Front harrow set for disc harrow and using method of front harrow set

A disc harrow and harrow blade technology, applied in the direction of harrow, application, agriculture, etc., can solve the problems of poor cultivated land effect, uneven spacing of harrow blades, unstable connection of harrow group, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

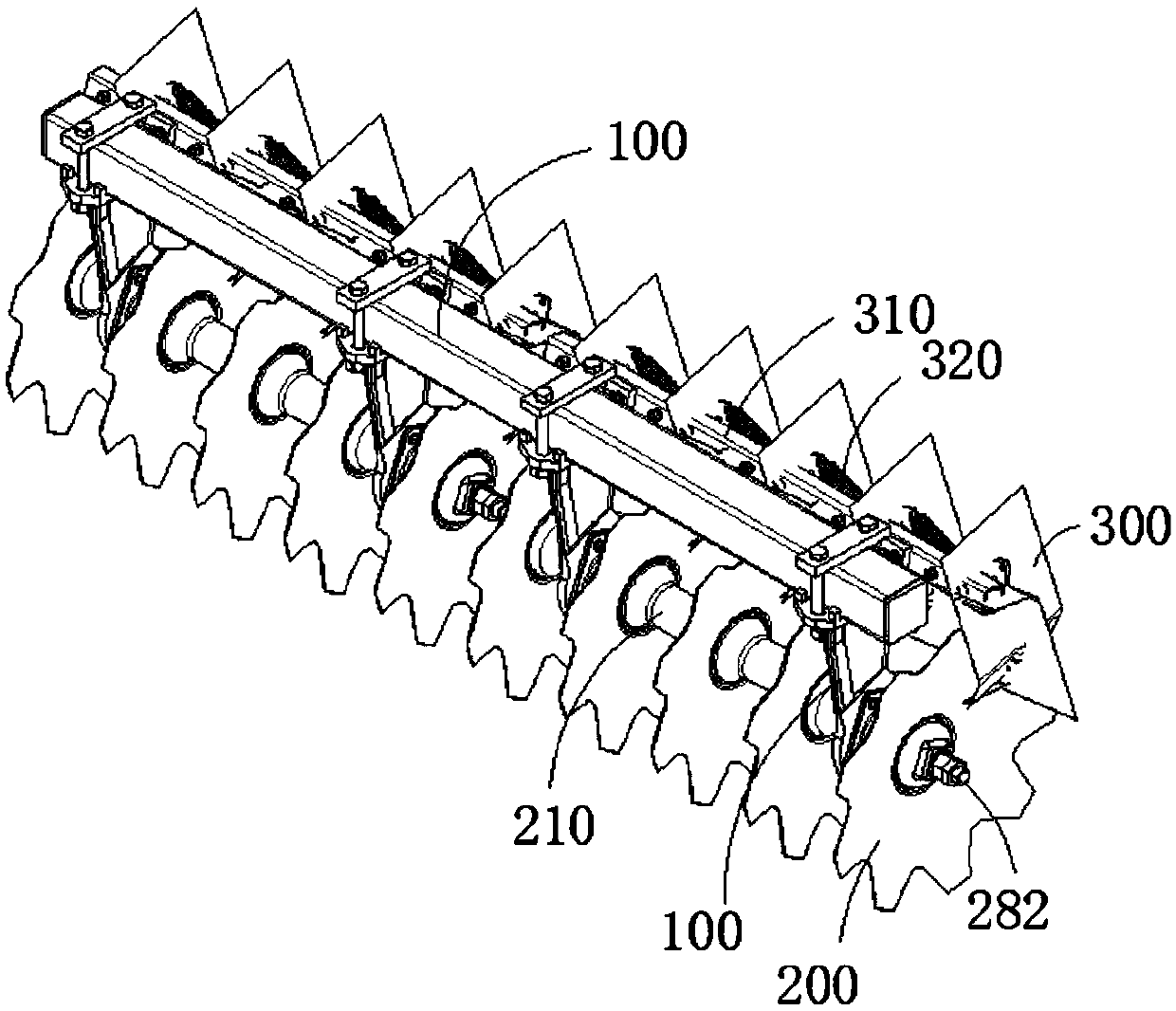

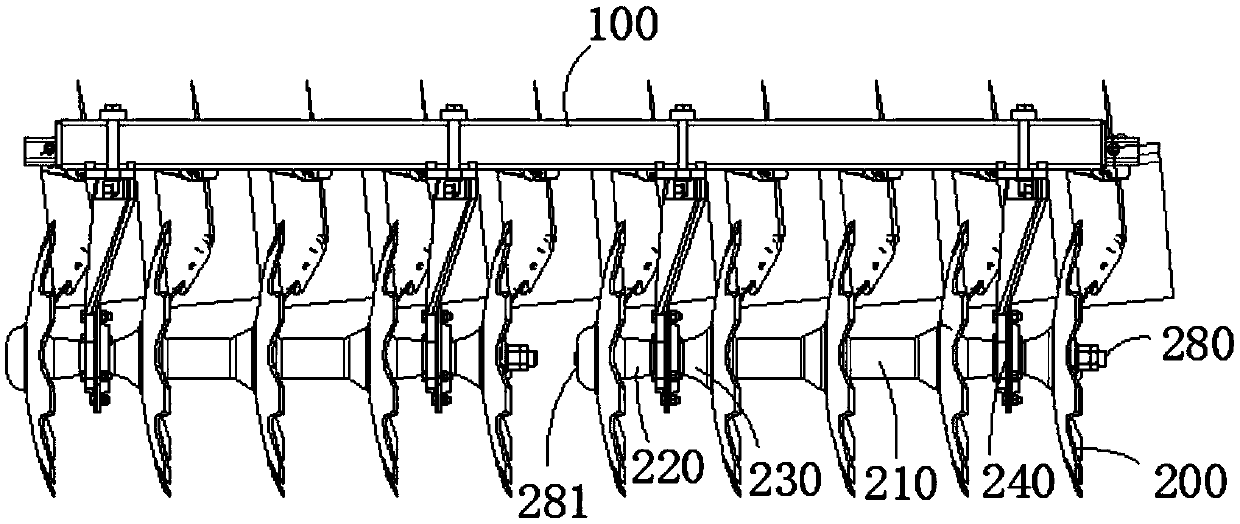

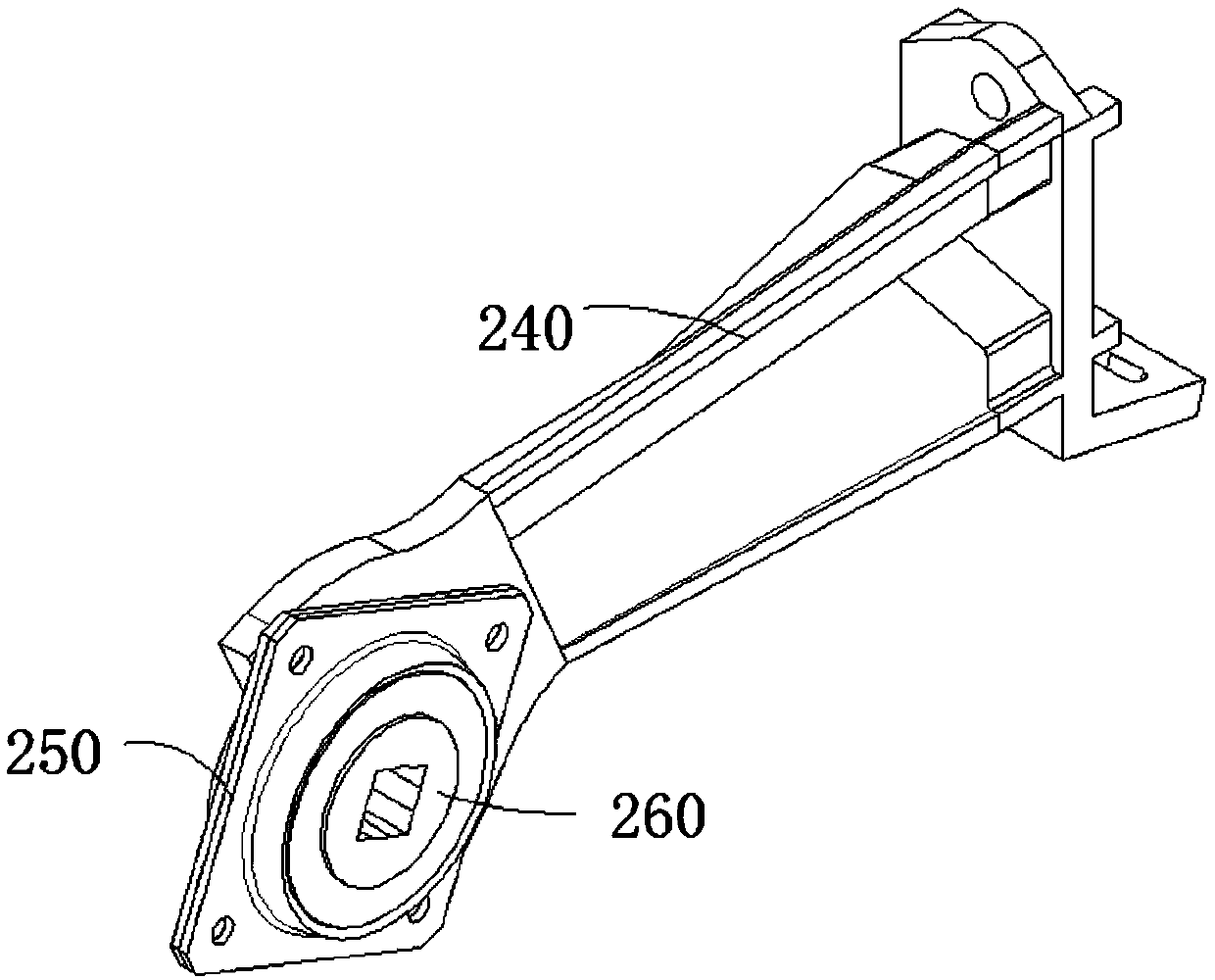

[0040] Refer to attached figure 1 , figure 2 , image 3 and Figure 4 As shown, a front rake group for a disc harrow in this embodiment includes a beam 100 and a plurality of rake blades 200 connected to the beam 100, and the blades 200 are divided into two groups with the same left and right sides and are arranged in a line below the beam 100. The rakes 200 in the middle of each group are separated by an inter-pipe 210, and the rakes 200 near both ends of the rake group are separated from the middle rakes 200 by splicing the long half-pipe 220 and the short half-pipe 230. A bearing bracket 240 is installed between the half tube 220 and the short half tube 230, the bearing bracket 240 is fixedly connected to the beam 100, the lower end of the bearing bracket 240 is fixedly connected to the bearing seat 250, and the bearing seat 250 is equipped with a square hole bearing 260 and a rake piece 200 , the middle pipe 210, the long half pipe 220 and the short half pipe 230 are a...

Embodiment 2

[0047] Refer to attached figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the method of using the front harrow group for a disc harrow in this embodiment is that the harrow group is fixed on the frame, and the tractor drives the harrow group on the frame to plow the land.

[0048] The usage method of this embodiment comprises the following steps:

[0049] S100, installing, fixing multiple harrow groups on the disc harrow frame;

[0050] S200, traction, the tractor pulls the disc harrow forward to drive the harrow group forward;

[0051] S300, arable land, the harrow blade 200 is embedded in the land, and the land is broken and cultivated as the tractor advances;

[0052] S400. Cleaning. After finishing the plowing, the harrow group is disassembled for cleaning and maintenance.

[0053] The specific method of step S300 in this embodiment is to embed the rake blade 200 into the land, and as the disc harrow advances, the square hole bearing 260 rotates t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com