Flow construction method of underground pipe gallery inner mold system

An underground pipe gallery and construction method technology, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of difficult production and transportation, long waiting time for demoulding, and large consumption of materials, and saves energy. Moving and preparation time, reduced demolding waiting time, ease of fabrication and shipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

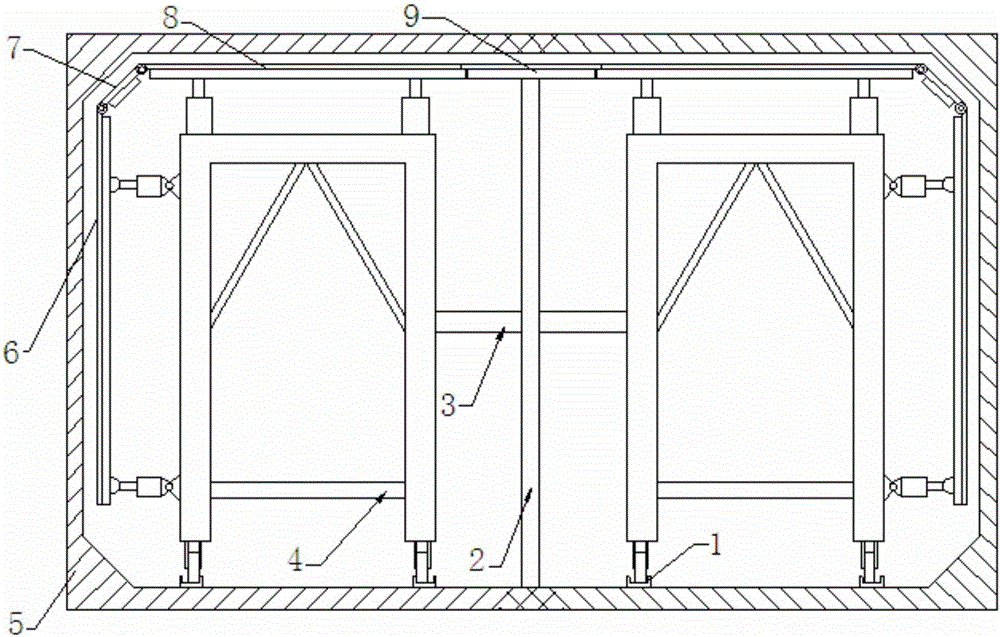

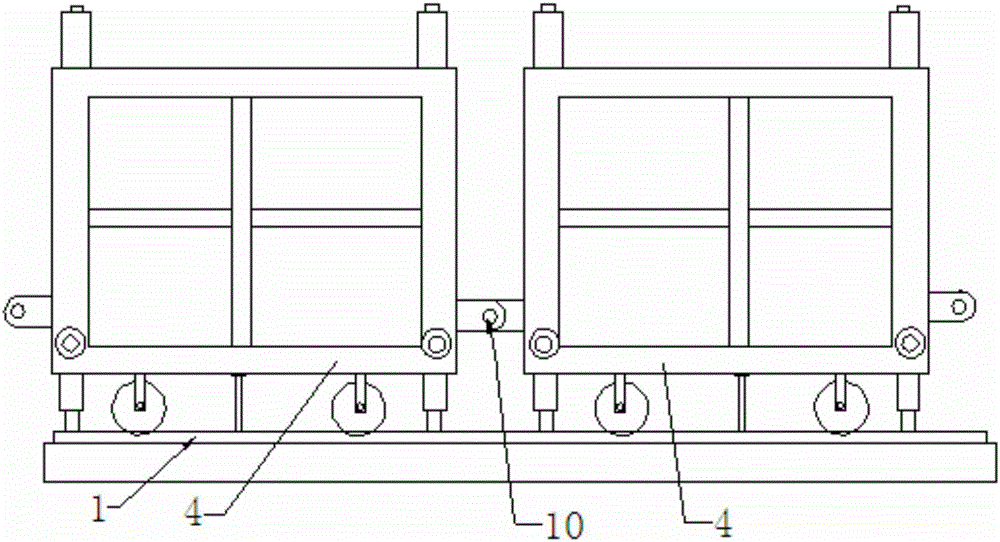

[0028] A flow-through construction method for the internal formwork system of an underground pipe gallery, such as figure 1 As shown, a pair of formwork automatic control units are set on the same section of the pipe gallery. The formwork automatic control unit includes a trolley 4 and an electrical control system. A retractable top formwork 8 and a side formwork 6 are installed on the trolley 4. A tucked angle formwork 7 is provided between the top formwork 8 and the side formwork 6, and there is a distance between the two top formworks 8. During construction, the top formwork 8, the side formwork 6 and the tucked angle formwork 7 are stretched to the design position and then placed on the two top formworks. Install independent early demolition formwork 9 at the distance between formwork 8, top formwork 8, side formwork 6, tuck angle formwork 7 and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com