Top plate siding device, suspended ceiling and suspended ceiling installing method

A roof and top surface technology, which is applied to ceilings, building components, buildings, etc., can solve the problems of reducing installation speed, increasing construction cost, and inconvenience in the installation process, and achieves the effects of improving flatness, increasing construction speed, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the embodiments. Wherein the same parts are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer" ” refer to directions towards or away from the geometric center of a particular part, respectively.

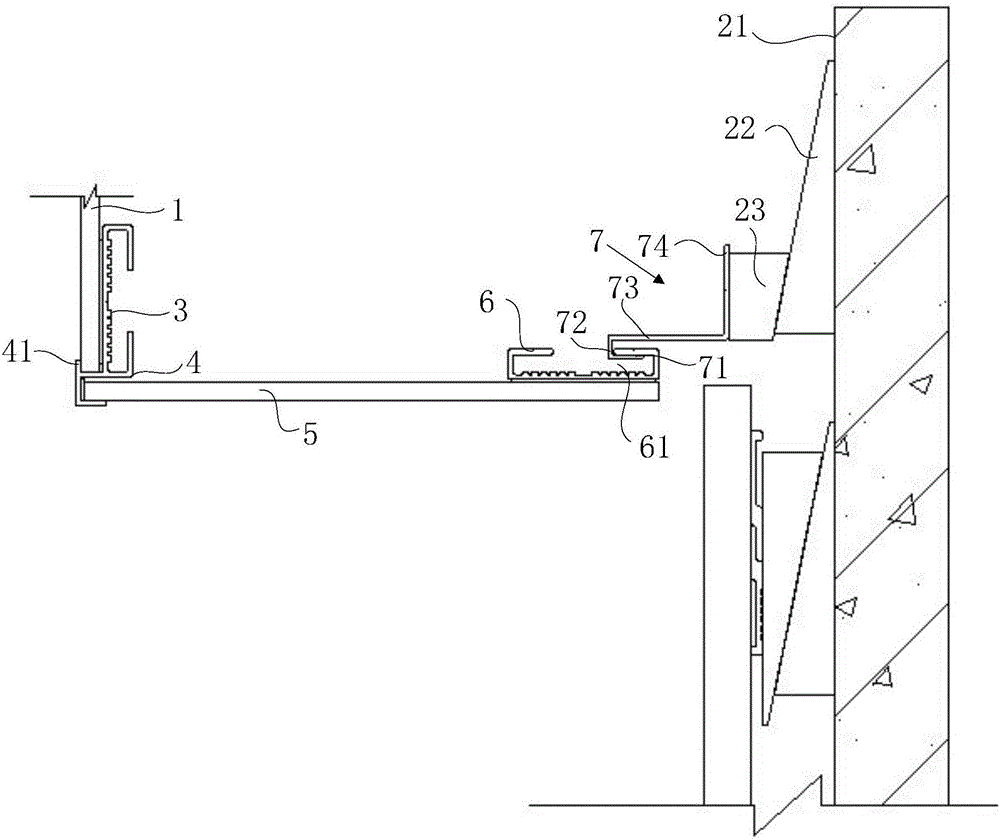

[0020] figure 1 It is a preferred embodiment of the structure of the top plate edge closing device provided by the present invention. like figure 1 As shown, the present invention provides a top plate edge closing device, comprising: a fixed vertical plate 1 and a fixed wall 2, a hanging keel 3, a retaining groove 4, a panel 5, a back hanging keel 6, and a hanging keel Bone 7.

[0021] Please refer to figure 1 , the vertical plate 1 and the wall surface 21 of the wall body 2 are arranged opposite to each other; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com