Transportation system and method of high concentration solid granule suspending solution

A solid particle, conveying system technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as failure to work properly, pipeline blockage, and system impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

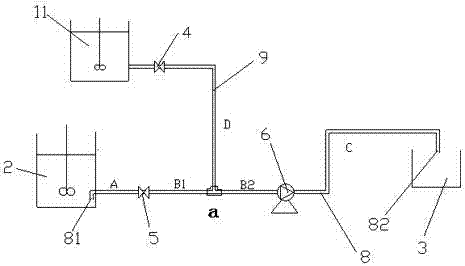

[0038] Please refer to figure 2 , the discharge nozzle 82 is higher than the liquid level of the solid particle suspension in the mixing device 2, and the discharge nozzle 82 is always lower than the liquid level of the clear water tank 11, and its function is to flush the delivery pipeline 8 with clean water In this process, the clean water can flow through the delivery pipeline B from the clean water tank 11 relying on potential energy 2 Section, delivery pump 6 and section C of delivery pipeline; when flushing section A of delivery pipeline, delivery valve 5 and delivery pipeline B 1During the section, because the discharge nozzle 82 of the delivery pipeline 8 should be higher than the liquid level of the suspension in the mixing device 2, the clear water will only flow to the A section of the delivery pipeline, but not to the C section of the delivery pipeline. .

Embodiment 2

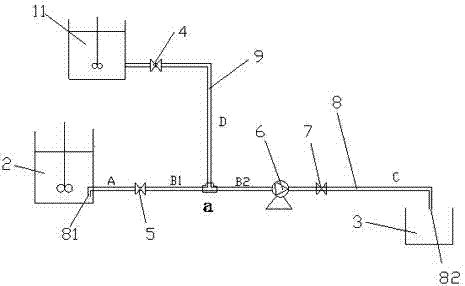

[0040] Please refer to image 3 , the liquid level of the clear water tank 11 is higher than the liquid level of the suspension in the mixing device 2, and the discharge nozzle position of the section C of the conveying pipeline is lower than the liquid level of the suspension in the mixing device 2. The trend of clear water is controlled by adding a control valve 7, that is, a control valve 7 is connected in series behind the delivery pump 6. In the process of flushing the delivery pipeline 8 with clean water, open the flushing valve 4 and the control valve 7, close the delivery valve 5, and the clean water can flow through the delivery pipeline B from the clean water tank 11 relying on potential energy 2 Section, delivery pump 6 and section C of delivery pipeline; when flushing section A of delivery pipeline, delivery valve 5 and delivery pipeline B 1 During a period of time, open the delivery valve 5 and close the control valve 7, and the clean water can flow through the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com