a furrowing machine

A border and frame technology, which is applied to agricultural machinery and implements, shovels, plows, etc., can solve the problems of unadjustable border firmness, uneconomical and practical, border height and width cannot be adjusted, etc., so as to facilitate maintenance. , Increase the adjustment function, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

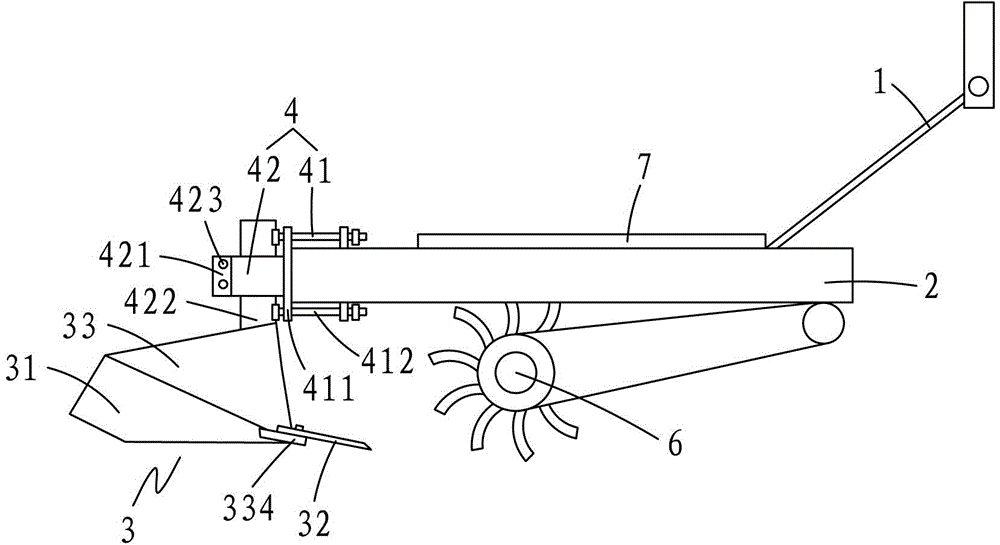

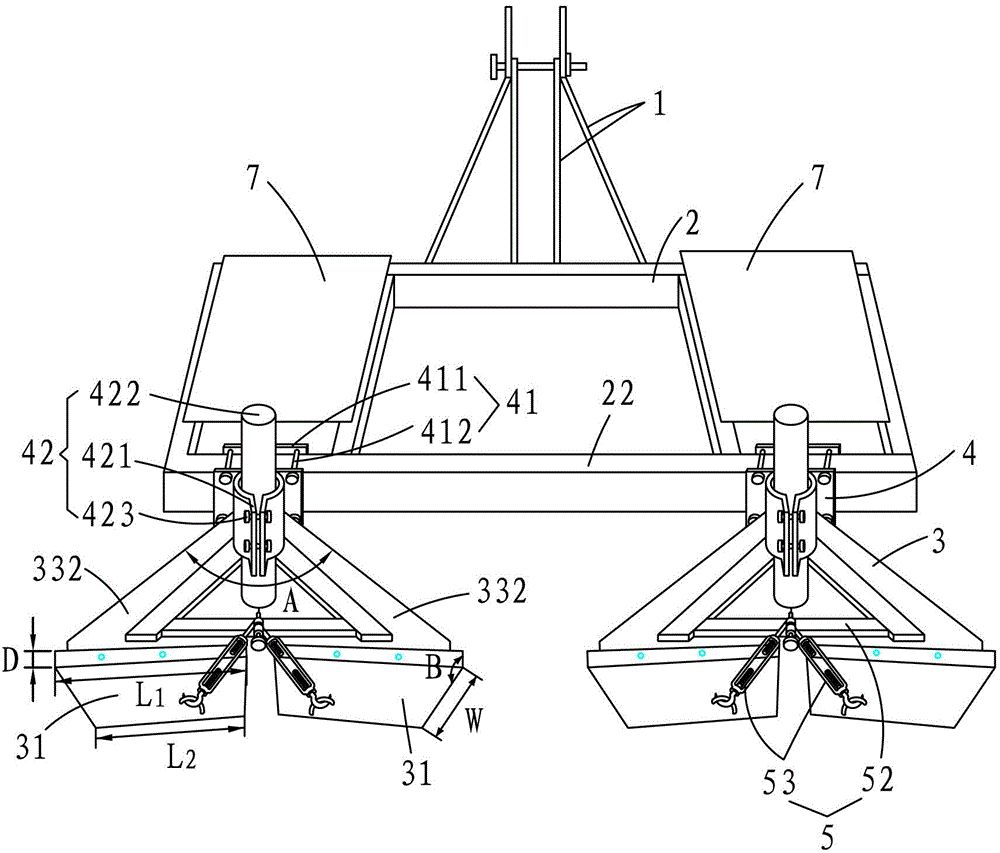

[0020] Such as figure 1 and figure 2 As shown, the whole furrow machine of the present invention includes the adjusting drawbar 1, the frame 2 and the ridge plow 3 connected in sequence, and the quantity of the ridge plow 3 is 2, which are respectively arranged at the front end of the frame 2 On both sides, any of the ridge plows 3 includes two furrow surface pressing plates 31 and a furrow blade 32, and the furrow blade 32 is connected to the backs of the two furrow surface pressing plates 31; wherein: any of the land ridges The plow 3 is connected to the frame through a furrow surface height and width adjustment device 4; the fixed sides of the two furrow surface pressing plates 31 are connected on the described furrow surface height and width adjustment device 4 through a pressure plate frame 33, and the pressure plate frame 33 is A furrow surface compactness adjustment device 5 is provided, one end of the furrow surface compactness adjustment device 5 is fixed on the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com