Straw throwing and burying combined machine

A combined operating machine and overturning technology, which is applied to agricultural machinery and tools, agriculture, agricultural machinery, etc., can solve the problems affecting the soil preparation and transplanting, uneven crushing and scattering of straw, and unsuitability for paddy field operations, etc., to achieve light weight, Less power consumption, less compaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and examples.

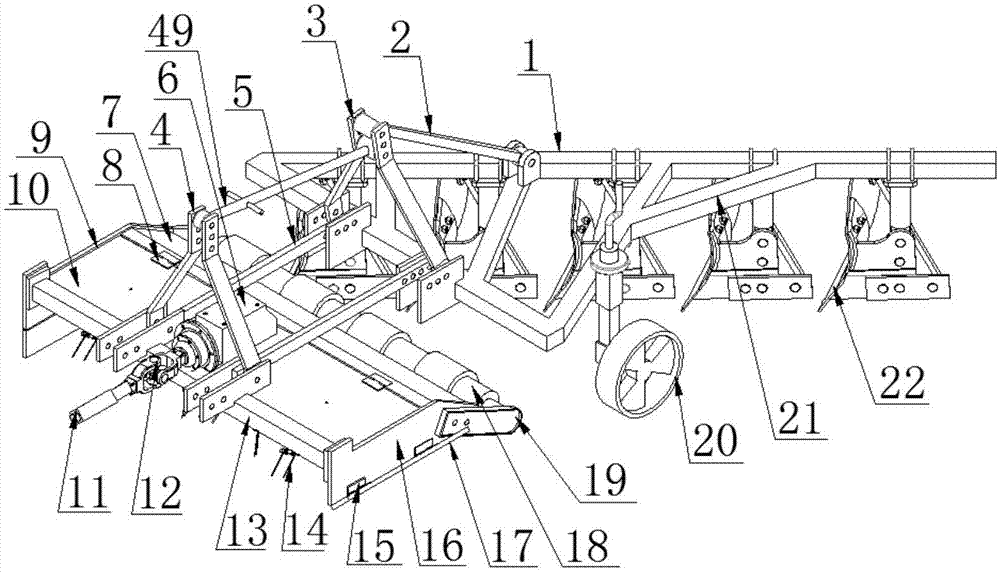

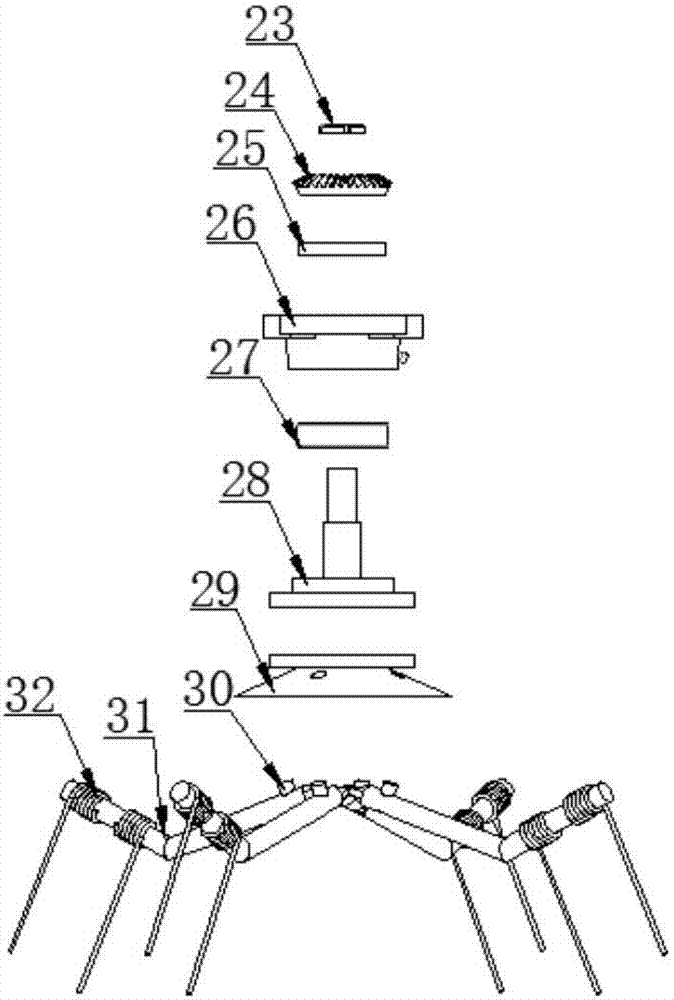

[0074] Such as Figure 1~2 As shown, a straw throwing and overturning combined operation machine includes a overturning device 1 , a hitch device 3 , a throwing device 9 and a power transmission device 12 . in:

[0075] The overturning device 1 includes a depth gauge wheel 20 , a plow frame 21 and a plow body 22 .

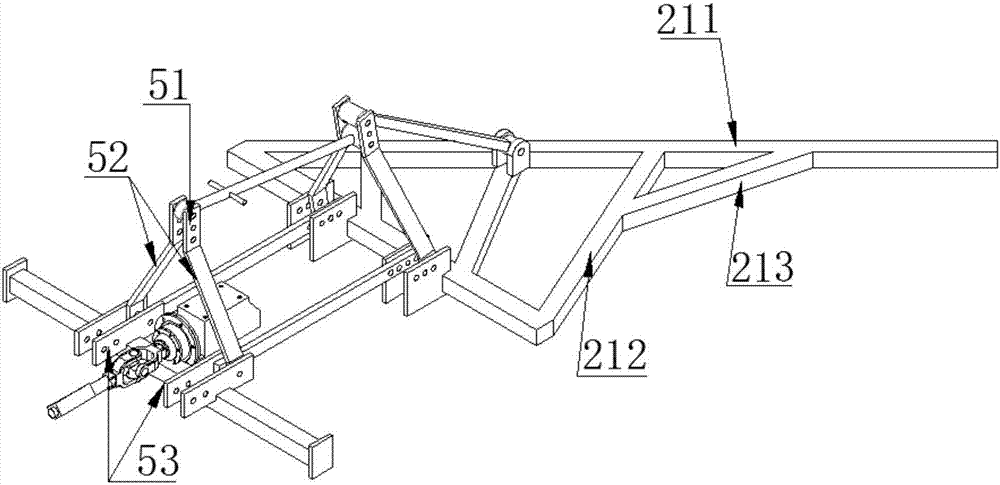

[0076] The plow frame 21 includes a main beam 211 , an auxiliary beam 212 and a reinforcing beam 213 . The secondary beam 212 is a bent structure, and its two ends are fixed on the main beam 211 to form a triangular fixed structure. In the triangular fixed structure, the sub-beam 212 and the main beam 211 are also fixed by connecting beams. The limited depth wheel 20 is fixedly connected below the auxiliary beam 212 . One end of the reinforcing beam 213 is fixed on the main beam 211 , and the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com