Patents

Literature

81 results about "Closed mouth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

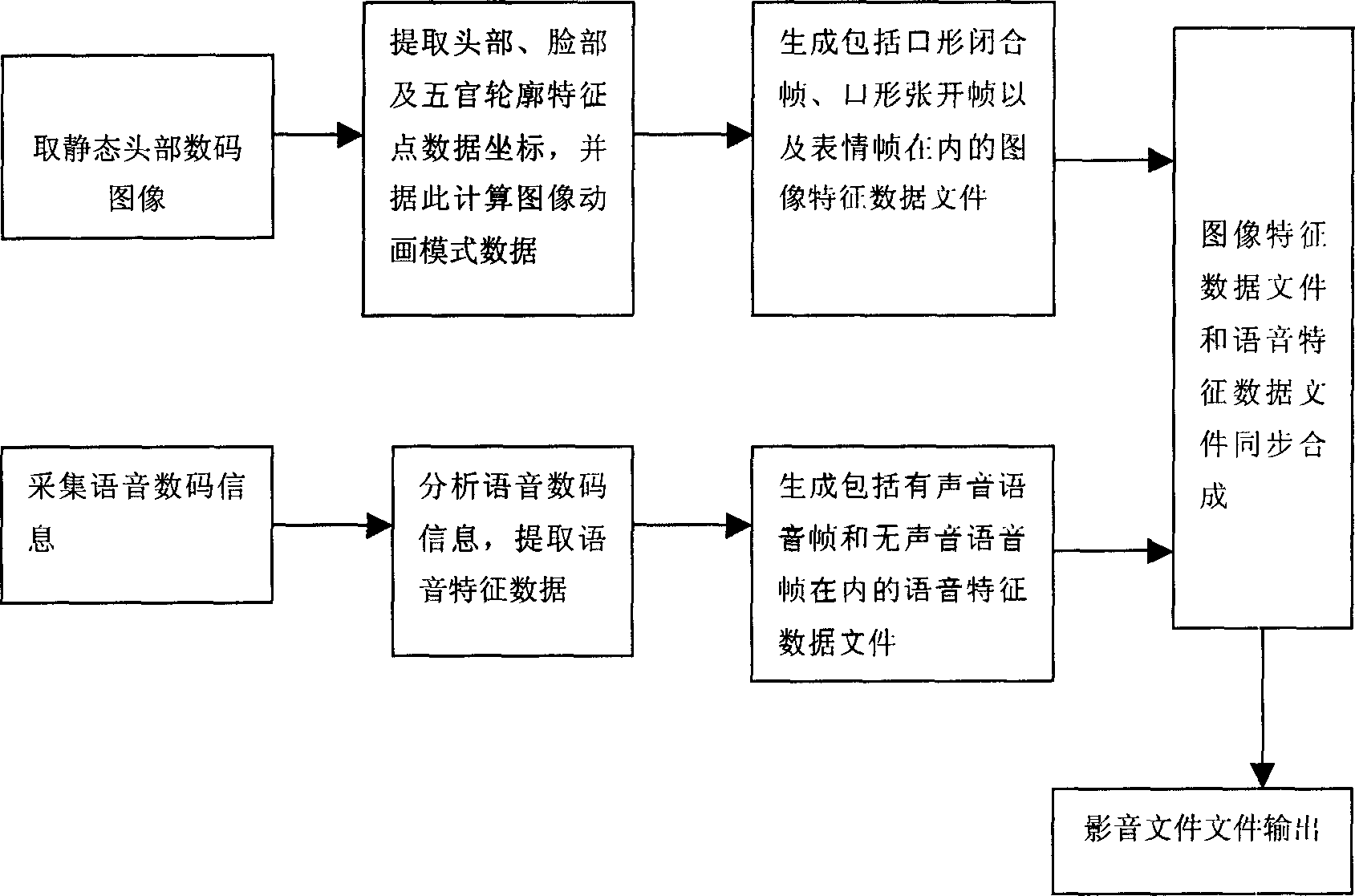

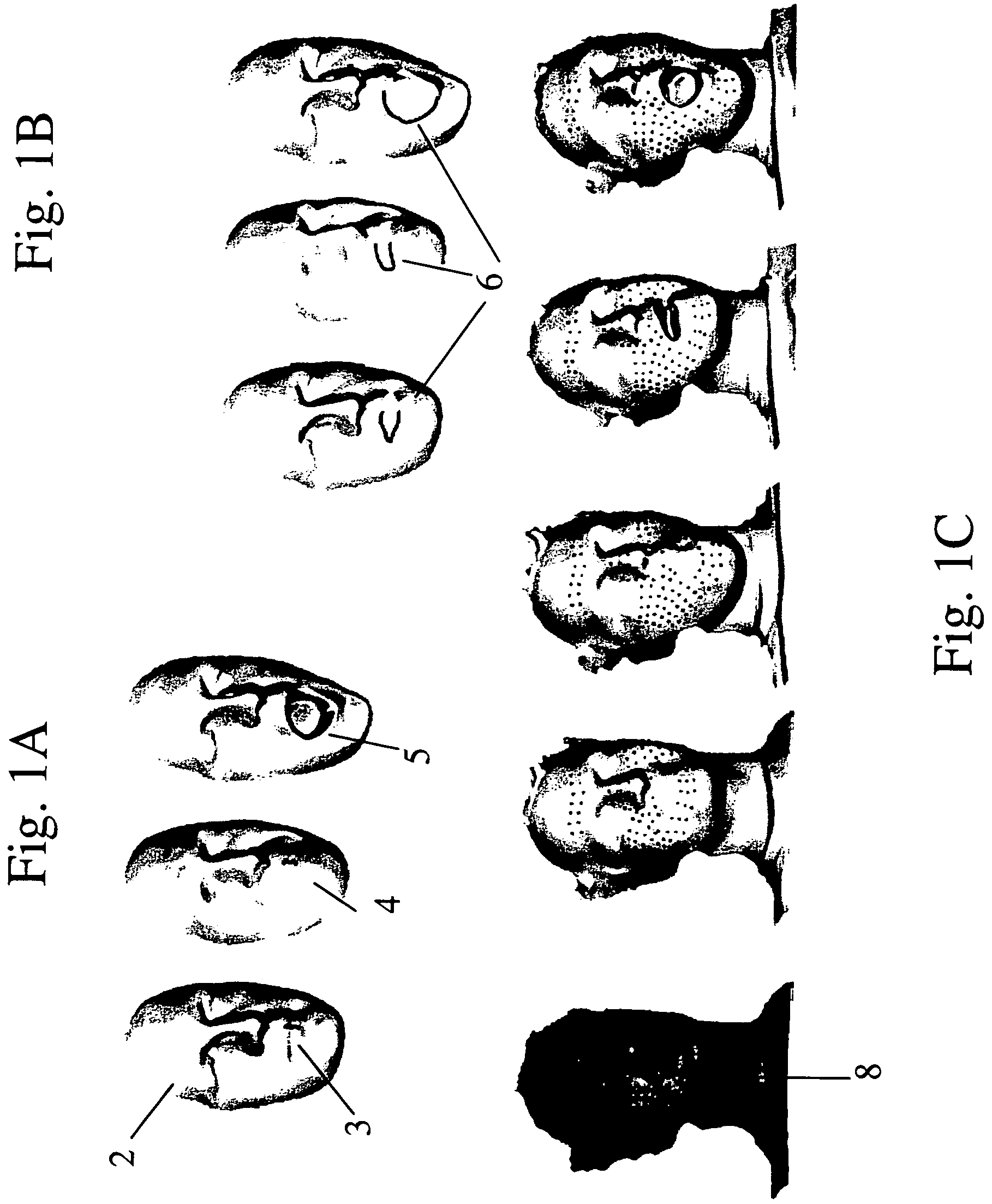

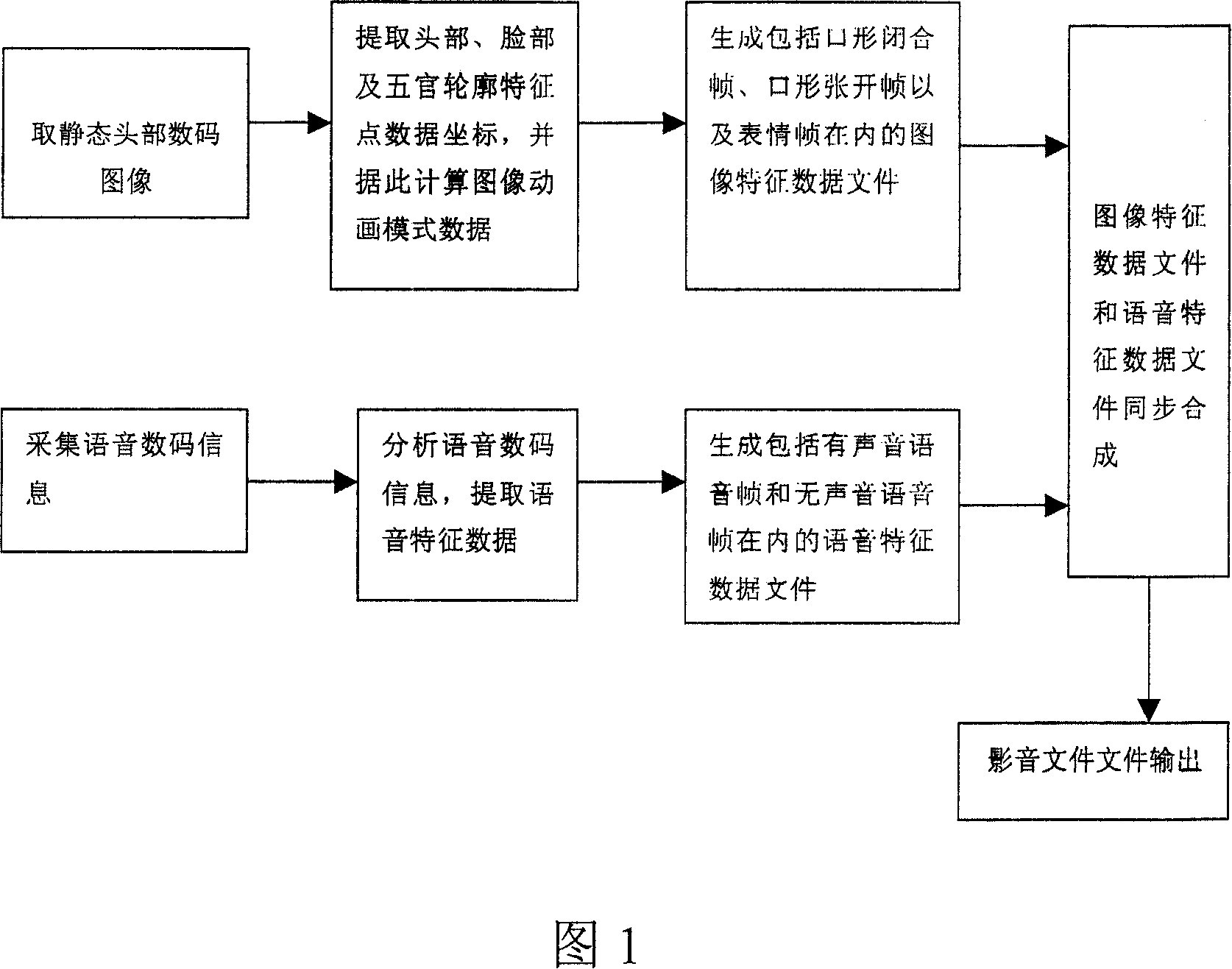

Method for composing audio/video file by voice driving head image

The invention relates to a method for compounding head pictures into video files in the drive of sound. The method comprises the steps as follow: a fixed digital head picture is captured; the data coordinates of the head, the face and the facial features are picked up and the picture animation mode data is counted; a closed mouth frame, an open mouth frame and an expression frame and a picture characteristics data file including the quantity of the three picture frames are generated; a sound digital information is collected; the sound characteristics data is analyzed and picked up so as to generate a sound characteristics data file including a voice sound frame and an assonant sound frame; the picture characteristics data file and the sound characteristics data file are compounded in-phase, so that the voice sound frame is corresponding to the open mouth frame, and the assonant sound frame is corresponding to the closed mouth frame, and then outputting. The invention has the advantages of vivid pictures, achieving the animation on human facial and animal facial expression, easy and simple production and being convenient for generalization and use.

Owner:GUANGZHOU EAPHONETECH CO LTD

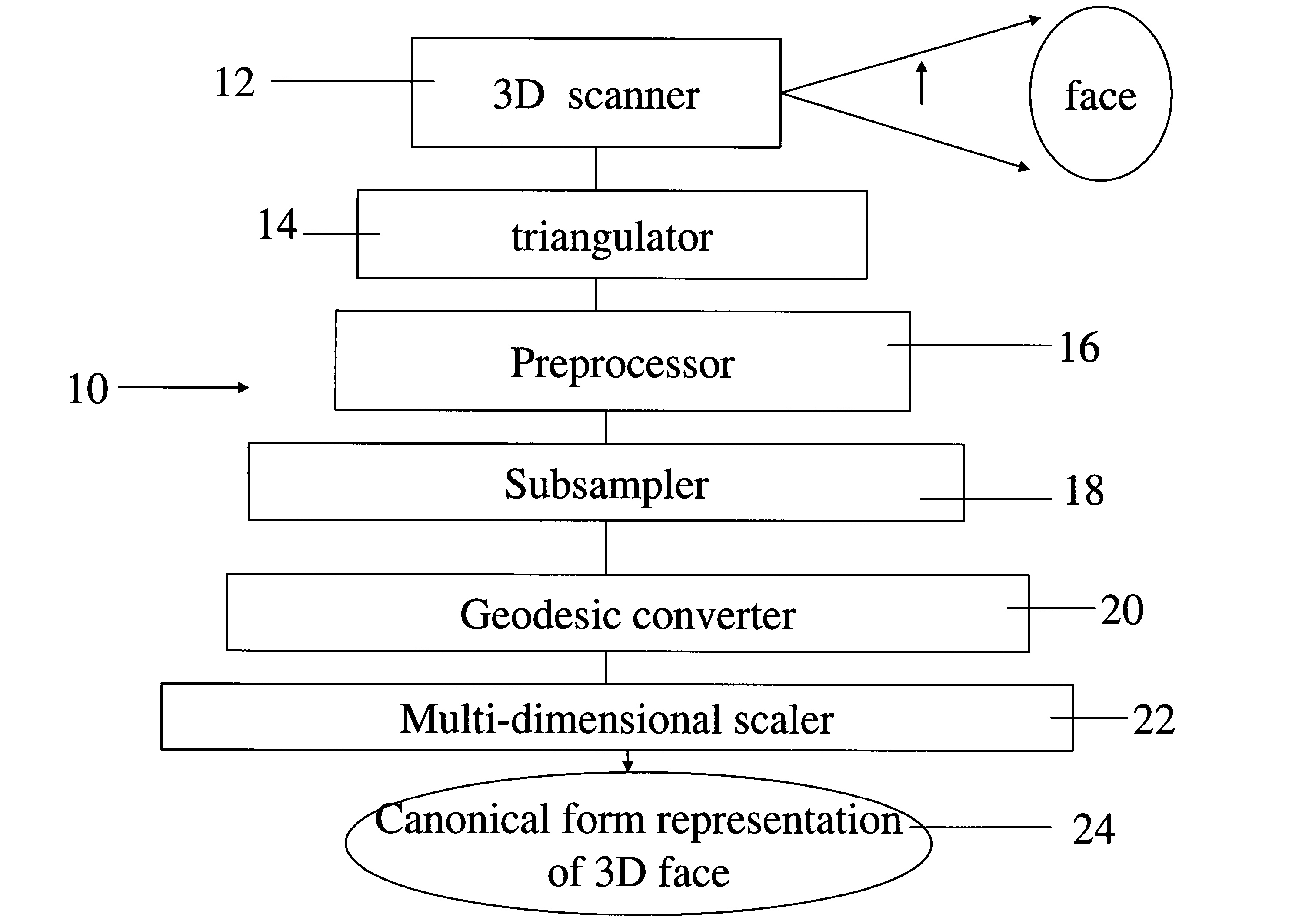

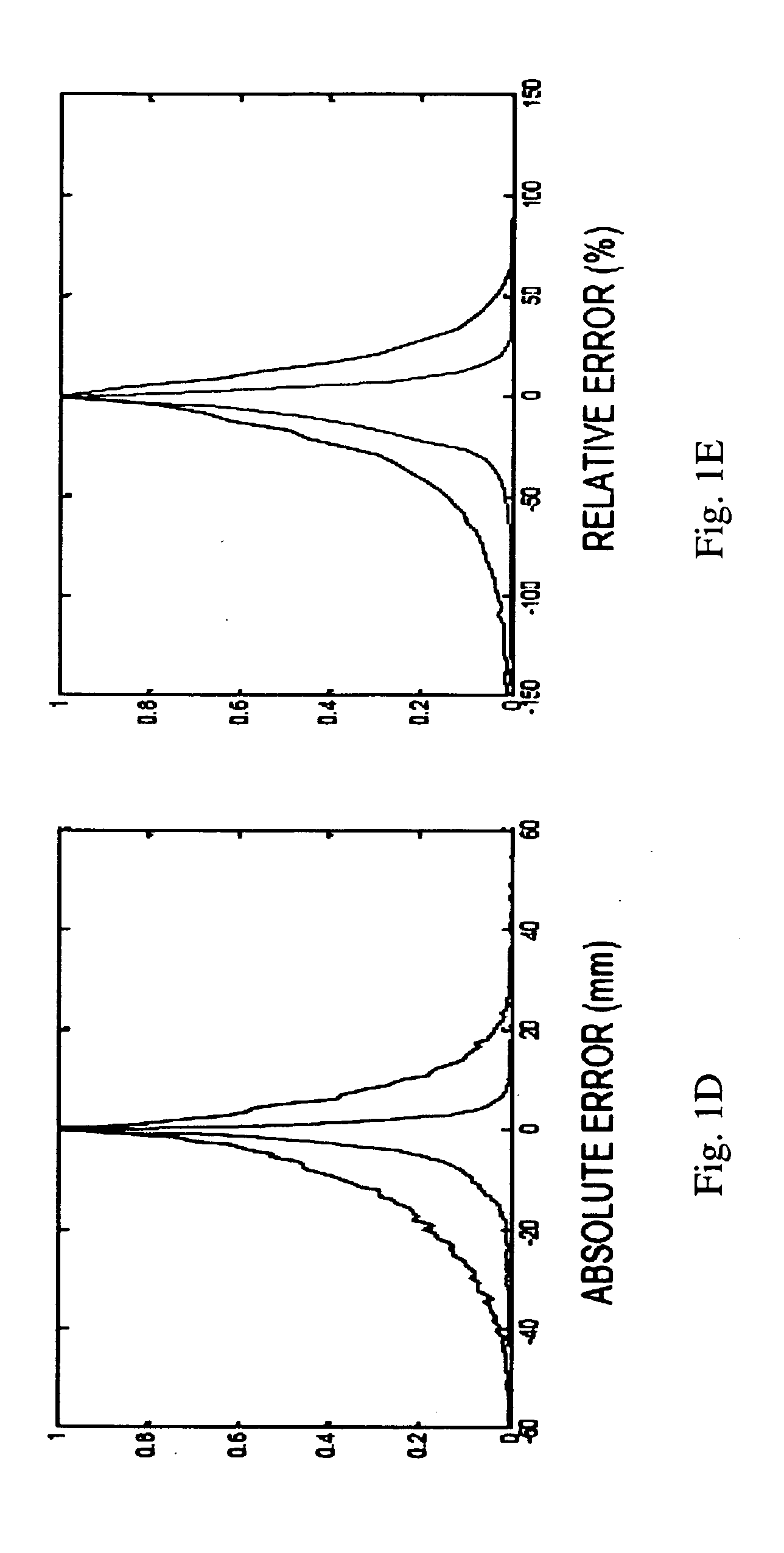

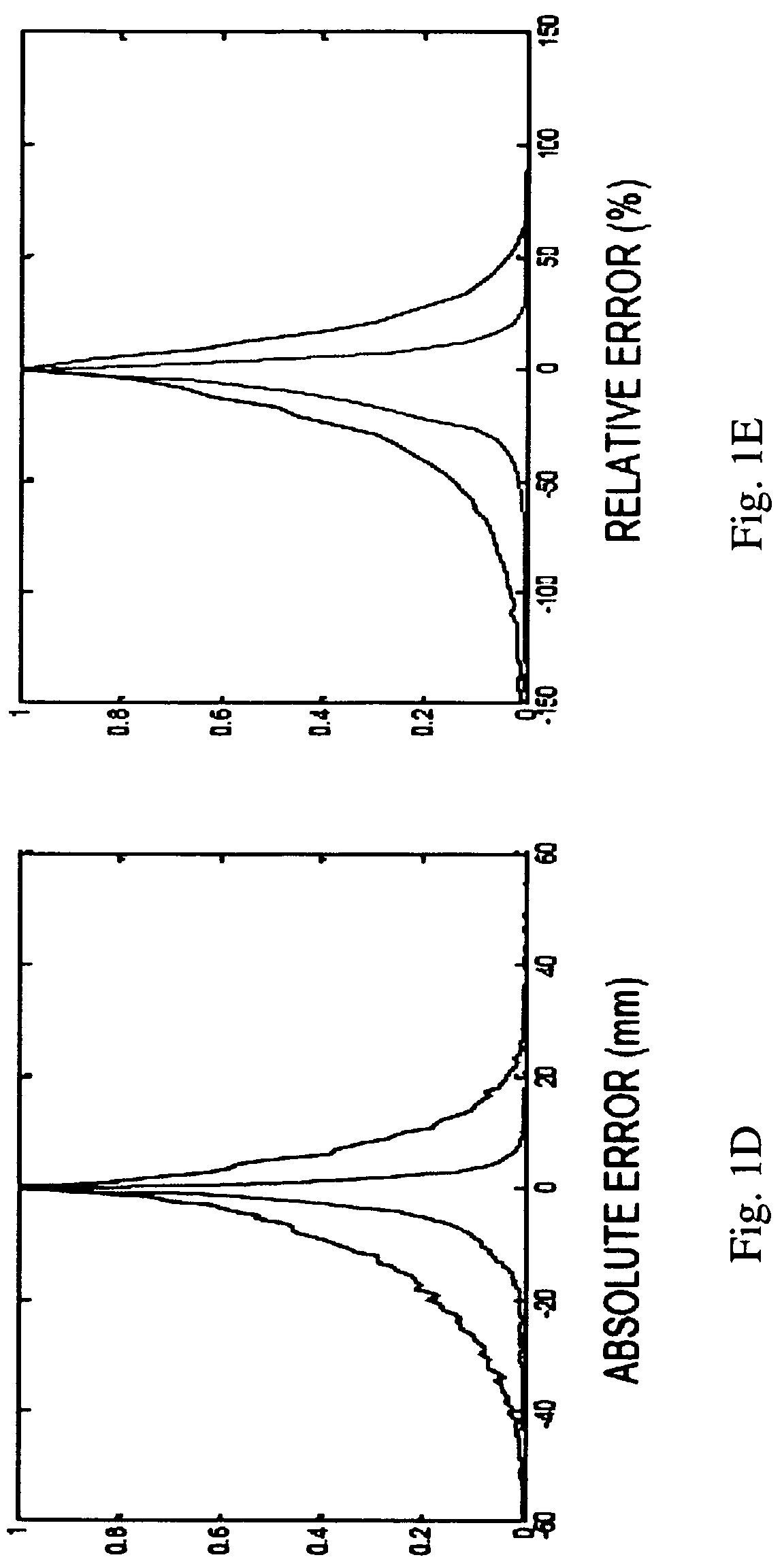

Facial recognition and the open mouth problem

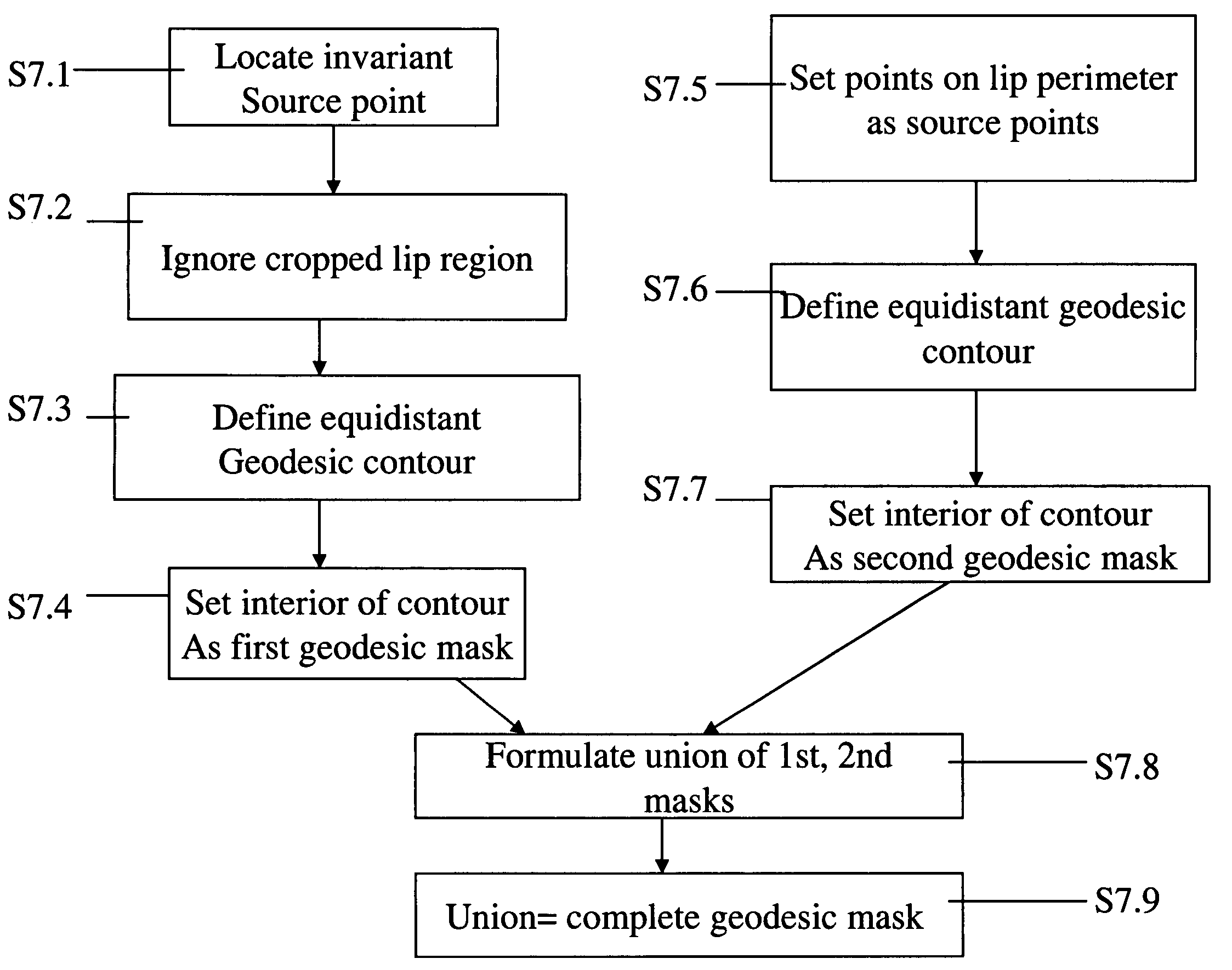

A method, for electronic face recognition using geodesic representations, of processing such a geodesic representation of a face having a mouth and being able to adopt open-mouthed or closed mouth states, so that the electronic recognition works regardless of whether the mouth in the representation is open or closed. The method comprises: identifying a mouth region within a face; applying a topological constraint to the mouth region, and representing the face with the constraint. The topological constraint is chosen to render the geodesic representation invariant to the mouth state being open or closed.

Owner:TECHNION RES & DEV FOUND LTD +1

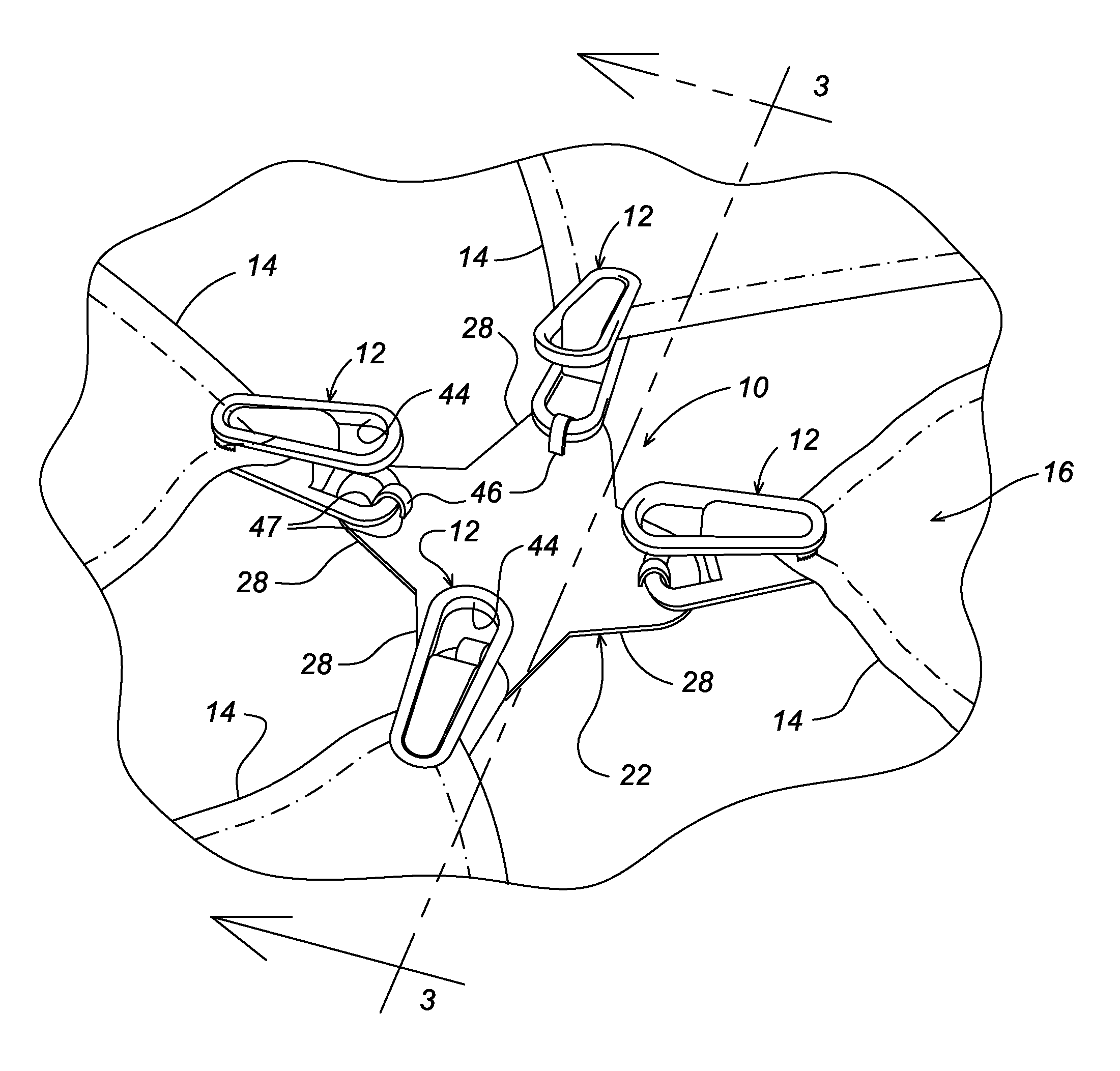

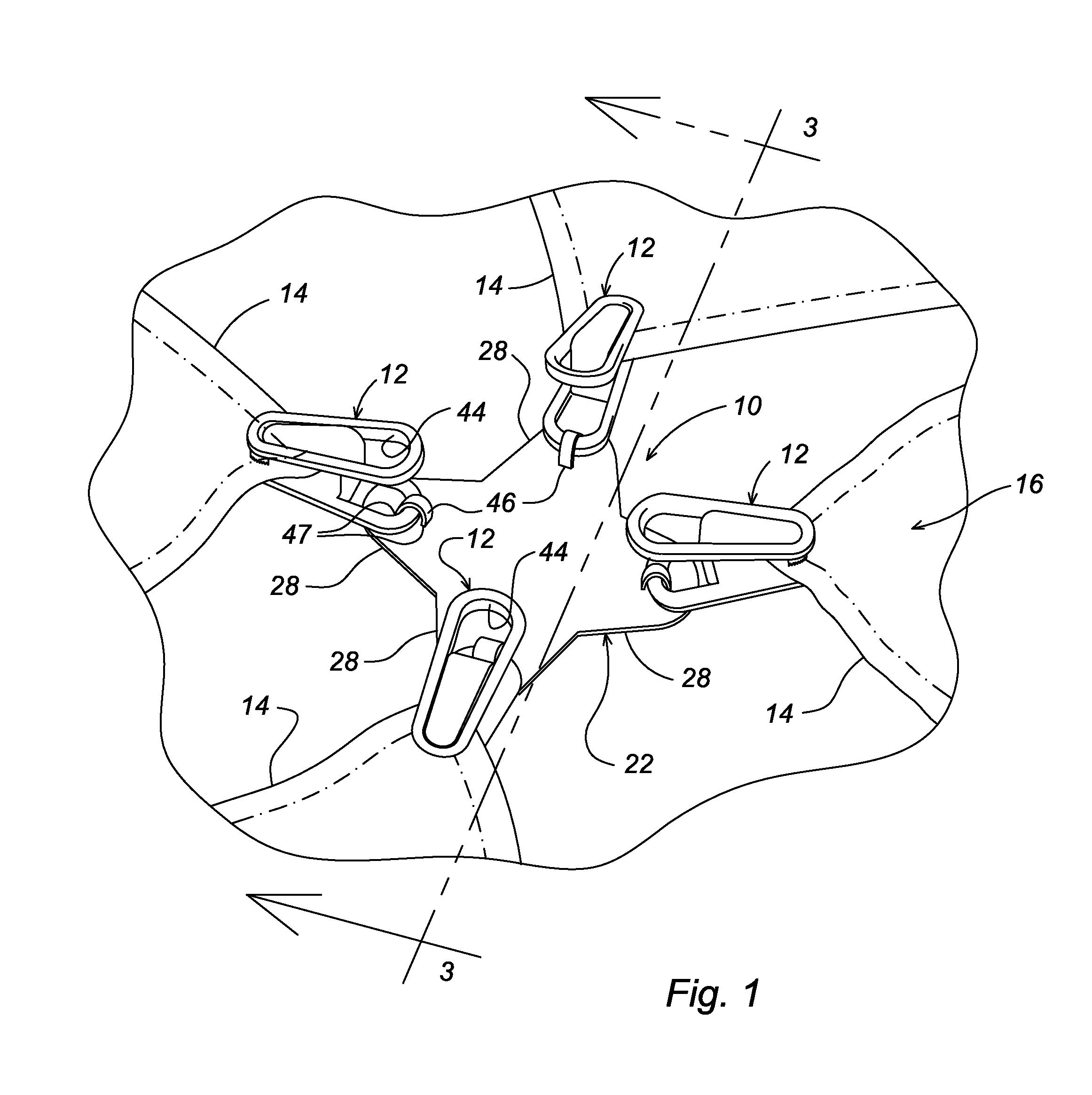

Laundry retainer for bed sheets

A laundry retainer for bed sheets to prevent entanglement with smaller items in a mixed load. The retainer has a base plate on which at least four clothes clips are mounted. The clothes clips grip the side edges of a sheet to form a generally closed mouth bag in which smaller items in a mixed load are less likely to become entangled.

Owner:AHERN MARCUS W

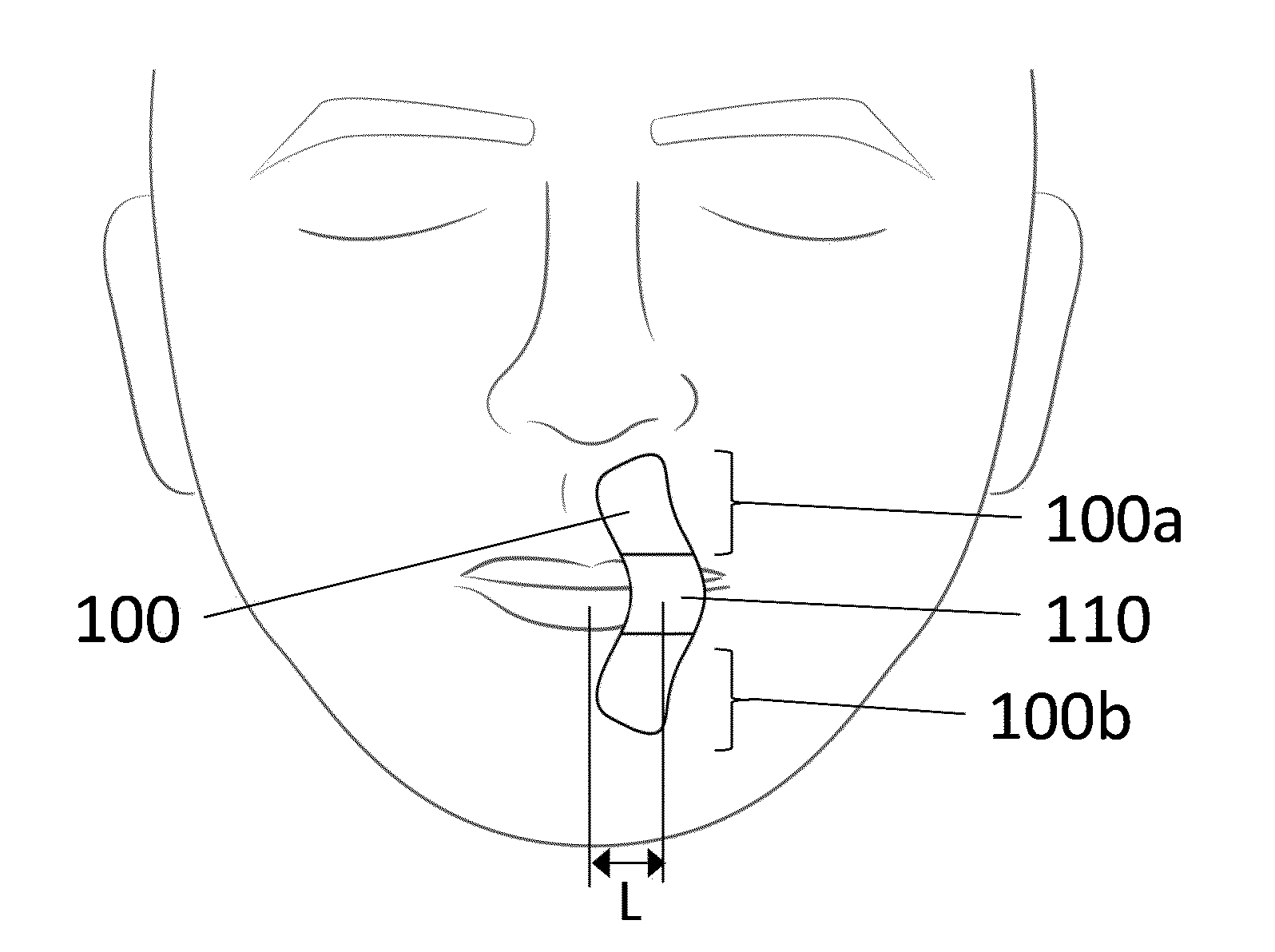

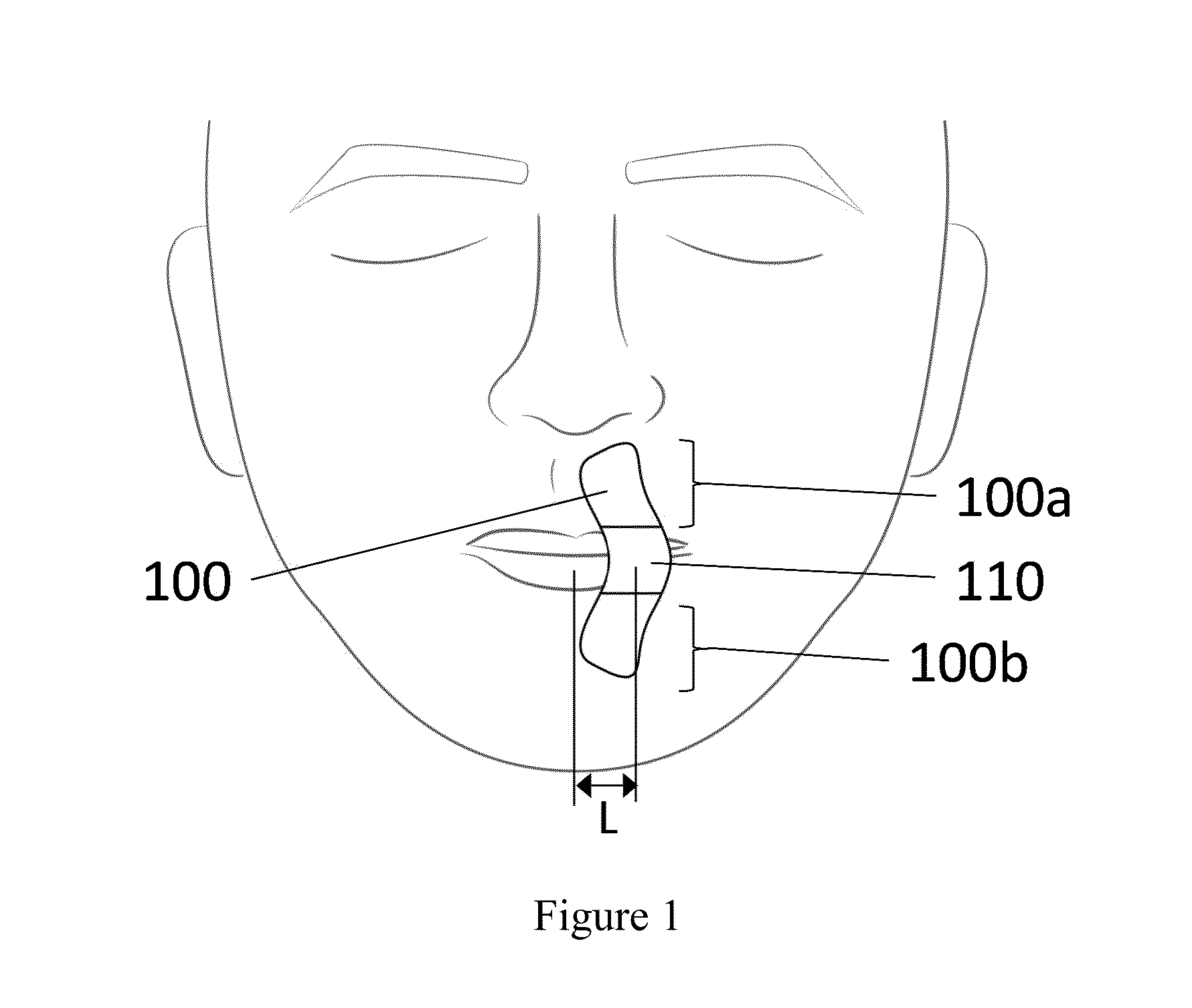

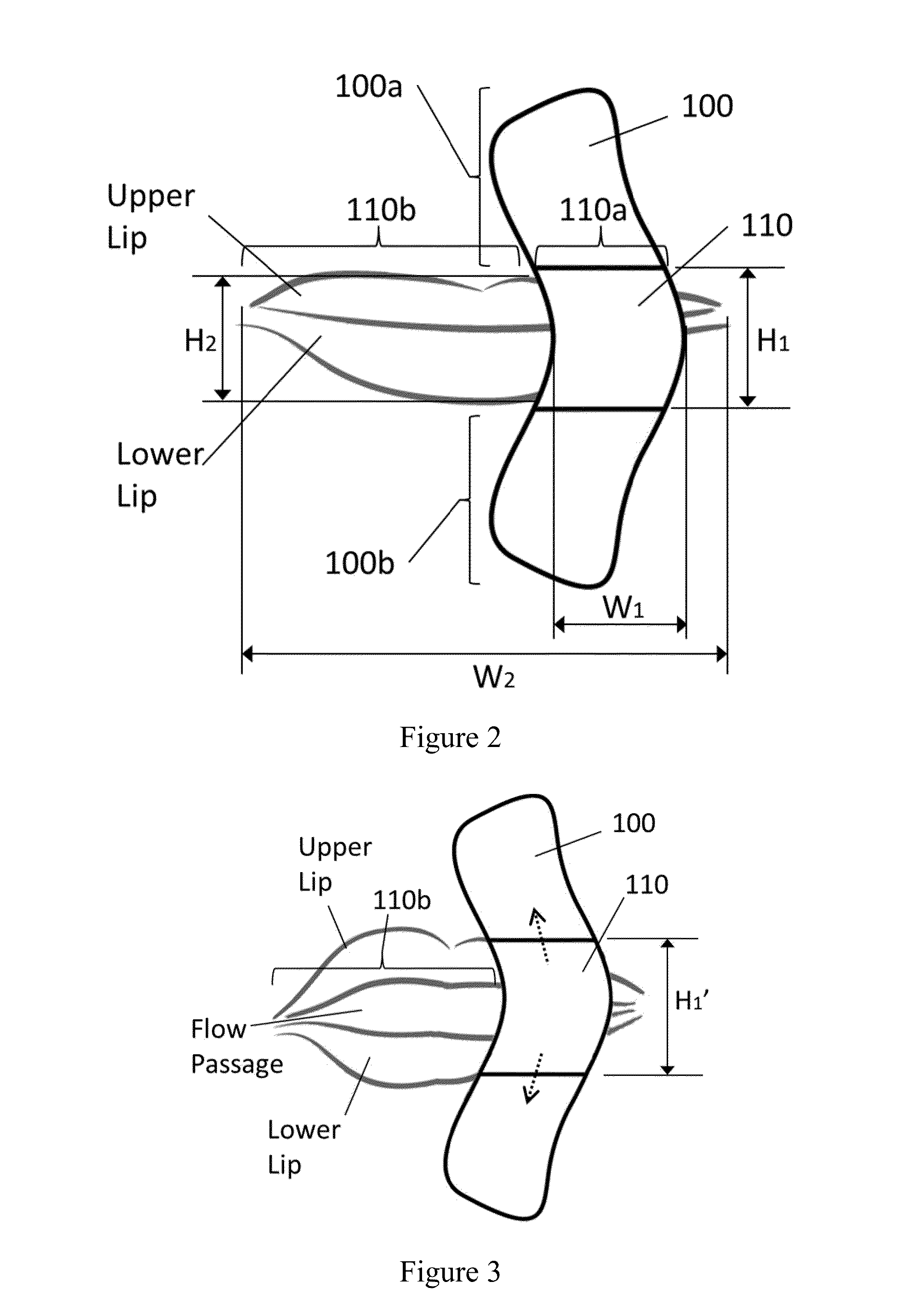

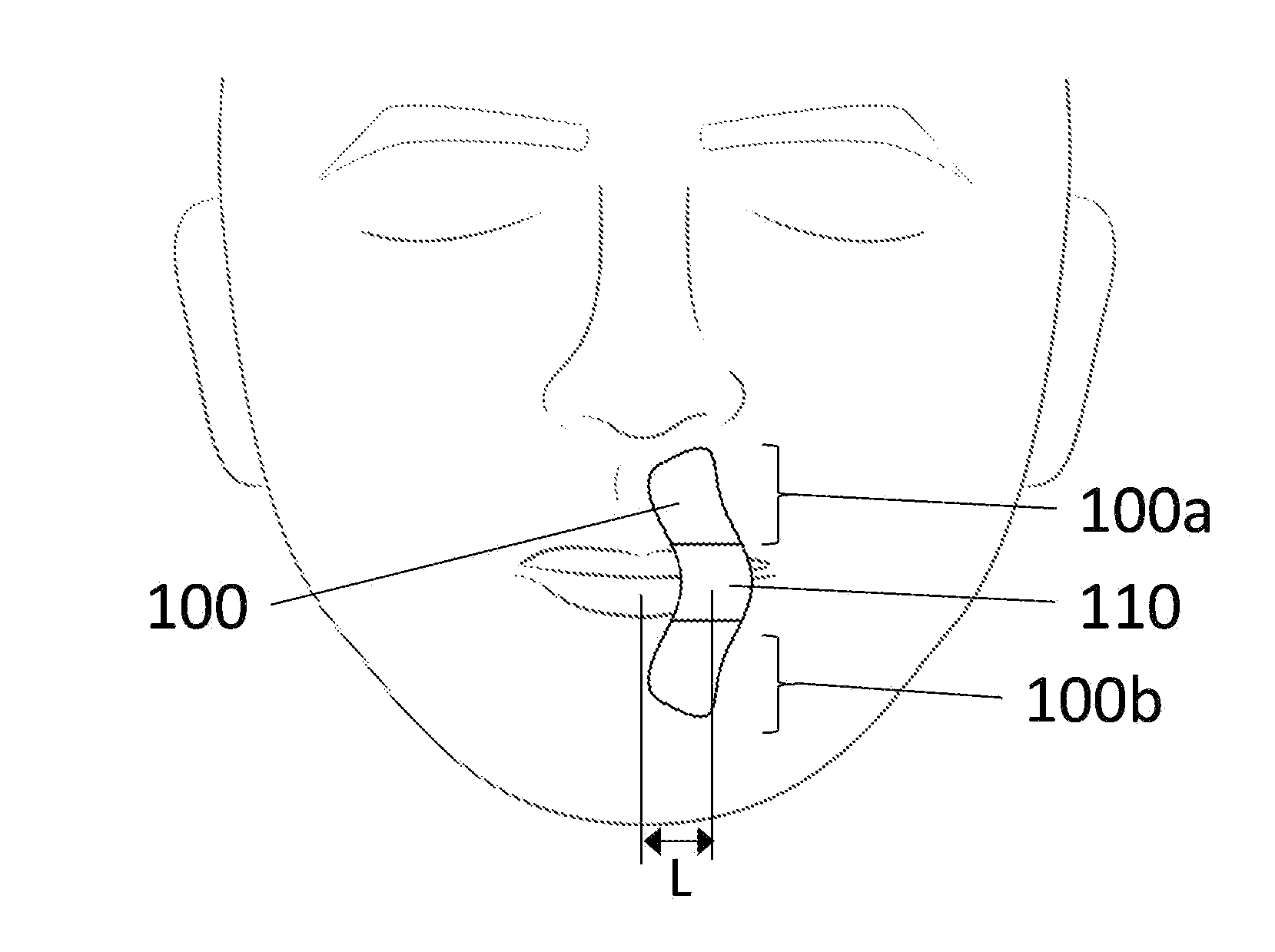

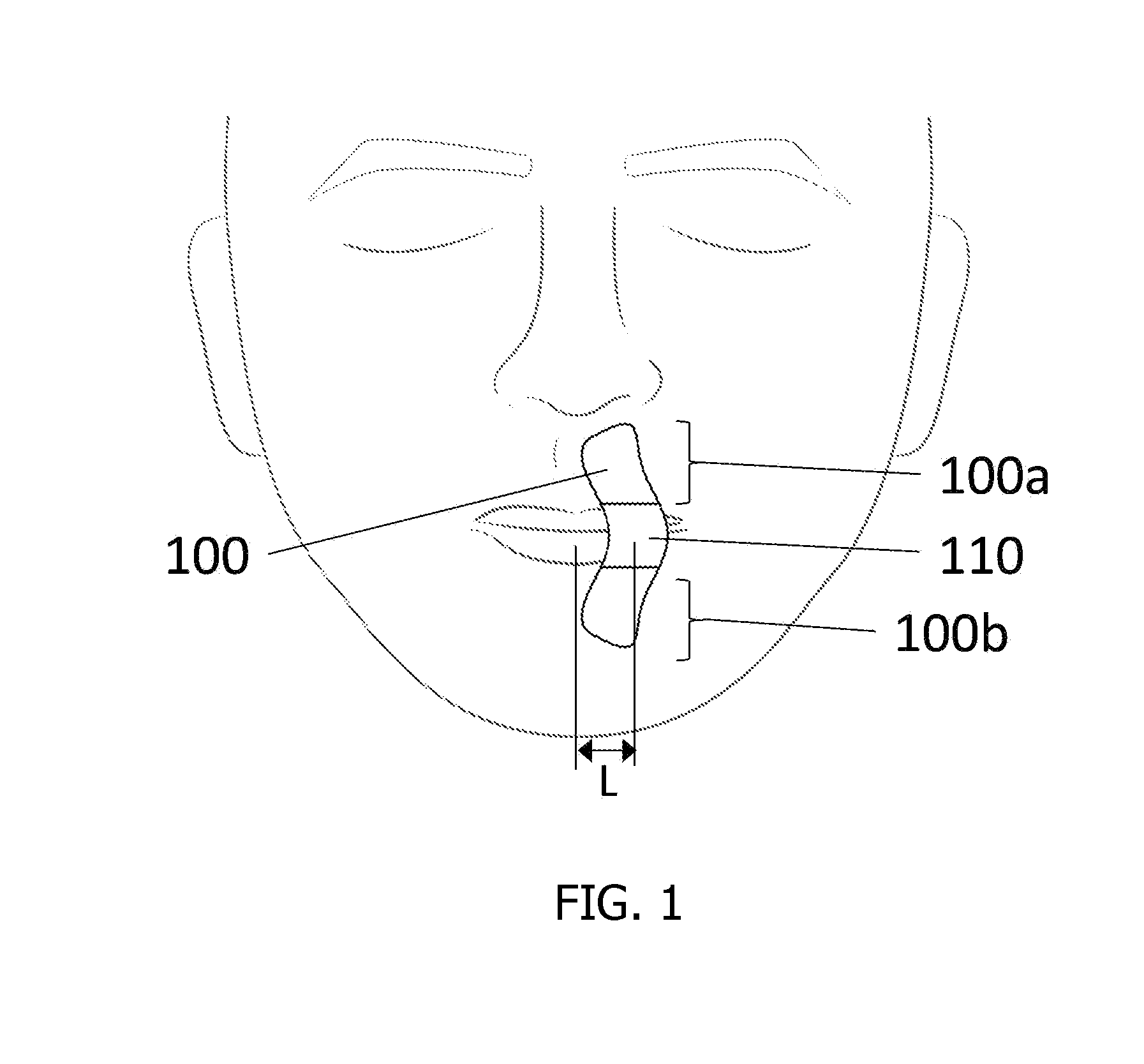

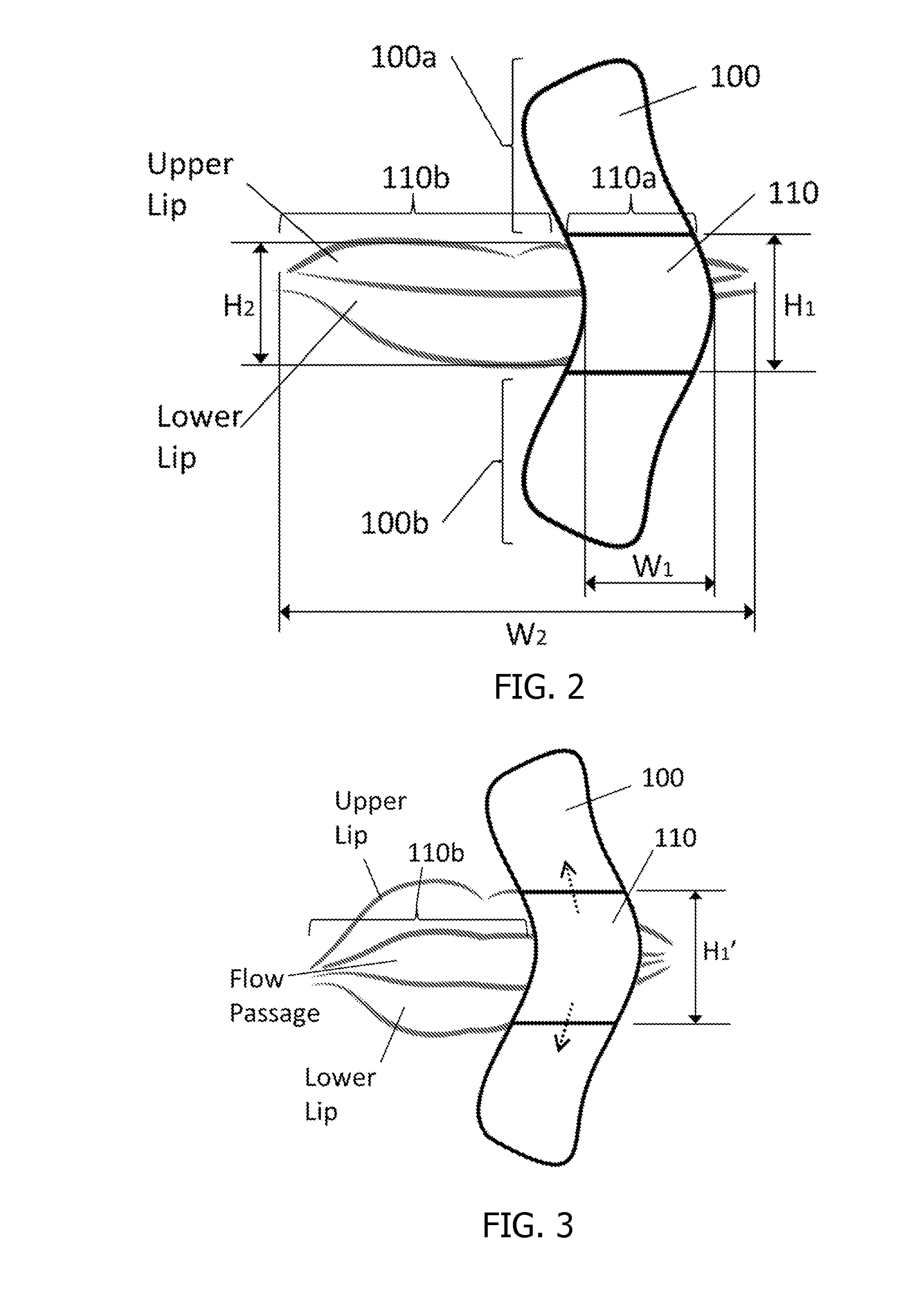

Adhesive strip with non-adhesive band and method to reduce mouth breathing using the same

InactiveUS20140000632A1Freedom of movementReduce adhesionRespiratorsSnoring preventionAdhesive beltMedicine

This invention provides an adhesive strip with non-adhesive band for preventing or reducing opening of a user's mouth. The adhesive strip with non-adhesive band comprises a non-adhesive band across a central portion of an adhesive side of an adhesive strip and divides the adhesive strip into an upper adhesive part and a lower adhesive part, and the non-adhesive band has a height larger than a thickness of an upper and lower lips of the user in a closed mouth state;

Owner:SOMNICS INC

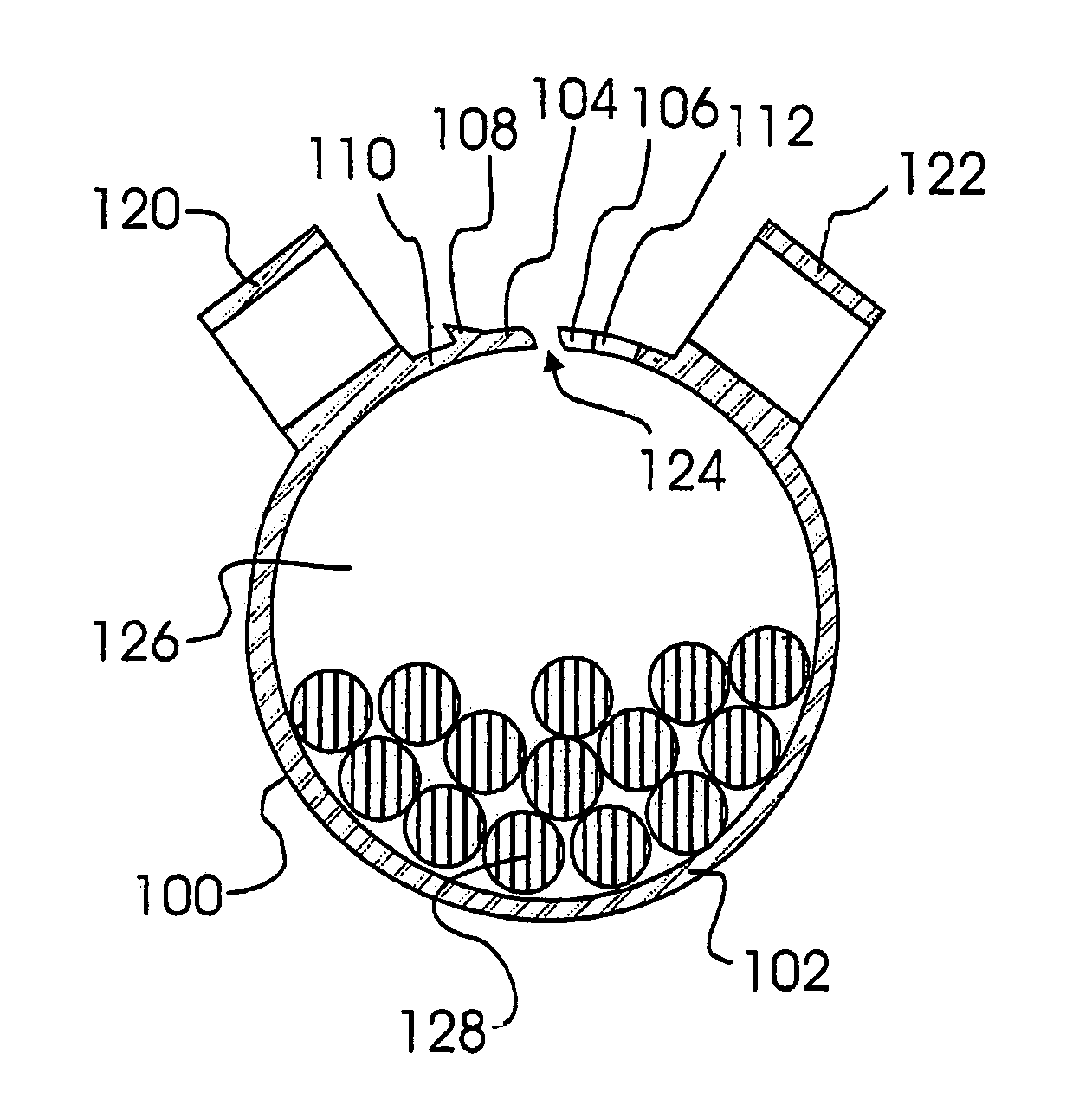

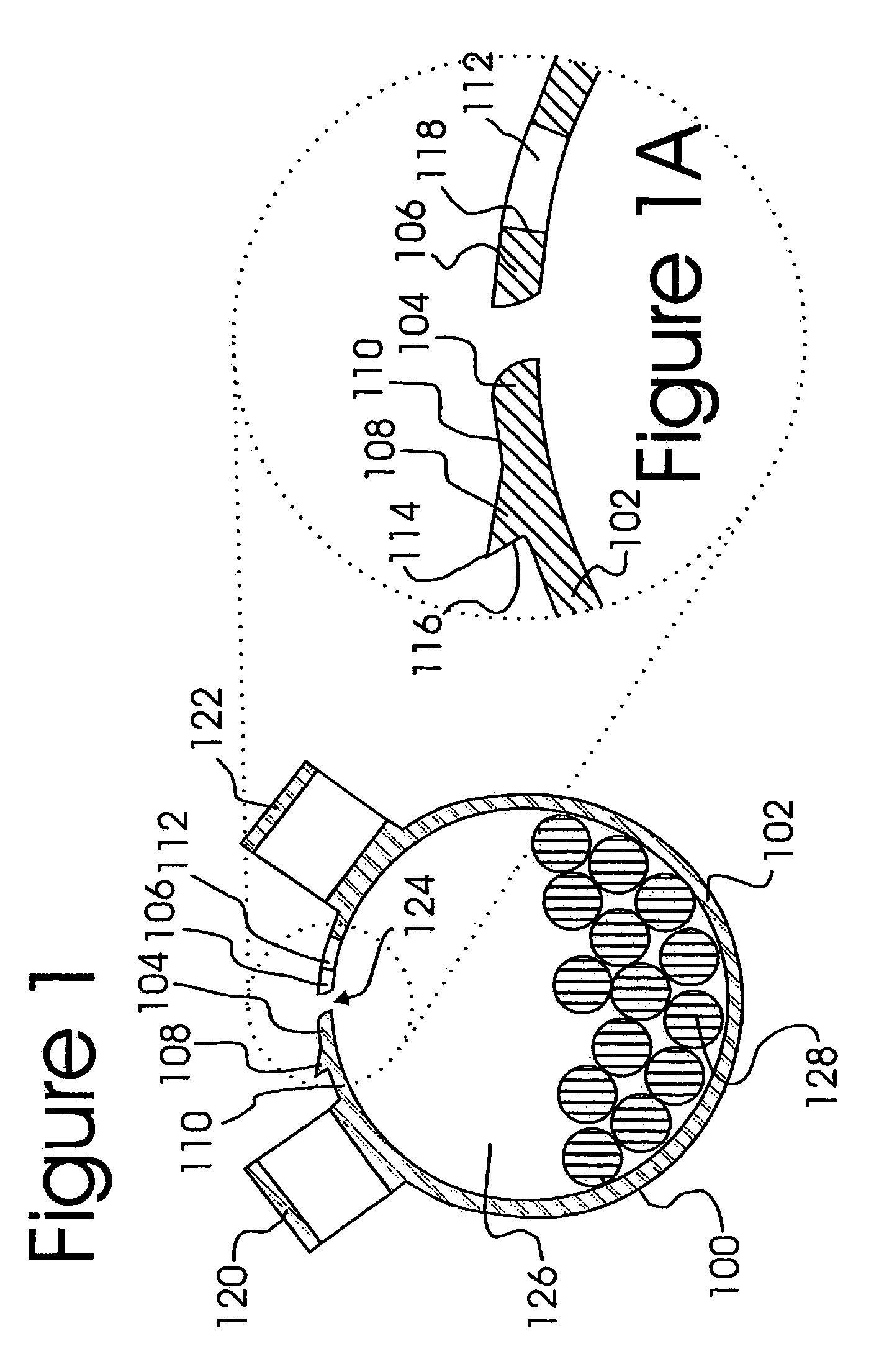

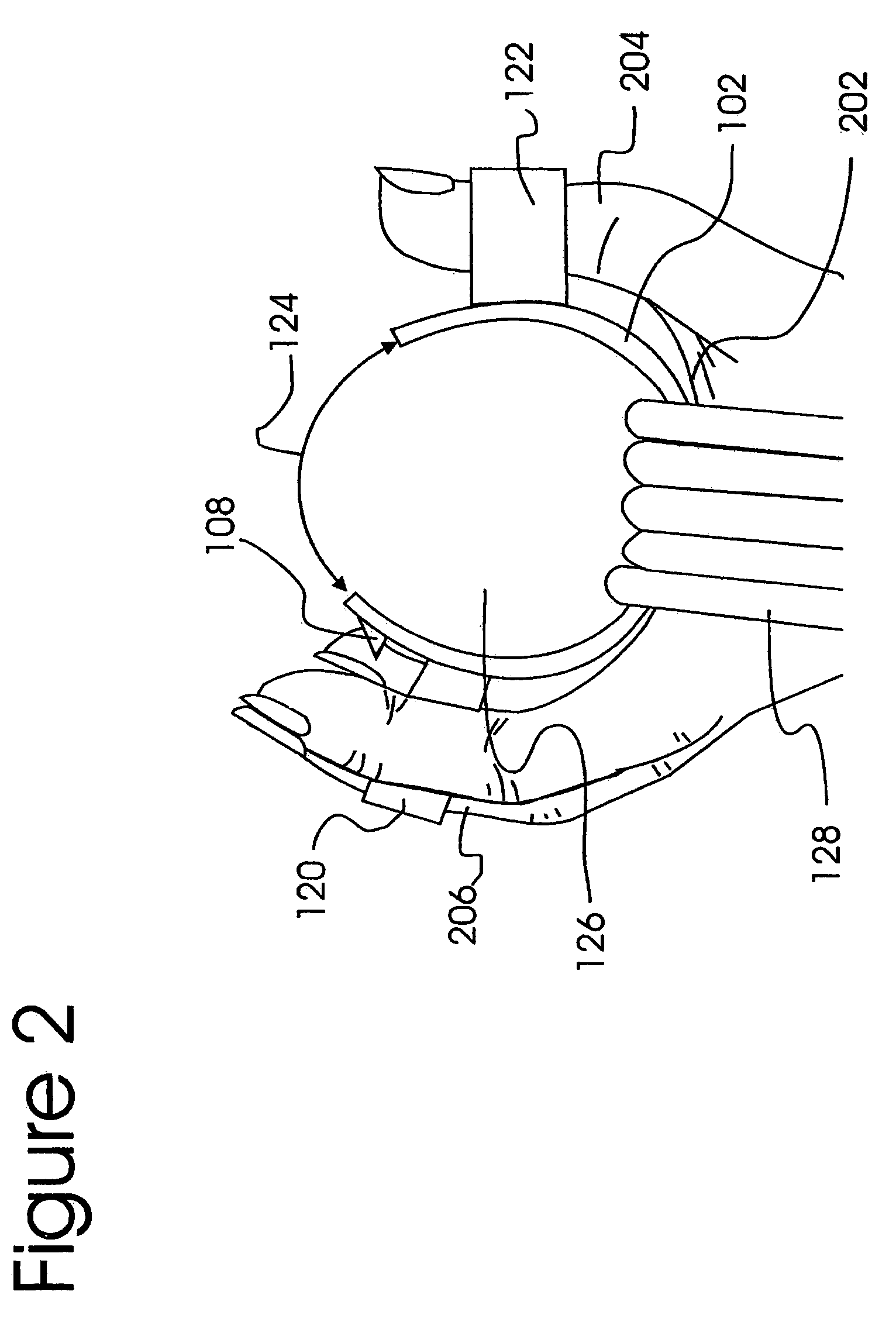

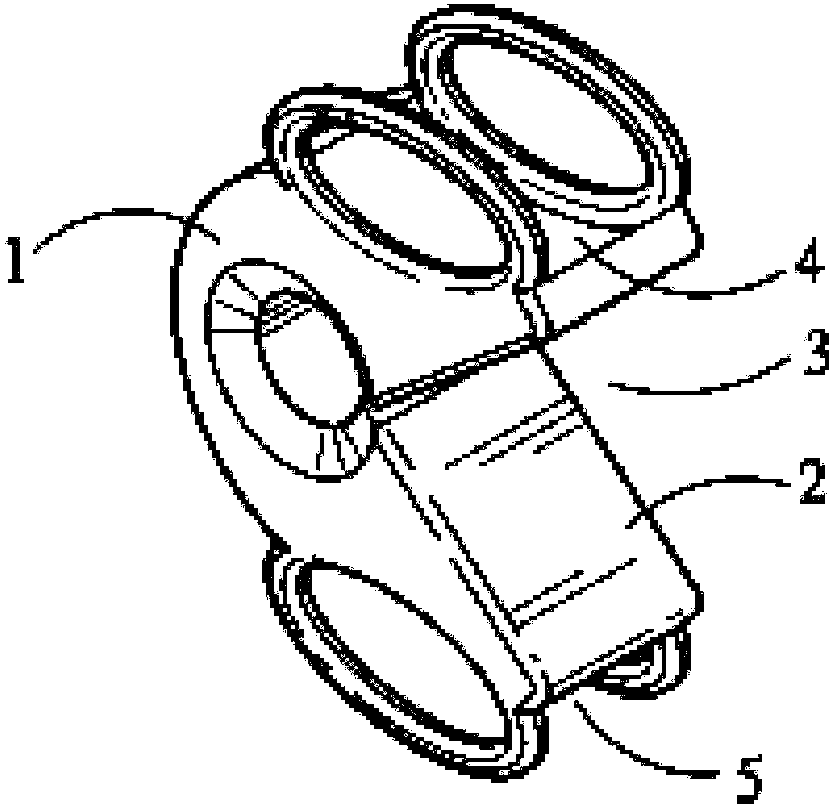

Single-handed cord/cable management device

The present invention is directed to a device for bundling cables, ropes, wires, or other long flexible materials that are desired to be bundled. The device comprises an arcuate strap for encircling bundled cables. The strap is preferably discontinuous, with first and second ends forming a mouth into a central cavity formed by an arcuate strap. Finger grips are located adjacent to the first and second ends, allowing fingers of a user to be used to pull the first and second ends of the strap to open the normally closed mouth of the device. The device also preferably includes engagement features on the first and second ends to allow the first and second ends to be forced into engagement to lock cables into the cavity formed by the arcuate shape of the strap.

Owner:RIVERA ALEXANDER F

Facial recognition and the open mouth problem

A method, for electronic face recognition using geodesic representations, of processing such a geodesic representation of a face having a mouth and being able to adopt open-mouthed or closed mouth states, so that the electronic recognition works regardless of whether the mouth in the representation is open or closed. The method comprises: identifying a mouth region within a face; applying a topological constraint to the mouth region, and representing the face with the constraint. The topological constraint is chosen to render the geodesic representation invariant to the mouth state being open or closed.

Owner:TECHNION RES & DEV FOUND LTD +1

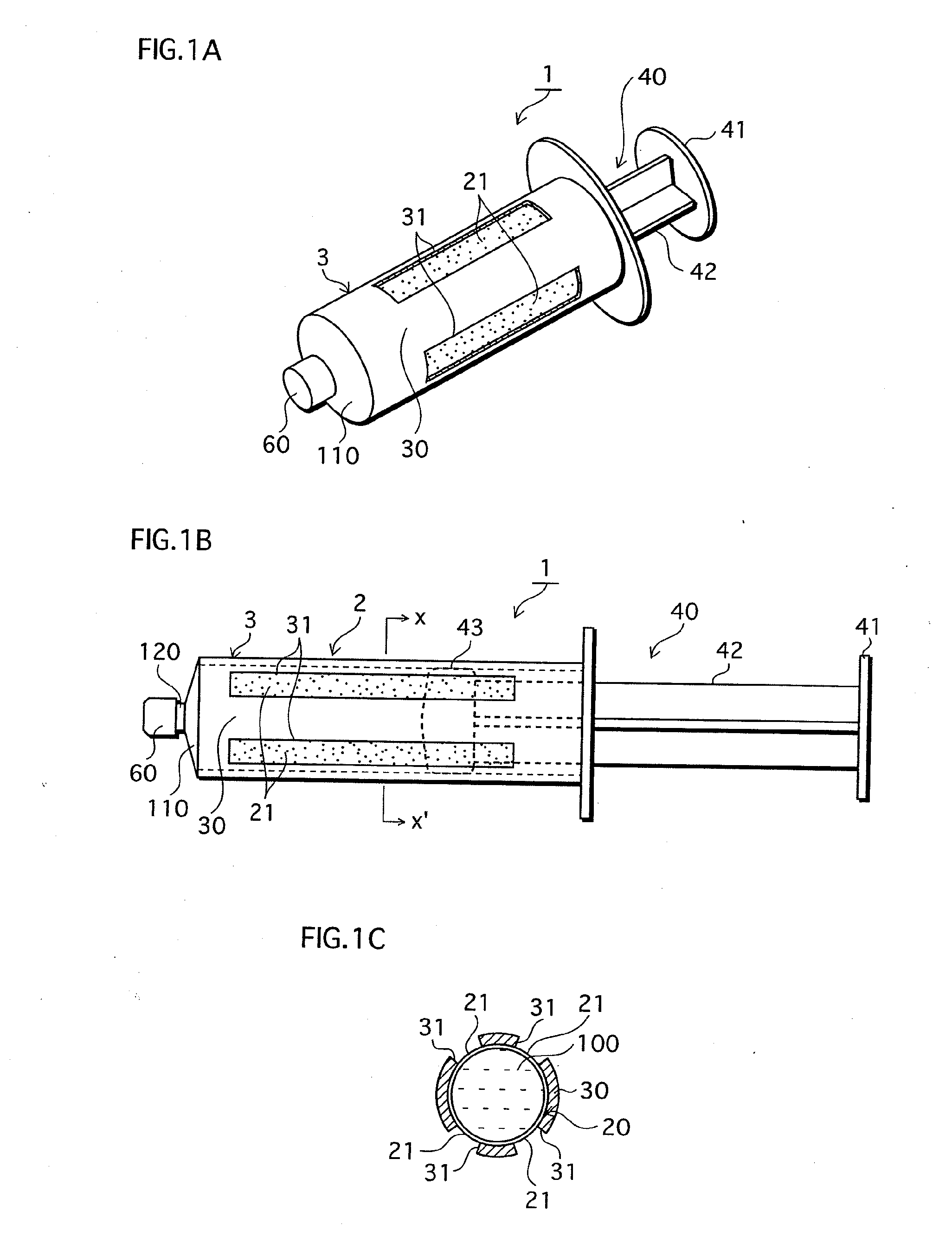

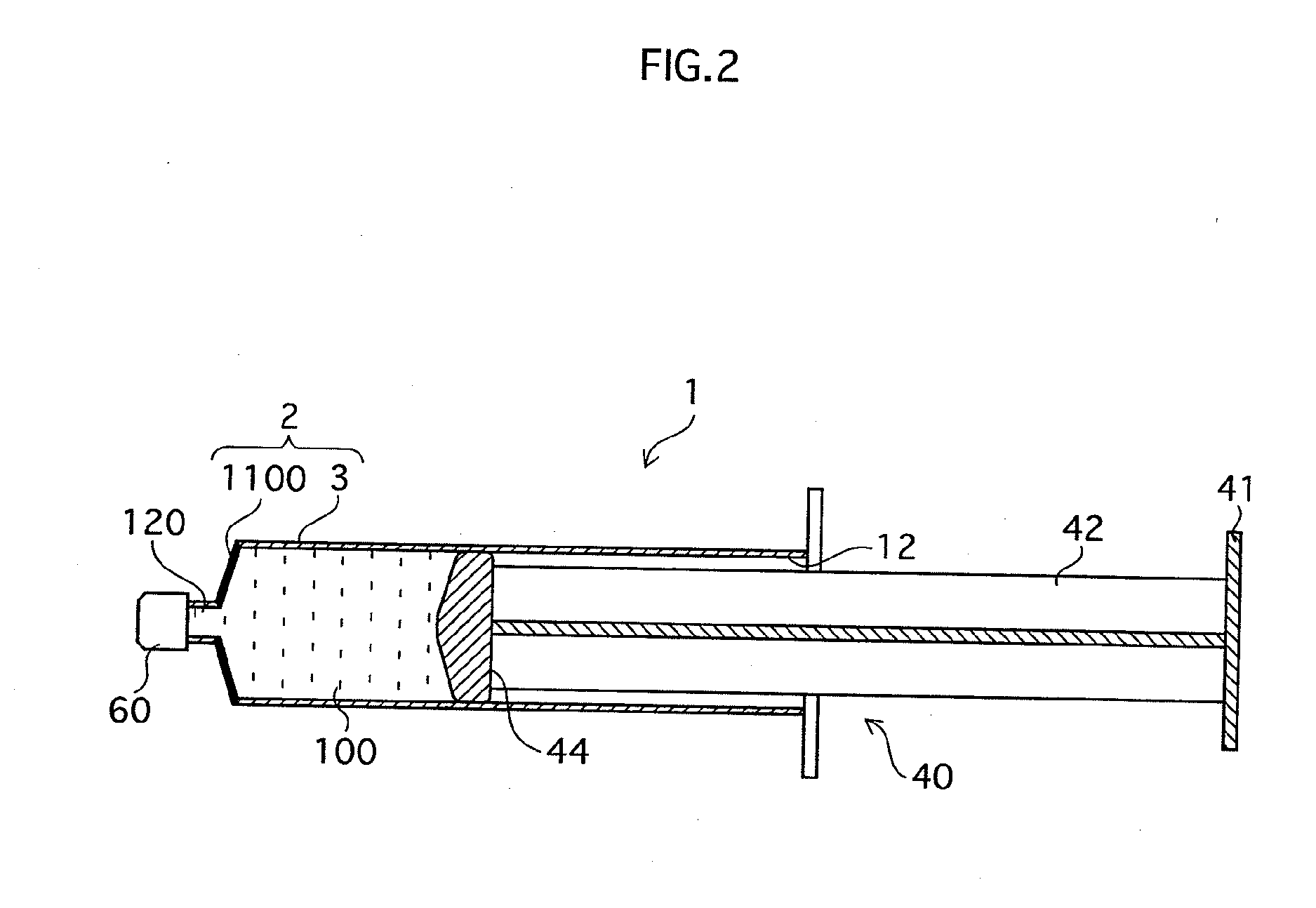

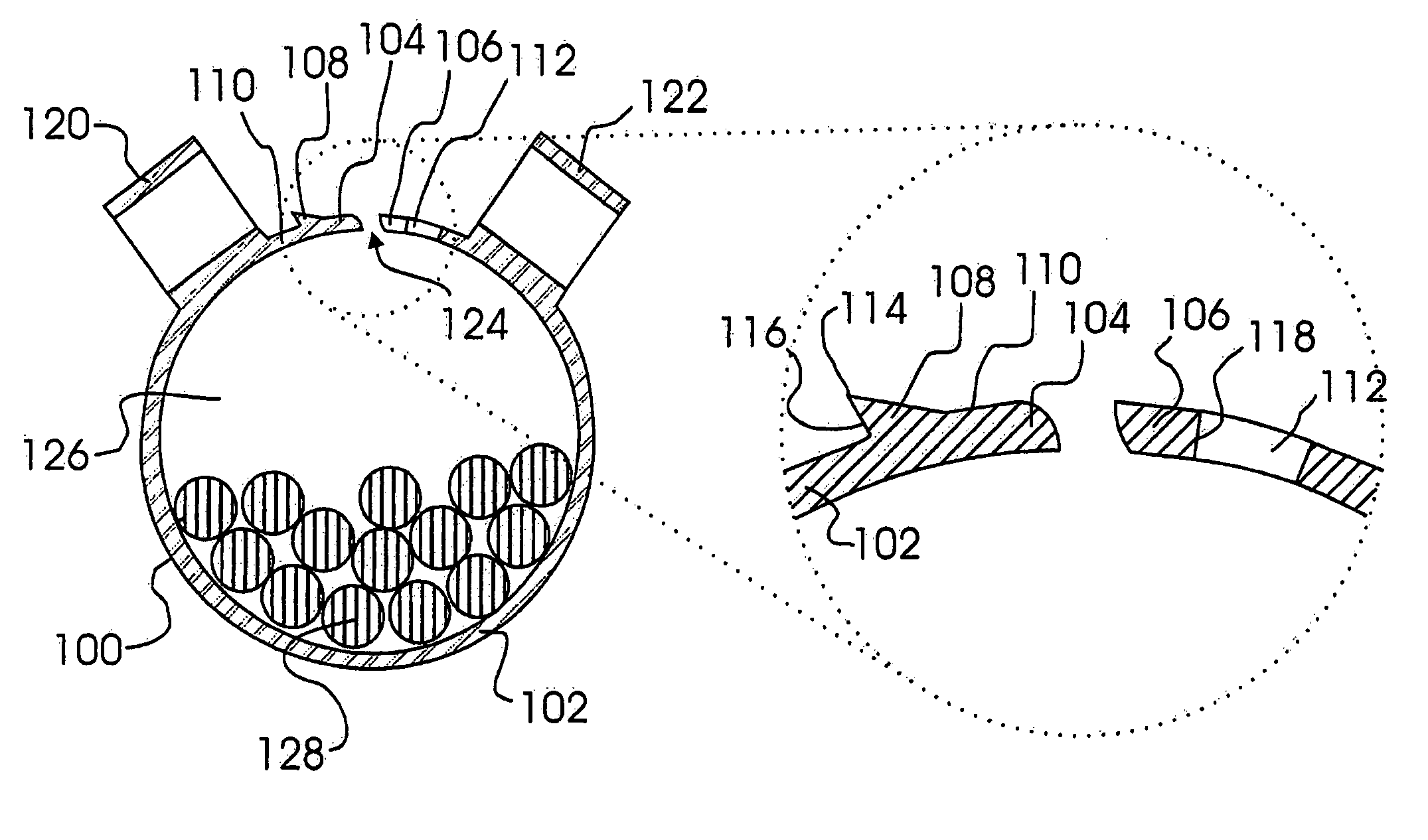

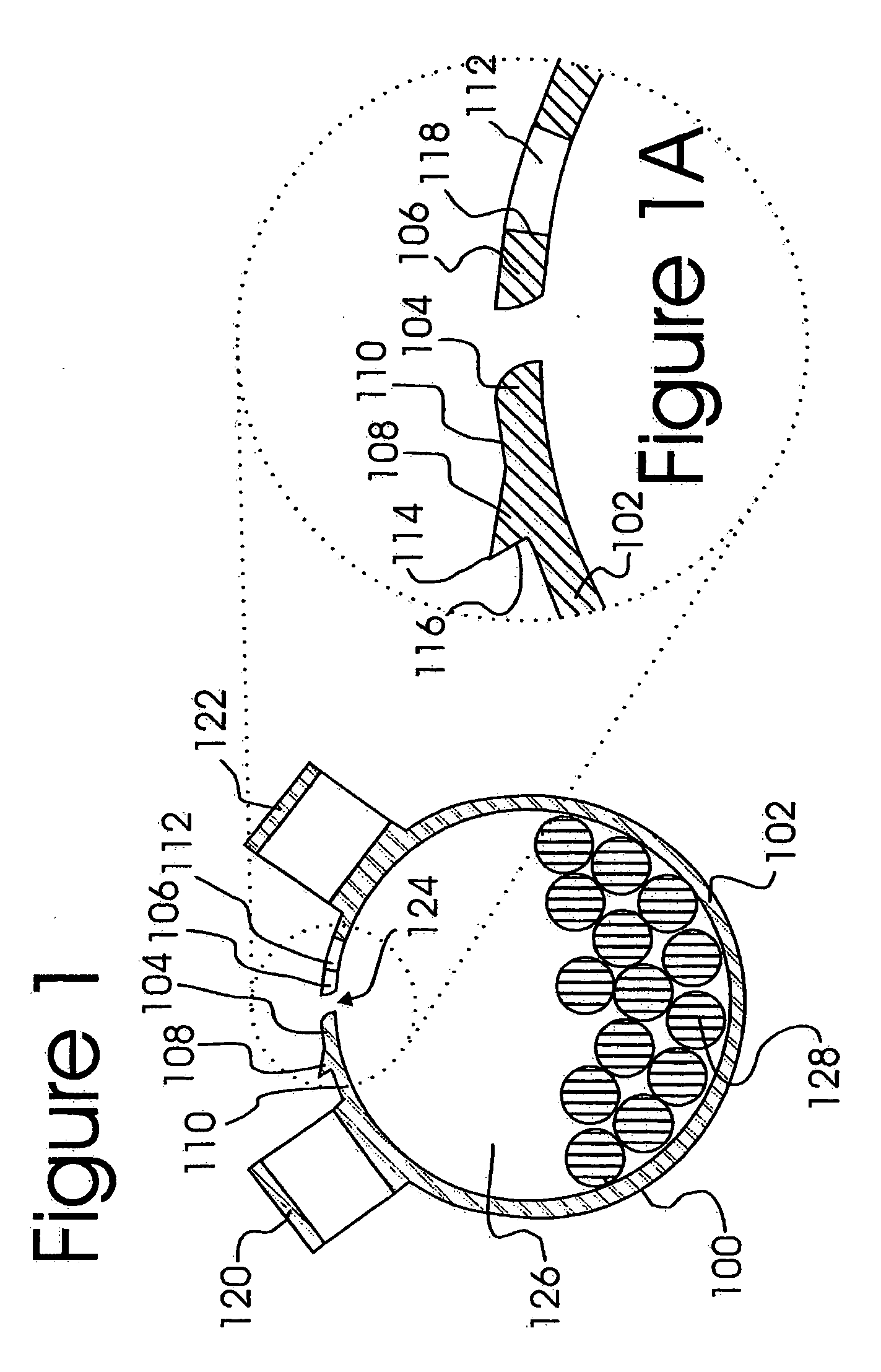

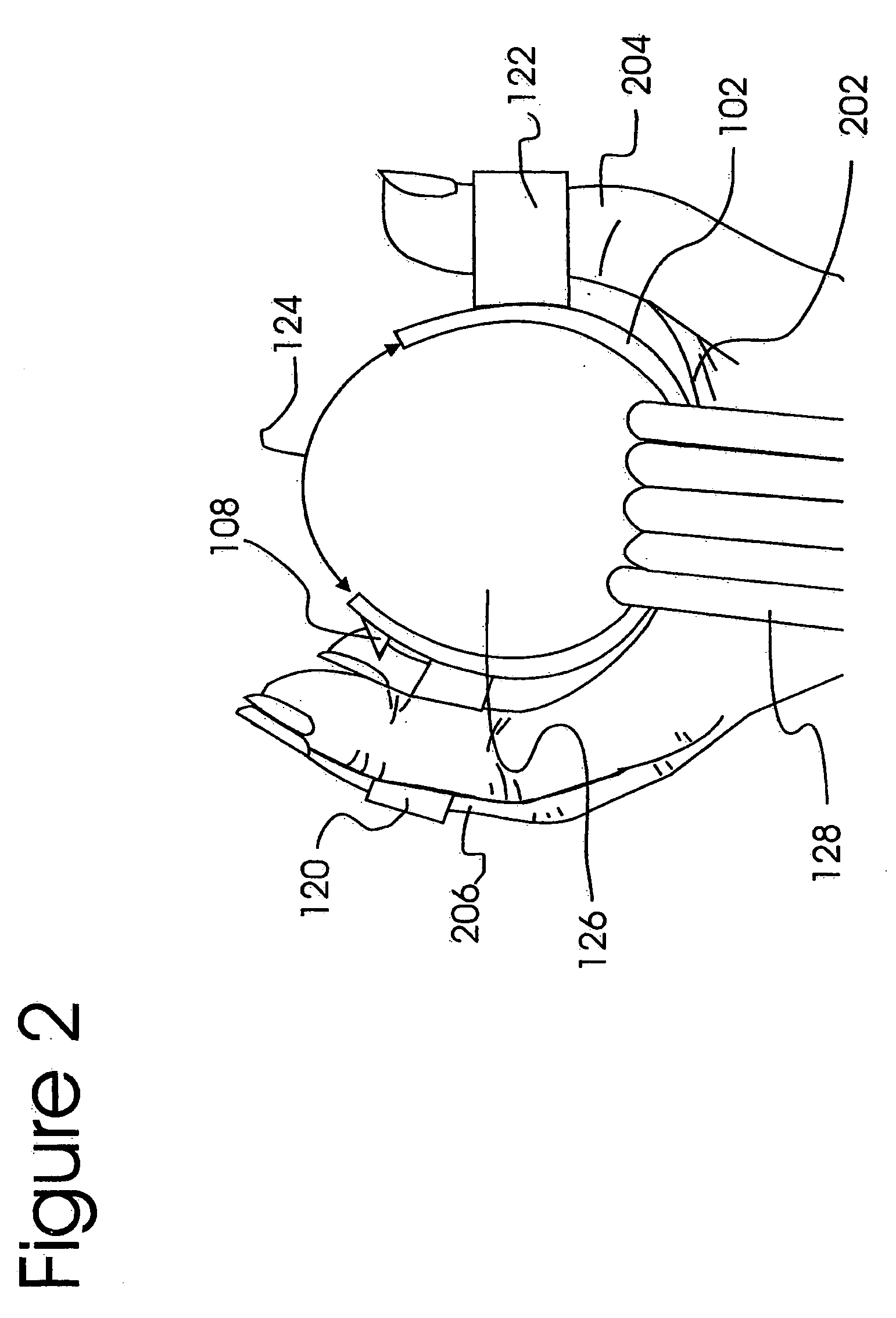

Cell handling device, tissue regeneration composition, and tissue regeneration method

InactiveUS20100137811A1Easy injectionBioreactor/fermenter combinationsNervous disorderCell handlingEngineering

A syringe-type cell handling device for storing and subsequently transplanting, into a living body, cells harvested from a living body or cells obtained by culturing harvested cells. The syringe-type cell handling device includes a vessel having a closed mouth and being at least partially composed of a main body, and a plunger that is slidably insertable into the main body such that the handling medium can be transplanted into a living body by applying a pushing force to the plunger. At least a part of the device that contacts the fluid handling medium, when the vessel holds the handling medium, is a gas permeable region for passing a quantity of gas necessary for survival of the cells. It is preferable that at least a part of the storage vessel inner wall in contact with the cells is formed from a cell non-adhesive material.

Owner:YUGE RUI +2

Single-handed cord/cable management device

The present invention is directed to a device for bundling cables, ropes, wires, or other long flexible materials that are desired to be bundled. The device comprises an arcuate strap for encircling bundled cables. The strap is preferably discontinuous, with first and second ends forming a mouth into a central cavity formed by an arcuate strap. Finger grips are located adjacent to the first and second ends, allowing fingers of a user to be used to pull the first and second ends of the strap to open the normally closed mouth of the device. The device also preferably includes engagement features on the first and second ends to allow the first and second ends to be forced into engagement to lock cables into the cavity formed by the arcuate shape of the strap.

Owner:RIVERA ALEXANDER F

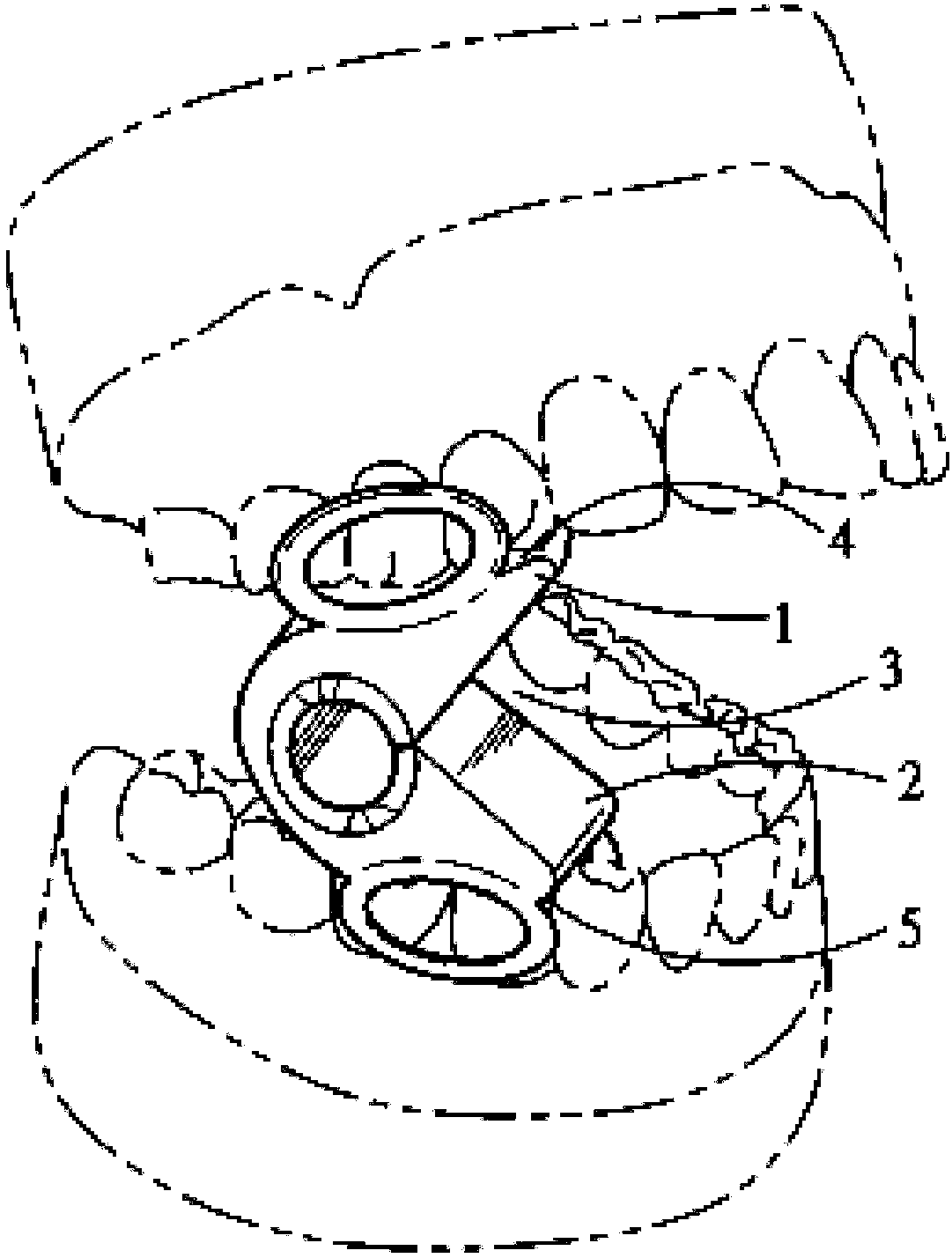

Oral cavity opening device

PendingCN107752973AExtended treatment timeSolve the problem of swallowing in the throatDentistrySomatoscopeOral problemsNursing staff

The invention relates to a rigid oral cavity opening device. By means of the rigid oral cavity opening device, the upper and lower palates of an oral cavity can be opened stably at an appropriate angle to make an opening device swallowed into the throat and prevent drooling, and the opening angle can be adjusted; the problem can be solved that in the prior art, a soft oral cavity opening device can be swallowed into the throat along with opening and closing of the mouth of a patient, or the hands of nursing staff are bitten by the teeth; the oral cavity opening device abuts against the upper palate of the oral cavity of the human body and opens the upper and lower teeth with a tongue, the opening angle can be adjusted, and the situation is avoided that since the patient suddenly closes themouth, swallows the device into the throat and spits the device out, the hands of the nursing staff are bitten by the teeth; meanwhile, without relaying on the teeth as support objects, the teeth cannot be shielded, and the dental operation is not affected.

Owner:黄伟

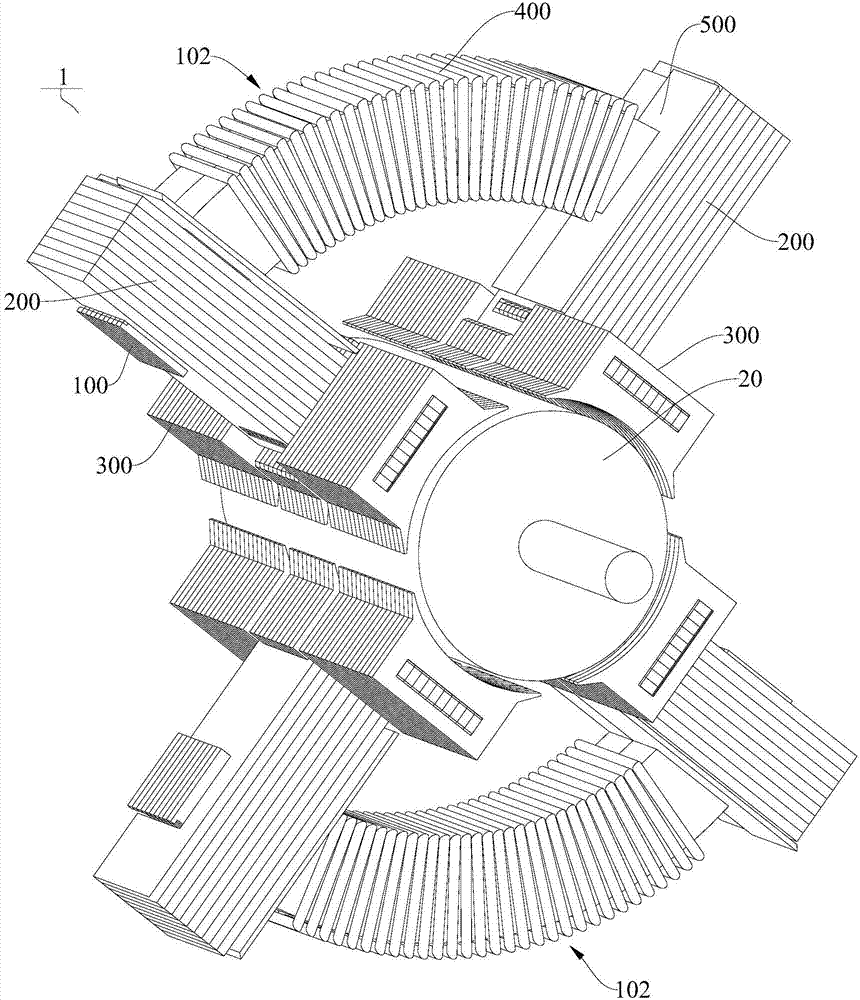

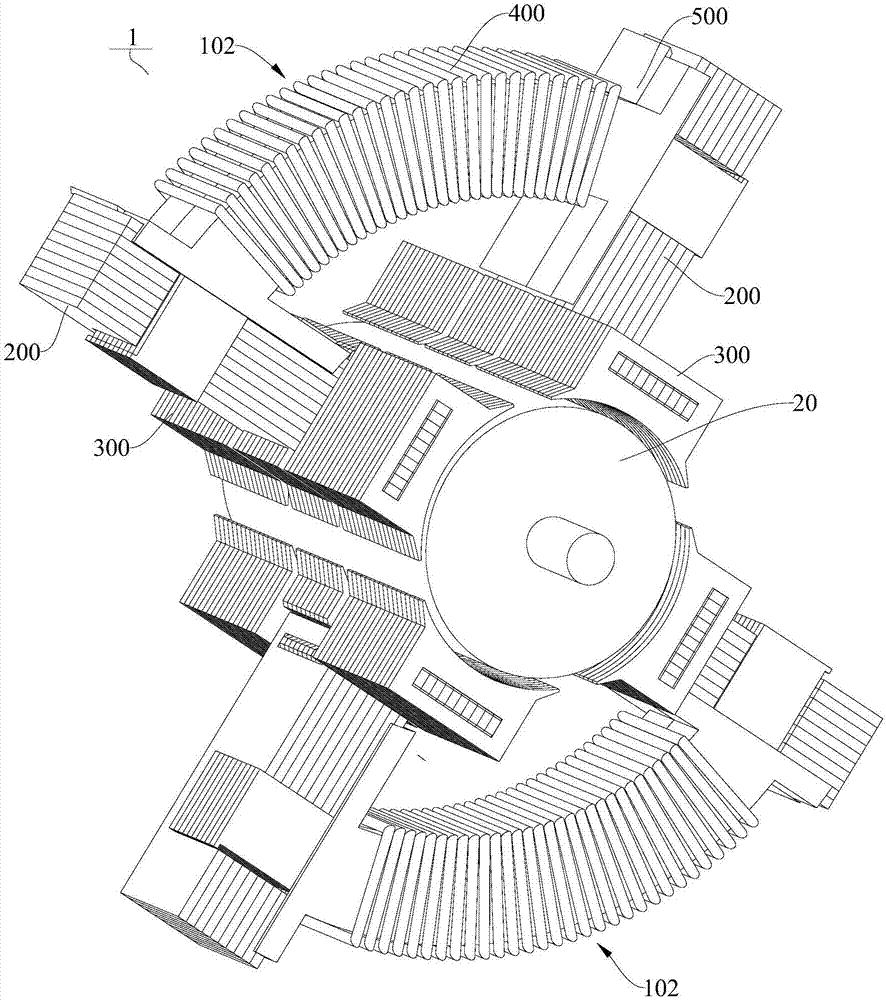

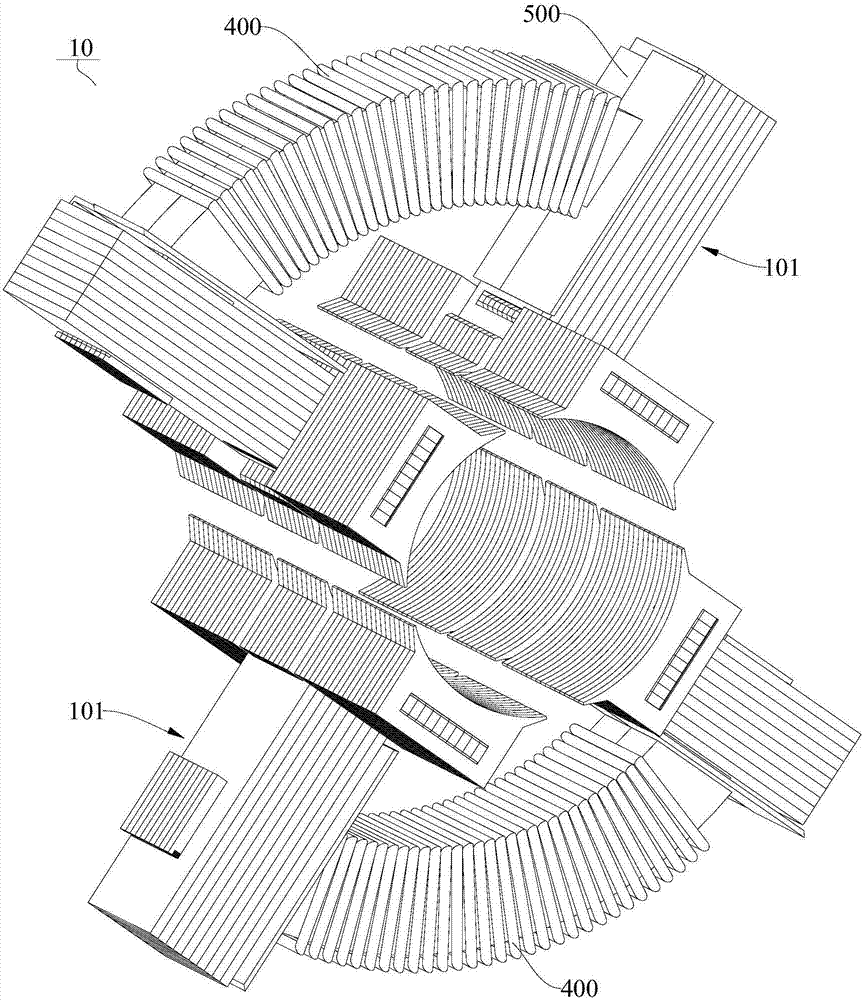

Stator iron core, stator and motor

ActiveCN106961169AImprove the magnetic effectLow costMagnetic circuit stationary partsShielding from electromagnetic fieldsPunchingEngineering

The invention discloses a stator iron core, a stator and a motor. The stator iron core is arranged on the periphery of the rotor and includes a plurality of stator individuals arranged in the circumferential direction in a spaced manner. Each stator individual includes a yoke part formed through stacking a plurality of yoke part punching sheets together; two main tooth parts clamped at the two circumferential ends of the yoke part and formed by stacking a plurality of tooth part punching sheets perpendicular to the yoke part punching sheets together, wherein each main tooth part is therein provided with an extension part extending along the axial direction of the yoke part and having at least one end protruding from the main tooth part, and a closed-mouth groove penetrating through the main tooth part in the stacking direction of the tooth part punching sheets; a main tooth boot part formed through stacking a plurality of main tooth boot punching sheets perpendicular to the tooth part punching sheets together and provided with a clip tongue through arranging an open groove whose opening direction is parallel with the stacking direction of the tooth part punching sheets, wherein the clip tongue is clamped in the closed-mouth groove from one side of the closed-mouth groove; an end tooth boot part formed through stacking a plurality of end tooth boot punching sheets together and clamped on the extension part. According to the embodiment of the invention, the magnetic concentrating capability of the stator iron core is enhanced and the cost is reduced.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

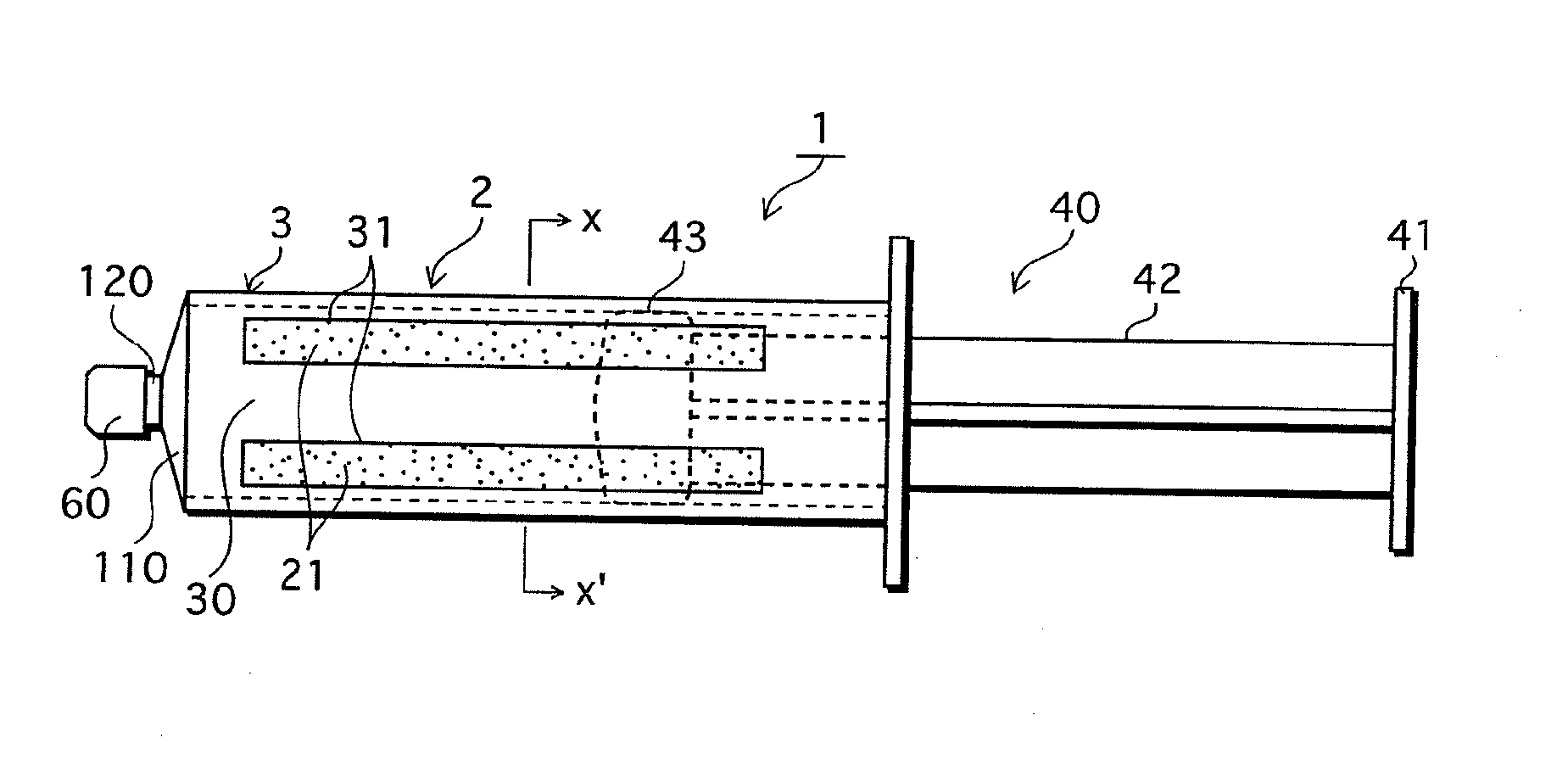

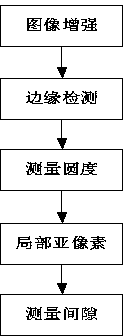

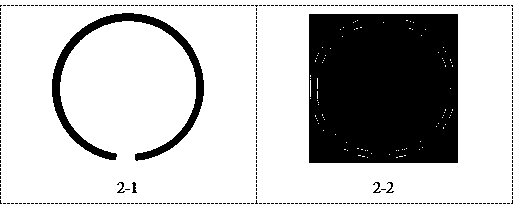

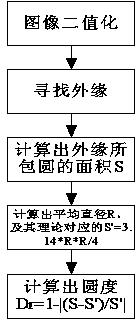

Piston ring detection method based on monocular vision detection

InactiveCN103968772AHigh measurement accuracyLarge measuring rangeImage enhancementImage analysisImaging processingClosed mouth

The invention provides a piston ring closed-mouth gap and roundness zero-damage measurement method based on computer vision according to the computer vision theory, the image processing theory and mathematical knowledge and particularly relates to a piston ring detection method based on monocular vision detection. The method includes the steps of image enhancement, edge detection, roundness measurement, local sub-pixel processing, gap measurement and the like. According to the method, local image processing is conducted on a gap portion through the sub-pixel technology, so that the measurement accuracy is improved; the length of the gap is measured, and the roundness of a piston ring is measured, so the measurement range is expanded, and the detection quality is improved.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Placement type probe and visual quantitative evaluation method for damage detection of metal component

ActiveCN108195931AImprove the detection rateImprove detection efficiencyMaterial magnetic variablesSensor arrayMagnetic field gradient

The invention discloses a placement type probe and a visual quantitative evaluation method for damage detection of a metal component. The placement type probe comprises a magnetism gathering magneticcore group, a disc-type exciting coil, a vertical magnetic field gradient sensor and a group of magnetic field gradient sensor arrays which are distributed annularly; the magnetism gathering magneticcore group consists of a cylindrical magnetic core of which the bottom centre of the axial cross section is a non-closed mouth shape and a cylindrical magnetic core of which the axial cross section isan inverted T shape; the two cylindrical magnetic cores are coaxial; the disc-type exciting coil and the magnetism gathering magnetic core group are coaxial; the vertical magnetic field gradient sensor is positioned at the top of the inverted T-shaped cylindrical magnetic core; the magnetic field gradient sensor arrays which are distributed annularly are uniformly arranged at the bottom of a gapbetween the cylindrical magnetic core of which the bottom centre of the axial cross section is the non-closed mouth shape and the cylindrical magnetic core of which the axial cross section is the inverted T shape. The invention also provides a method for implementing damage detection and visual quantitative evaluation of a metal component by applying the probe; quick and high-precise detection, imaging and quantitative evaluation can be performed on the metal component; the placement type probe and the visual quantitative evaluation method for the damage detection of the metal component have an important engineering application value.

Owner:XI AN JIAOTONG UNIV

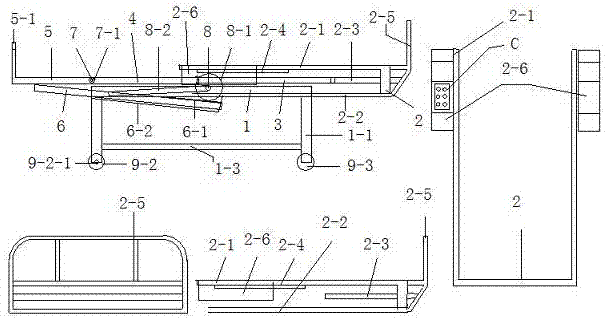

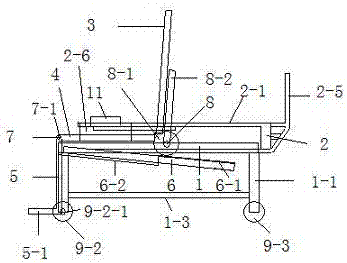

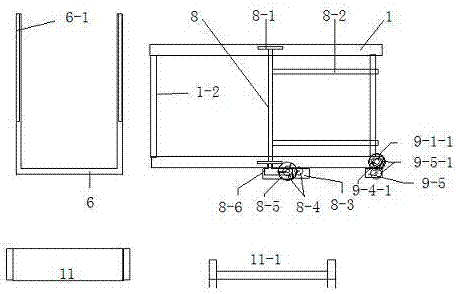

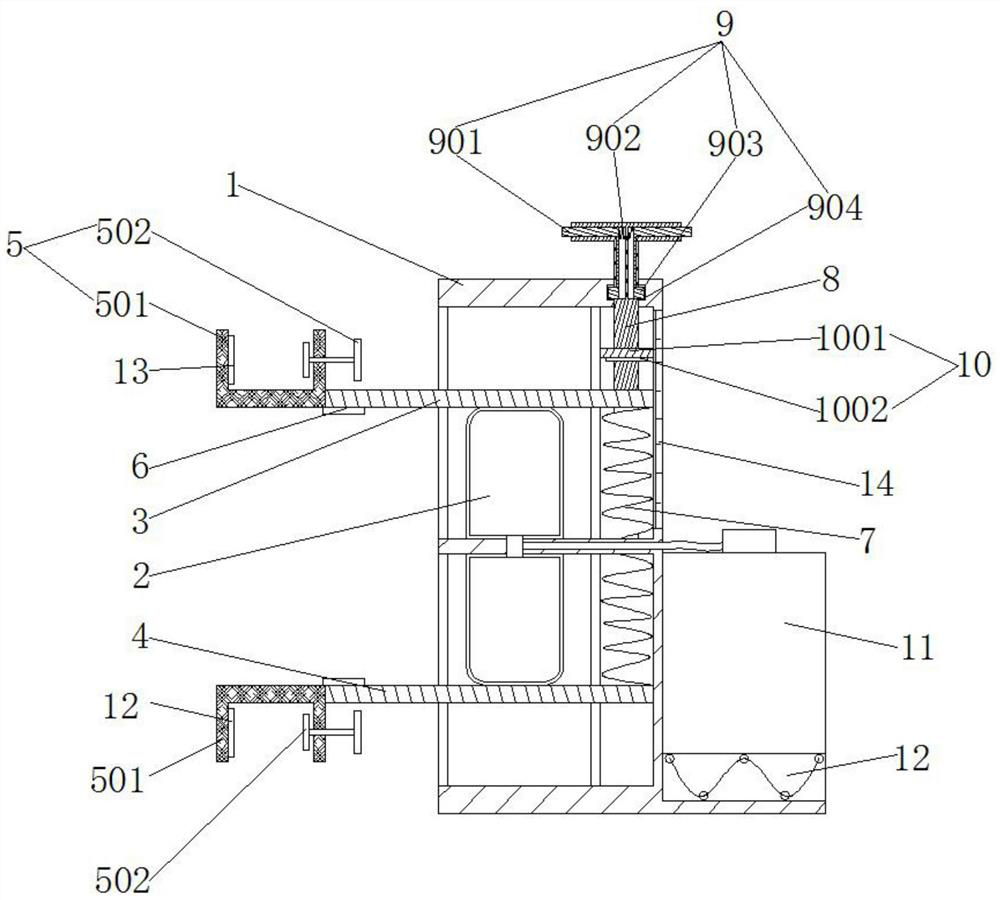

Electric one-hand self-service safe standing-sitting massage bowel-relief-assisting moving bed capable of cleaning after bowel relief

InactiveCN107049652AReduce troubleIncrease the burdenVibration massageNursing bedsButtocksEngineering

An electric, one-handed, self-safe, sitting up, massage, and cleaning mobile bed after defecation. The reducer is used as power transmission to complete the functions of equipment expansion, rotation, and movement. It is used in homes, hospitals, and nursing homes for elderly apartments to help lower limbs. Paralyzed patients, hemiplegic patients, etc., can help the body to lie down, massage the back, sit down with the legs bent, fasten the safety belt on the upper body, open the toilet port when it is convenient, Pull out the bedpan, clean the buttocks after defecation, close the toilet opening, eat, read books and watch mobile TV on it, can move in multiple barrier-free rooms on the same plane, and complete daily homework such as eating, drinking, loosening, sleeping, sitting, lying down, massage, walking, etc., reducing the number of patients The troubles caused by moving or standing can reduce the burden on family members and caregivers due to day and night care, so that patients will no longer be psychologically shadowed by disability. Self-help behaviors can not only achieve self-fitness of patients but also build confidence in recovery.

Owner:刘开南 +1

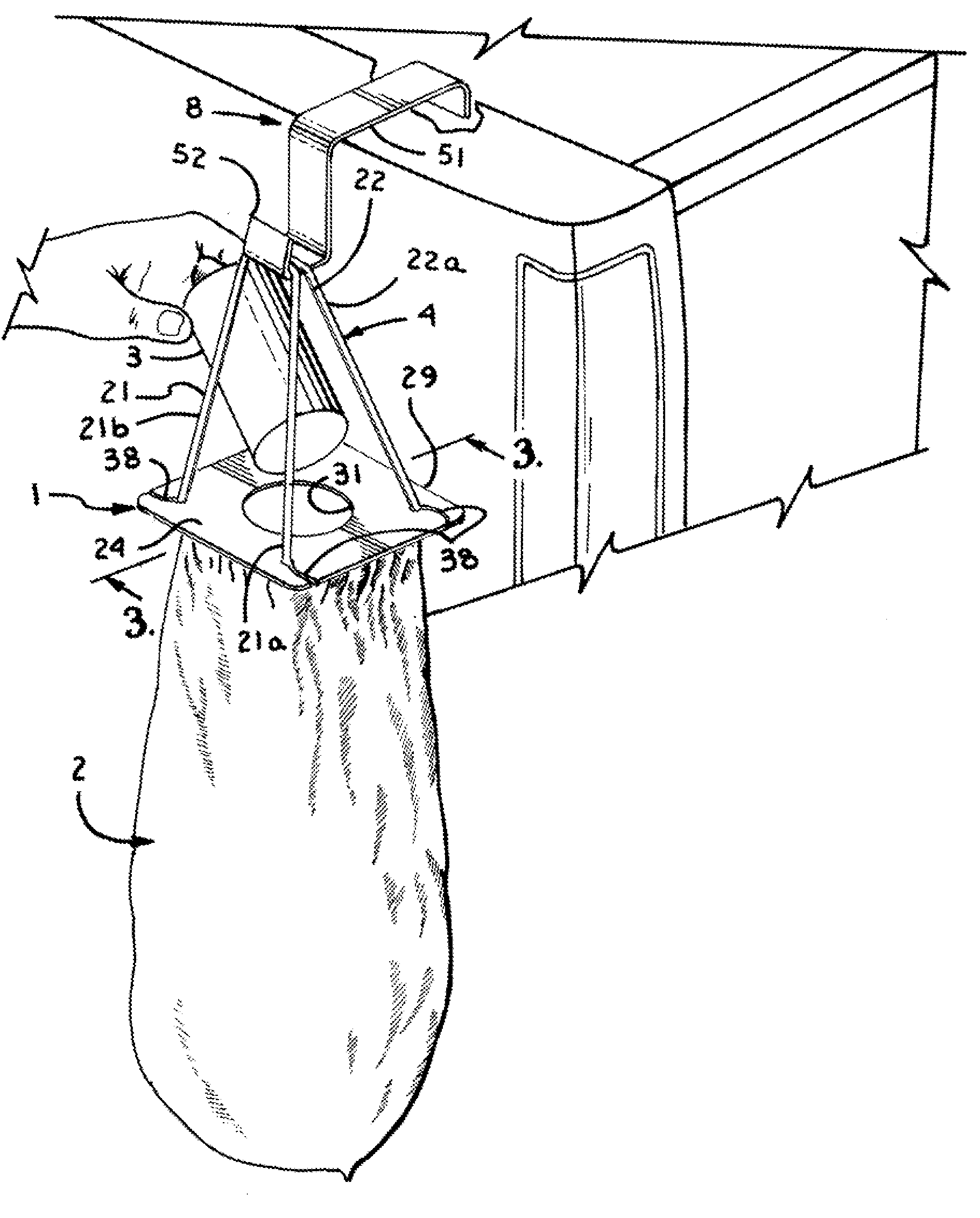

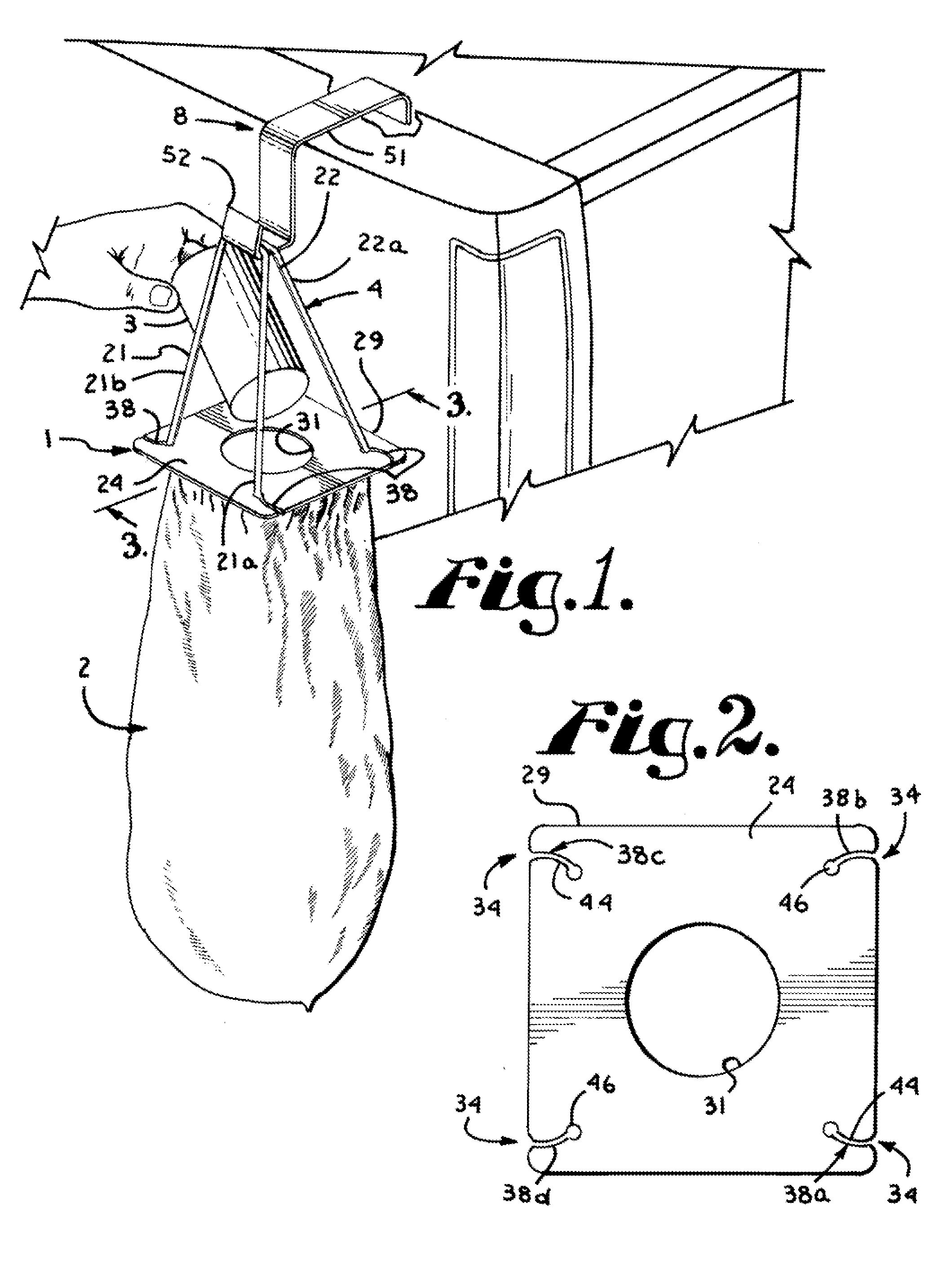

Trash bag supporting device

A device for holding open the mouth of a drawstring trash bag is disclosed. The device rests on top of the partially closed mouth of the trash bag and is secured in place by the bag's drawstrings. Ideally, the bag will be hanging to create the necessary tension in the drawstrings to keep the device in place. The device comprises a rigid plate with a hole, and notches for receiving the drawstrings. The hole is sized to receive disposable beverage cans or other similar waste. A portion of the upper surface of the plate may be dedicated to the display of promotional indicia. A holder for hanging the trash bag by its drawstrings is also disclosed. The holder may be mounted to the rear bumper of an automobile or other similar location.

Owner:UNIQUE NECESSITIES

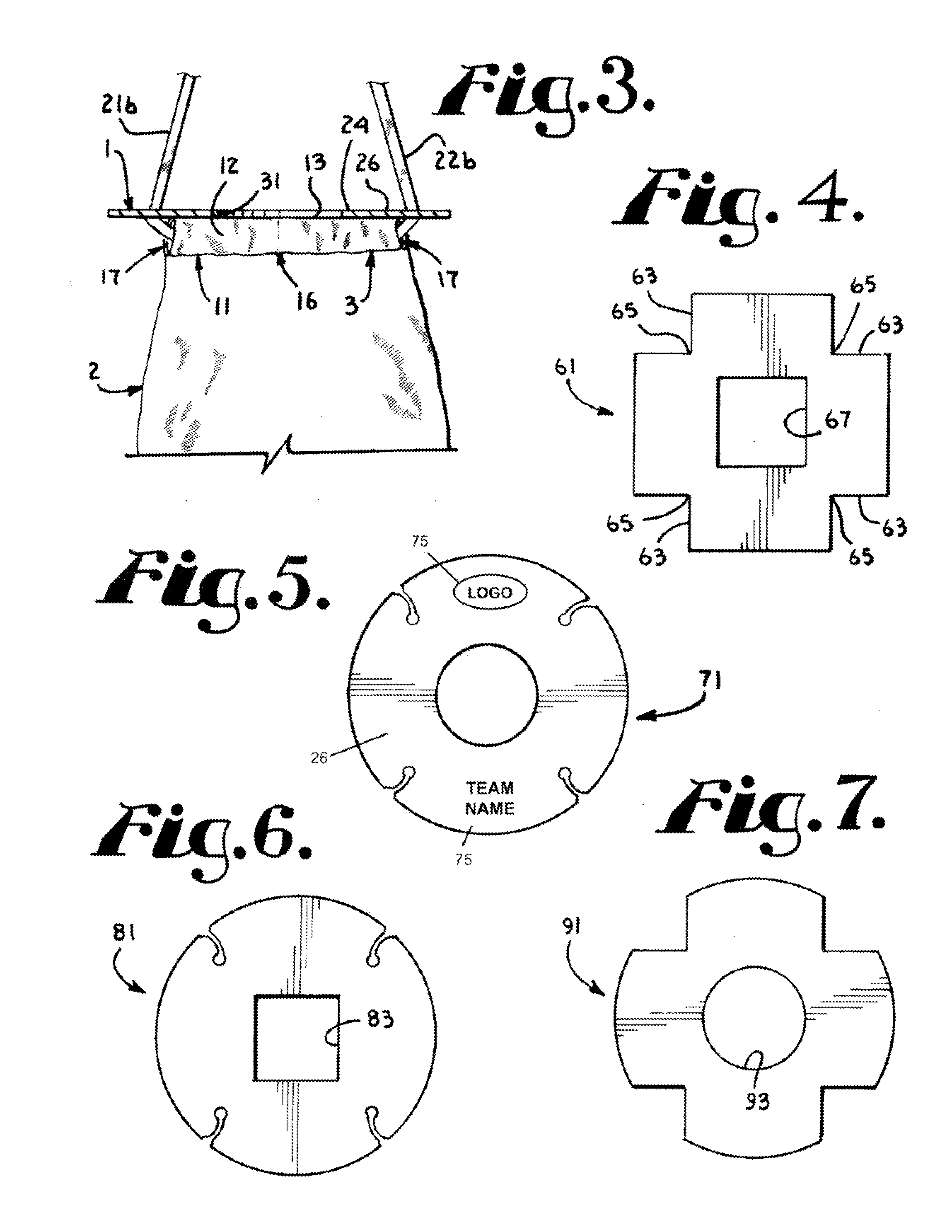

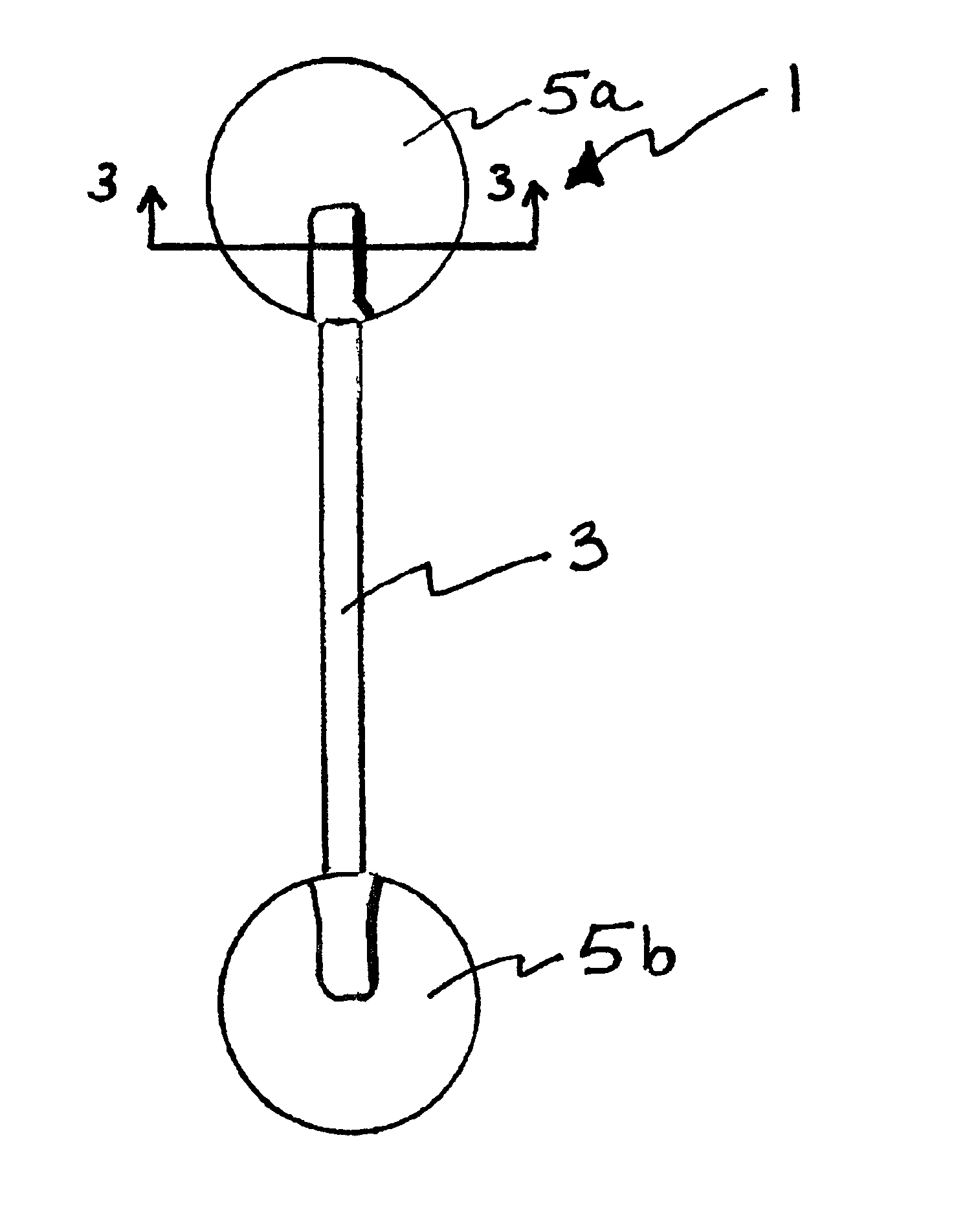

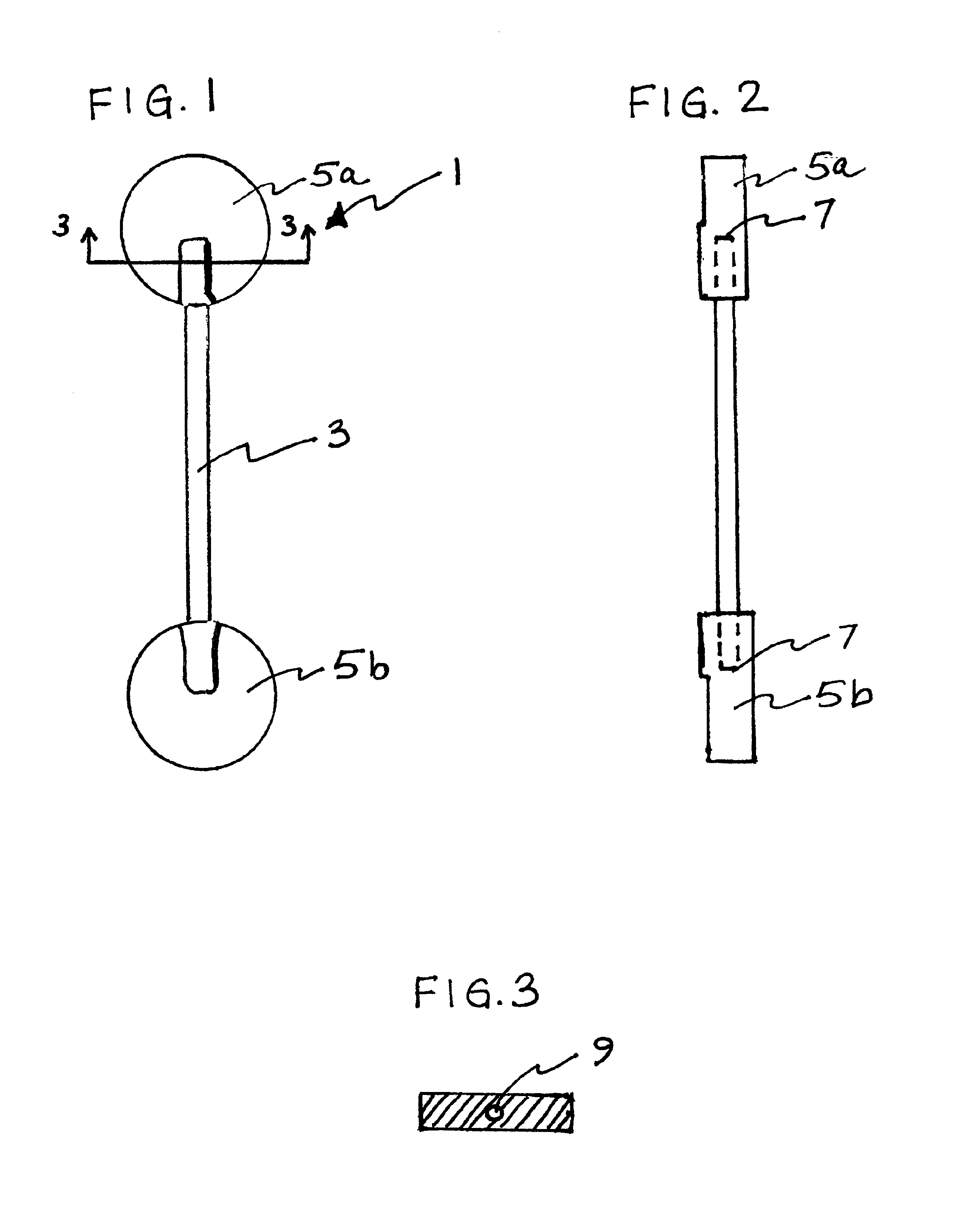

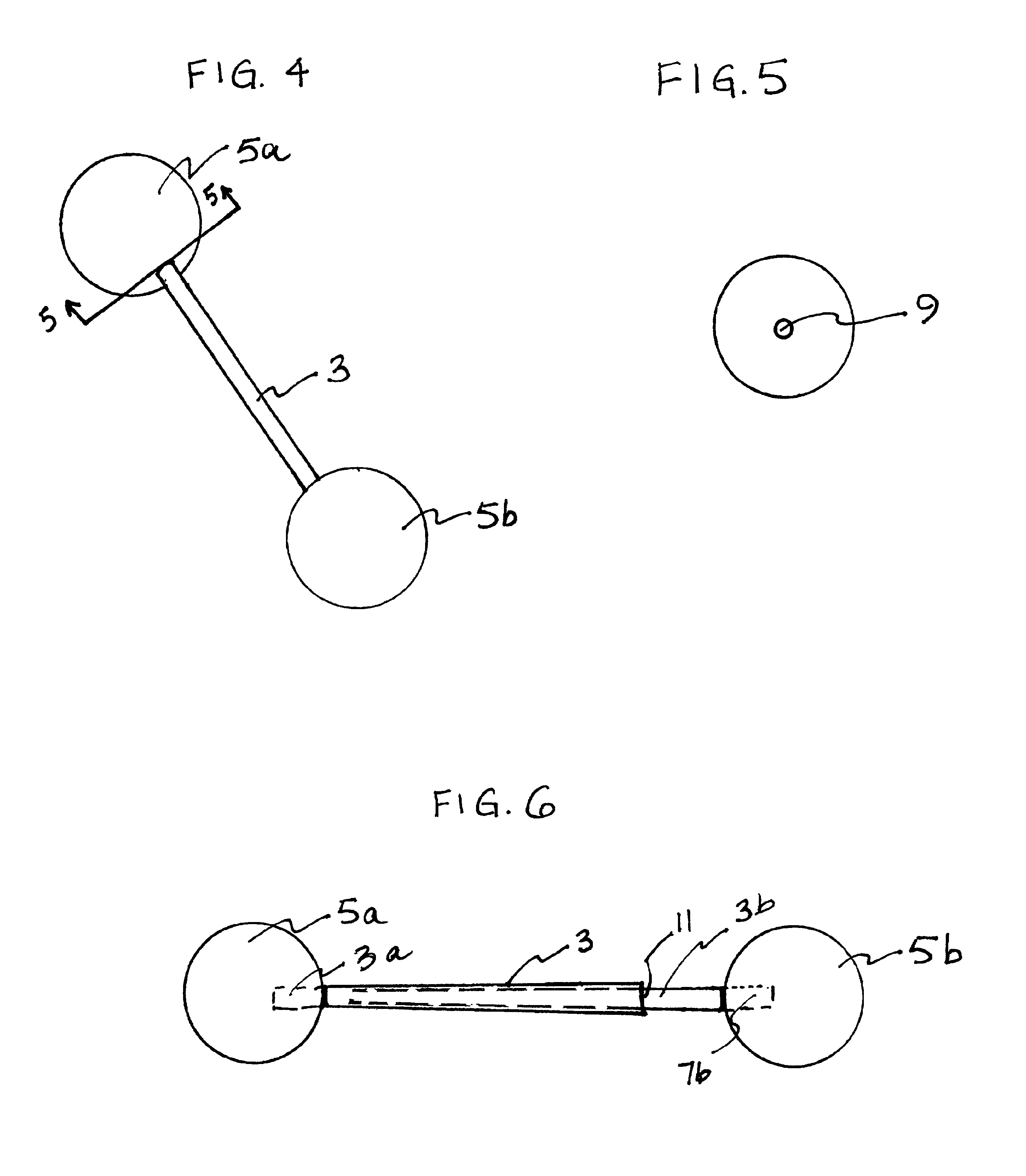

Double-headed, closed-mouth cough suppressant and cold relief device

InactiveUS6932978B2Reducing wholesale spreadSuppress coughBiocideSmall article dispensingMentholMedicine

A double-headed, closed-mouth cough suppressant and cold relief device in which an individual having the symptoms of a cough is able to suppress the cough by inserting the device into an open mouth, and by sucking on one end of the device, is able to release a menthol medicament disposed within the device to thereby suppress a cough. Additionally, by sucking on another end of the device a eucalyptus medicament is released to thereby relieve a sore throat. By suppressing the cough, the device prevents the spread of germs to the immediate environment.

Owner:HUNTLEY JAMES BENJAMIN

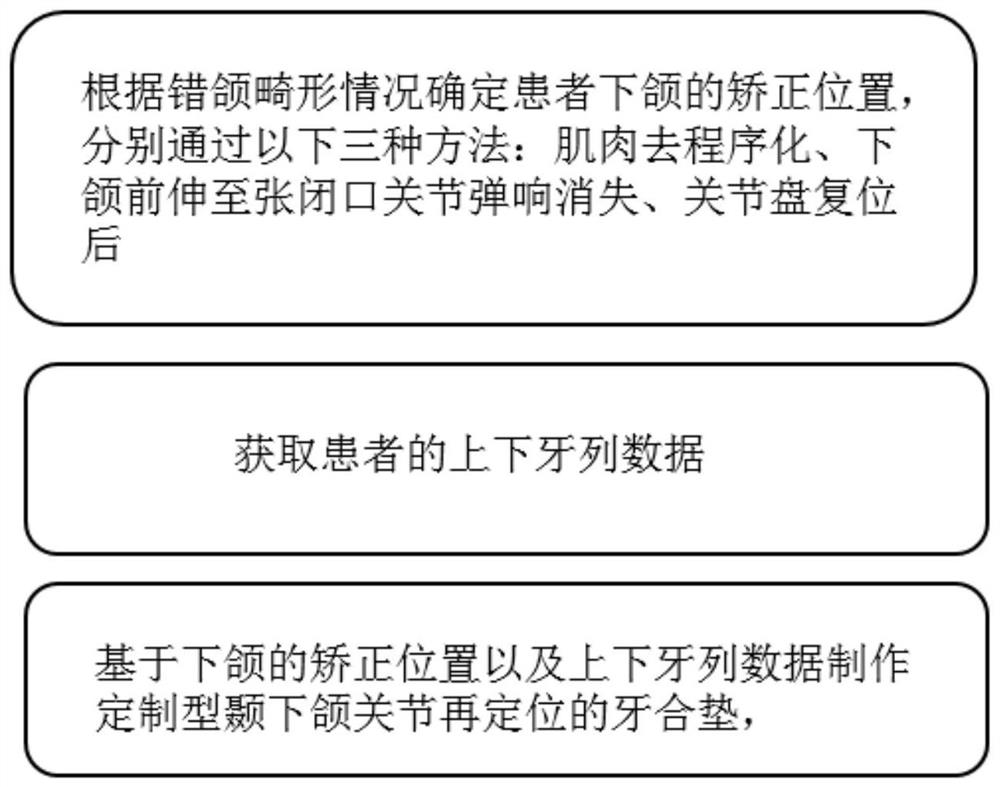

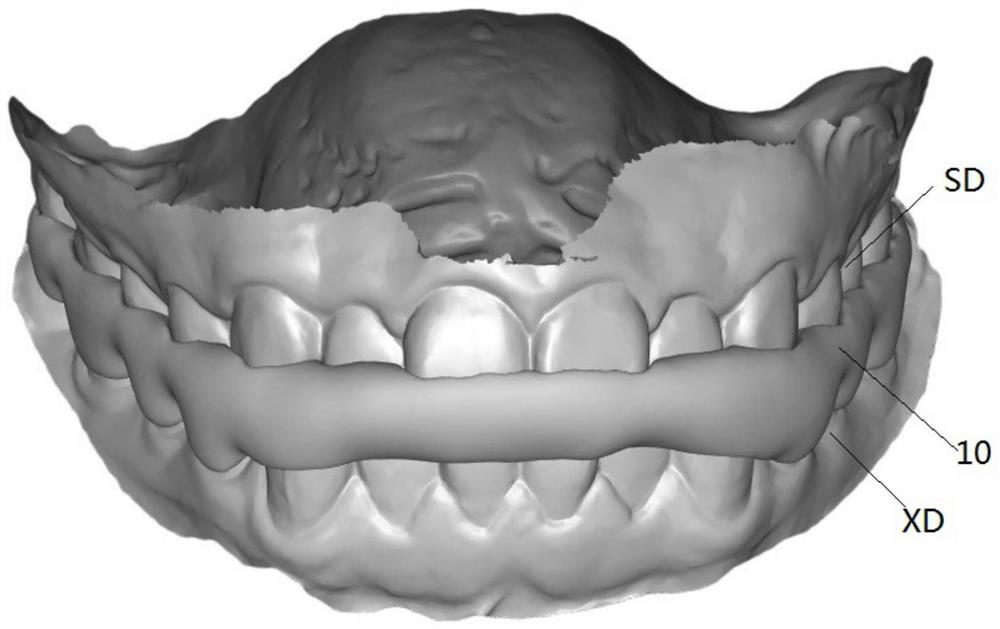

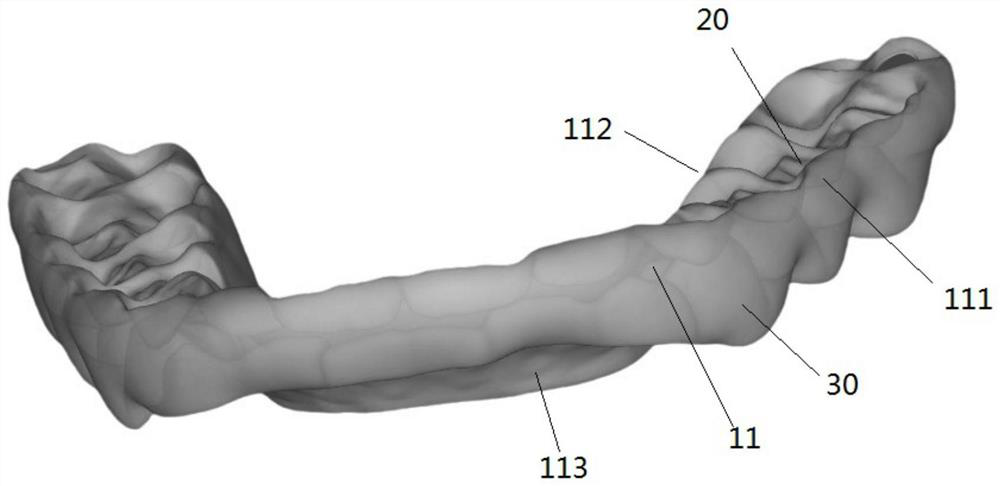

Customized temporomandibular joint repositioning occlusal pad and manufacturing and application methods thereof

ActiveCN112754693APromote regenerationStabilize joint positionAdditive manufacturing apparatusOthrodonticsLower dentitionLower tooth socket

The invention provides a customized temporomandibular joint repositioning occlusal pad and manufacturing and application methods. The manufacturing method comprises the following steps: according to malocclusion conditions, determining the correction position of the lower jaw of a patient through the following three methods: muscle de-programming, forward stretching of the lower jaw to disappearance of springing of open and closed joints, and restoration of an articular disc, and acquiring upper and lower dentition data of the patient. The customized temporomandibular joint repositioning occlusal pad is manufactured on the basis of the correction position of the lower jaw and upper and lower dentition data and comprises an integrally formed occlusal pad body, and an upper tooth socket and a lower tooth socket are formed between a lip side wrapping surface and a tongue side wrapping surface of the occlusal pad body. The upper tooth socket and the lower tooth socket are respectively arranged on the upper side and the lower side of the occlusal pad body, a tongue side inclined surface is arranged below the tongue side wrapping surface, and the occlusal pad is particularly used for occlusal treatment of temporomandibular joint disorder caused by malocclusion and temporomandibular joint relocation after joint disc reduction.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

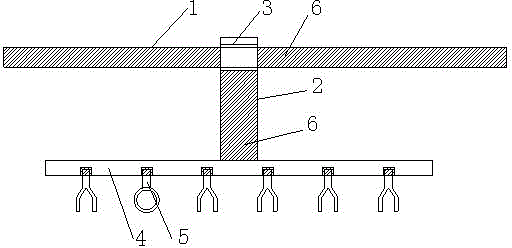

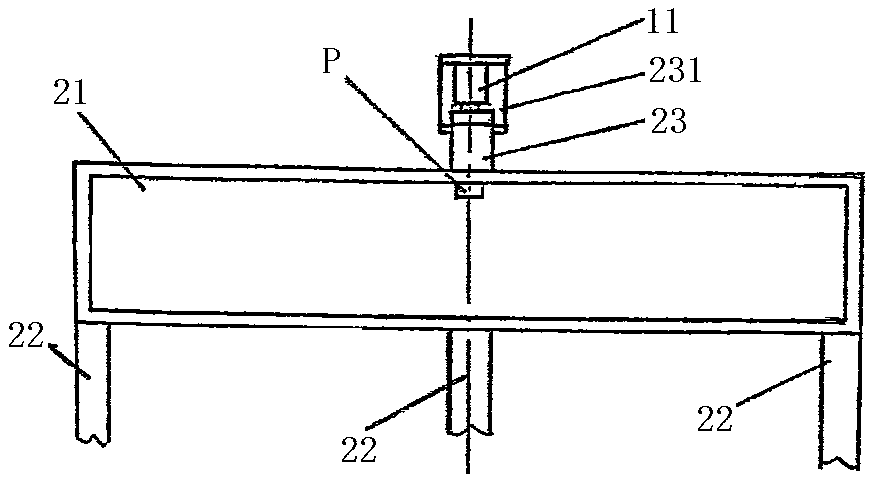

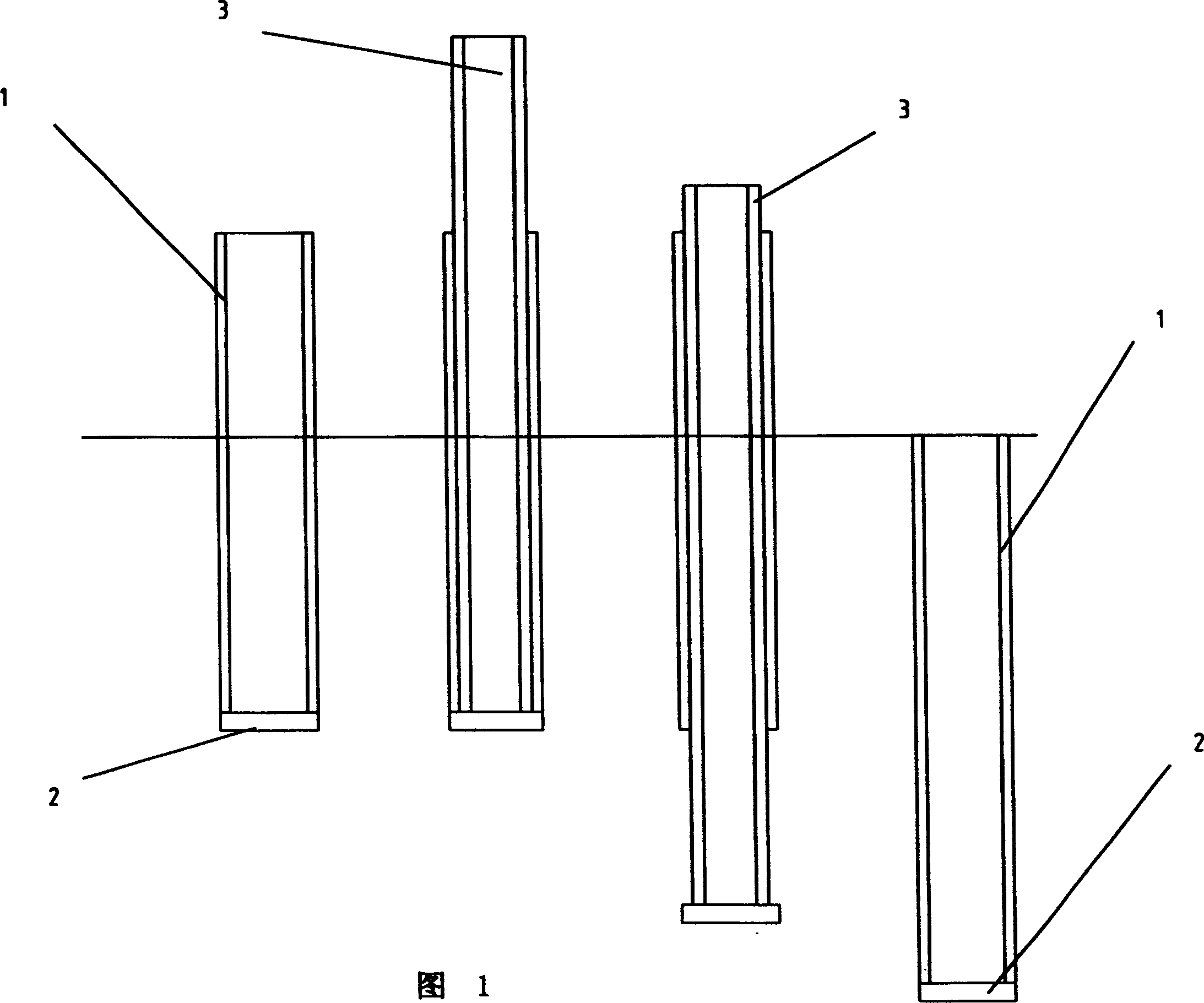

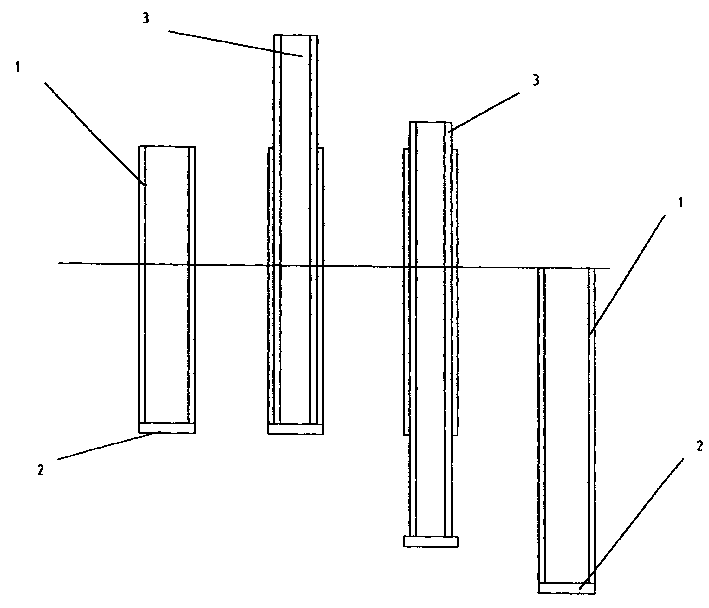

Movable electroplate hanger

InactiveCN104131329AFor lateral movementElectrolysis componentsAgricultural engineeringStructural engineering

The invention relates to an electroplate hanger, and especially relates to a movable electroplate hanger. The movable electroplate hanger comprises a cross rod and a fixed rod; the head part of the fixed rod is provided with a connection hole, which can movably connect the fixed rod and the cross rod; the bottom part of the fixed rod is connected to a hanging rod set, which is composed of at least two main rods parallel to each other; the lower end of each main rod is provided with a clamping device, the clamping devices are divided into two types: an open-mouth type and a closed-mouth type, and the two types of clamping devices are staggeredly arranged. The cross rod and the fixed rod are moveably connected together through the connection hole, and thus the fixed rod can freely move in the horizontal direction, so during the electroplating process, the hanger can be quickly moved. Furthermore, the two types of clamping devices arranged on the lower ends of the main rods are staggeredly arranged, so a proper hanging mode can be selected according to the size of a product to be electroplated.

Owner:周元忠

Adhesive Strip with Non-Adhesive Band and Method to Reduce Mouth-Breathing Using the Same

InactiveUS20160278973A1Prevent peelingReducing mouth breathingRespiratorsSnoring preventionAdhesive beltEngineering

This invention provides an adhesive strip with non-adhesive band for preventing or reducing opening of a user's mouth. The adhesive strip with non-adhesive band comprises a non-adhesive band across a central portion of an adhesive side of an adhesive strip and divides the adhesive strip into an upper adhesive part and a lower adhesive part, and the non-adhesive band has a height larger than a thickness of an upper and lower lips of the user in a closed mouth state;

Owner:SOMNICS INC

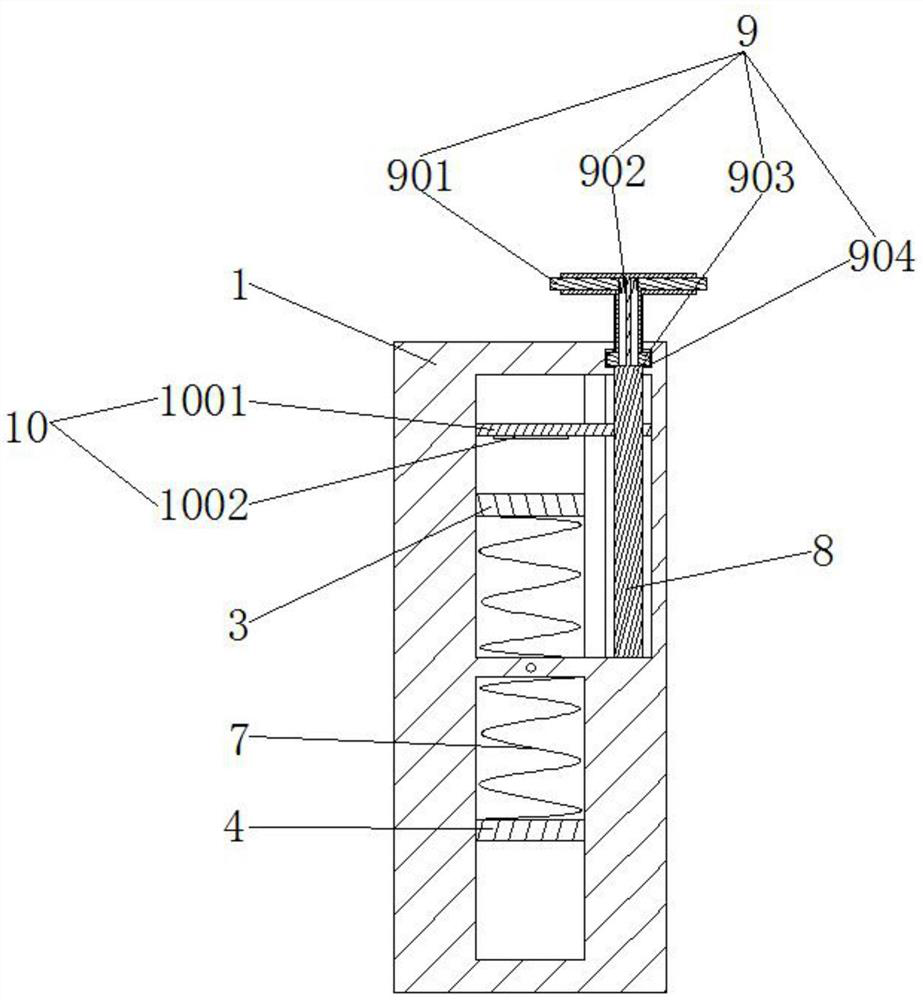

Inflatable mouth opening trainer

PendingCN112973015AEnsure the progress of postoperative rehabilitation trainingAvoid damageResilient force resistorsPhysical medicine and rehabilitationEngineering

The invention discloses an inflatable mouth opening trainer which comprises a mounting base, an air bag, an upper tooth moving plate, a lower tooth moving plate, a tooth fixing mechanism, a first switch, a first spring, a driving rod, a locking mechanism, a limiting mechanism, an inflation pump and a battery.According to the inflatable mouth opening trainer, firstly, the tooth fixing mechanism is used, so that the inflatable mouth opening training device is fixed with teeth of a patient; meanwhile, stress points are dispersed, a limiting mechanism is controlled through an adjusting mechanism, then the limiting mechanism expands an air bag to push the distance between an upper tooth moving plate and a lower tooth moving plate to restrain, and then the mouth of the patient is in a passive reciprocating opening and closing training state through rebounding of a first spring; in this way, it is ensured that the amplitude of mouth opening training of the patient is consistent each time, and the mouth opening degree can be adjusted. By means of the device, the mouth opening training effect of the patient is improved, the postoperative rehabilitation training progress of the patient is ensured, and meanwhile stress points are dispersed, so that tooth damage is prevented.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

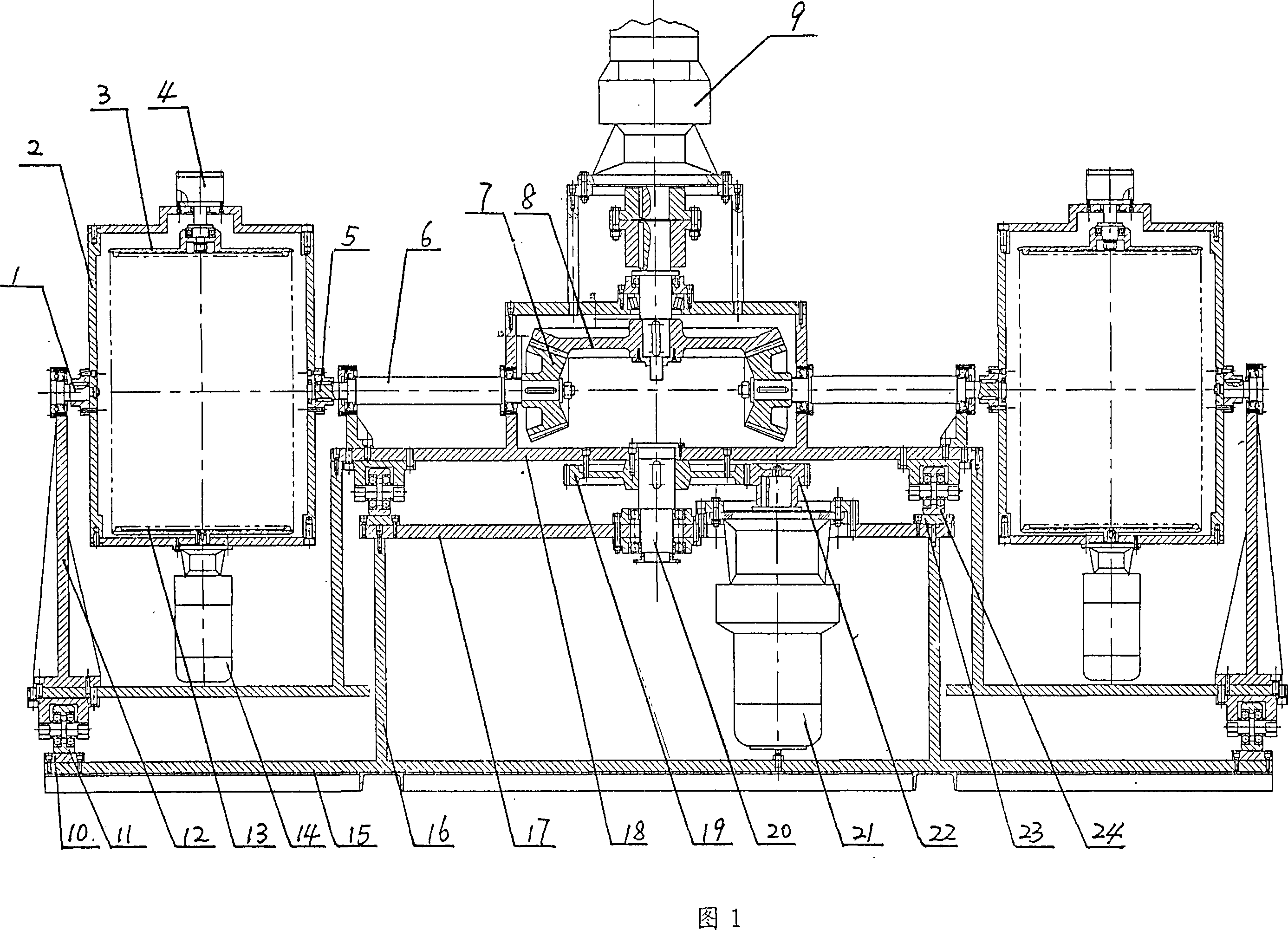

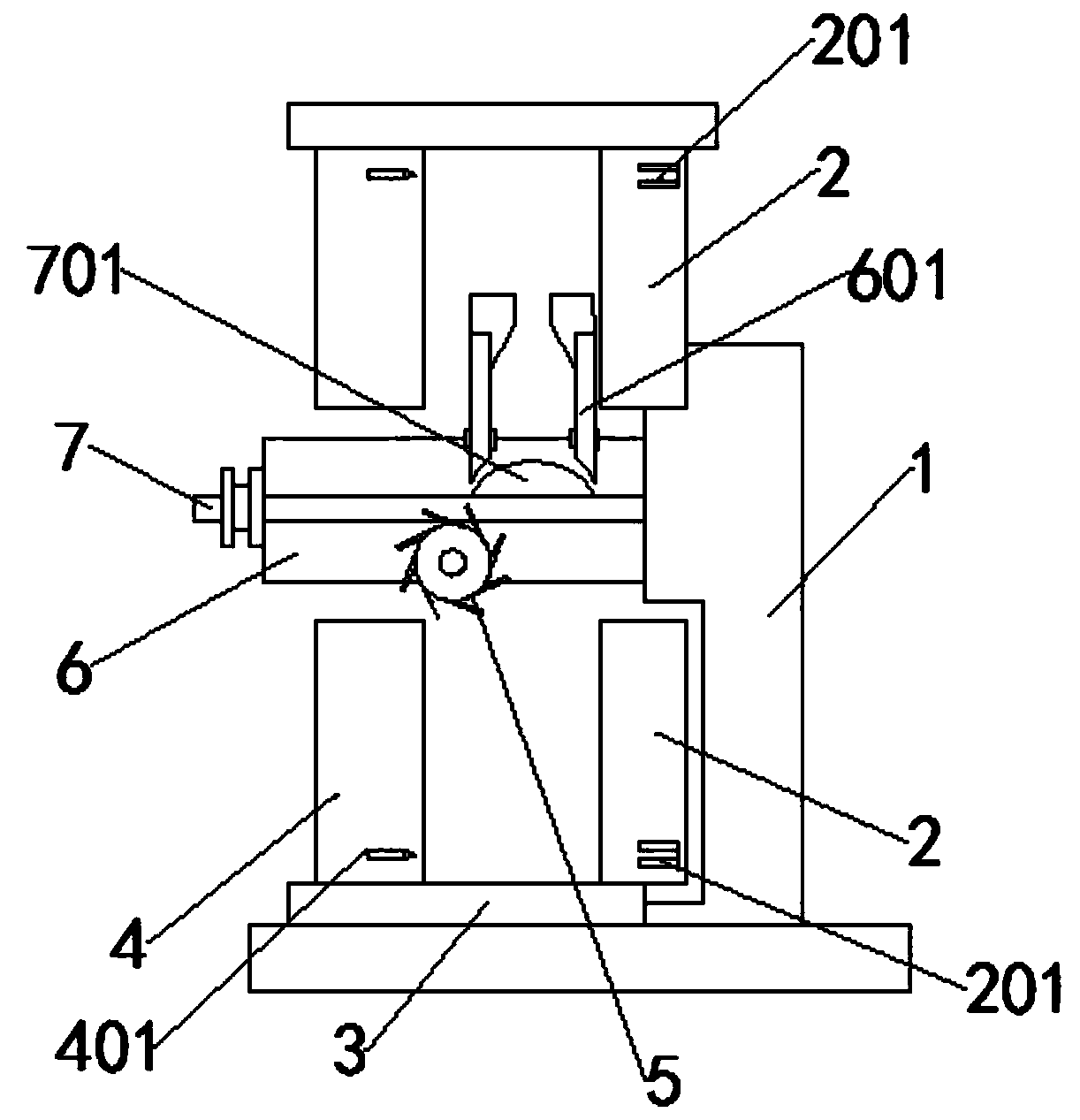

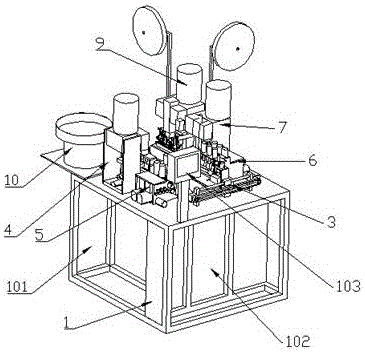

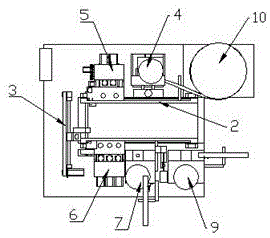

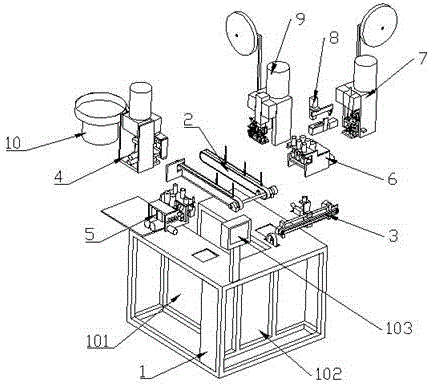

Bucket-brushing system for closed-mouth bucket

InactiveCN101077498AQuick scrub cleanIncrease flushing powerHollow article cleaningGear wheelDrive shaft

The present invention is one barrel cleaning machine capable of flushing and flushing the inside of barrel through rotating and swinging. The barrel cleaning machine has one pedestal, one worktable rotating motor connected to the worktable, and at least one barrel cleaning unit comprising one barrel swinging frame and one barrel supporting frame. The barrel swinging frame has one end connected to the barrel supporting frame, the other end connected to one barrel swinging motor through one support shaft and gears, and the bottom connected to one barrel rotating motor through one locating disc. The barrel cleaning machine has high cleaning efficiency and high cleaning quality.

Owner:TIANJIN LYUBOTE ENVIRONMENTAL PROTECTION EQUIP MFG

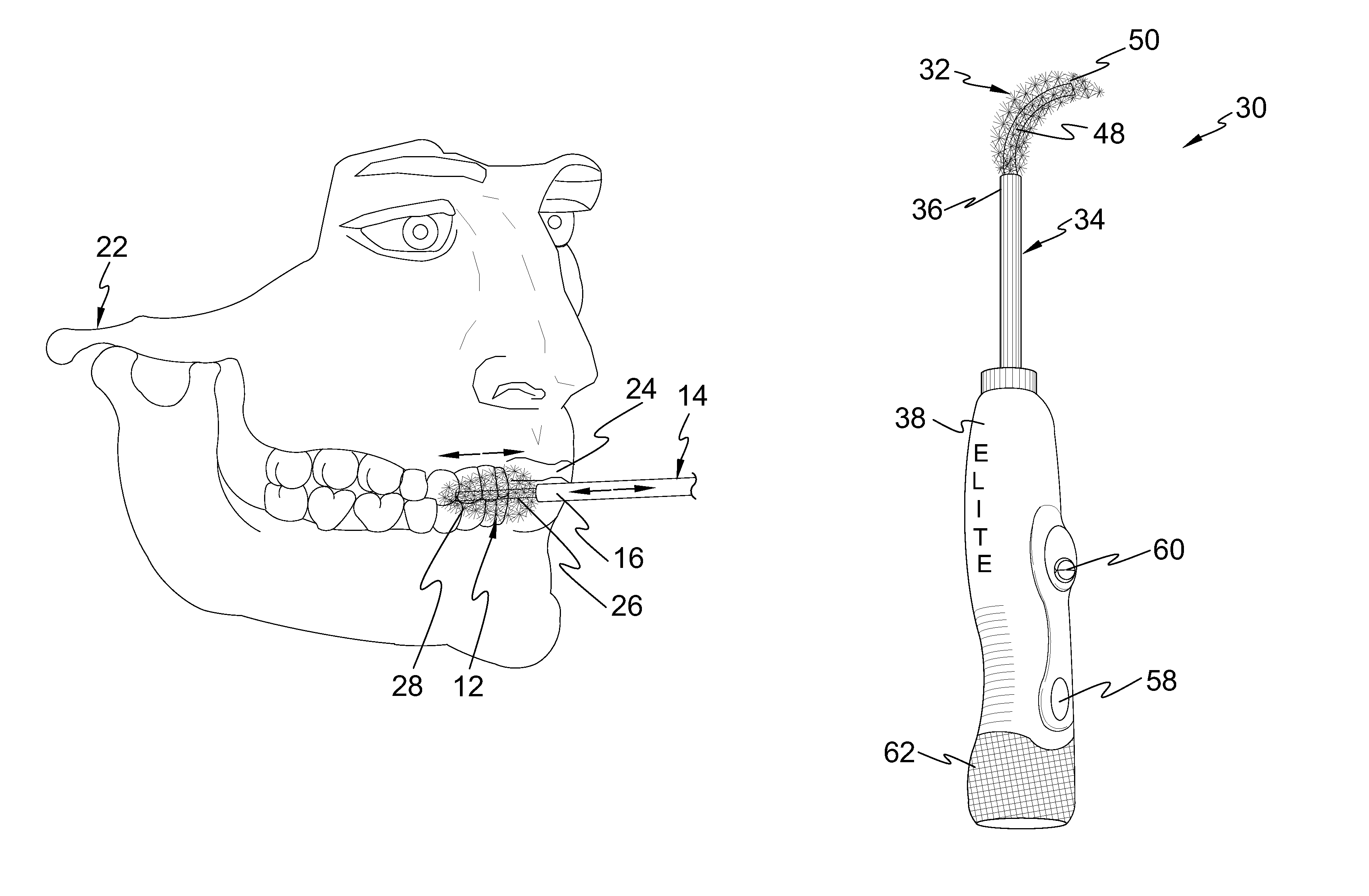

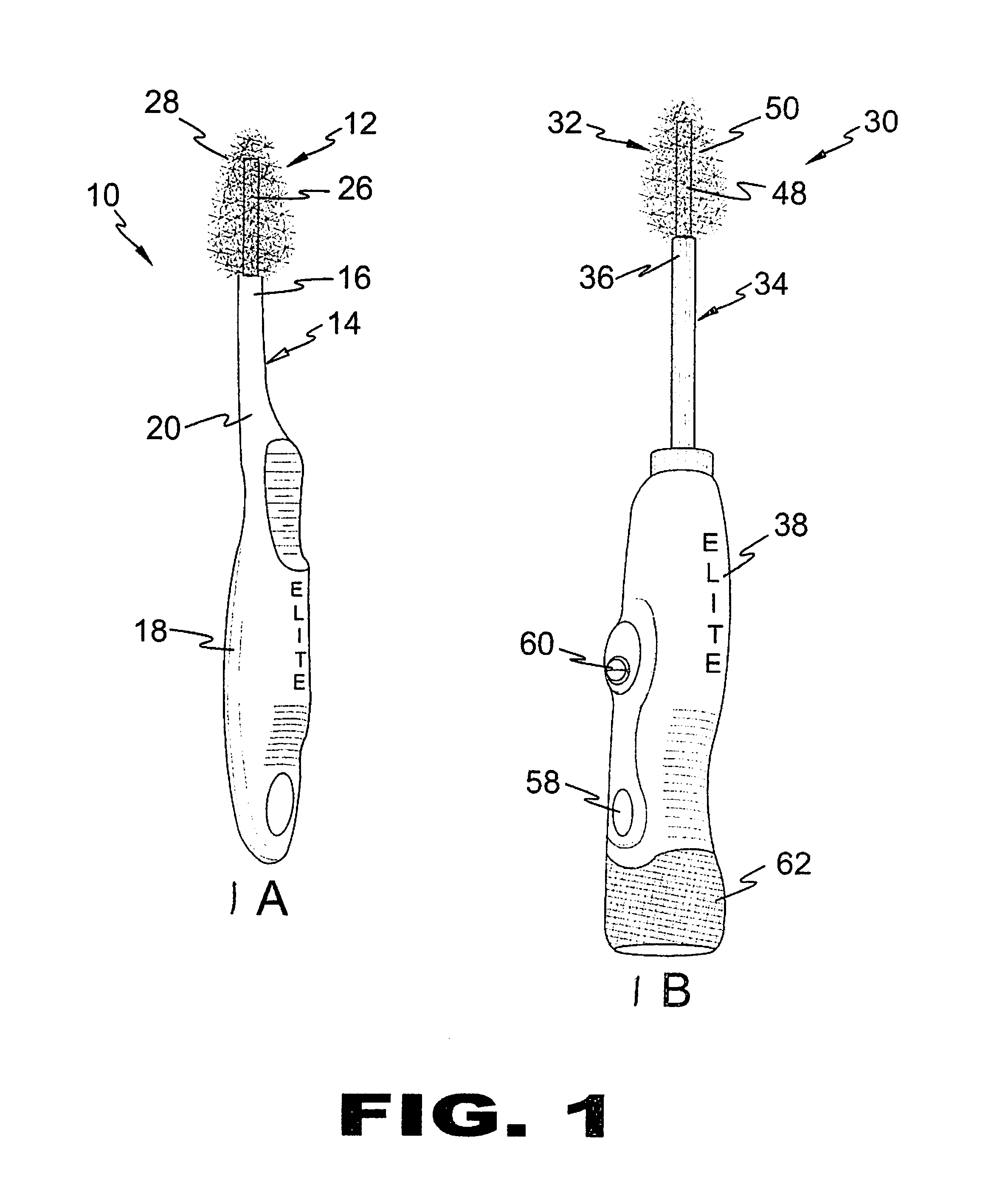

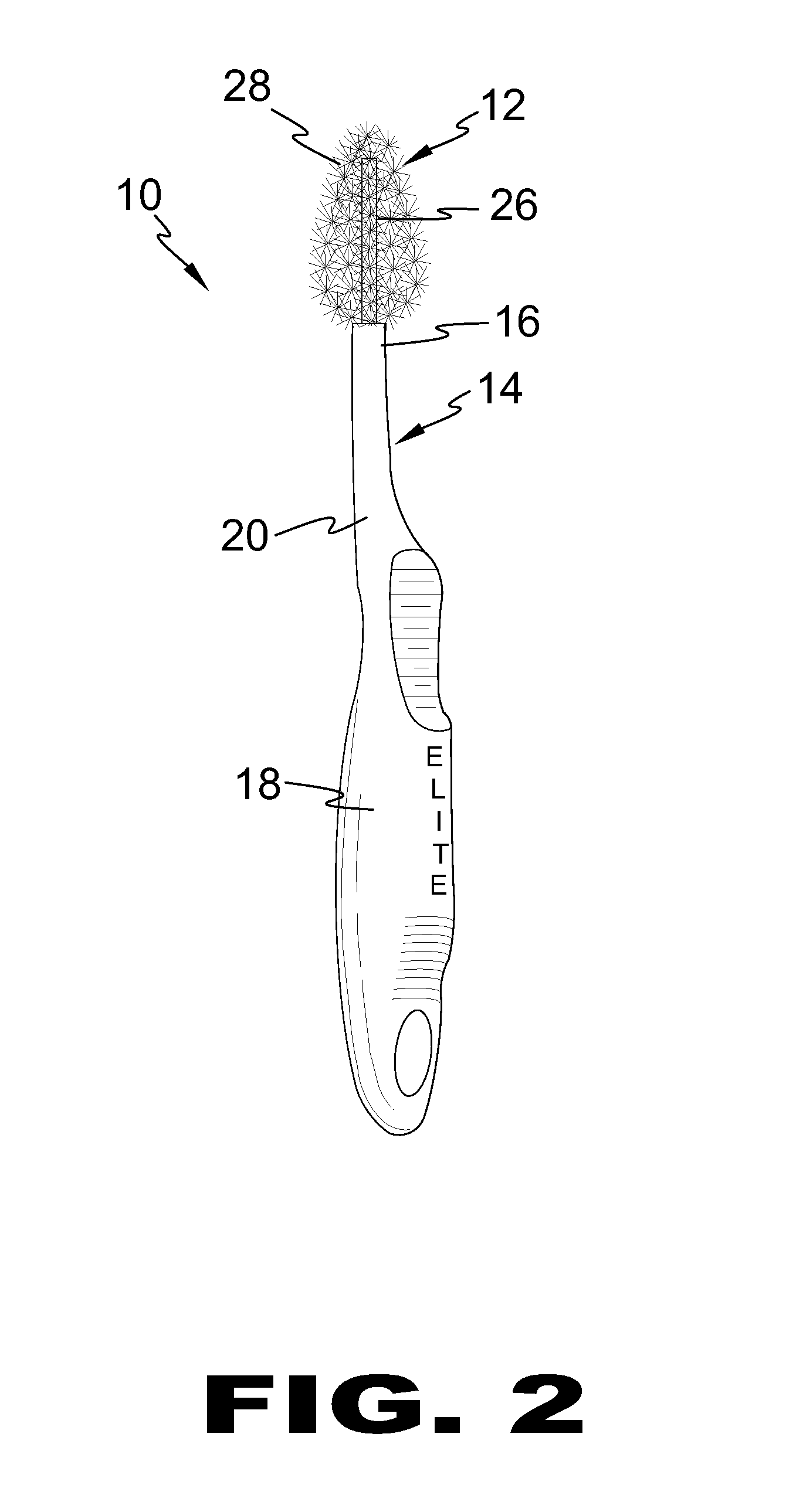

Closed mouth toothbrush

InactiveUS8966695B1Surface cleaningLess timeCarpet cleanersKitchenware cleanersClosed mouthMechanical engineering

A first embodiment of the present invention is a closed mouth toothbrush which comprises a flexible brush head. A shaft is connected at a first end to the flexible brush head. An ergonomic handle is connected to a second end of the shaft, whereby a person can grip the ergonomic handle comfortably and manually move the shaft in a reciprocating manner to cause the flexible brush head to clean all surfaces within a closed mouth of the person. A second embodiment of the present invention contains a mechanism for automatically moving the shaft in a reciprocating manner from within the ergonomic handle to cause the flexible brush head to clean all surfaces within a closed mouth of the person.

Owner:BORNEMANN NANCY

Corn straw shaping and baling machine

The invention provides a corn straw shaping and baling machine, comprising a limiting plate, first arc-shaped plates, chutes, second arc-shaped plates, an extrusion roller wheel, a swivel plate, a fixed shaft, a conveyor belt, a cutter groove, a cutter, movable fan plates, shaping plates, a bump, a locating shaft and a torsion spring, wherein the rear of the limiting plate is movably connected with the conveyor belt; one side of the limiting plate is fixedly connected with the first arc-shaped plate, and the chutes are respectively and fixedly connected with the upper sides and lower sides ofthe first arc-shaped plates; the second arc-shaped plates are connected with the interiors of the two chutes in a sliding way by means of roller wheels. By utilizing the lever rule, positioning bearings arranged at the upper edges of the shaping plates can be enabled to contract inwardly under the action of rotation, so that bayonets on the two shaping plates can be combined into a hollow plate with a closed mouth, and corn straw can be further pulled downwards by means of the bayonets; the direction of movement of the corn stalk on the conveyor belt is changed, and the corn stalk can enter aspace between the first arc-shaped plate and the second arc-shaped plate, so that the disordered corn stalk is more orderly, and mechanical jamming is prevented.

Owner:张东升

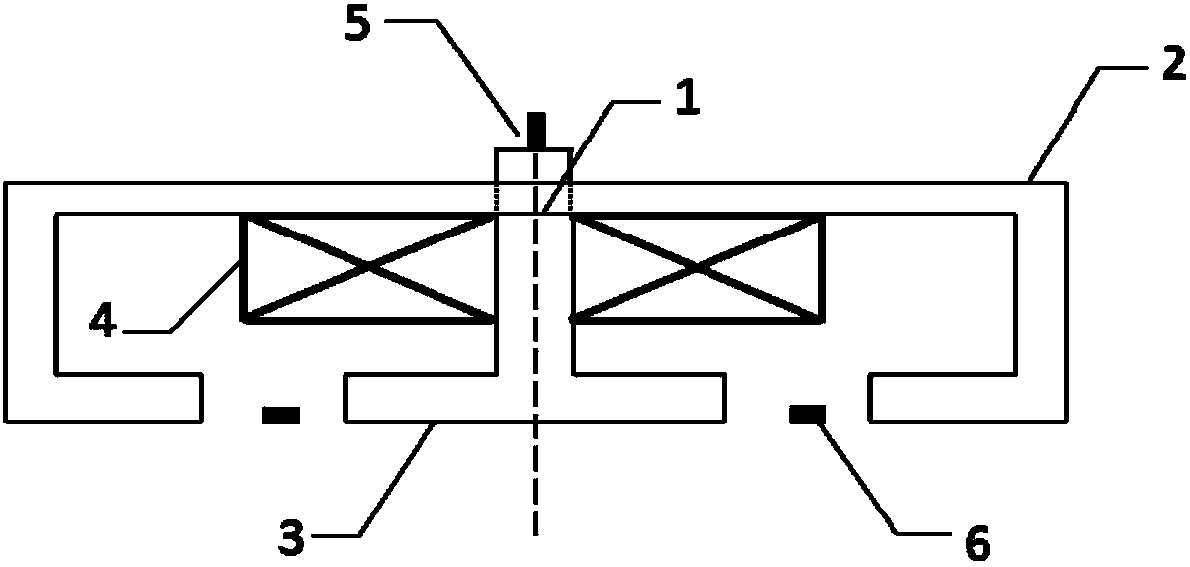

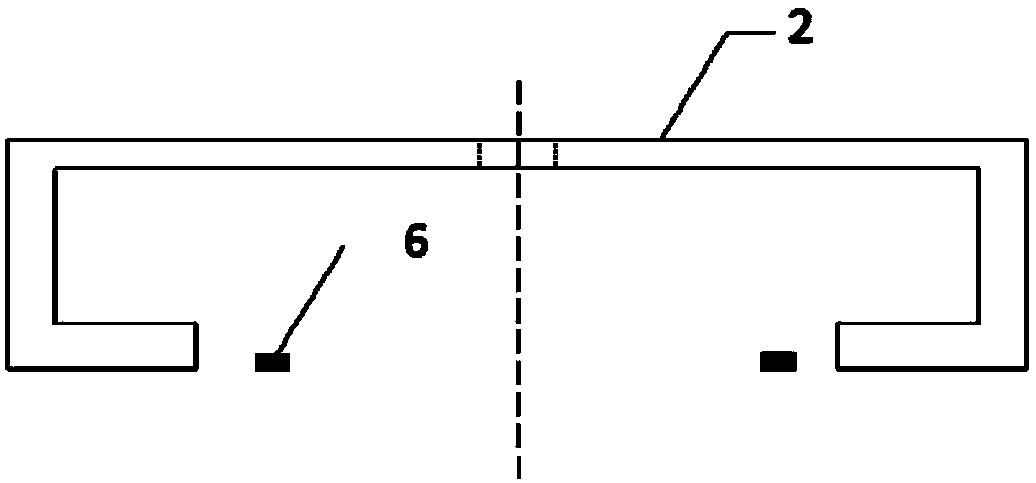

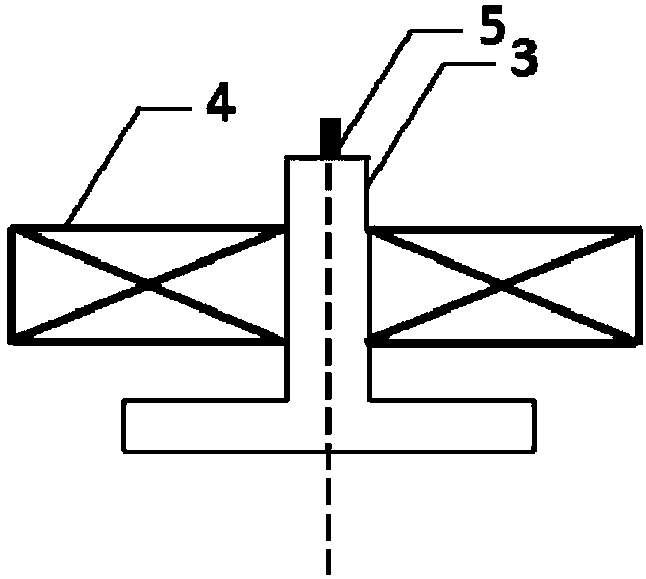

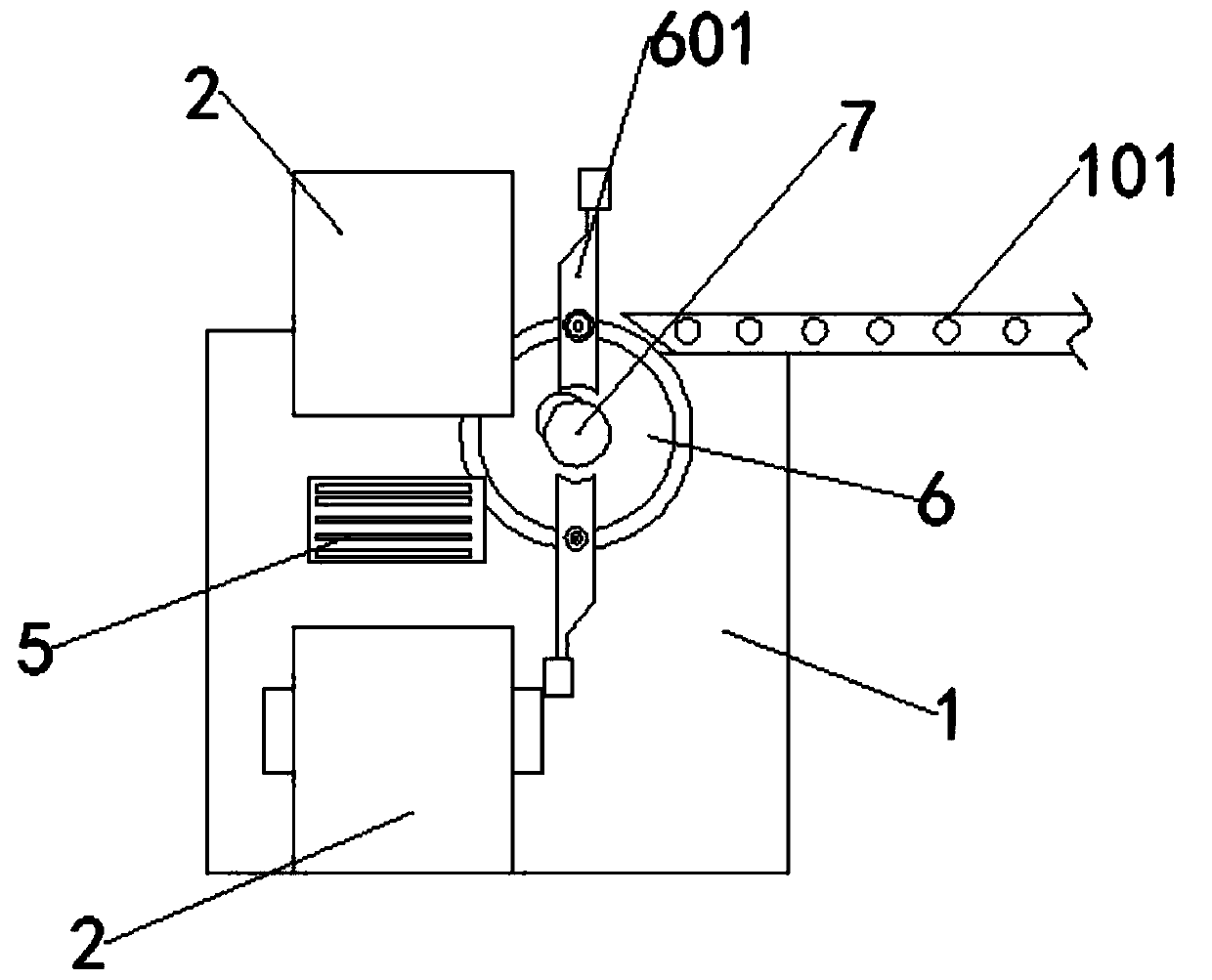

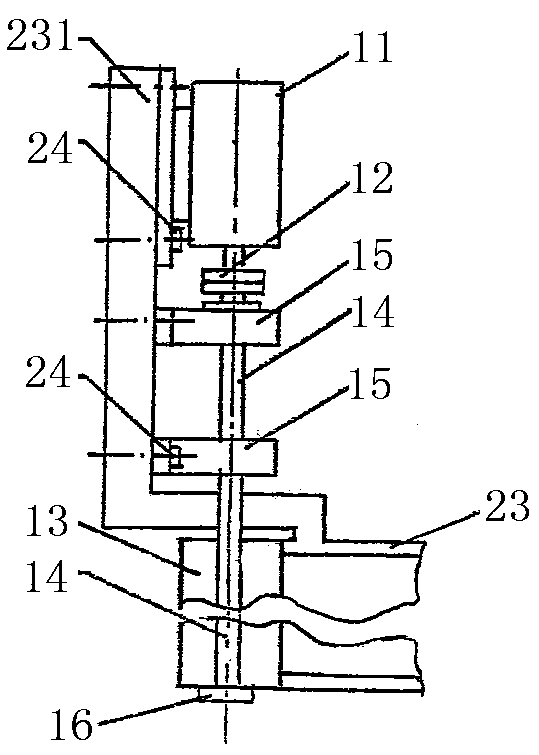

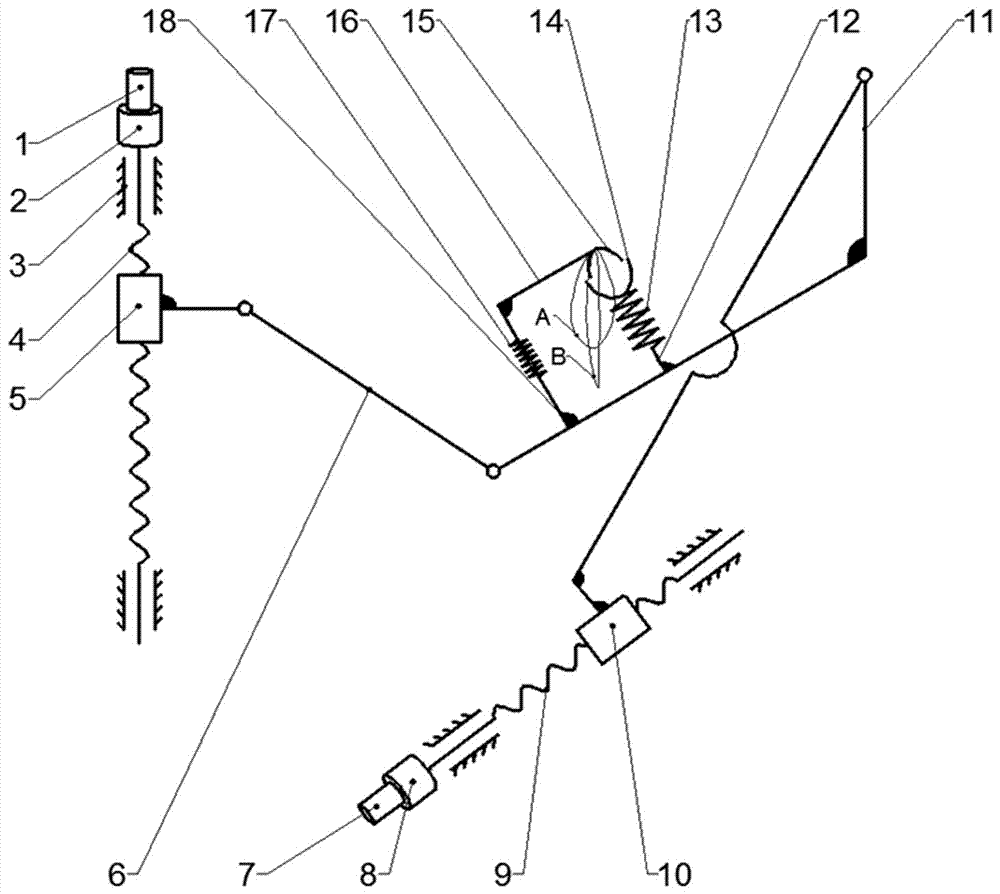

Closed-mouth type water wave generator with safety gate

InactiveCN108571417AHigh energyReduce the cross-sectional areaWind energy with water energyHydro energy generationElectric power transmissionElectricity

The invention relates to a closed-mouth type water wave generator with a safety gate. The closed-mouth type water wave generator with the safety gate comprises a generator unit (1) and a closed-mouthpart (2) which are connected with an electric power transmission device, wherein the generator unit comprises an electric generator (11); an input shaft of the electric generator is connected with a blade shaft (14) with a blade (13) through a coupler (12); the closed-mouth part comprises a closed mouth (21) for introducing water wave and conveying the water wave; a water inlet facing the water wave is formed in one end of the closed mouth; the other end of the closed mouth is integrally communicated with one end of each of two straight mouths (23); the blade shaft with the blade is arranged at the back end outlet position of one straight mouth; a normally closed first gate (3) is arranged at the front end of the other straight mouth; the internal part of each straight mouth is hollow; theclosed mouth and the straight mouths are supported by a supporting column (22) fixedly in the water wave. A large quantity of sea water waves can be collected to generate electricity, and small waveson other water surfaces can be collected to generate electricity.

Owner:李晓亮

Method for composing audio/video file by voice driving head image

The invention relates to a method for compounding head pictures into video files in the drive of sound. The method comprises the steps as follow: a fixed digital head picture is captured; the data coordinates of the head, the face and the facial features are picked up and the picture animation mode data is counted; a closed mouth frame, an open mouth frame and an expression frame and a picture characteristics data file including the quantity of the three picture frames are generated; a sound digital information is collected; the sound characteristics data is analyzed and picked up so as to generate a sound characteristics data file including a voice sound frame and an assonant sound frame; the picture characteristics data file and the sound characteristics data file are compounded in-phase, so that the voice sound frame is corresponding to the open mouth frame, and the assonant sound frame is corresponding to the closed mouth frame, and then outputting. The invention has the advantages of vivid pictures, achieving the animation on human facial and animal facial expression, easy and simple production and being convenient for generalization and use.

Owner:GUANGZHOU EAPHONETECH CO LTD

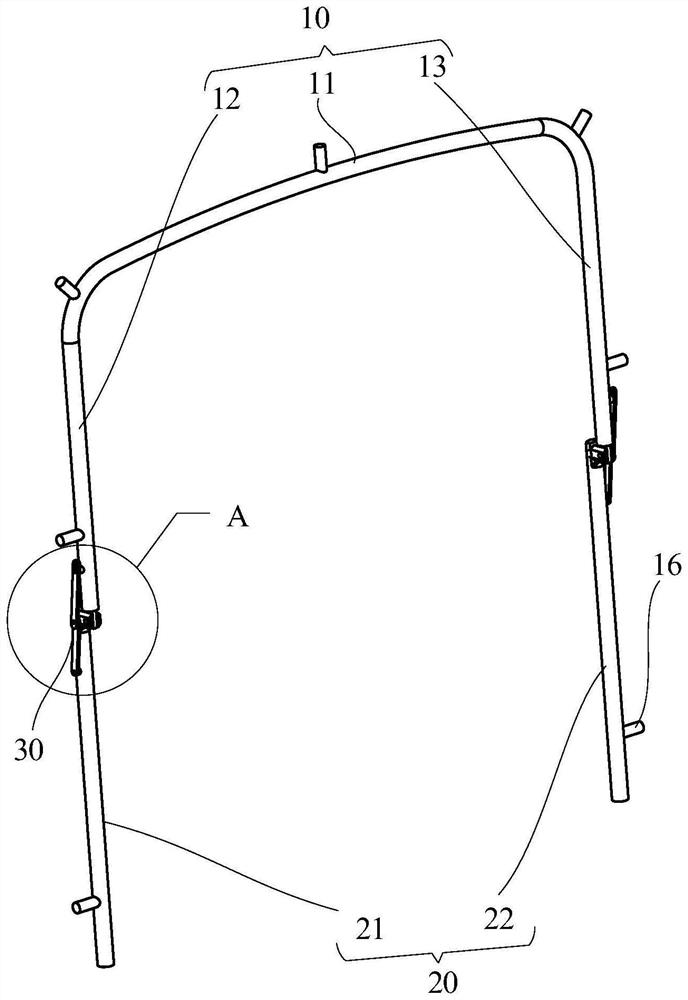

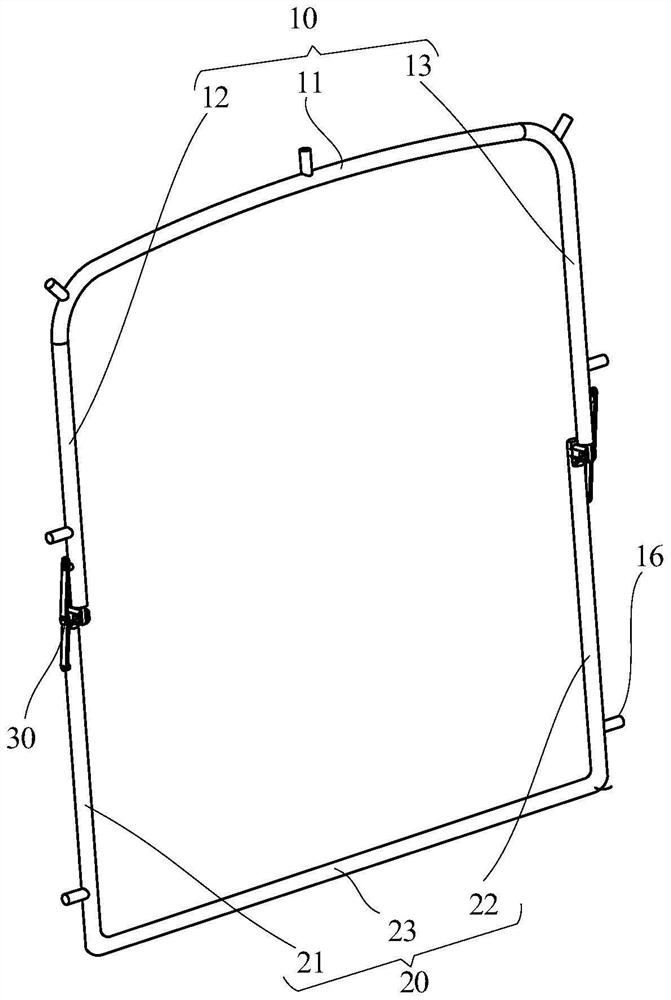

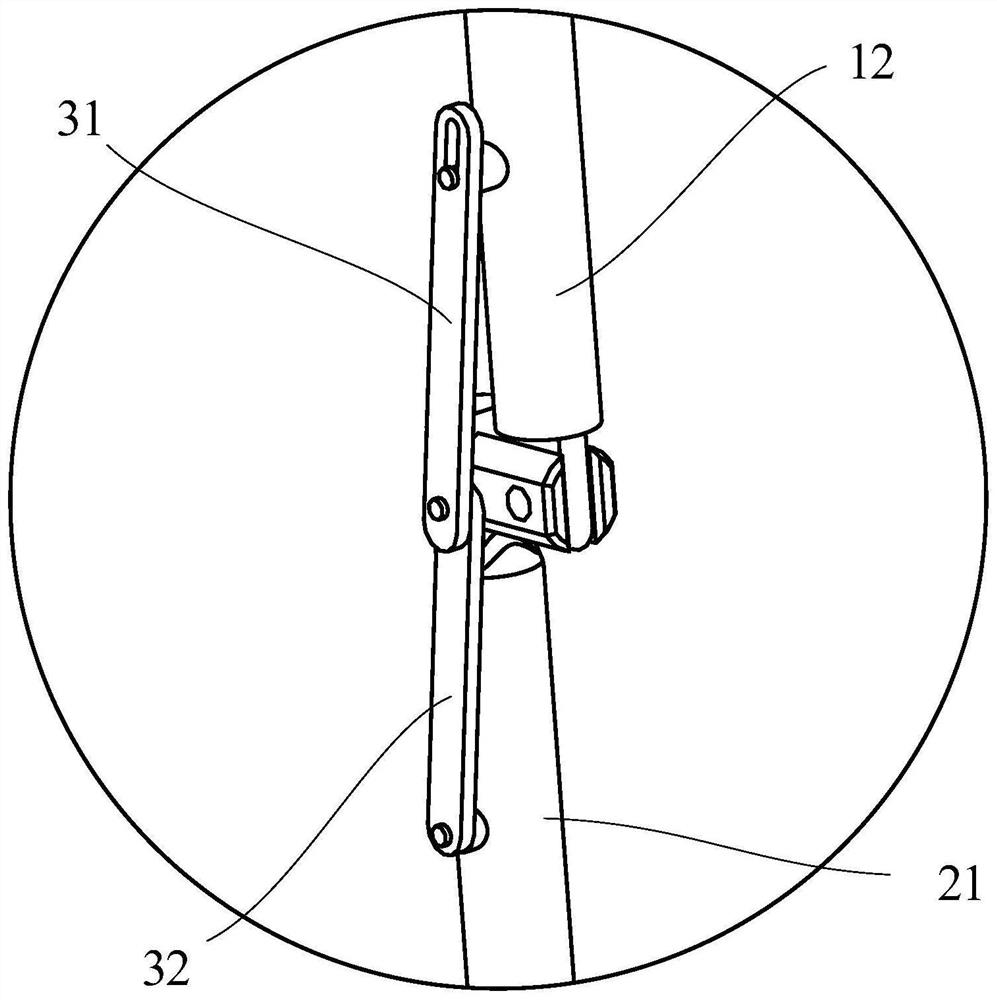

Rubber barrier frame

PendingCN114366350AImprove comfortHumanization of the treatment processDental aidsClassical mechanicsStructural engineering

The invention provides a rubber barrier frame. The rubber barrier frame comprises a first support body and a second support body. The first support body comprises a bottom beam, a first supporting arm and a second supporting arm, wherein the first supporting arm and the second supporting arm are located at the two ends of the bottom beam. The first supporting arm, the bottom beam and the second supporting arm form a U-shaped frame. The second support body comprises a first extension arm hinged to the first supporting arm and a second extension arm hinged to the second supporting arm. The second support body is configured to be in a supporting state and a folding state relative to the first support body. In the supporting state, the second support body and the first support body jointly support and unfold the rubber barrier. In the folding state, the second support body can rotate relative to the first support body. According to the technical scheme, the rubber barrier can be well supported and unfolded, the rubber barrier frame is of a foldable structure, a patient can have a rest in a closed mouth midway, and the treatment comfort of the patient is improved.

Owner:BEIJING STOMATOLOGY HOSPITAL CAPITAL MEDICAL UNIV

Child safety seat for simulation automobile cab

The invention discloses a child safety seat for simulating a car cab, relates to the field of auto parts, and specifically belongs to a child safety seat. The purpose of the present invention is to provide a car safety seat that can greatly improve children's interest. In order to achieve this purpose, the present invention includes a child safety seat, which is characterized in that the square position also includes a simulated car cab inflation device, so The inflatable equipment for the simulated car cab includes: inflatable steering wheel, inflatable shift lever, inflatable realistic instrument panel, low-decibel simulated car horn, inflatable accelerator pedal, inflatable brake pedal, etc.; also includes a self-inflating miniature air pump , the micro air pump can automatically detect the air pressure of the inflatable device, if it is less than the rated air pressure, it will automatically open to inflate the inflatable device; when the air pressure reaches a certain value, it will automatically close and close the sealing mouth. The invention has the advantage of greatly improving children's interest.

Owner:农立艳

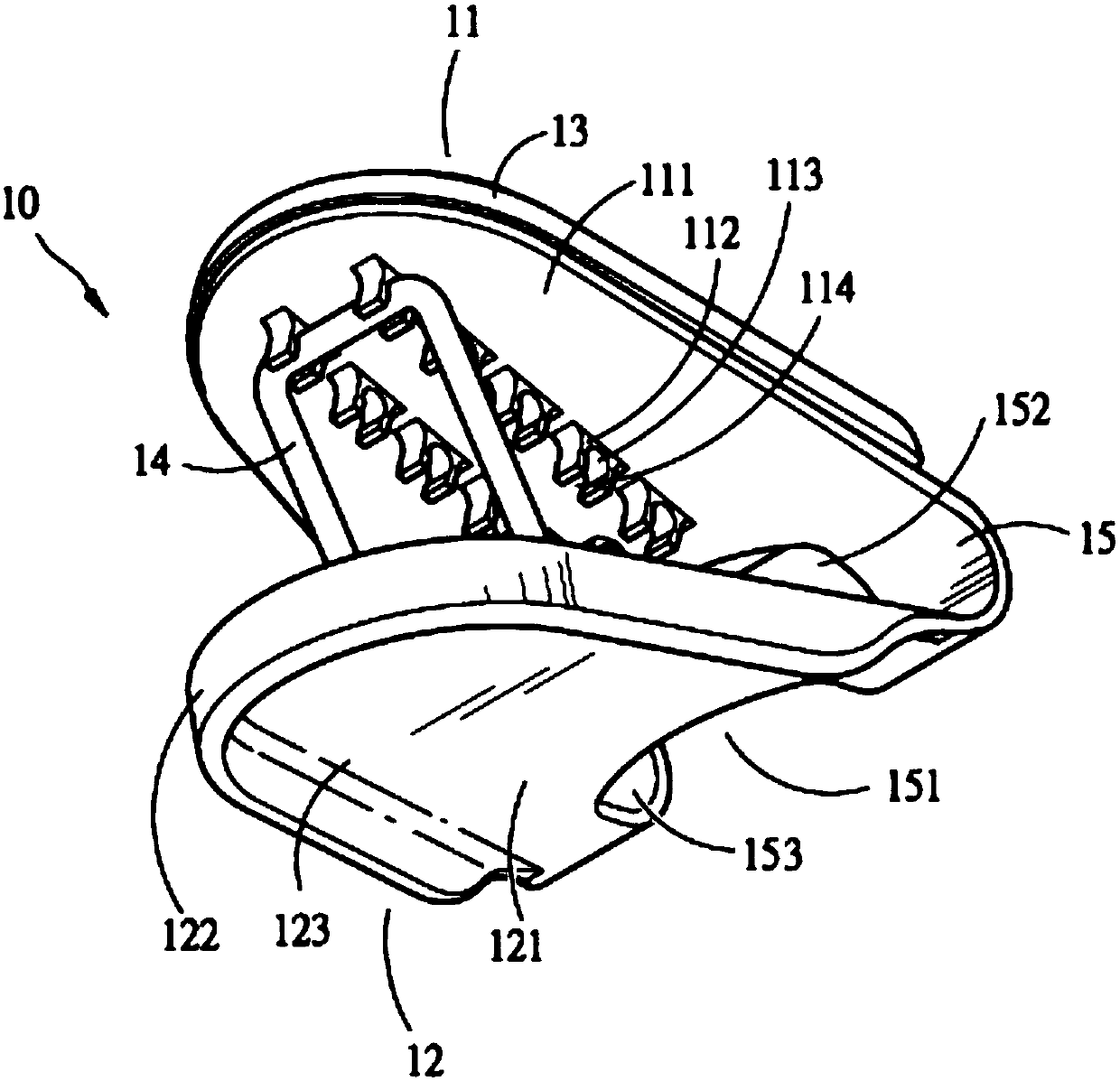

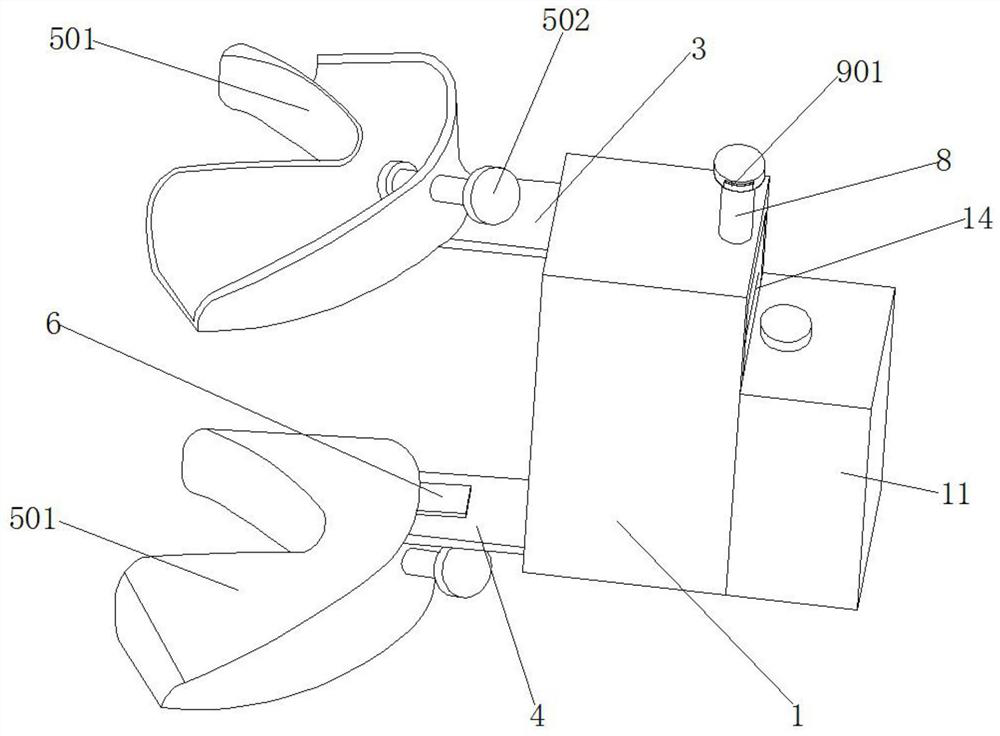

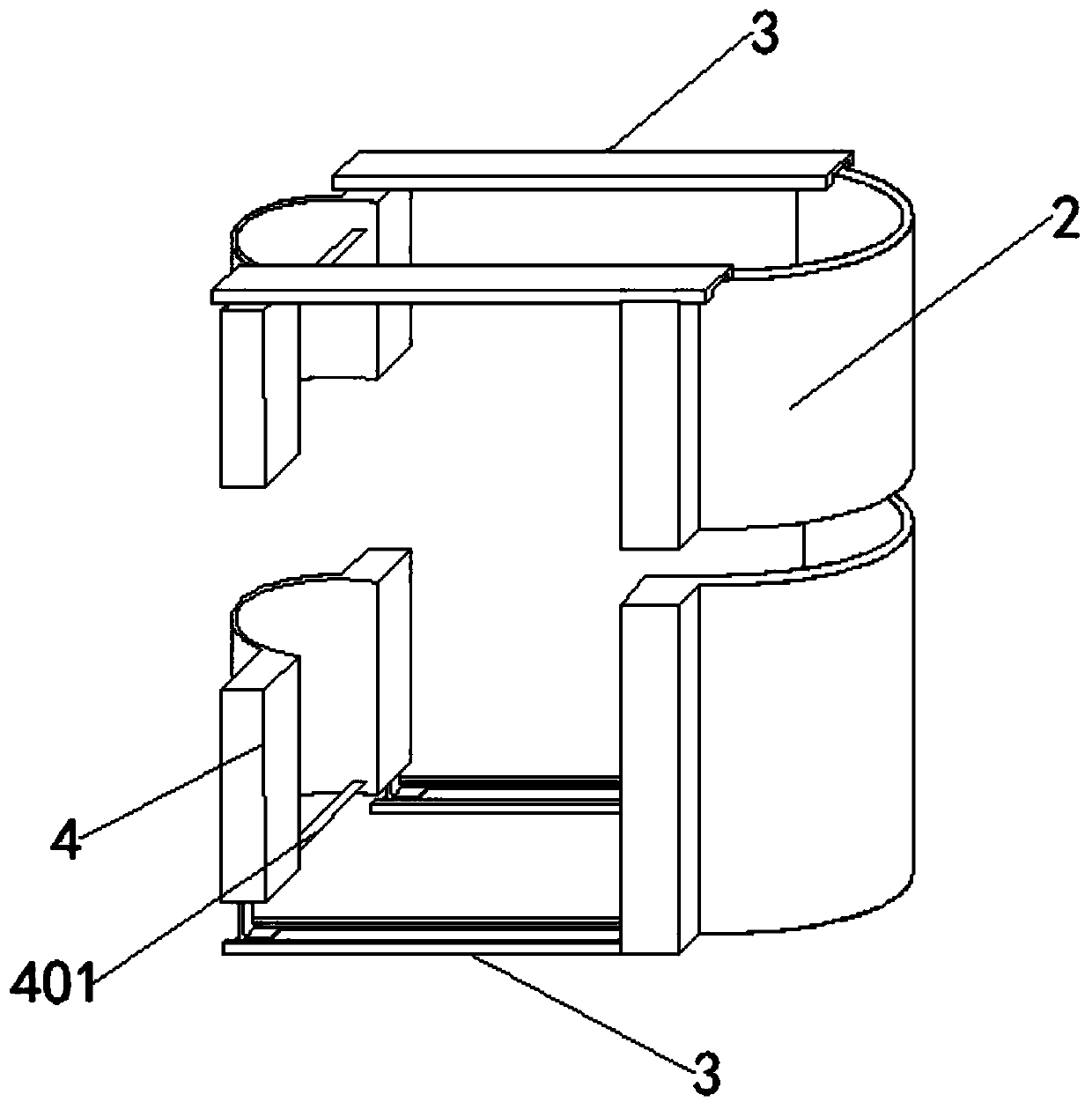

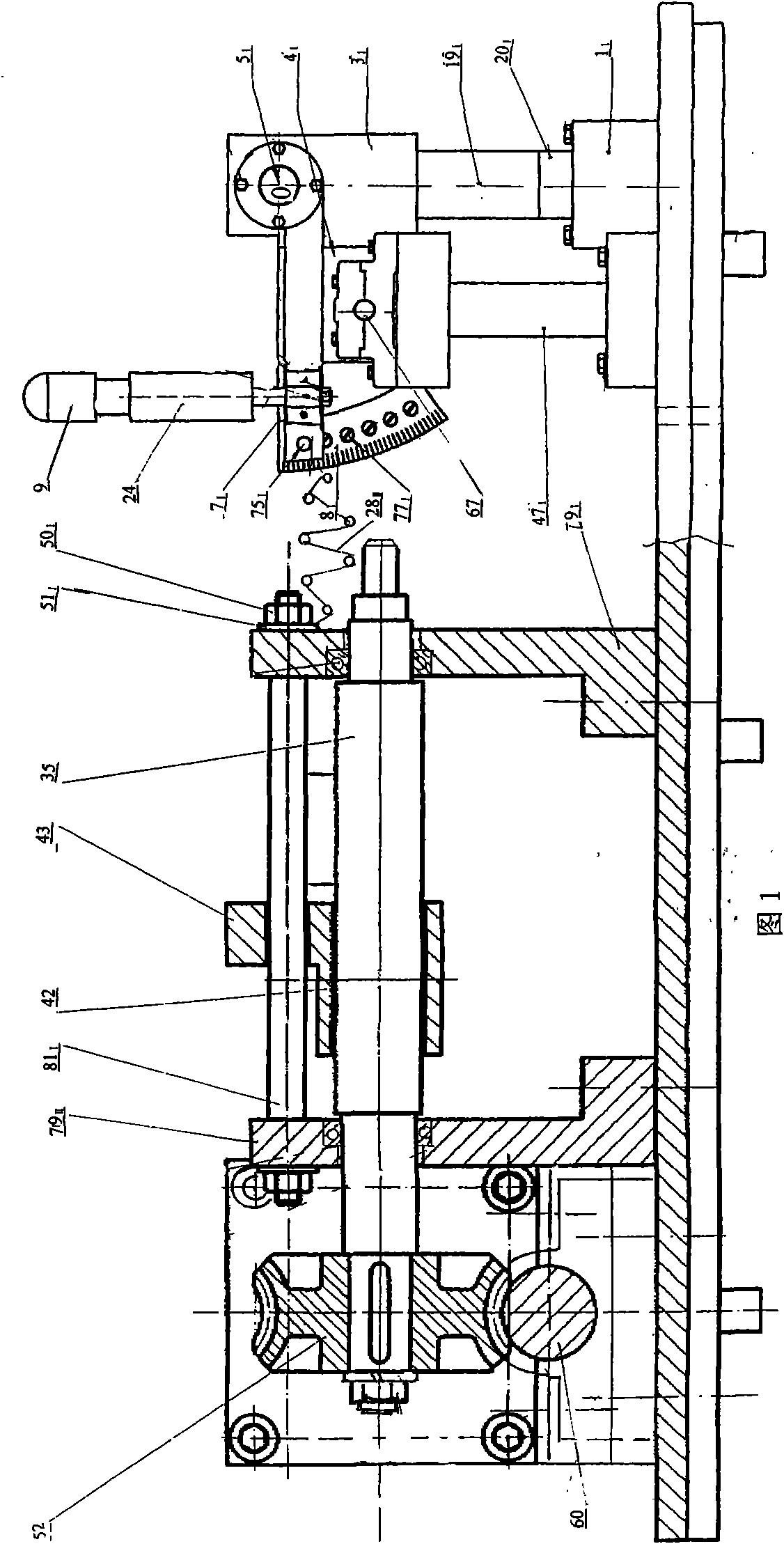

Jaw opening and closing rehabilitation robot

PendingCN107440885ACompact structureEasy to operateChiropractic devicesPhysical medicine and rehabilitationPhysical therapy

The invention discloses a jaw opening and closing rehabilitation robot which is suitable for patients who suffer from temporomandibular joint disturbance syndrome and need to carry out rehabilitation training in the jaw opening and closing direction. The jaw opening and closing rehabilitation robot structurally mainly comprises two servo motors, two speed reducers, two pairs of lead screw nuts, a first connecting rod, a second connecting rod, a first spring, a second spring, a jaw connecting piece, a jaw supporting piece, a dental tray, a dental tray connecting piece, a spring fixing piece and a rack, wherein the speed reducers are fixedly connected with lead screws; the lead screws are connected with nuts in a matched manner; the two nuts are separately connected with the first connecting rod and the second connecting rod by hinges; the two connecting rods are connected by a hinge; the first spring is separately connected with the jaw connecting piece and the jaw supporting piece fixedly; the second spring is separately connected with the spring fixing piece and the dental tray connecting piece fixedly; and the dental tray is fixedly connected with the dental tray connecting piece. The device is compact in structure, convenient to operate, high in safety and low in cost, and can be used for rehabilitation training in hospitals or families.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

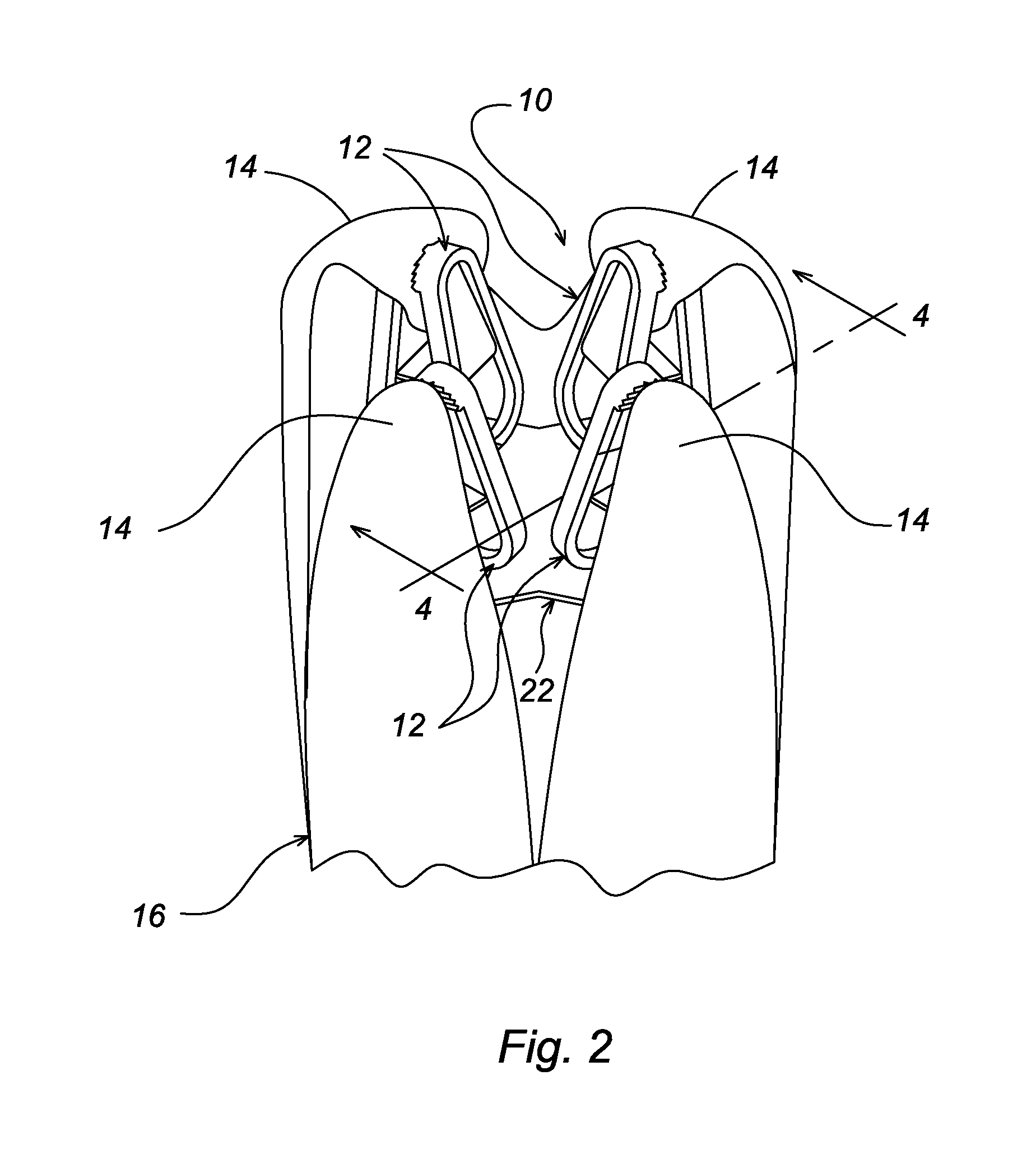

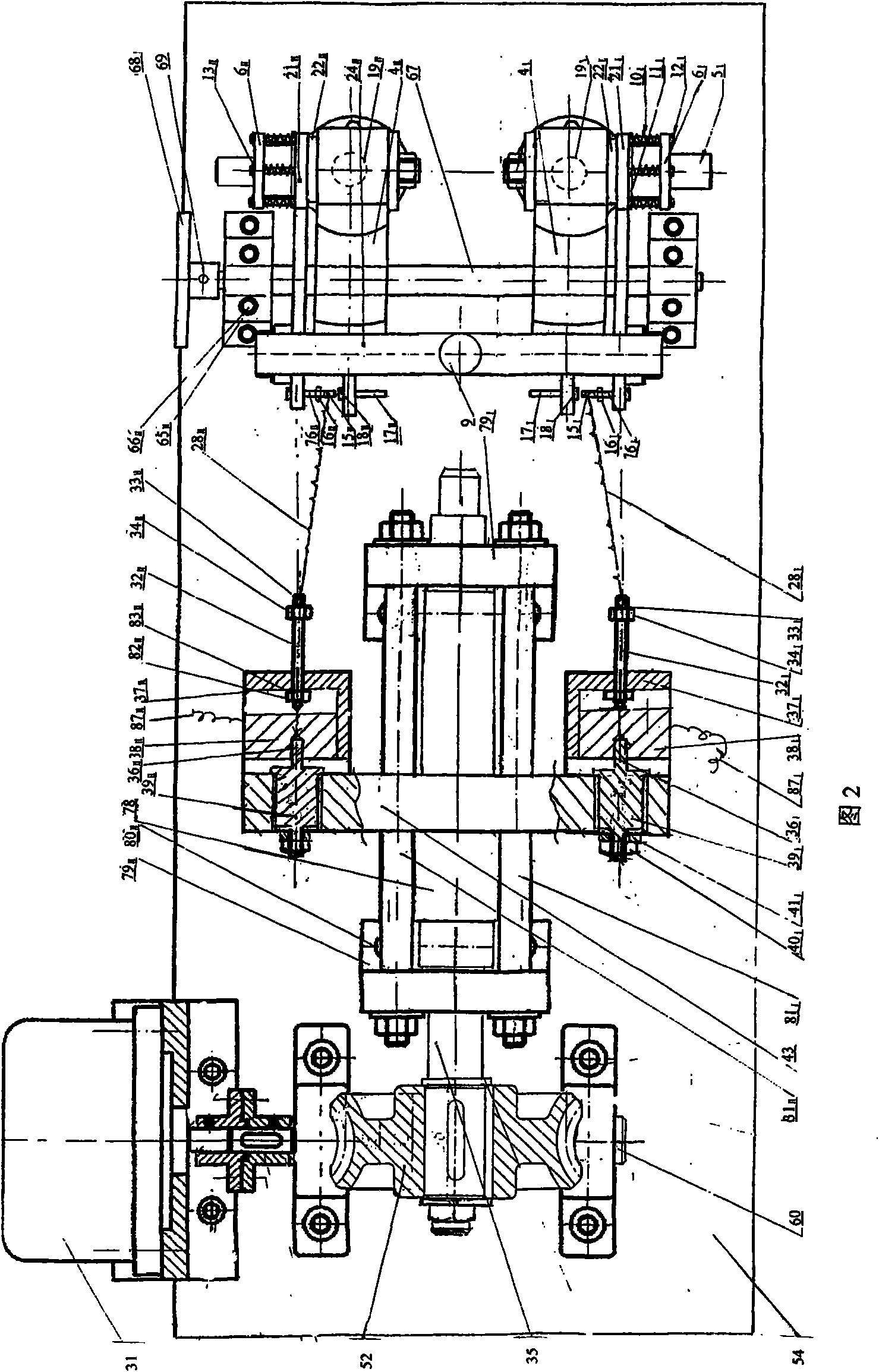

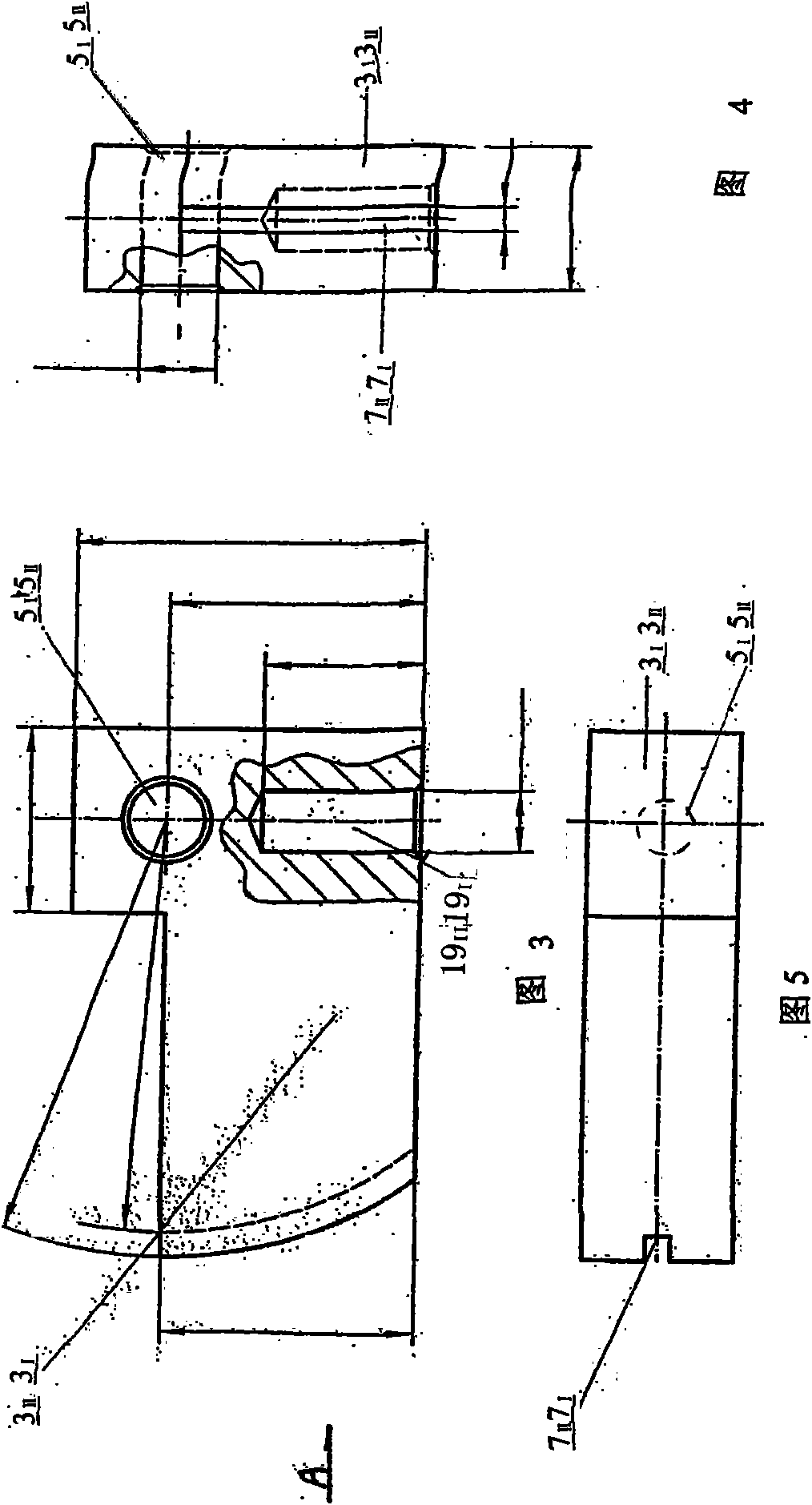

Buccal multi-bending spring space three-dimensional dynamometer

The invention relates to a buccal multi-bending spring space three-dimensional dynamometer, which is applied to simulating a maxilla, a mandible and a temporomandibular joint, and predicting the push and pull force values generated on crossover points of the maxilla and the mandible when a correction patient wears multi-bending springs 28I and 28II to perform mouth opening and closing motions. The dynamometer has accurate measurement and can instruct the clinical allopathic wearing according to the following steps: (1) putting two terminal filaments of the 28I and the 28II into a 15I, a 15II and upper jaws 33I and 33II fastening the terminal filaments, and moving a bracket 43 leftwards and rightwards so as to measure the pulling-pressing stress values and the displacements of the 28I and the 28II to a full denture; (2) elongating the 28I and the 28II, fastening the same into holes of the 15I, the 15II, the 33I and the 33II, moving a 32I and a 32II to adjust the stress values to approach to 0, driving a 35, the 32I and the 32II to move rightwards, and measuring the maximum pressing stress value of the full denture of the upper jaw and the lower jaw when the 28I and the 28II are pressed to a mouth-closing state; and (3) measuring the stress values and the displacements of the 28I and the 28II along the scales of 5 degrees, 10 degrees and 15 degrees of a 8I and a 8II by the 15I and the 15II; and if a 21I and a 21II move around a center leftwards and rightwards (the 15I and the 15II are 3 millimeters away from the central displacement), repeating the steps (1) and (2) to measure acting forces and displacement values.

Owner:侯录 +1

Automatic production equipment for power wires

ActiveCN106078194ARealize automated productionAdjustable lengthAssembly machinesEngineeringPower cord

The invention discloses automatic production equipment for power wires. The automatic production equipment comprises a body structure which is in an integral U shape. A chain transmission mechanism is erected at a U-shaped opening in the upper surface of the body structure. A clamping jaw wire feeding structure, a head wire peeling structure, a tail integrated inner rack end-cutting and reshaping mechanism and a vibration feeding tray are sequentially installed on the left side of the upper surface of the body structure from the closed end to the opened end. A tail wire peeling structure, a ground wire end-cutting mechanism, a ground wire detaching mechanism and a null and live wire end-cutting and reshaping mechanism are sequentially installed on the right side of the upper surface of the body structure from the closed end to the opened end. According to the automatic production equipment, a plurality of independent mechanisms capable of operating horizontally at the same time are integrated on the same equipment, and therefore the power wires can be automatically produced, production efficiency is improved, manual cost is reduced, and meanwhile product quality stability is improved. The power wires produced by the equipment have the advantages of being adjustable in length, adjustable in terminal variety, capable of meeting the requirements of different countries and the like, and the practicability is high.

Owner:常熟利星光电科技有限公司

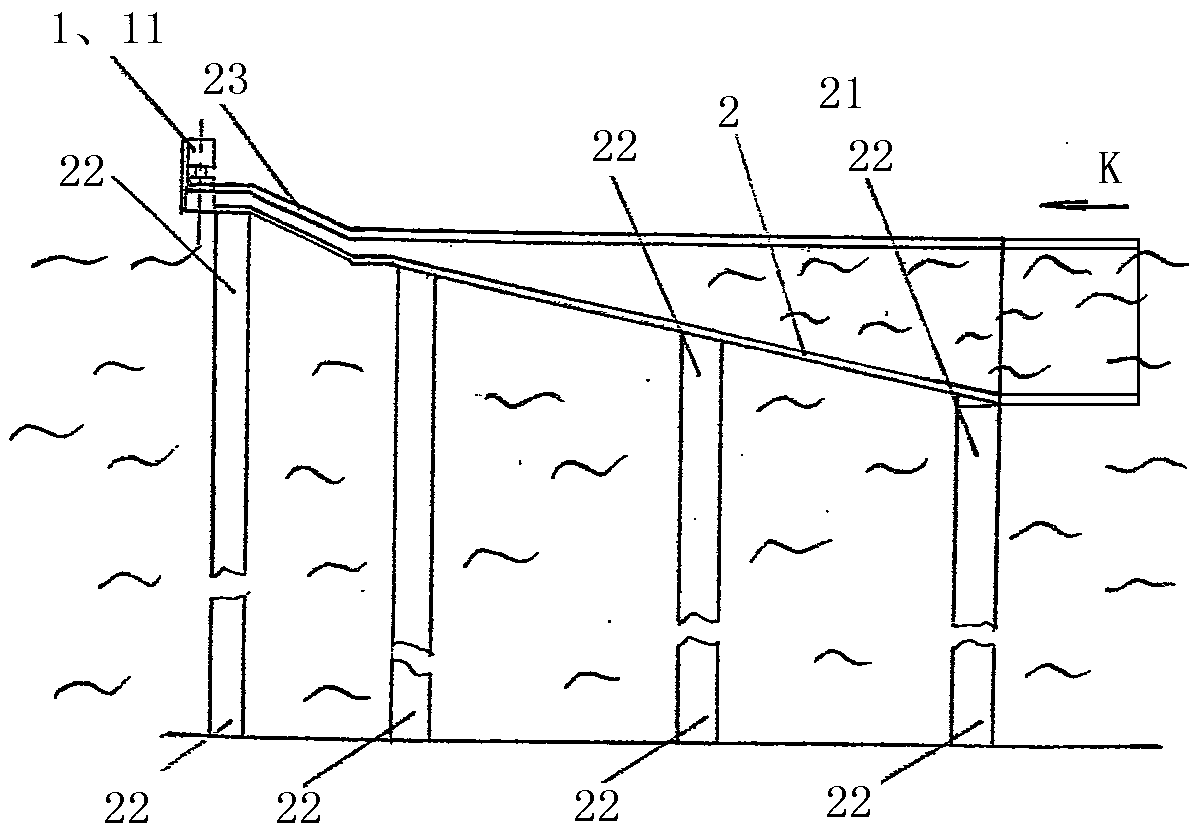

Drawing bore method for pile shoe

InactiveCN1189629CEasy to dial outAvoid the problem of strengthBulkheads/pilesArchitectural engineeringPipe

Owner:应义淼

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com