Diamond frame saw adjustable in sawing trajectory

A diamond and frame saw technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problem of inability to adjust the sawing trajectory according to actual needs, the trajectory of the saw blade is not easy to determine, and the quality and efficiency of sawing are not high. problems, to achieve the effect of improving processing quality and efficiency, small length and small swing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

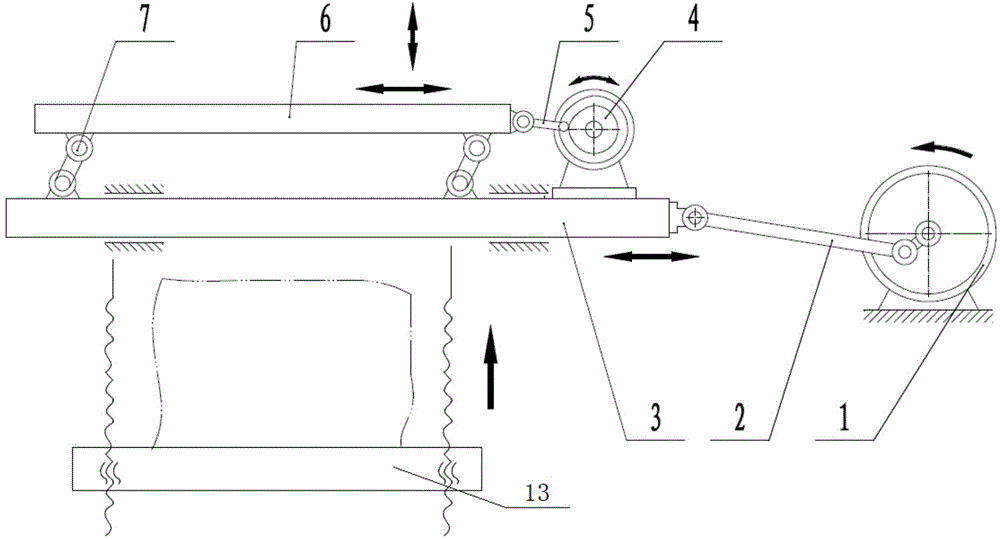

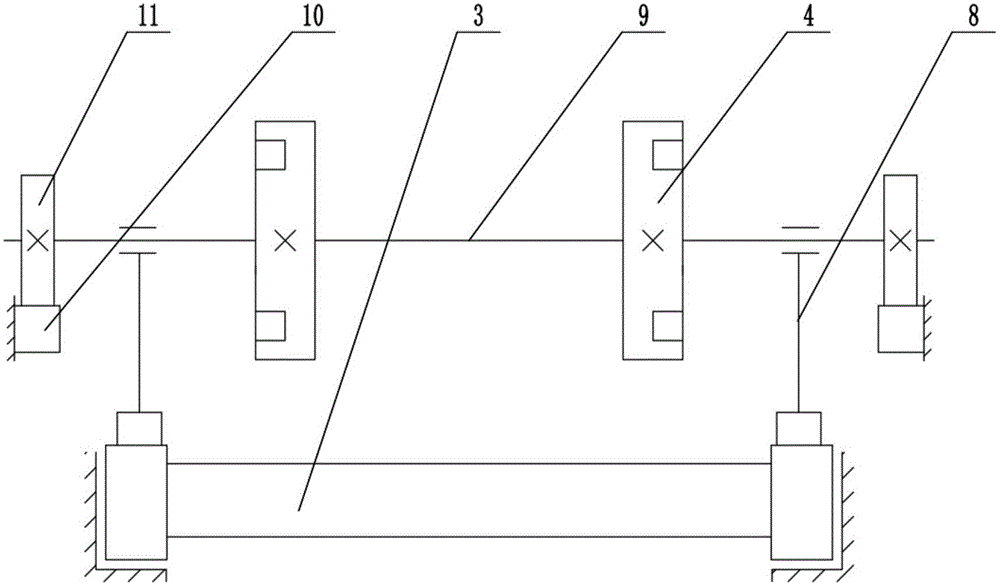

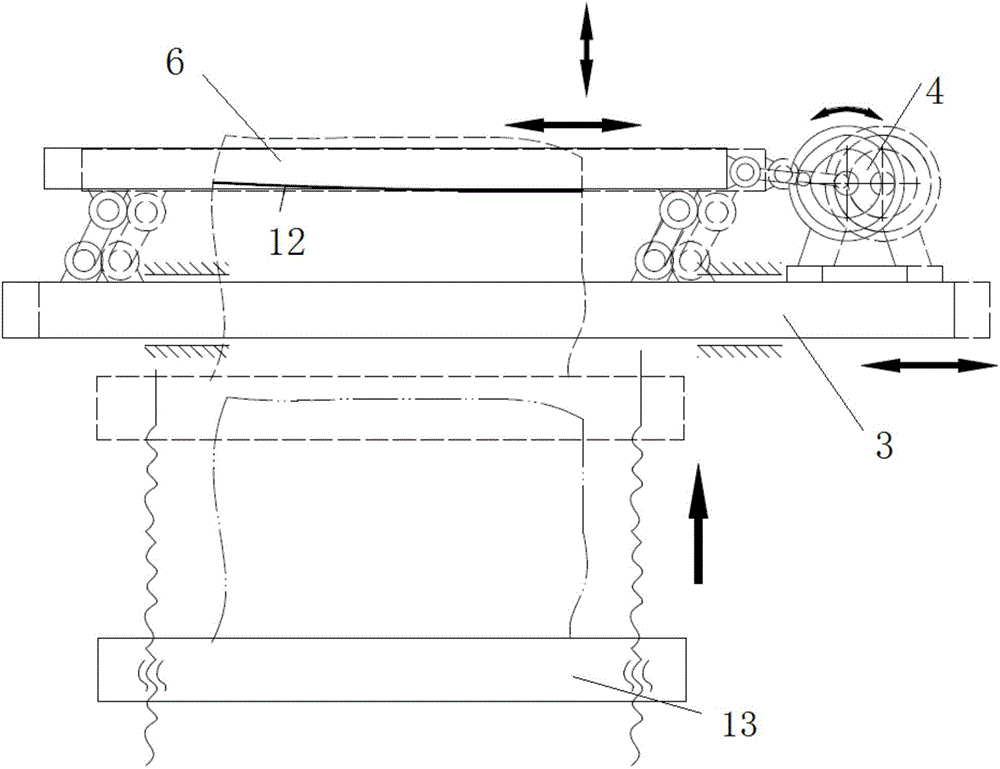

[0024] Such as Figure 1-Figure 2 As shown, the adjustable sawing track type diamond frame saw includes flywheel 1, crank connecting rod 2, translation frame 3, cam 4, cam connecting rod 5, saw frame 6, saw frame pendulum rod 7, bearing seat 8, transmission Shaft 9, rack 10, gear 11. The translation frame 3 only has the degree of freedom to move in the horizontal direction. There are many specific implementation methods, which can be realized by roller guide rails or static pressure guide rails. The saw frame swing bar 7 is hinged with the saw frame 6 and the translation frame 3 respectively. There are four groups of frame pendulum bars 7, the bearing block 8 is fixed on the translation frame 3, the cam 4 is hinged with the saw frame 6 through the cam connecting rod 5, and the cam connecting rod 5 has two groups. Lifting workbench 13 is arranged below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com