Stubble-plow type tilling machine for plowing ground

A technology for tillers and disc harrows, applied in the directions of harrows, agricultural machinery and implements, applications, etc., can solve problems such as inability to remove the discs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

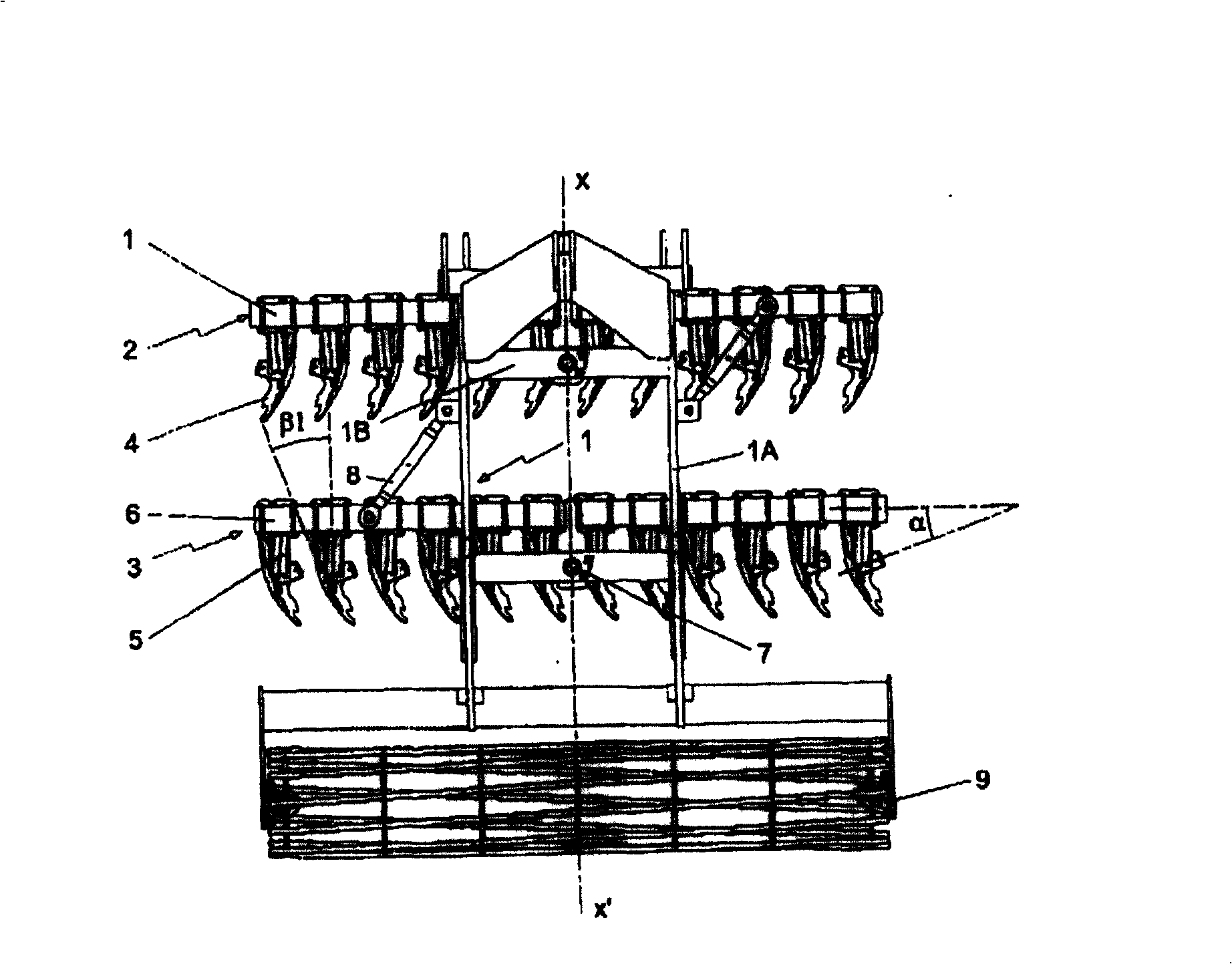

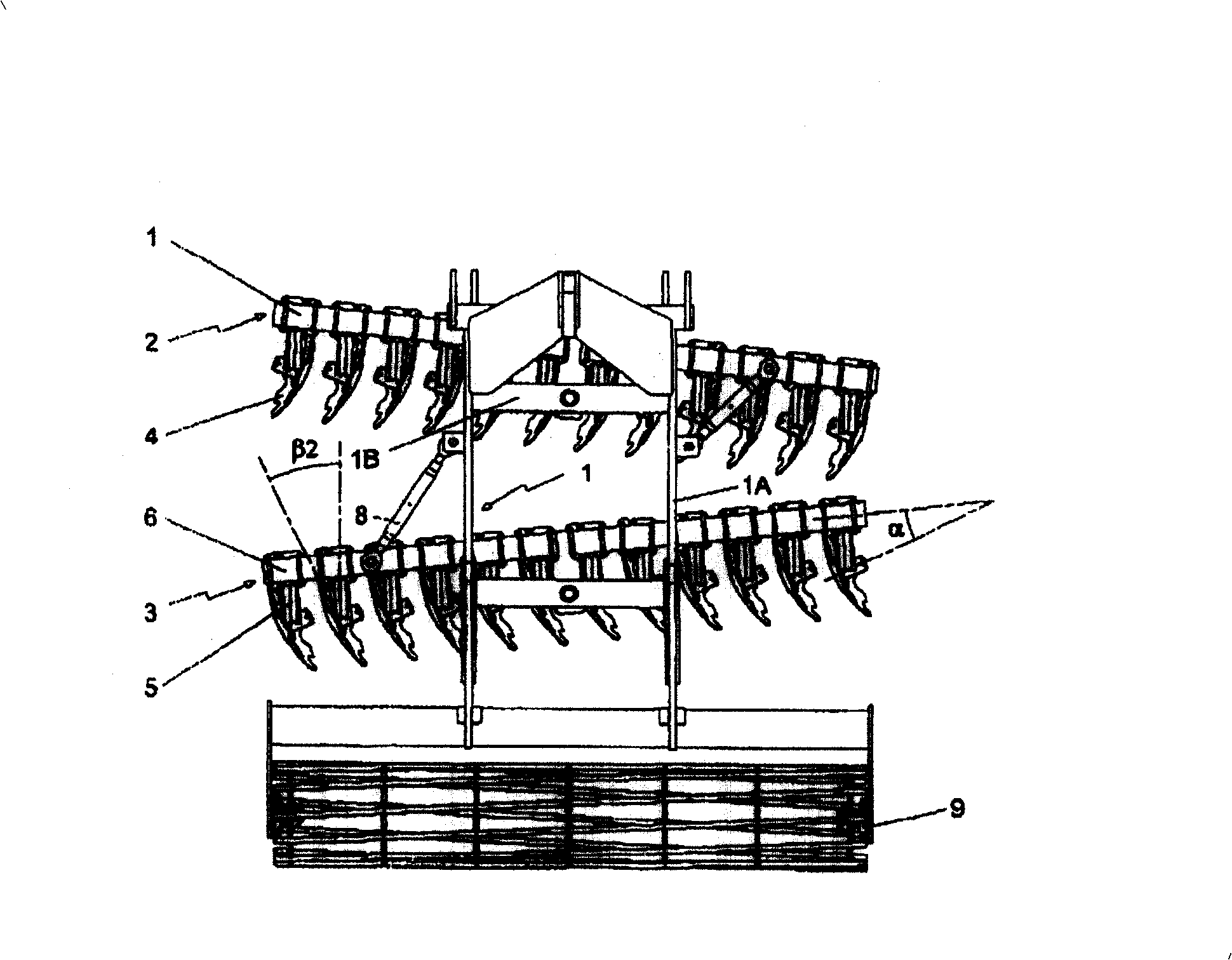

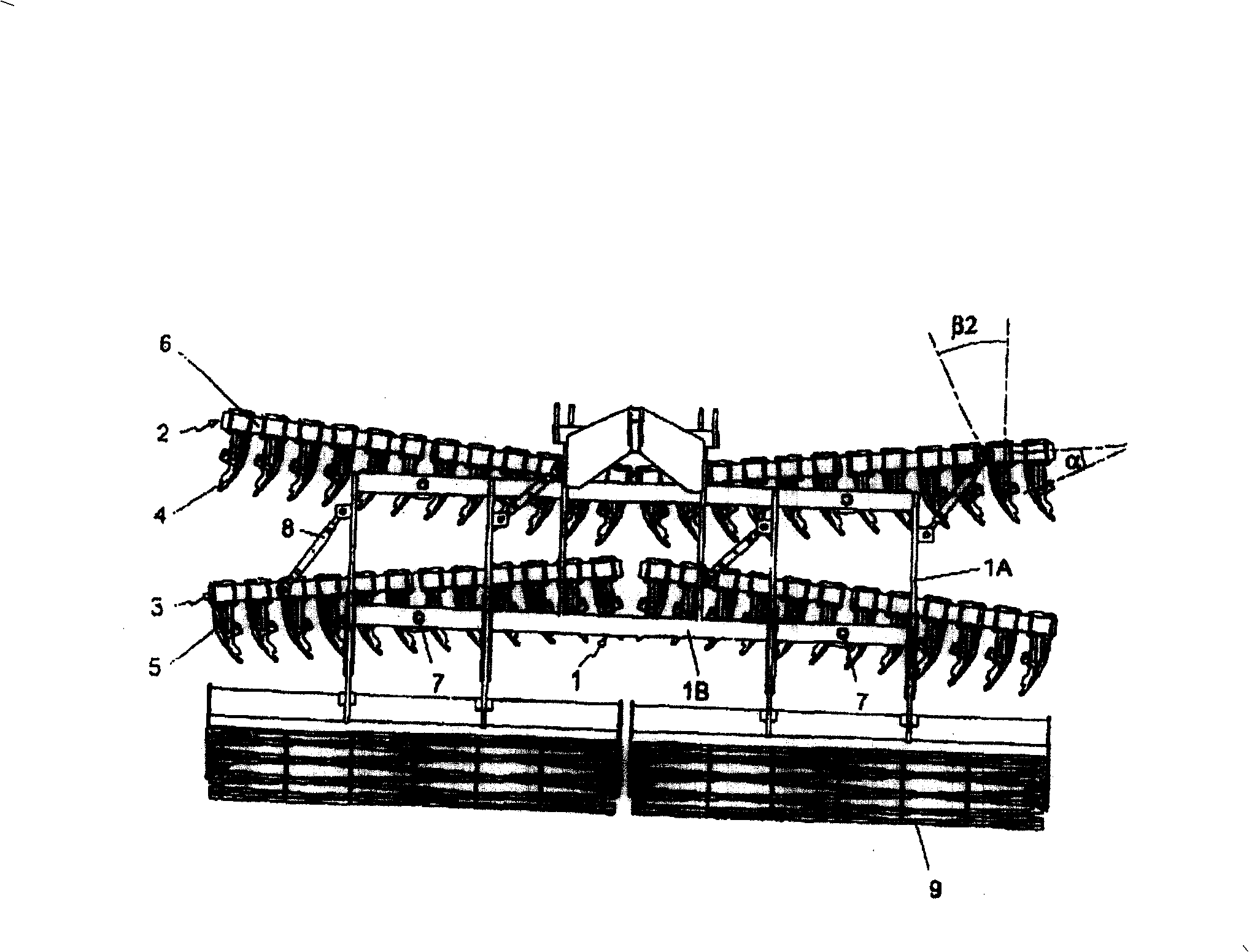

[0016] As mentioned above, the precision disc harrow type soil tillage machine according to the present invention comprises a suspended or trailed chassis 1 provided with tillage implements, which can have a large number of forms. In the examples shown, this chassis 1 is constituted by at least one frame formed by two bars 1A interconnected by a cross bar 1B substantially perpendicular to the line of advancement XX' of the machine. The chassis 1 is furthermore provided with a device for attachment to a towing vehicle (not shown). The connection will preferably be of the three-point type. The tillage implement itself consists of at least a front string 2 and a rear string 3 of non-driven rotatable discs 4 . These front and rear disc strings each extend along a tillage width (that is to say along a line perpendicular to the advancing or pulling line XX' of the chassis 1). It should be noted that a non-driven disc harrow refers to a harrowing disc whose rotational drive occurs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com