Model stage special for pipeline compressor

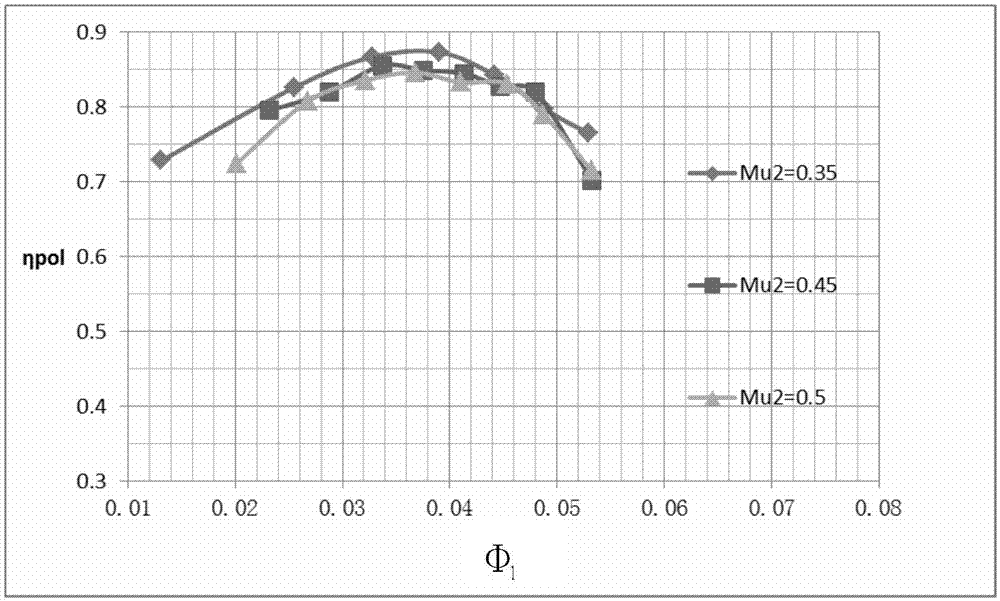

A pipeline compressor and model technology, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as product design difficulties, small shaft diameters, and large axial spans, and achieve reduced bearing spans, The effect of large wheel hub ratio and small span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

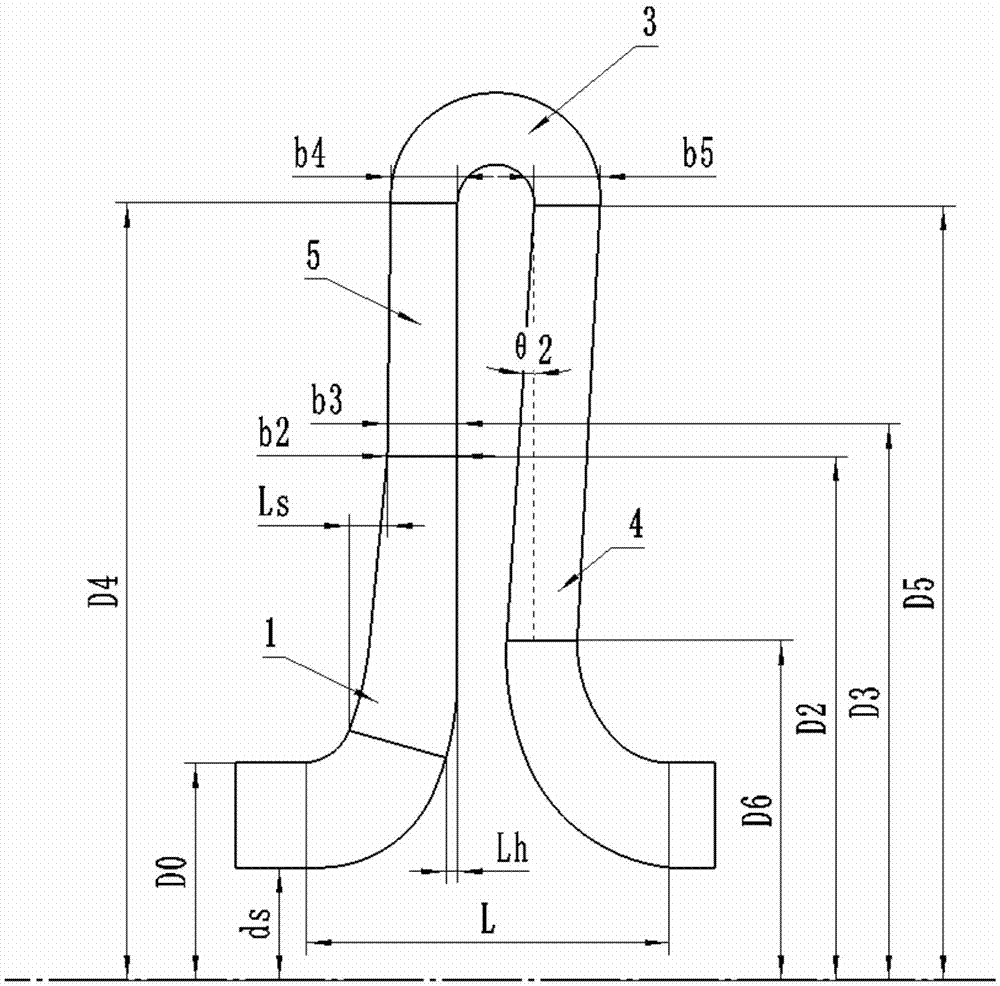

[0040] like figure 1 As shown, the structure of the model-level meridian flow channel of the pipeline compressor of the present invention is as follows:

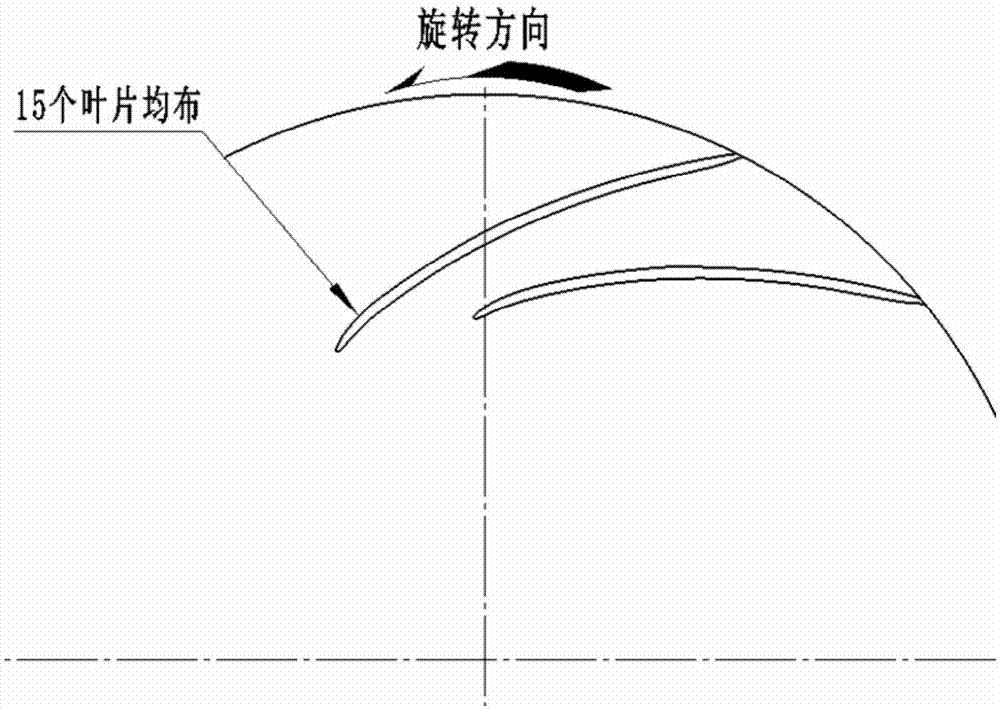

[0041] The special model stage of the pipeline compressor is located in the pipeline compressor, including the impeller 1, the vaneless diffuser 2, the bend 3 and the return device 4. The impeller 1 is set at the inlet of the model stage, and the outlet of the impeller 1 is provided with a The vane diffuser 2 and the recirculator 4 are arranged at the outlet position of the model stage, and the vaneless diffuser 2 and the recirculator 4 are connected through the bend 3 . The impeller 1 is a closed binary impeller, and the recirculator 4 adopts a full-height banana-shaped blade. The impeller blade of impeller 1 is a binary blade. The position of the impeller 1 from the 15% chord length to 85% chord length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com