Patents

Literature

82 results about "Disc harrow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A disc harrow is a harrow whose cutting edges are a row of concave metal discs, which may be scalloped, set at an oblique angle. It is an agricultural implement that is used to till the soil where crops are to be planted. It is also used to chop up unwanted weeds or crop remainders.

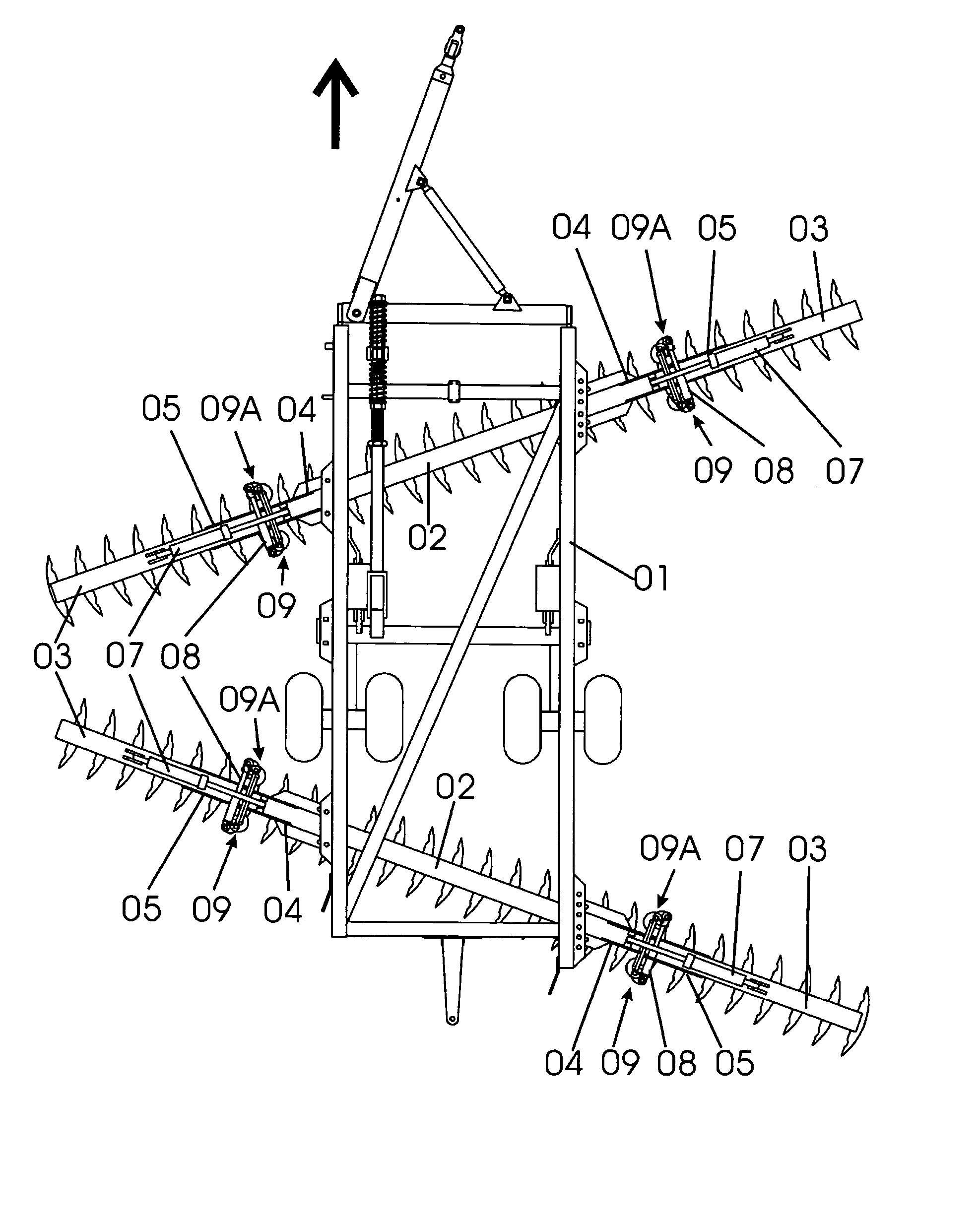

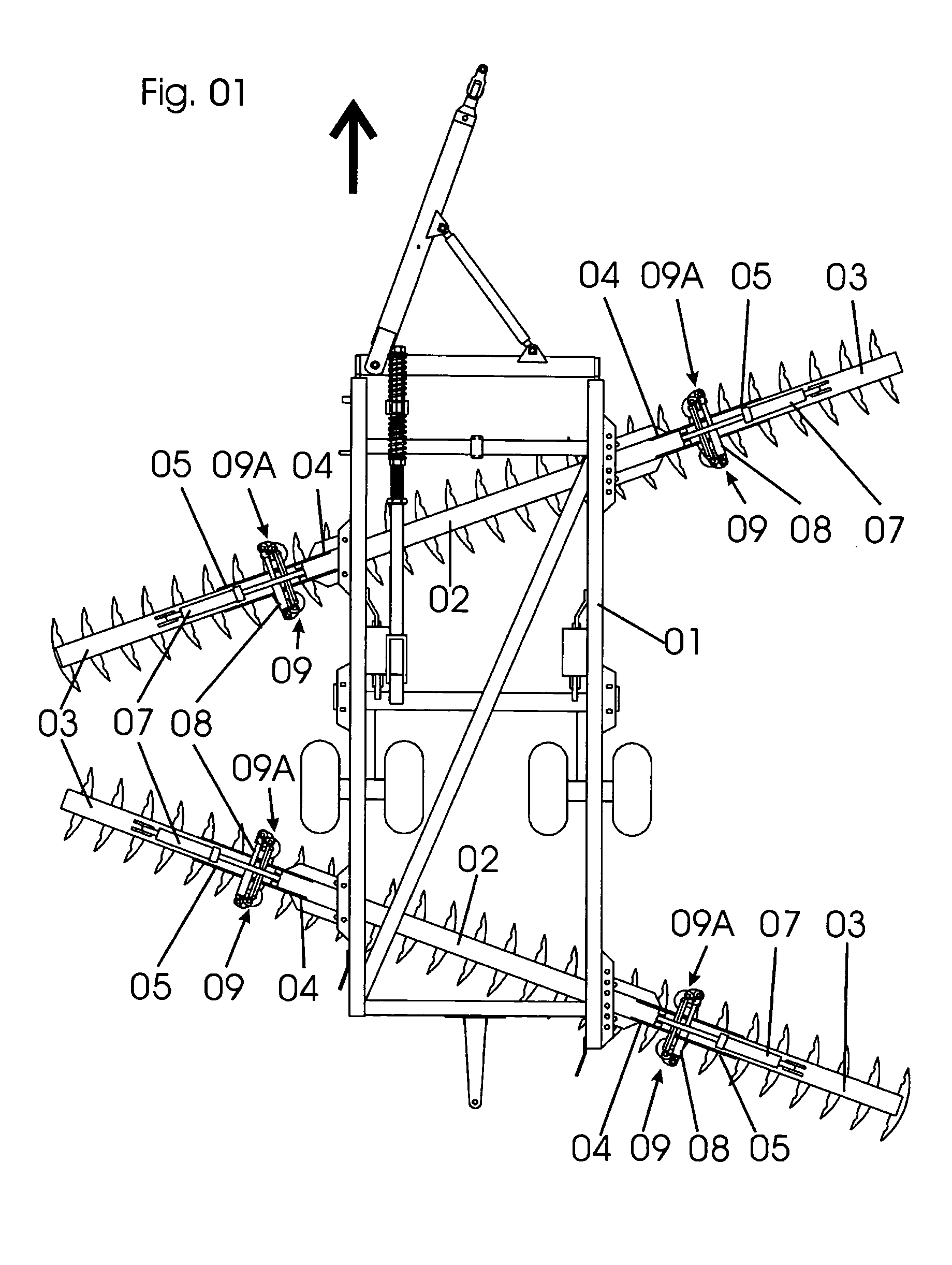

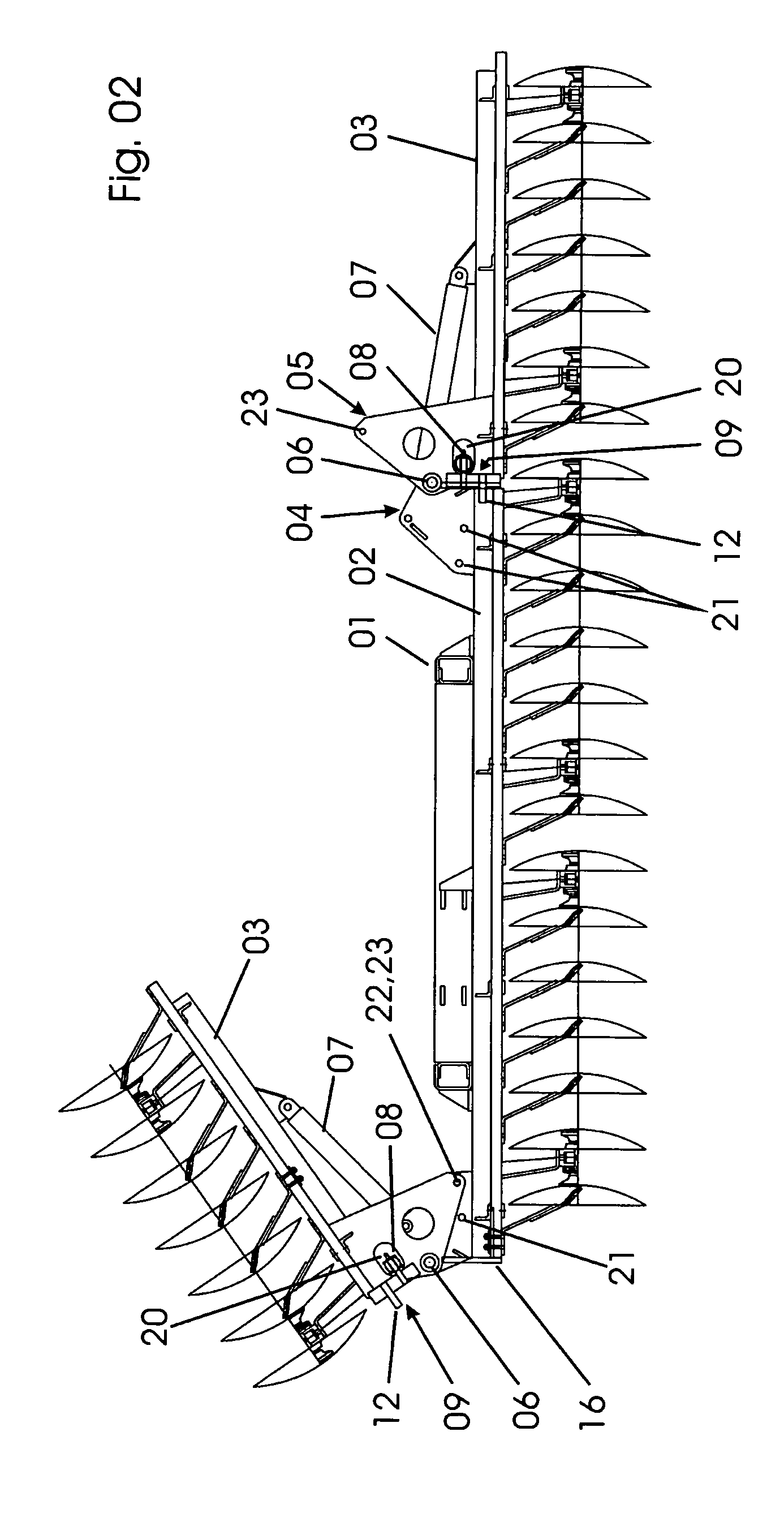

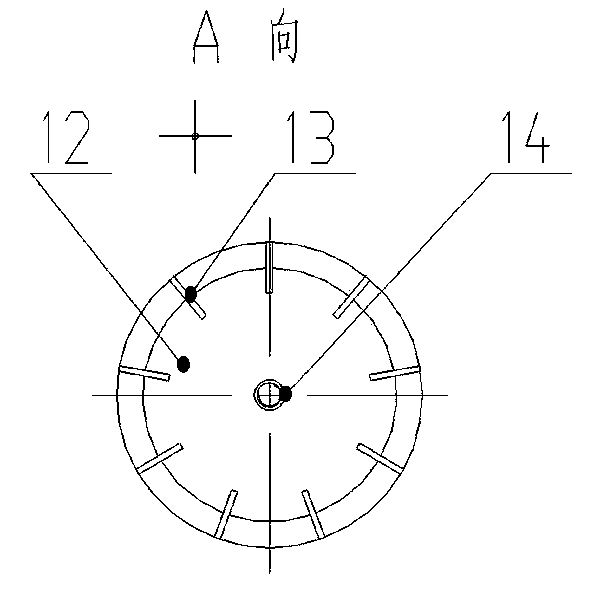

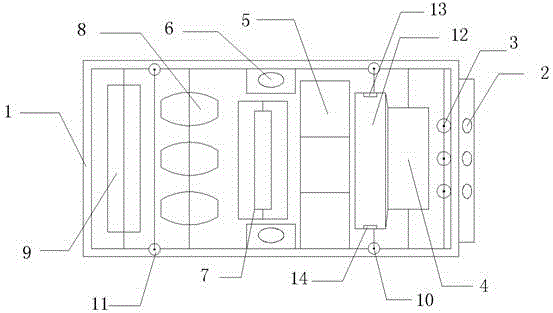

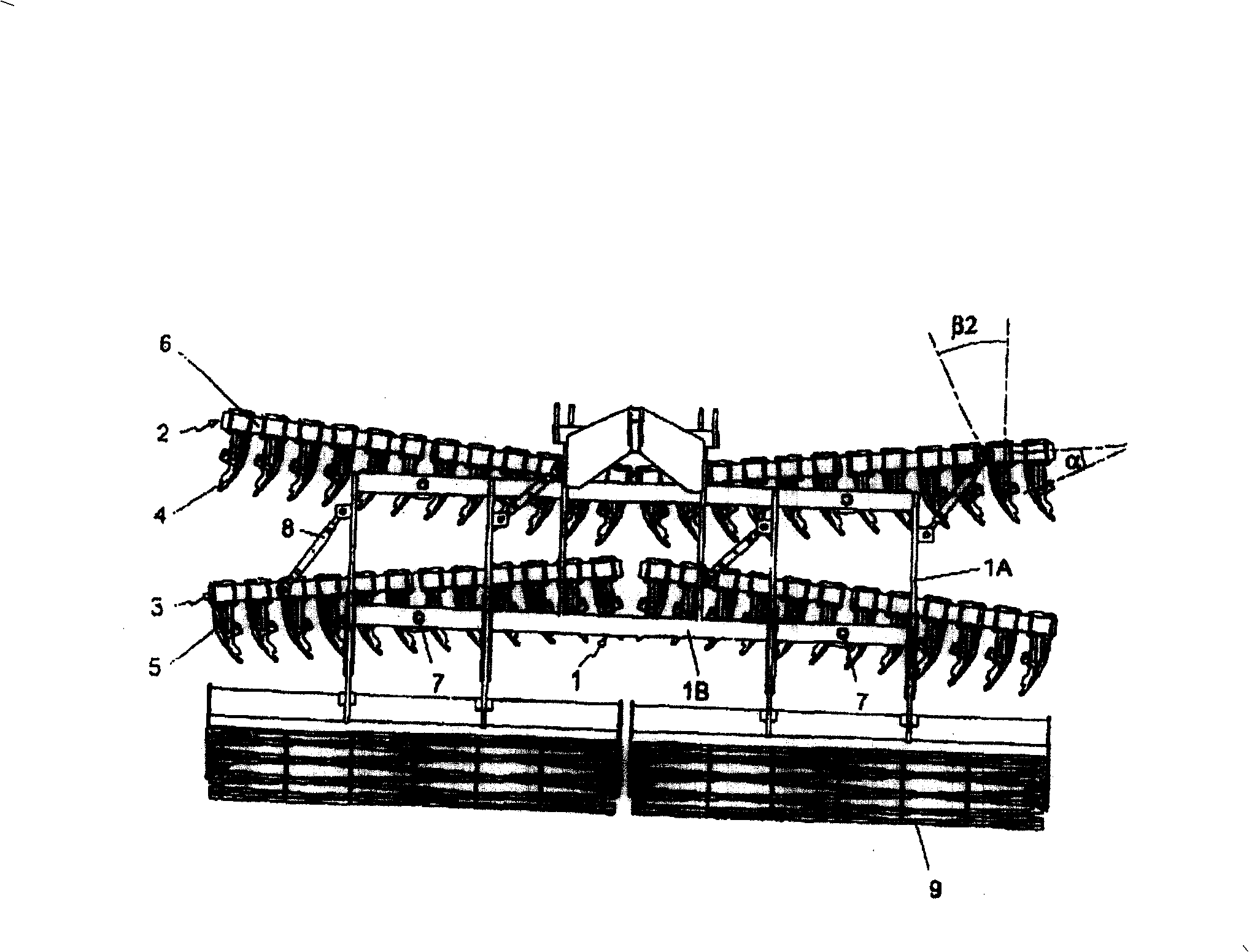

Articulating and locking mechanism for farm implement chassis

ActiveUS20050039932A1Fast and simple and safe mannerOvercome limitationsSpadesAgricultural machinesHydraulic cylinderLocking mechanism

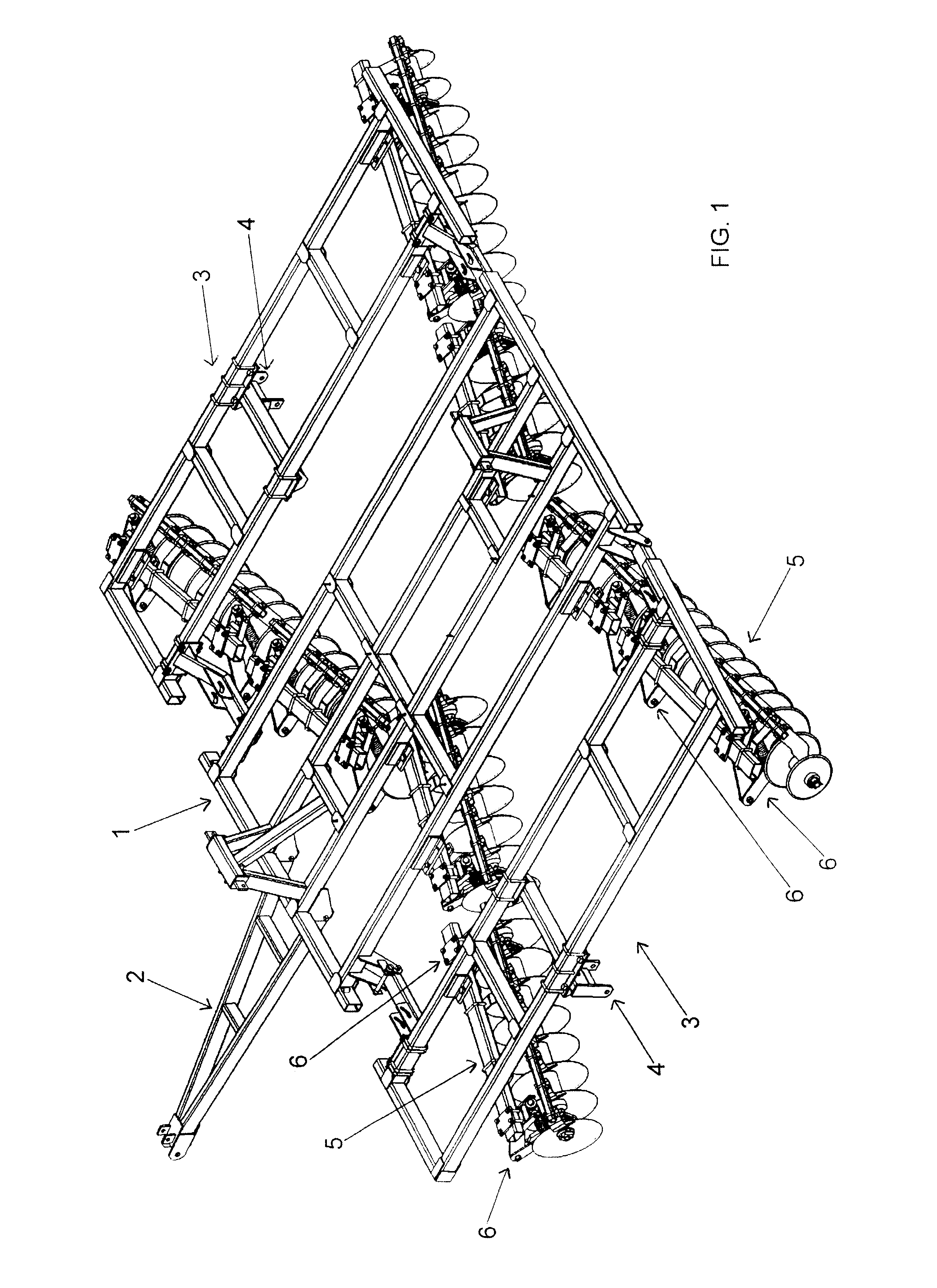

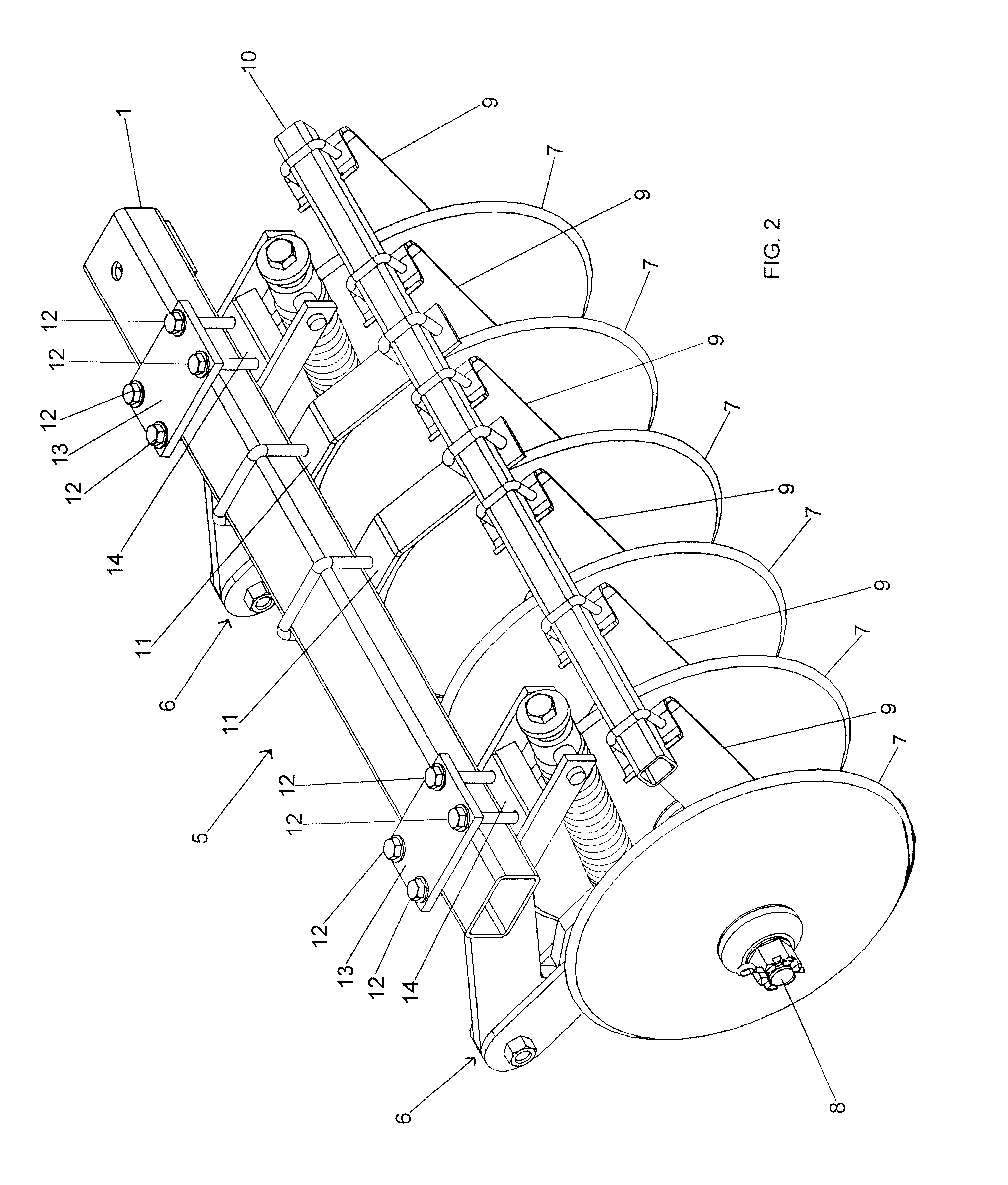

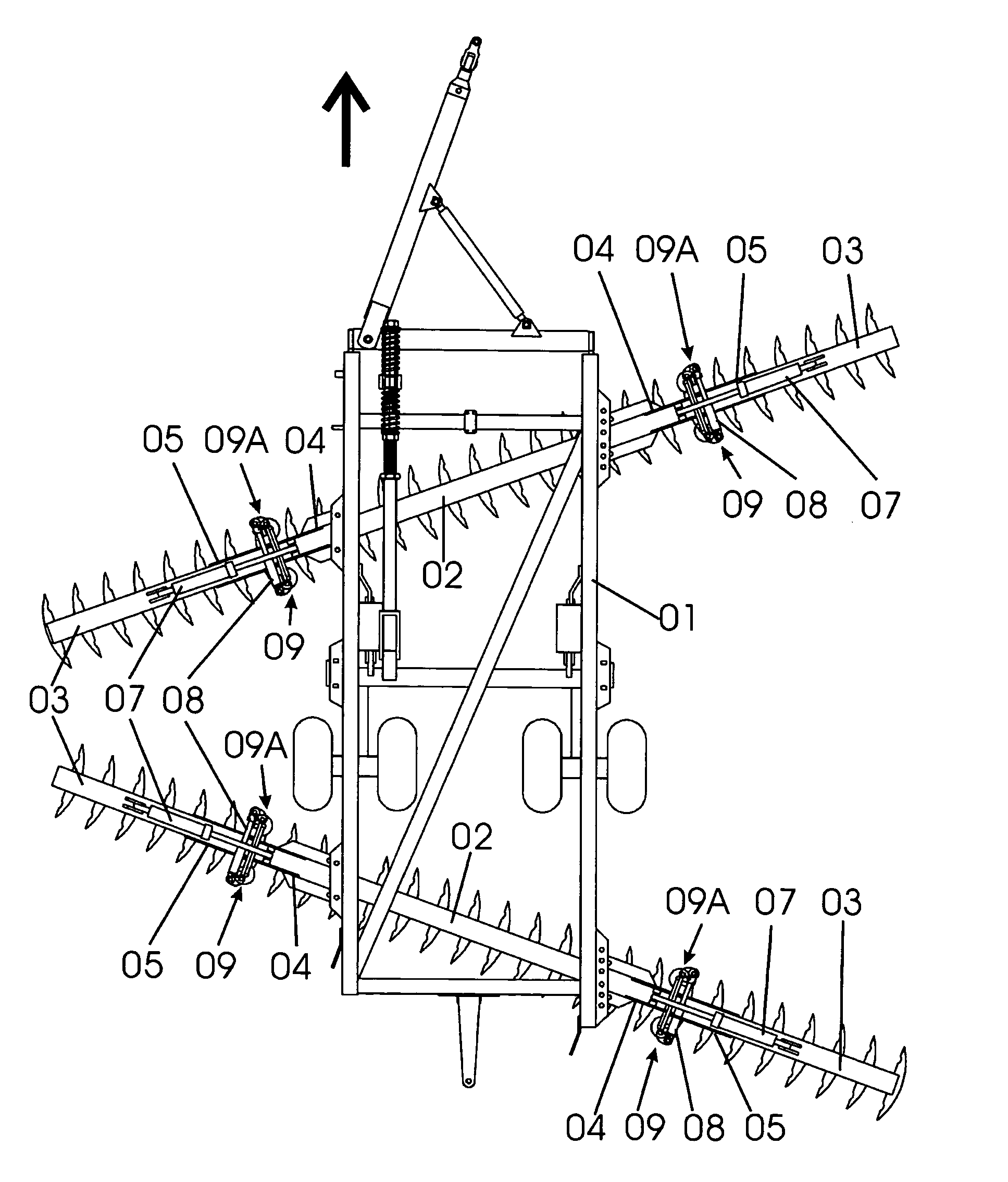

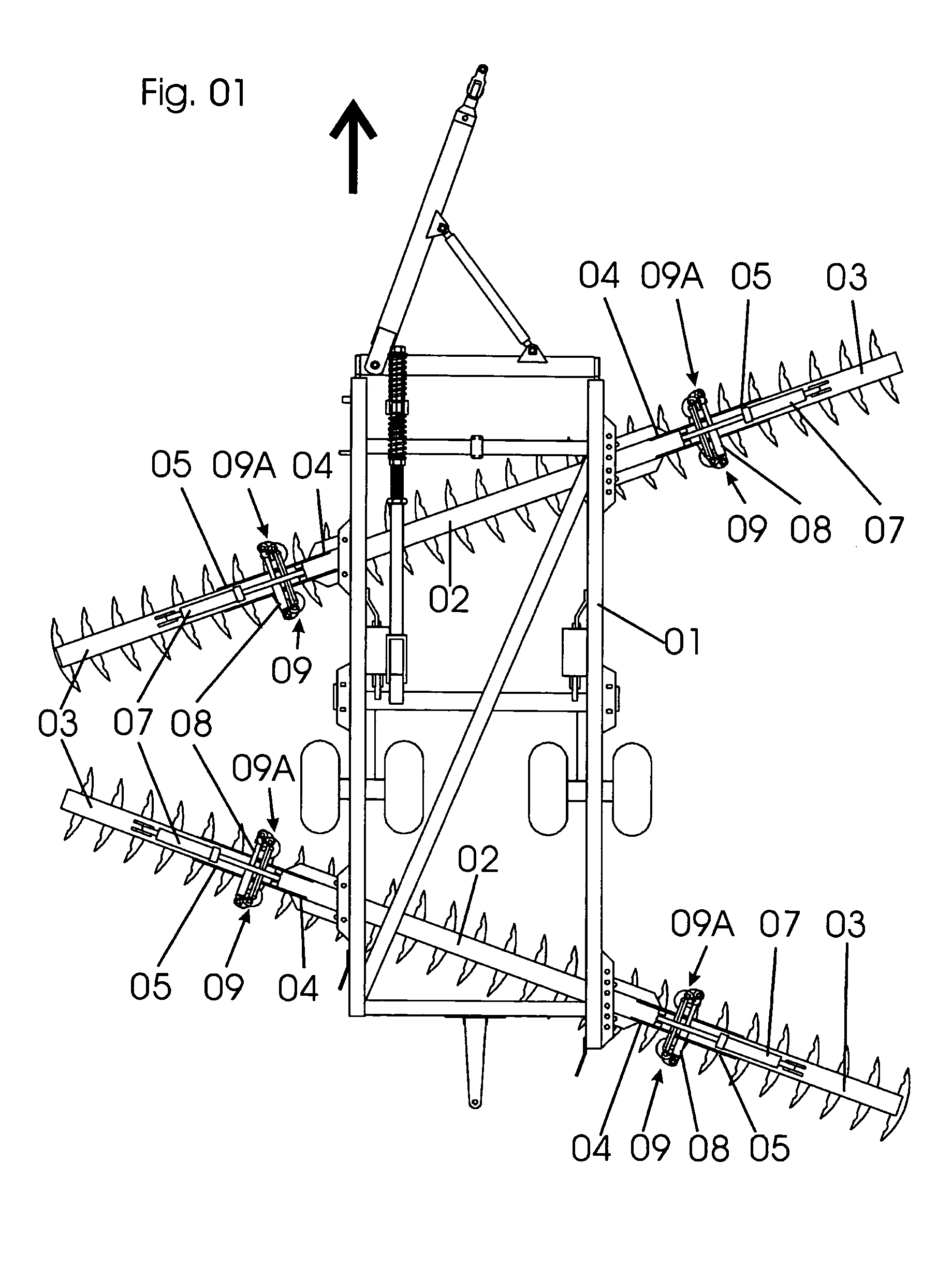

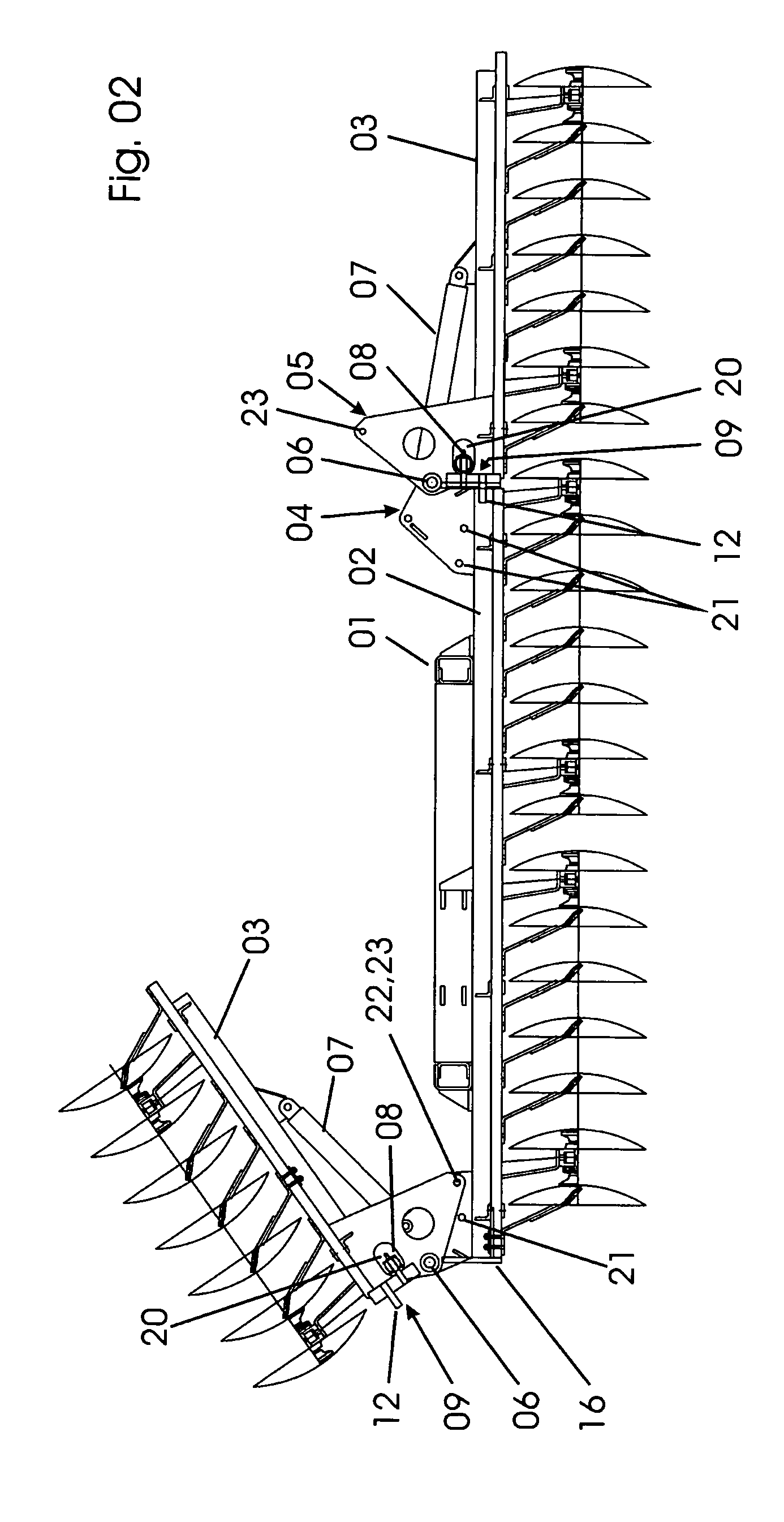

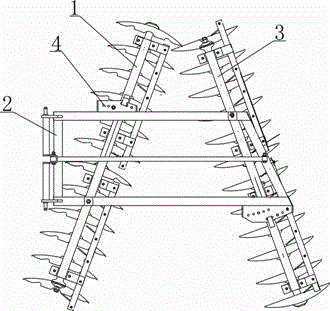

An articulating and locking mechanism of agricultural implement chassis is disclosed, intended for disc harrows and other implements with great working width, which are characterized by articulation to reduce the total width so as to facilitate transportation and storage, constituted of a main structure or chassis (1), central disc gang chassis (2), lateral and articulating disc gang chassis (3), with arrangements of vertical plates or extensions (4 and 5) welded and joined by shafts (6) for articulation by means of hydraulic cylinders (7), equipped with locking mechanism made up of hydraulic cylinders (8), locking and unlocking actuators (9, 9A), locks (12, 12A), coupling shafts (13, 13A) inserted in sleeves (14, 14A) and joined to the vertical closure plates (15) of the inner ends of the articulating chassis (3). Locking flanges (17) welded to the central chassis (2) form a quick closing action with the locks (12, 12A) providing rigidity in the locking between said rigid and articulating chassis during the implement's field operation.

Owner:MARCHESAN IMPLEMENTOS E MAQUINAS AGRI TATU

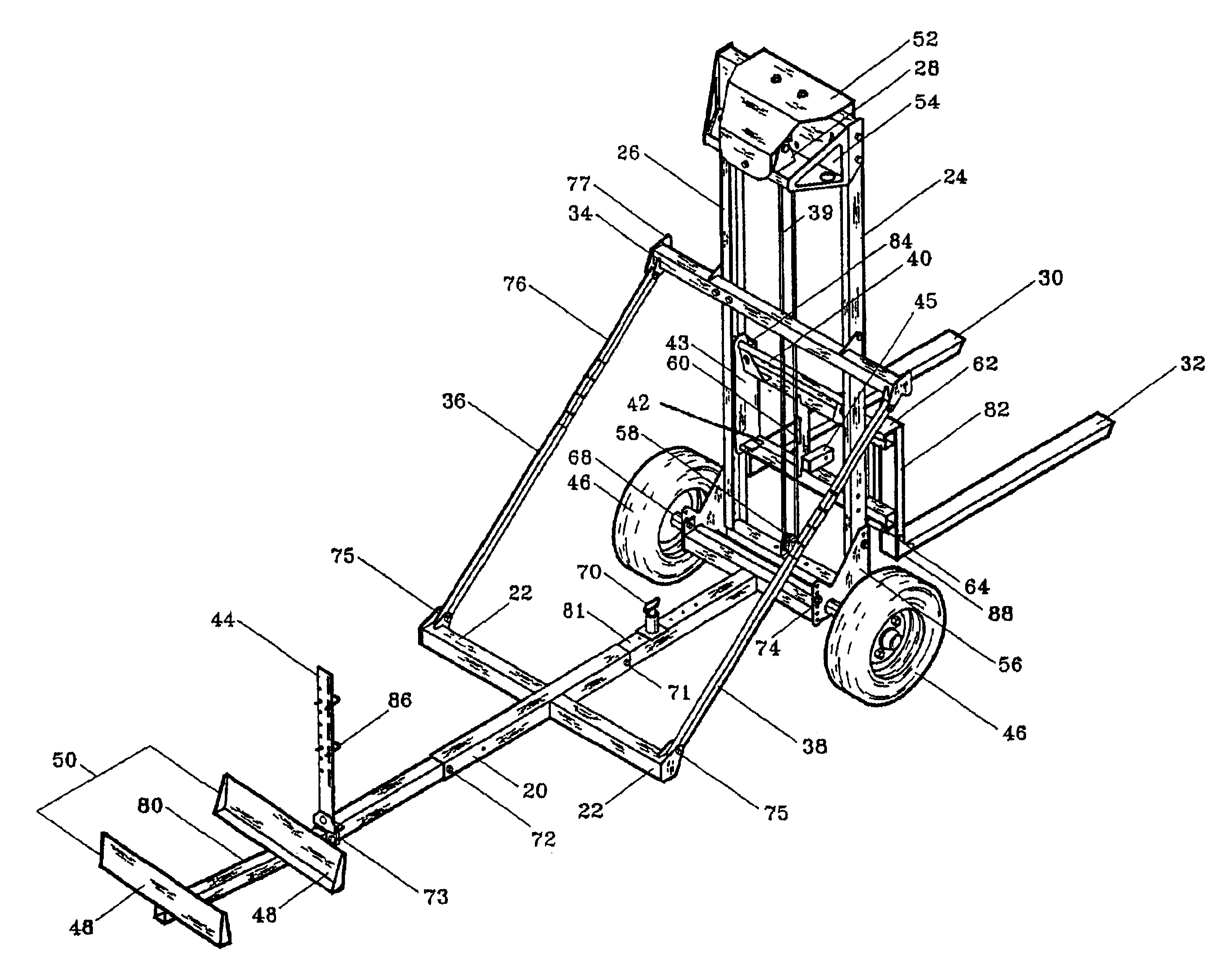

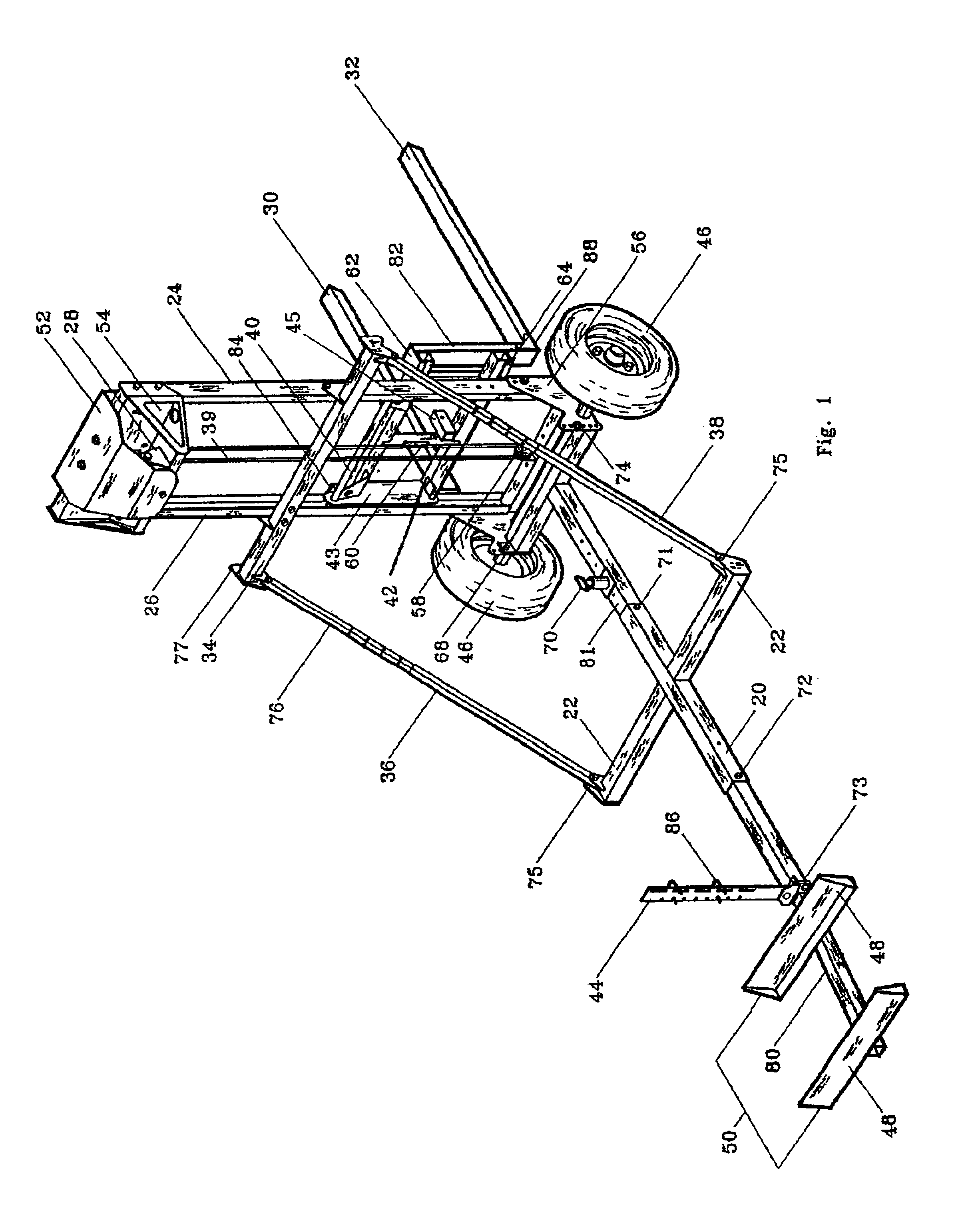

Multi-purpose load bearing assembly for all terrain vehicle (ATV)

An support structure is provided comprising: (a) a mast extending upwards; (b) a center bar extending horizontally from the mast, the center bar configured to extend along the bottom of the light vehicle; (c) a T bar extending from the center bar, along the bottom of the light vehicle to a T bar end at a lateral side of the light vehicle; and (d) a first truss member extending upwards on an incline from the first T bar end to a truss position on the mast. A counter load bearing mount may be attached to the center bar at the second end of the vehicle. Also taught is a load bearing apparatus comprising a support structure of the invention and at least one load bearing member selected from the group consisting of a dump box, 3-point hitch, hitch, dump bucket, log skidder, pallet forks, backhoe, agricultural plow, folding forks, tiller, scraper, disk harrow, disk harrow, hydraulic hammer, auger, grinder, and grapples.

Owner:1326033 ONTARIO

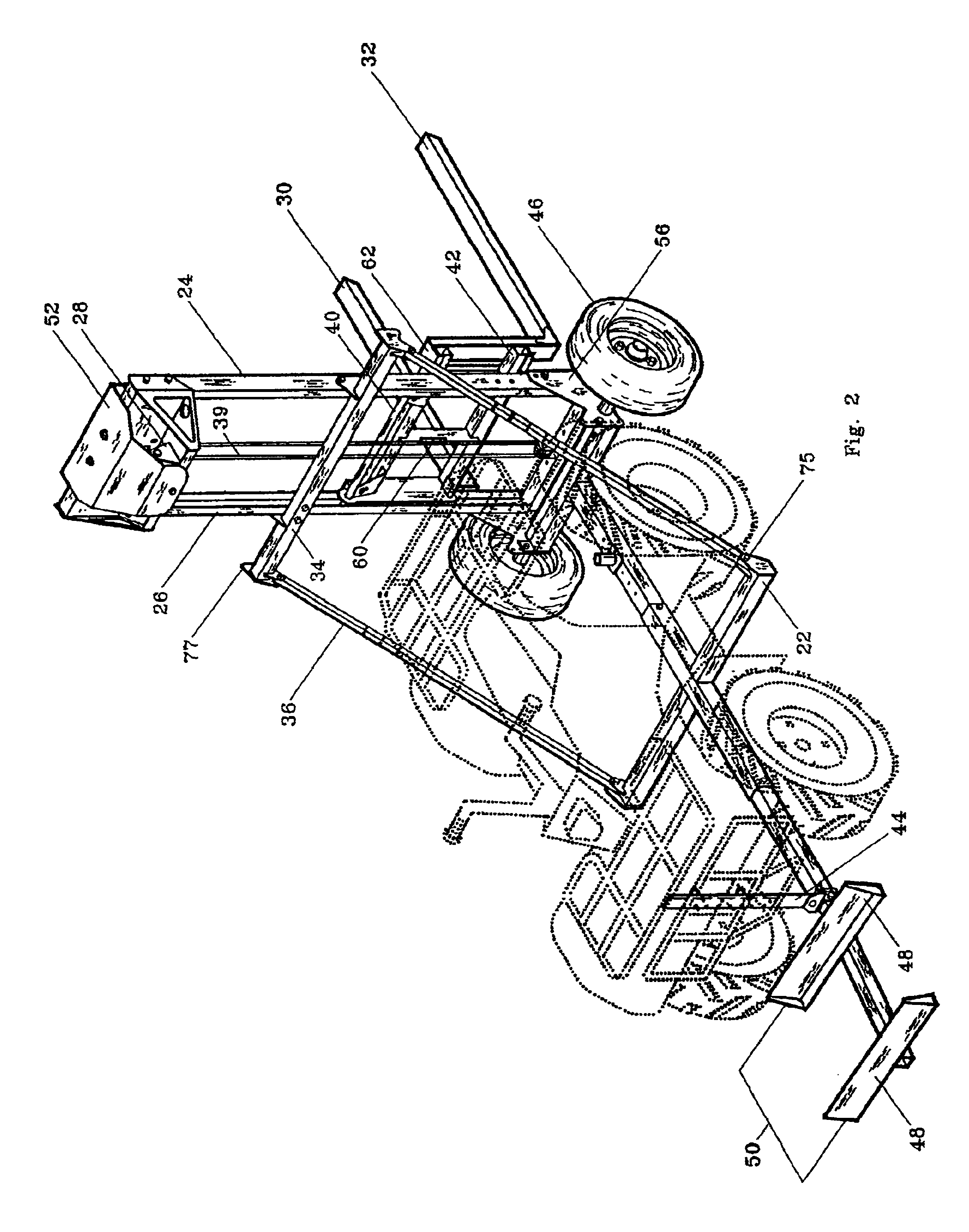

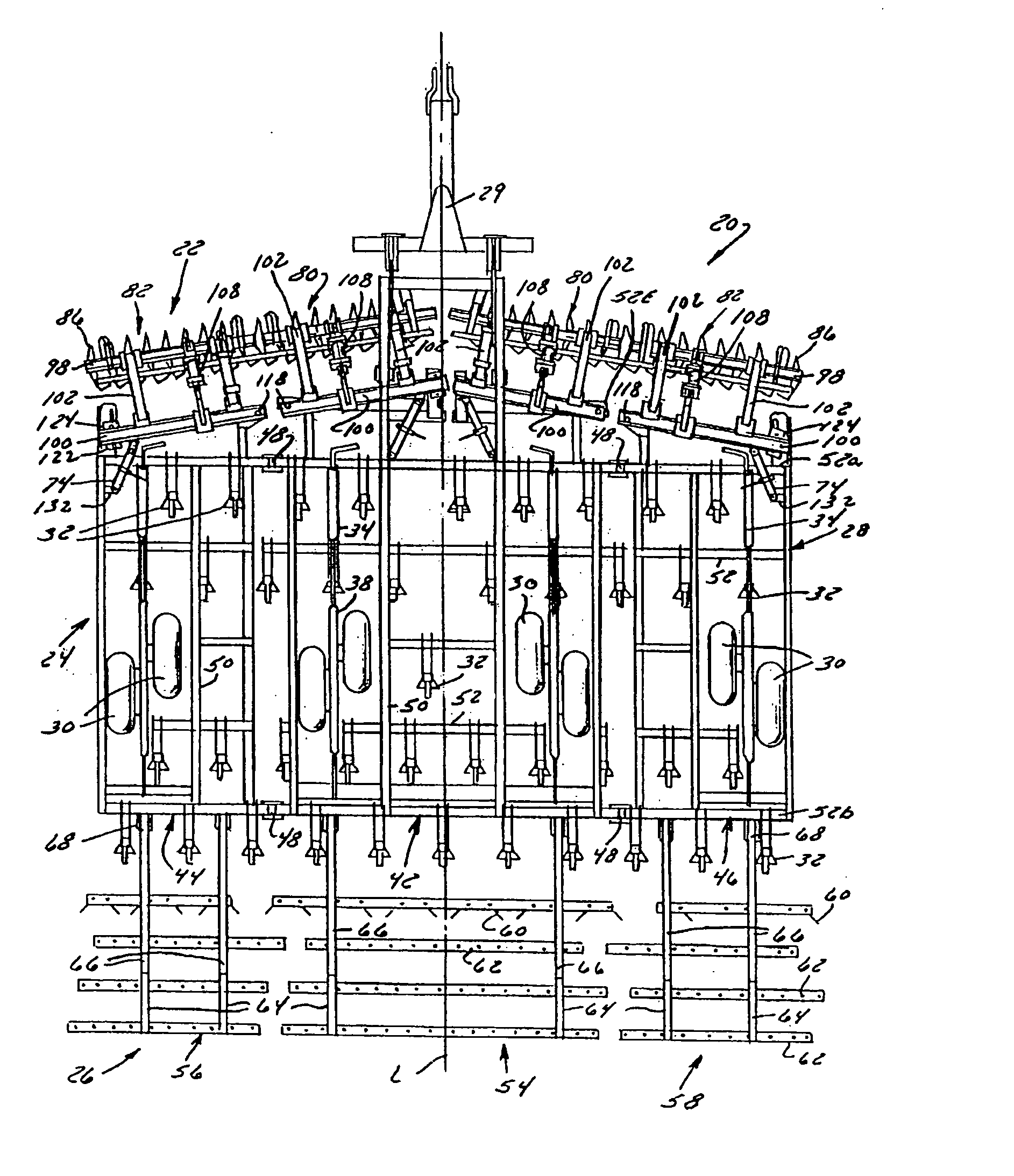

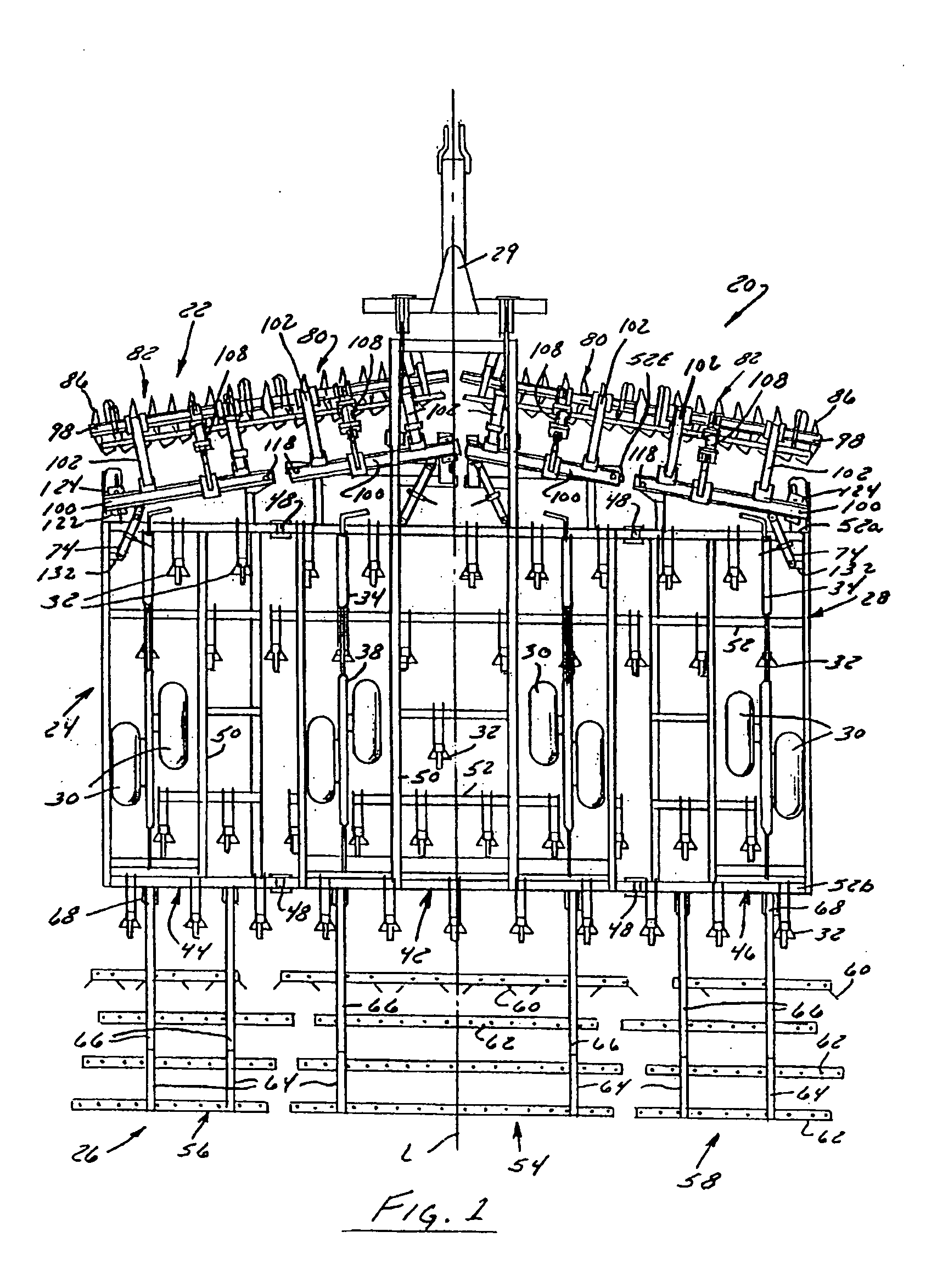

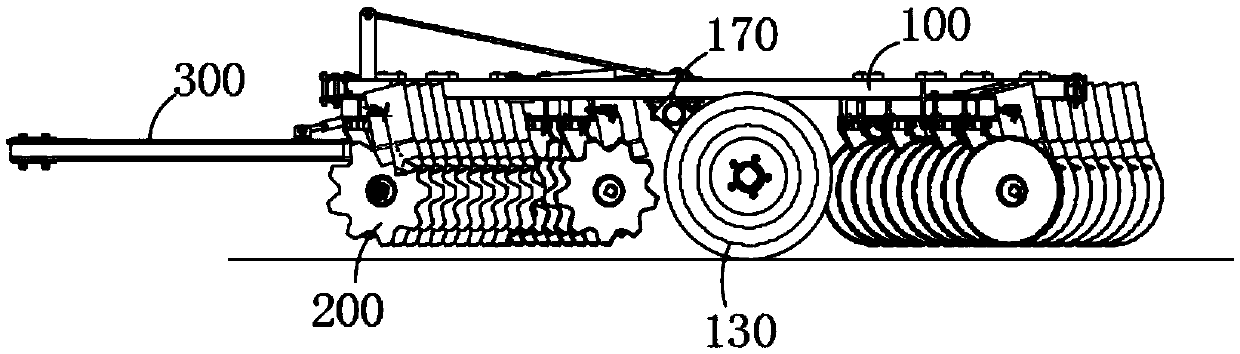

Agricultural disc harrow and method

An agricultural implement consisting primarily of a towed frame supported on retractable wheels, the frame having a plurality of independently adjustable spindles for setting height and angle of attack for various size rotatable discs. Each disc is staggered to reduce resistance and clogging. Each group of discs further includes descending diameter discs at each end with the angle of attack increasing with each decrease in diameter while spacing between the discs decreases as the diameters are reduced. The implement further including harrow teeth or picks located at strategic points adjacent the discs to ensure uniform soil disruption, the disc assembly being convertible from single gang to double gang assembly and may include conventional harrow teeth sets and or unique soil leveler attachments.

Owner:BOLLICH GERALD

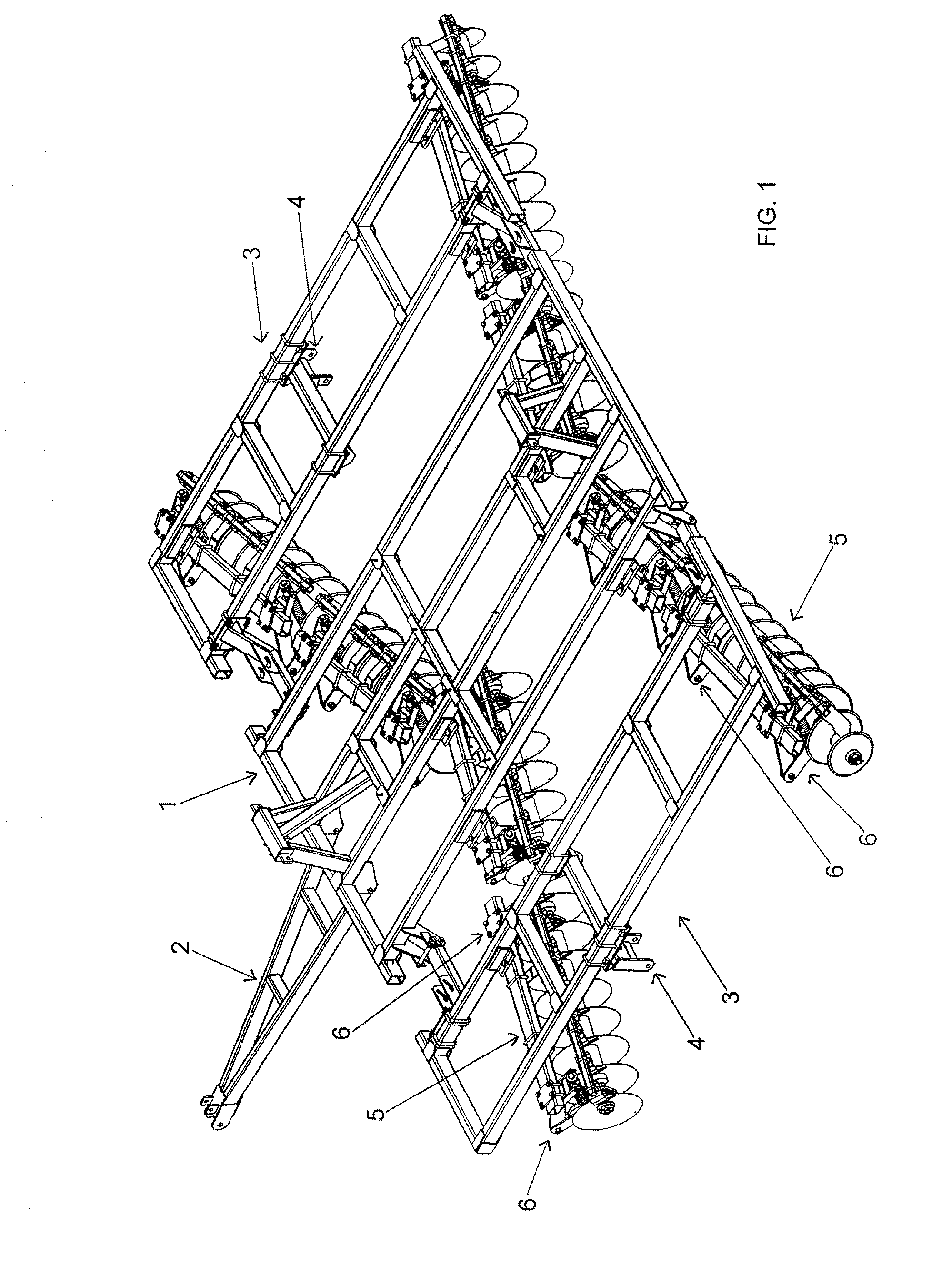

Disc harrow agricultural implement

ActiveUS7607489B2Effectively cut and uprootGood effectSpadesSoil-working equipmentsCircular discAgricultural engineering

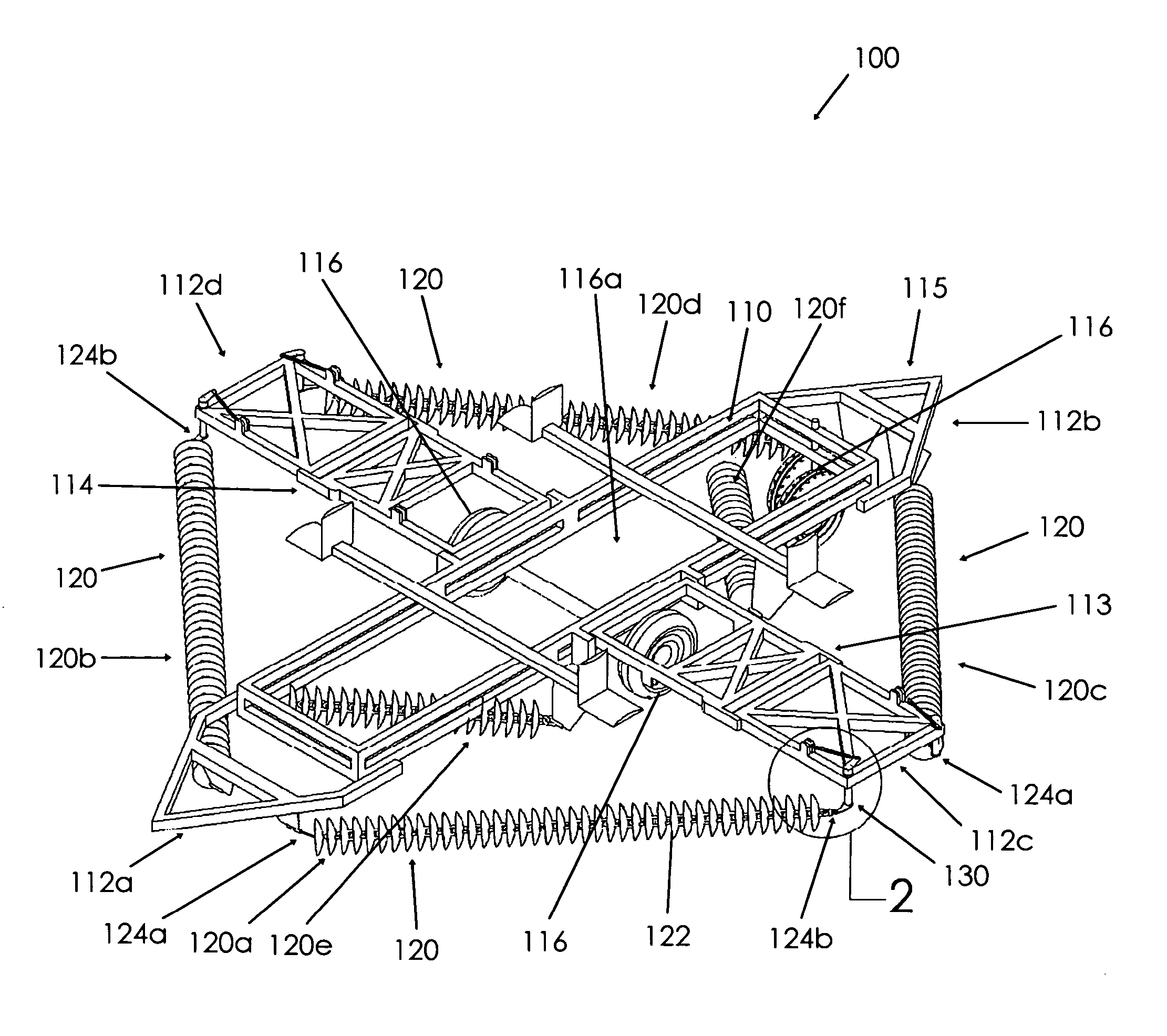

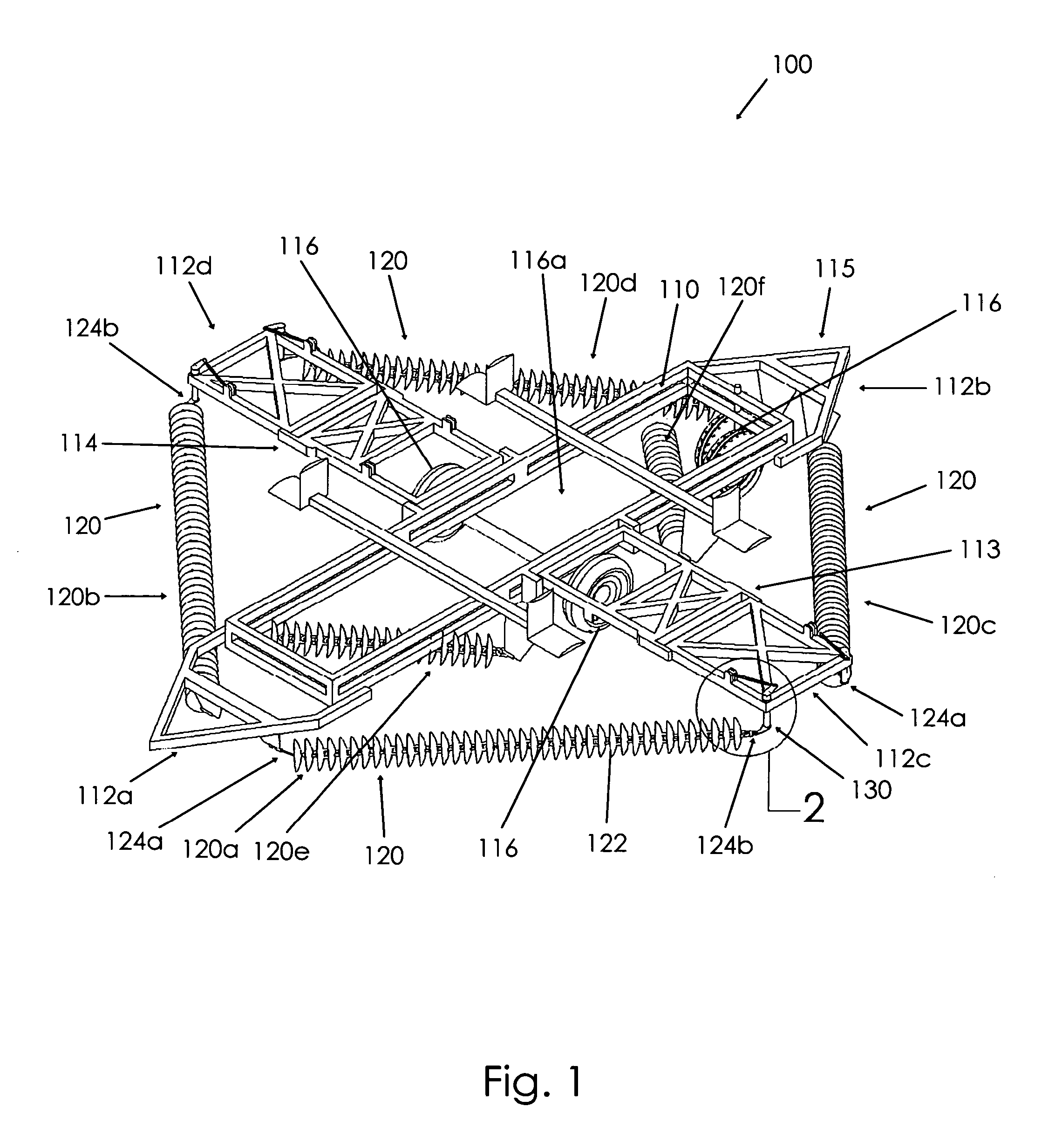

An agricultural implement includes first and second outer harrows positioned adjacent front and left sides and front and right sides of a frame, respectively, at generally opposite diagonal directions. Third and fourth harrows are similarly positioned adjacent rear and left sides and rear and right sides of the frame, respectively, at generally opposite diagonal directions. The implement may include inner harrows positioned to close gaps left by the outer harrows and positioned at generally opposite diagonal configurations. Each harrow includes a plurality of discs and a chain with a plurality of links that are rotatable about the longitudinal direction of the chain so as to affect multi-purpose actioning of the soil by being able to level the surface rather than dragging material while also breaking up or uprooting weeds or stubble. Left and right sides of the frame are foldable upwardly and inwardly for transport and storage.

Owner:KELLY SHANE P +1

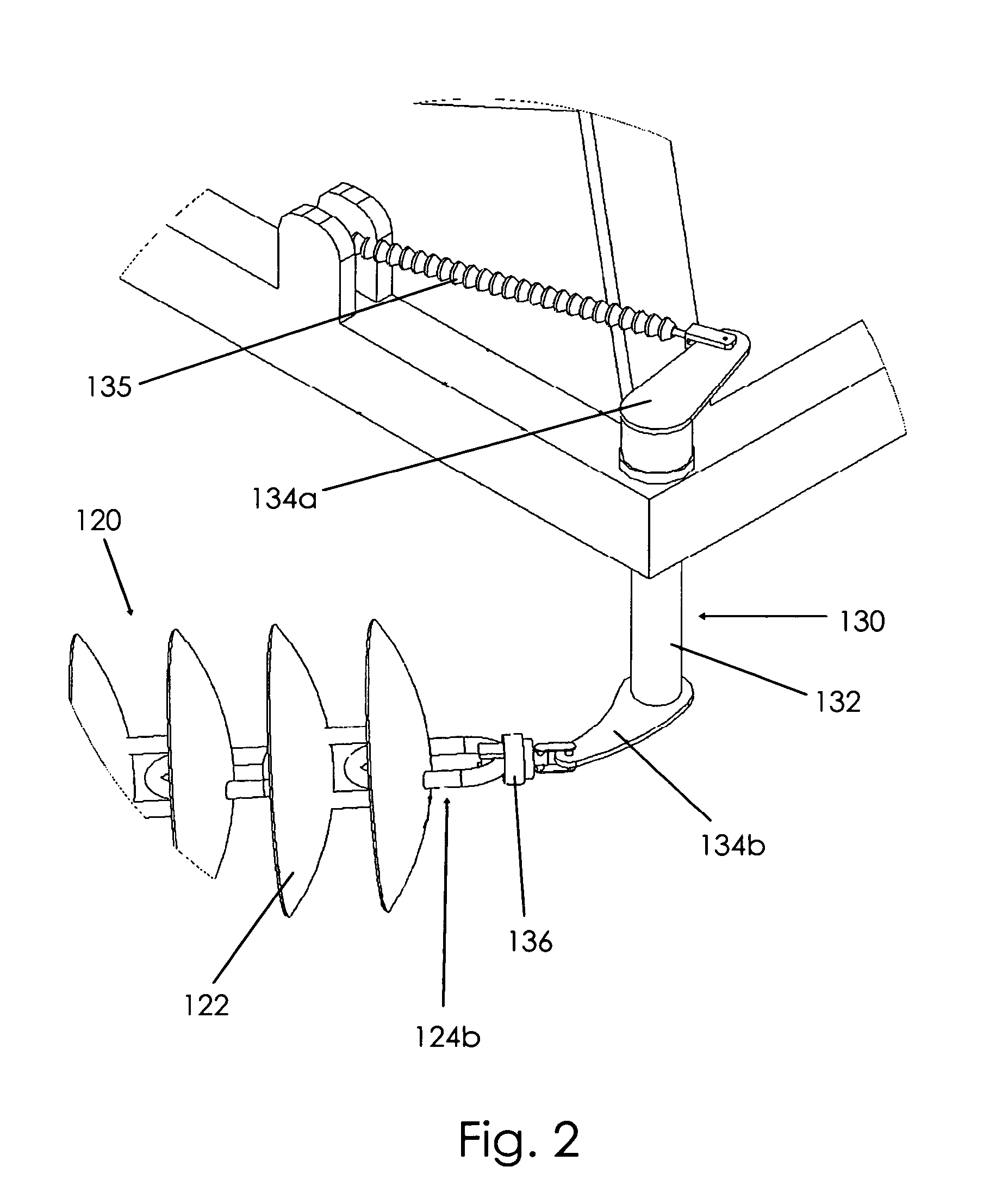

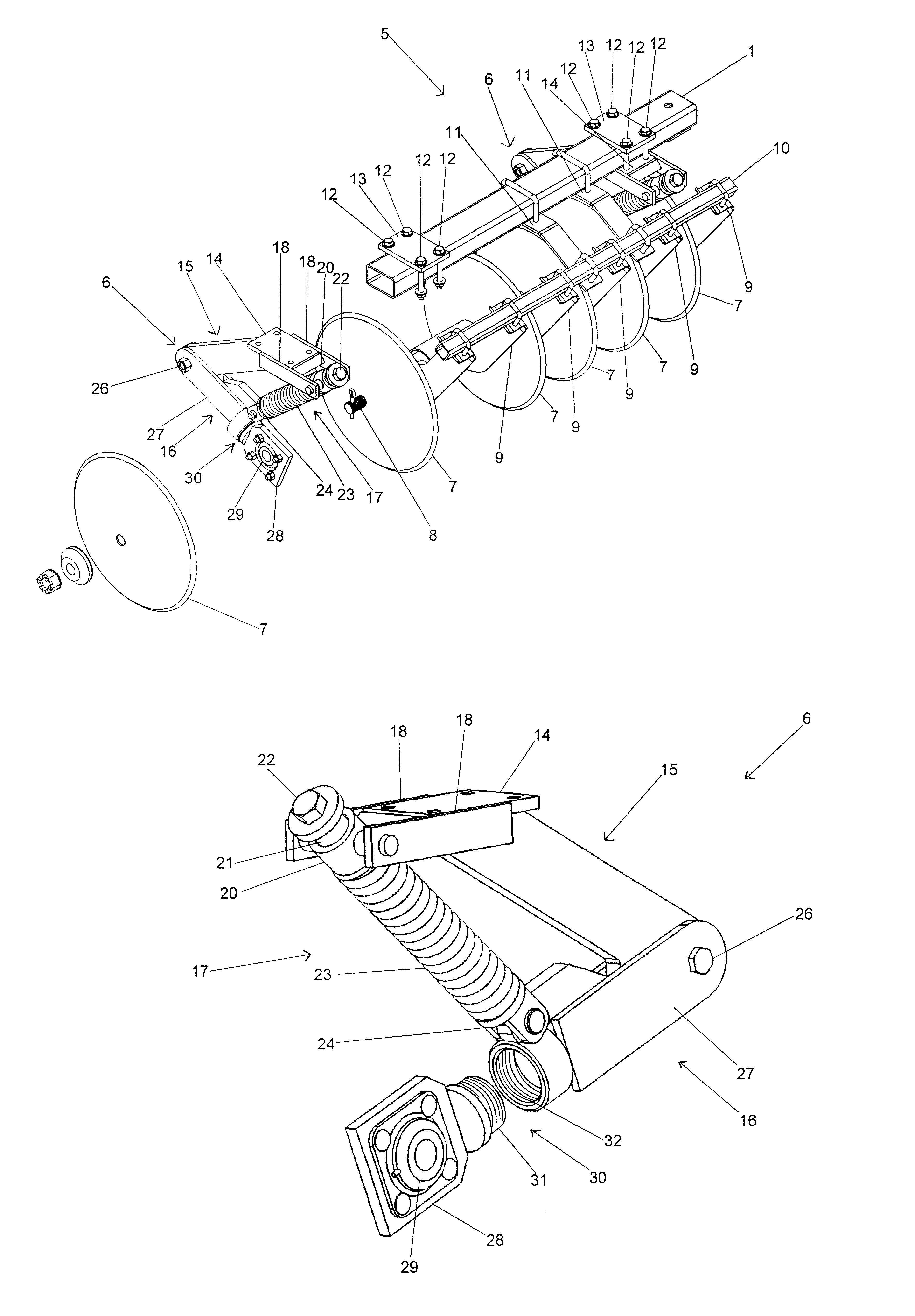

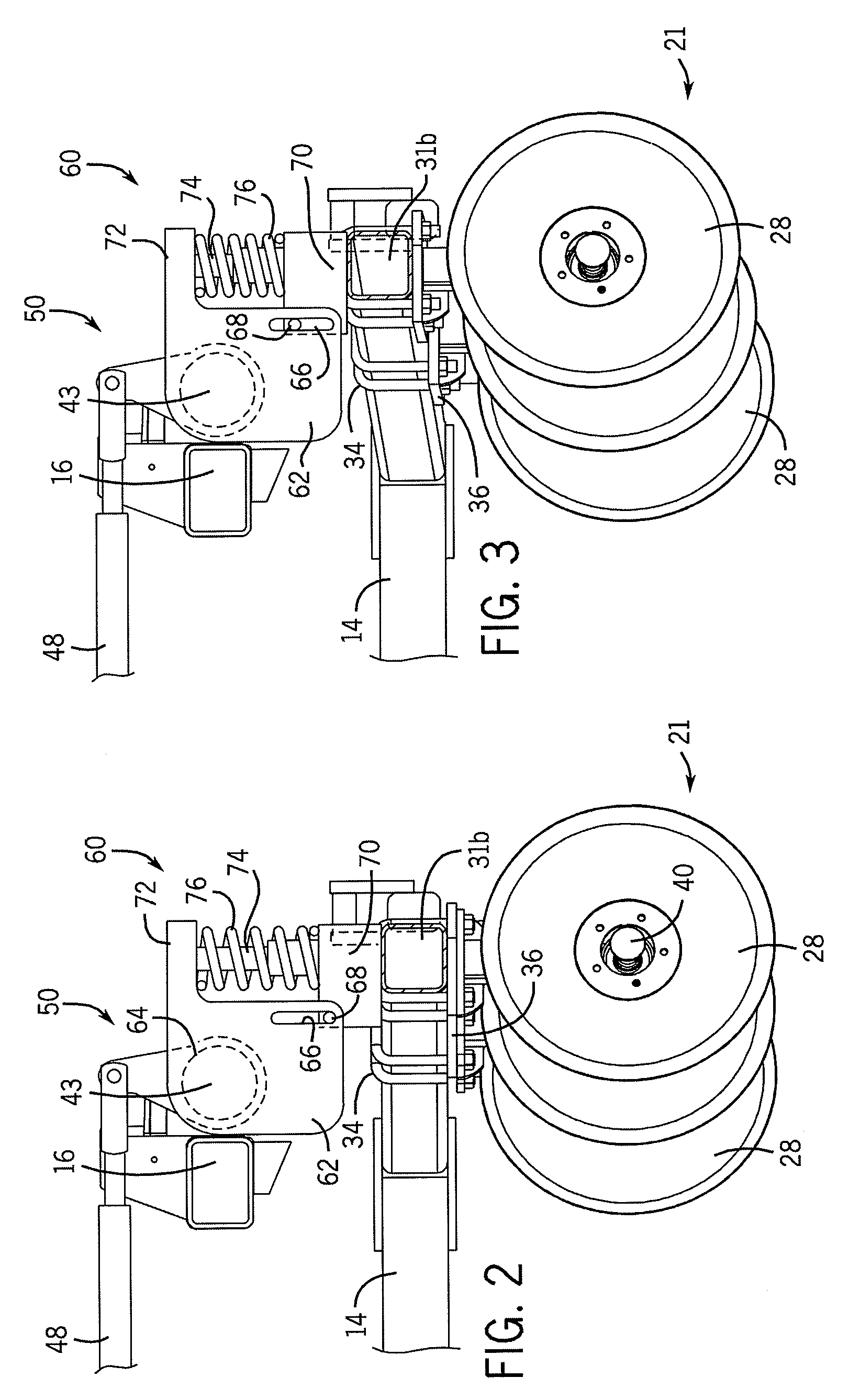

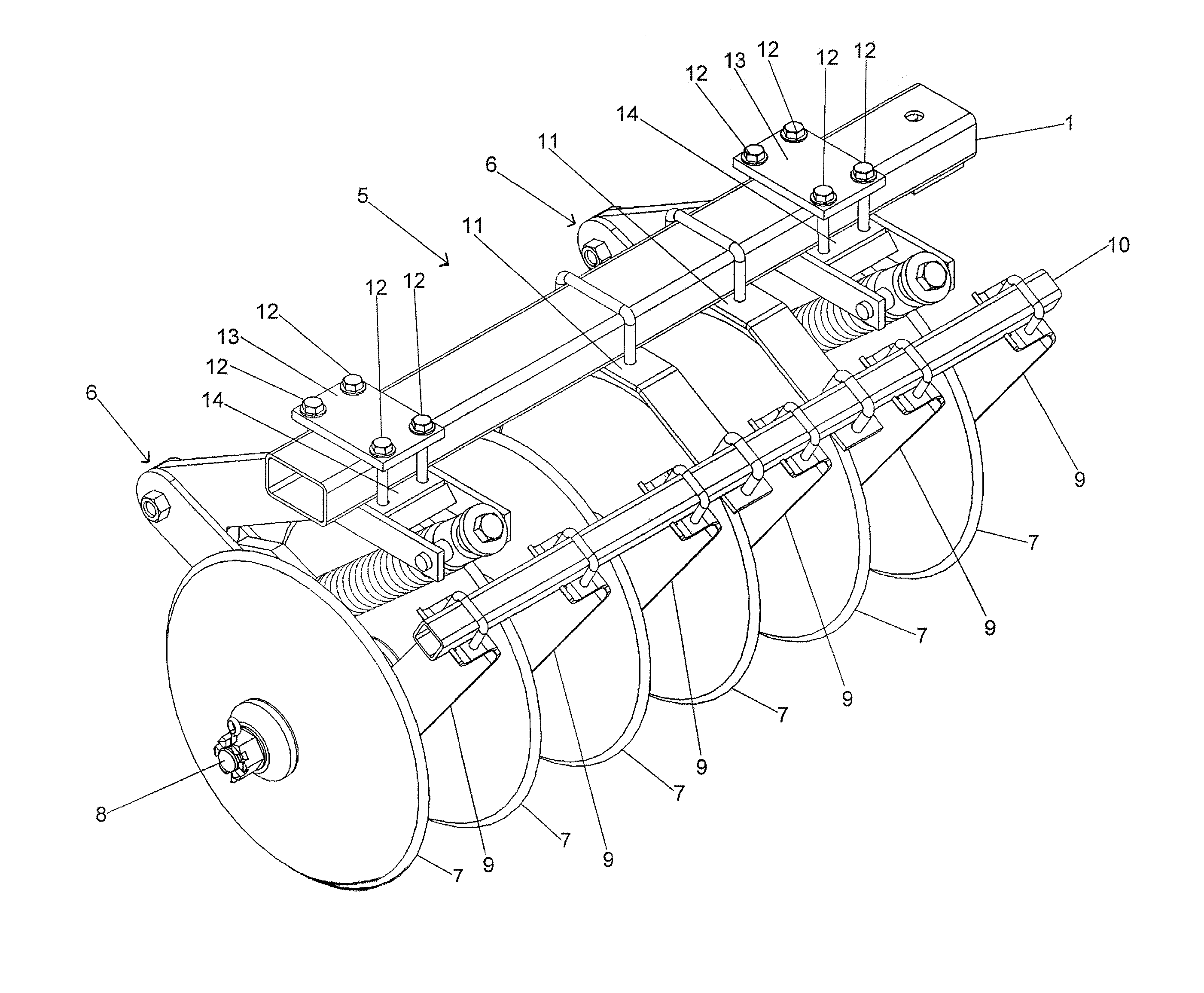

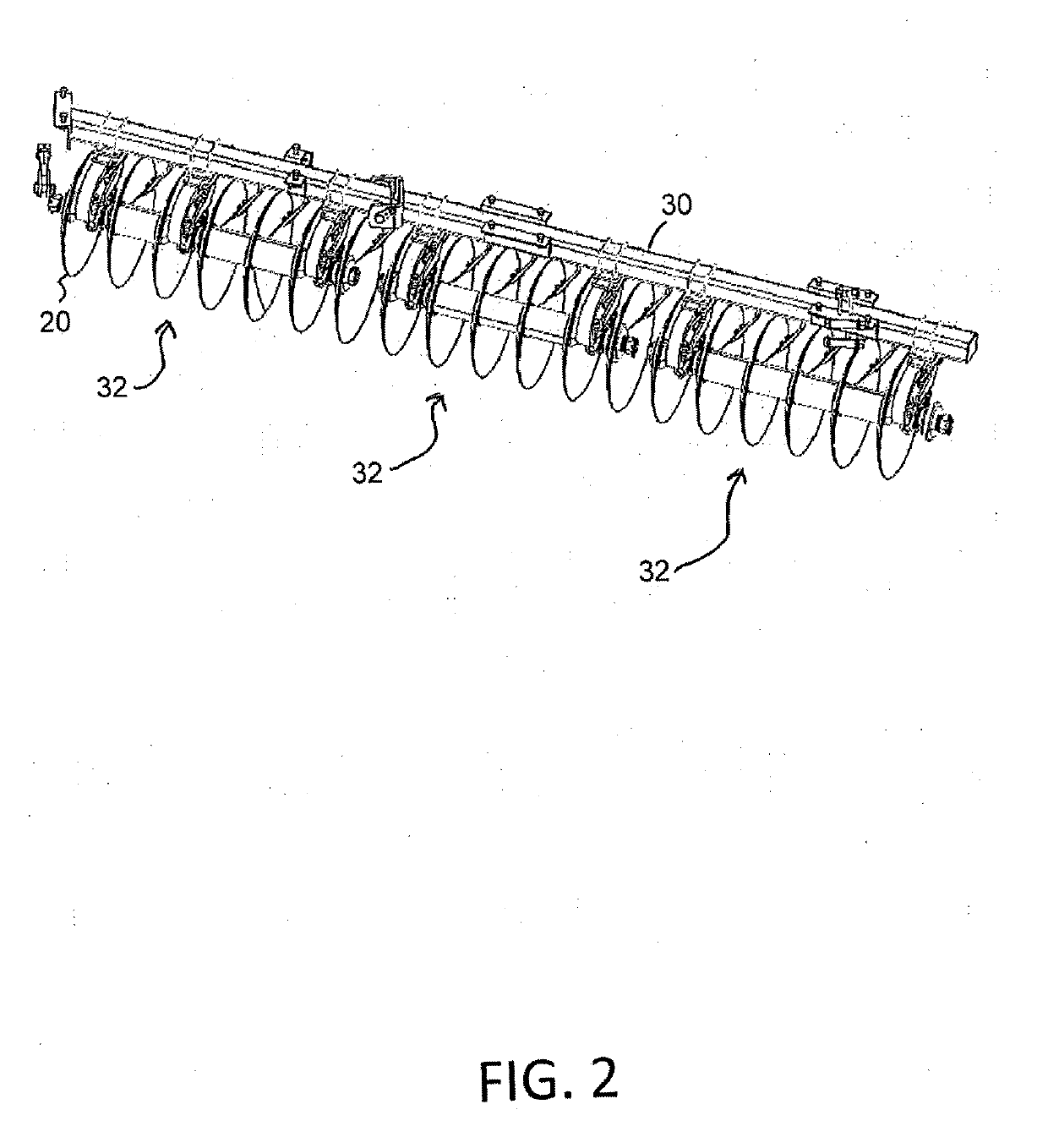

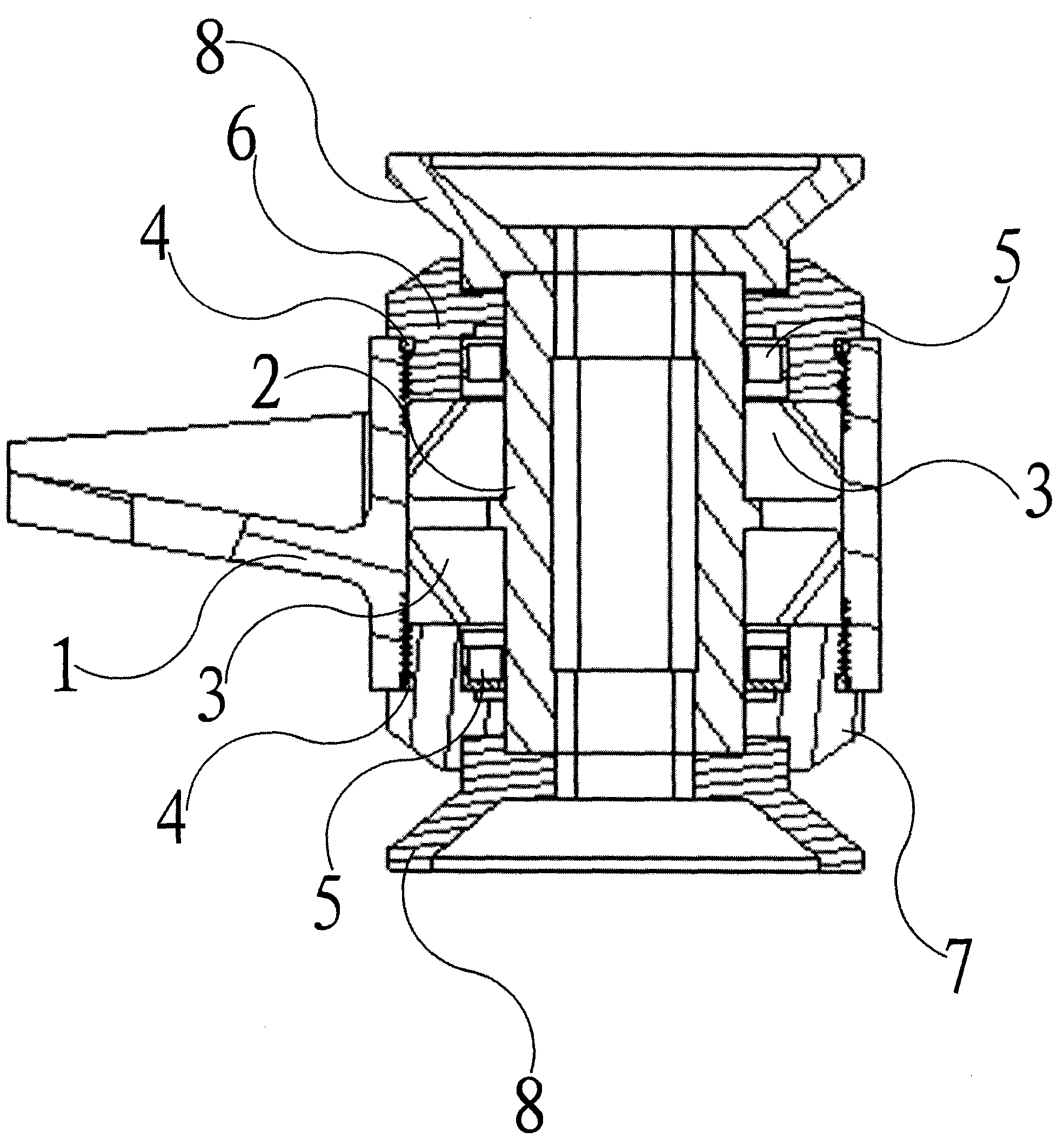

Spring rockflex bearing arm

A disc harrow has a frame and a plurality of earth working discs. Each disc has a central aperture for attachment to a gang shaft. A mount attaches the gang shaft to the underside of the frame and has bearings to permit rotation of the shaft in response to forward movement of the disc harrow. The mount includes a first structural member, a second structural member and a resilient spring connected between the two members. In operation, upon striking of an obstacle by the discs, the gang shaft is permitted to upwardly deflect by the mount to prevent damage to the disc harrow. The second structural member has first and second portions with aligned longitudinal axes. The first and second portions are rotationally connected to permit rotation of the second portion in response to an angular moment applied to the second portion by deflection of the gang shaft. The rotational connection permits the bearing to automatically maintain a preferred alignment with the gang shaft during deflection, thereby preventing damage to the bearing.

Owner:SALFORD FARM MACHINERY

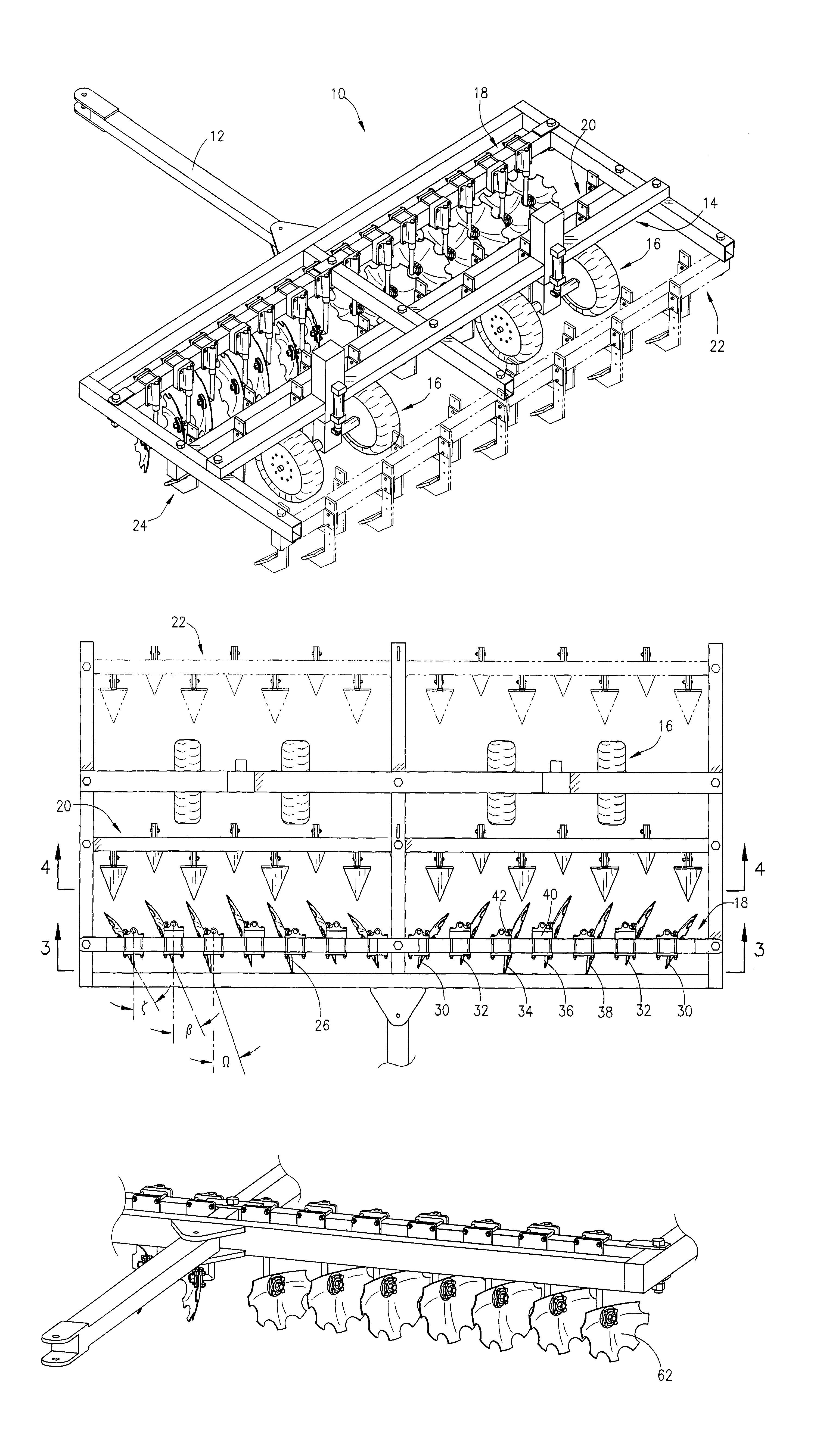

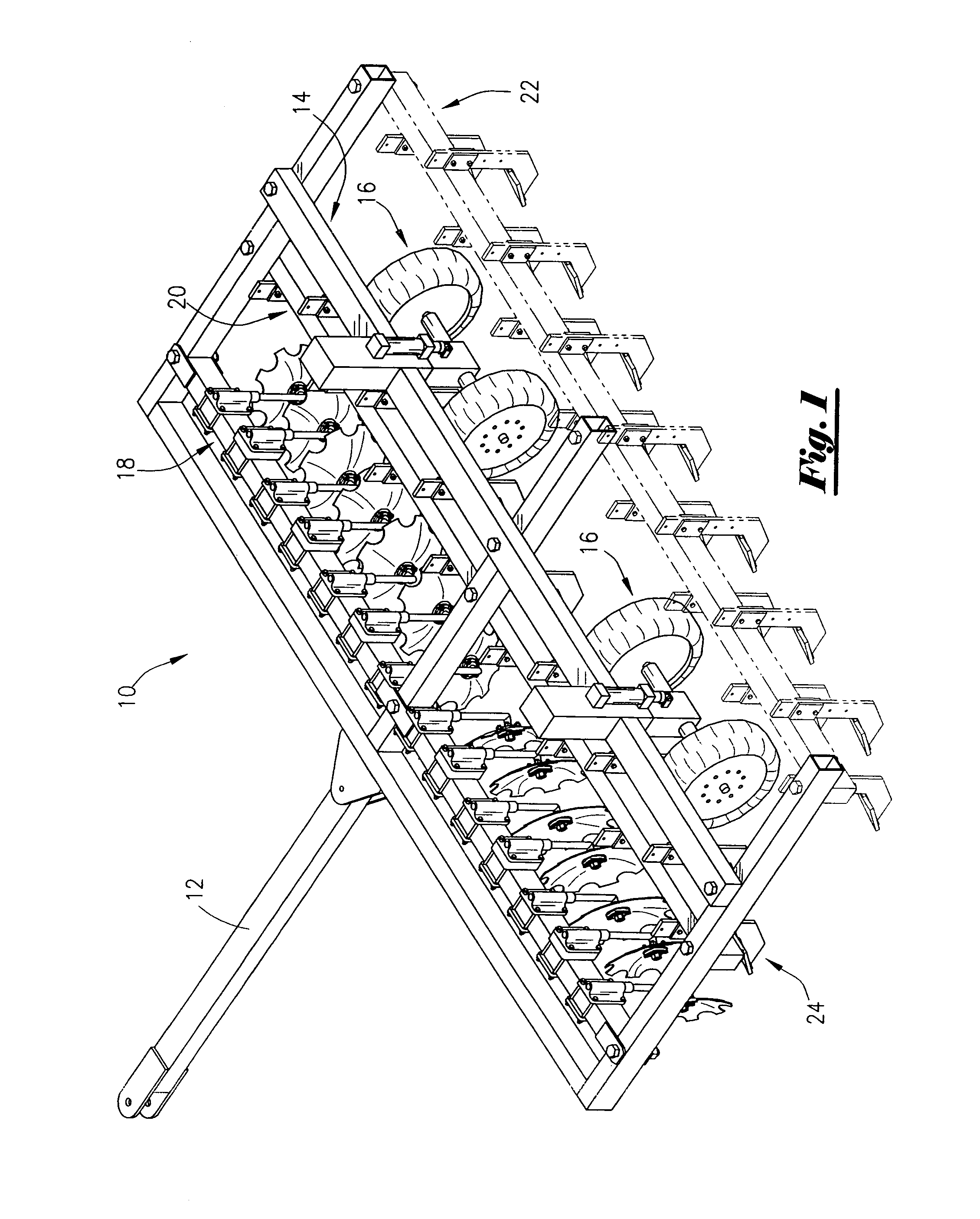

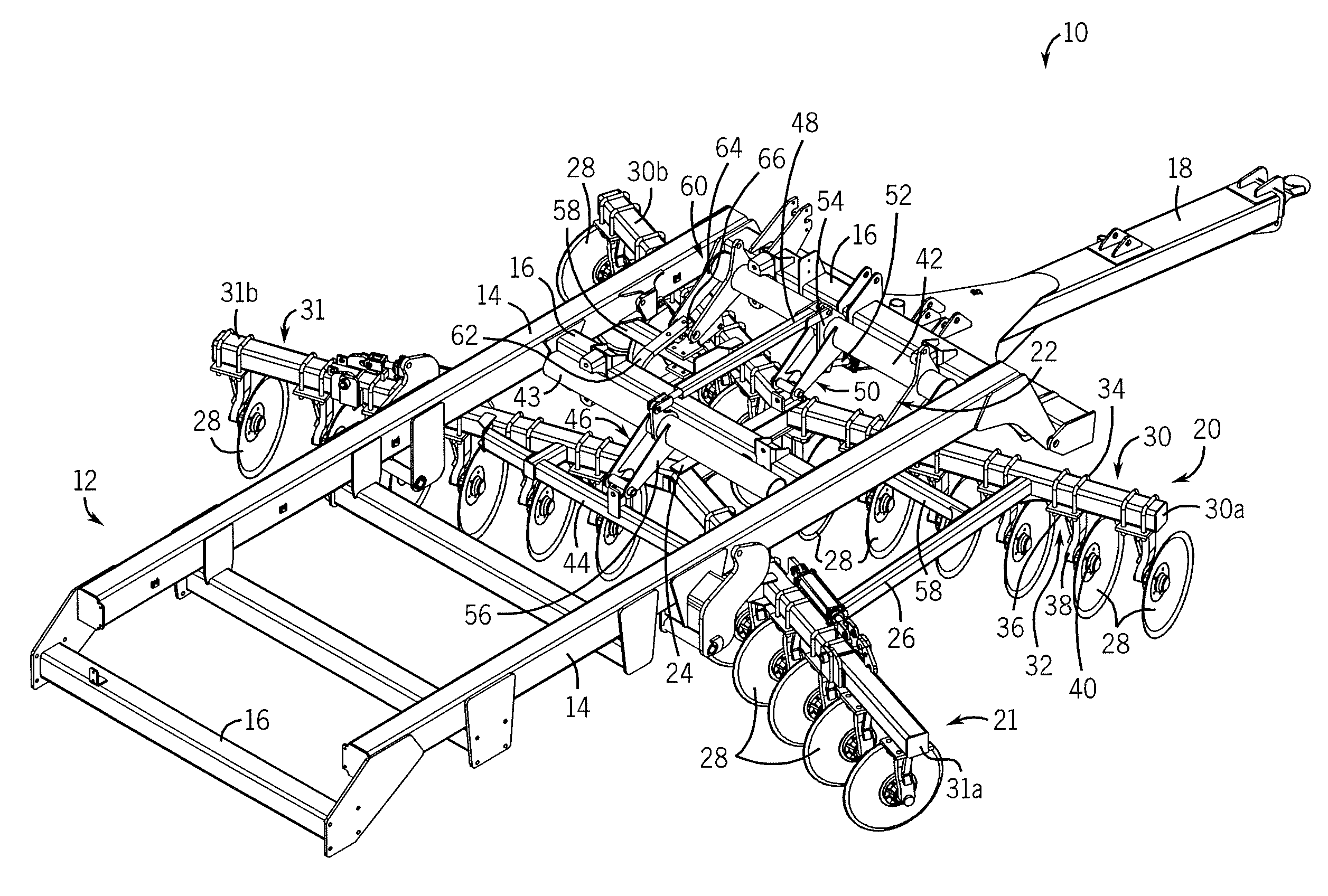

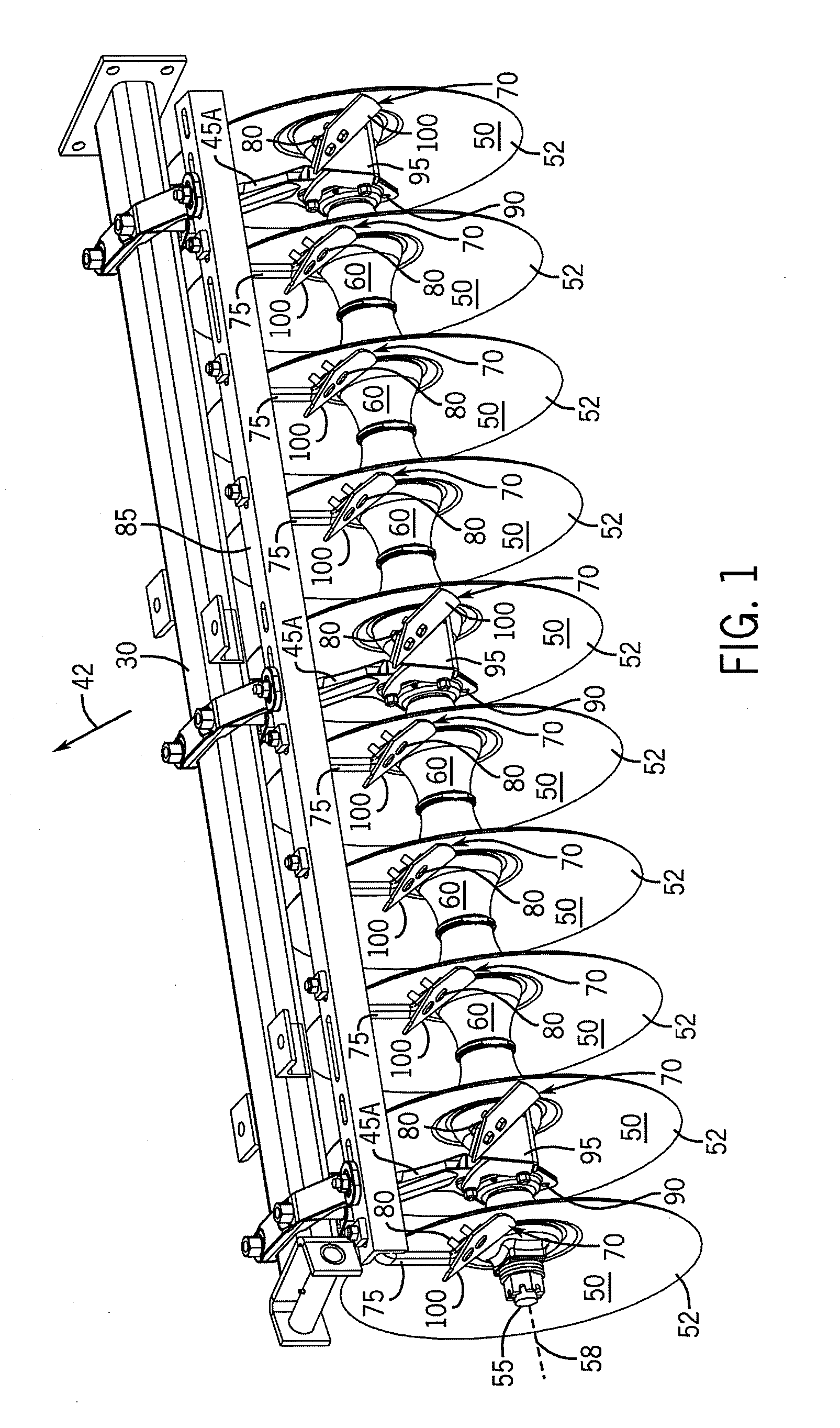

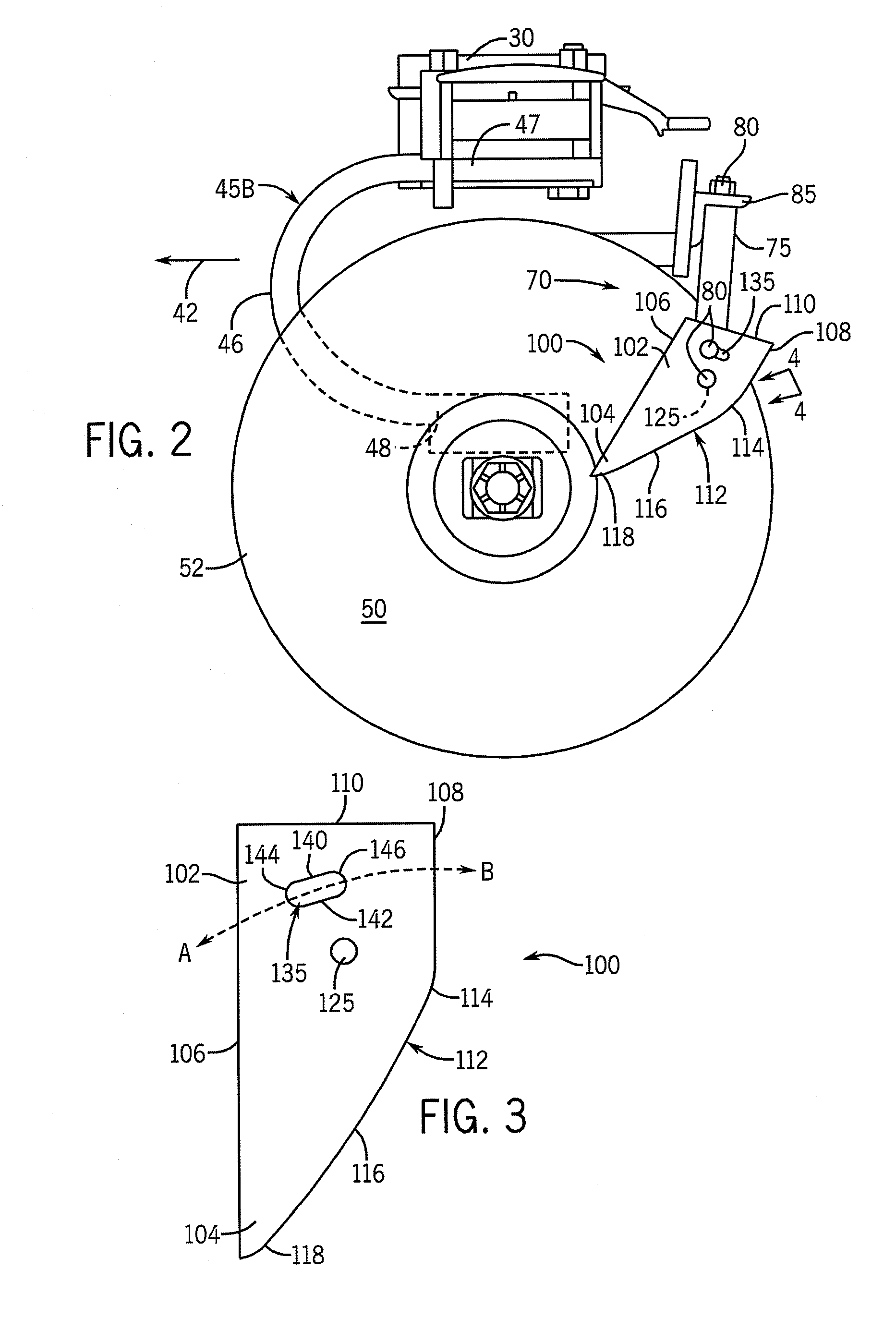

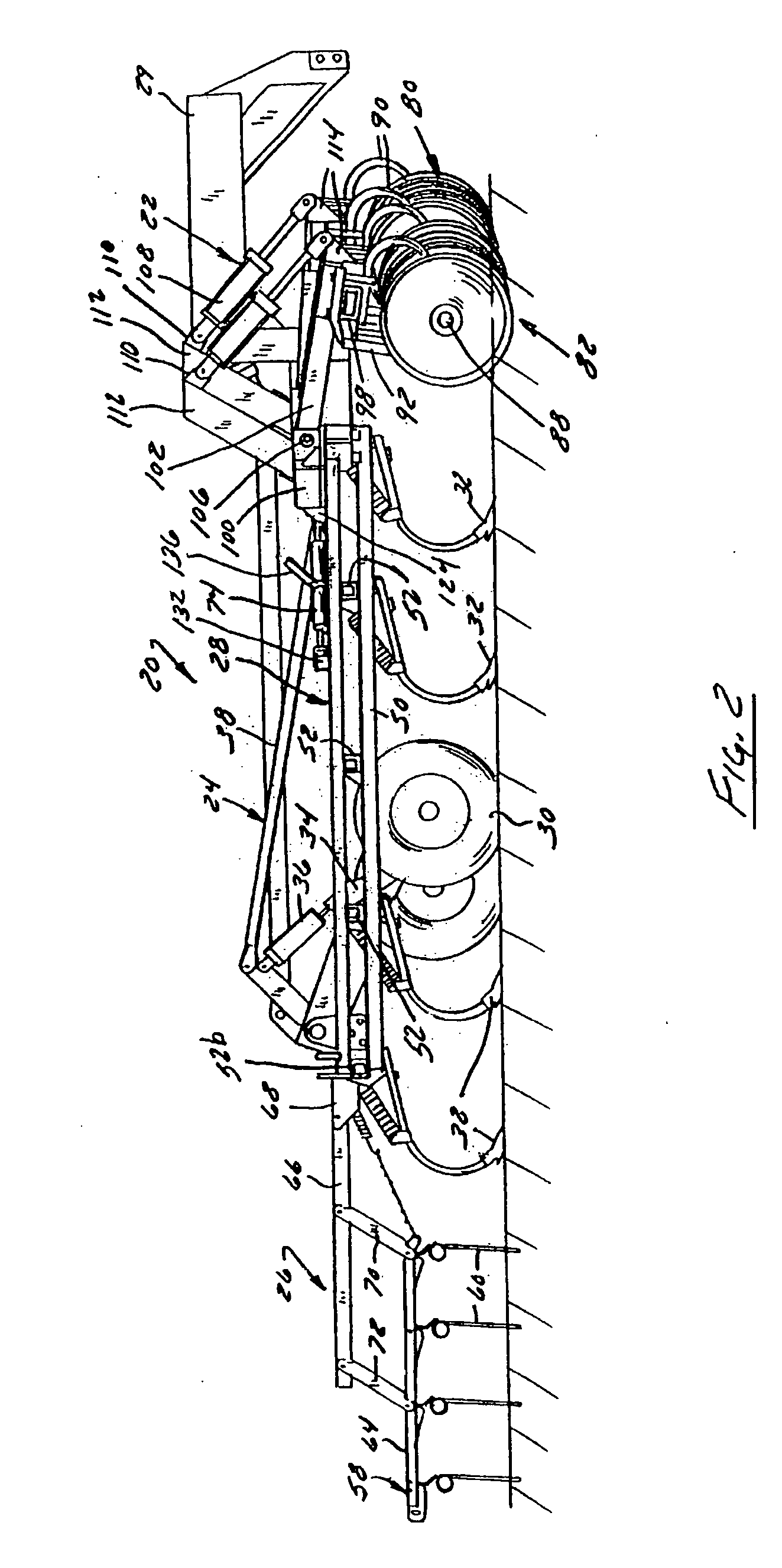

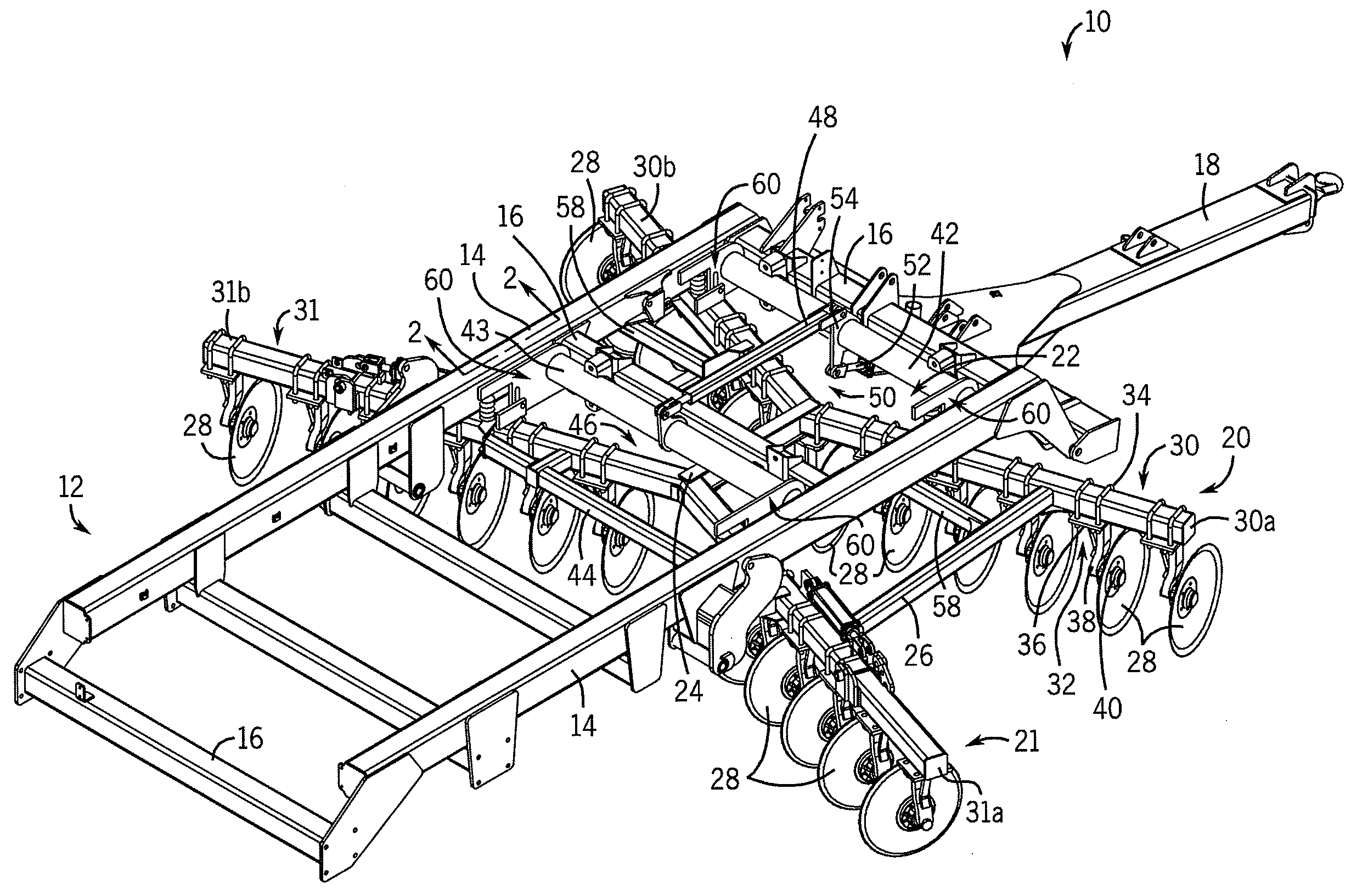

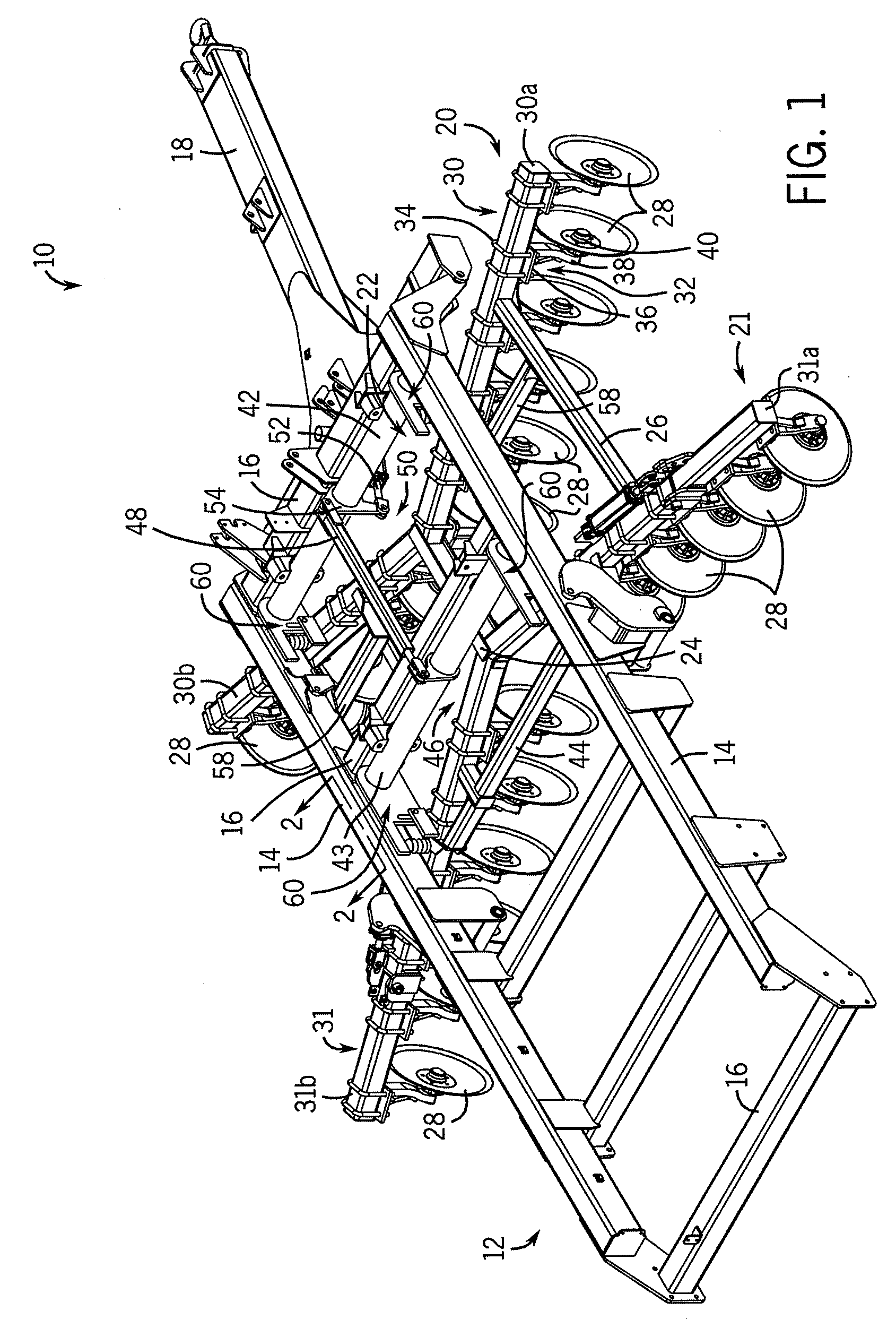

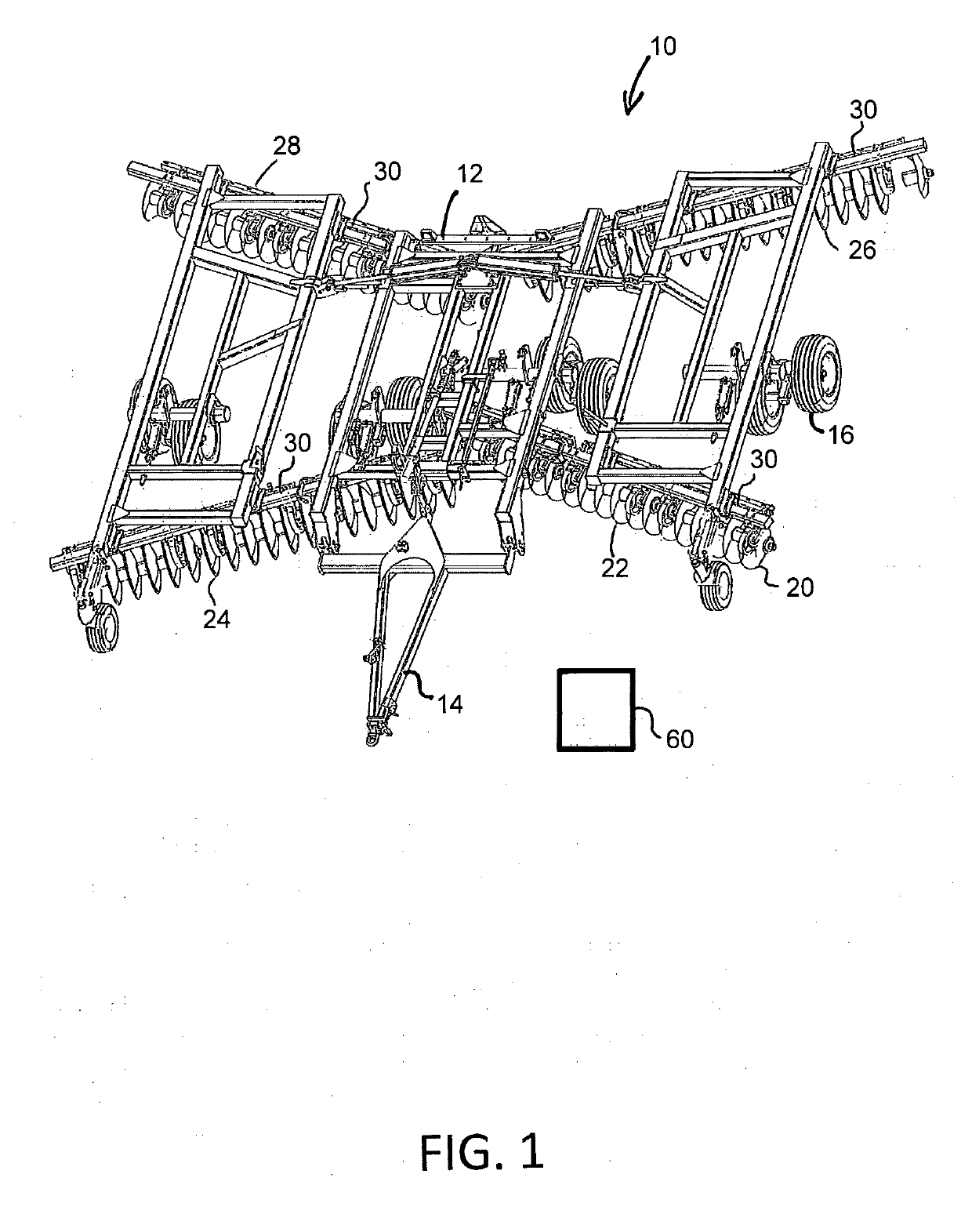

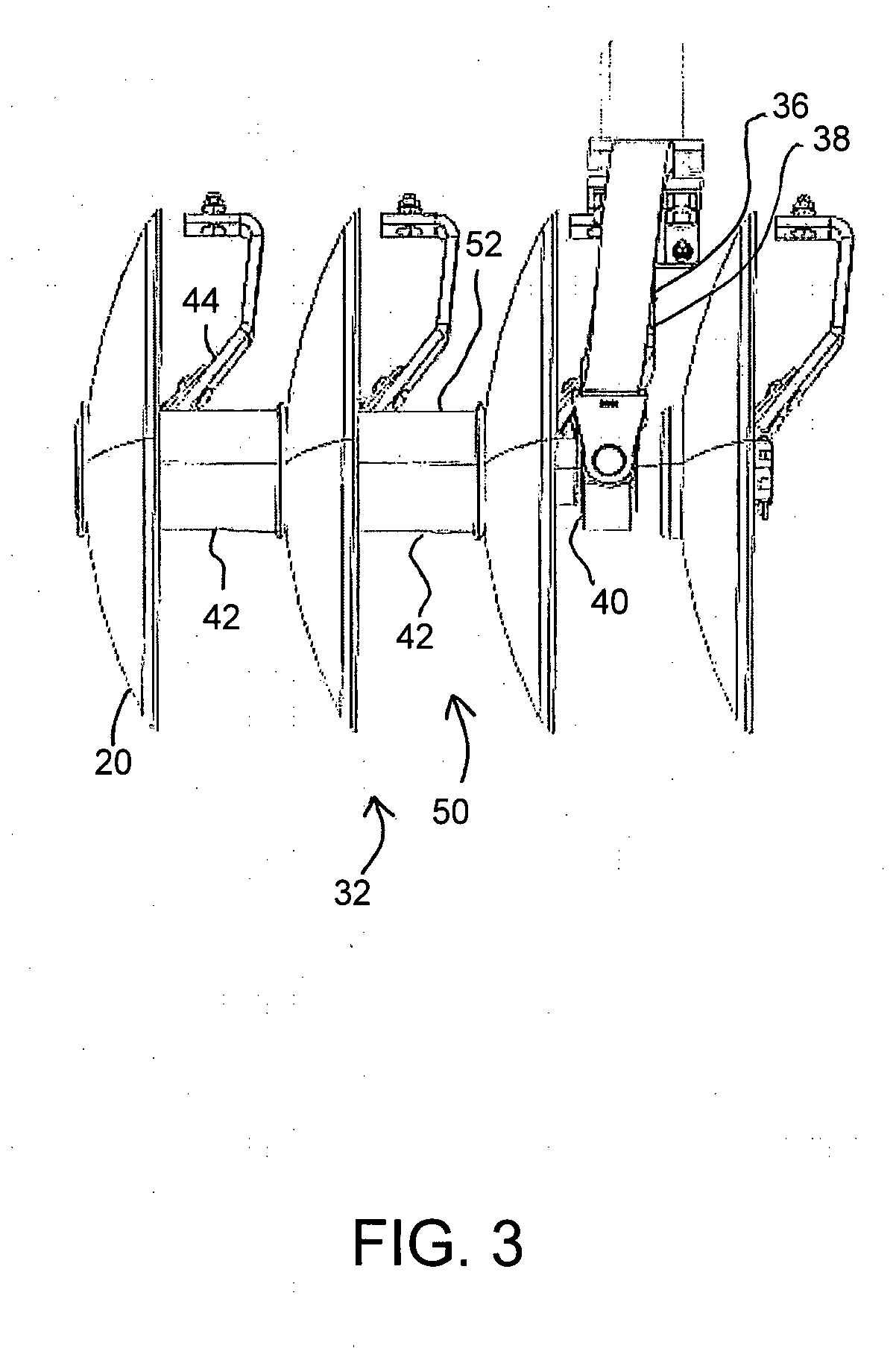

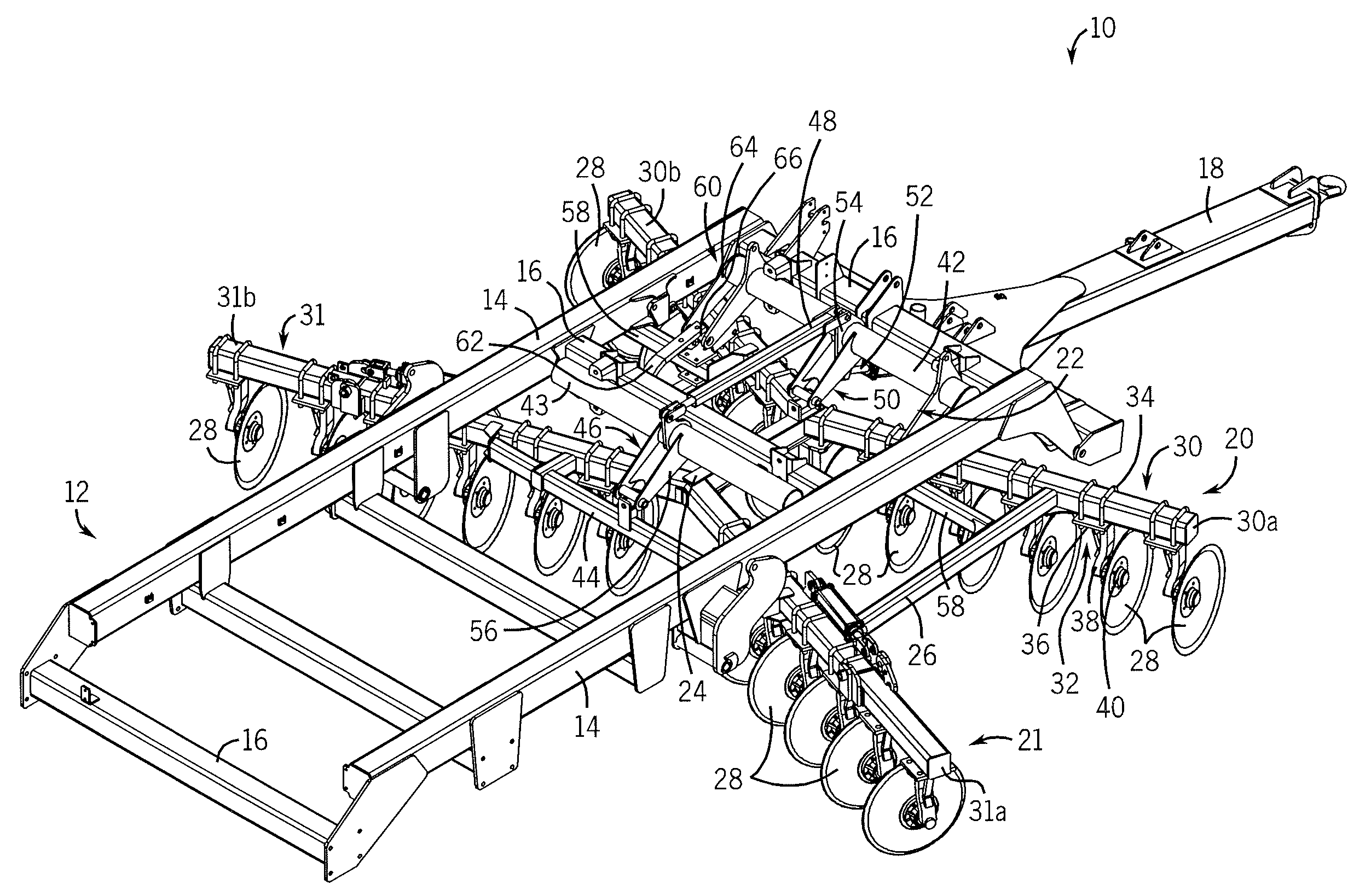

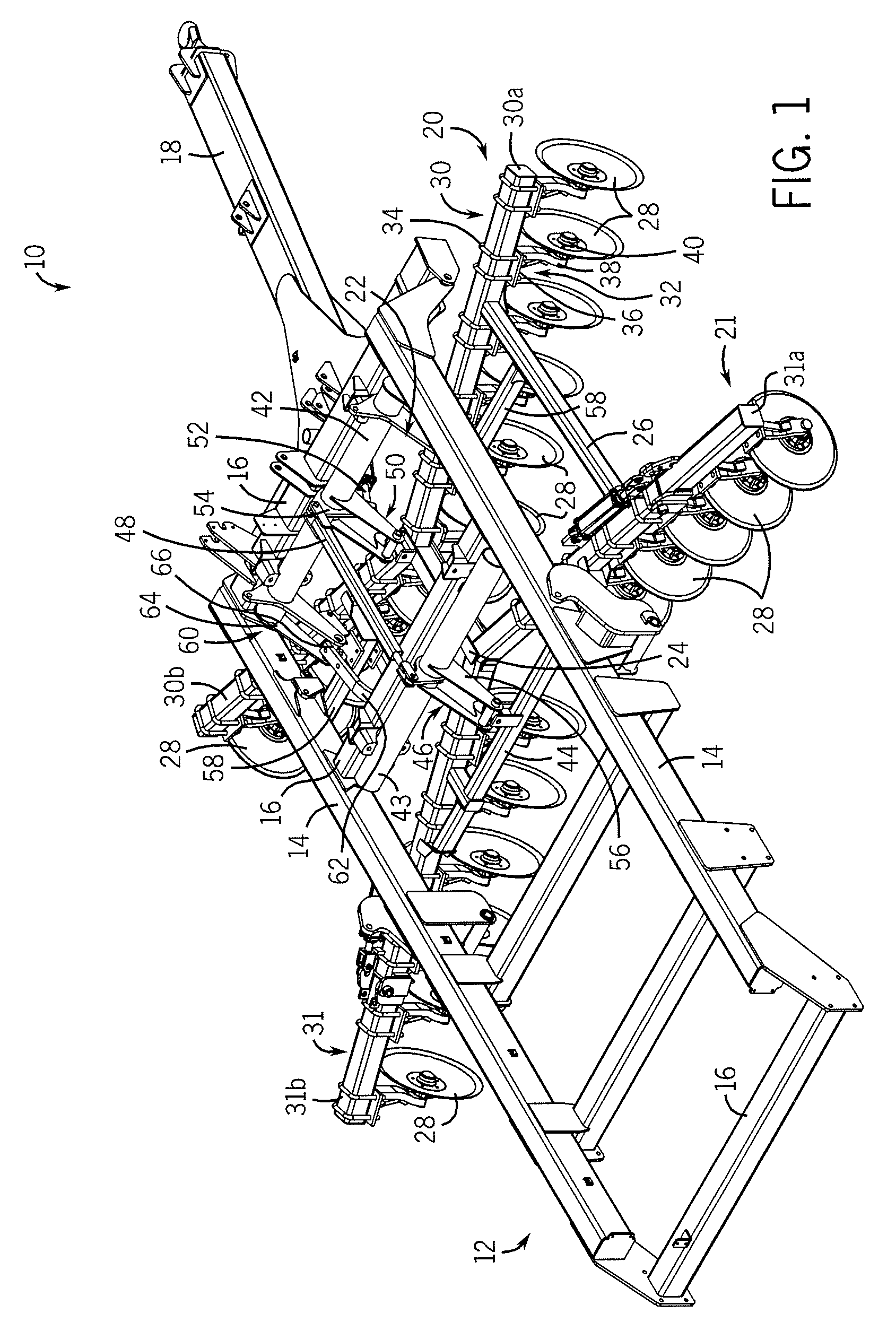

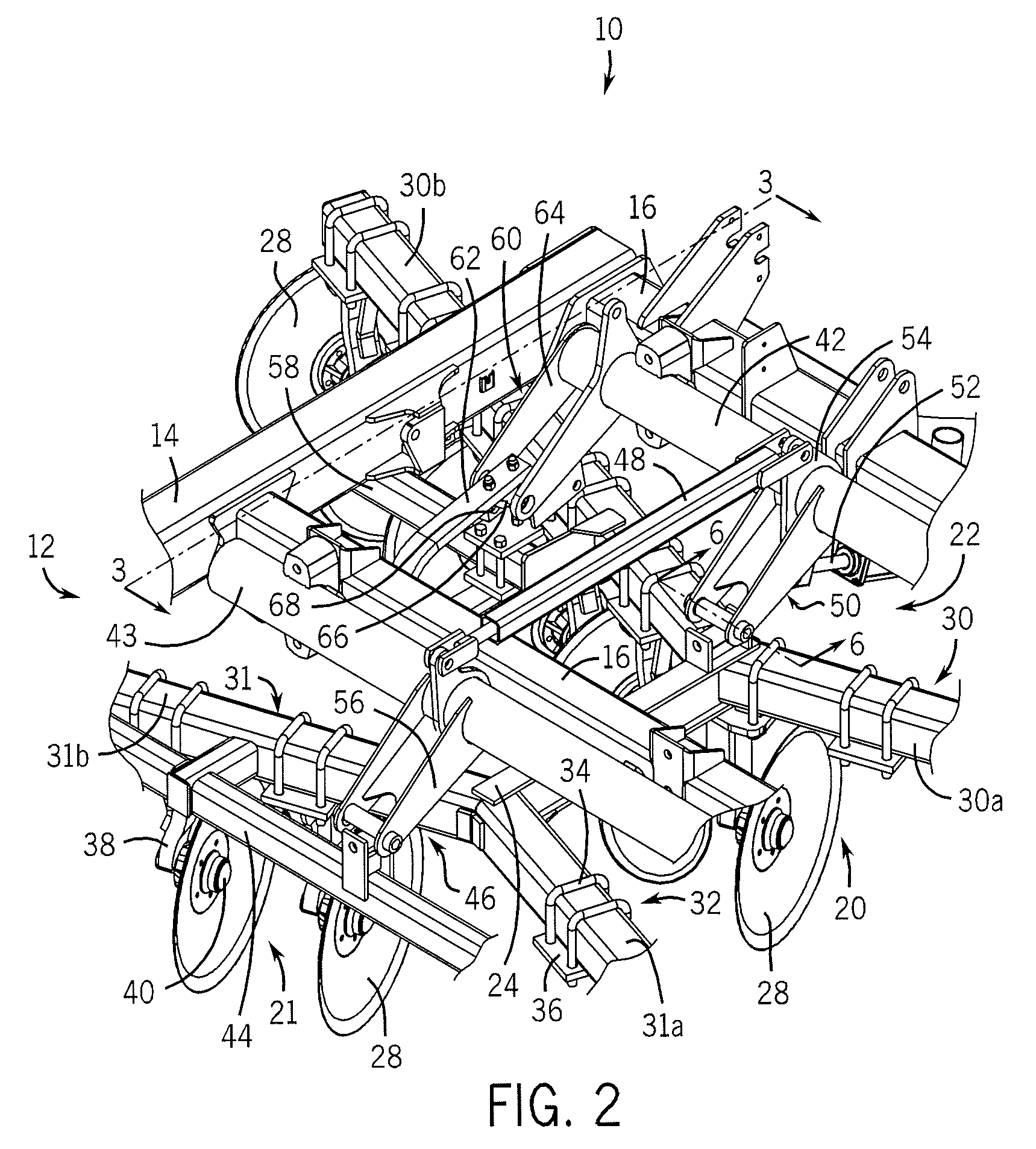

Crop residue and soil conditioning agricultural implement

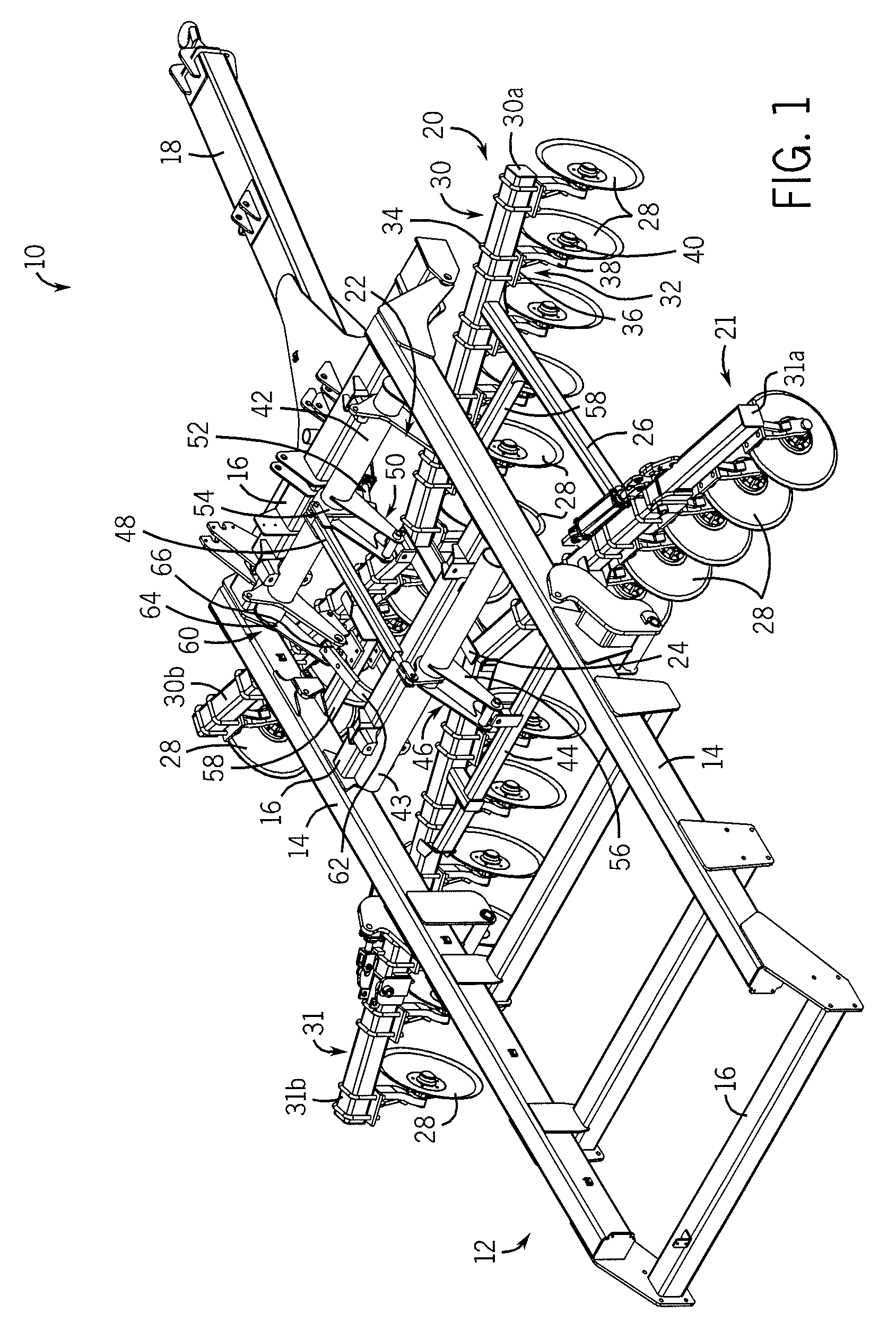

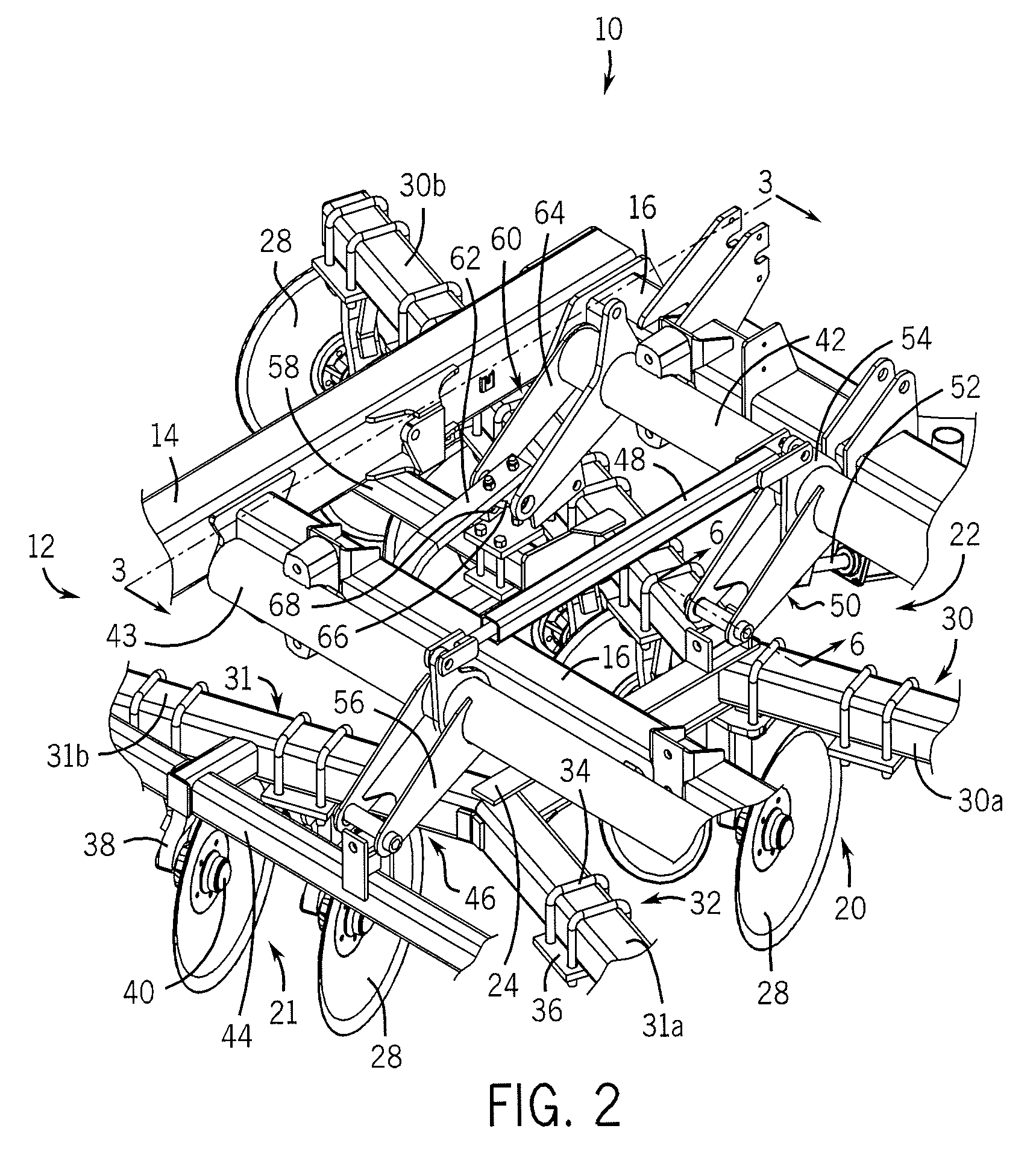

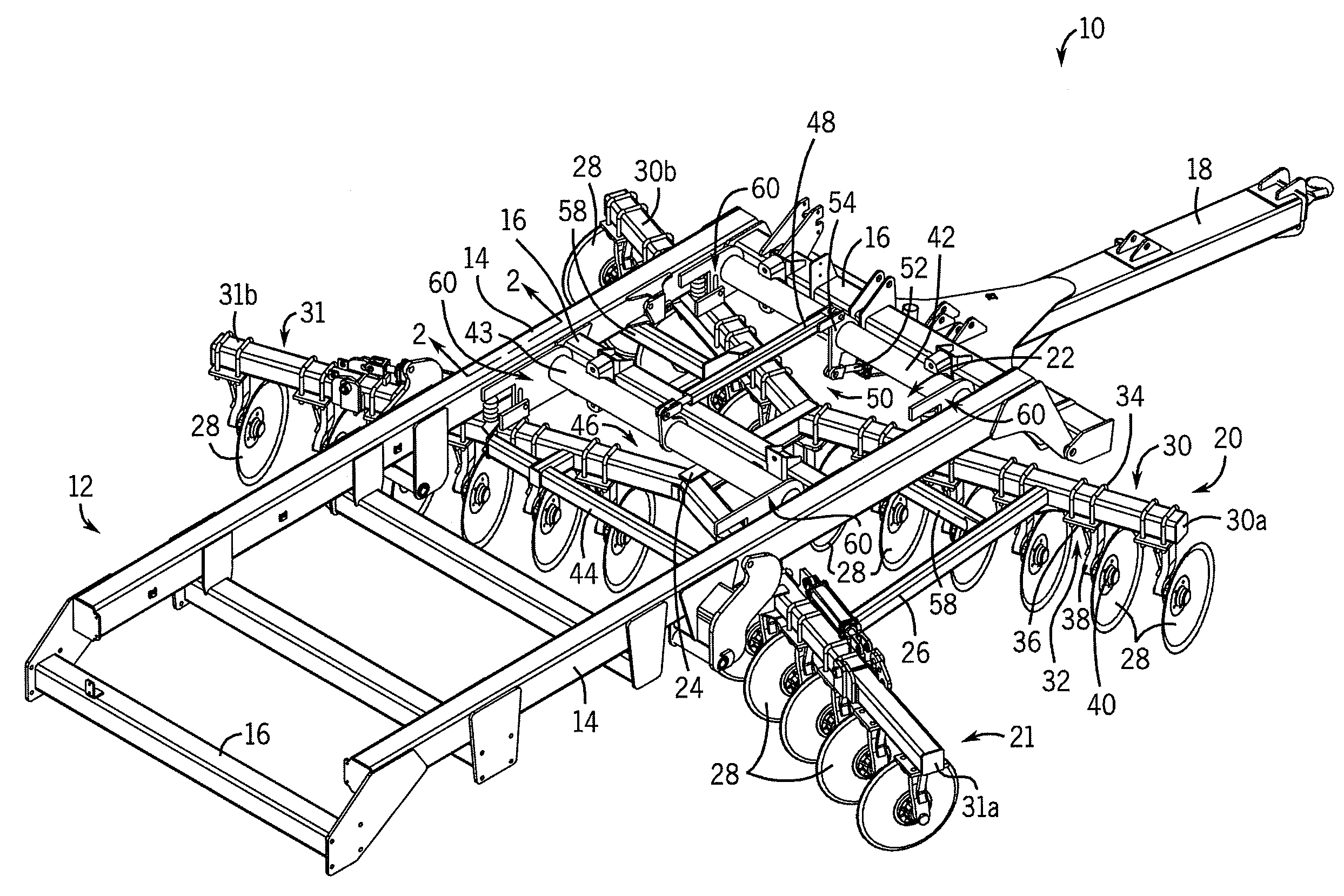

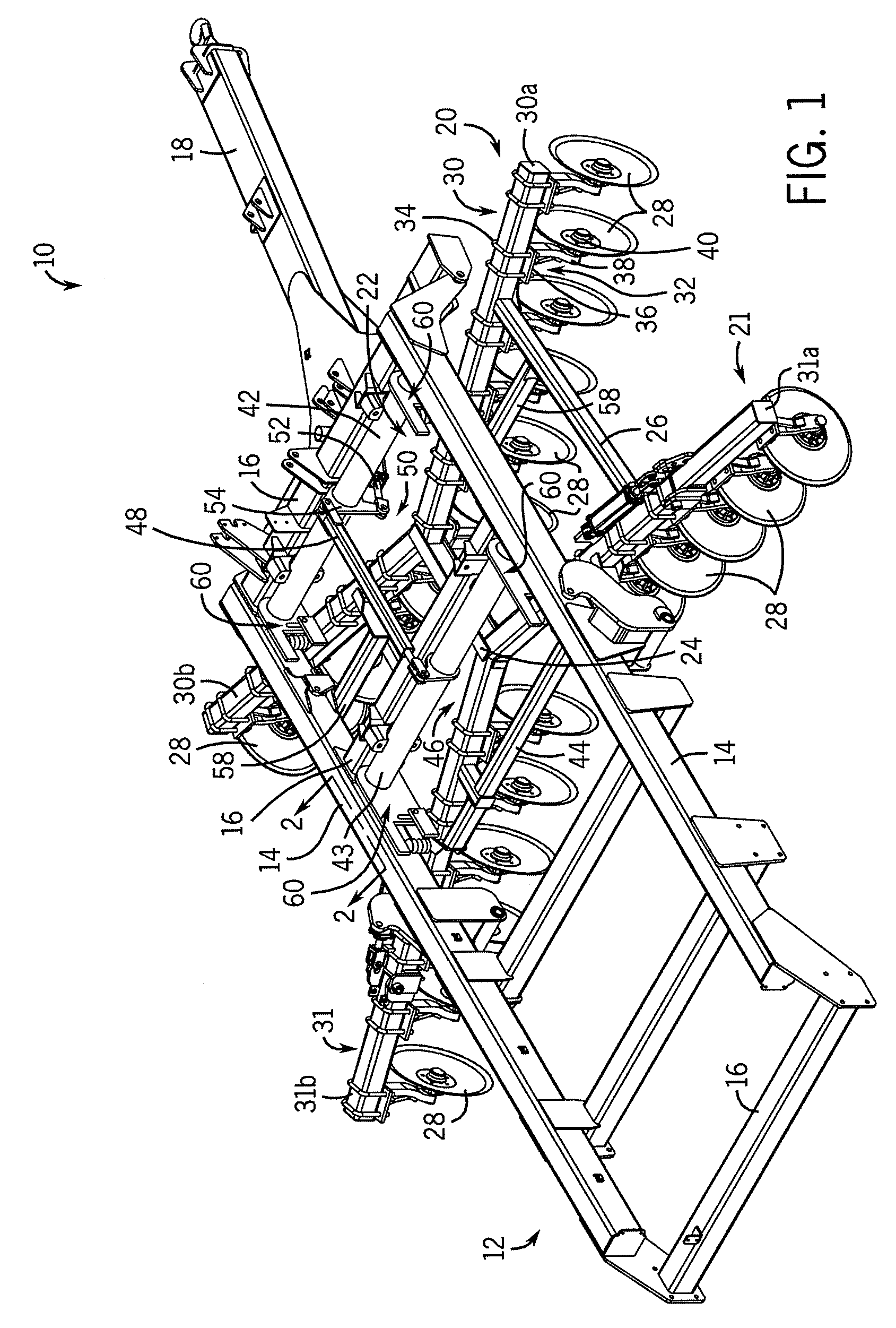

InactiveUS7743844B2Control impactReducing potentially-damaging impactAgricultural machinesSoil-working equipmentsTerrainCircular disc

A disc harrow composed of one or more disc gangs has a subframe coupled to the disc gangs to move the disc gangs in response to variations in farmland terrain to limit the impact of obstructions when encountered during the harrowing process. When the obstruction is cleared, the subframe automatically returns the disc gangs to their pre-obstruction position. In addition to reducing the potentially-damaging impact of obstructions, the subframe also maintains a more consistent reel depth during undulations or changes in the farmland terrain, such as during harrowing of slopes or unleveled fields such as valleys, near waterways, and along fence rows.

Owner:BLUE LEAF I P INC

Disc frame vibration dampening system

InactiveUS7578356B2Control impactReduce the amount requiredAgricultural machinesSoil-working equipmentsTerrainCircular disc

Owner:BLUE LEAF I P INC

Articulating and locking mechanism for farm implement chassis

ActiveUS7021394B2Fast and simple and safe mannerOvercome limitationsSpadesAgricultural machinesHydraulic cylinderLocking mechanism

Owner:MARCHESAN IMPLEMENTOS E MAQUINAS AGRI TATU

Adjustable scraper blade system for disk harrows

An adjustable scraper blade system for use with disk harrow implements is provided. The adjustable scraper blade system includes a mounting bracket secured at one end to the harrow implement, a scraper blade, and fasteners for selectively fixing the scraper blade in position. The scraper blade includes an arcuate scraping edge and an anchoring aperture defining an axis of pivotation of the scraper blade. It further includes an elongate adjustment slot that defines a range of arcuate adjustment of the scraper blade. The adjustability features of the adjustable scraper blade system facilitate alignment of the scraper blade so its scraping edge can be fixed in aligned face-to-face registration with the disk blade concave surface defining a clearance or gap therebetween of generally constant width.

Owner:CNH IND AMERICA LLC

Seedbed preparation implement having rotary disc with adjustable gang angle

A disc gang is provided that is suitable for use as part of a multifunctional seedbed preparation implement or in a standalone disc harrow. The disc gang is configured to permit a gang angle of the disc gang to be adjusted to accommodate differing soil conditions and / or to obtain different tillage characteristics. The disc gang may include a frame mounted on a mainframe of a primary tillage implement such as a cultivator. The frame includes a main beam mounted on the implement's mainframe and a disc support beam connected to the main beam and supporting a plurality of rotating discs. The gang angle can be infinitely adjusted through a designated range by pivoting one end of the disc gang about a vertical pivot axis while permitting another end portion of the disc gang to slide along a support surface for that end. The disc support beam may also be configured to be raised and lowered relative to the main beam so as to permit the cutting depth of the discs to be adjusted independently of the working depth of the remainder of the implement. The disc gang preferably is modular so as to negate the need for complex mechanical and hydraulic connections between the disc gang and the remainder of the implement.

Owner:CNH IND AMERICA LLC

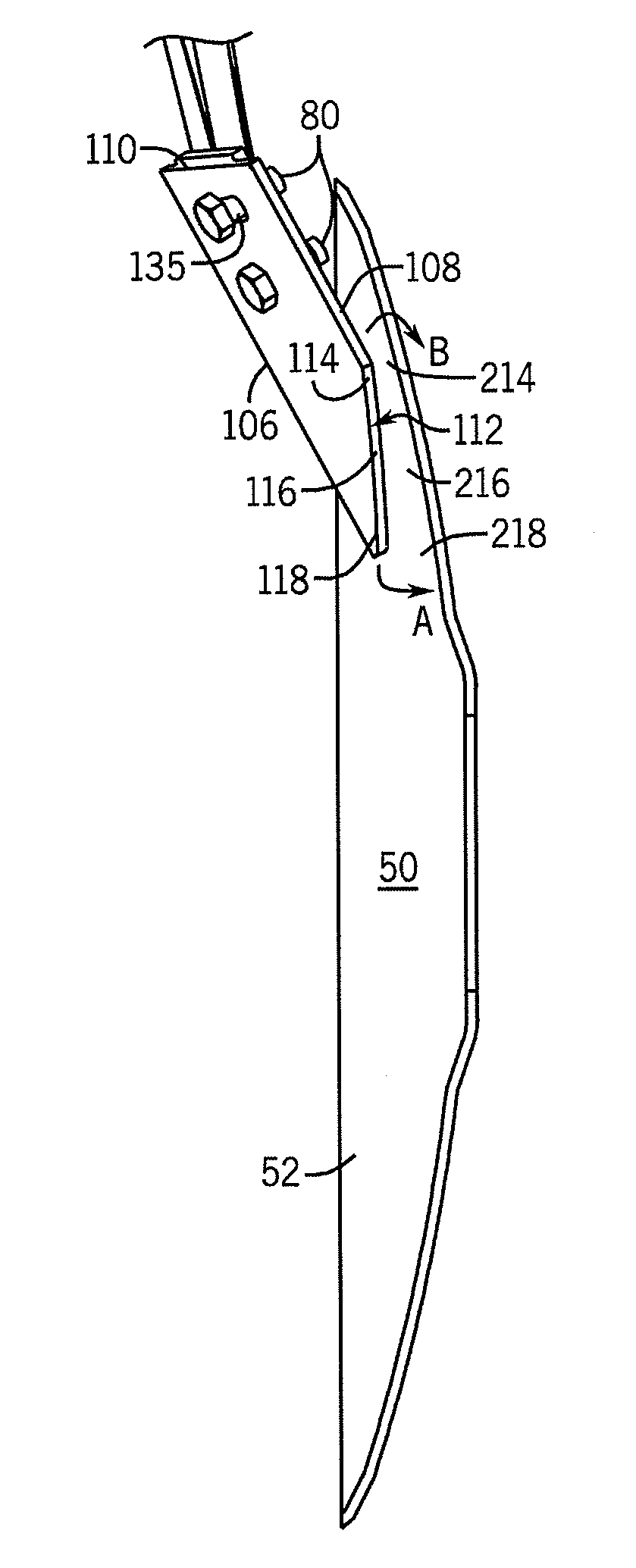

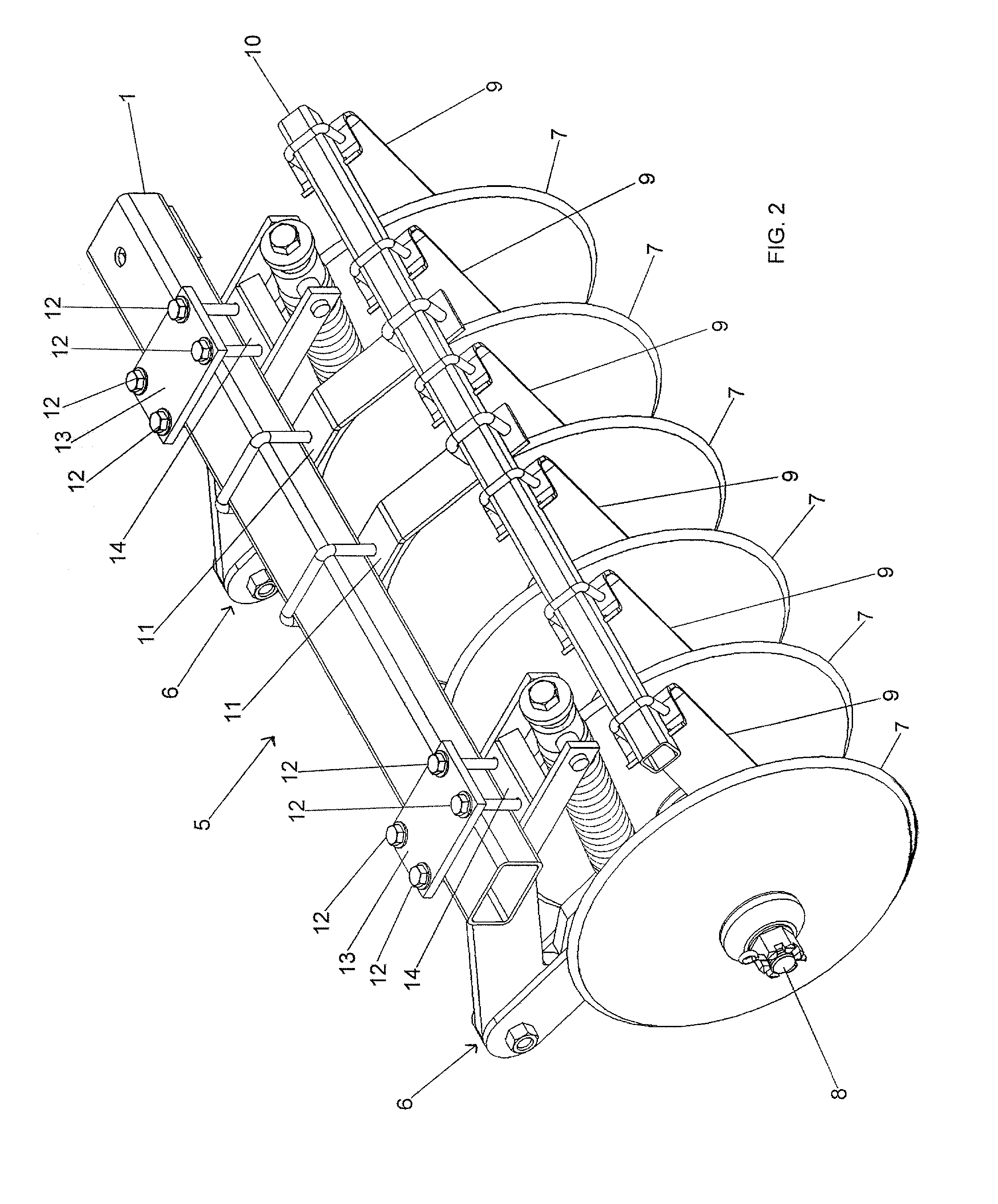

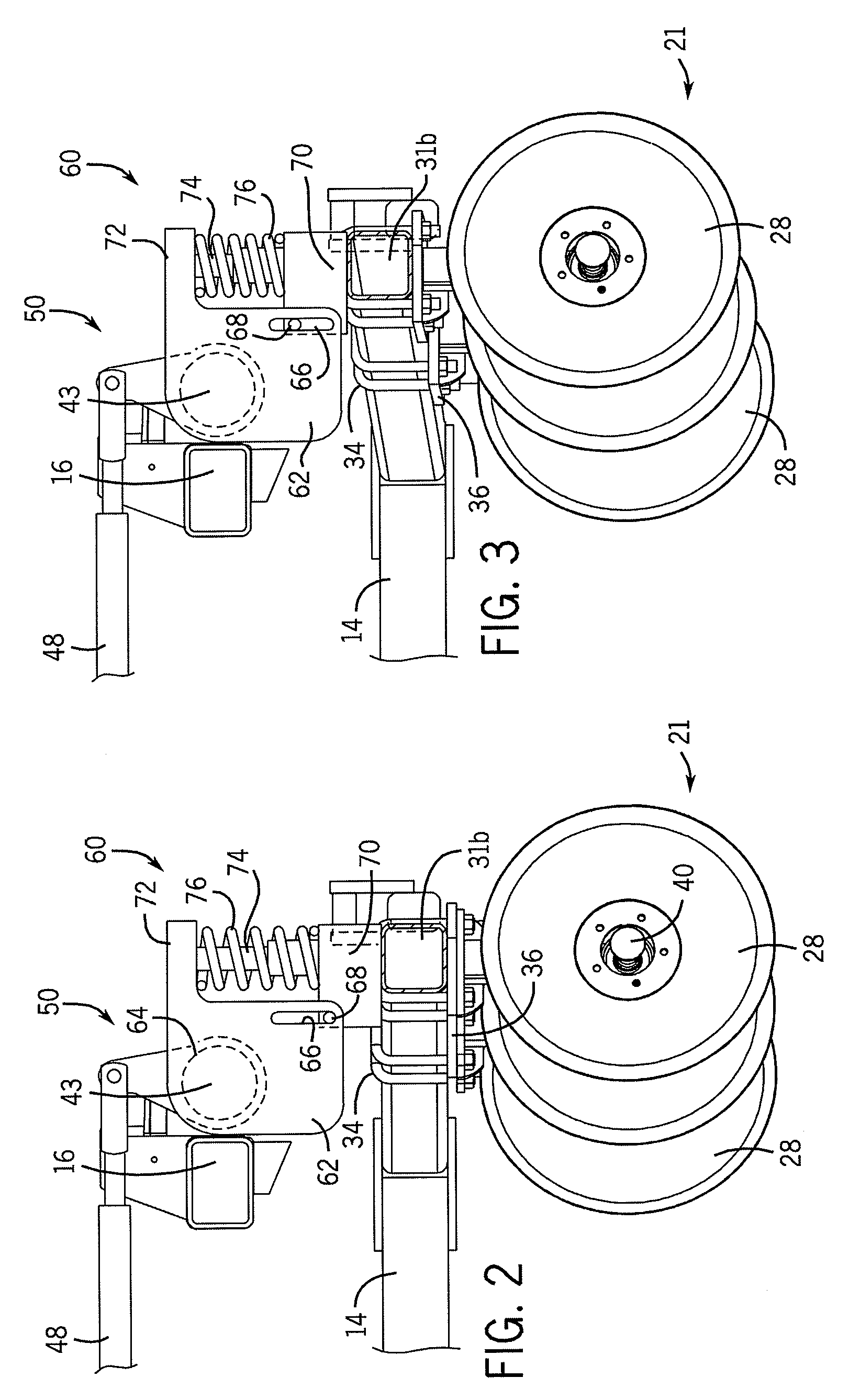

Spring rockflex bearing arm

A disc harrow has a frame and a plurality of earth working discs. Each disc has a central aperture for attachment to a gang shaft. A mount attaches the gang shaft to the underside of the frame and has bearings to permit rotation of the shaft in response to forward movement of the disc harrow. The mount includes a first structural member, a second structural member and a resilient spring connected between the two members. In operation, upon striking of an obstacle by the discs, the gang shaft is permitted to upwardly deflect by the mount to prevent damage to the disc harrow. The second structural member has first and second portions with aligned longitudinal axes. The first and second portions are rotationally connected to permit rotation of the second portion in response to an angular moment applied to the second portion by deflection of the gang shaft. The rotational connection permits the bearing to automatically maintain a preferred alignment with the gang shaft during deflection, thereby preventing damage to the bearing.

Owner:SALFORD FARM MACHINERY

Disc frame vibration dampening system

InactiveUS20090090523A1Control impactReduce the amount requiredAgricultural machinesSoil-working equipmentsCircular discTerrain

A disc harrow composed of one or more disc gangs has a subframe coupled to the disc gangs to move the disc gangs in response to variations in farmland terrain to limit the impact of ground variation when encountered during the harrowing process. When the obstruction is cleared, the subframe automatically returns the disc gangs to their pre-obstruction position. In addition to reducing the potentially-damaging impact of obstructions, the subframe also maintains a more consistent reel depth during undulations or changes in the farmland terrain, such as during harrowing of slopes or unleveled fields such as valleys, near waterways, and along fence rows.

Owner:BLUE LEAF I P

Sugar cane planter

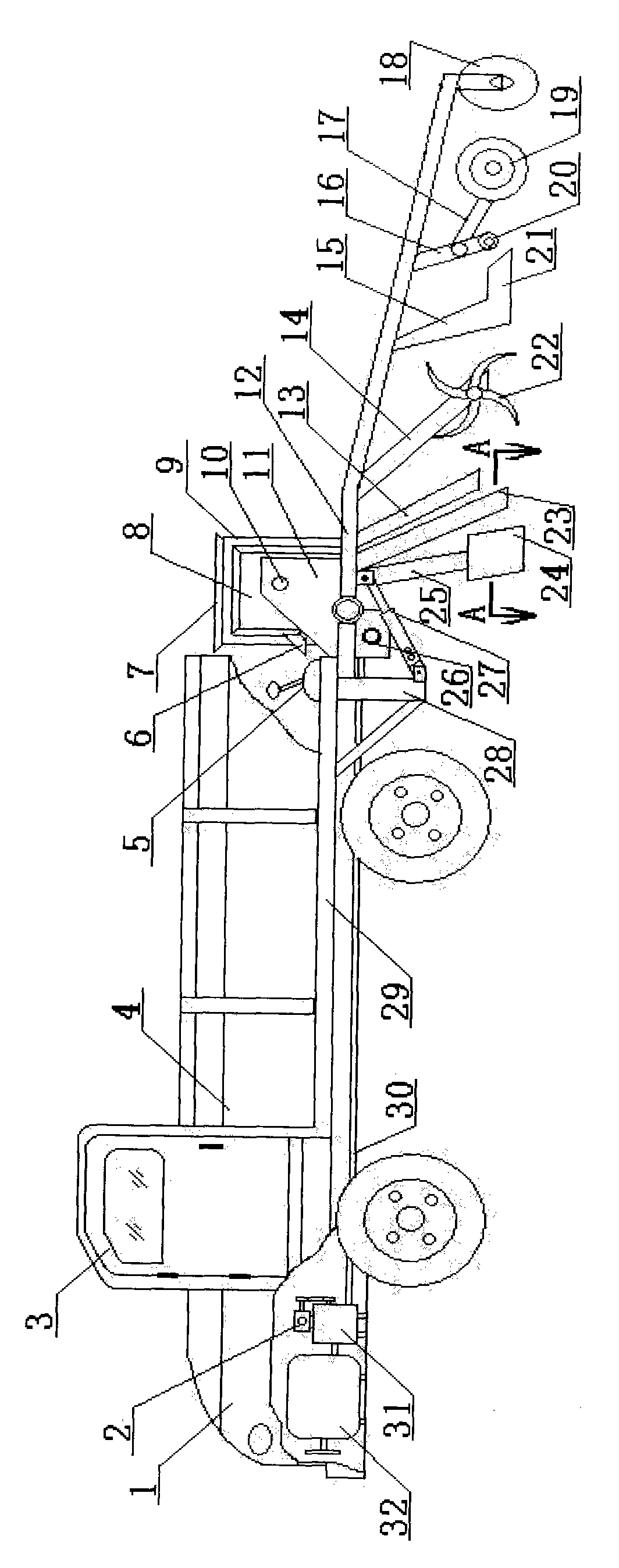

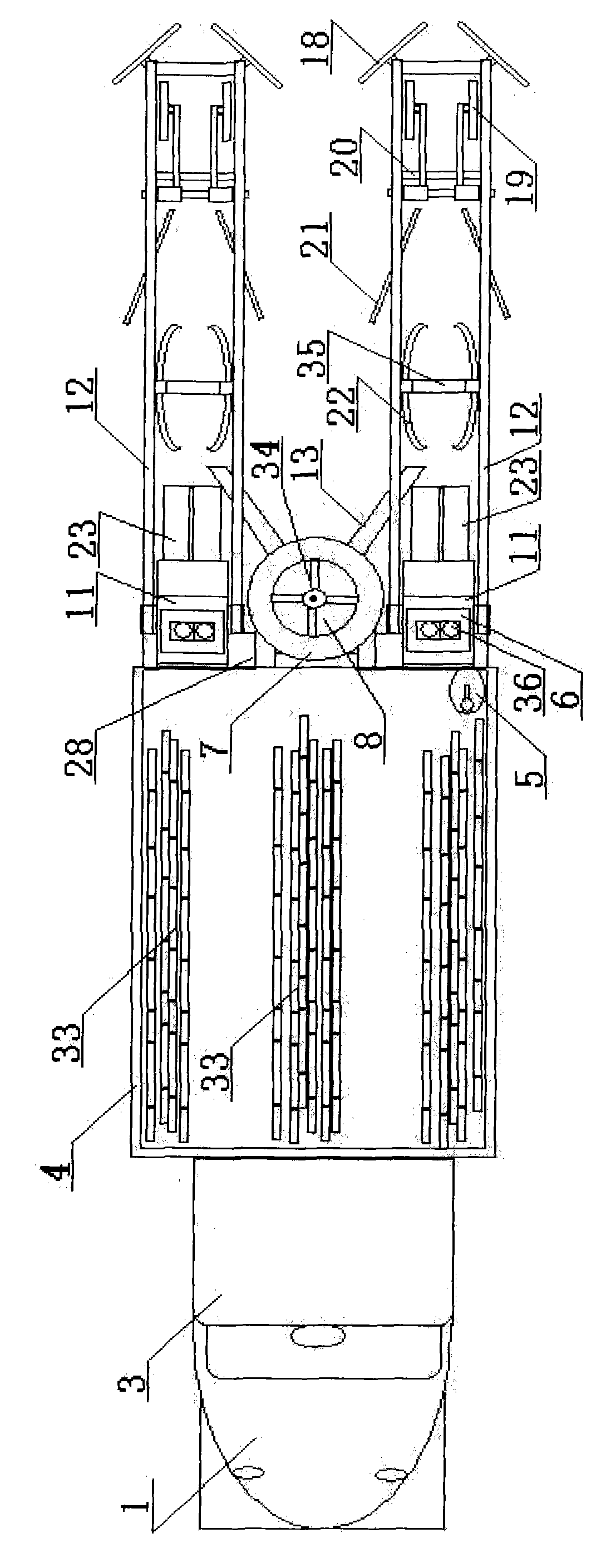

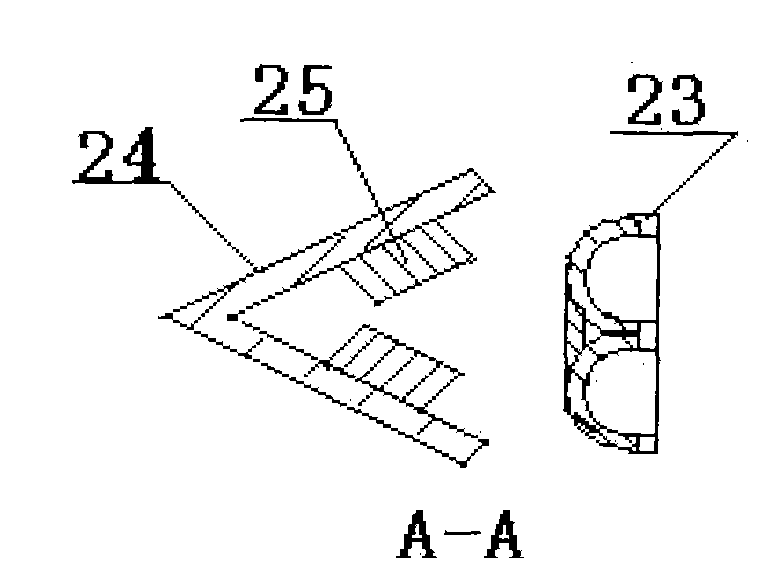

InactiveCN102150495AEasy to disassembleShorten the timeSeed depositing seeder partsPlant protective coveringsHydraulic cylinderAgricultural engineering

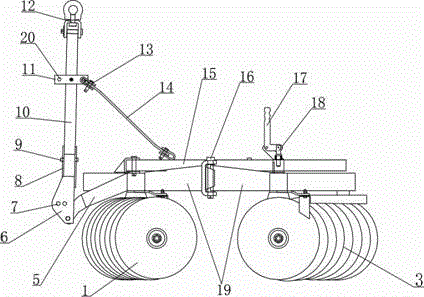

The invention discloses a sugar cane planter which comprises a motor vehicle with an engine and a loading carriage and is characterized by also comprising a rack, arm supports, a cane seed sectionalizer, a cane seed diversion trench, a V-shaped mud guider, a rotary tillage harrow, a splayed mud scrapping plate, a film mulching frame, a film pressing wheel, a disc harrow, a hydraulic cylinder and a fertilizer applicator, wherein the rack is fixedly connected with the rear end of the carriage; the arm supports mainly comprise two parallel levers, and the front ends of the arm supports are connected with the rack in a vertical rotation way; the cane seed sectionalizer and the cane seed diversion trench are arranged between the two parallel levers of the arm supports; the V-shaped mud guider, the rotary tillage harrow, the splayed mud scrapping plate, the film mulching frame, the film pressing wheel and the disc harrow are arranged behind the cane seed sectionalizer and under the arm supports in sequence; the hydraulic cylinder is arranged between the rack and the arm supports and enables the rear ends of the arm supports to rise / descend; and the fertilizer applicator is arranged at the middle part of the rear side of the rack and between the two arm supports at two sides. The distance between the two arm supports at two sides is equal to the distance between two cane planting ditches, and the arm supports are arranged above the cane planting ditches. The planter is concise and practical, basically realizes mechanical automation for sugar cane planting, can greatly save manpower and material resources, has a remarkable cane planting effect, and is suitable for sugar cane planting on a cane field with the area being more than 0.5mu.

Owner:彭志强

Soil preparation and pesticide spraying combined machine

InactiveCN103891439AAvoid volatile lossReduce harmful compactionSpadesPloughsProduction rateEngineering

The invention belongs to agricultural equipment, and relates to a soil preparation and pesticide spraying combined machine which comprises a traction frame, a pesticide spraying device, a rack, a pesticide box, a disc harrow set, a lifting oil cylinder, a conveying wheel, a soil crushing roll, a soil crushing and pressing roll frame, a supporting arm and a pressing roll. The pesticide box is arranged on the rack. The pesticide spraying device is arranged on the front portion of the rack, and the disc harrow set, the soil crushing roll and the pressing roll are arranged on the lower portion of the rack. The soil crushing roll and the pressing roll are arranged on the soil crushing and pressing roll frame through bearings, one end of the supporting arm is fixedly connected with the rack, and the other end of the supporting arm is hinged to the soil crushing and pressing roll frame. When the machine works, the pesticide spraying device firstly sprays pesticide on the earth surface, then the disc harrow set carries out soil aeration and soil loosening work, meanwhile, the pesticide and soil are mixed, then the soil is crushed through the soil crushing roll and is further mixed with the pesticide, and finally the soil is pressed by the pressing roll. The soil preparation and pesticide spraying combined machine is adopted for work, the pesticide and the soil can be mixed timely, volatilization losses of the pesticide are avoided, and meanwhile the production rate of the machine is improved.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

Traveling leaf pulling mechanism

A traveling leaf pulling mechanism is applicable to operating with an operation machine for farmlands or ridges with residual sugarcane leaves after sugarcane is harvested and mainly comprises fixing blocks of connecting sleeves, 7-shaped shafts, T-shaped sleeves, adjusting blocks of vertical tubes of connecting rods, adjusting fixing plates, disc harrows, bearing blocks of connecting shaft seats and connecting shafts. The fixing blocks of the connecting sleeves, the 7-shaped shafts, the T-shaped sleeves, the adjusting blocks of the vertical tubes of the connecting rods, the adjusting fixing plates, the disc harrows, the bearing blocks of the connecting shaft seats and the connecting shafts are respectively symmetrically fixed to a left suspension beam and a right suspension beam at the rear of a tractor and are connected with one another correspondingly. The traveling leaf pulling mechanism is simple, compact and practical in structure.

Owner:广西农业机械研究院有限公司

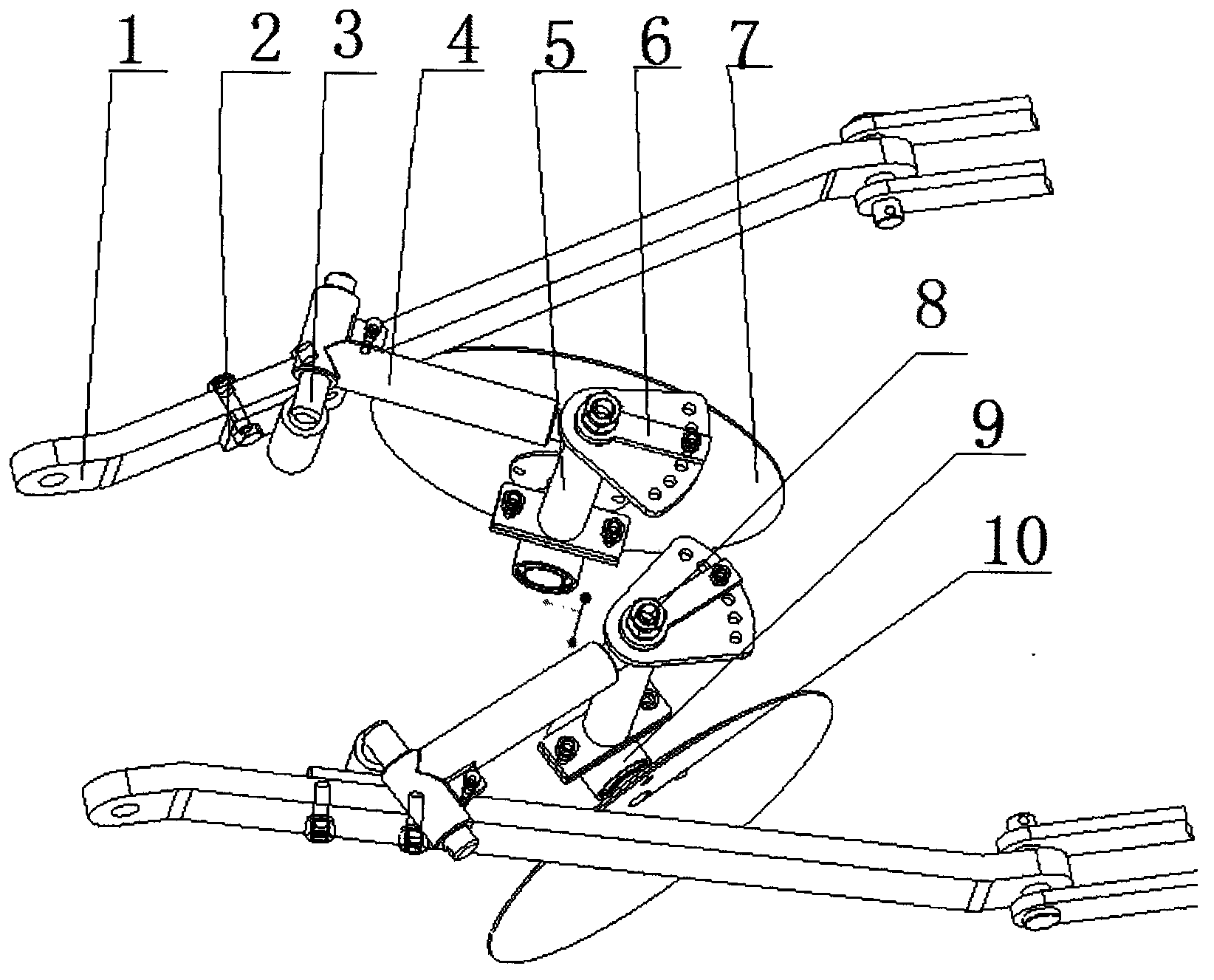

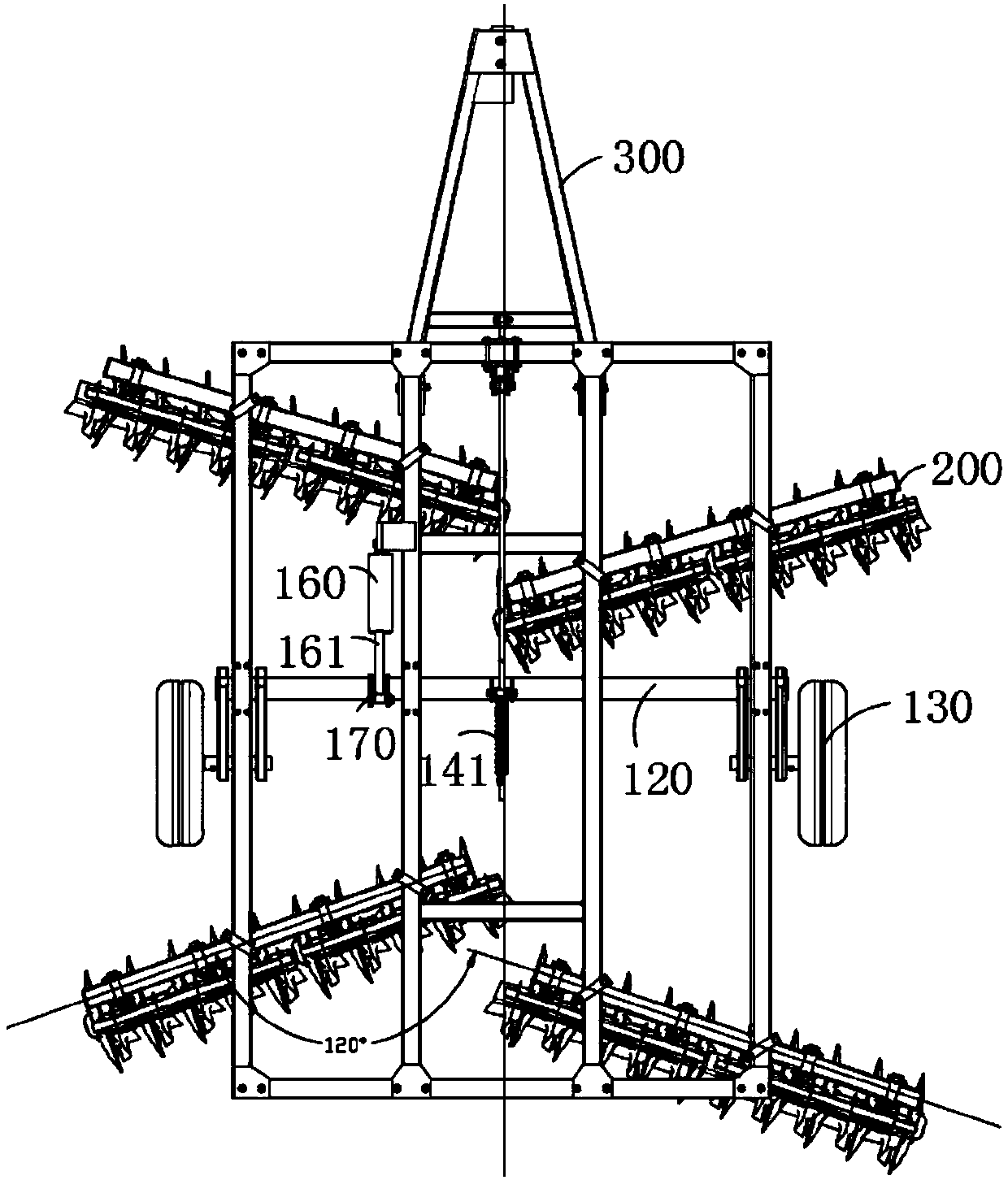

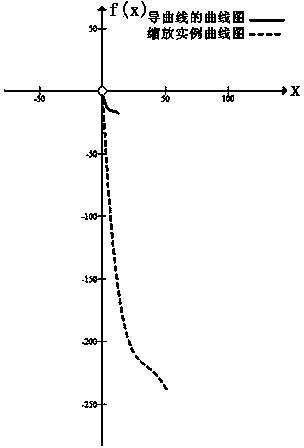

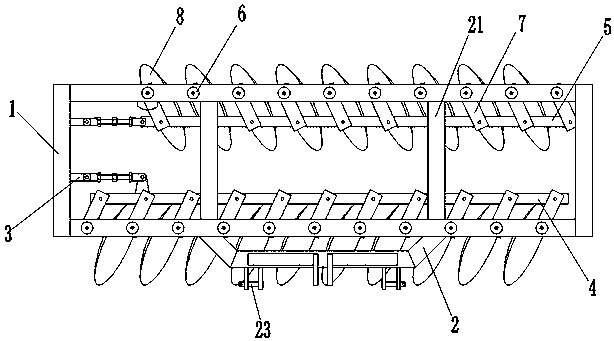

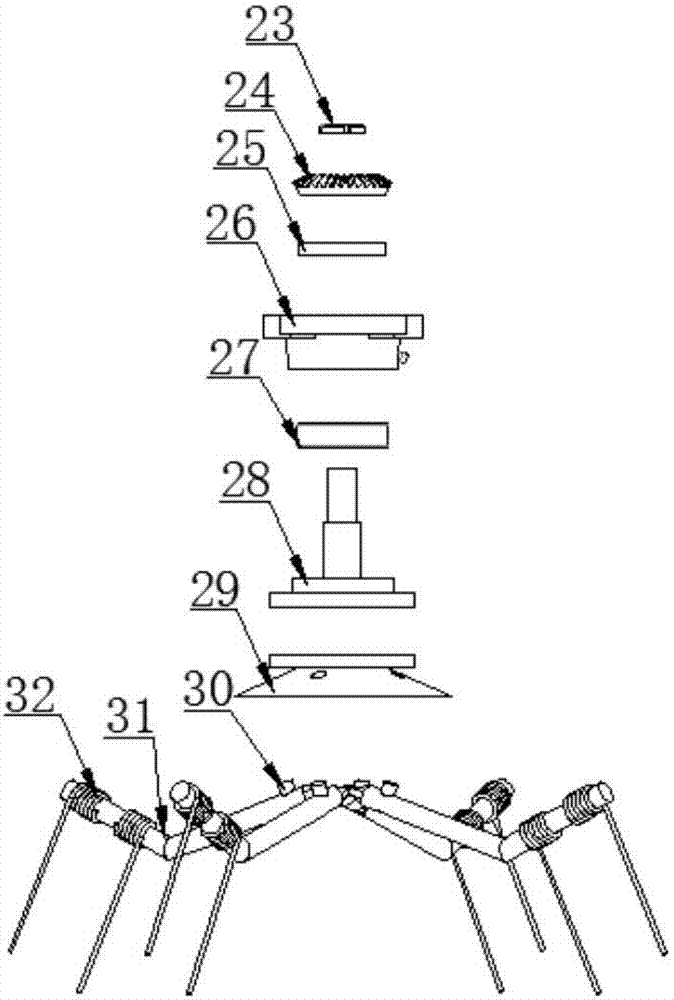

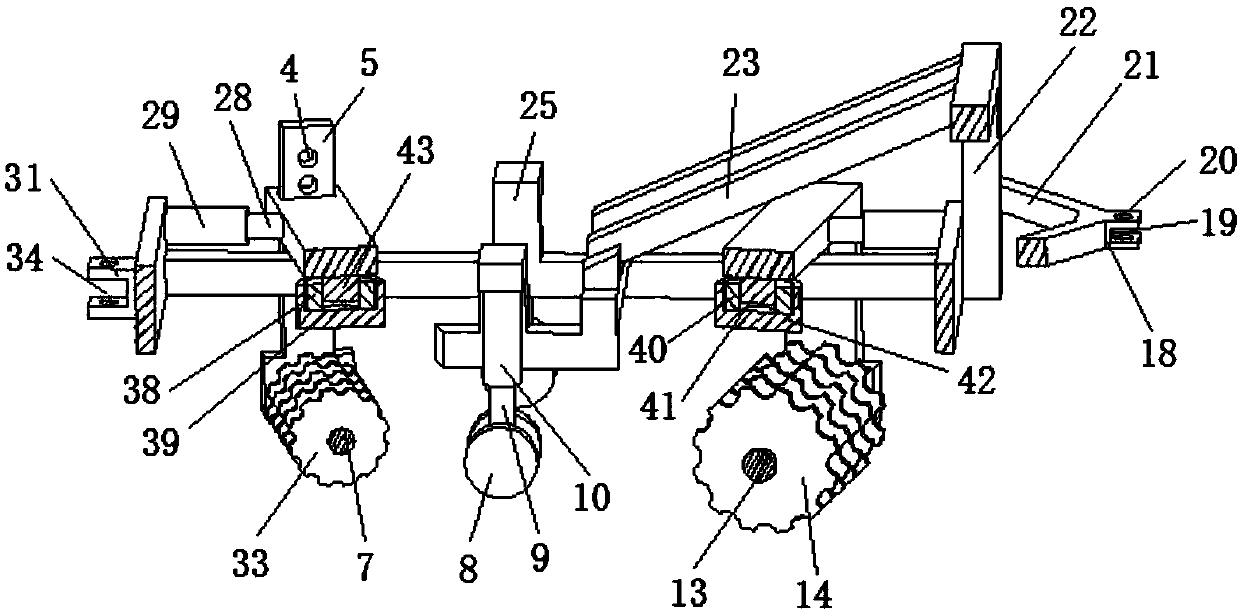

Novel disc harrow and using method thereof

The invention relates to a novel disc harrow and a using method thereof, and belongs to the technical field of disc harrows. The novel disc harrow comprises a rack and a plurality of harrow assemblies, wherein the harrow assemblies are detachably connected with the rack; the rack has a square structure formed by a plurality of side beams in a welded manner; the rack is provided with a traction rack in the symmetric axis direction; a wheel axle is transversely arranged in the middle of the rack; wheels are arranged at two ends of the wheel axle; a connecting rod control mechanism is arranged inthe middle of the rack; one end of the connecting rod control mechanism is fixedly connected with the side beams of the rack while the other end is connected with the wheel axle; the harrow assemblies are arranged on the two sides of the rack in a staggered manner along the symmetric axis of the rack; and the cross beams of each two adjacent harrow assemblies form an angle of 120 degrees; and thelowest end of each harrow assembly is lower than the lowest end of a wheel. The novel disc harrow has the advantages of high cultivation efficiency, large cultivation area, good effect, convenience in use and avoidance of loosening even if the harrow assemblies are used for a long time.

Owner:北京德邦大为科技股份有限公司

Disc harrow with gang plugging detection

A disc harrow implement has gang assemblies each having aligned disc gangs carried by a support bar. Each disc gang has disc blades spaced along an axis of the disc gang. The disc gangs of each gang assembly are coaxially aligned to create a line of substantially equally spaced disc blades. A plugging detection system alerts an operator if one or more of the disc gangs are rotating at a rotational speed that is slower than rotational speeds of the remaining disc gangs. The plugging detection system includes a gang rotation sensor for each of disc gangs. Each gang rotation sensor is configured to measure the rotational speed of the connected disc gang. A control module compares the rotational speed of each disc gang to the rotational speed of the disc gangs and generates an output that indicates when a disc gang is rotating more slowly that the other disc gangs.

Owner:AGCO CORP

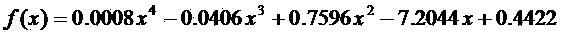

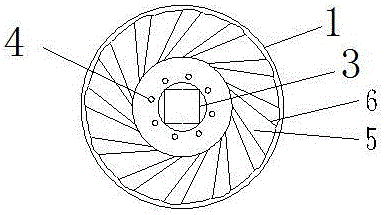

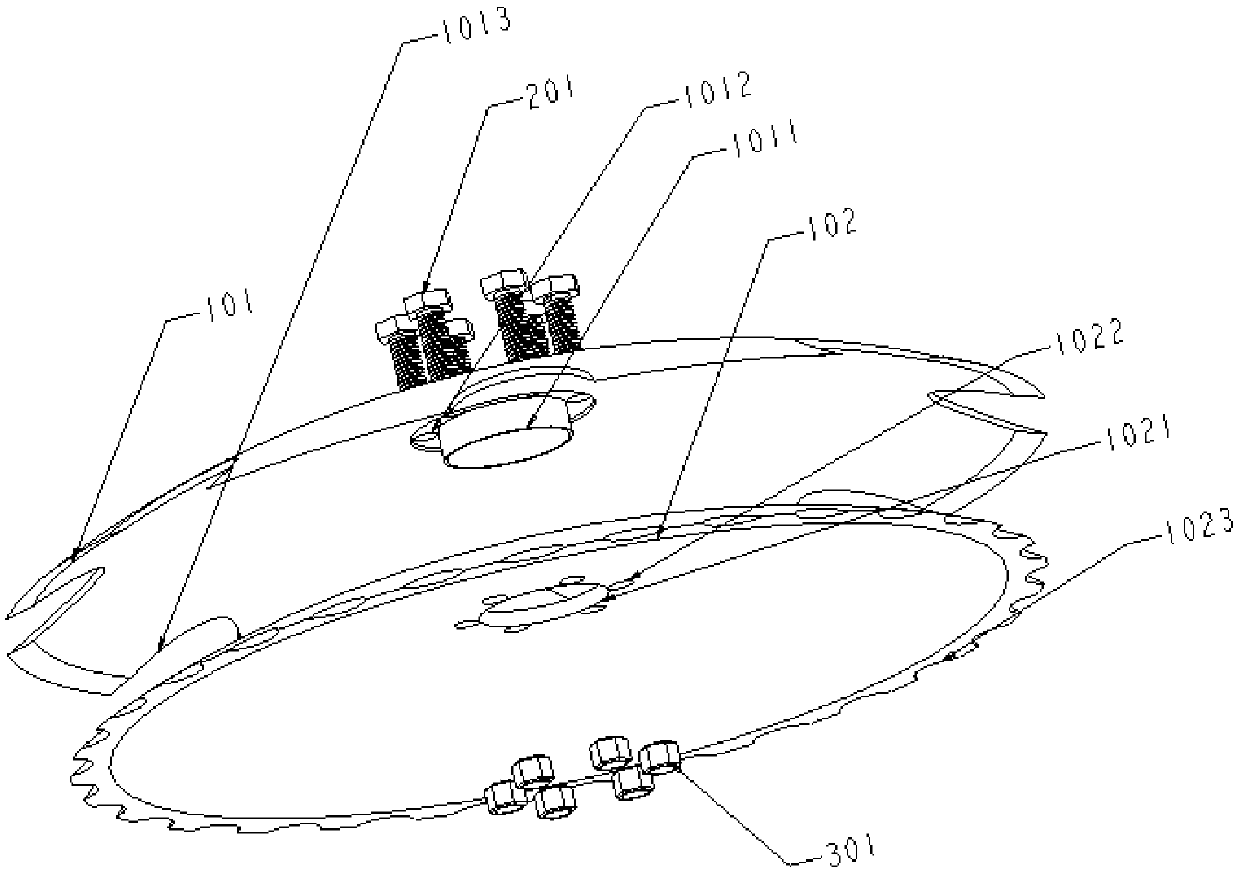

Variable-curvature soil-desorption/resistance-reduction disc harrow

The invention provides a variable-curvature soil-desorption / resistance-reduction disc harrow. The variable-curvature soil-desorption / resistance-reduction disc harrow comprises a disc harrow body which is of an integrated structure and uniform in thickness; an assembly part for connecting with a power device is arranged at the center of the disc harrow body; a cutting blade for breaking soil is arranged at the outer peripheral surface of the disc harrow body; disconnected circular-shaped cutting edges are evenly distributed on the cutting blade; the two convex and concave surfaces, arranged oppositely, of the disc harrow body are an outer soil contacting curved surface and an inner soil contacting curved surface, respectively; the inner soil contacting curved surface is a curved surface obtained based on 360-degree continuous rotating movement of a lead curve around the center of the disc harrow body, and the lead curve conforms to the equation f(x)=0.0008x4-0.0406x3+0.7596x2-7.2044x+0.4422, wherein the numerical area of x is within the range of 0-18. The variable-curvature soil-desorption / resistance-reduction disc harrow has the advantages that the variable-curvature inner soil contacting curved surface is attached on the disc harrow so that the contact probability of soil particles with the surface of the disc harrow is reduced, and the resistance and the adhesion of the soil to the surface of the disc harrow are decreased.

Owner:HENAN UNIV OF SCI & TECH

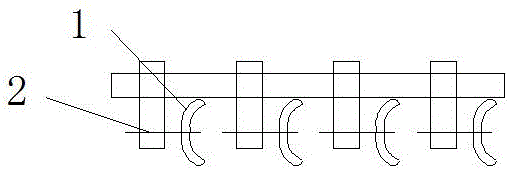

Novel folding disc harrow

The invention discloses a novel folding disc harrow which comprises a disc harrow section and spacing pipes. The novel folding disc harrow is characterized in that the disc harrow section is composed of a plurality of disc harrow blades which are loaded on a square shaft, an interval is kept between two adjacent disc harrow blades by virtue of one spacing pipe, a fixing hole is formed in the center of each disc harrow blade, small holes are distributed at the periphery of each fixing hole, radial concave slots are formed in the periphery of the disc harrow, radial convex slots are formed in the periphery of the disc harrow, intervals are kept between the concave slots and the convex slots, and a circular blade part is arranged at the edge of the disc harrow. The novel folding disc harrow has the characteristics of simple structure, strong manufacturability and good rigidity.

Owner:LIUZHOU YIHE TECH

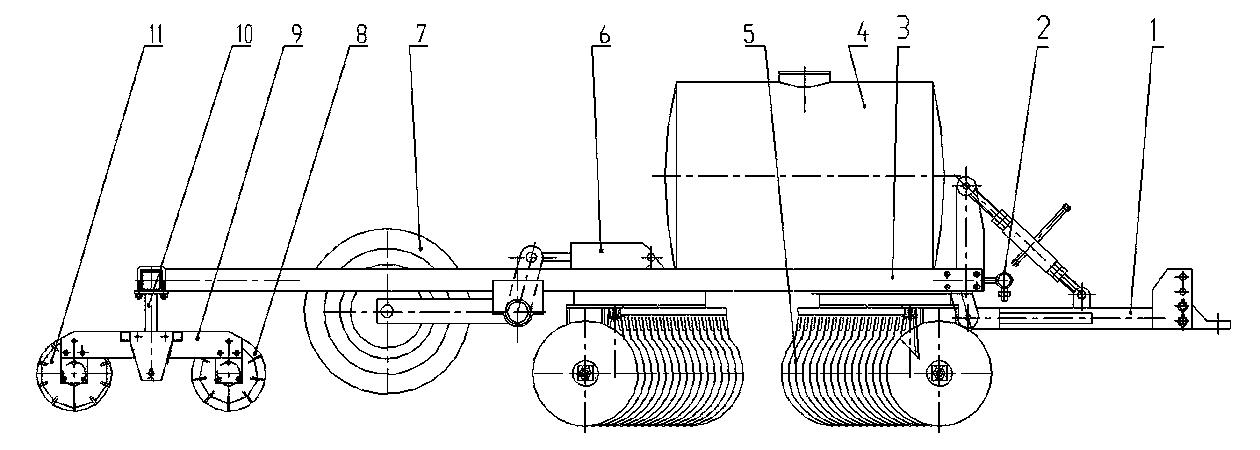

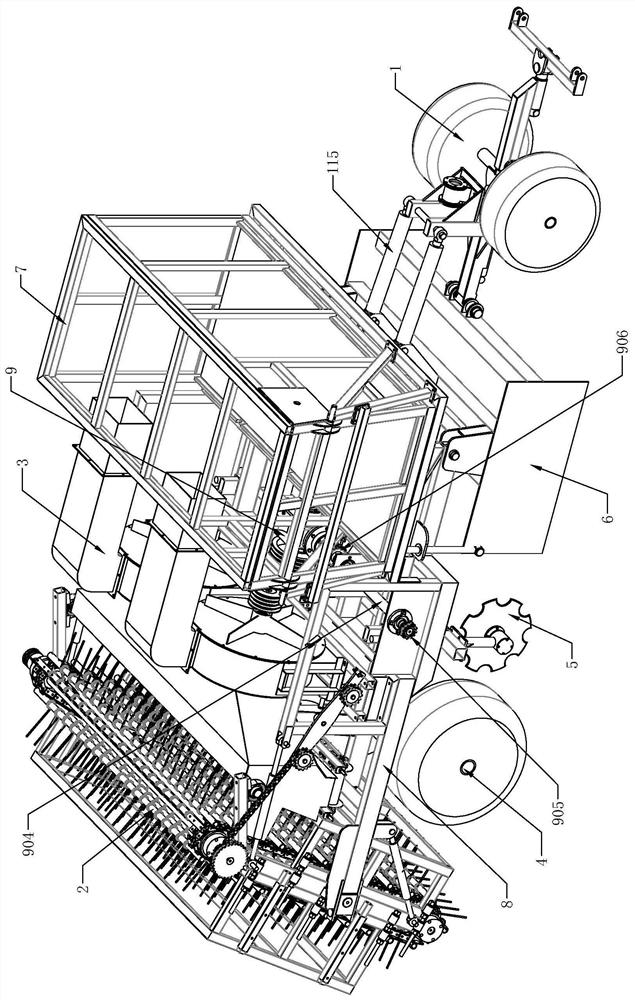

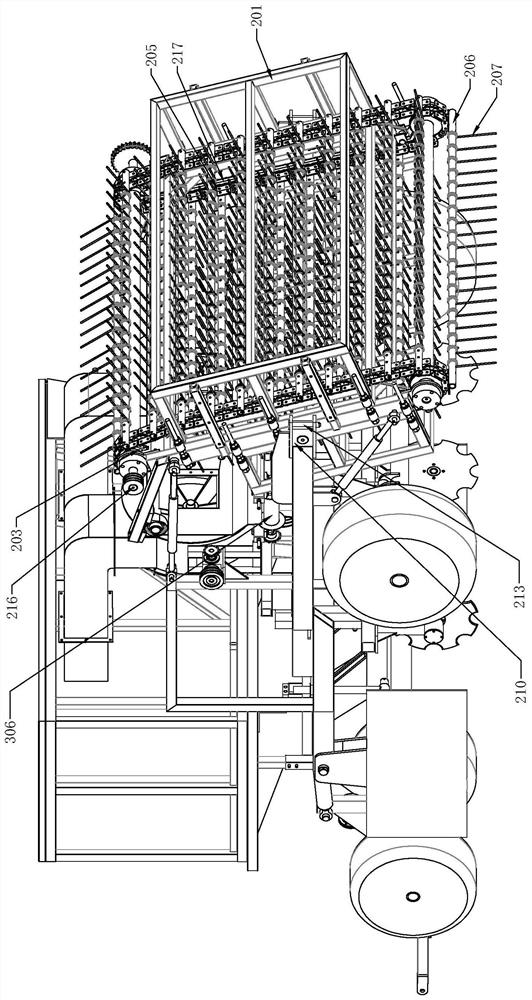

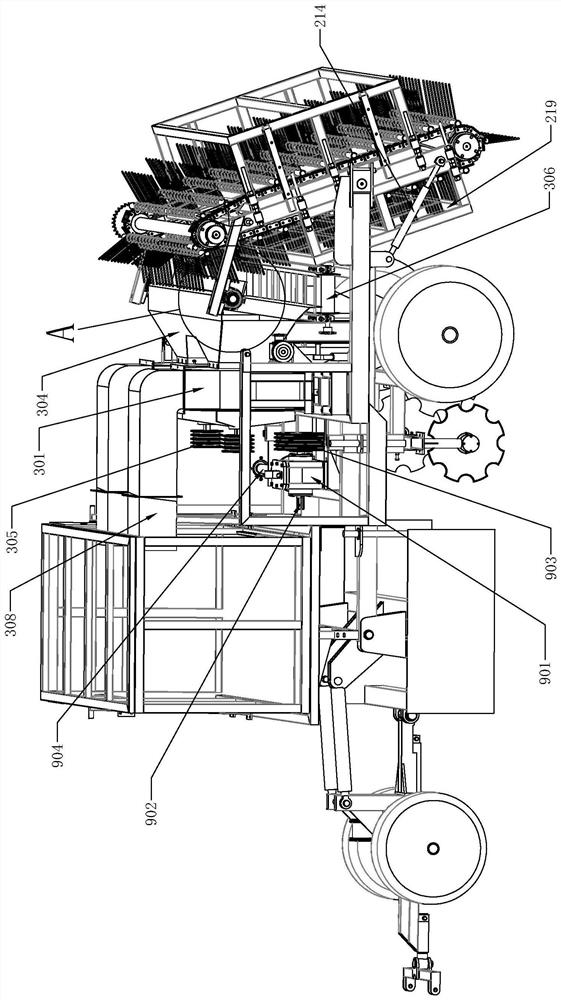

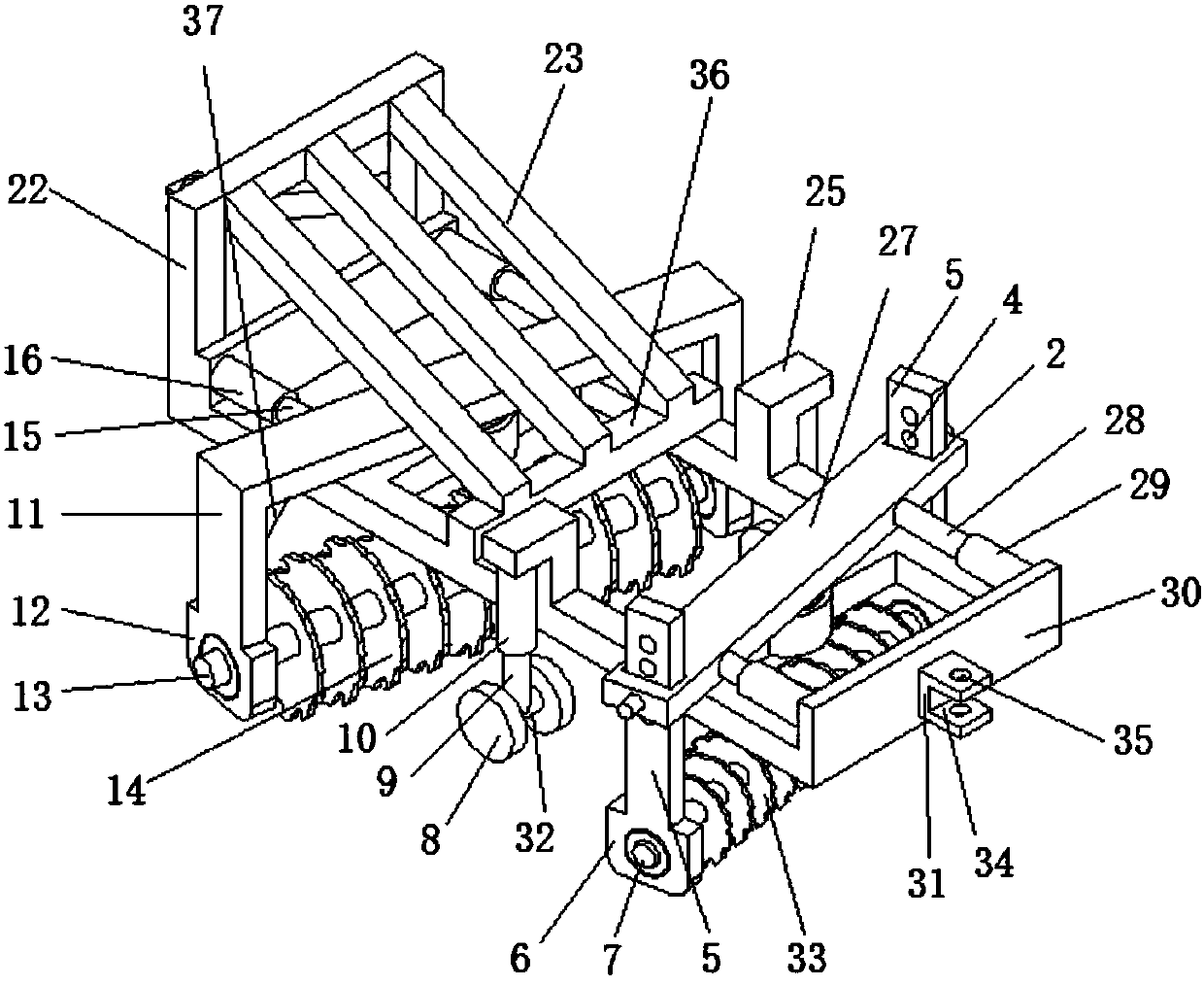

Traction type multi-functional residual film cleaning and recovering machine

The invention discloses a traction type multi-functional residual film cleaning and recovering machine. The traction type multi-functional residual film cleaning and recovering machine comprises a traction device, a vibrator tooth chain harrow device, a drainage and sorting device, lifting wheels, a plurality of film breaking disc harrow pieces, a rotary cultivator and a film recovery box, whereinthe traction device is rotatably connected with the front end of the machine frame; the rear end of the machine frame is used for rotatably supporting the oblique vibrator tooth chain harrow device;the discharge end at the upper end of the vibrator tooth chain harrow device communicates with the feeding end of the drainage and sorting device; the drainage and sorting device is mounted at the middle position of the upper surface of the machine frame; the lifting wheels which are driven to lift by a lifting hydraulic oil cylinder are supported by the bottom of the machine frame; two rows of the film breaking disc harrow pieces which are arranged in a spacing manner are fixed to the bottom of the machine frame on the front side of the lifting wheels; and the rotary cultivator is fixed to the film breaking disc harrow pieces, at the bottom of the front side of the machine frame. Through the adoption of the traction type multi-functional residual film cleaning and recovering machine disclosed by the invention, working procedures including stubble breaking, film removing, film and impurity separation, residual film storage and the like can be completed in one operation, so that the operation efficiency is high, and the performance is stable.

Owner:山东福生金地农业机械装备有限公司

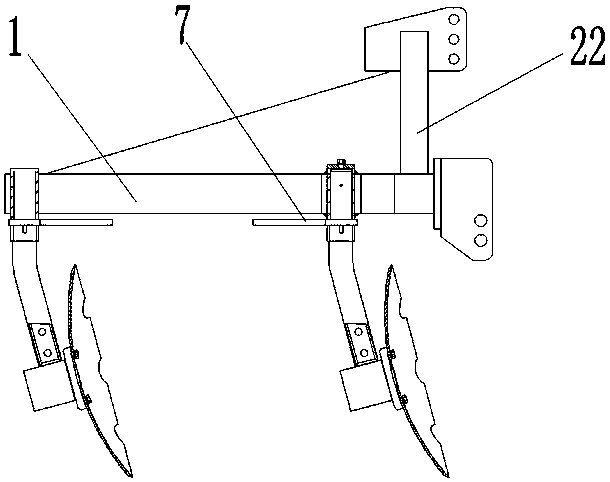

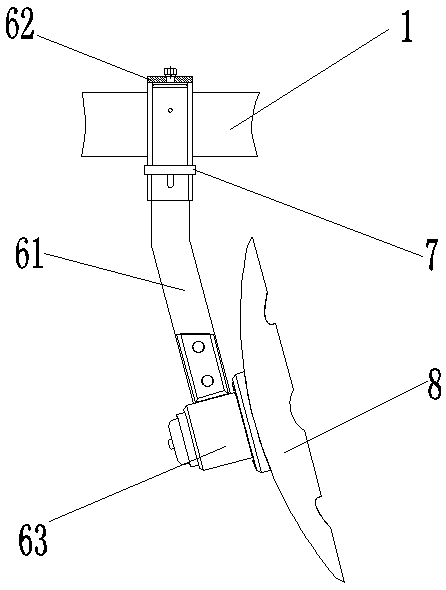

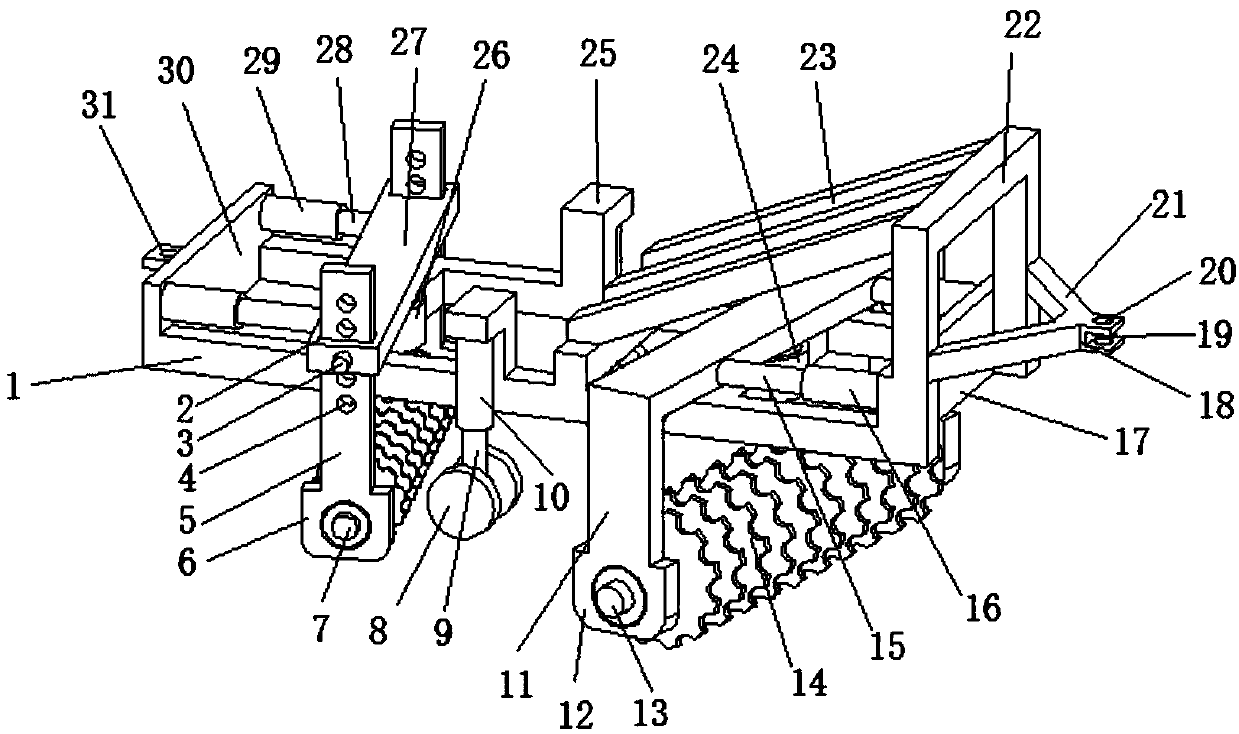

Medium-sized disc harrow convenient to adjust

PendingCN108738388AEasy to adjustEasy and labor-saving adjustmentHarrowsArchitectural engineeringDisc harrow

The invention discloses a medium-sized disc harrow convenient to adjust. The disc harrow comprises a harrow frame, a suspending lug support, adjustment screw rod assemblies, a front angle adjustment rod, a rear angle adjustment rod, independent harrow group assemblies, adjustment blocks and harrow pieces; a suspension mechanism is welded to the harrow frame, the independent harrow group assembliesin a row shape are arranged on front and rear beams of the harrow frame, the adjustment screw rod assemblies are movably connected to a side beam of the harrow frame and hinged to one end of the front angle adjustment rod and one end of the rear angle adjustment rod, the adjustment blocks are hinged to the outer walls of the front and rear angle adjustment rods, and each independent harrow groupassembly comprises a vertical column, a clamping member and a hinge base, wherein the top of the vertical column is fixed in the harrow frame through the clamping member; the adjustment blocks are welded to side beams of the vertical columns, the hinge bases are fixed to the bottoms of the vertical columns through screws, and the harrow pieces are arranged in the hinge bases. According to the discharrow, by adjusting screw rods in pulling rod assemblies, the front and rear angle adjustment rods are pulled to move, angles of the harrow pieces of the harrow group assemblies are easy and convenient to adjust, and manpower is saved.

Owner:YUCHENG YIJIA MACHINERY

Stubble removing and remained film recovering machine

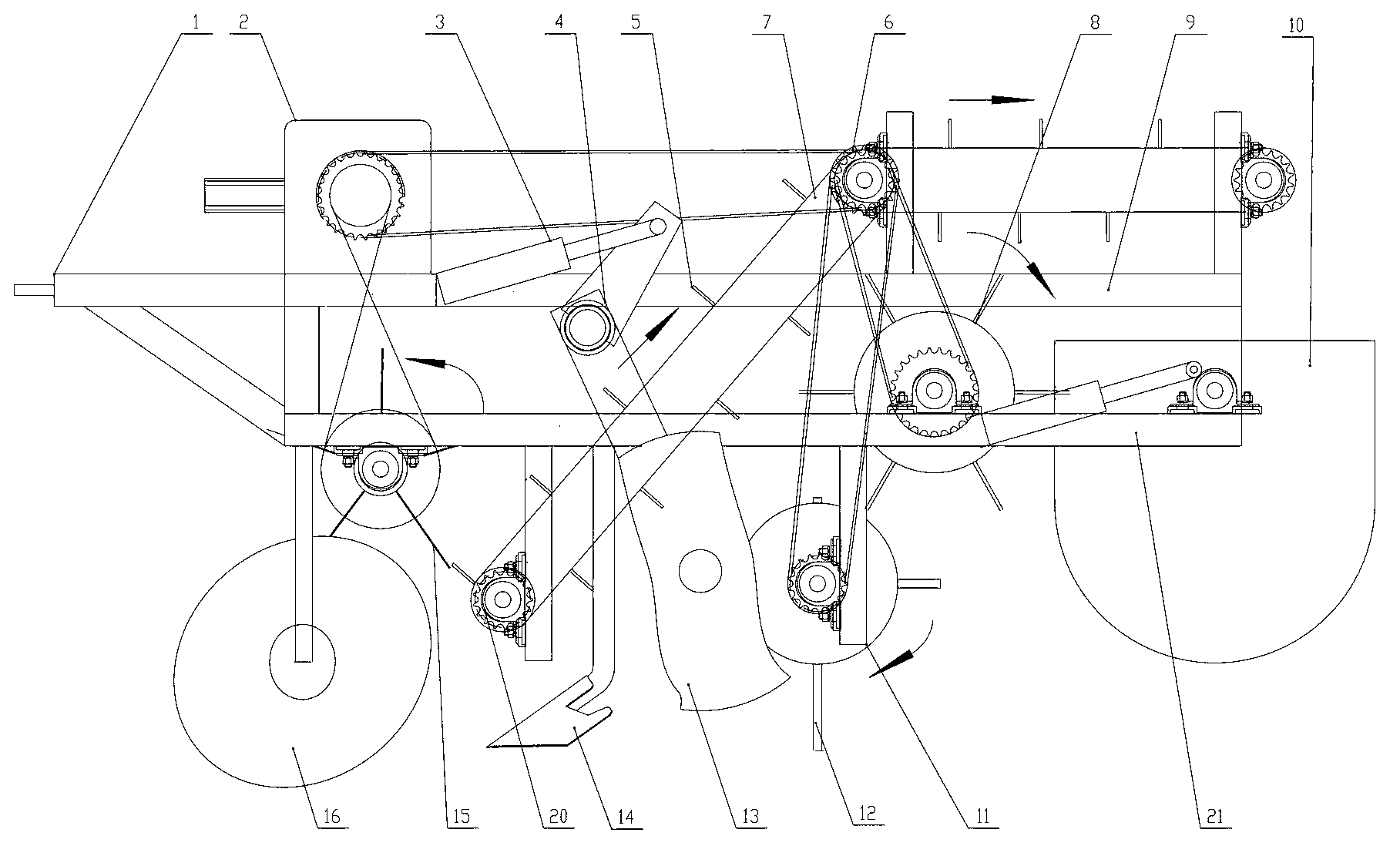

InactiveCN103004360AEasy to reuseHigh structural reliabilityMowersAgricultural engineeringTraction frame

The invention relates to the field of agricultural machinery, in particular to a stubble removing and remained film recovering machine, which is suitable for crops with larger root stubbles. The stubble removing and remained film recovering machine comprises a machine frame (9), wherein the machine frame (9) is provided with a traction frame (1) and a transmission system (2). The stubble removing and remained film recovering machine is characterized in that the back part of the machine frame (9) is provided with a remained film and root stubble box (10), a group of disc harrows (16) is fixedly arranged at the lower part of the front end of the machine frame (9), a root stubble scraping plate (15) is arranged between the group of disc harrows (16) and is positioned above the back part of the group of disc harrows (16), a conveyor belt (7) is correspondingly arranged at the lower side of the back part of the root stubble scraping plate (15), the conveyor belt (7) extends to the back part of the machine frame (9) through multi-stage transmission and corresponds to a back half box of the remained film and root stubble box (10), an edge film shovel (14) is arranged under the middle part of the machine frame (9), an eccentric adjusting shaft cylinder (11) is arranged on the machine frame (9), a film stripping plate (8) is correspondingly arranged above the back part of the eccentric adjusting shaft cylinder (11), and the back part of the film stripping plate (8) corresponds to a front half box of the remained film and root stubble box (10).

Owner:CHINA AGRI UNIV

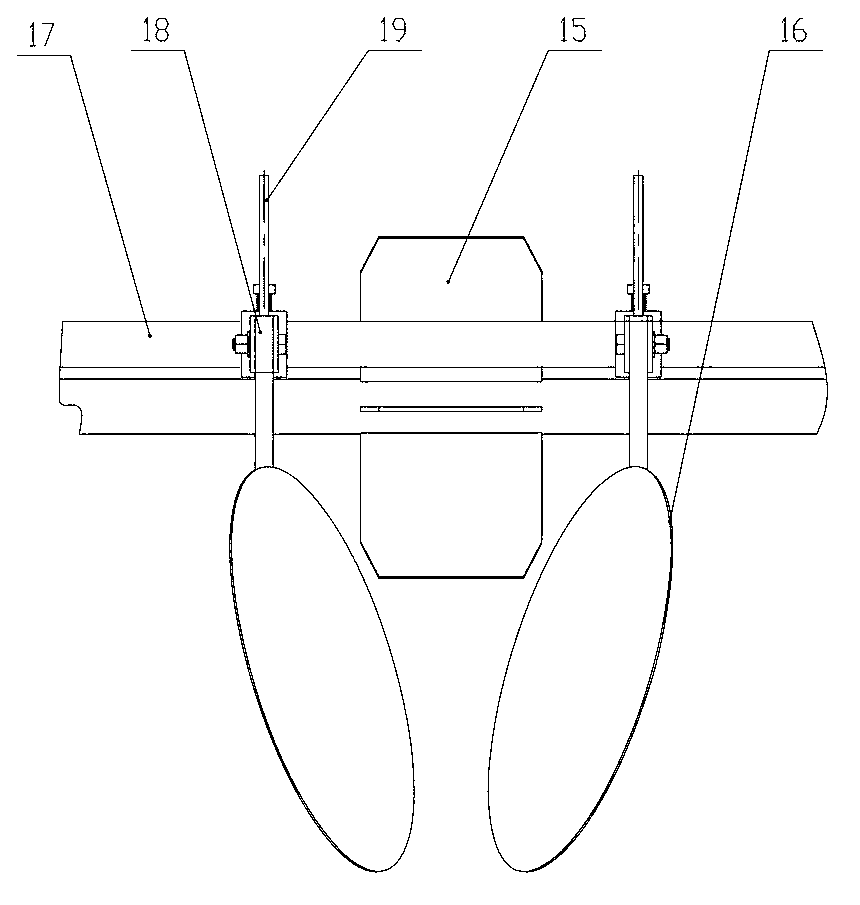

High-yielding planting machine for peanut wide-ridge planting

InactiveCN105594345ASolve the mismatch,Solve the problem of difficult promotionPlantingWatering devicesCircular discSeeder

The invention discloses a high-yielding planting machine for peanut wide-ridge planting. The machine includes a frame, a disc harrow opener, a laminating machine and a banking machine. The disc harrow opener is arranged at the front end of the frame; the laminating machine is arranged in the middle of the frame; a ground cover disc is arranged at the end of the frame; the front side of the disc harrow opener is provided with a sprinkler; a fertilizer bucket and a seeder are arranged between the disc harrow opener and the laminating machine in turn; a driving wheel is arranged between the fertilizer bucket and the seeder; both sides of the laminating machine are provided with a drug spraying device; the banking machine is arranged between the laminating machine and the ground cover disc; a driven wheel is arranged between the ground cover disc and the banking machine. The original two-ridge tillage is upgraded to three-ridge tillage, so as to effectively improve the efficiency of sowing, solve the problems of matching of a two-ridge peanut seeder with the local agricultural machinery, and the difficulty in promotion, and improve the land utilization. The seeder and the laminating machine are connected to reduce manual operation, and the structure is simple and easy to use, thereby effectively saving manpower and time.

Owner:王勇

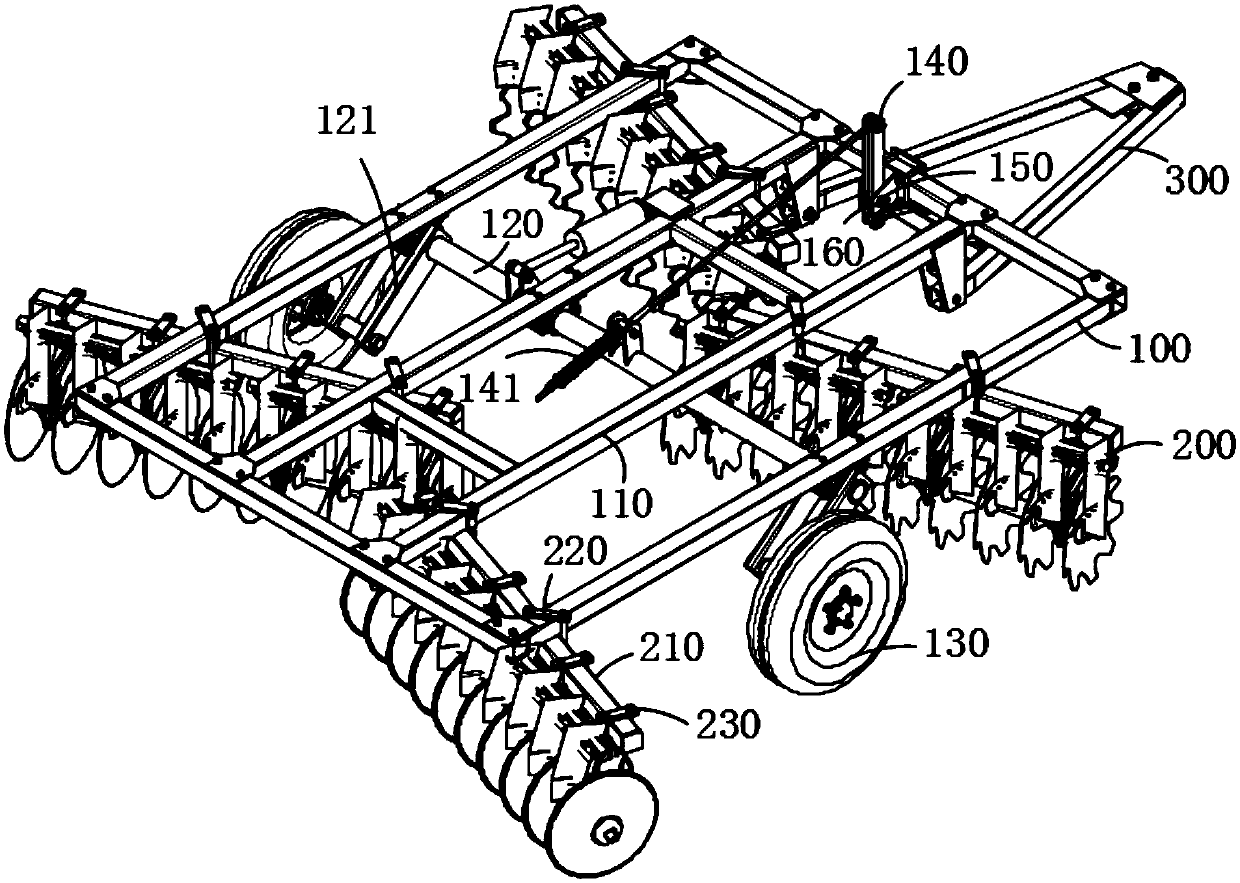

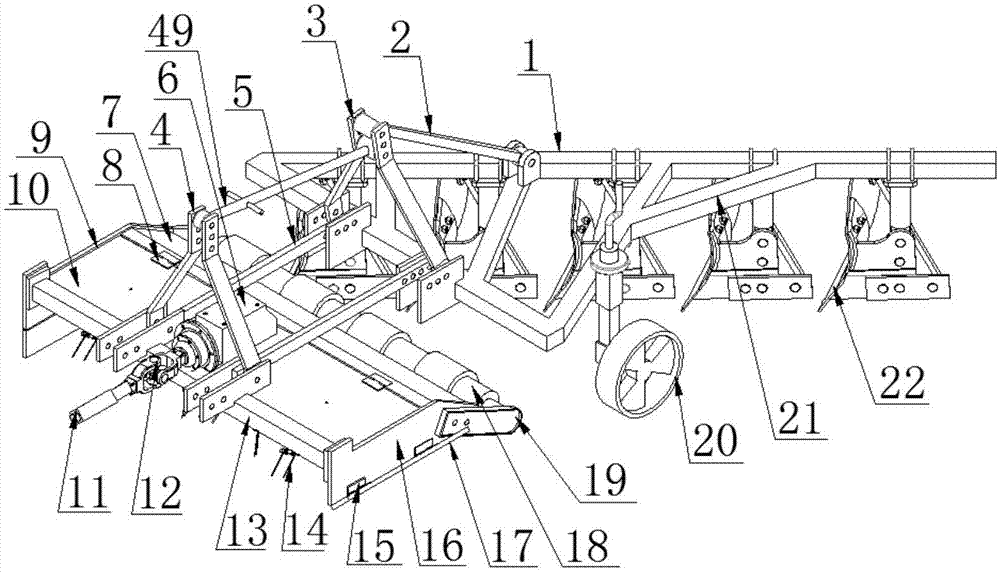

Straw throwing and burying combined machine

ActiveCN107950101AExpand the spreading widthRealize individual workSpadesAgricultural machinesAgricultural engineeringCentrifugal force

The invention relates to the field of agricultural equipment, in particular to a straw throwing and burying combined machine. The combined machine comprises a burying device (1), a hanging device (3),a throwing device (9) and a power transmission device (12). A vertical rotation mode is adopted by the throwing device (9) of the combined machine according to a tedding machine principle, and underthe action of centrifugal force, straw is thrown to the two sides; air flow is formed between adjacent throwing mechanisms (14), so that the straw throwing range is further expanded. When the combinedmachine goes to the field once, straw throwing work and straw burying work can be completed at the same time; meanwhile, the burying device (1) at the rear end of the combined machine can be removedso that separate straw throwing operation can be achieved, and moreover, combined operation of the throwing device (9) and a land preparation machine without power drive, such as a disc plough and a disc harrow, can be achieved through adjustment, the number of times for the machine to go to the field is reduced, and the energy consumption is reduced.

Owner:CHINA AGRI UNIV

Drag type disc harrow

The invention discloses a drag type disc harrow which comprises a frame body. A first rotating connecting piece is arranged on the left side of the upper surface of the frame body, a mounting plate isarranged at the upper end of the first rotating connecting piece, and both ends of the mounting plate are provided with mounting grooves, supporting plates are arranged in the mounting grooves and fixed to the mounting plate through adjusting pins, the lower ends of the supporting plates are provided with first bearing blocks, inner rings of the two first bearing blocks are in sleeving connectionwith first rotating shafts, first disc harrow pieces are evenly distributed on the outer surfaces of the first rotating shafts, the left end of the upper surface of the frame body is provided with afirst fixed plate, the two ends of the right side surface of the first fixed plate are provided with first electric telescopic rods, the first electric telescopic rods are connected with the mountingplate through first movable rods, and the right side of the upper surface of the frame body is provided with a second rotating connecting piece. The drag type disc harrow is convenient to use, the angle of the disc harrow pieces is adjusted conveniently without manual adjustment, the depth of the disc harrow pieces into the soil can be adjusted, and the work efficiency is high.

Owner:霍邱县夏时农机制造有限公司

Disc harrow blades suitable for agricultural machines

The invention provides a disc harrow blade suitable for agricultural machines, comprising a main harrow blade, an auxiliary harrow blade, a plurality of clamping bolts and a plurality of fixing nuts; the main harrow blade passes through a plurality of clamping bolts and a plurality of fixing nuts It is connected with the auxiliary rake; the auxiliary rake is set under the main rake, the first rake is arranged on the main rake, and the second rake is arranged on the auxiliary rake, and the stress of the device is controlled by the main rake and the auxiliary rake. The structure as a whole is upgraded, and then the stress of different situations can be fully accommodated. The disc harrow suitable for agricultural machines of the present invention improves the combined structure of the harrow and enhances the stress bearing strength of the harrow in actual conditions, thereby further protecting the structural integrity of the disc harrow group.

Owner:绍兴市齐翔贸易有限公司

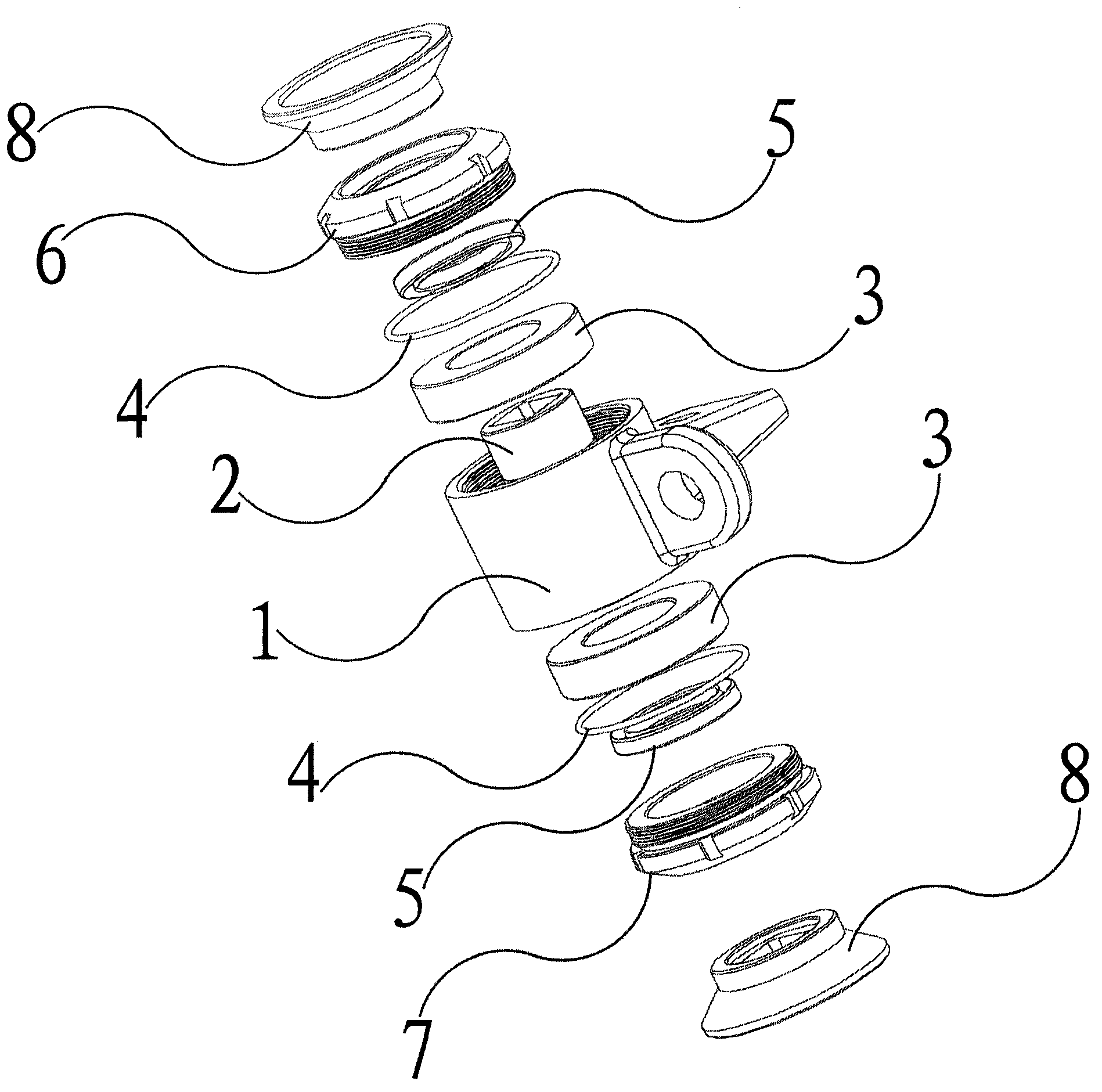

Disc harrow axle base

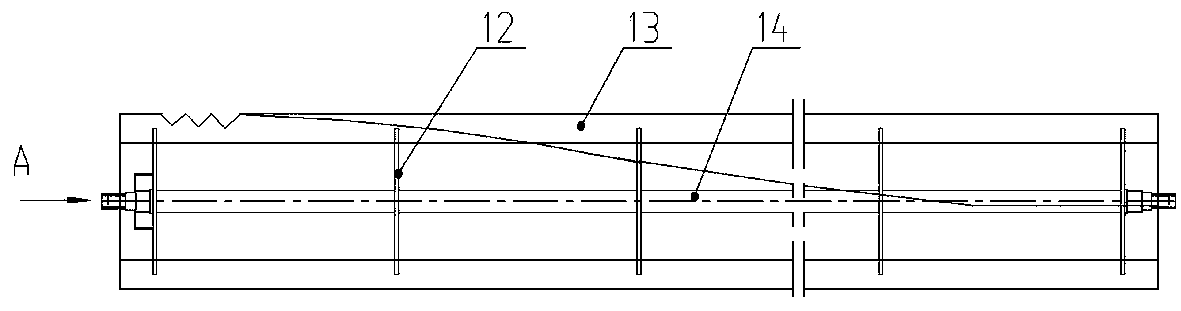

ActiveCN103527642ASimple structureImprove practicalityBearing unit rigid supportCircular discEngineering

The invention relates to a disc harrow axle base. The disc harrow axle base comprises an ear part arranged outside a shell and connected with a harrow body; the disc harrow axle base is characterized in that: a left-handed thread and a right-handed thread are arranged at two ends of the inner side of the shell, a core shaft is arranged inside the shell, a convex edge is arranged at the middle part of the core shaft, tapered-roller bearings are respectively arranged at two sides of the convex edge, and the tapered-roller bearings with tapers are assembled oppositely; double oil seals are arranged at the inner sides of a left-handed pressure cover and a right-handed pressure cover, sealing rings are arranged at outer sides of the left-handed pressure cover and a right-handed pressure cover, then the left-handed pressure cover and the right-handed pressure cover are sheathed on the core shaft and are respectively connected with the tapered-roller bearings; the left-handed pressure cover and the right-handed pressure cover are screwed on the left-handed thread and the right-handed thread of the shell, semi-intercalated pipes are arranged on the left-handed pressure cover and the right-handed pressure cover respectively, the semi-intercalated pipes are clamped at two ends of the core shaft and are connected with the left-handed pressure cover and the right-handed pressure cover in a clearance fitting manner. The disc harrow axle base has a simple structure and good practicability, the repairing and maintaining operations during production are reduced and the producing efficiency is improved.

Owner:任丘市沃田农机有限公司

Crop residue and soil conditioning agricultural implement

InactiveUS20090025946A1Control impactReducing potentially-damaging impactAgricultural machinesSoil-working equipmentsCircular discTerrain

A disc harrow composed of one or more disc gangs has a subframe coupled to the disc gangs to move the disc gangs in response to variations in farmland terrain to limit the impact of obstructions when encountered during the harrowing process. When the obstruction is cleared, the subframe automatically returns the disc gangs to their pre-obstruction position. In addition to reducing the potentially-damaging impact of obstructions, the subframe also maintains a more consistent reel depth during undulations or changes in the farmland terrain, such as during harrowing of slopes or unleveled fields such as valleys, near waterways, and along fence rows.

Owner:BLUE LEAF I P INC

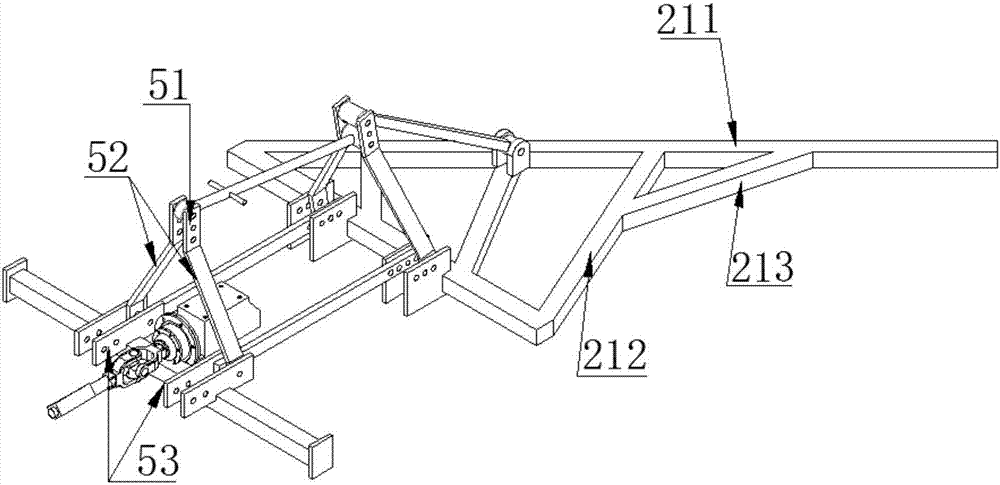

Dragging type middle-sized disc harrow

The invention discloses a dragging type middle-sized disc harrow. The dragging type middle-sized disc harrow comprises a front harrow set and a rear harrow set, wherein hinging arms extending to the middle are fixed to the same ends of the front harrow set and the rear harrow set, the top ends of the two hinging arms are hinged through a rotary shaft, a longitudinal beam is arranged between the front harrow set and the rear harrow set, the front end of the longitudinal beam is hinged to the front harrow set, a plurality of positioning holes are formed in the rear middle portion of the longitudinal beam, and an adjusting pin is arranged on the rear harrow set; two connecting plates are arranged on the front side of the front harrow set in a relatively fixed mode, and the two connecting plates are hinged to a traction assembly located in front of the connecting plates. Due to the fact that the front harrow set and the rear harrow set are hinged together, deflection adjustment is convenient and quick, time and labor are saved, and efficiency is extremely high. In work, a tractor is in one-point dragging connection with a harrow body, the influence of swinging of the tractor on a harrow disc and the harrow body is reduced, and then the service life of a whole set of equipment can be prolonged; when the disc harrow is transported in an idle state, the whole device is fixed to the tail of the tractor safely and firmly through a three-point suspension mechanism formed by a suspension hole and two suspension pins.

Owner:YUCHENG YIJIA MACHINERY

Stubble-plow type tilling machine for plowing ground

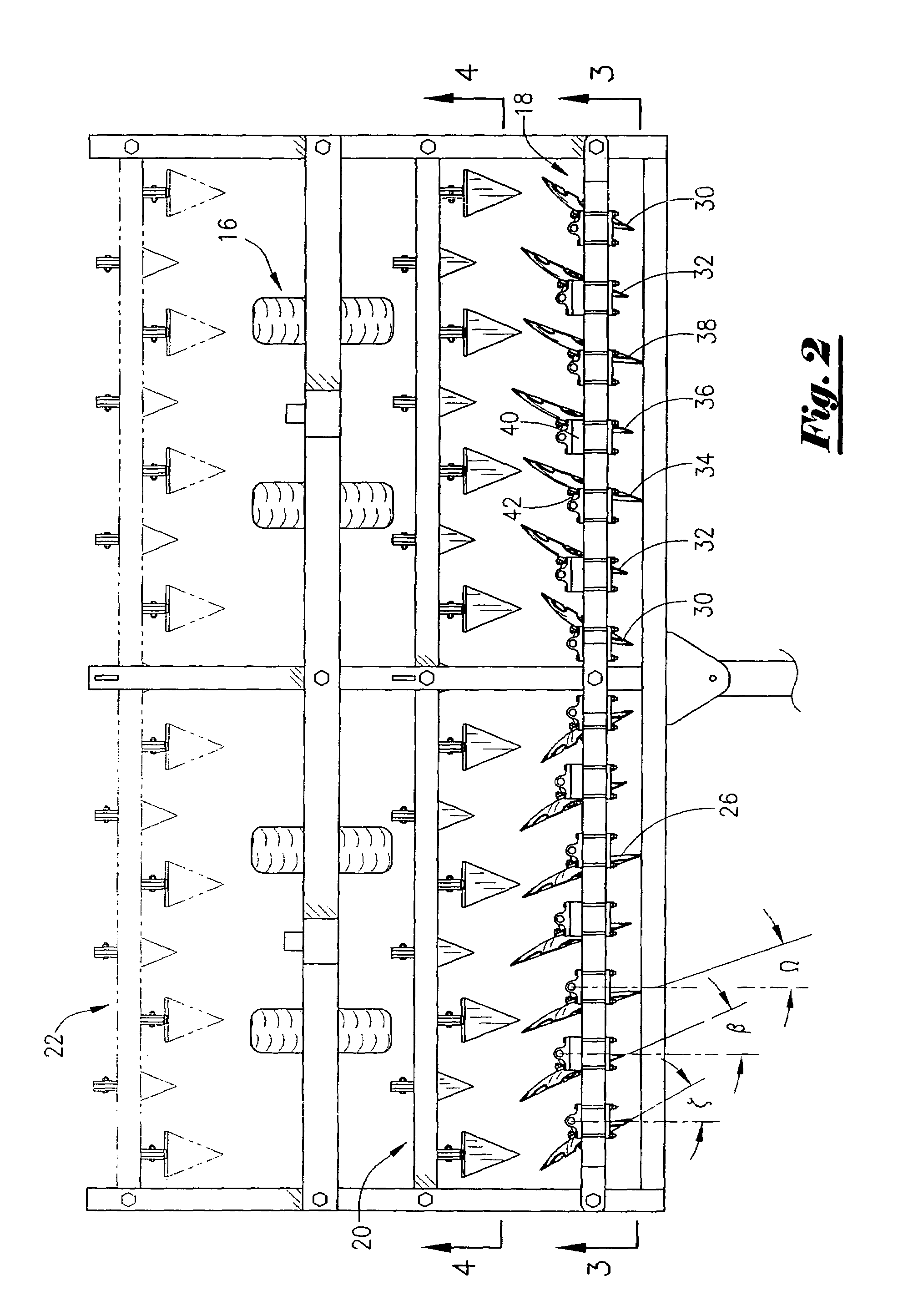

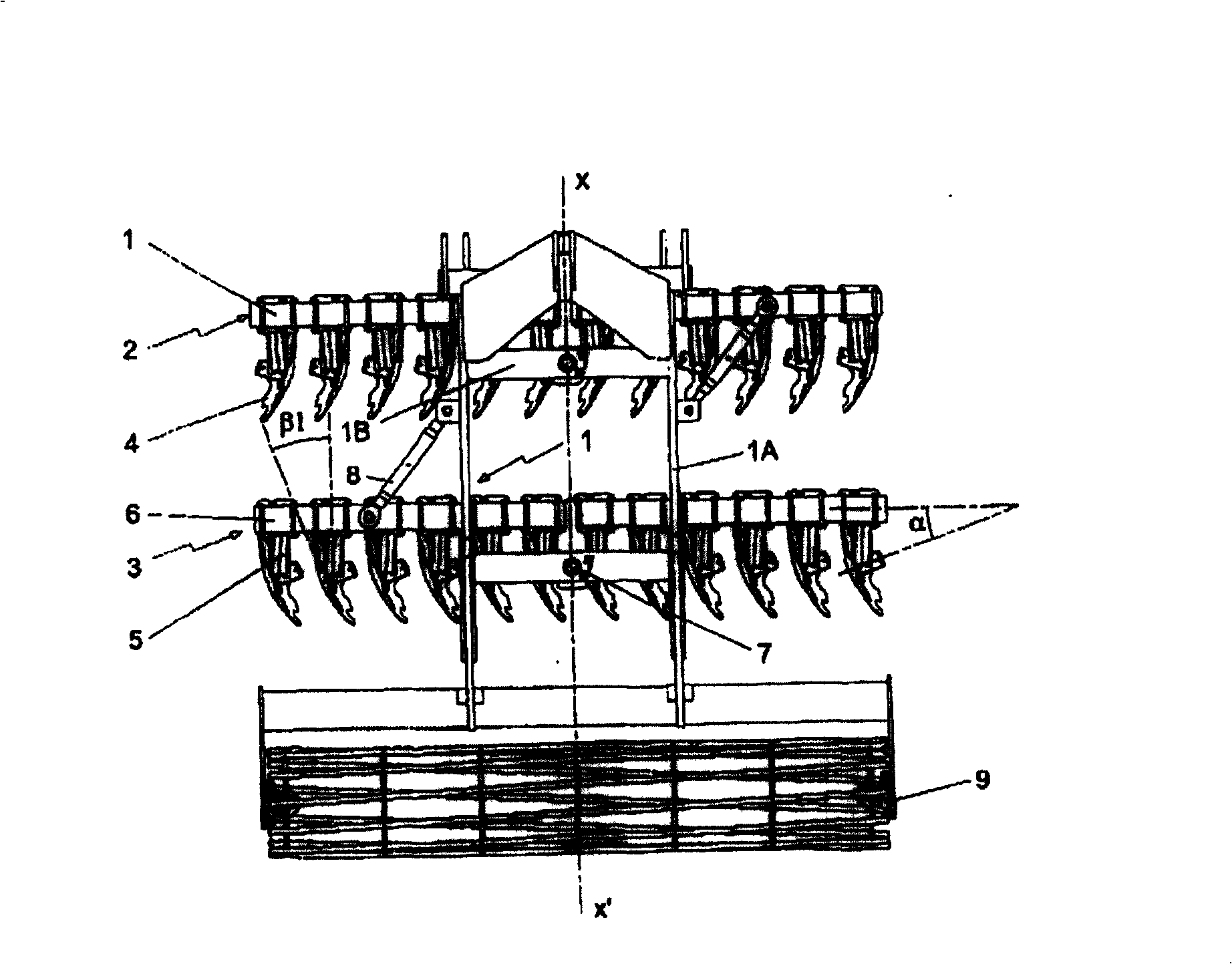

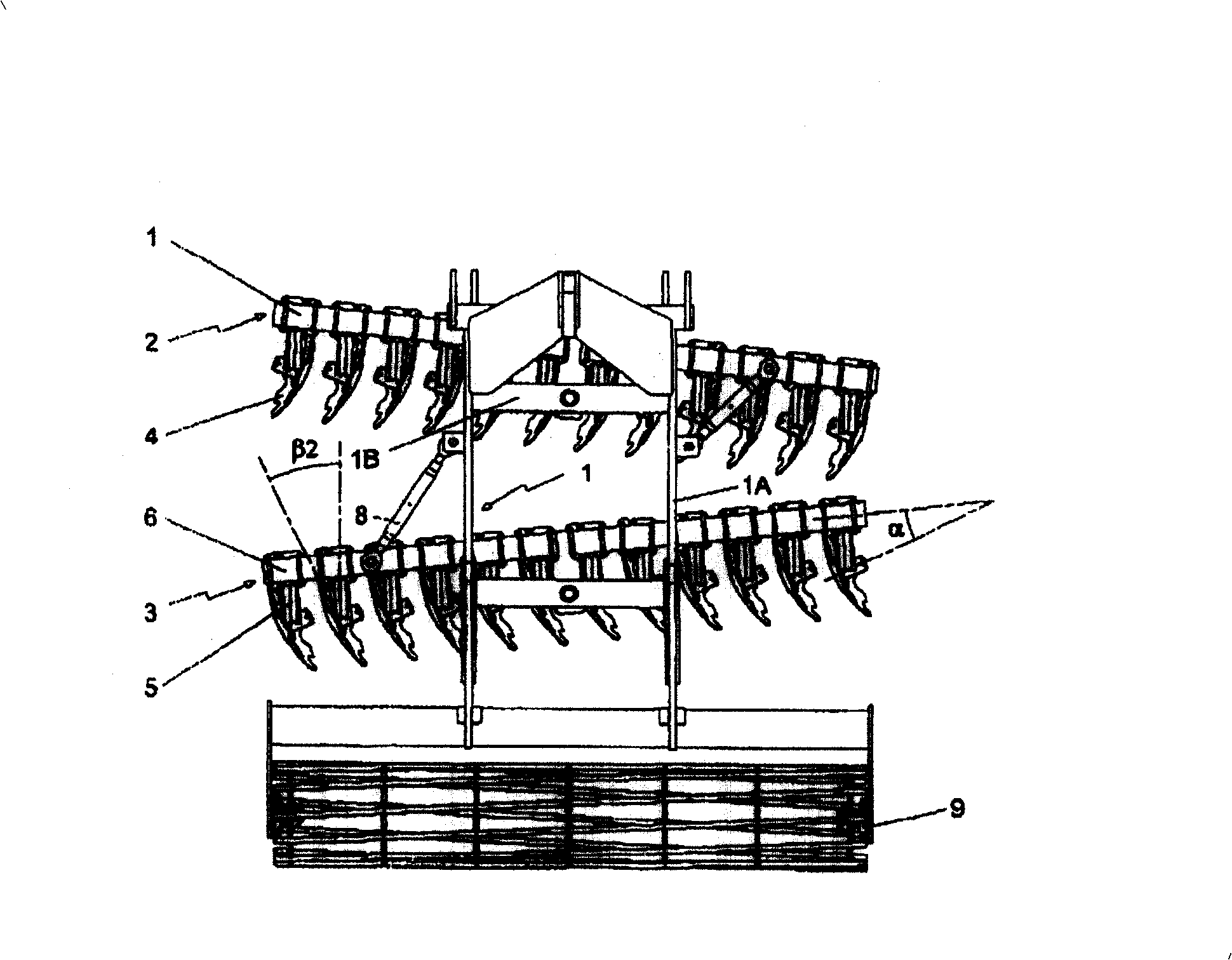

The machine has front and rear trains (2, 3) of discs (4), where each disc coupled to its support (6), is driven to rotate around an axis which forms an opening angle (alpha ) in the range of 3-40 degrees, with a longitudinal axis of the support. Each support is mounted on a frame (1) to pivot around a vertical axis in order to allow an adjustment of the value of the angle of the discs within a preset angular range.

Owner:米歇尔·埃文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com