Working procedure-saving art engraving production process

A technology of making crafts and prints, applied to the specialized technology of artistic painting, crafts for producing decorative surface effects, decorative art, etc., can solve the problems affecting the consistency of the work style and the production process, so as to achieve convenient operation and saving time, to ensure consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

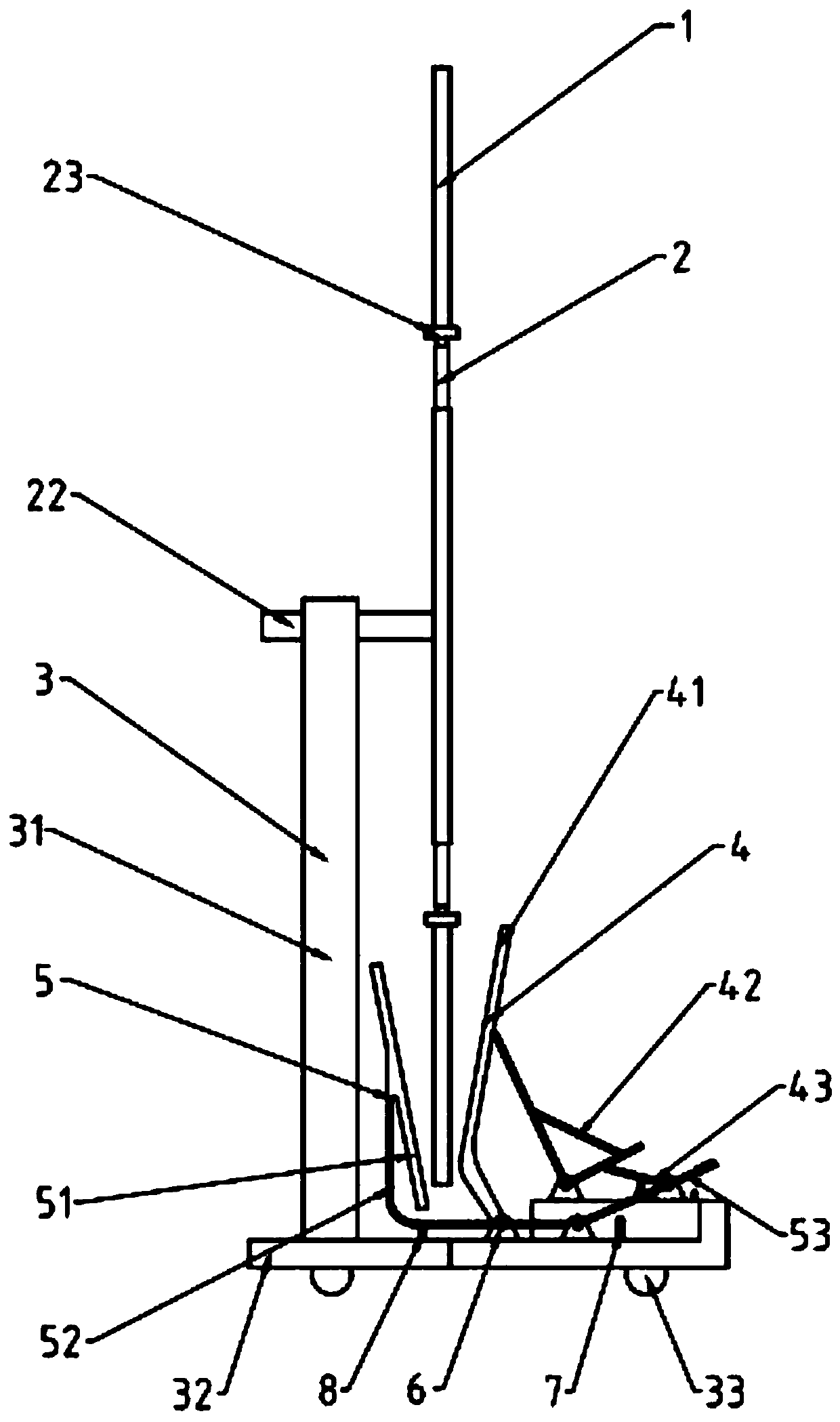

[0039] A process-saving art print making process, comprising the following steps:

[0040] Step 1: Use manual or engraving machine to carve lines on the drawing board to make the base plate of the print;

[0041] Step 2: Coloring the surface of the bottom plate;

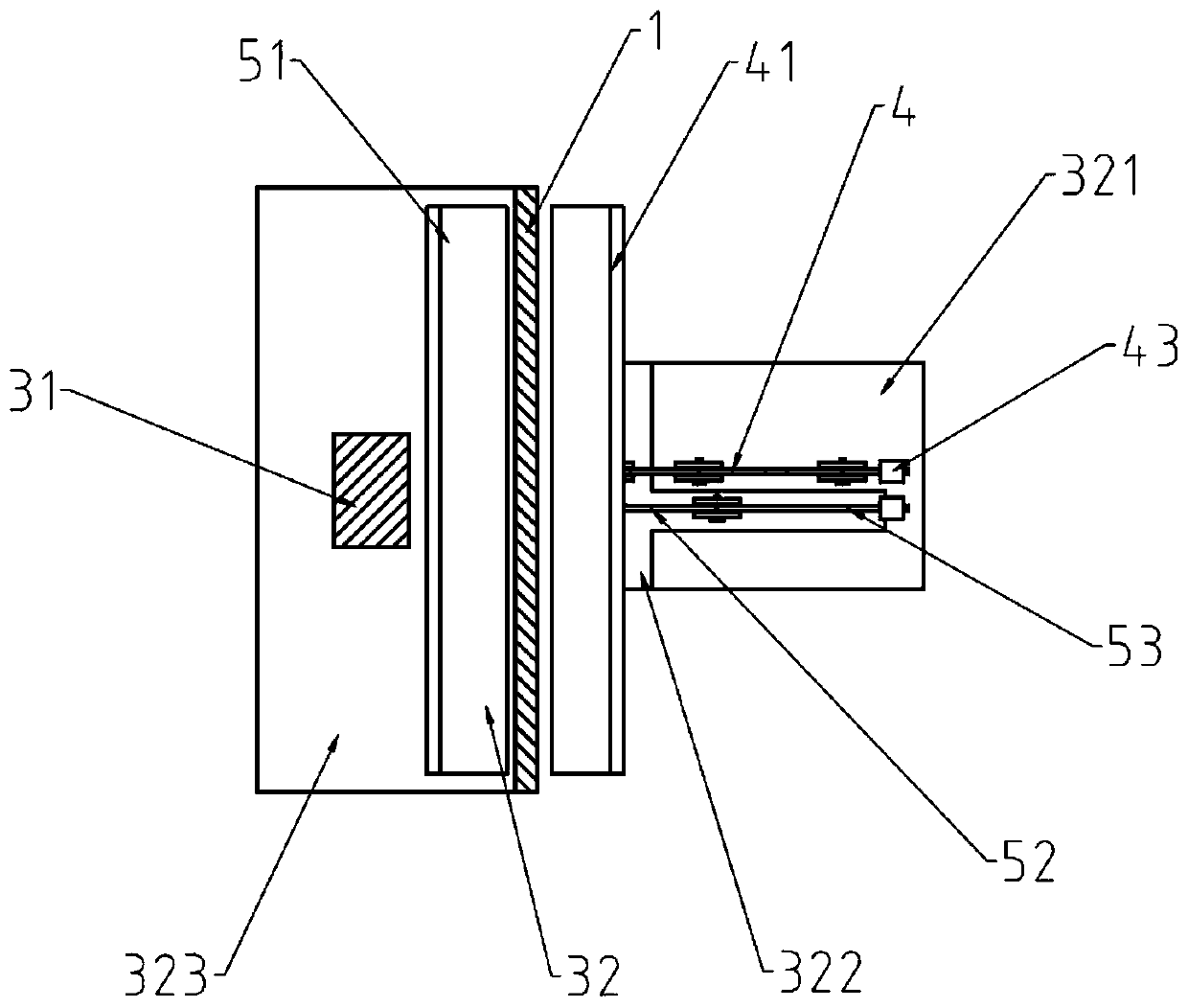

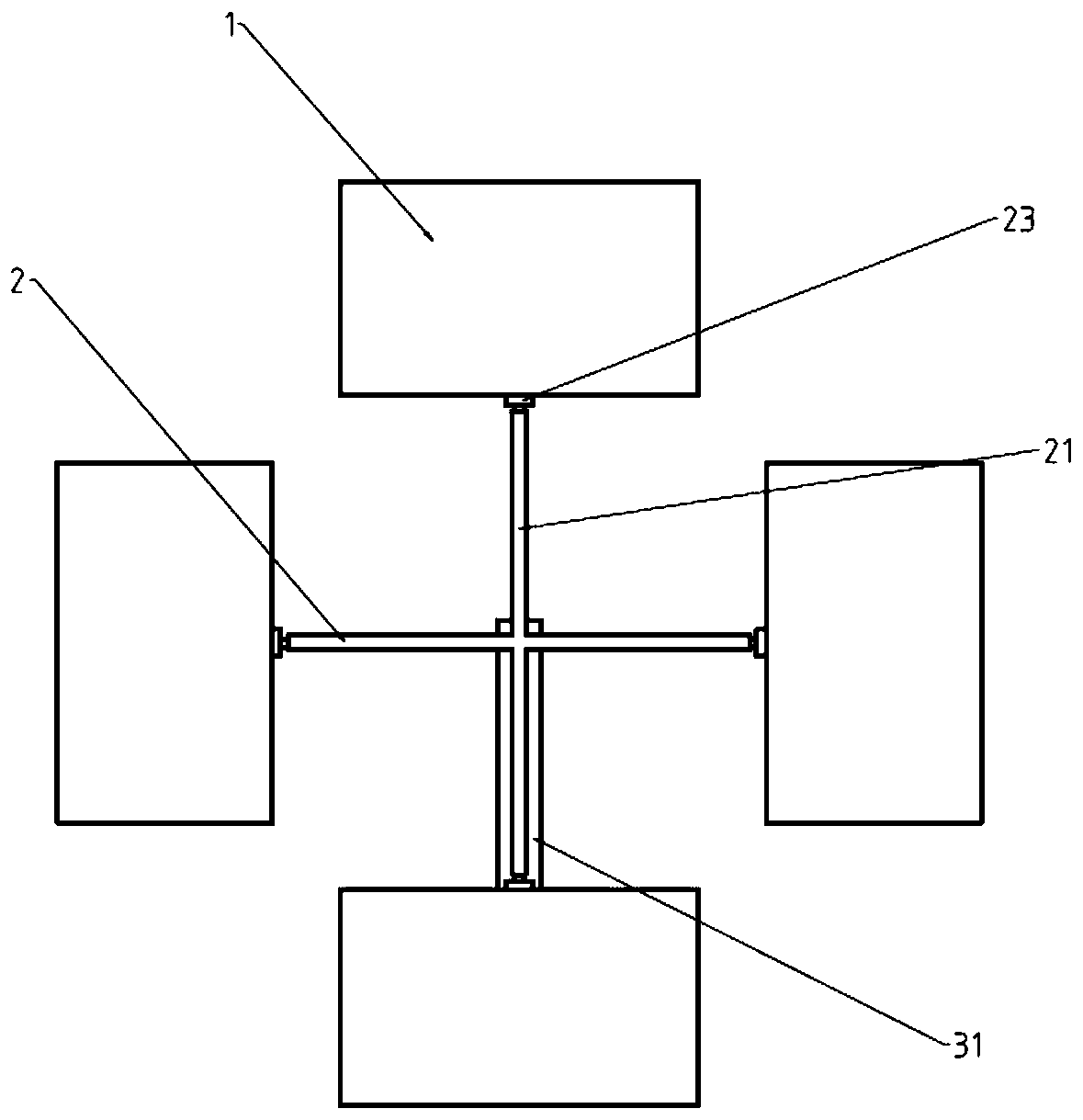

[0042] Step 3: Put the bottom plate on the mold printing assembly 4 to fix it, connect several flat plates 1 to the rotating mechanism, place drawing paper on the flat plate 1, and the drawing paper faces the front of the bottom plate;

[0043] Step 4: push the stamping assembly 4 to contact the drawing paper on the first flat plate 1, and squeeze the surface color of the bottom plate onto the drawing paper;

[0044] Step 5: Rotate the first flat plate 1 to dry, and then push the molding assembly 4 to contact and squeeze the drawing paper on the second flat plate 1;

[0045] Step 6: Rotate the dried first plate 1 to the coloring area for coloring;

[0046] Step 7: After the first flat plate 1 is painted, push the ...

Embodiment 2

[0074] In the production process of the above-mentioned art prints, the operator only needs to divide according to the fixed area, and operate on the flat plate 1 in the fixed area, but if he wants to operate in a certain position in the middle, such as the mold printing drying area, coloring and drying It is a little inconvenient to operate in the area. Therefore, in this embodiment, an auxiliary table 9 is provided beside the rotating mechanism, and the height of the auxiliary table 9 corresponds to the height when the rotating frame 2 and the corresponding flat plate 1 are turned to the horizontal plane. After the flat panel 1 is turned to the level, the auxiliary table 9 can be pushed under the flat panel 1 for use, which is convenient for the operator to perform other minor operations.

[0075] Combine below Figure 7 and Figure 8 , the auxiliary table 9 includes a fixed table 91 and a movable table 92, the fixed table 91 and the movable table 92 can be connected toget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com