Intelligent automobile part spraying production system

A technology for auto parts and production systems, which is applied to coatings, paint booths, spray devices, etc., can solve the problems of inconvenient cleaning of parts conveying equipment, inconvenient hot air drying, inconvenient collection, etc., and achieve convenient conveying equipment. The effect of cleaning work, adding dustproof function, adding adjustment function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

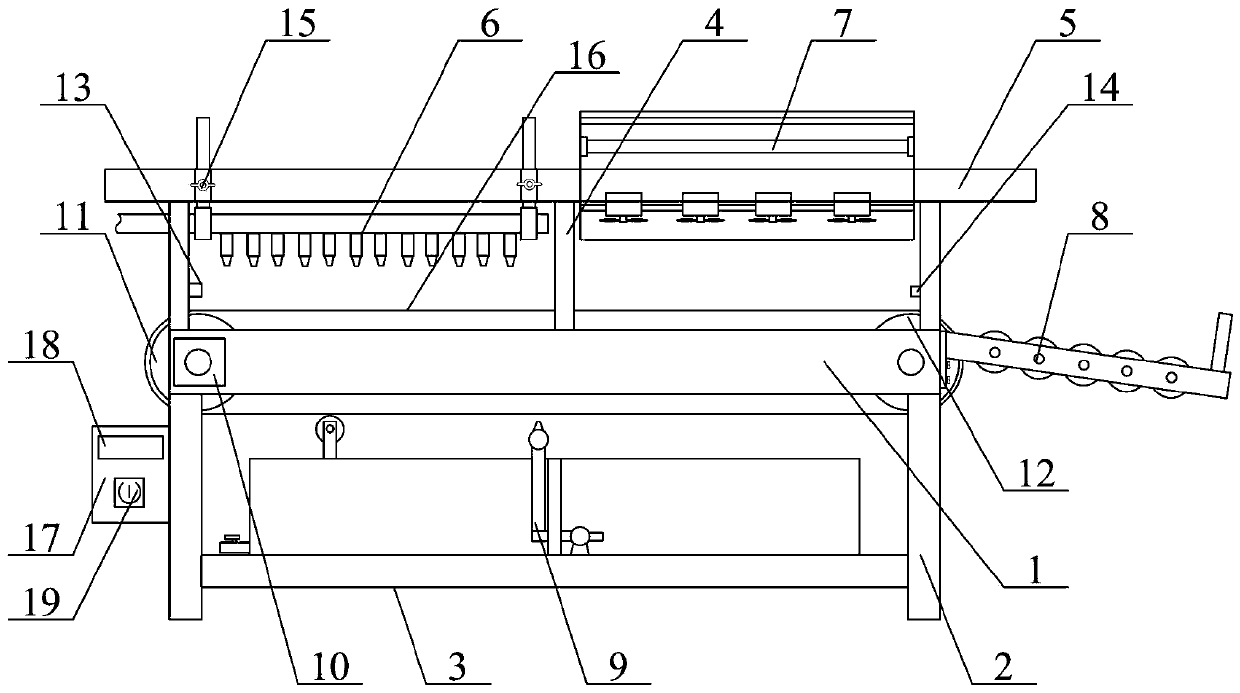

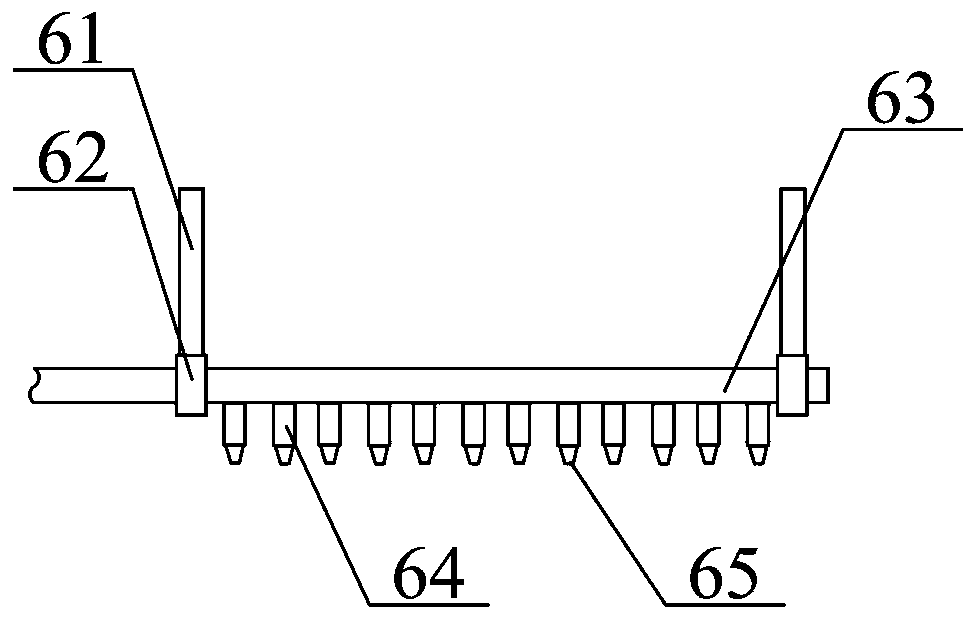

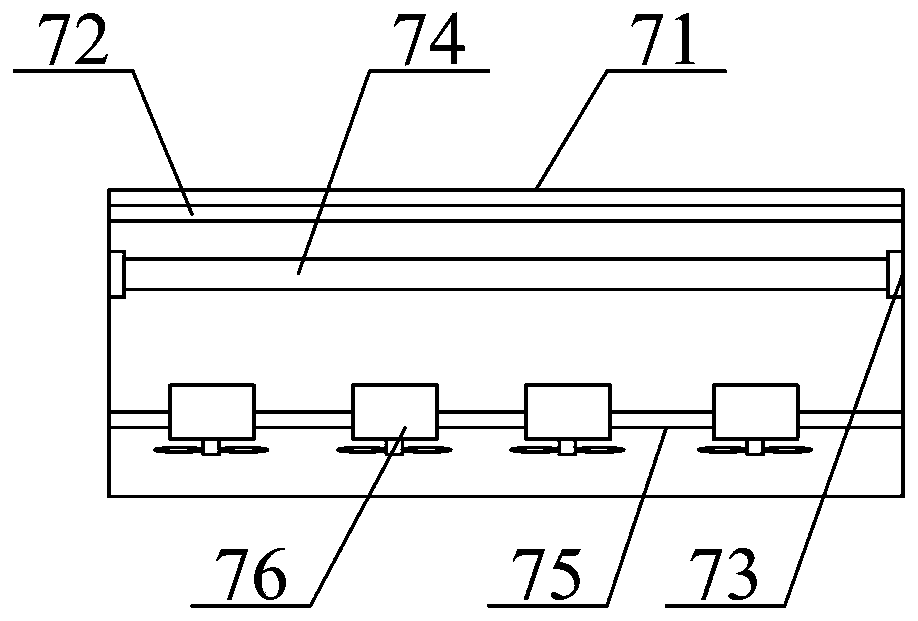

[0039] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, the intelligent spraying production system for auto parts includes a working frame 1, a supporting leg 2, a first connecting plate 3, a supporting rod 4, a shielding plate 5, an adjustable spraying pipe structure 6, and a filter heating and drying box structure 7. Can block the collection frame structure 8, can spray and wipe the collection box structure 9, drive motor 10, driving roller 11, driven roller 12, infrared sensor 13, proximity switch 14, wing bolt 15, conveyor belt 16, control box 17, PLC18 and power switch 19, the upper ends of the support legs 2 are respectively bolted to the four corners of the lower end of the work frame 1; the first connecting plate 3 is bolted to the lower part between the support legs 2; the support rods The lower end of 4 is bolted to the upper end of the working frame 1 from left to righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com