Corn straw shaping and baling machine

A technology of corn stalks and shaping boards, which is applied in the agricultural field, can solve the problems of uncompressed straws, easy jamming, messy straws, etc., and achieve the effects of neat and tidy appearance, prevention of mechanical jamming, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

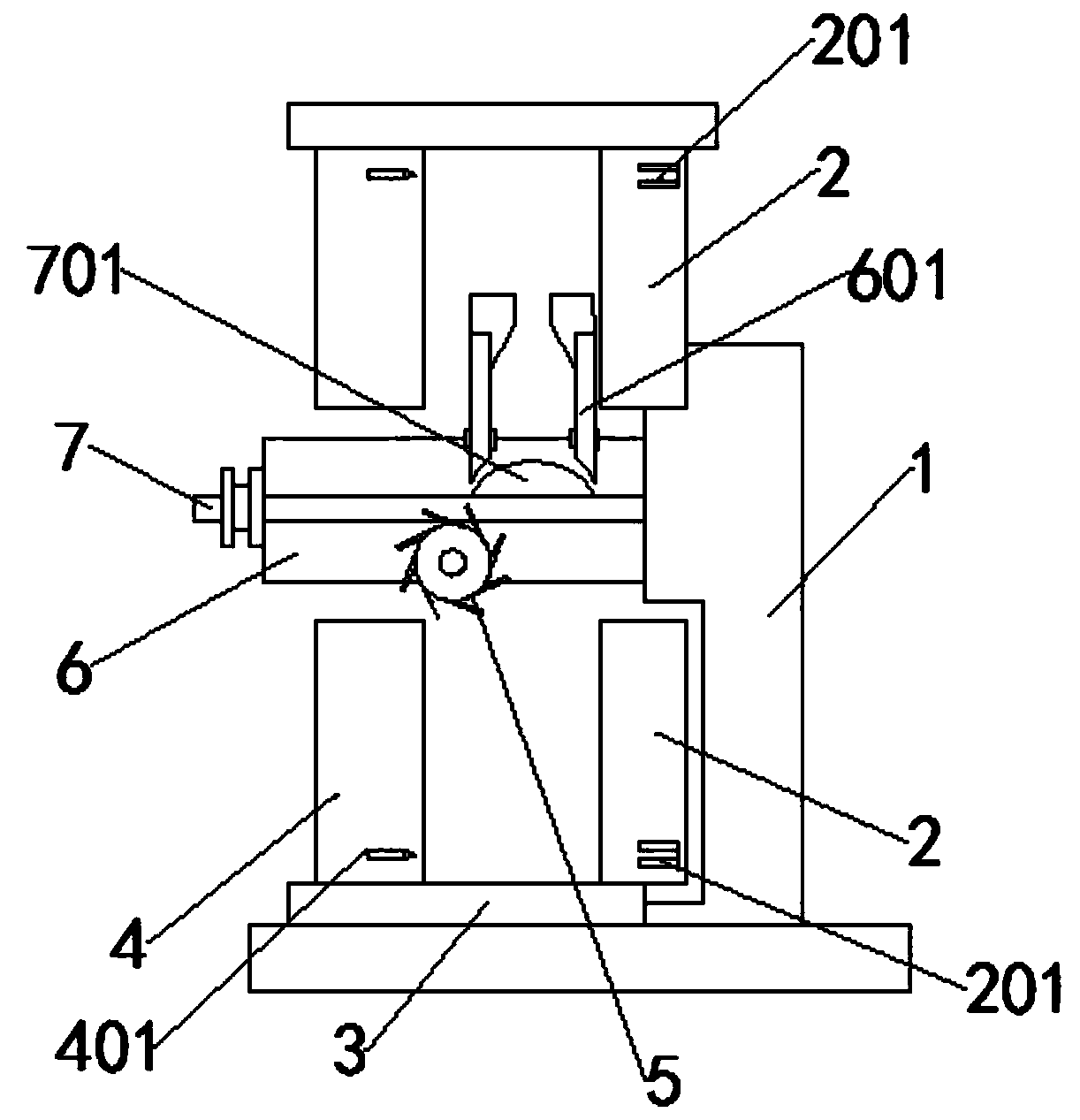

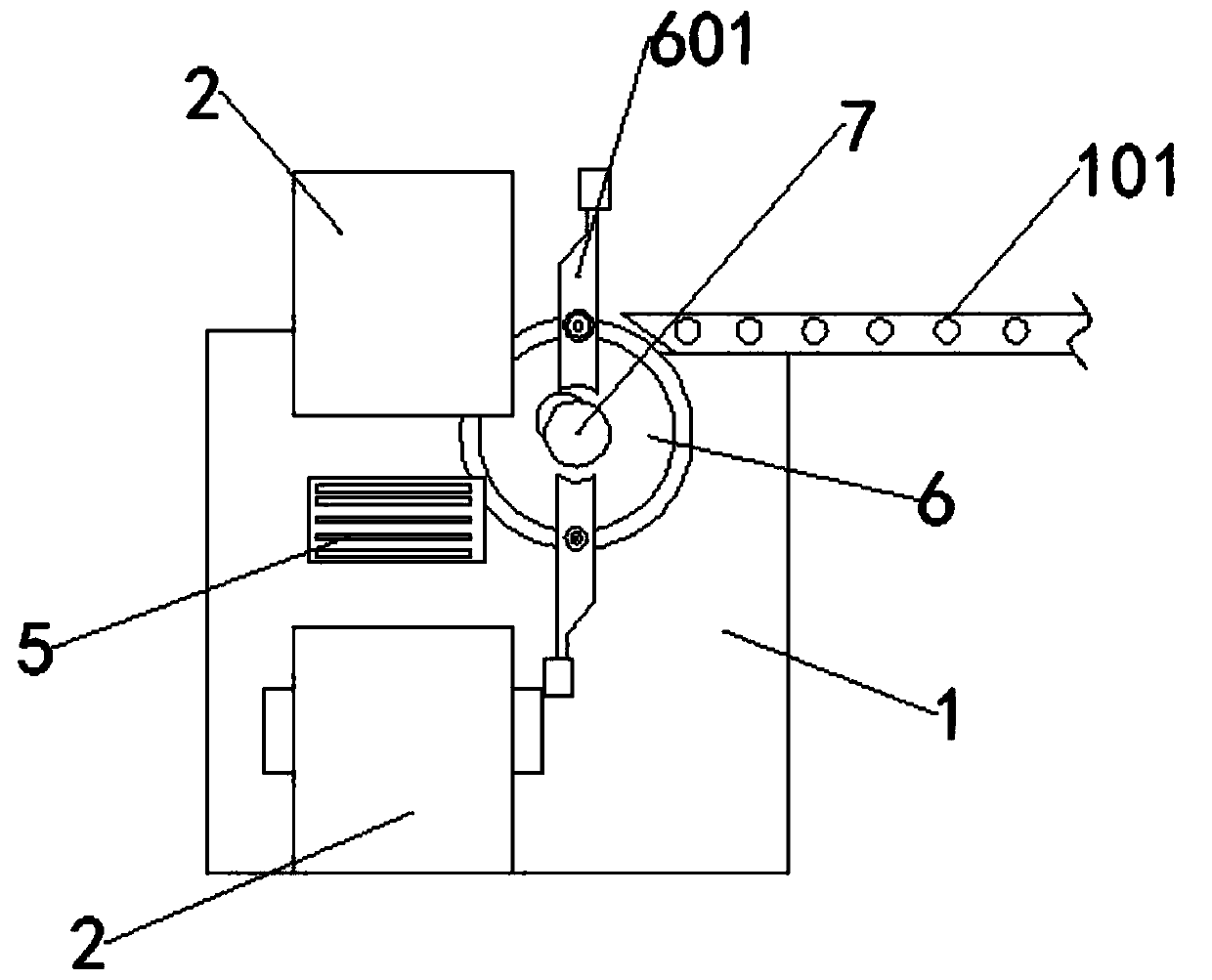

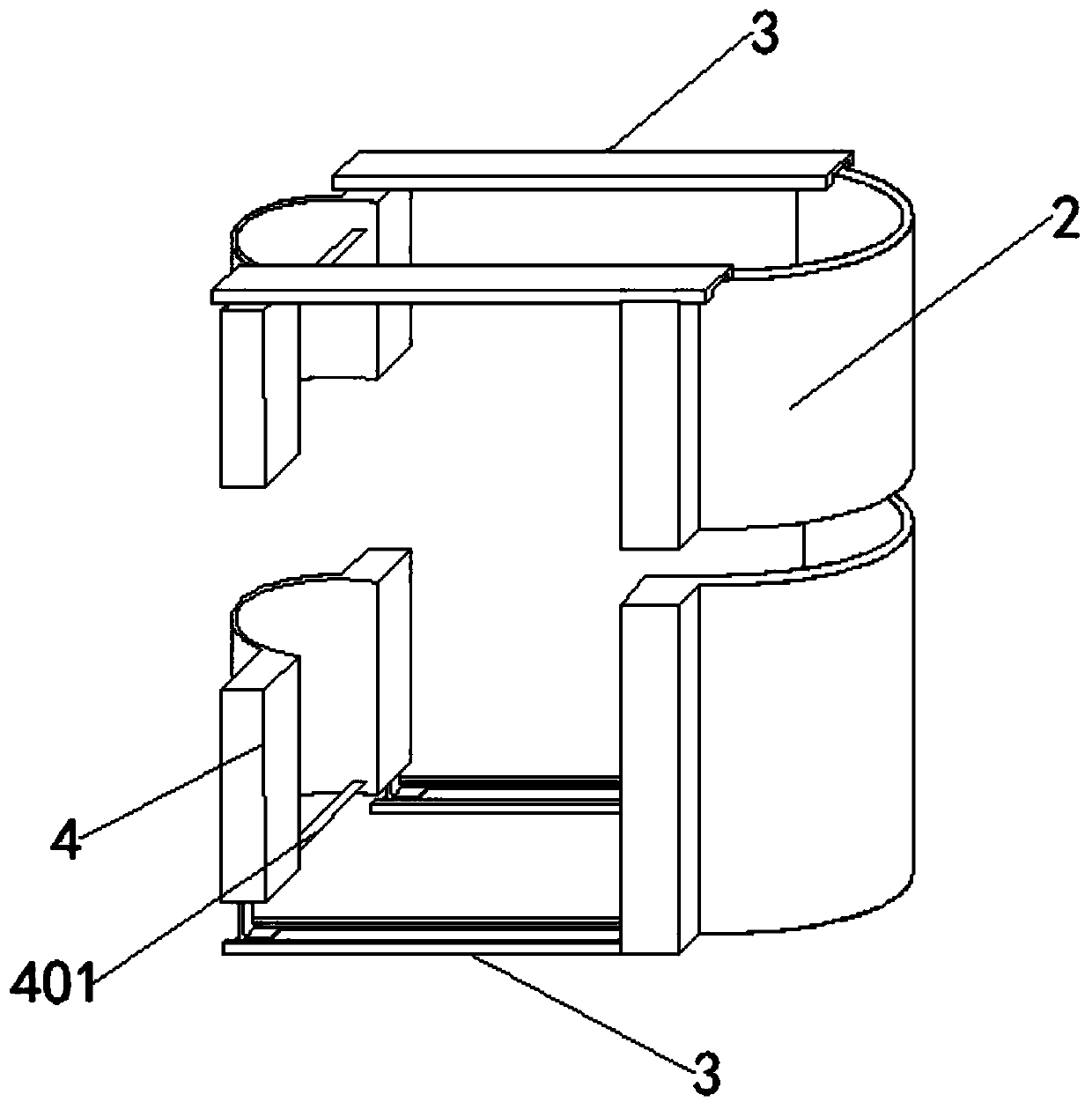

[0031] as attached figure 1 to attach Figure 6 Shown:

[0032] The present invention provides a corn stalk shaping and packing machine, which comprises a limit plate 1, a first arc-shaped plate 2, a chute 3, a second arc-shaped plate 4, extrusion rollers 5, a turntable 6, Fixed axis 7, conveyor belt 101, knife groove 201, cutting knife 401, movable fan plate 501, shaping plate 601, bump 701, bayonet 6011, concave surface 6022, positioning shaft 6033 and torsion spring 6044; the rear of the limit plate 1 is connected flexibly There is a conveyor belt 101, one side of the limiting plate 1 is fixedly connected with a first arc-shaped plate 2, the upper and lower sides of the first arc-shaped plate 2 are fixedly connected with a chute 3, and the inside of the two chute 3 is slidably connected with a second arc-shaped plate 2. The opposite sides of the arc-shaped plate 4, the first arc-shaped plate 2 and the second arc-shaped plate 4 are respectively movably connected with a kni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com