Soil preparation and pesticide spraying combined machine

A combined operation machine and frame technology, applied in agricultural machinery and tools, agriculture, animal husbandry, etc., can solve the problems of drug volatilization and waste, low production efficiency, long interval time, etc., to reduce harmful compaction and improve operation efficiency , The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

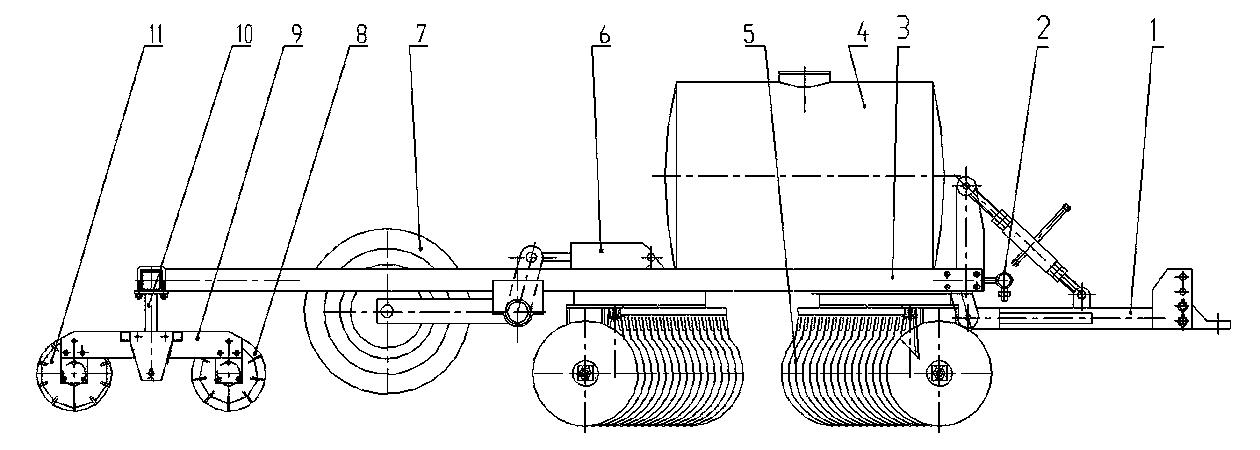

[0015] exist figure 1 Among them, the land preparation and spraying combined operation machine includes a traction frame 1, a spraying device 2, a frame 3, a medicine box 4, a disc harrow group 5, a lifting cylinder 6, a transport wheel 7, a soil crushing roller 8, and a soil crushing roller frame 9. It is composed of support arm 10 and pressing roller 11. The medicine box is installed on the frame; the spraying device is installed in front of the frame, and the disc harrow group, crushing roller and pressing roller are installed under the frame; the crushing roller and pressing roller are installed on the frame of the crushing roller through bearings. One end of the support arm is fixedly connected to the frame, and the other end is hinged to the frame of the crushing roller.

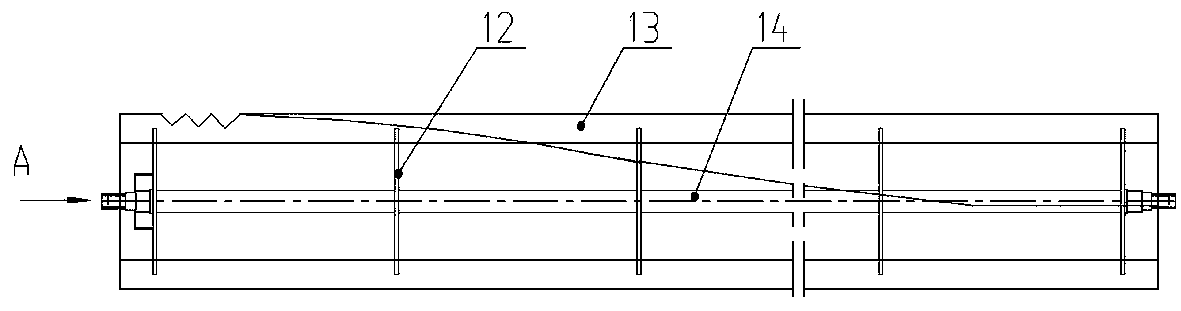

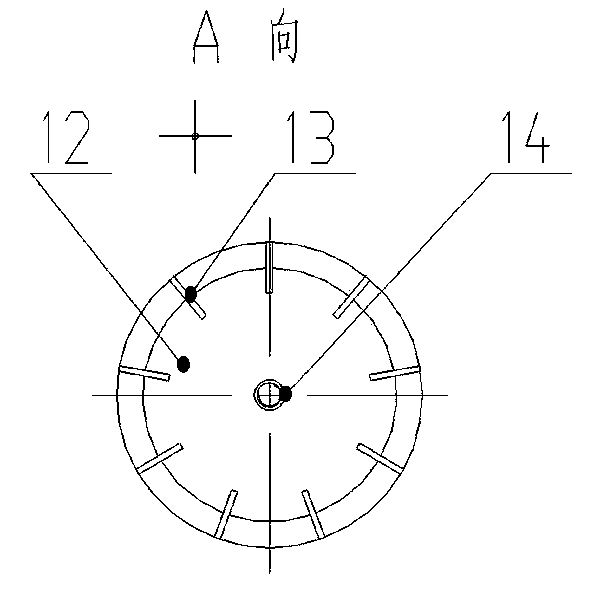

[0016] exist figure 2 Among them, the soil crushing roller is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com