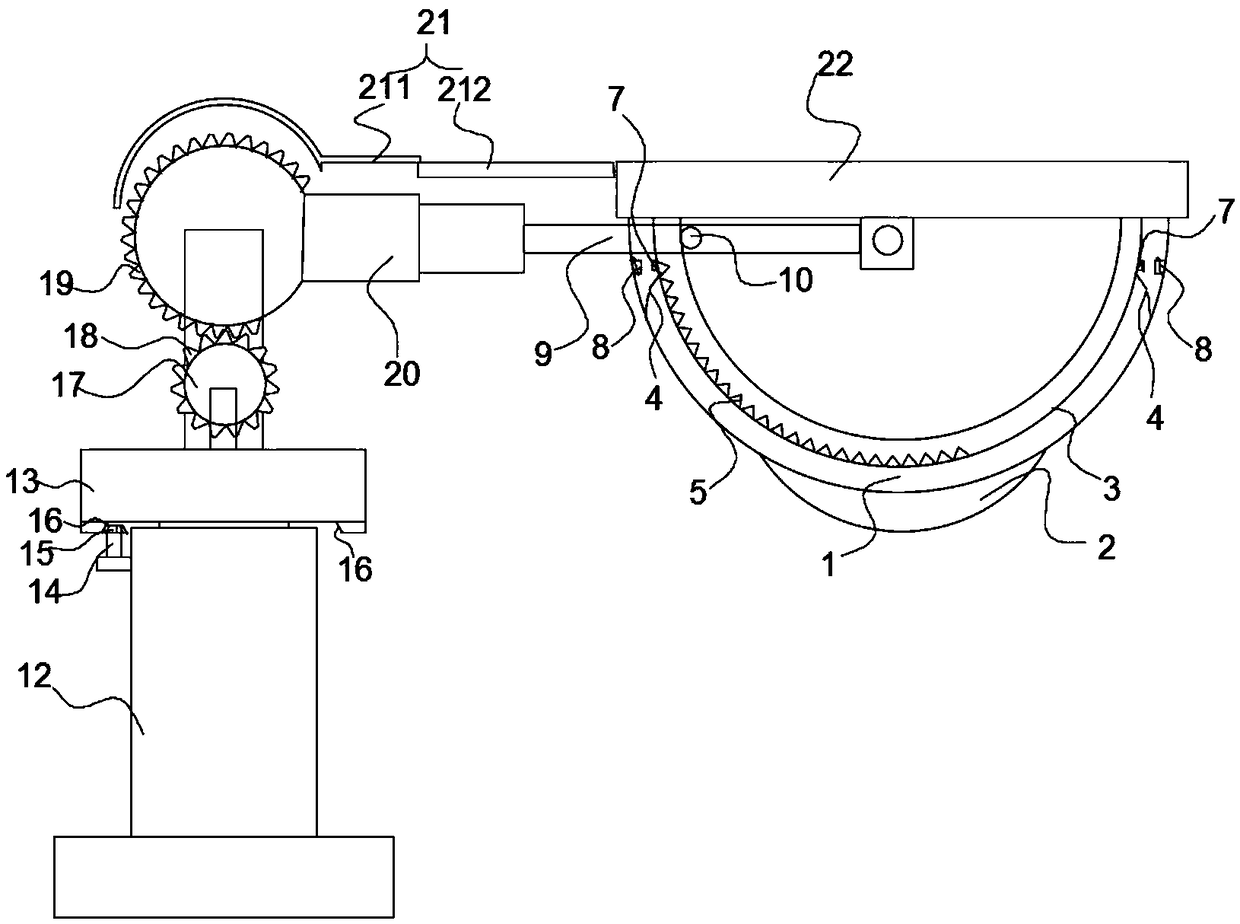

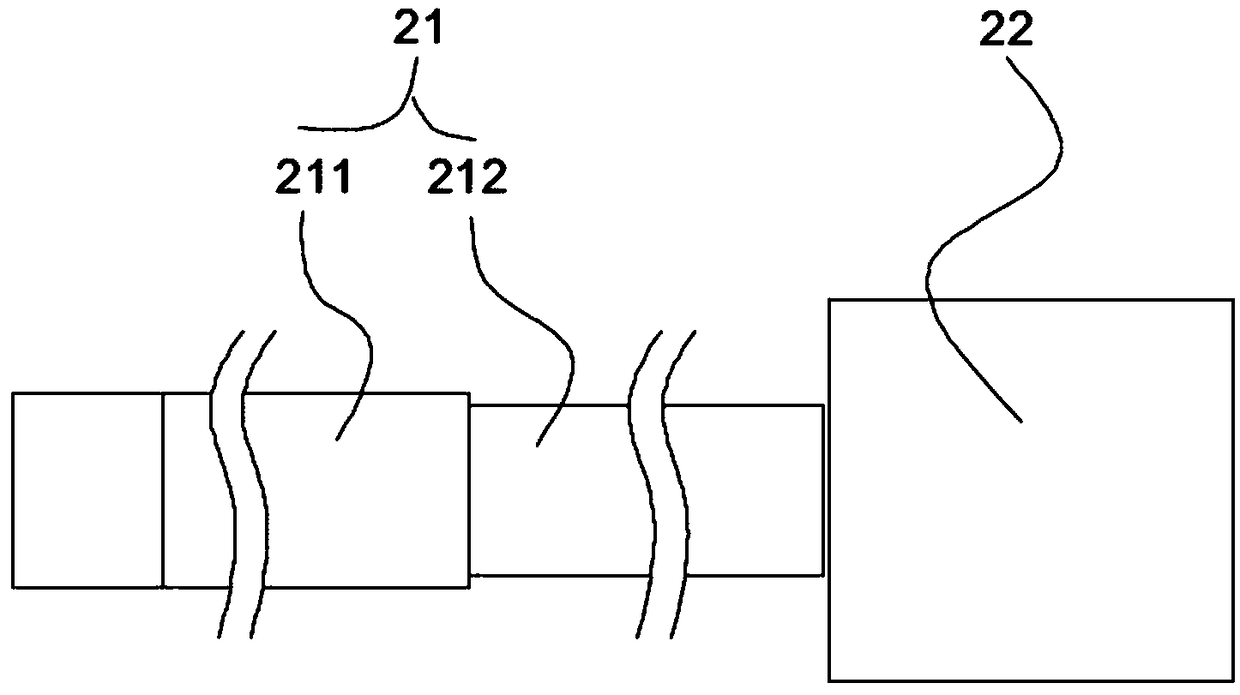

Elastic polishing device and method for special-shaped workpiece

InactiveCN107498446APolished evenlyMove preciselyPolishing machinesAutomatic grinding controlMotor driveSymmetry line

The invention provides an elastic polishing device and method for a special-shaped workpiece and belongs to the technical field of polishing. The elastic polishing device for the special-shaped workpiece comprises a base frame, a master control circuit storing three-dimensional data of the special-shaped workpiece, at least four polishing units and a driving mechanism; the polishing units are symmetrically arranged on the two sides of the base frame and form a symmetry line; and the driving mechanism is controlled by the master control circuit to drive the polishing units to get close to or be far away from the symmetry line so as to adapt to different sizes of different portions of the workpiece. Each polishing unit comprises a support, a mandrel, a polishing wheel and a spring capable of making the polishing wheel elastically move on the support, and further comprises a hardness detecting device used for detecting the workpiece, a motor driving the polishing wheel to rotate and a three-dimensional scanning device; and data generated by the three-dimensional scanning device are transmitted to the master control circuit to make the driving mechanism drive the polishing units to move relative to the symmetry line. The elastic polishing device for the special-shaped workpiece has the beneficial effects that each polishing unit can be flexibly and conveniently controlled, polishing is performed according to different materials, and the polishing effect is good.

Owner:XIAMEN UNIV OF TECH

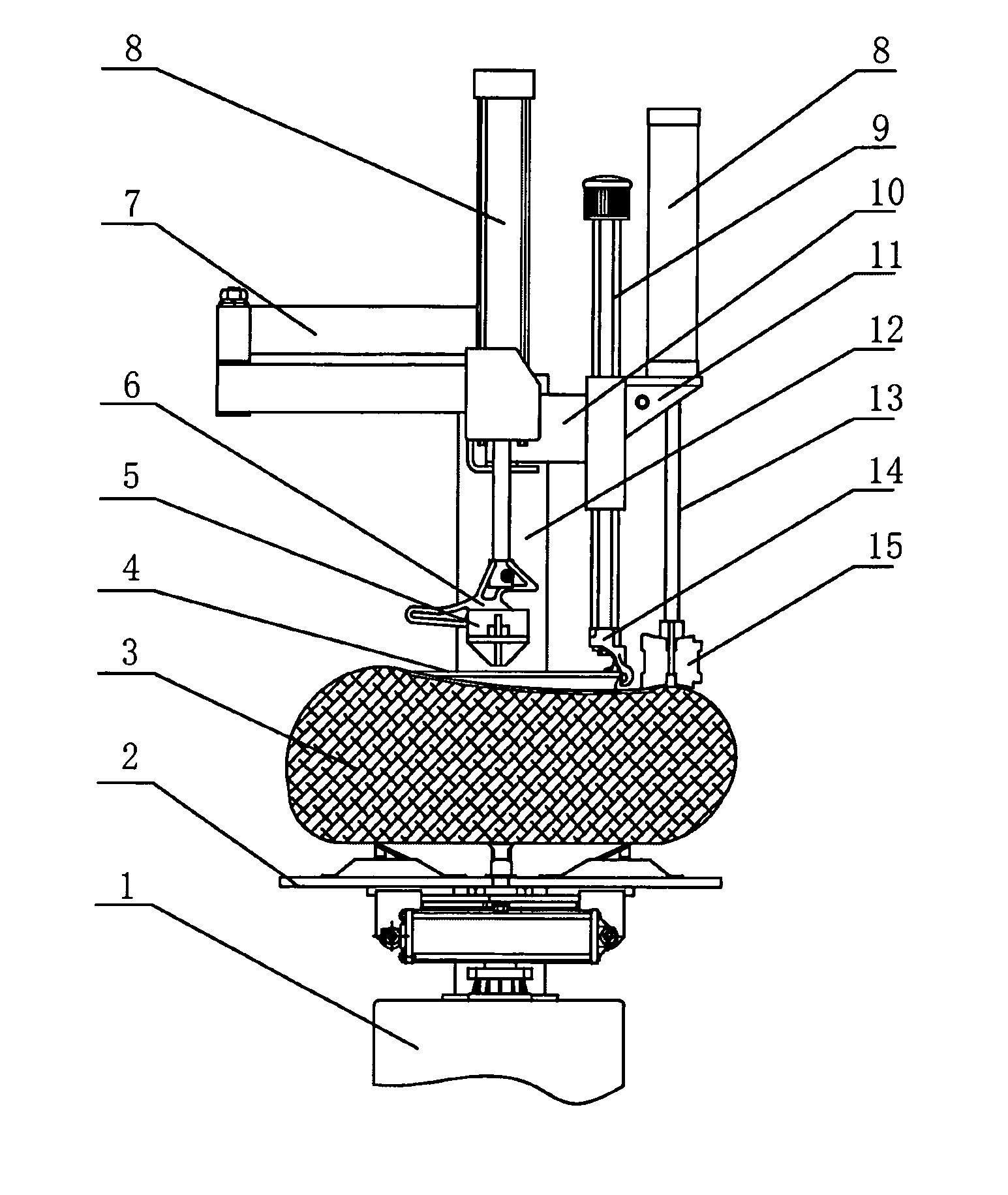

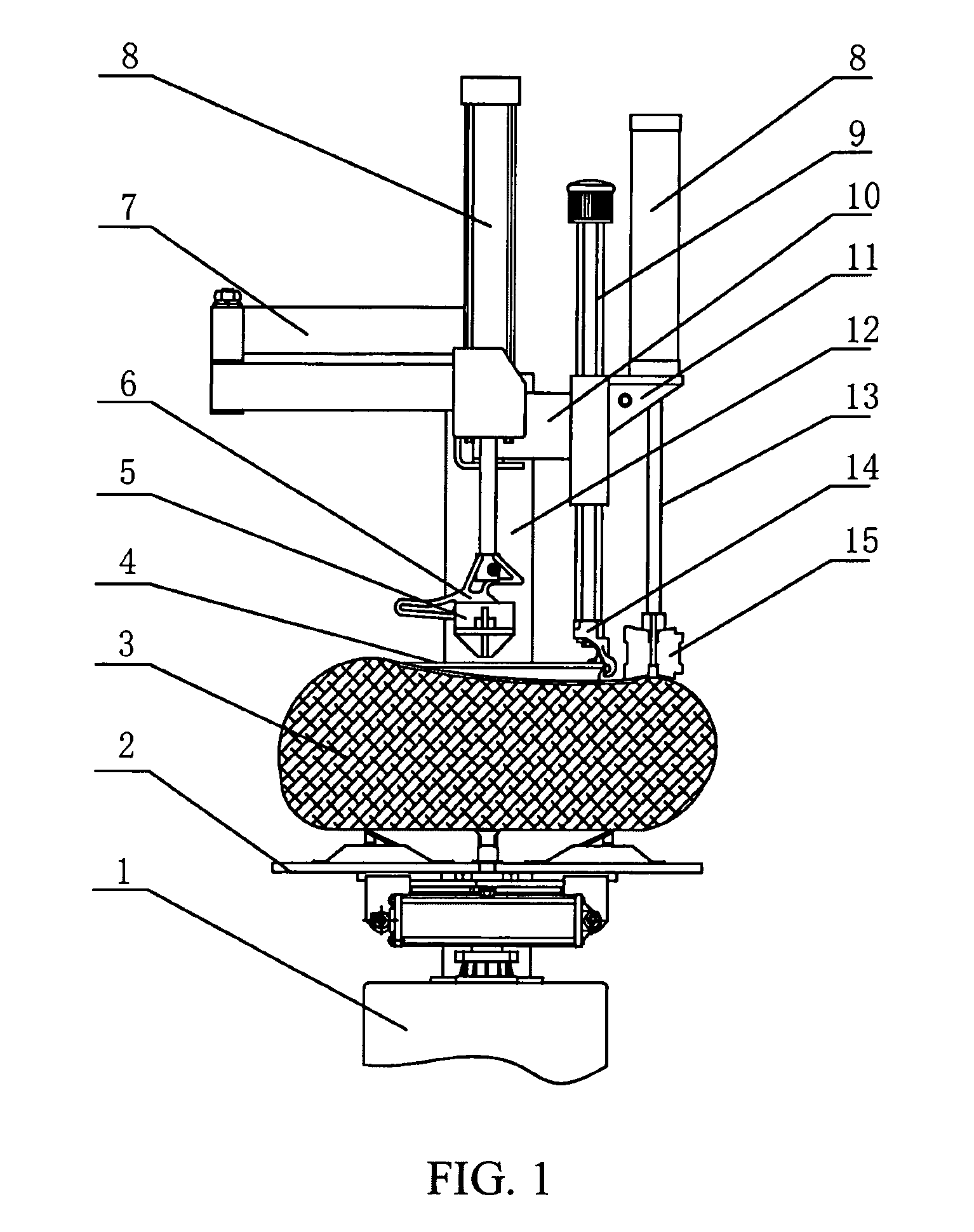

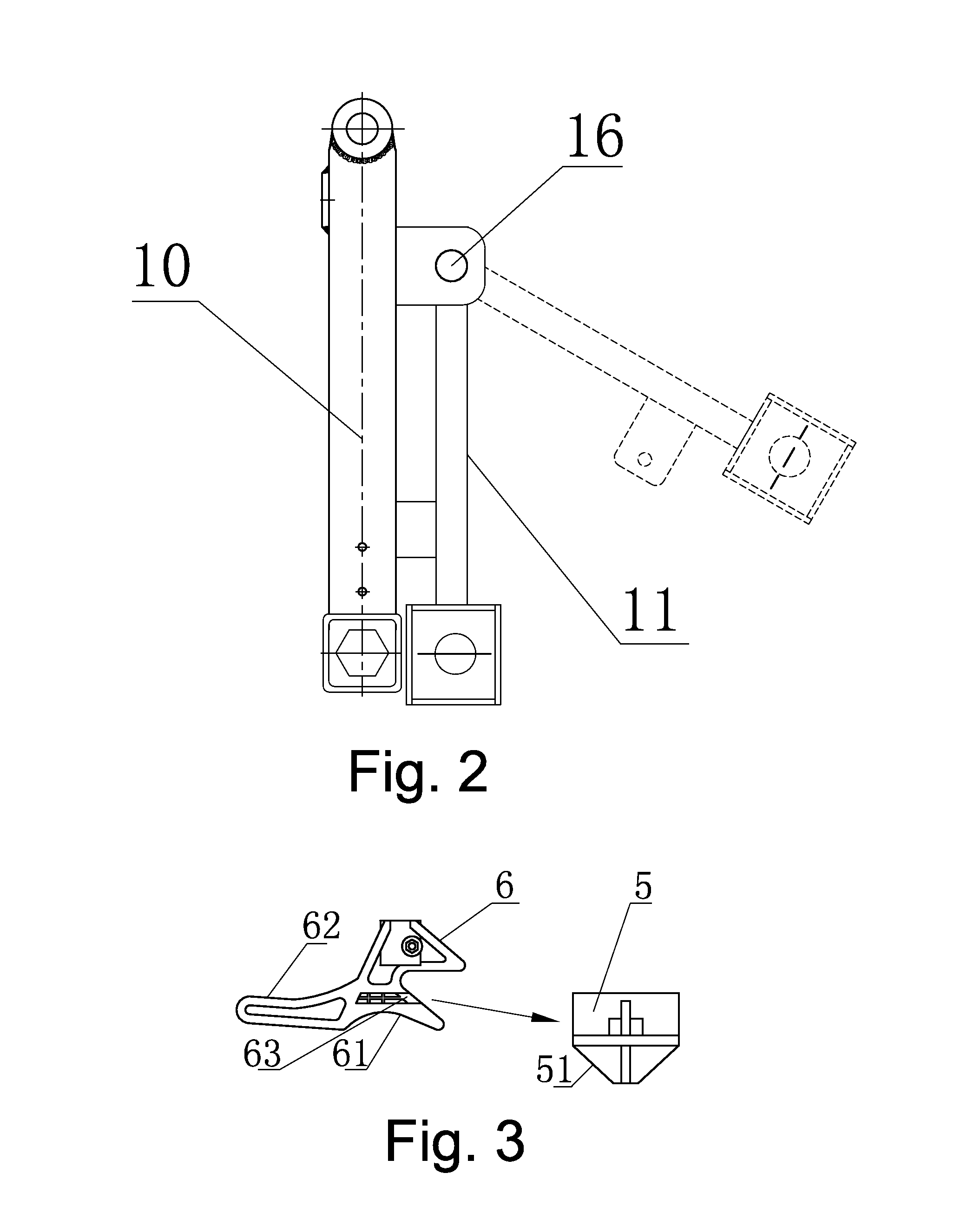

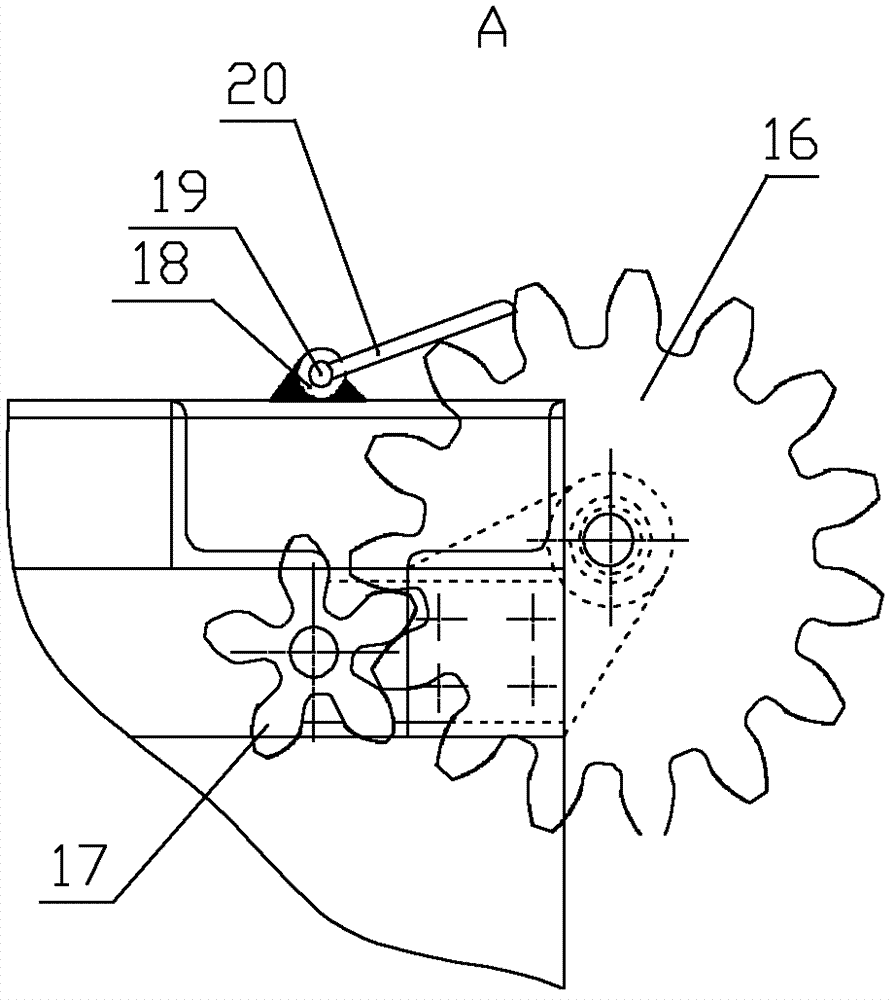

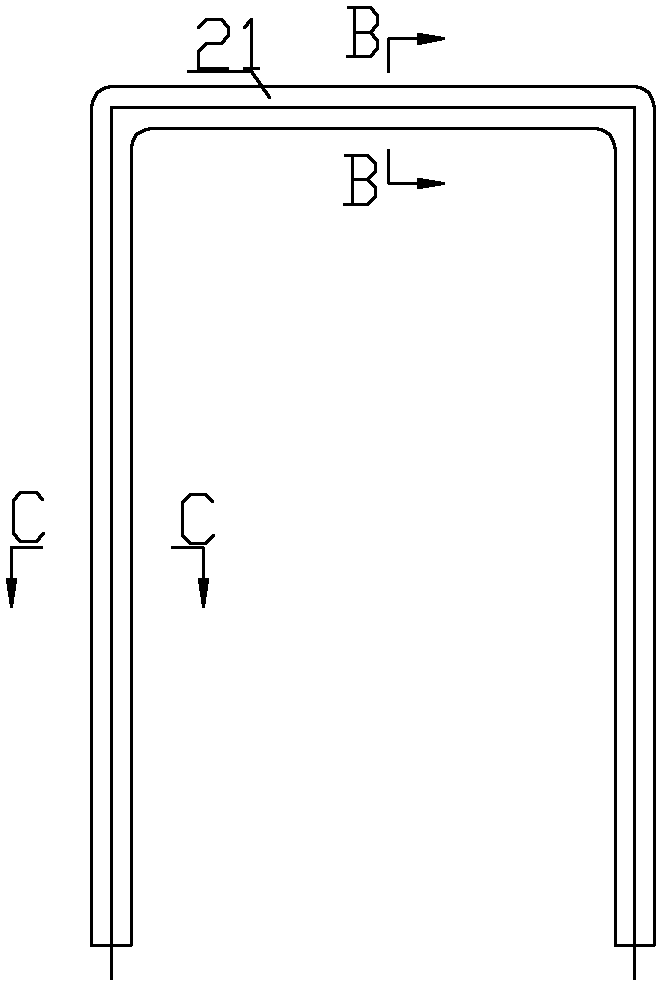

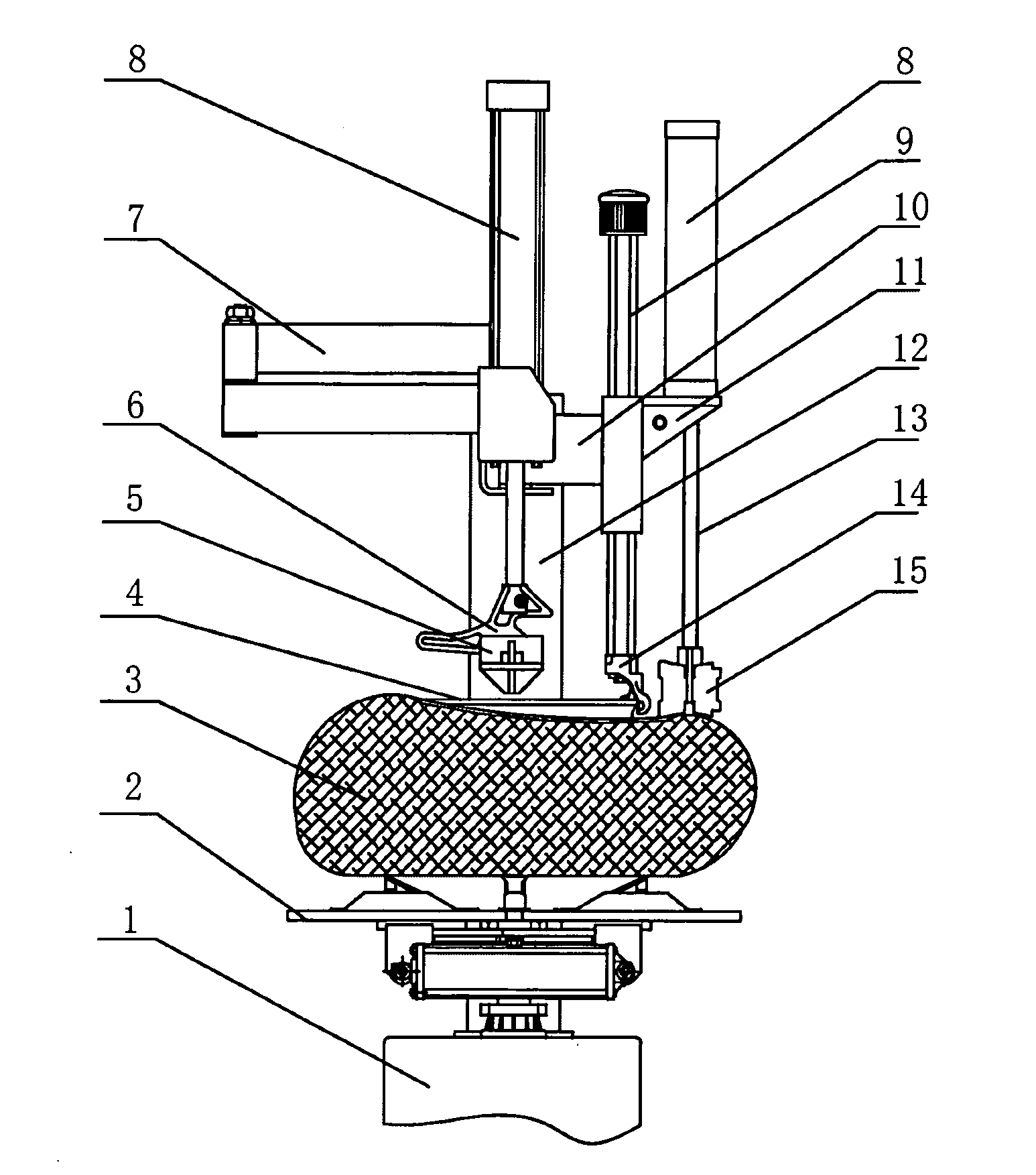

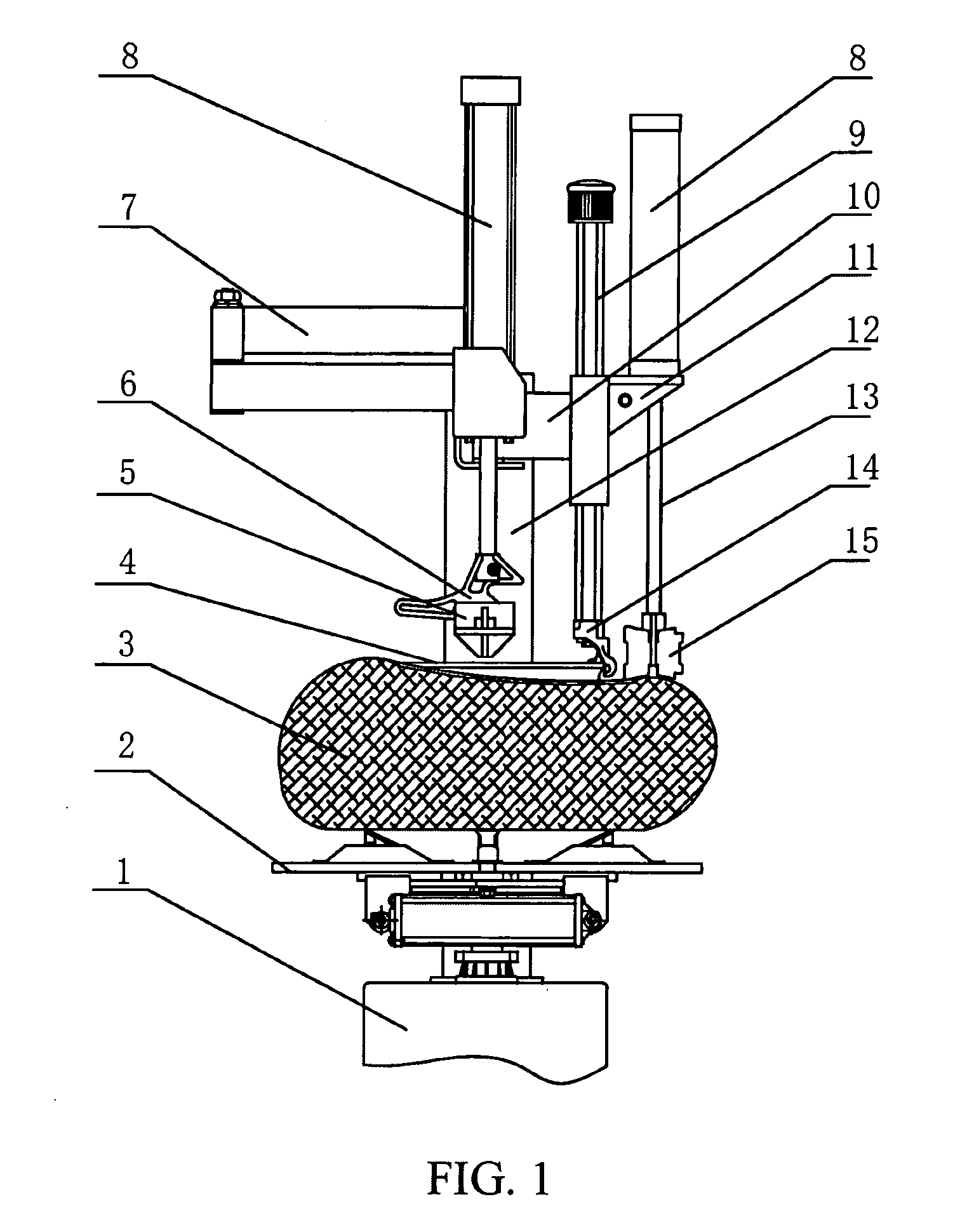

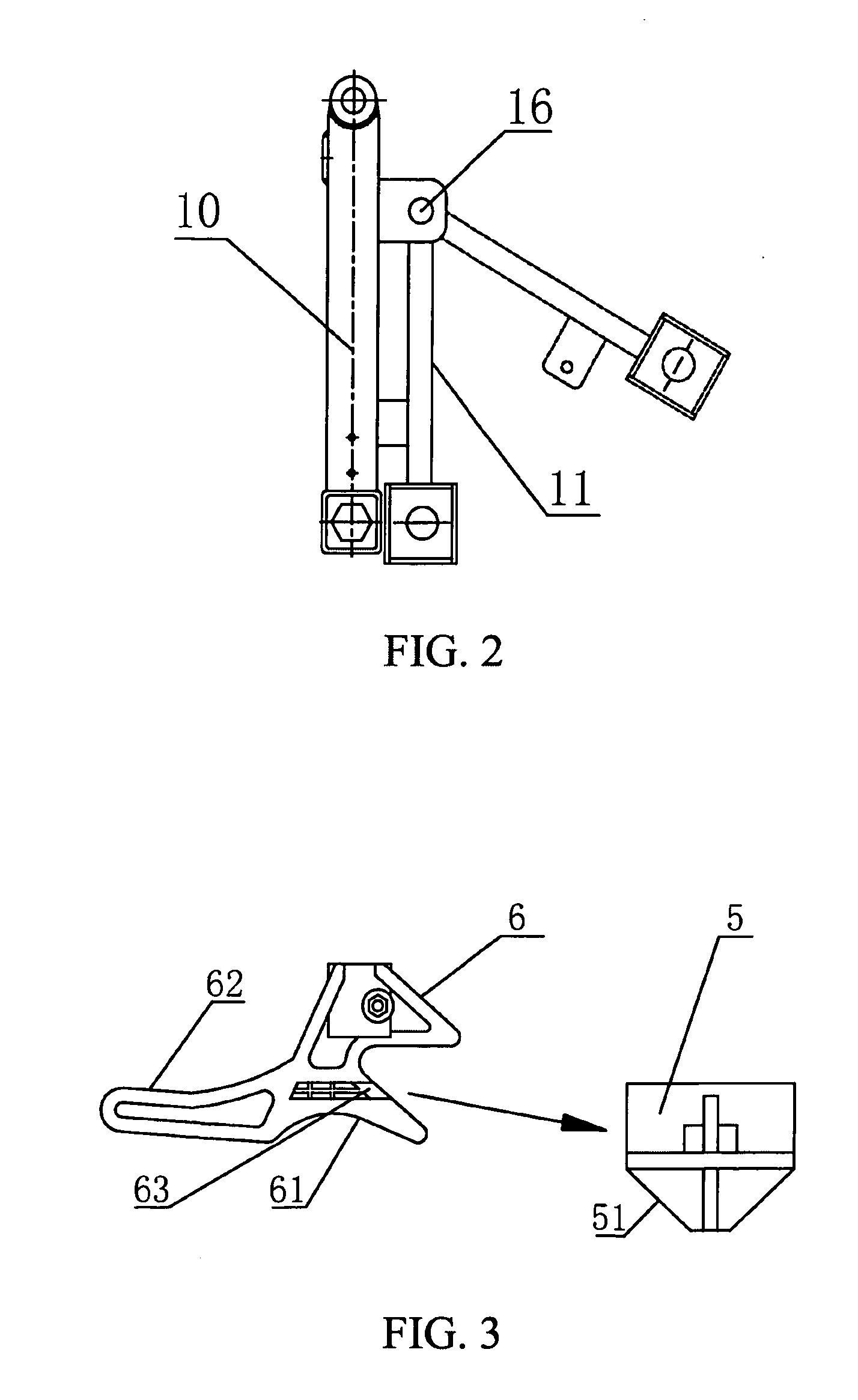

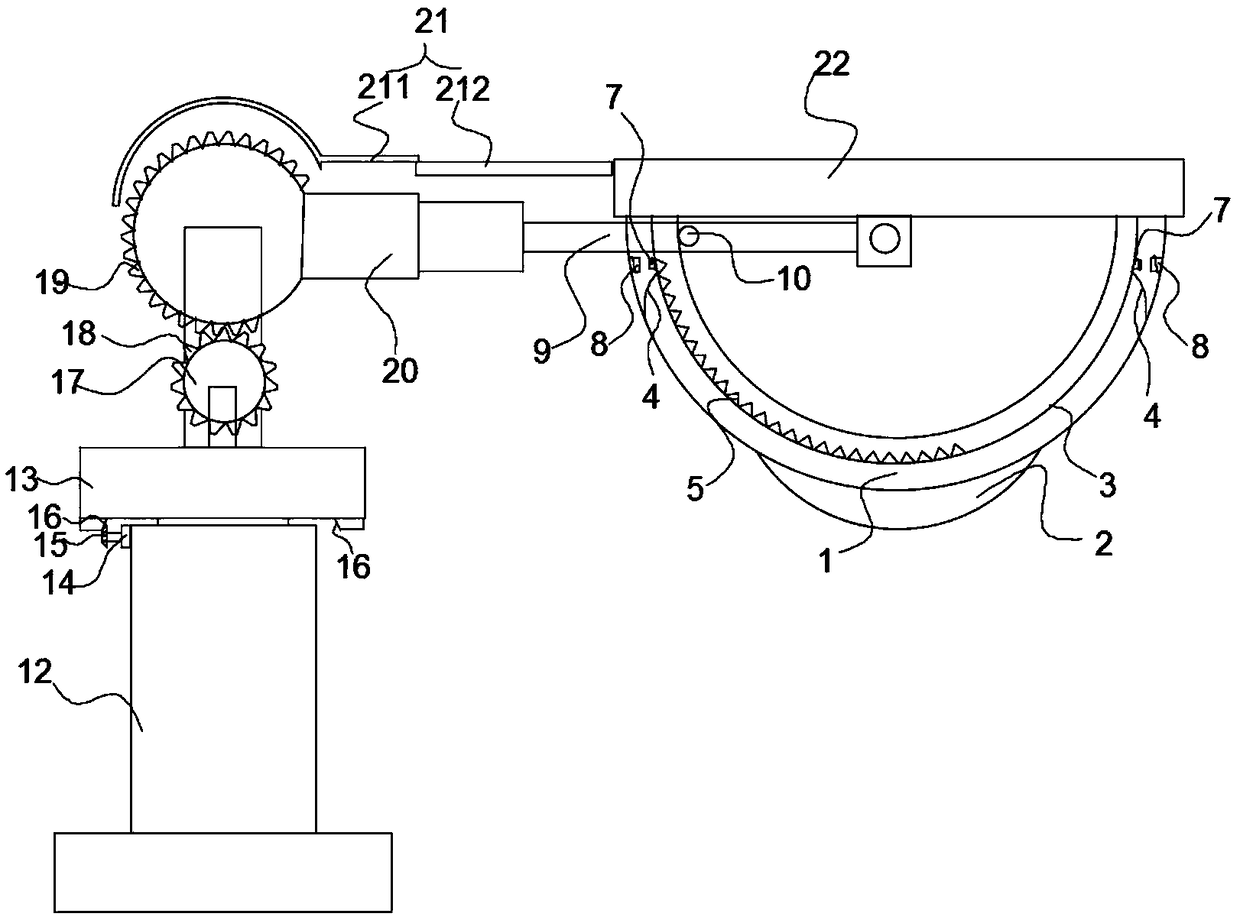

Swing arm style tire changer

ActiveUS8528620B2Avoid deformationSolve easy distortionTyre repairingMechanical engineeringPneumatic cylinder

Owner:SHANGHAI BALANCE AUTOMOTIVE EQUIP

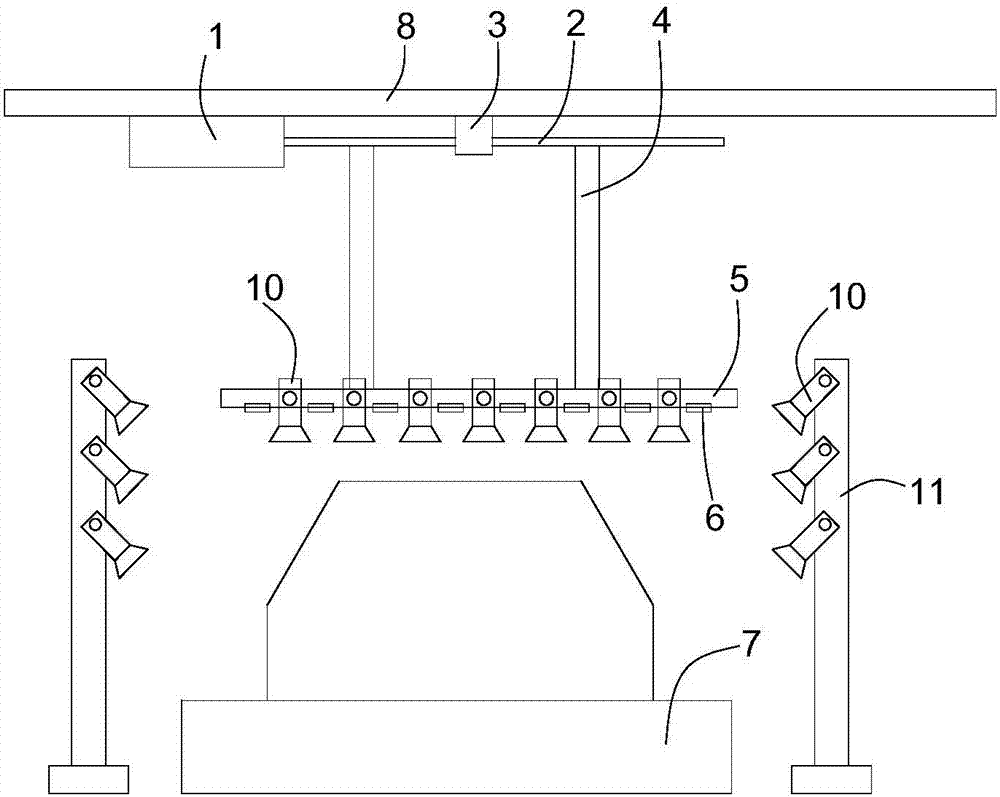

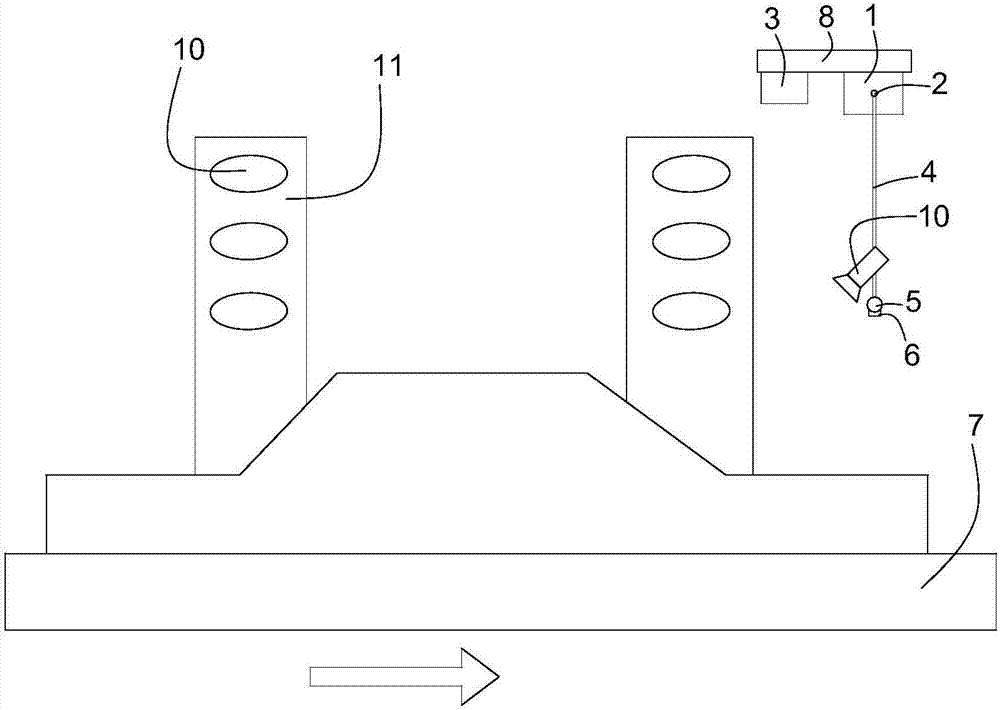

Servo cleaning device and method for automotive body painting production line

PendingCN107350213AReduce rework and rework costsReduce the chance of overreactingDrying gas arrangementsVehicle body dryingCar modelManufacturing line

The invention provides a servo cleaning device and method for an automotive body painting production line. Servo spray washing is carried out on an automotive body after the phosphating treatment, thereby greatly reducing residual phosphating liquid on the upper surface of the automotive body. Furthermore, during the process when the phosphating liquid is transferred from a phosphating slot to a washing tank, the probability of excessive reaction happening between the residual phosphating liquid and the automotive body can be reduced, thereby improving the once qualified rate of products and reducing the reworking and repairing cost of the automotive body. The servo cleaning device for the automotive body painting production line has the advantages of being adapt to car models of different height and achievable in automatically setting the height of nozzles, thereby making the automotive body sprayed more uniformly. Maintaining a reasonable distance, water can be saved while the residual phosphating liquid can be removed. Blowing is carried out on the automotive body after being sprayed, and drops of water on the surface of the automotive body can be removed, thereby preventing the residue of the phosphating liquid. The automotive body can move back and forth along with a horizontal transmission mechanism, thereby ensuring the uniformity of the spraying and blowing operation. Forward, backward and forward again, the spraying and blowing operation should be completed two times and there are no extra steps, thereby reducing the process cost.

Owner:大唐互联科技(武汉)有限公司

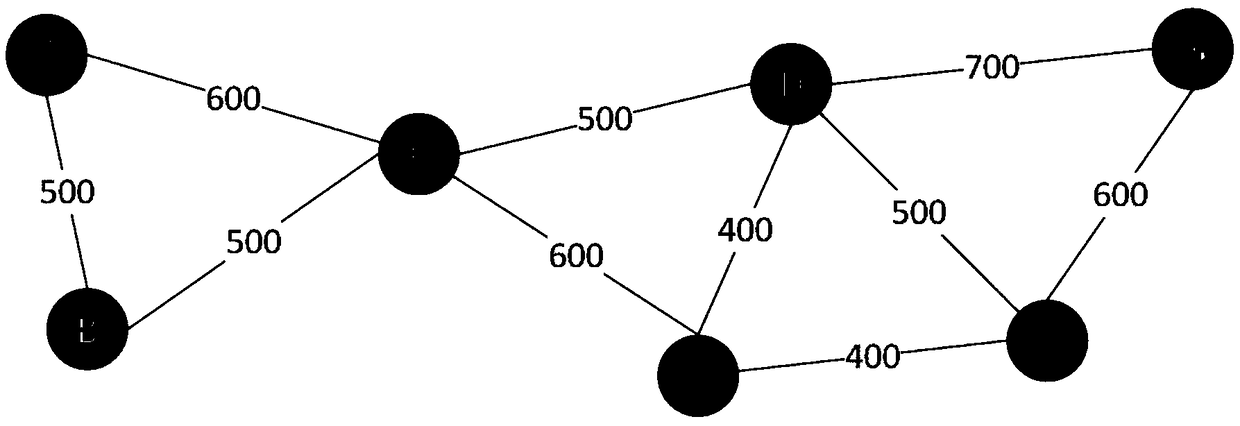

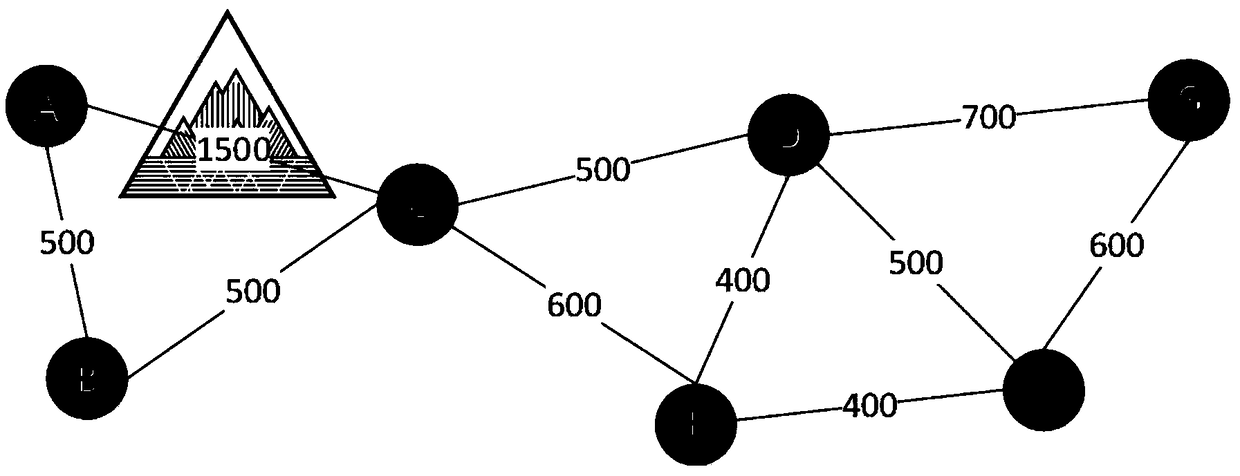

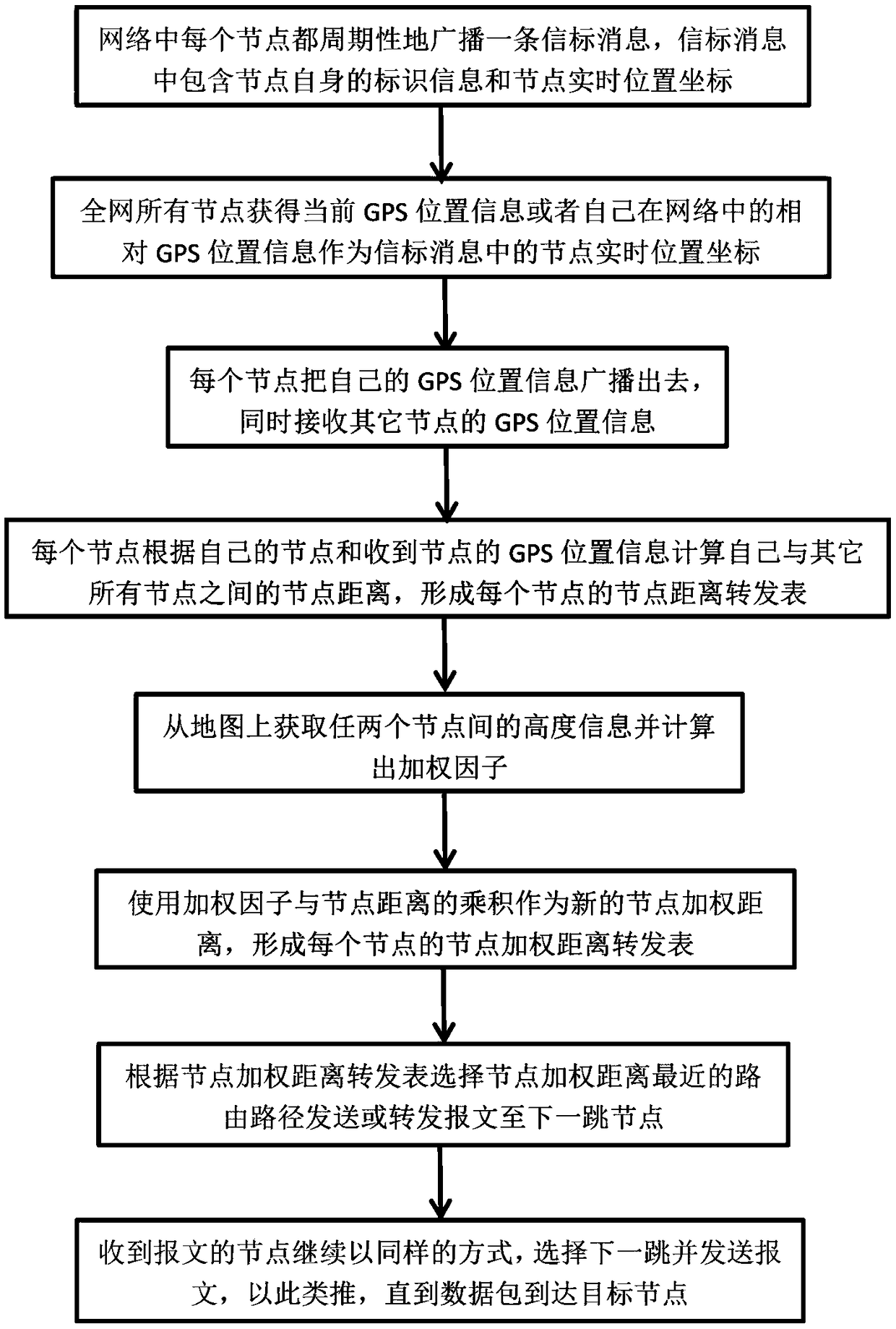

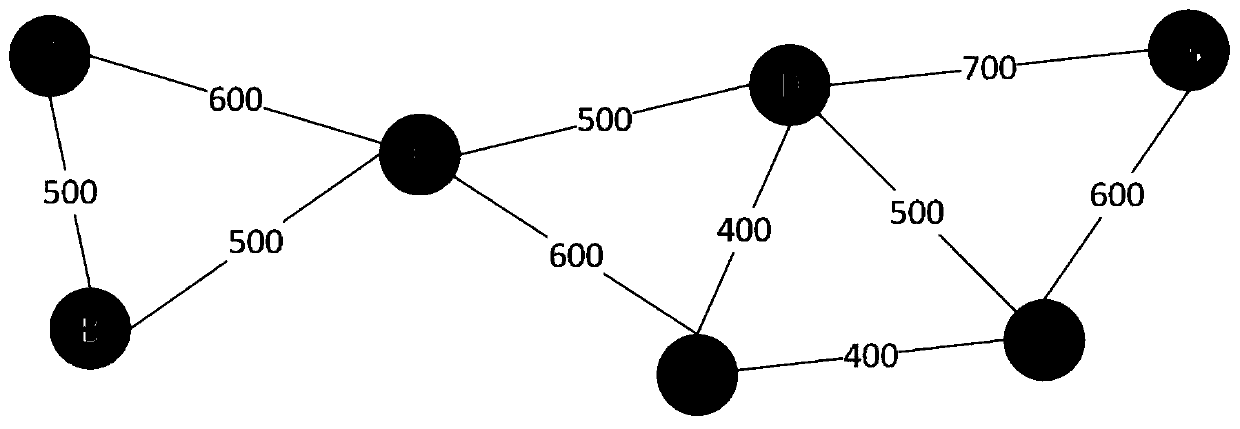

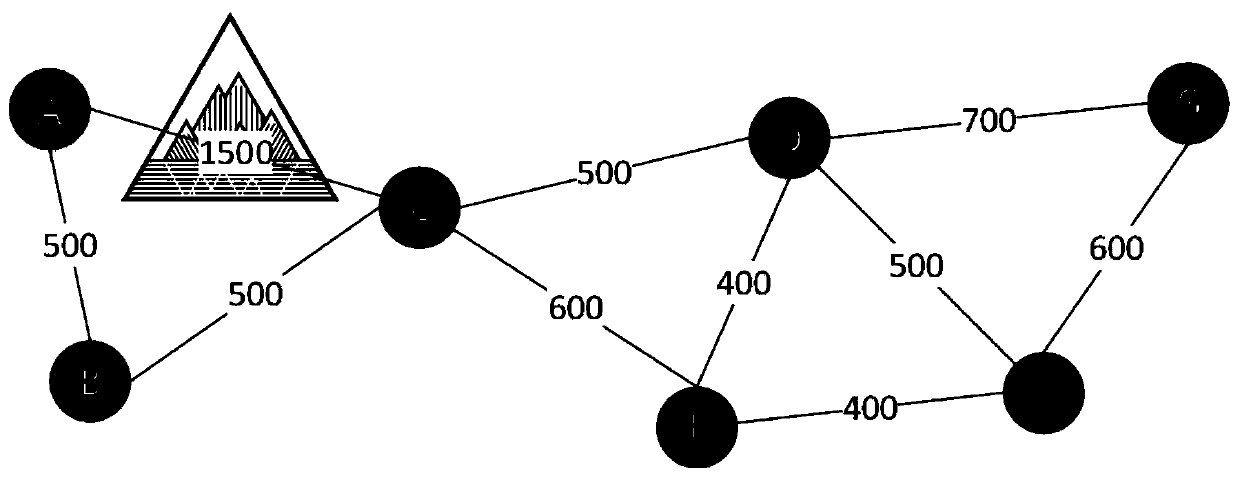

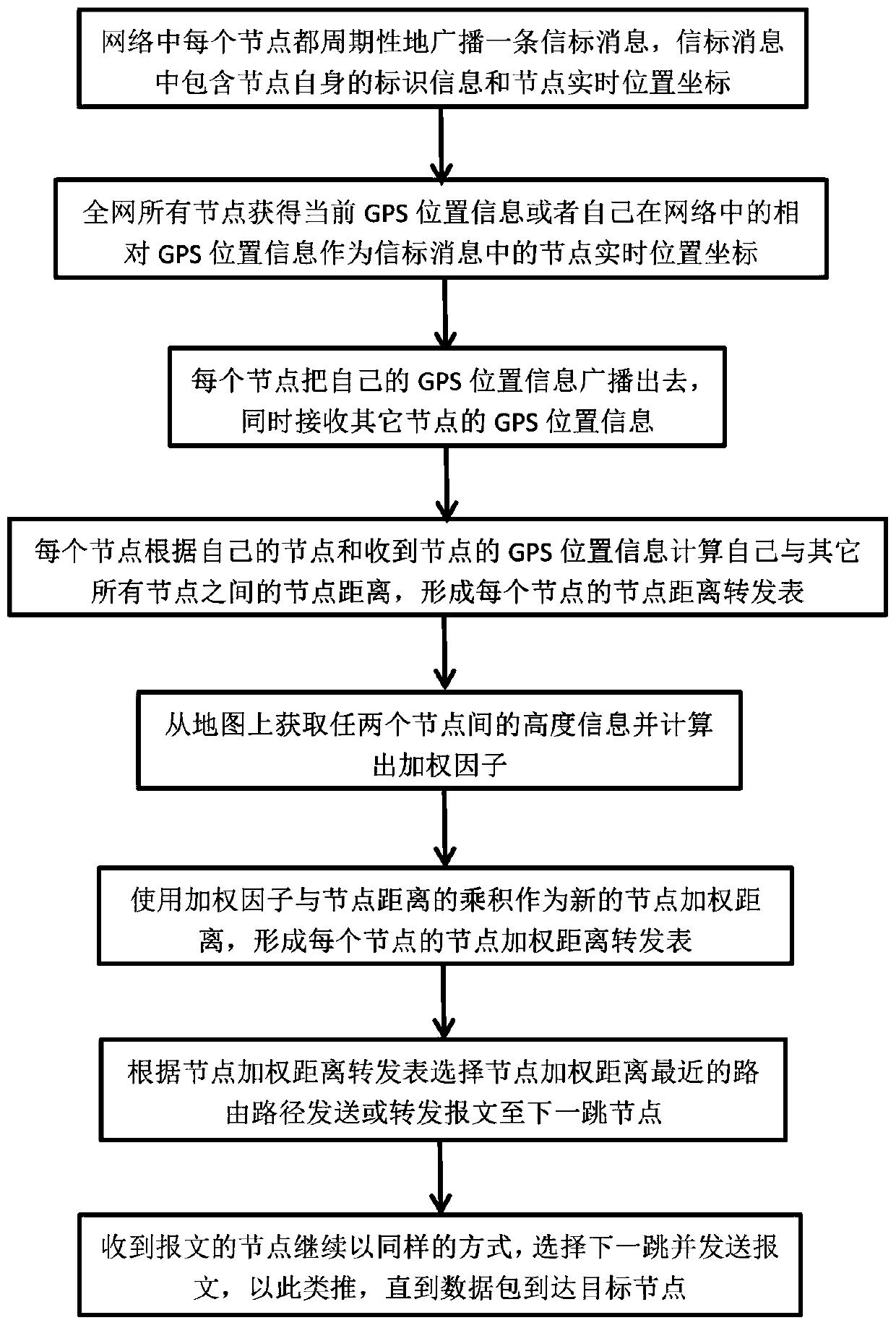

Distance-weighting-based routing algorithm and node-routing functional module thereof

ActiveCN108769897AReasonable distanceForward messages accurately and correctlyLocation information based serviceData switching networksRouting tableGlobal Positioning System

The invention discloses a distance-weighting-based routing algorithm and a node-routing functional module thereof. The node-routing functional module comprises a Radacat CPU (Central Processing Unit),a GPS (Global Positioning System) / Beidou module, a map module, a weighting distance calculation module, a routing list module and an RF (Radio Frequency) receiving and transmitting module, wherein the GPS / Beidou module, the map module, the weighting distance calculation module,, the routing list module and the RF receiving and transmitting module, are connected to the Radacat CPU. The distance-weighting-based routing algorithm disclosed by the invention calculates a reasonable wireless communication distance through weighing calculation so as to display a relative distance between two nodes more accurately; in a GPS position aid-based distance forwarding protocol, the technology is used more reasonably; and a more accurate distance can enable a Mesh network to forward a more accurate correctness forwarding message.

Owner:BEIJING RADACAT CO LTD

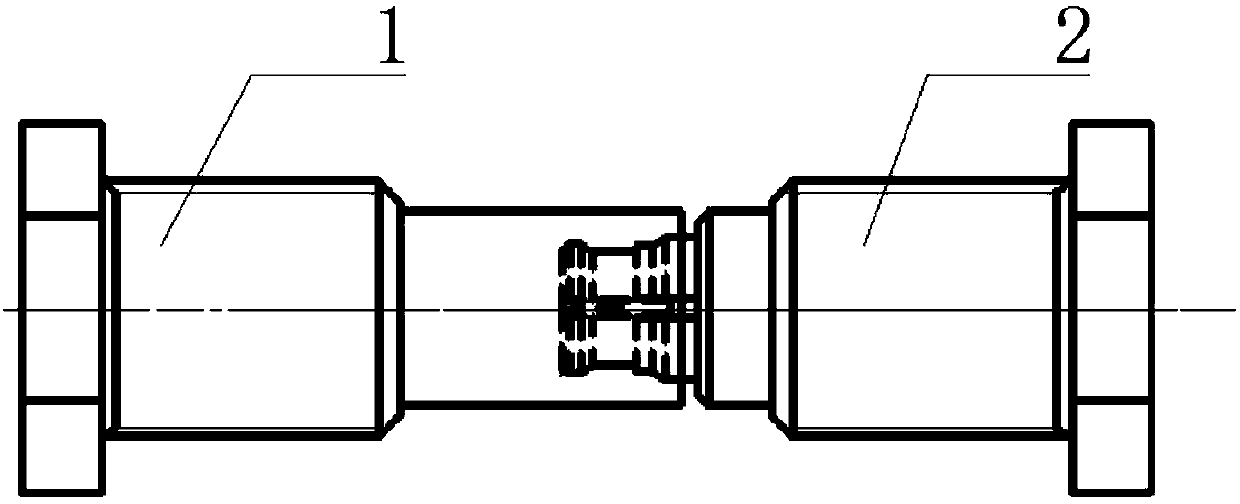

Quick insertion device for SMP connectors

ActiveCN108281847AReasonable distanceReduce mistakesCoupling device detailsTesting/measuring connectorsDevice PanelRadio frequency signal

The invention discloses a quick insertion device for SMP connectors. The quick insertion device comprises a device panel, an upper insertion panel, a lower insertion panel and a connecting-rod drive mechanism; the upper insertion panel and the lower insertion panel are arranged on the drive panel, radio-frequency line mounting holes are correspondingly formed in the upper insertion panel and the lower insertion panel; locking blocks and sliders which are mutually connected are respectively arranged on upper and lower surfaces of the device panel, the sliders are connected with the connecting-rod drive mechanism, and the locking blocks are movably connected with the upper insertion panel and drive the same to move vertically. More radio-frequency lines can be installed on the same quick insertion device, a safe, reliable, rapid and efficient way of locking is achieved, tightness in docking of the radio-frequency lines and radio-frequency heads can be well controlled, error of radio-frequency signals is lowered, and service life of the quick insertion device is prolonged; locking is performed by pushing a handle, and working efficiency of working personnel is improved.

Owner:ACETEC SEMICON

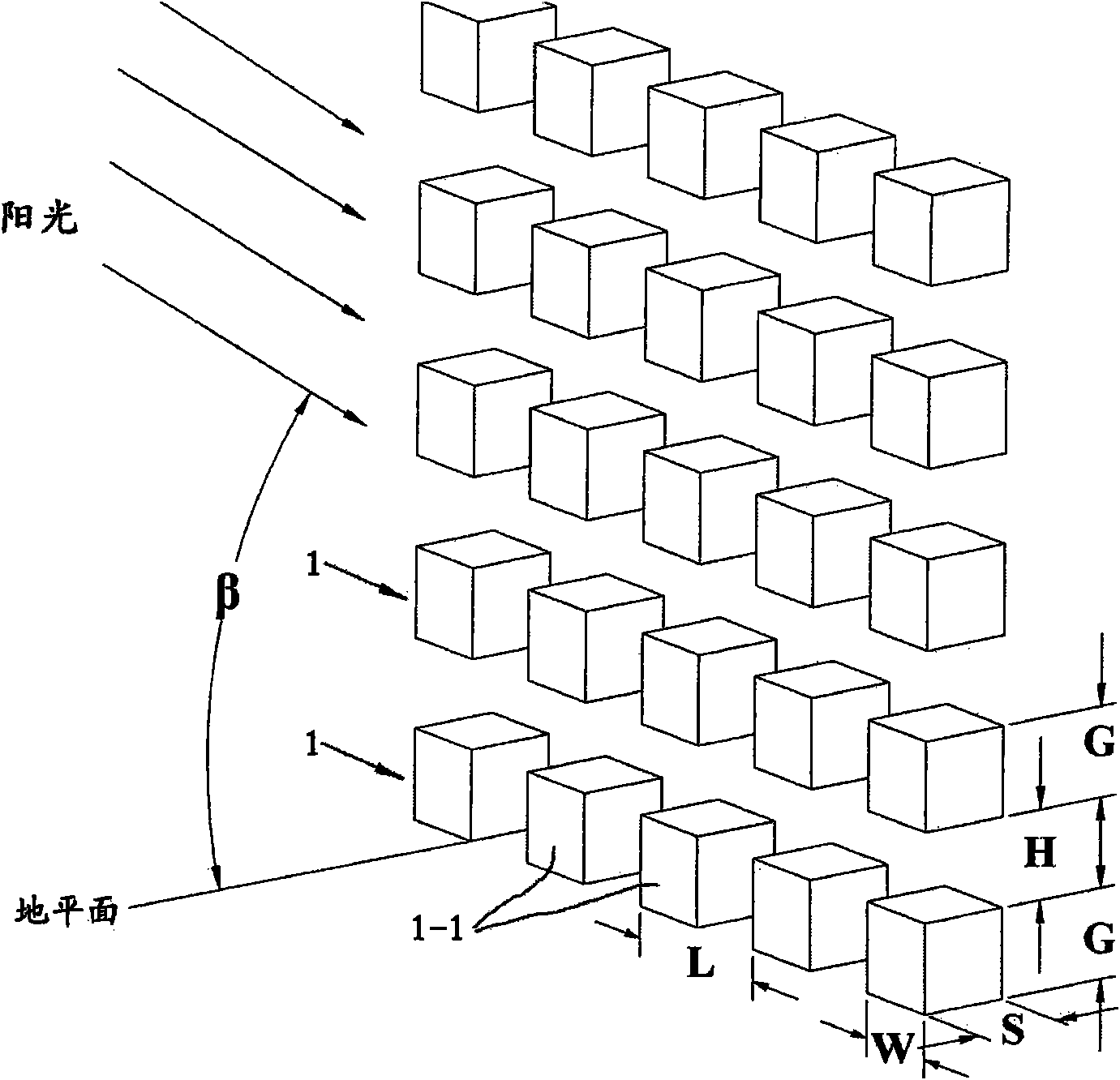

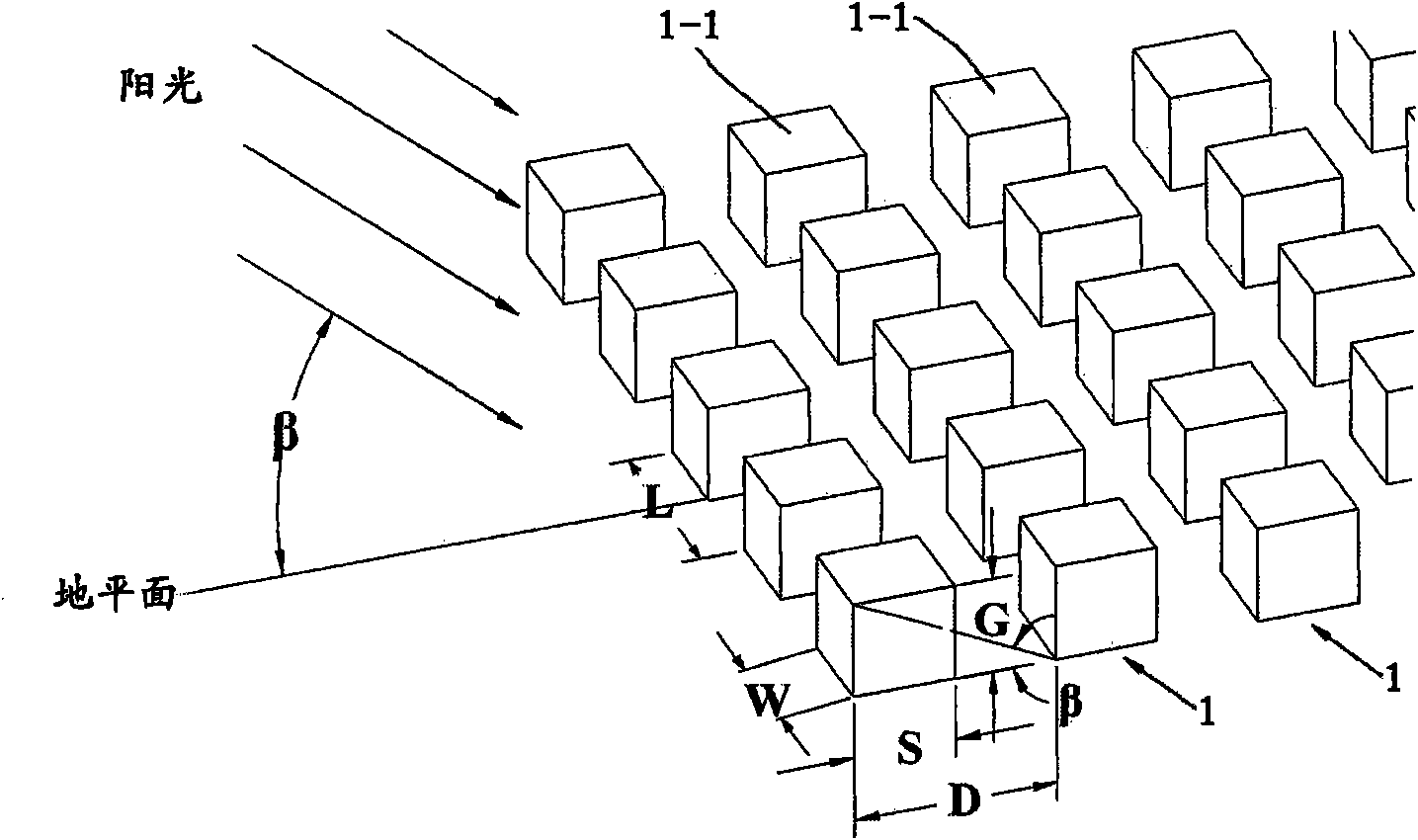

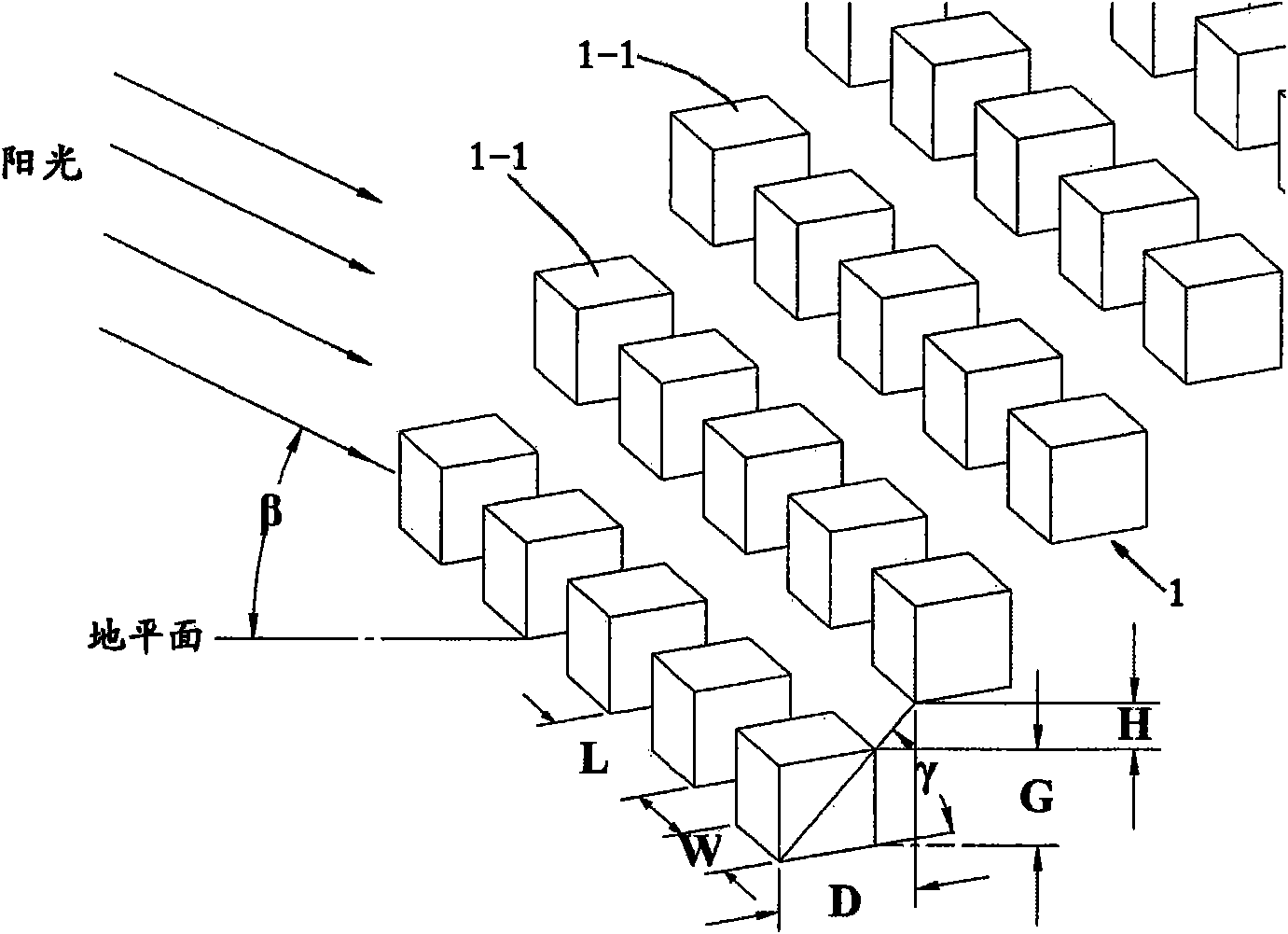

Solar power station

InactiveCN101567647AReduce location requirementsNot easy to damagePhotovoltaic supportsSolid-state devicesCondensing lensSmall footprint

The invention discloses a solar power station, which comprises a plurality of concentrated solar cell monomer modules which are electrically connected. Each monomer module comprises a condensing lens, a solar cell semiconductor chip, a horizontal and pitching rotation driving mechanism for driving the monomer module to carry out horizontal and pitching motion by following the sun. The plurality of concentrated solar cell monomer modules form module arrays which are arranged in mutually-spaced L distance along the horizontal direction, and the L meets a relational expression that L is equal to W / cosine alpha, wherein in the formula, W is the width of the concentrated solar cell monomer modules, and alpha is a solar azimuth determined by the latitude theta of a mounting site of the power station. The power station has low requirement on the mounting site and position, is not easy to damage under strong wind, and is convenient to mount and maintain; and the arrangement structure of the concentrated solar cell monomer modules in the power station and the distance of mutual intervals are reasonable, the occupied area is small, and the monomer modules are not mutually affected during working and can absorb sunlight more effectively so as to achieve maximum generating efficiency.

Owner:王旭 +2

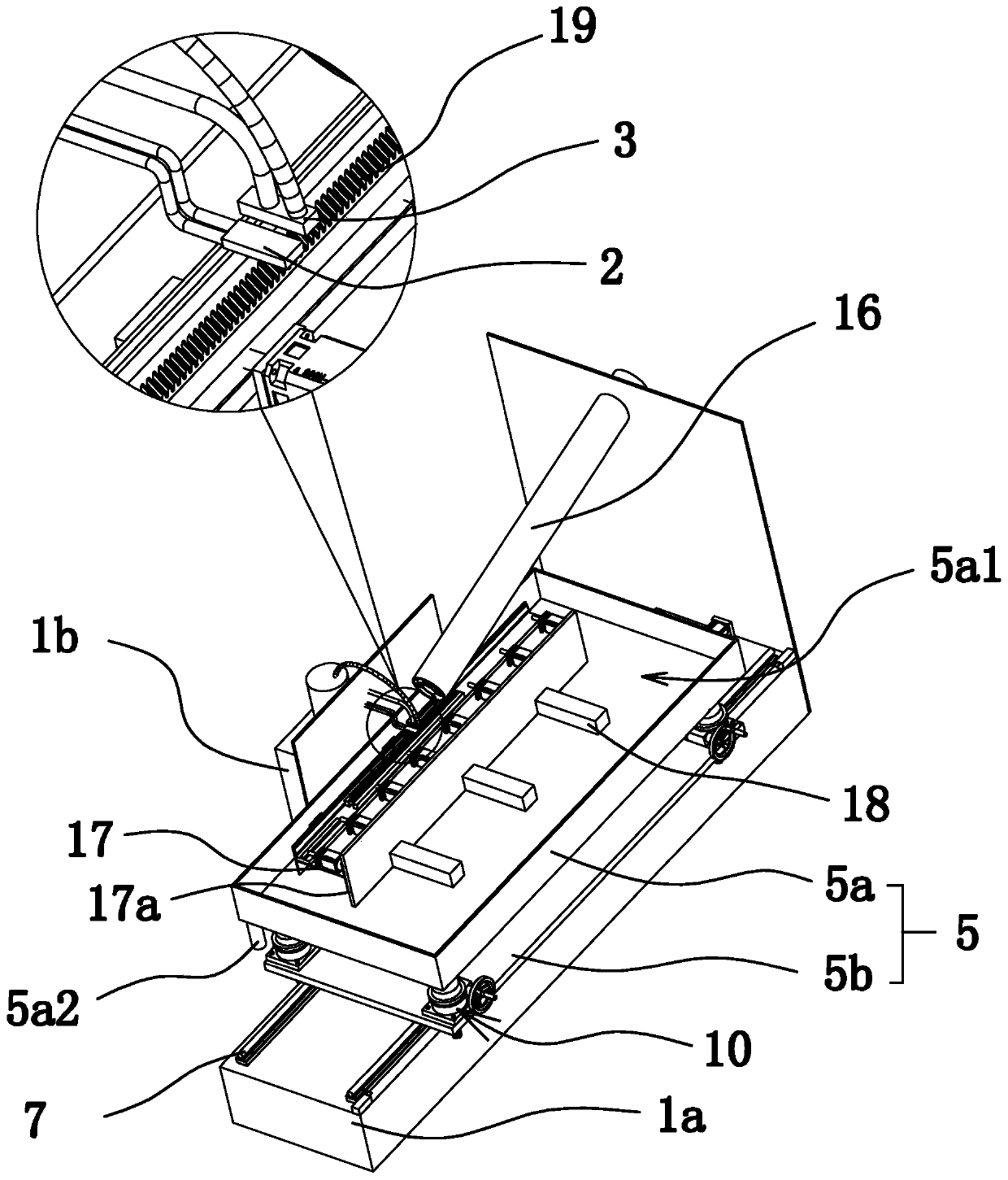

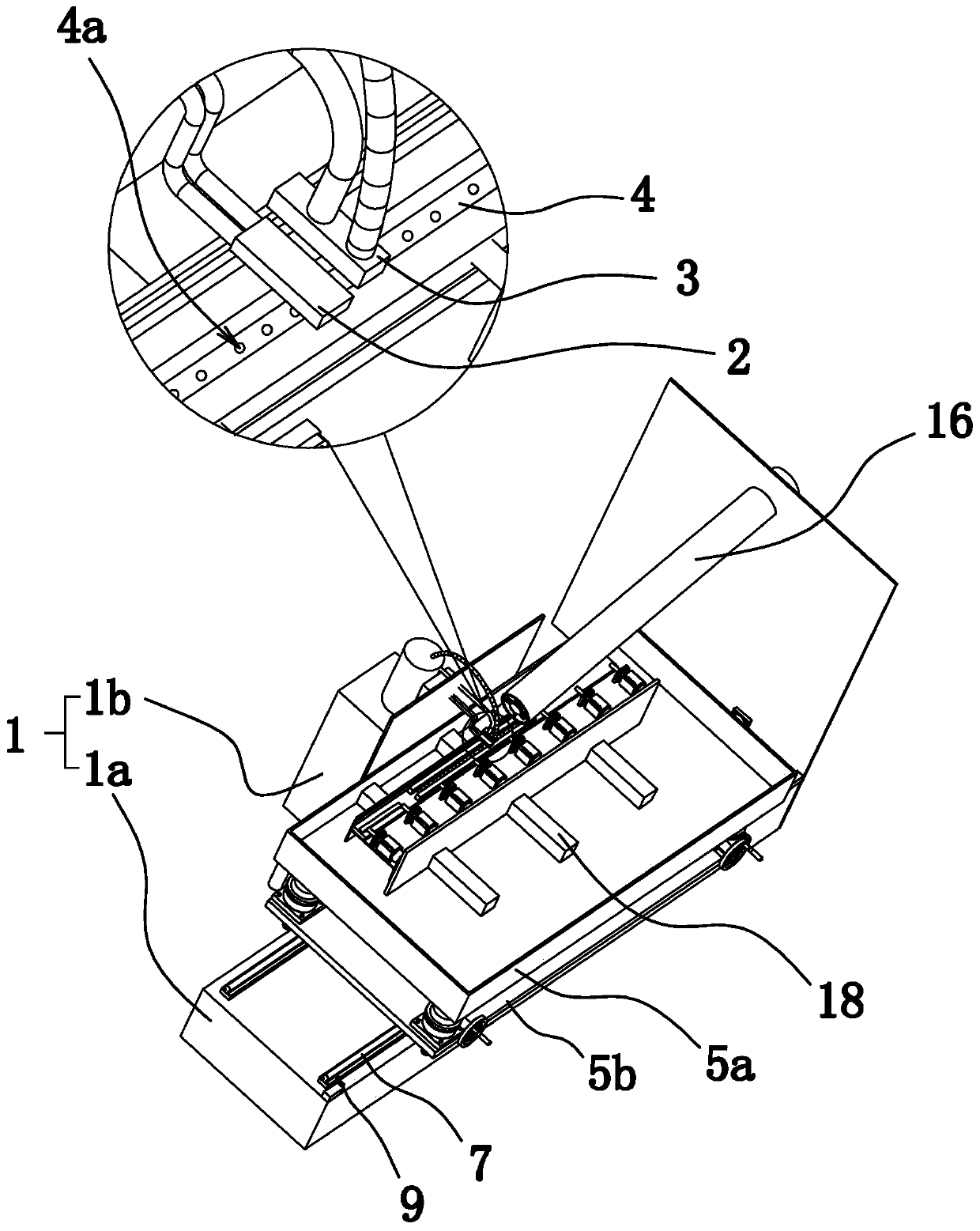

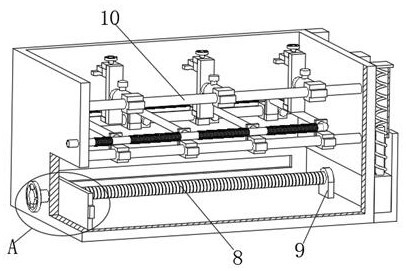

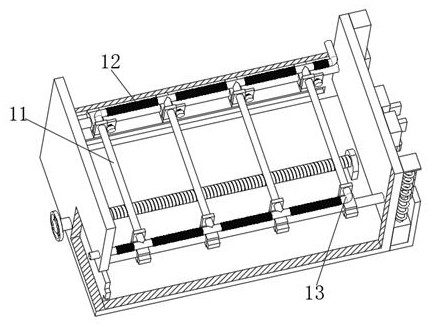

Tooth surface quenching device for rack

PendingCN111411200AImprove quenching effectNo deformation and upturningFurnace typesHeat treatment furnacesMachinePhysics

The invention provides a tooth surface quenching device for a rack, and belongs to the technical field of machines. The problem that an existing quenching device is poor in quenching effect is solved.The tooth surface quenching device for the rack comprises a machine frame, a quenching head, a quenching liquid nozzle, a quenching disc with a mounting cavity and a clamp used for clamping and positioning the rack, the quenching head and the quenching liquid nozzle are fixed to the machine frame, the quenching head and the quenching liquid nozzle are located above the clamp and are opposite to the clamp, the quenching disc is mounted on the machine frame and can slide back and forth in the horizontal direction relative to the machine frame, the clamp is mounted in the mounting cavity of thequenching disc, the bottom face of the clamp is a plane, the quenching disc is provided with a sucking part, the sucking part can suck the bottom of the rack to enable the rack to be tightly attachedto the bottom face of the clamp, the sucking part can generate sucking force to enable the bottom of the rack to be firmly sucked, in the quenching process, even if the rack is heated, deforming and upwarping cannot be generated, the tooth surface quenching effect is improved, and the product quality is ensured.

Owner:台州莱德齿条有限公司

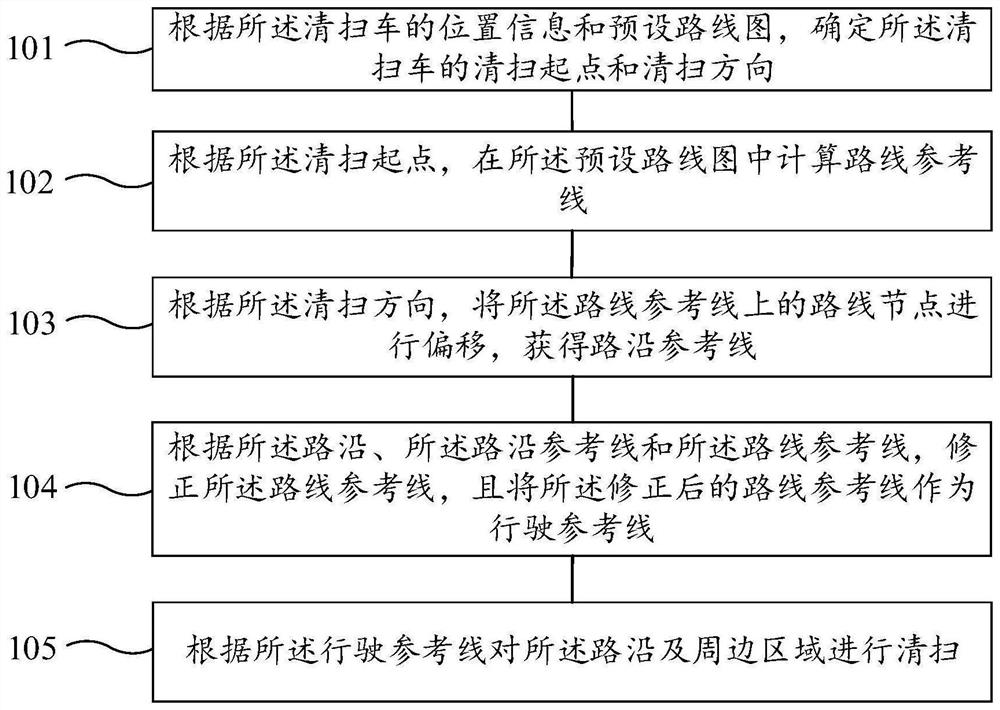

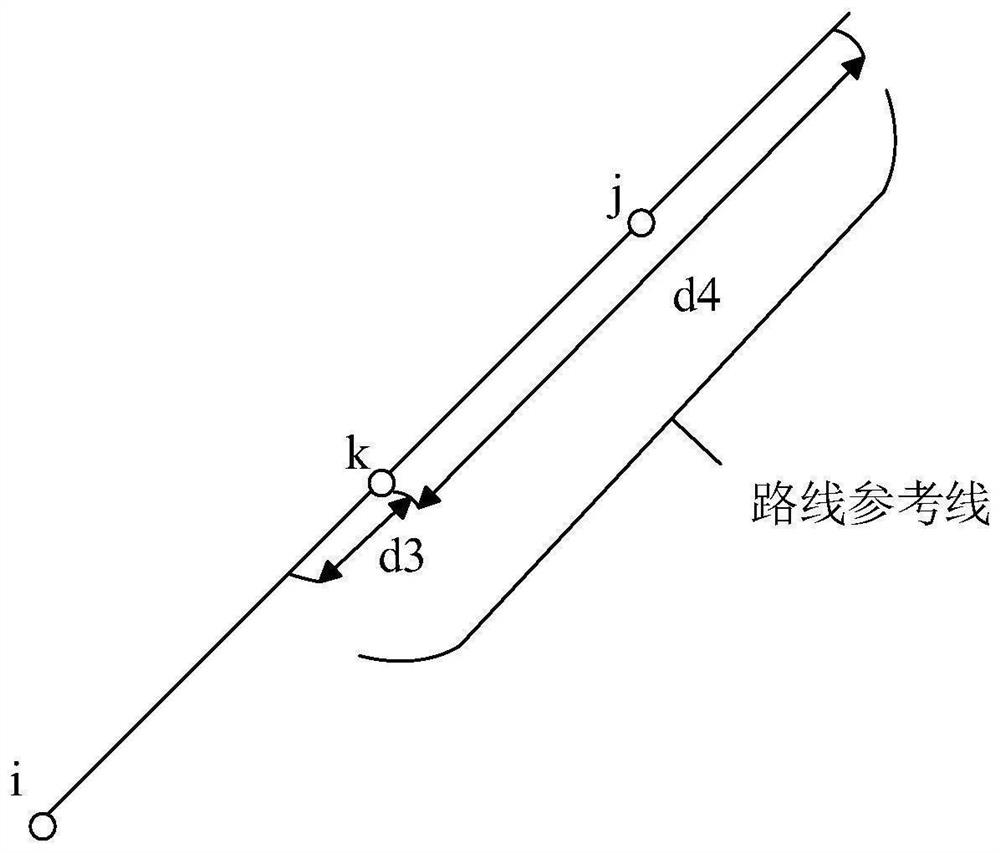

Edge sweeping method, device and sweeping vehicle

ActiveCN112982252AHigh positioning accuracyAvoid the problem of inaccurate positioning accuracyRoad cleaningPosition/course control in two dimensionsReference lineReal-time computing

The embodiment of the invention relates to an edge sweeping method, a device and a sweeping vehicle. The method comprises the steps: determining a sweeping starting point and a sweeping direction of the sweeper according to the position information of the sweeper and a preset route map; calculating a route reference line in the preset route map according to the cleaning starting point; according to the cleaning direction, deviating route nodes on the route reference line to obtain a road edge reference line; according to the road edge, the road edge reference line and the route reference line, correcting the route reference line, and taking the corrected route reference line as a driving reference line; and cleaning the road edge and the surrounding region according to the driving reference line. According to the embodiment of the invention, the route map is accurately preset, so that the distance between the unmanned sweeper and the road edge is reasonable, and the sweeping precision is effectively improved.

Owner:深圳一清创新科技有限公司

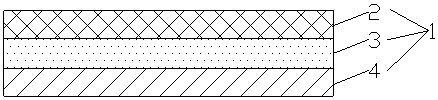

Seed piece unit and seed piece

The invention discloses a seed piece unit which is characterized by comprising a fiber layer and a nutritive water-absorbing layer from top to bottom, wherein seeds are arranged between the fiber layer and the nutritive water-absorbing layer; and the nutritive water-absorbing layer comprises a nutrient layer and a water absorbing material layer. According to the seed piece provided by the invention, the seeds can be uniformly spread, and the fiber layer can enable the seeds to meet appropriate resistance during growth while providing nutrients for the seeds, so that the seed growth is healthyand strong; since the nutritive water-absorbing layer comprises the nutrient layer and the water absorbing material layer, fertilization of a planter is not needed, only the seed piece needs to be arranged in a place close to water, the operation is convenient and rapid, and the germination rate of the seeds is increased.

Owner:上海亮籽智能科技有限公司

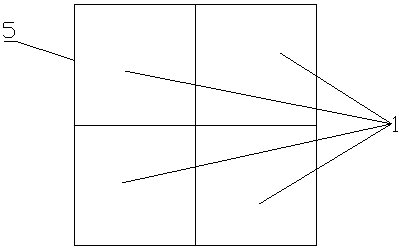

Bottom channel inner support of foundation pit supporting structure

InactiveCN102322065AOvercoming technical difficulties of crackingOvercoming technical difficulties of insufficient strengthExcavationsBasementRebar

The invention discloses a bottom channel inner support of a foundation pit supporting structure. The bottom channel inner support comprises a plurality of inner supports (1) which are positioned on the bottommost layer and have the same elevation, wherein four sides of a node area of each inner support (1) are provided with annular concrete bosses (2) which protrude the four sides; a circle of water stop steel plate (3) is anchored on the concrete bosses (2) and protrudes four sides of the concrete bosses (2); and a plurality of horizontal connecting steel bars (6) and a plurality of verticalconnecting steel bars (7) which protrude each inner support (1) are embedded into each inner support. The bottom channel inner support of the foundation pit supporting structure can be poured and tamped in a basement bottom plate.

Owner:HUAFENG CONSTR CO LTD

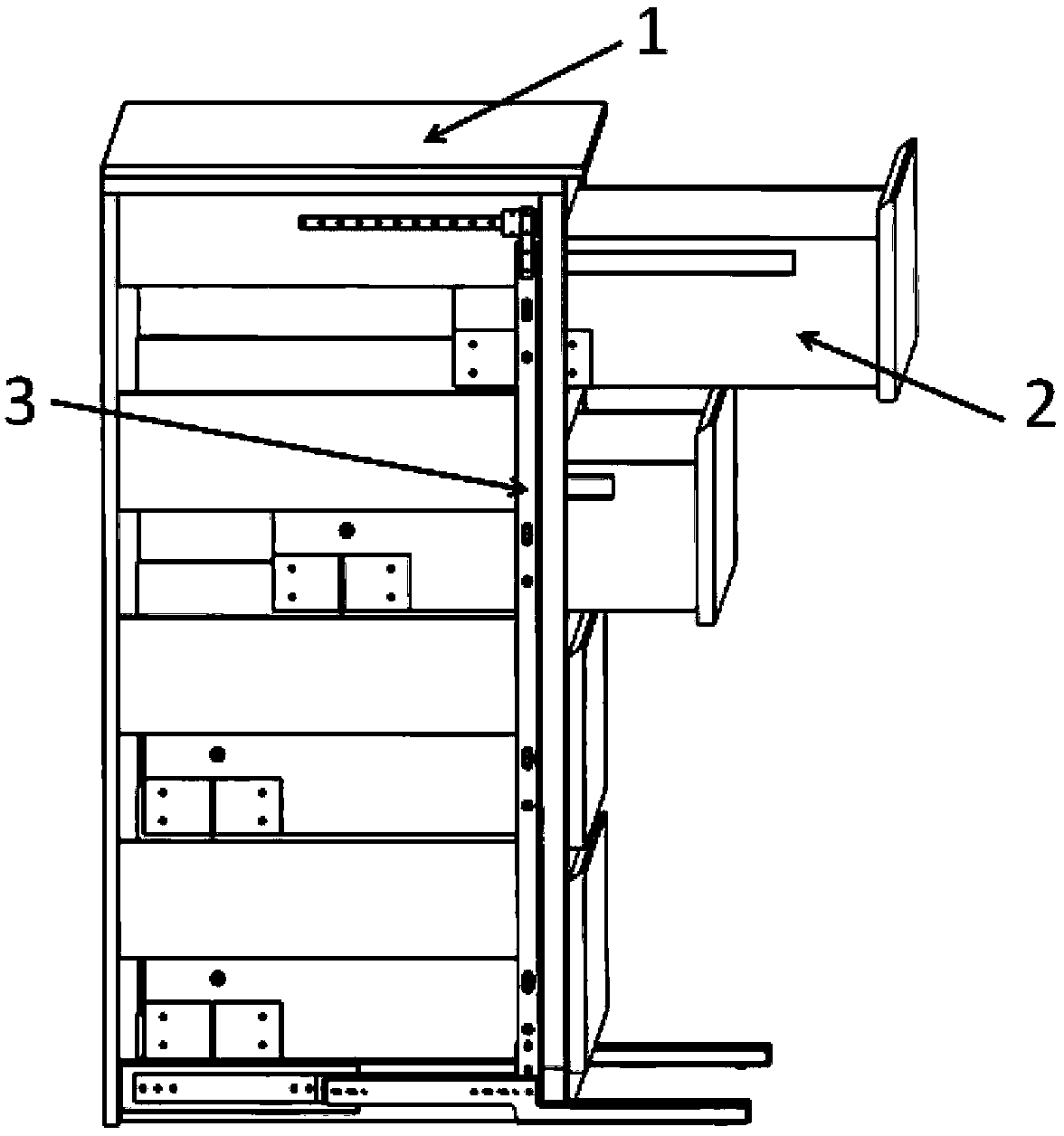

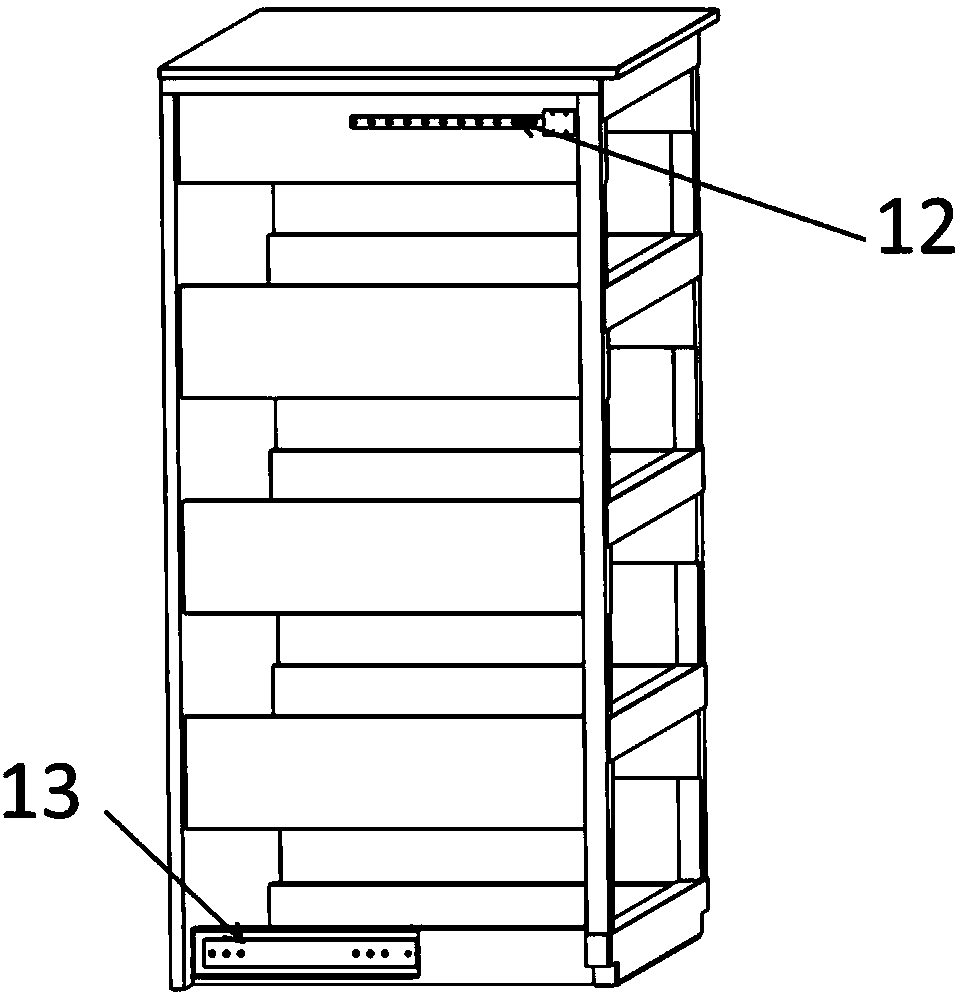

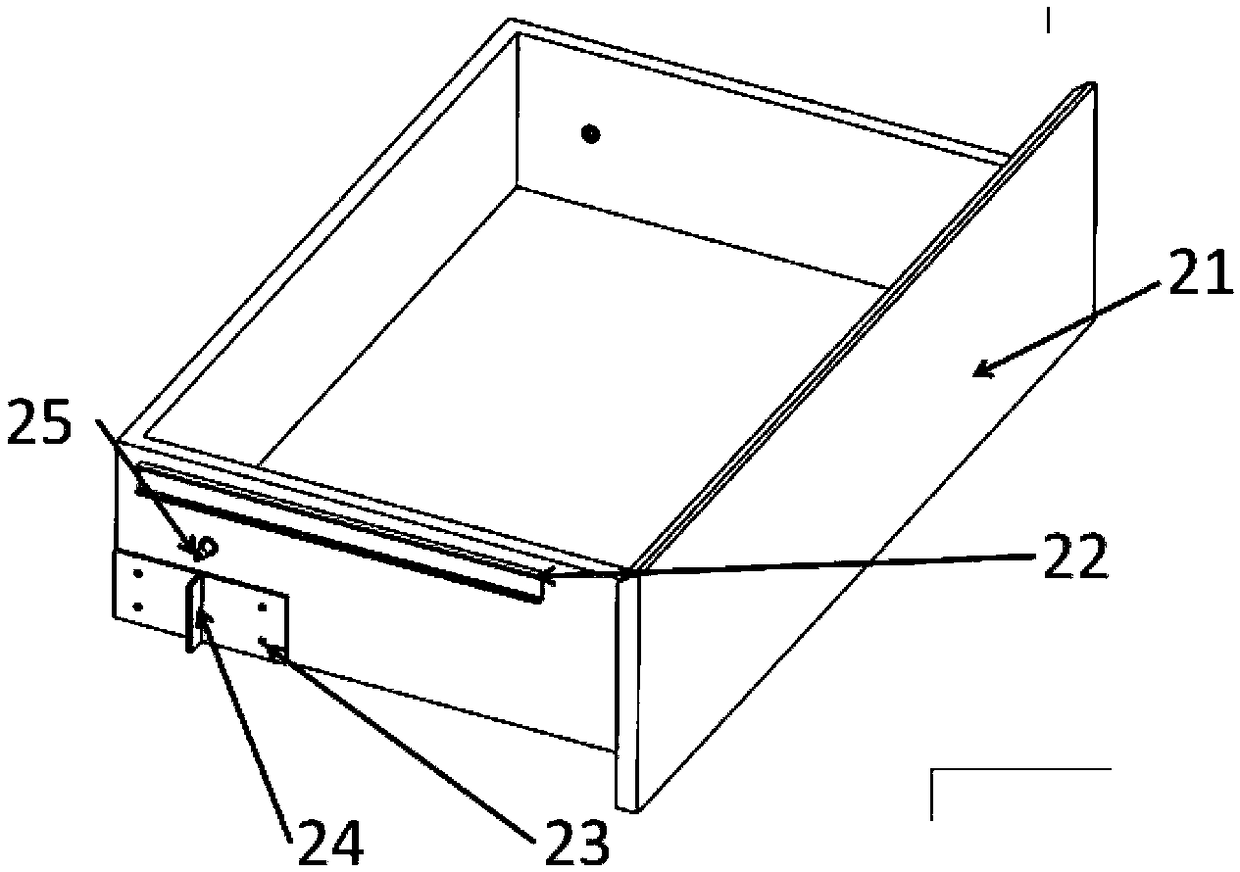

Toppling-prevention drawer chest

Owner:GUANGZHOU 37 DEGREE SMART HOME CO LTD

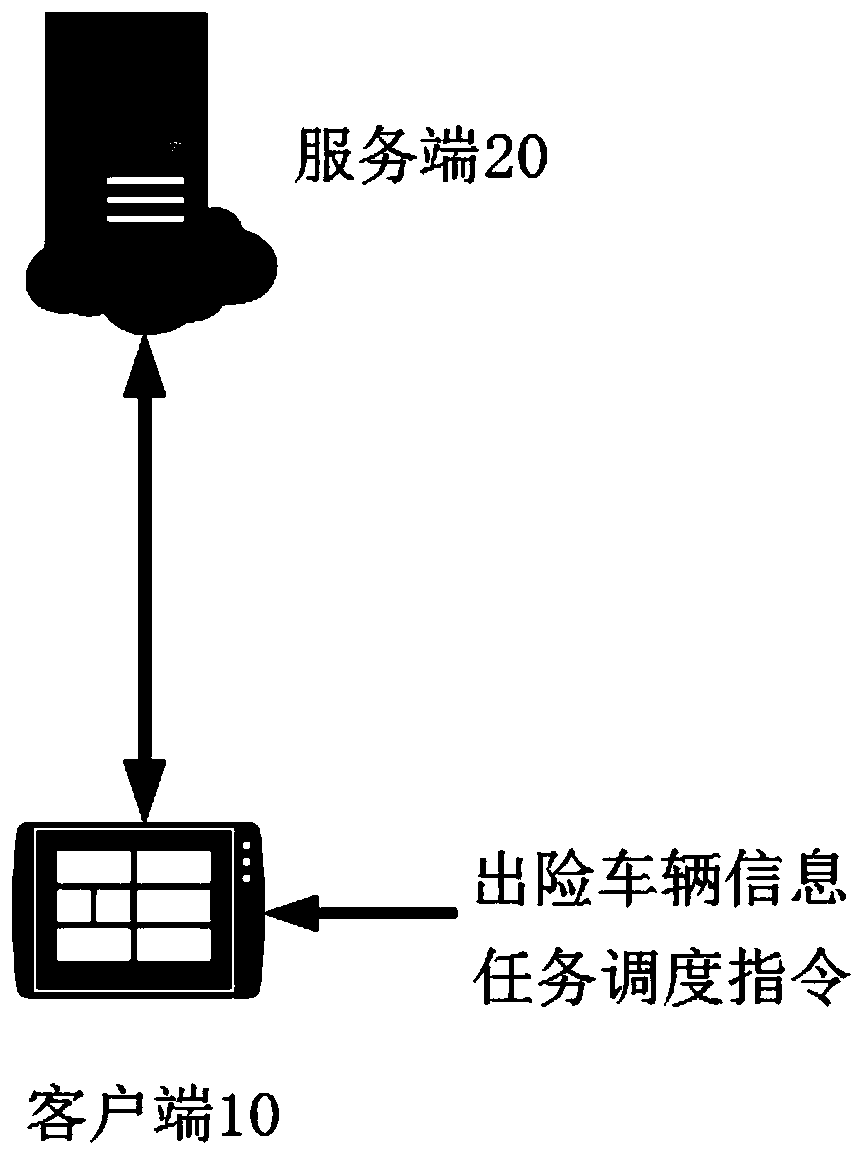

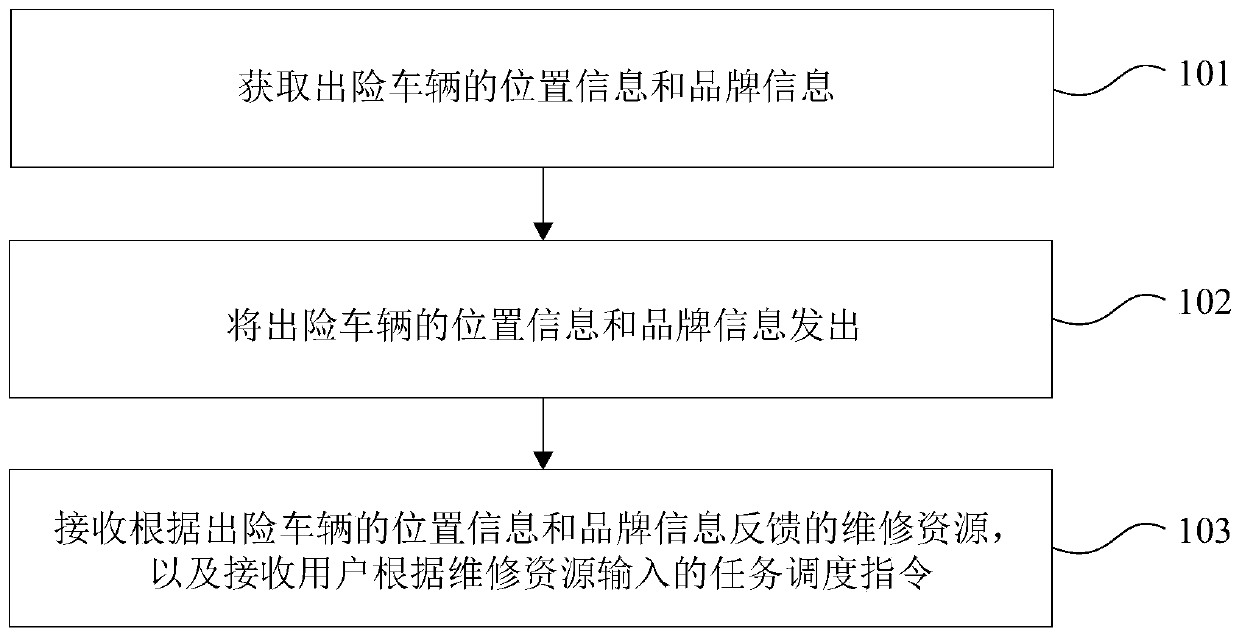

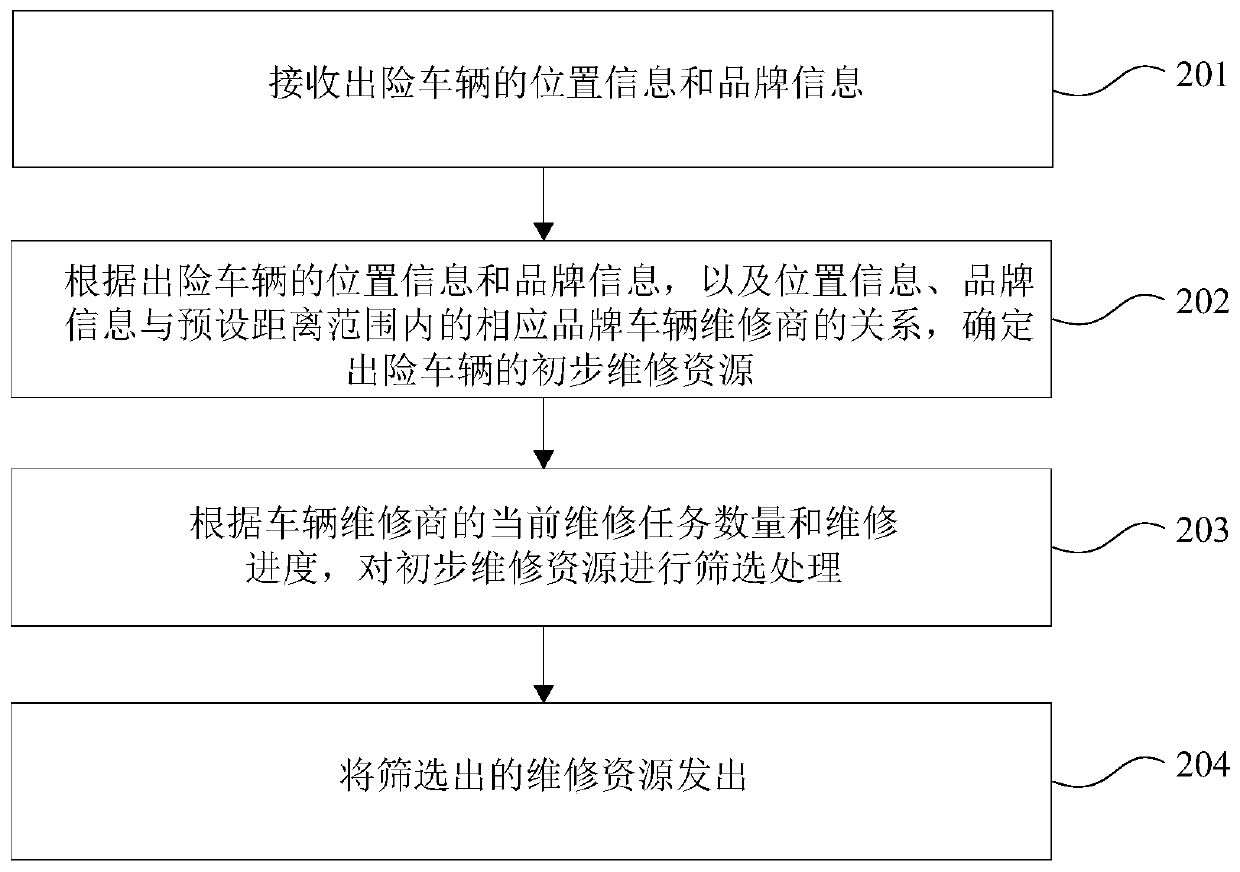

Maintenance task scheduling method, client and server

InactiveCN110472849AAccurate and reasonable distributionReasonable distanceFinanceResourcesAccidents vehicleScheduling instructions

The invention provides a maintenance task scheduling method, a client and a server, and the method comprises the steps: obtaining the position information and brand information of an accident vehicle;sending out the position information and brand information of the accident vehicle; receiving maintenance resources fed back according to the position information and brand information of the accident vehicle, and receiving a task scheduling instruction input by a user according to the maintenance resources, wherein the maintenance resources are determined after screening according to the numberof current maintenance tasks and the maintenance progress of a vehicle maintainer. According to the technical scheme, maintenance tasks can be reasonably and accurately distributed.

Owner:SUNSHINE PROPERTY & CASUALTY INSURANCE CO

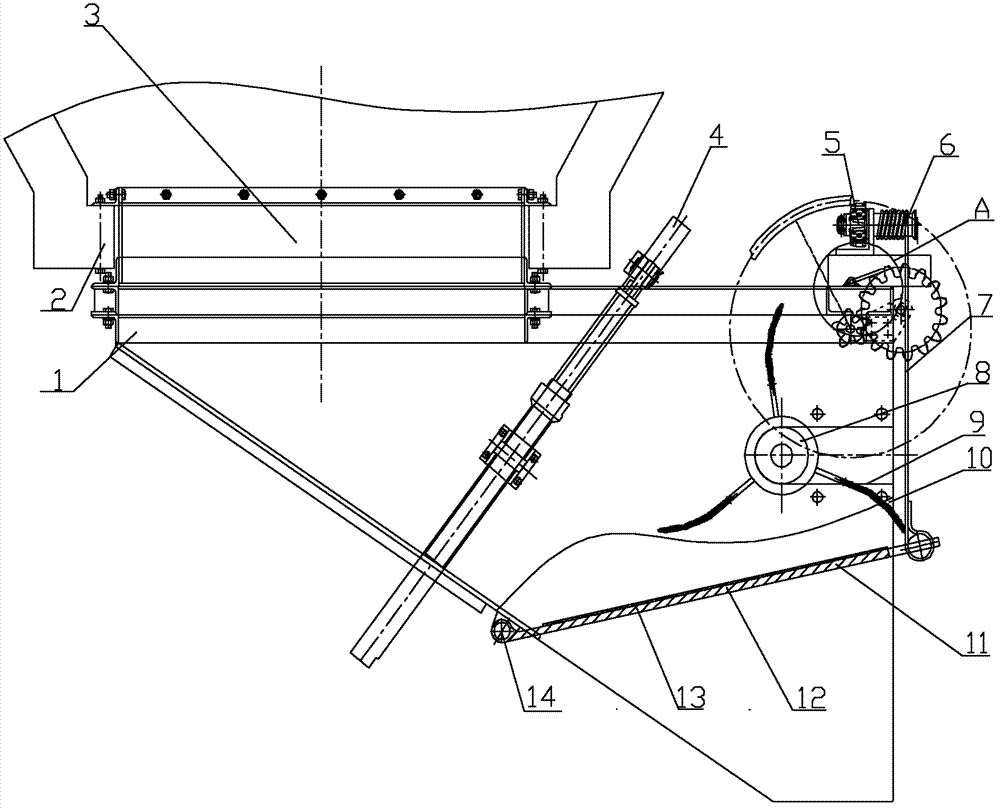

Anti-impact rotating plate feeding machine

The invention belongs to the field of material delivery and particularly relates to a mining anti-impact rotating plate feeding machine. The feeding machine comprises a material guide groove and further comprises a rotating plate device which comprises a rotating lifting mechanism and a rotating plate. The material guide groove is directly connected with a bunker port, the rotating plate device is arranged in the material guide groove and avoids the feeding end of the material guide groove, the rotating plate device is hinged with the material guide groove, one end of the rotating plate is hinged with the material guide groove, and the rotating lifting mechanism drives the other end of the rotating plate to be lifted. The anti-impact rotating plate feeding machine achieves effective sealing of the material guide groove and the rotating plate device, greatly reduces adjusting resistance of the rotating plate, increases control flexibility, enables feeding quantity to be adjusted and controlled immediately and timely and achieves the aims of improving efficiency, saving energy and achieving optimum feeding transshipment.

Owner:刘素华

Swing arm style tire changer

ActiveUS20110079362A1Avoid deformationSolve easy distortionTyre repairingEngineeringMechanical engineering

A swing arm style tire changer includes a base (1), a workbench (2), an upright stem (12), a swing arm (10) and a dismounting head (14). The swing arm (10) is attached to the upright stem (12) and is capable of rotating horizontally. The swing arm style tire changer also includes a first helper arm (11) connected to the swing arm (10); under said first helper arm (11) and connected thereto is a tire-pressing wheel (15) that may be moved vertically upwards and downwards. The first helper arm (11) is attached to the swing arm (10) and is capable of rotating horizontally, and a pneumatic cylinder (8) is arranged on said first helper arm (11). The swing arm style tire changer also includes a second helper arm (7).

Owner:SHANGHAI BALANCE AUTOMOTIVE EQUIP

Casting equipment with good cooling effect

InactiveCN112371956AReasonable distanceImprove qualityMoulding flasksCooling effectStructural engineering

The invention discloses casting equipment with a good cooling effect, and relates to the technical field of casting equipment. The casting equipment comprises a forming box, wherein a sand leaking hole is formed in the side wall of the forming box; a fixed block, two L-shaped fixed rods and two extrusion barrels are fixedly connected on the side wall of the forming box; the side walls of the two L-shaped fixed rods are fixedly connected with the side walls of the two extrusion barrels separately; a fixed slot is formed in the side wall of the fixed block; pressing slots are formed in the bottoms of the two extrusion barrels; a concave block is fixedly connected on the side wall of the forming box; a pulling block is in sliding connection on the side wall of the concave block; a fixed partis arranged on the pulling block; the bottom end of the pulling block is fixedly connected with a baffle plate; the baffle plate is in sliding connection on the side walls of the two L-shaped fixed rods; and a pressing part is arranged on the top of the baffle plate. The casting equipment is reasonable in structure, is quick in heat dissipation, is high in cooling speed, is high in casting speed,and is easy to take out a casting.

Owner:含山县清溪兴隆铸件厂

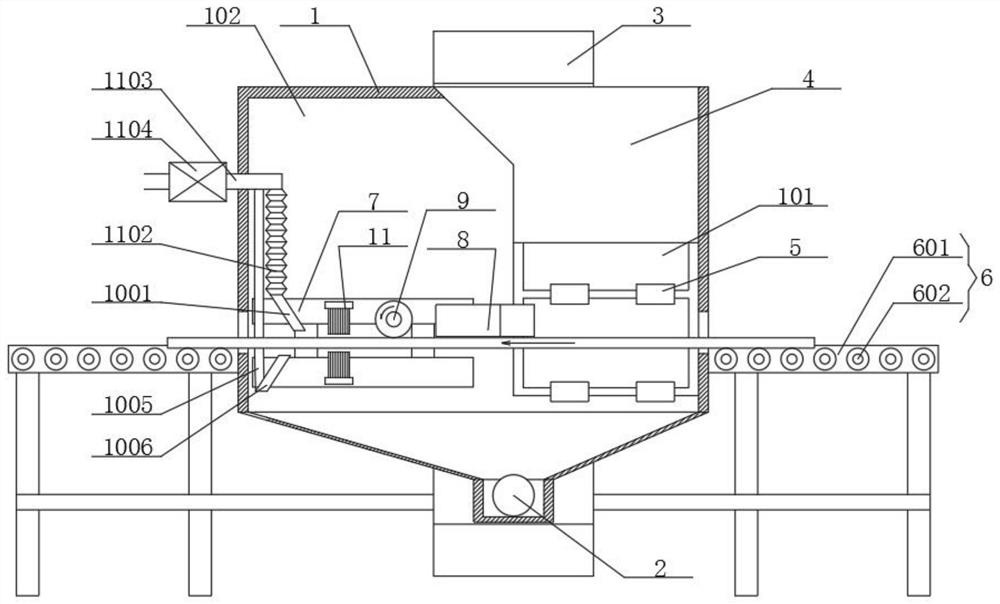

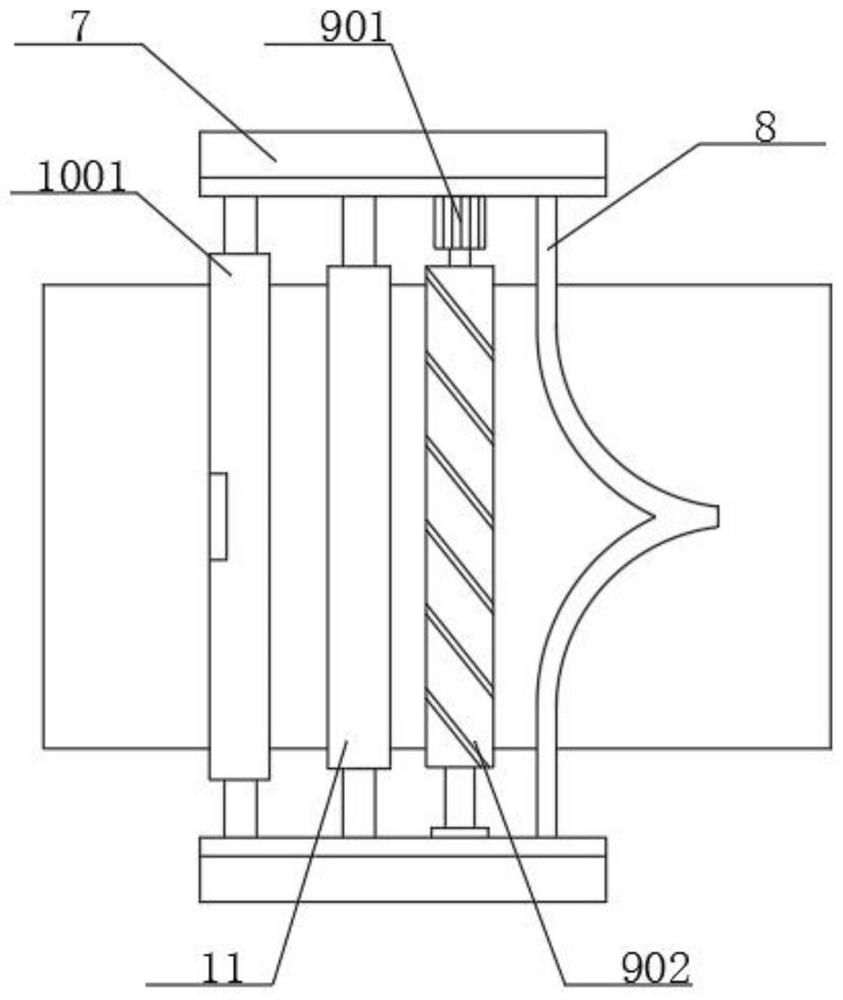

Shot blasting machine for rust removal of steel member

InactiveCN113183041ASolve the problem of a large amount of steel shot remainingReduce labor intensityImpeller wheelsRotor bladesMetallurgyStructural engineering

The invention relates to the technical field of shot blasting machines, in particular to a shot blasting machine for rust removal of a steel member. A supporting mechanism for supporting a steel plate is arranged on the outer portion of a machine shell, the lower end of the machine shell is connected with a lower spiral conveyor in a penetrating manner, a shot blasting chamber and a cleaning chamber are arranged in the machine shell, a shot-ash separator is arranged in the shot blasting chamber, a shot blasting device is arranged below the shot-ash separator, and the shot-ash separator is connected with the shot blasting device through a steel shot conveying mechanism. A scraping plate scrapes off most of steel shots on the surface of the steel member, a rolling brush cleaning mechanism cleans away the steel shots remaining on the surface of the steel member, a secondary cleaning mechanism cleans away dust on the surface of the steel member, and a high-pressure dust blowing mechanism blows off the dust on the surface of the steel member. By means of the shot blasting machine for rust removal of the steel member, the problem that after shot blasting, a large number of steel shots remain on the steel member is solved, shots and dust remaining on the surface of the steel member are thoroughly removed, and labor intensity and operation safety risks are reduced.

Owner:TONGLING FERROUS CONSTR & INSTALLATION STEEL STRUCTURE

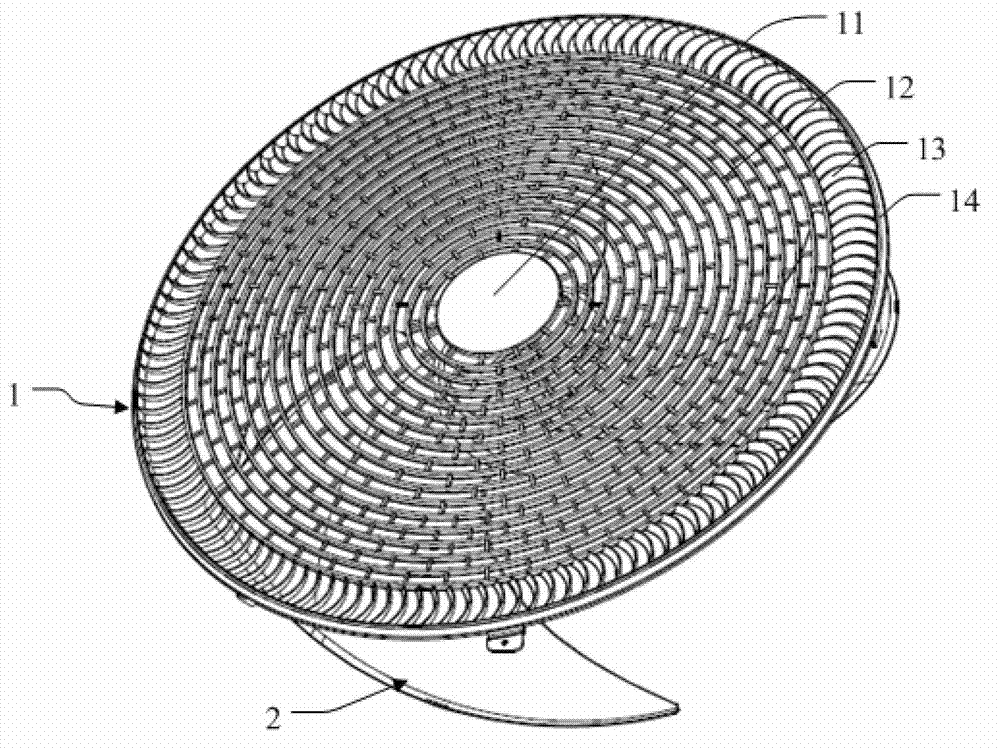

Device capable of automatically adjusting position of transmitting coil

InactiveCN109177762AImprove energy transfer efficiencyImprove transmission efficiencyBatteries circuit arrangementsCharging stationsElectric vehicleEngineering

The invention discloses a device capable of automatically adjusting the position of a transmitting coil, being applied to adjustment of the position of the transmitting coil in the wireless charging process of an electric vehicle. The device comprises a circumferential adjusting device, a distance adjusting device, a radial adjusting device and a horizontal adjusting device, wherein the circumferential adjusting device is used for adjusting the circumferential position; the distance adjusting device is used for adjusting the vertical distance between the transmitting coil and the charging coil; the radial adjusting device is used for adjusting the position in the radial direction; and the horizontal adjusting device is used for maintaining the horizontal position of the transmitting coil.The device capable of automatically adjusting the position of a transmitting coil can automatically adjust the position of the transmitting coil so as to increase the energy transfer efficiency between the transmitting coil and the receiving coil.

Owner:卢昆丽

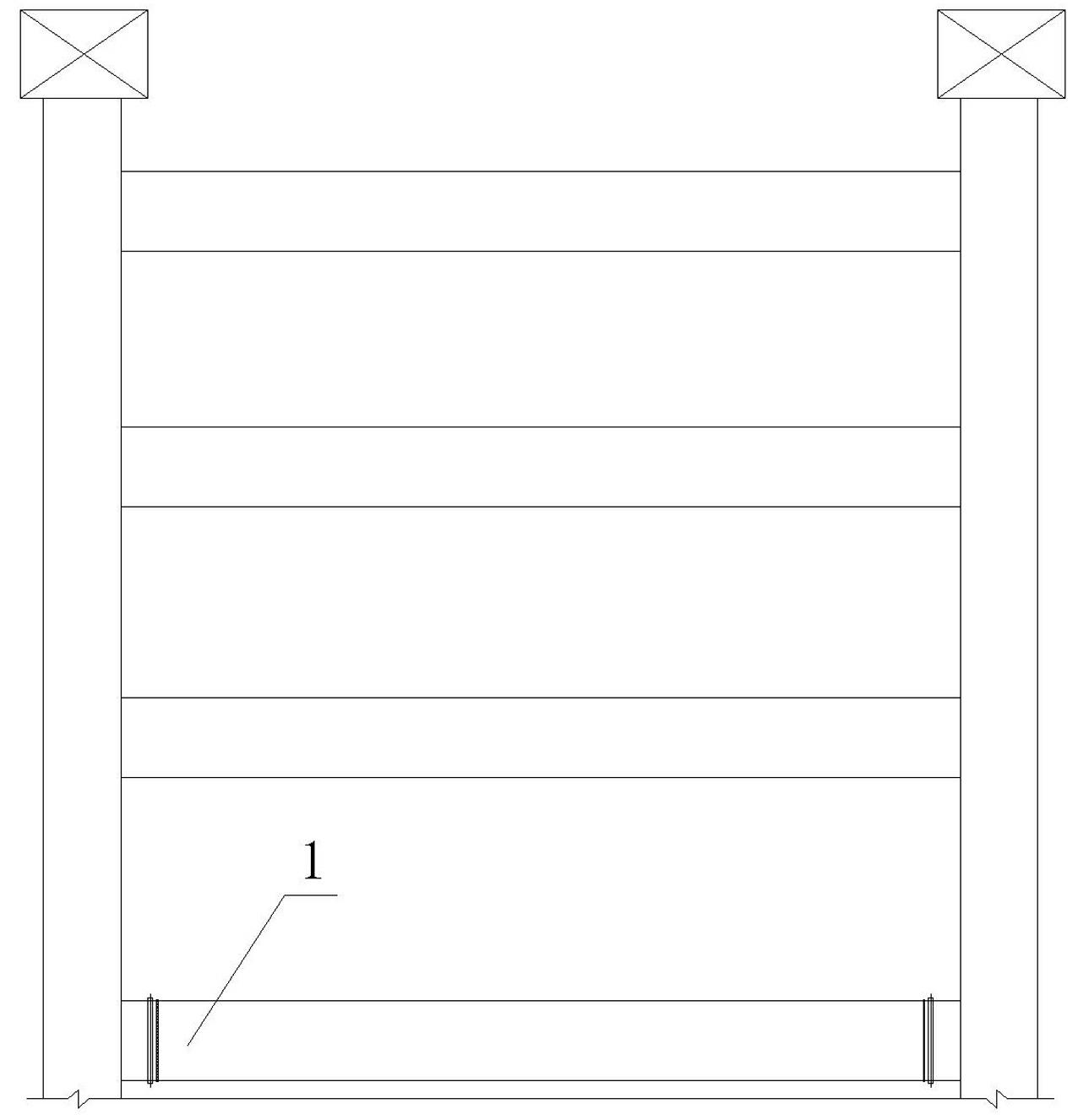

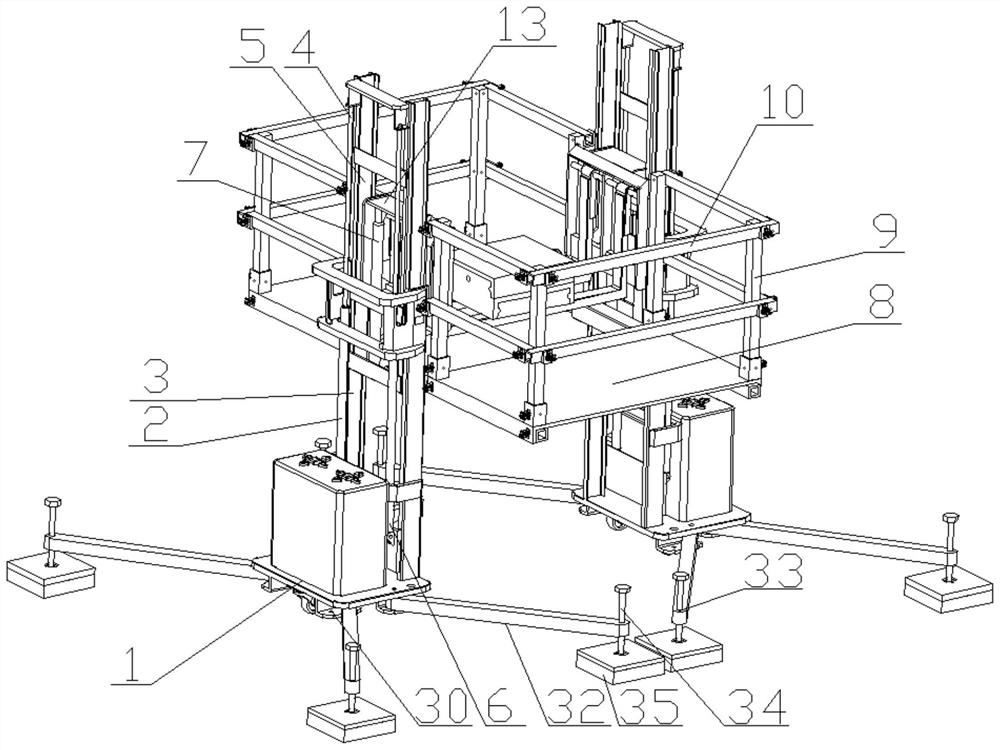

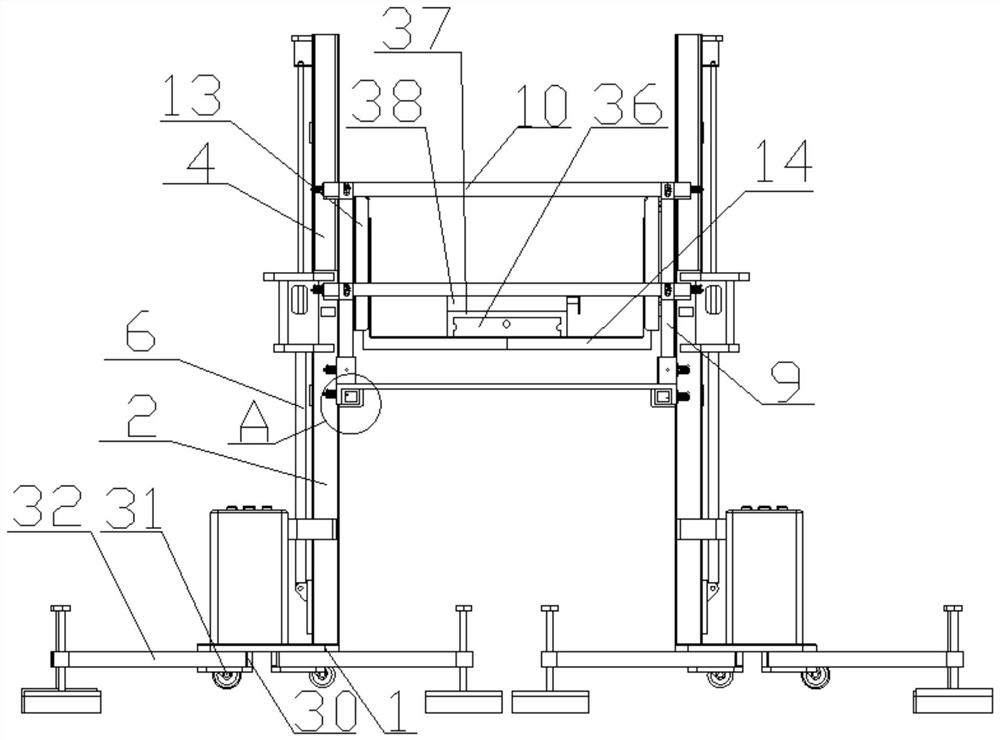

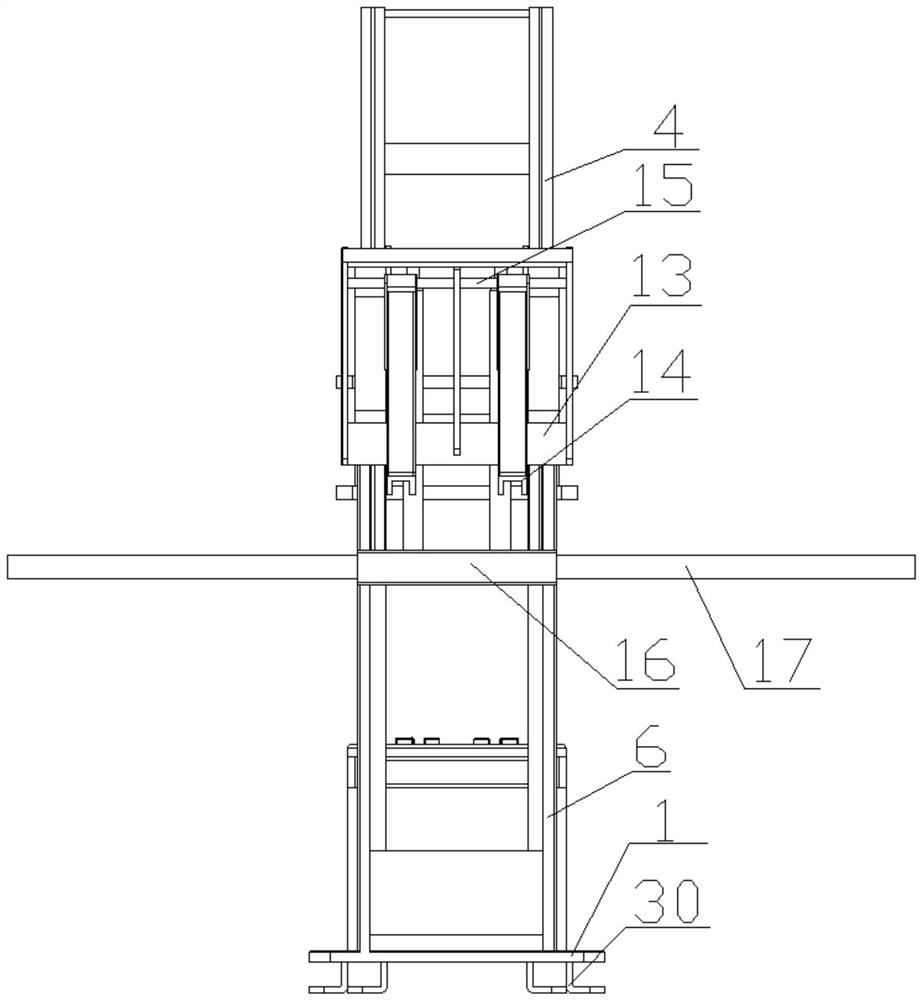

Platform system for transformer installation

The invention discloses a platform system for transformer installation. The platform system is characterized in that a first lifting device and a second lifting device are symmetrically arranged, eachof the first lifting device and the second lifting device comprises a base and two supporting columns arranged on the base, the opposite side walls of the two supporting columns are concave inwards to form first sliding grooves, rectangular frames are arranged in the first sliding grooves, the faces opposite to two edges, parallel to the supporting columns, of the rectangular frames are concave inwards to form second sliding grooves, transformer lifting parts are arranged in the second sliding grooves, first hydraulic telescopic cylinders are arranged between the supporting columns and the rectangular frames, and second hydraulic telescopic cylinders are arranged between the rectangular frames and the transformer lifting parts; and insertion holes are formed in a bottom plate, stand columns are detachably inserted into the insertion holes, installation bases are arranged on the stand columns, surrounding rods are installed on the installation bases, one end of the bottom plate is detachably connected with the first lifting device, and the other end of the bottom plate is detachably connected with the second lifting device. The device is convenient to build, and a construction platform is arranged, so that the work is safe.

Owner:四川精点企业管理有限公司

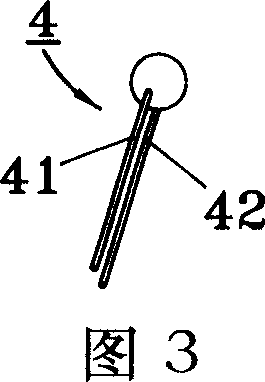

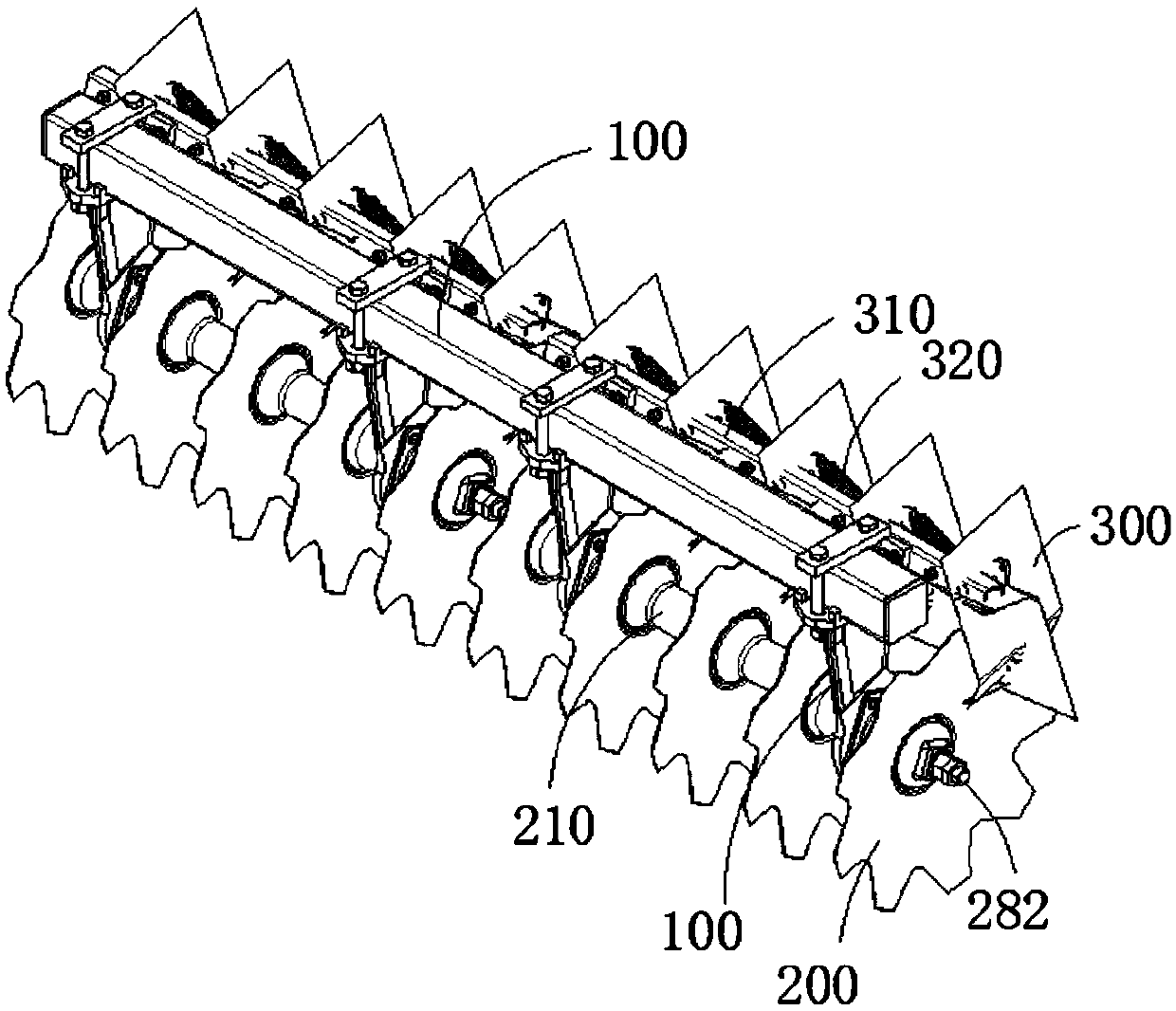

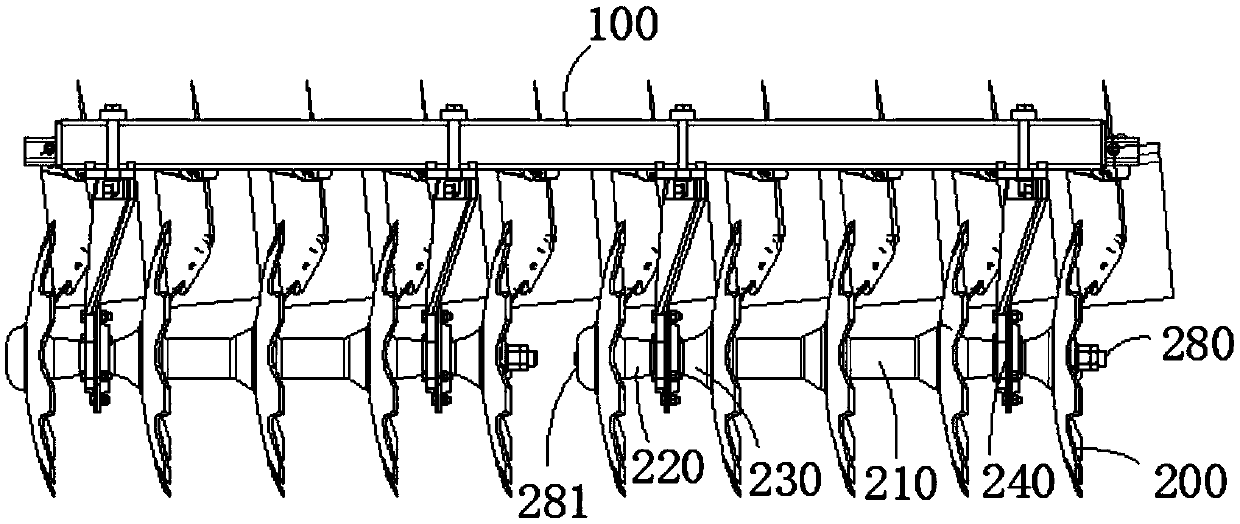

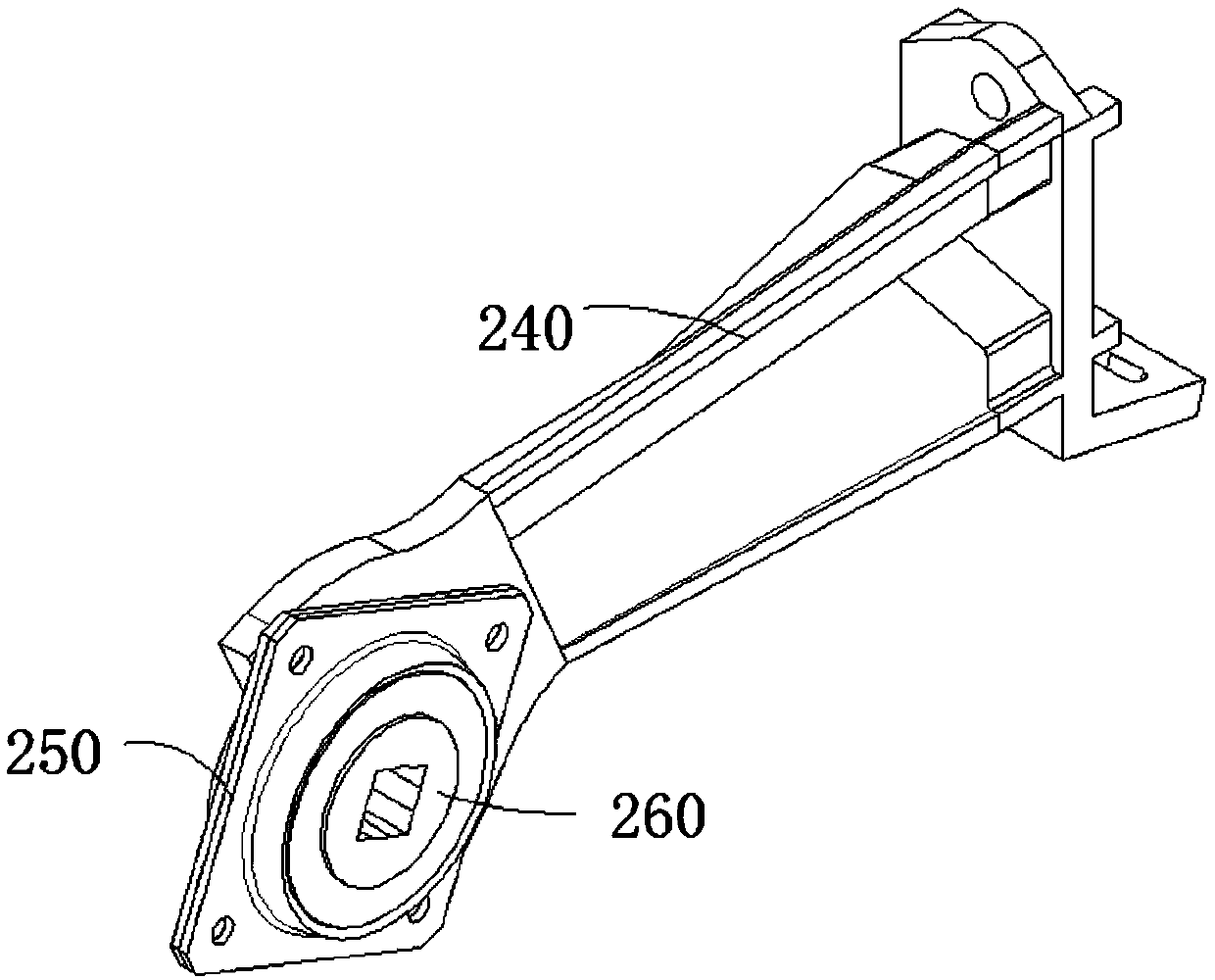

Front harrow set for disc harrow and using method of front harrow set

The invention relates to a front harrow set for a disc harrow and a using method of the front harrow set and belongs to the technical field of disc harrows. The front harrow set comprises a cross beamand a plurality of harrow sheets connected with the cross beam; the harrow sheets are divided into a left group and a right group which are identical in number and are arrayed below the cross beam; the harrow sheets in the middle of each group are separated by partition pipes, the harrow sheets close to the two ends in the harrow set and the middle harrow sheets are separated by splicing long semi-partition pipes with short semi-partition pipes, and a bearing bracket is mounted between each long semi-partition pipe and the corresponding short semi-partition pipe and fixedly connected with thecross beam; the lower end of each bearing bracket is fixedly connected with a bearing base, a square hole bearing is mounted in each bearing base, and square holes with the same size are formed in the harrow sheets, the partition pipes, the long semi-partition pipes and the short semi-partition pipes and communicated with the square hole bearings; a square shaft is fixed in each square hole. Theharrow set has the advantages of stable integral structure, uniform harrow sheet spacing and good tillage effect.

Owner:北京德邦大为科技股份有限公司

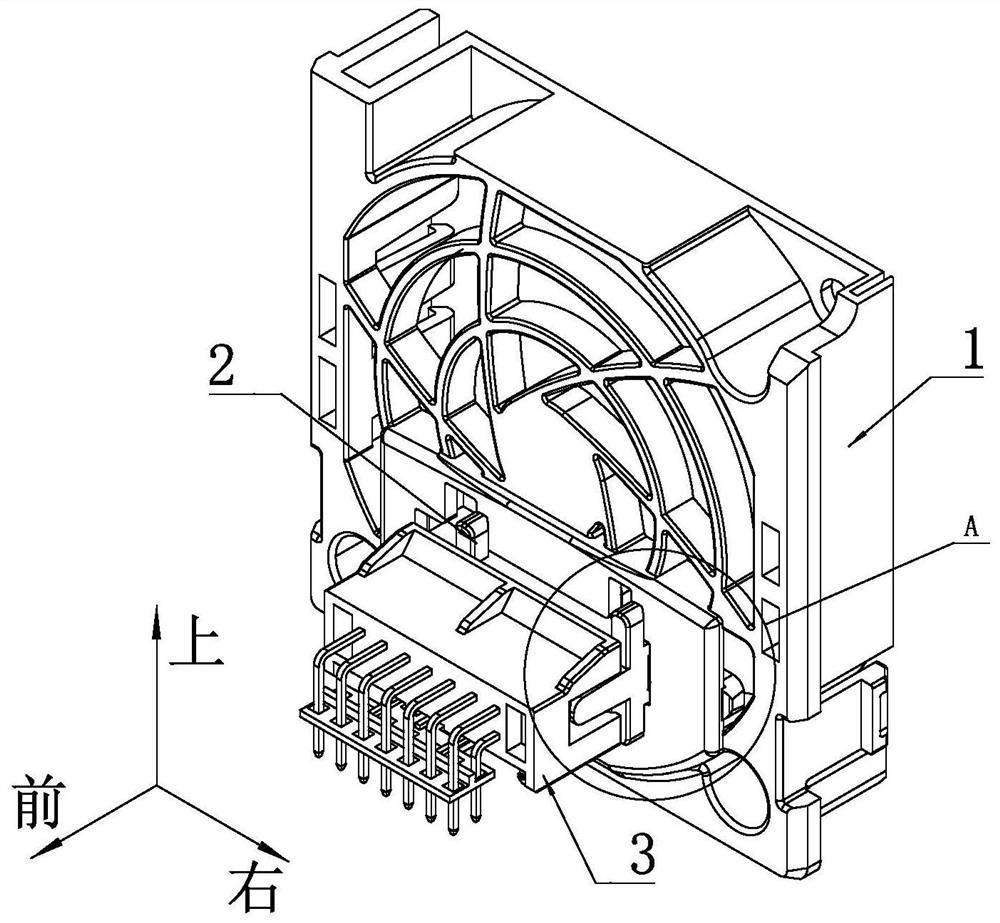

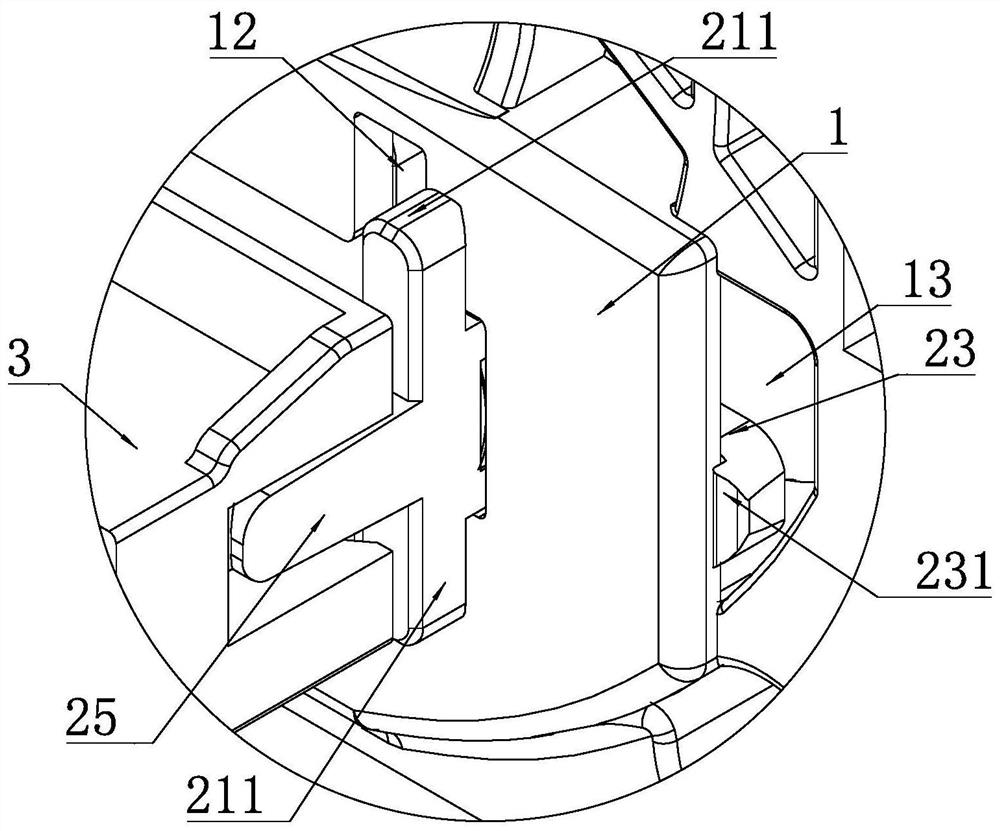

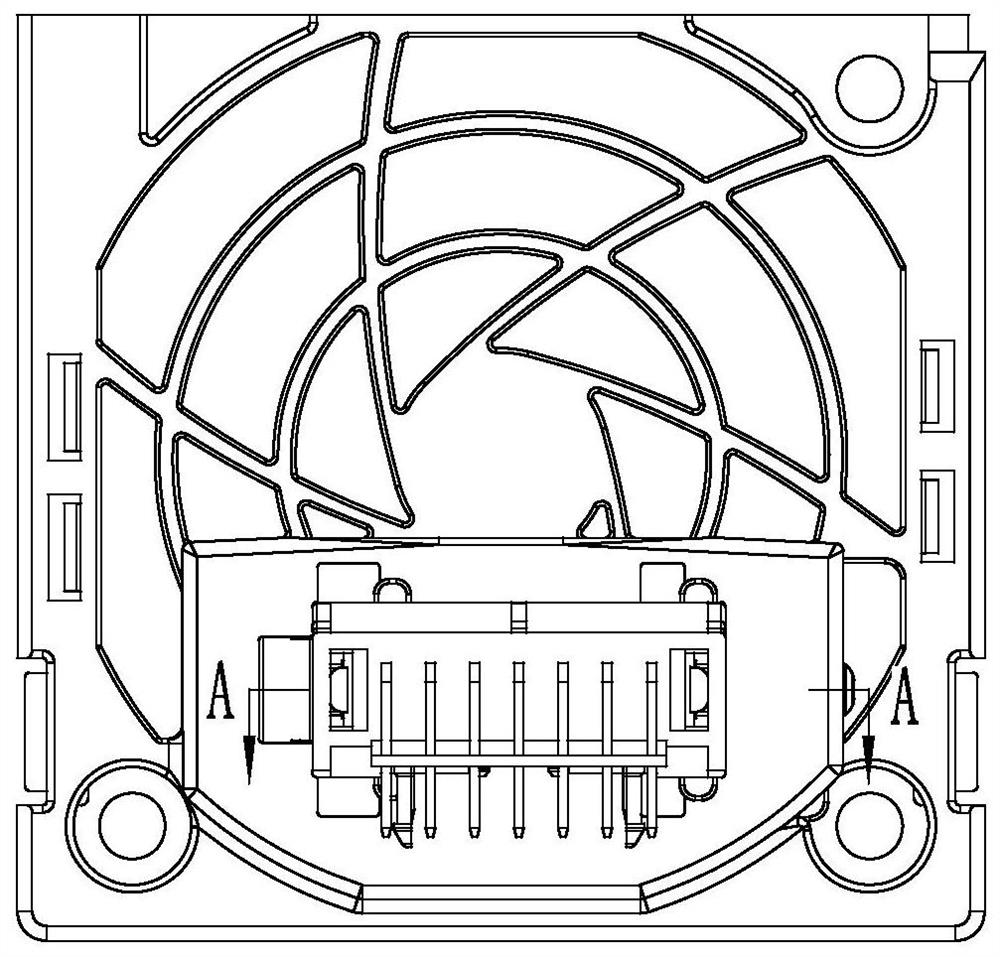

Tool-free mounting structure of fan connector

ActiveCN112838436AEasy maintenanceEasy to useCoupling device detailsDigital data processing detailsStructural engineeringMechanical engineering

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

A routing method based on distance weighting and its node routing function module

ActiveCN108769897BReasonable distanceForward messages accurately and correctlyLocation information based serviceData switching networksTransceiverRouting table

The invention discloses a routing method based on distance weighting and its node routing function module. The node routing function module includes: Radacat CPU, GPS / Beidou module, map module, weighted distance calculation module, routing table module and RF transceiver module , the GPS / Beidou module, the map module, the weighted distance calculation module, the routing table module and the RF transceiver module are connected to the Radacat CPU. The present invention calculates a reasonable wireless communication distance through weighted calculation, and can more accurately display the relative distance between two nodes. In the distance forwarding protocol based on GPS position assistance, using this technology is more reasonable and more accurate. It can make the Mesh network forward more accurate correct forwarding messages.

Owner:BEIJING RADACAT CO LTD

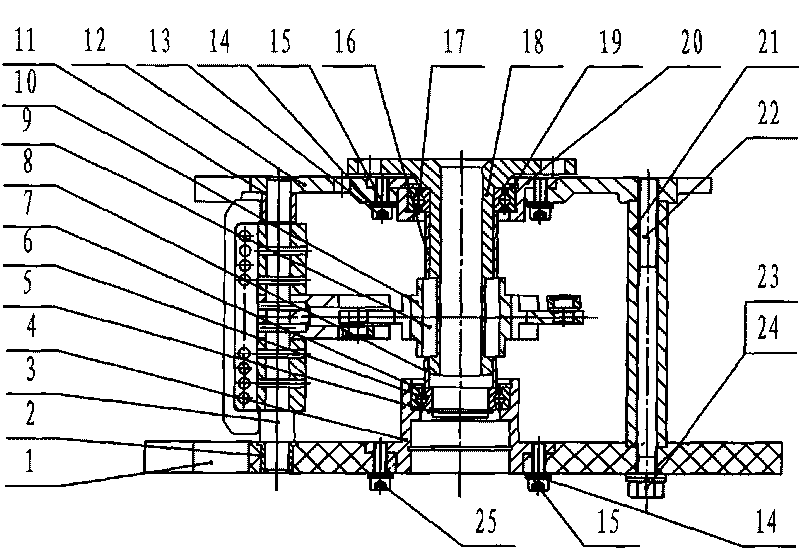

A main current-carrying contact system

ActiveCN101699592BSimple structureGuaranteed uptimeVariable inductancesVariable transformersEngineeringContact system

The invention discloses a main current-carrying contact system, comprising: an upper mounting plate; a lower mounting plate connected to the upper mounting plate through a first liner; a first bearing bracket fixed on the lower mounting plate , the first bearing bracket has a first bearing; the second bearing bracket is fixed on the upper mounting plate, and the second bearing bracket has a second bearing; the rotating shaft is connected with the first bearing and the second The bearing is connected; the driving disc is connected with the rotating shaft through a key; the main contact is connected with the driving disc. The structure of the main current-carrying contact system of the present invention is simple, and it can cooperate with the program requirements of the on-load tap changer to operate in a relatively large range. The rotation angle is small, and the opening distance in the middle process of disengaging and closing is reasonable. At the same time, the locking circle structure effectively guarantees the reliable operation of the mechanism.

Owner:贵州长征电气有限公司

Novel portable adjustable temperature control smoke moxibustion device

InactiveCN109419619AControl burning rateReach temperature controlDevices for heating/cooling reflex pointsTemperature controlEngineering

The invention provides a novel portable adjustable temperature control smoke moxibustion device which adopts double-air-hole upper and lower overlying arrangement. By rotating a first cover to changeexternal air flow and air flow in a box cavity, the burning speed of a moxa cone in a wall is controlled, and the purpose of controlling temperature and smoke is achieved; as a clamping groove and a hook of a sliding block form a rotary limiting relationship, the danger of cover fall caused by tilt or inversion of the device is prevented, and meanwhile support is provided for airflow control of air holes; as an insertion hole for inserting the moxa cone is formed in the side face of a box, the distance between the burning end of the moxa cone and the human skin can be effectively controlled; the moxa cone is fixed through a rotary handle, a clamping part is eccentrically arranged on the rotary handle, and by rotating the rotary handle, the distance between the end of the moxa cone and thehuman skin can be further reasonably selected within a certain range; an annular base is arranged at the edge of the bottom opening of the box, an appropriate distance is reserved between the box andthe human skin, and the probability of accidental burns is reduced.

Owner:陈讲华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com