Vapor compressor model machine

A compressor and water vapor technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of low model group efficiency, and achieve the effects of simple structure, high economic benefits, and high variable efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

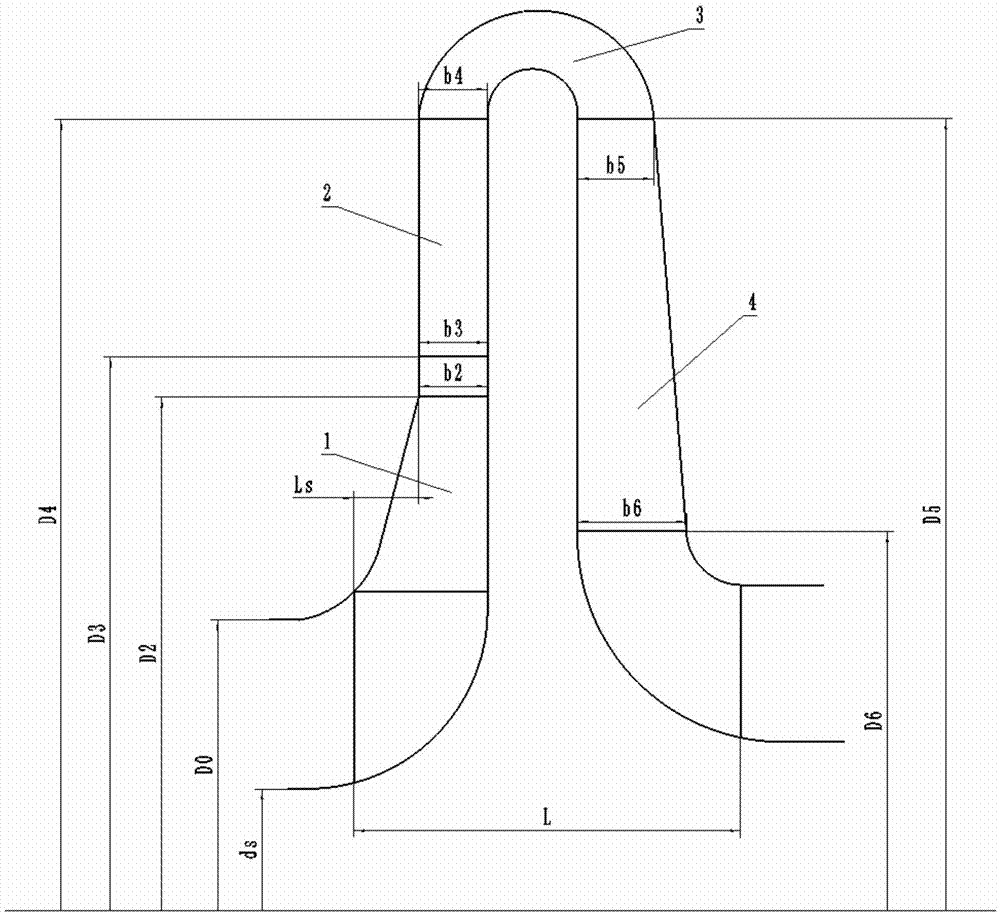

[0052] Such as figure 1 Shown, the structure of the water vapor compressor model stage meridian runner of the present invention is as follows:

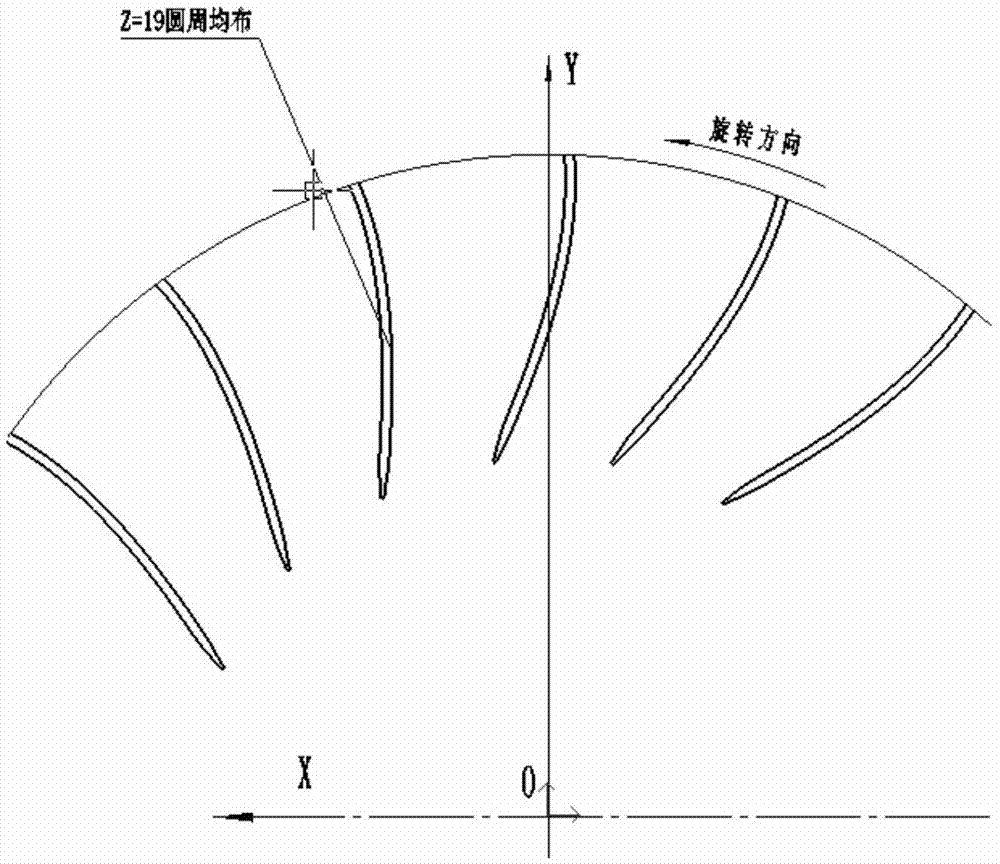

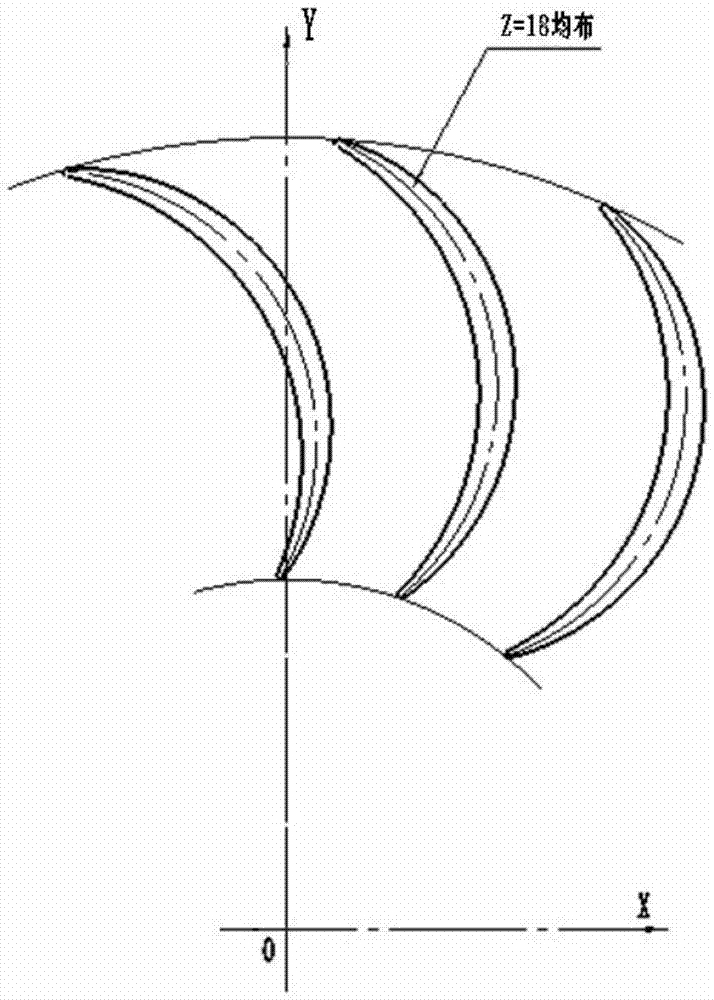

[0053] The water vapor compressor model stage is located in the water vapor compressor, including impeller 1, vaneless diffuser 2, bend 3 and reflux device 4, impeller 1 is located at the inlet of the model stage, and the outlet of impeller 1 is provided with The vaneless diffuser 2 and the return device 4 are located at the outlet of the model stage, and the vaneless diffuser 2 and the return device 4 are connected through a bend 3 . The impeller 1 is a closed binary flow impeller. The impeller blades of the impeller 1 are binary blades. The chord length of the surface is 201.2mm, the chord length of the pressure surface is 197.9mm, the profile line of the impeller 1 inlet cover is composed of an arc of R=84.2mm and a straight line with an angle of 14.66° with the plumb line, and the profile line of the hub is a Plumb line; the mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com