A kind of engineering site sewage treatment method

A sewage treatment method and sewage treatment technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of affecting construction area operations, zero recycling rate, and poor purification effect and other problems to achieve the effect of ensuring tight performance, reducing leakage, and facilitating centralized processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

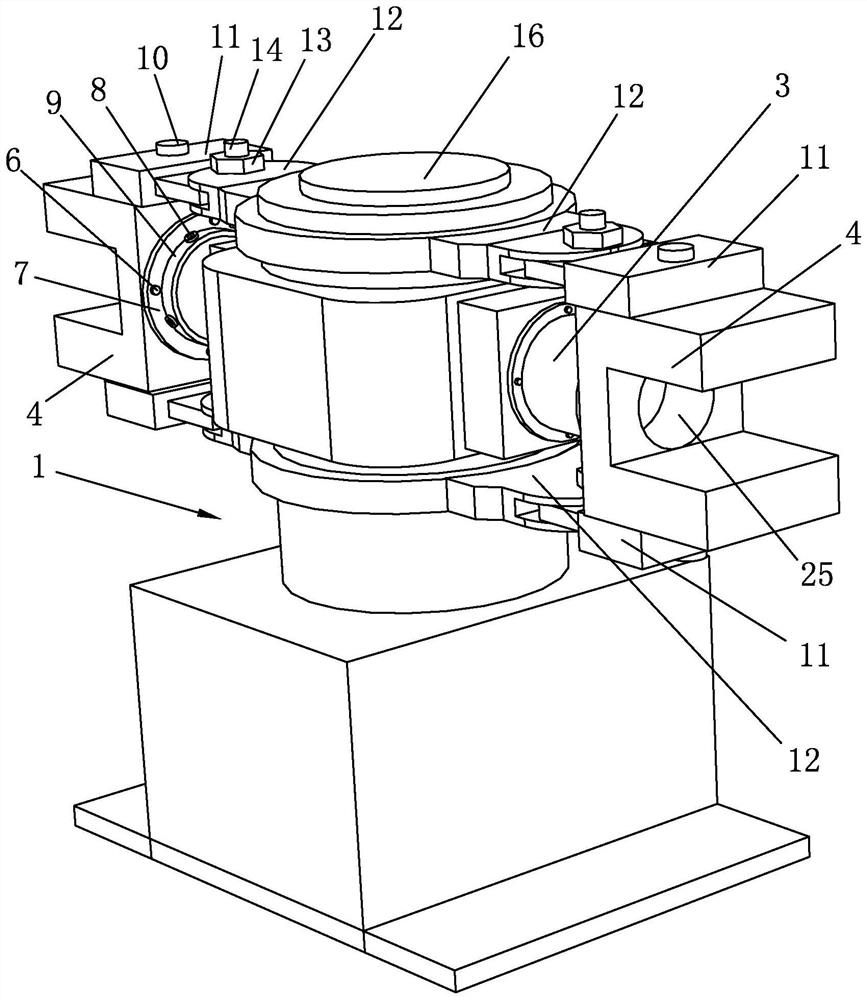

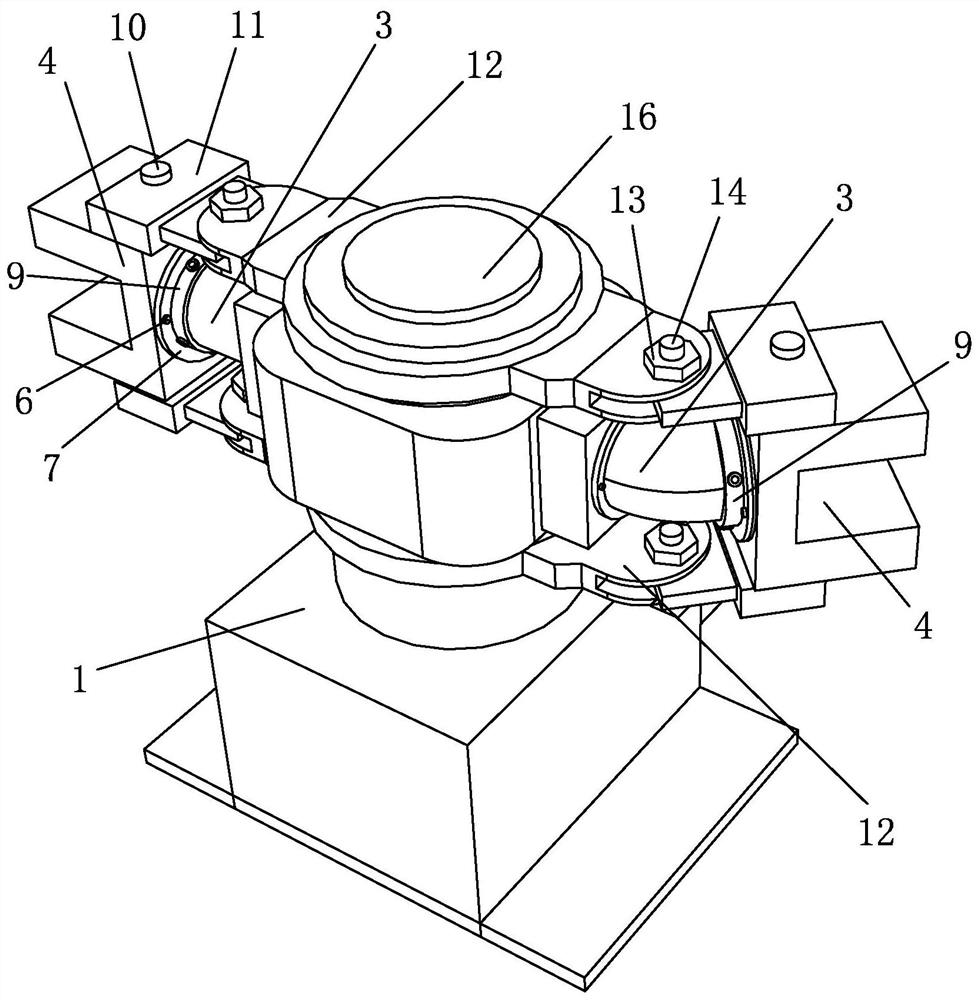

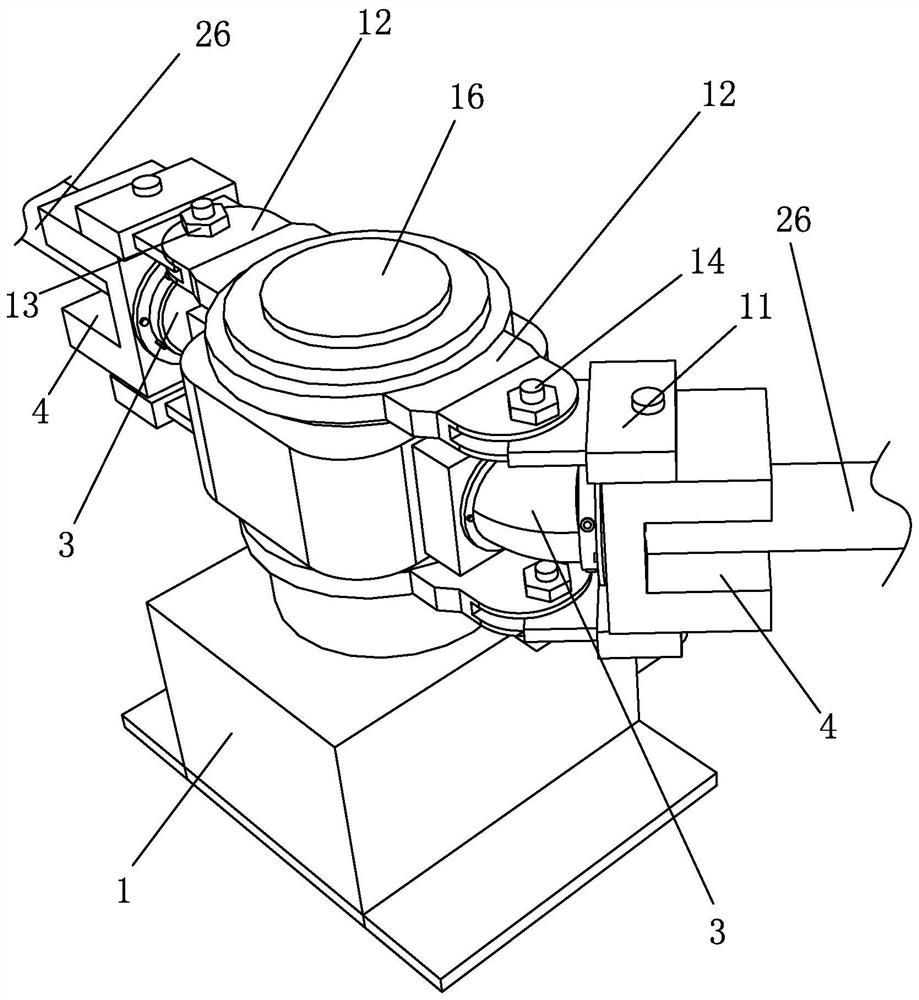

[0036] like Figure 1 to Figure 7 Shown, be a kind of project site sewage treatment method of the present invention, comprise the following steps:

[0037] 1) Area division: first determine the construction area according to the construction drawings, then determine the sewage treatment area according to the construction area and the topography of the construction site, ensure that the distance between the sewage treatment area and the construction area is at least 10m, and the sewage treatment area avoids the equipment in the construction area The entry and exit path, and then dig the treatment pool in the sewage treatment area, and realize the separate operation between the construction area and the sewage treatment area by dividing the area, which can facilitate the actual construction work and reduce the mutual influence between the two areas;

[0038] 2) Centralized introduction of sewage:

[0039] a. First lay the drainage branch pipes in the construction area, position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com