Casting equipment with good cooling effect

A technology of casting equipment and cooling effect, which is used in casting molding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient casting seat processing, reduced casting production speed, and reduced casting speed, etc., to achieve reasonable structure and casting quality. Good, the effect of speeding up the casting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

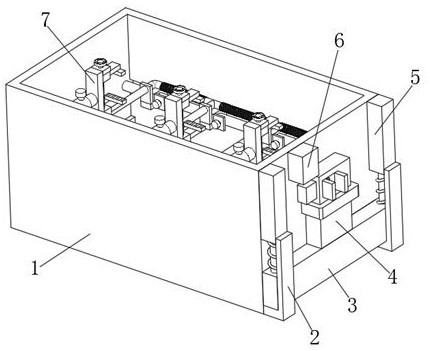

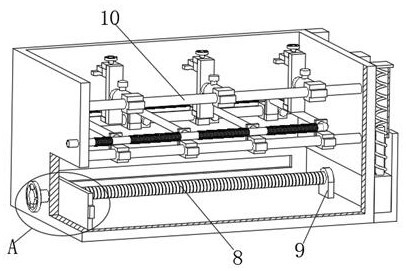

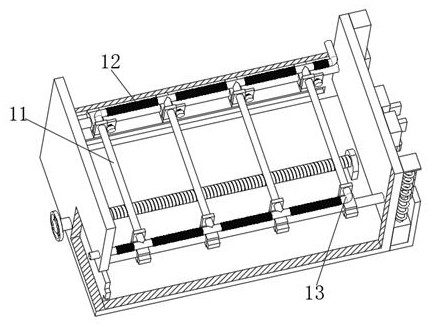

[0041] Example: Reference Figure 1-9 The casting equipment shown has a good cooling effect, including a molding box 1, a sand leakage hole is opened on the side wall of the molding box 1, and a fixing block 6 and two L-shaped fixing rods are fixedly connected to the side wall of the molding box 1 2. The two extrusion cylinders 5 and the fixing block 6 can be any metal block in the prior art, which are welded to the side wall of the forming box 1 for fixing.

[0042] The L-shaped fixing rod 2 can be any metal rod in the prior art, which is welded with the side wall of the forming box 1 for fixing.

[0043] The extrusion cylinder 5 can be any cylinder in the prior art, such as a metal cylinder, which is welded to the side wall of the forming box 1 for fixing.

[0044] The side walls of the two L-shaped fixing rods 2 are fixedly connected with the side walls of the two extruding cylinders 5 respectively, and the extruding cylinder 5 and the side walls of the L-shaped fixing rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com