Patents

Literature

94 results about "Discharge coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

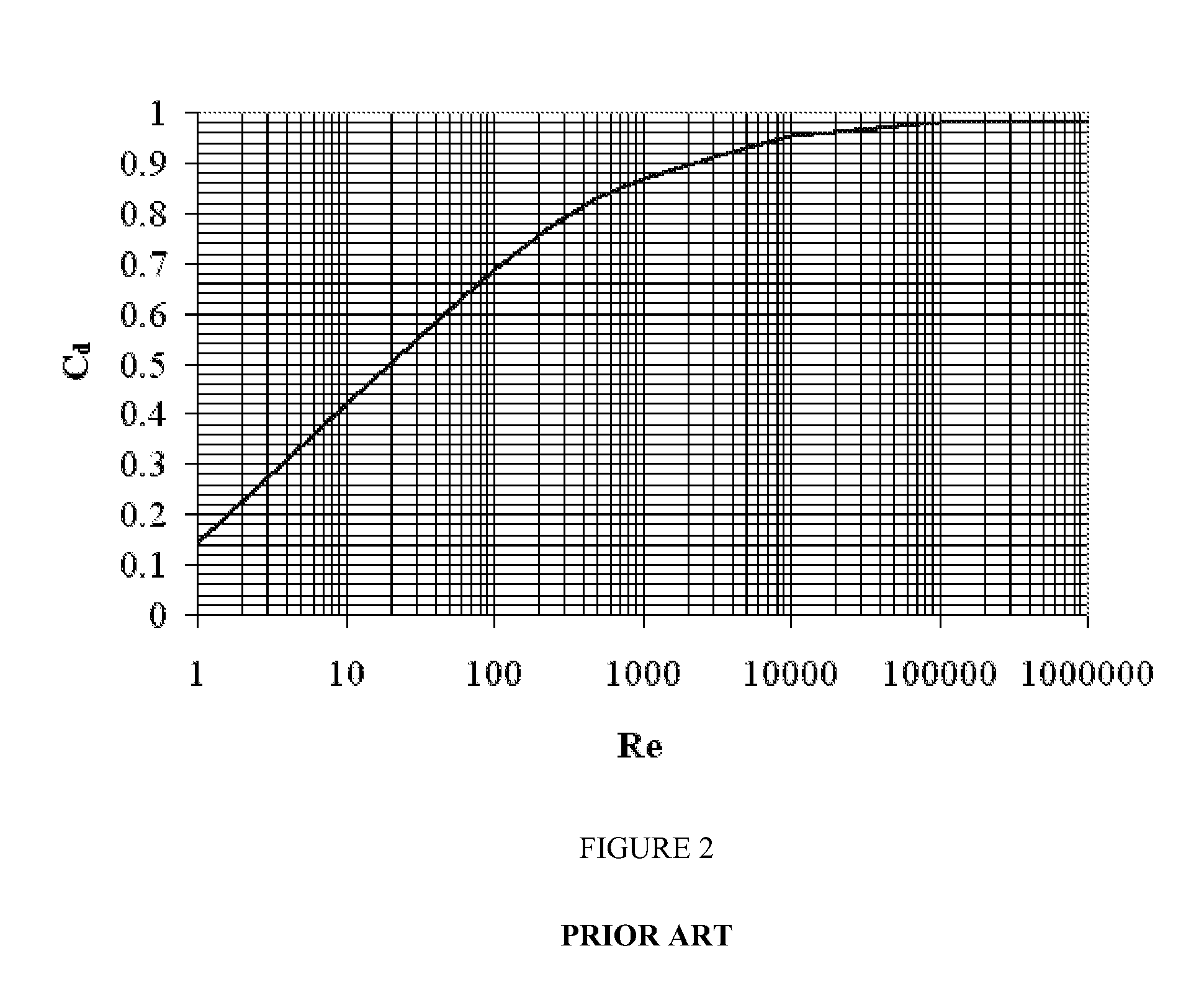

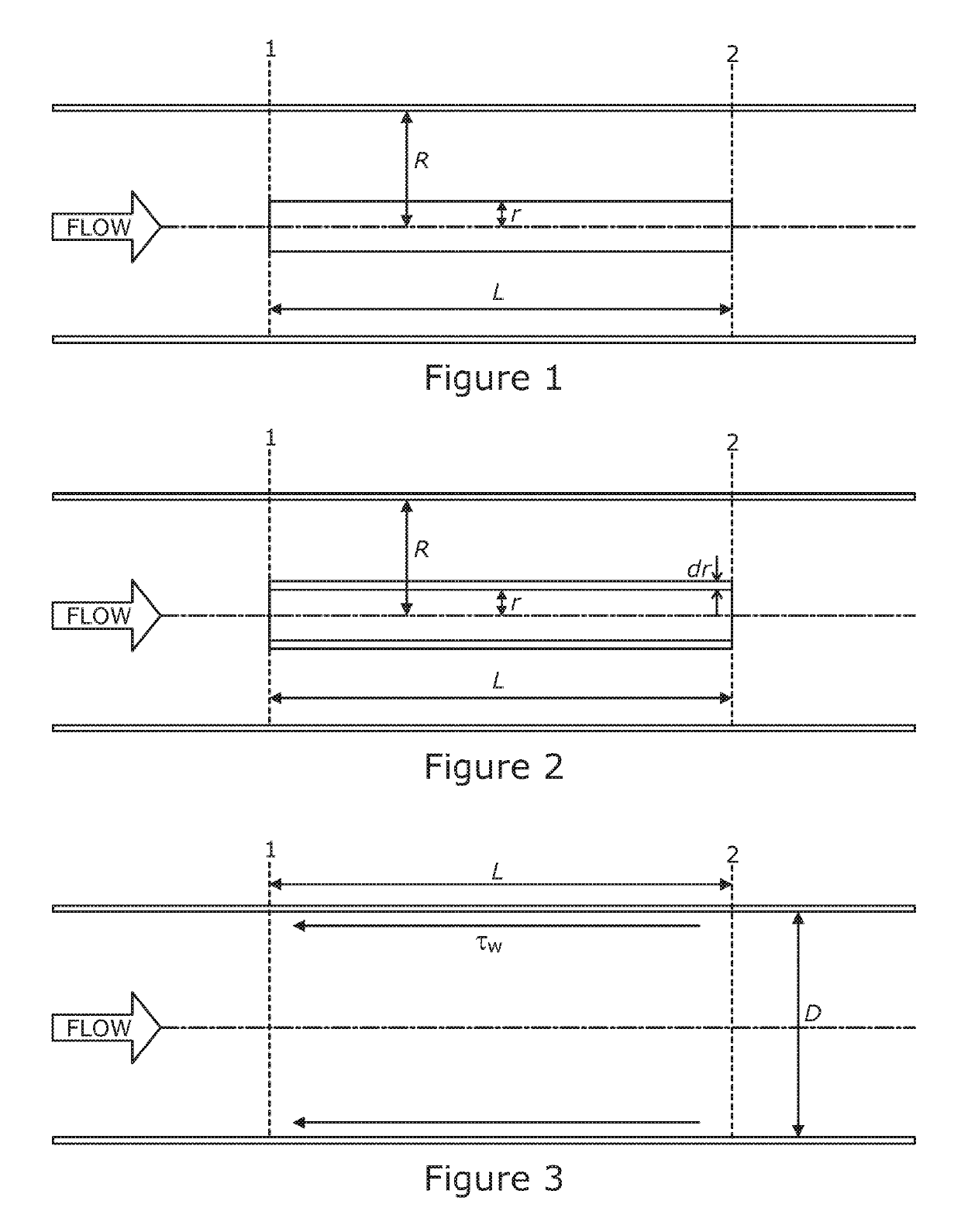

In a nozzle or other constriction, the discharge coefficient (also known as coefficient of discharge) is the ratio of the actual discharge to the theoretical discharge, i.e., the ratio of the mass flow rate at the discharge end of the nozzle to that of an ideal nozzle which expands an identical working fluid from the same initial conditions to the same exit pressures. Mathematically the discharge coefficient may be related to the mass flow rate of a fluid through a straight tube of constant cross-sectional area through the following Cd=m/ρV=m/ρAu=m/ρA√(2ΔP/ρ)=m/A√(2ρΔP) Cd=Qₑₓₚ/Qₜₕₑₒ Where: Cd, discharge coefficient through the constriction (dimensionless).

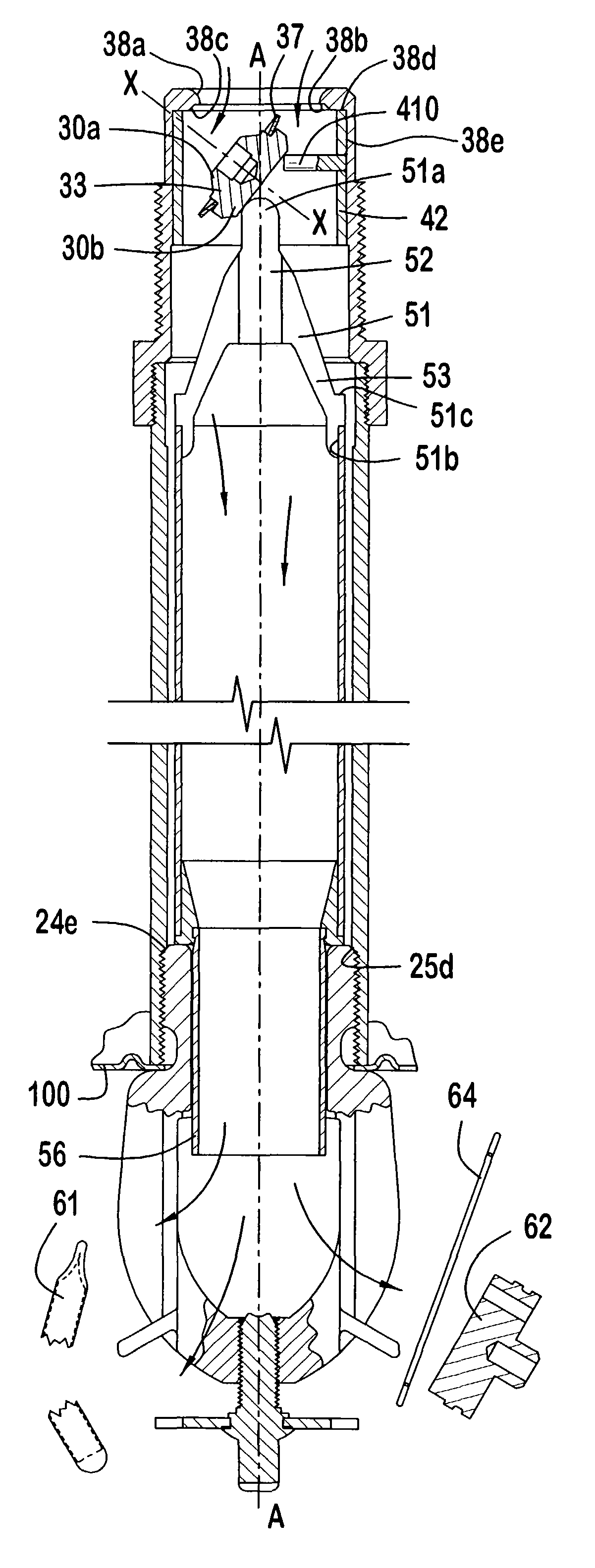

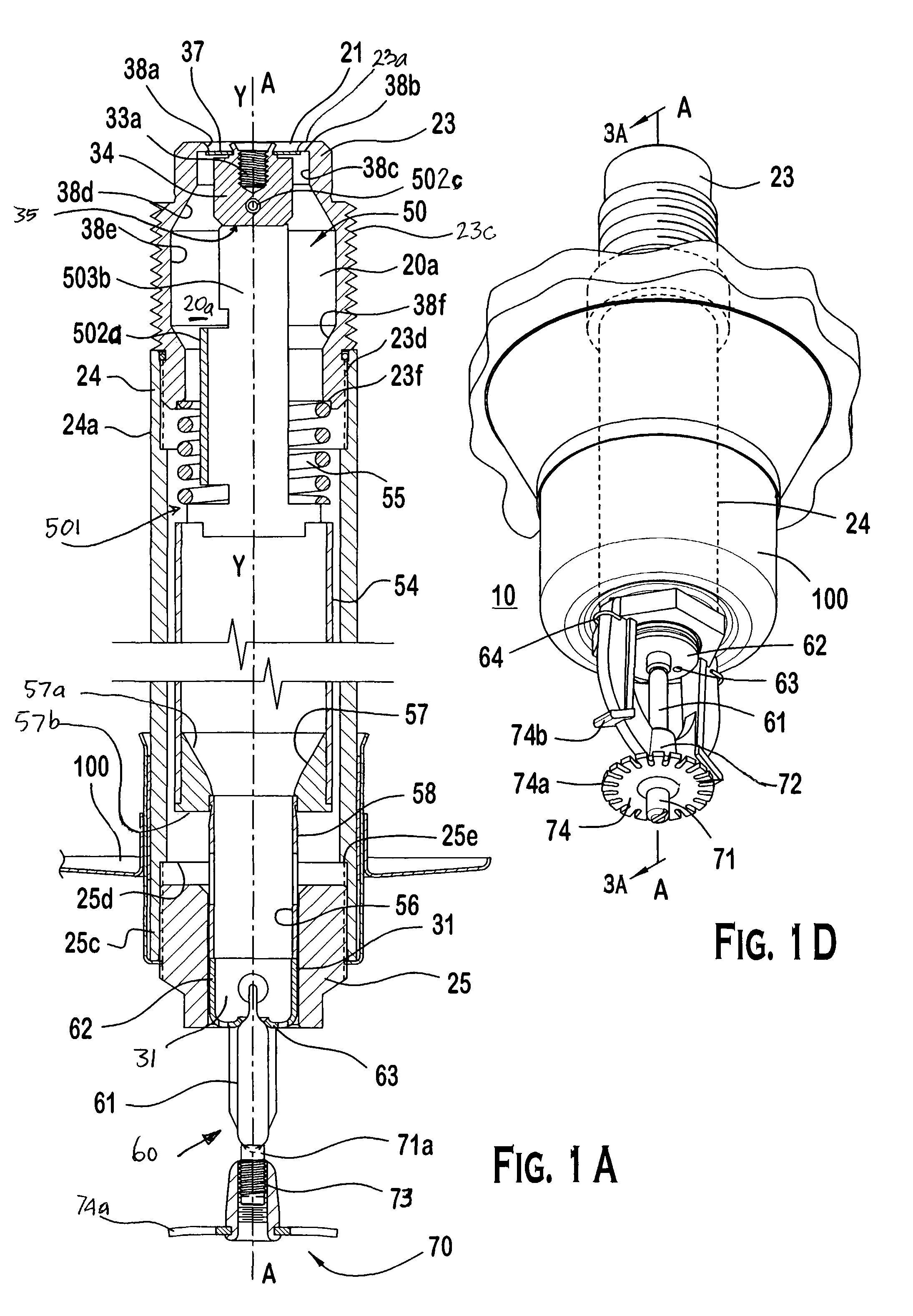

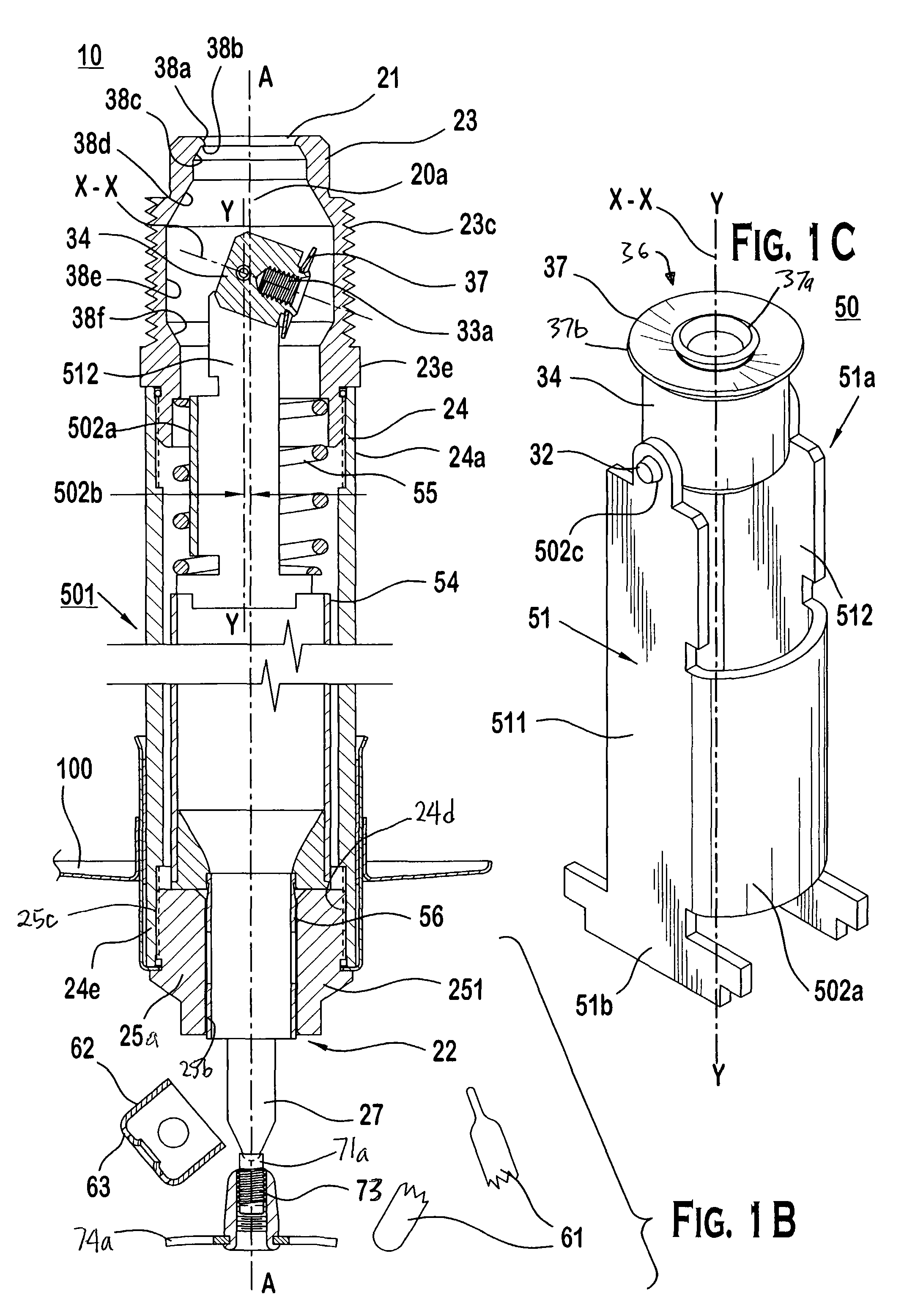

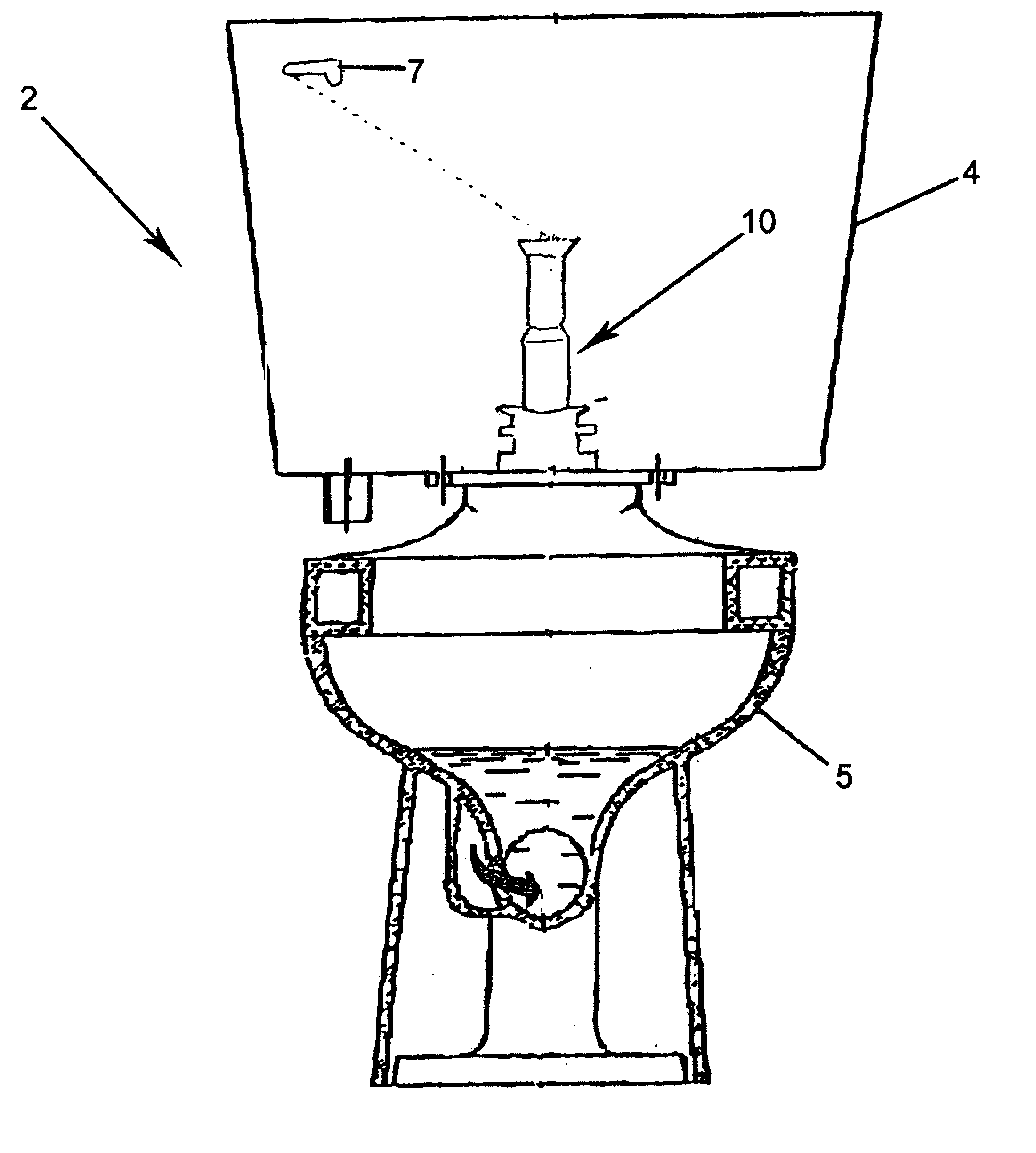

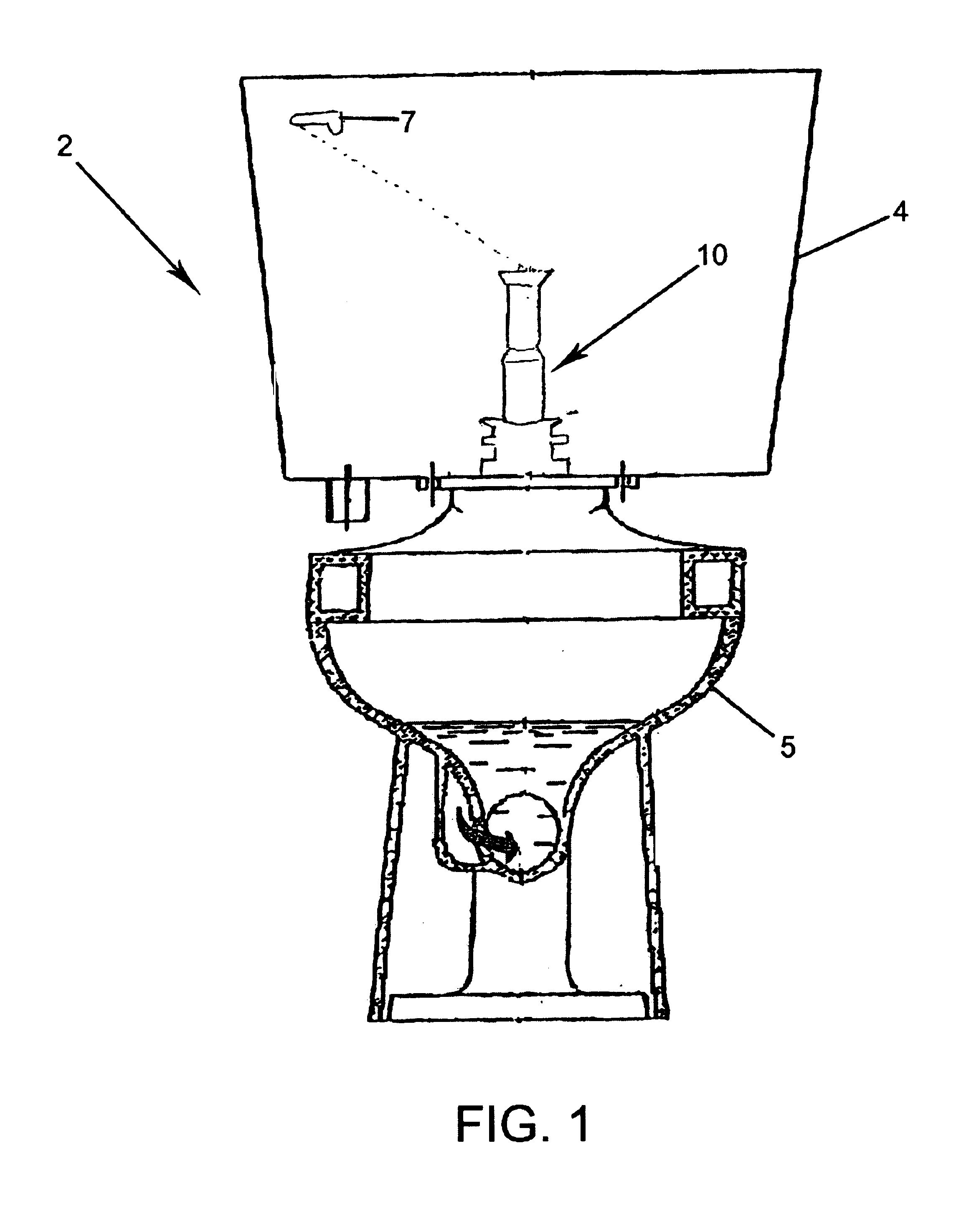

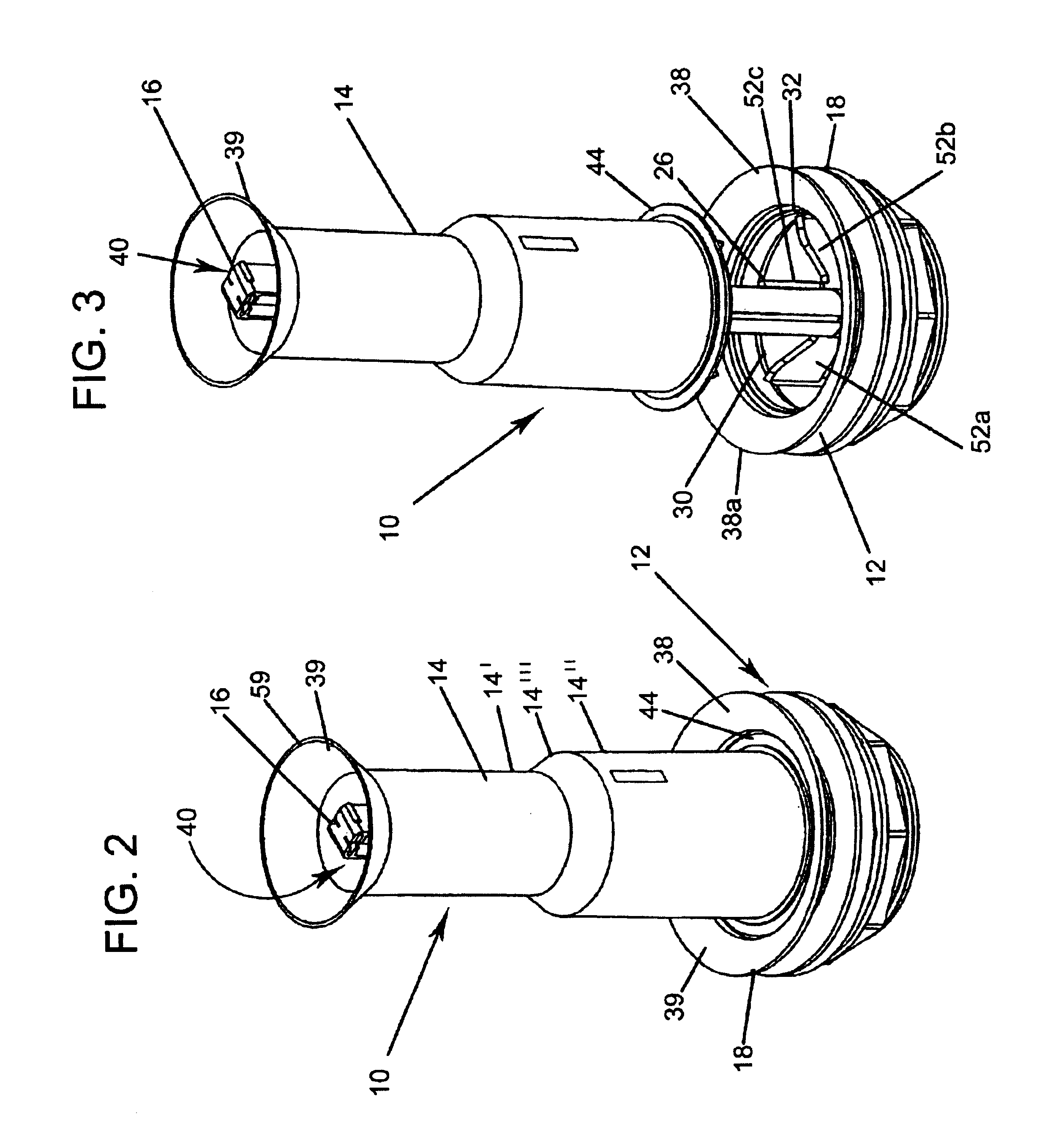

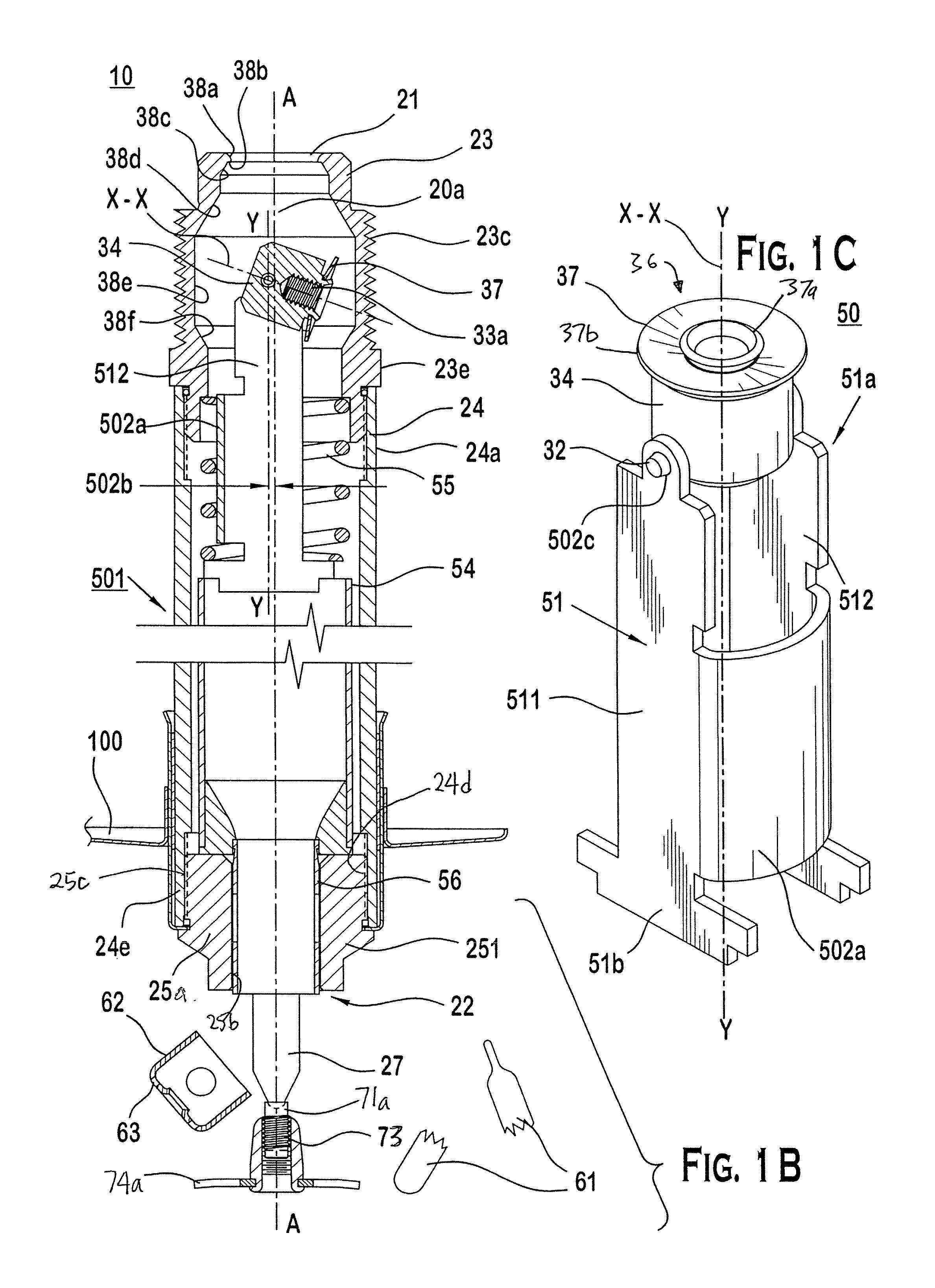

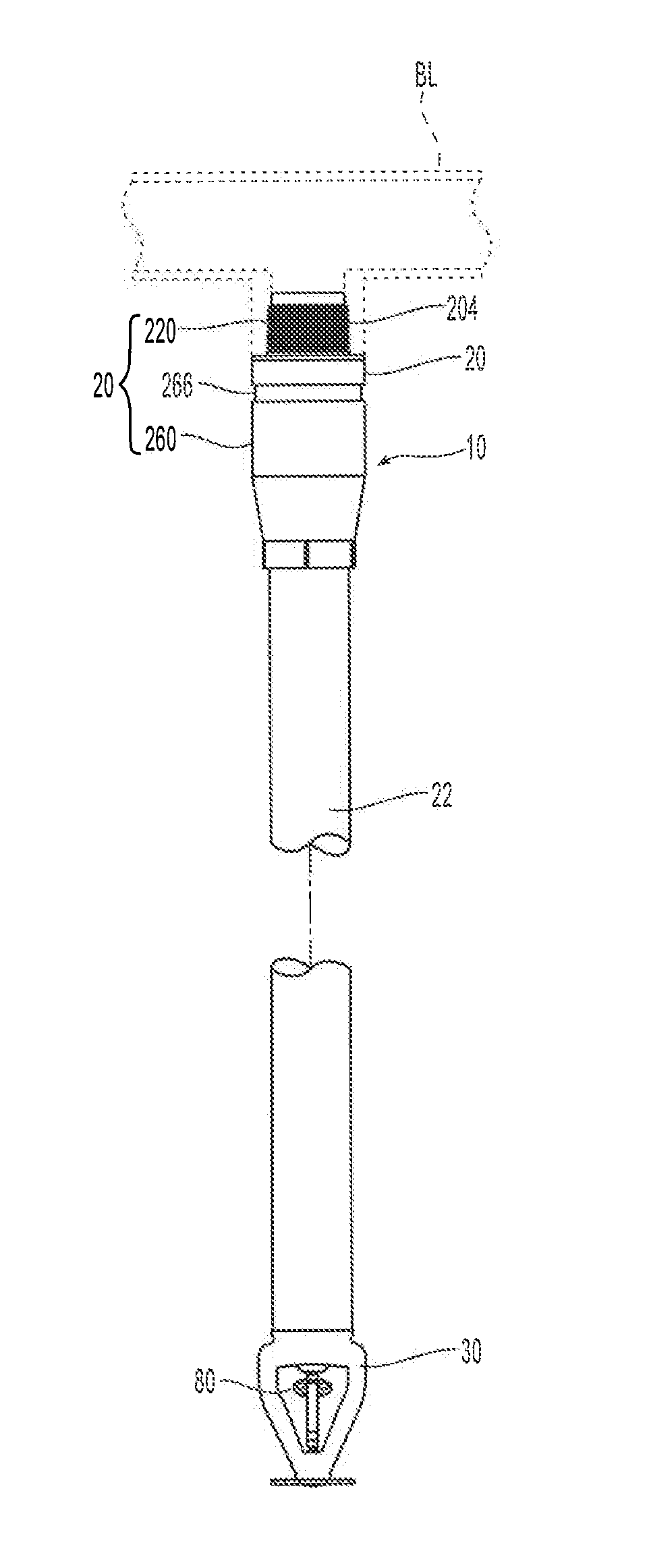

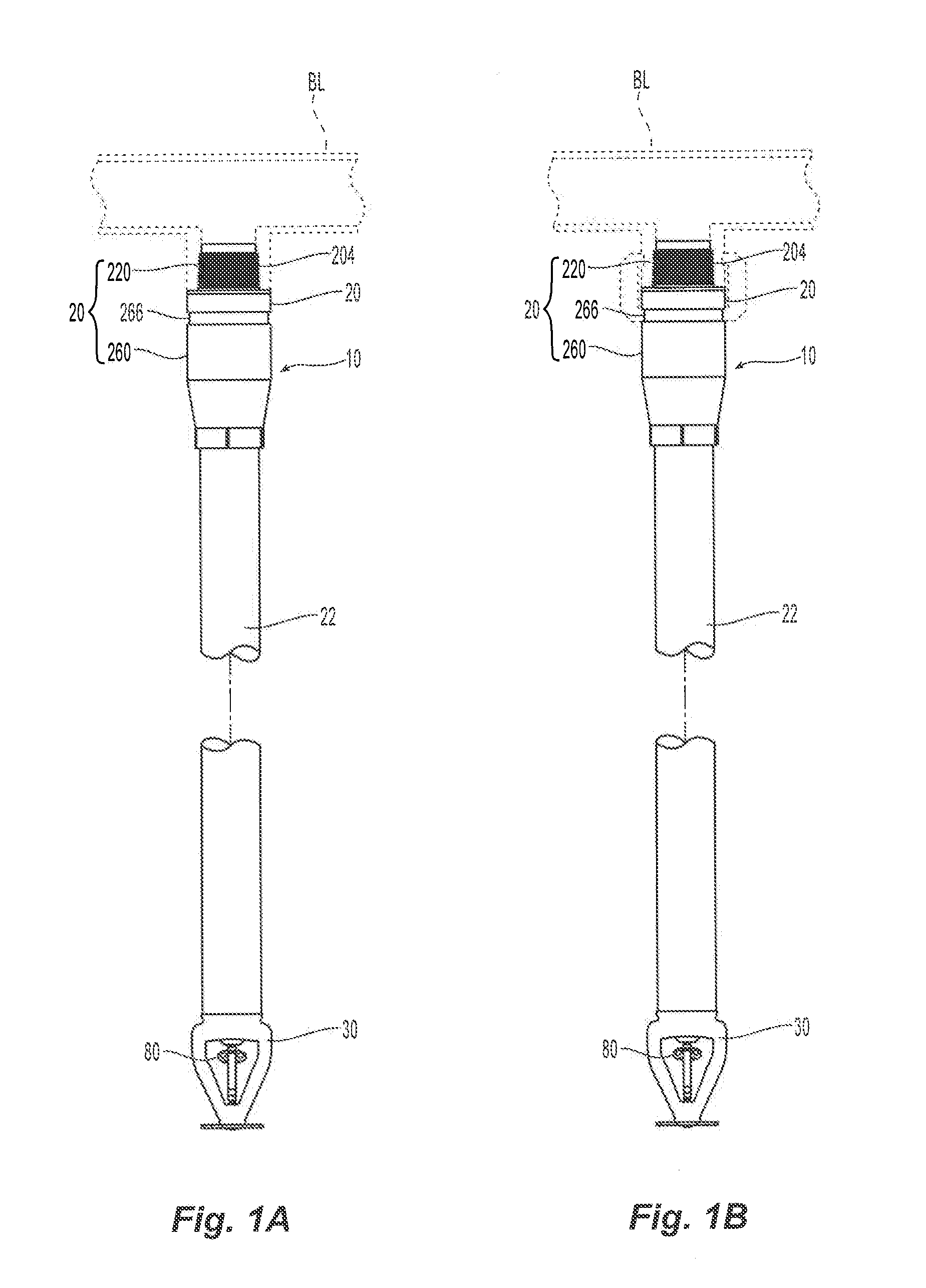

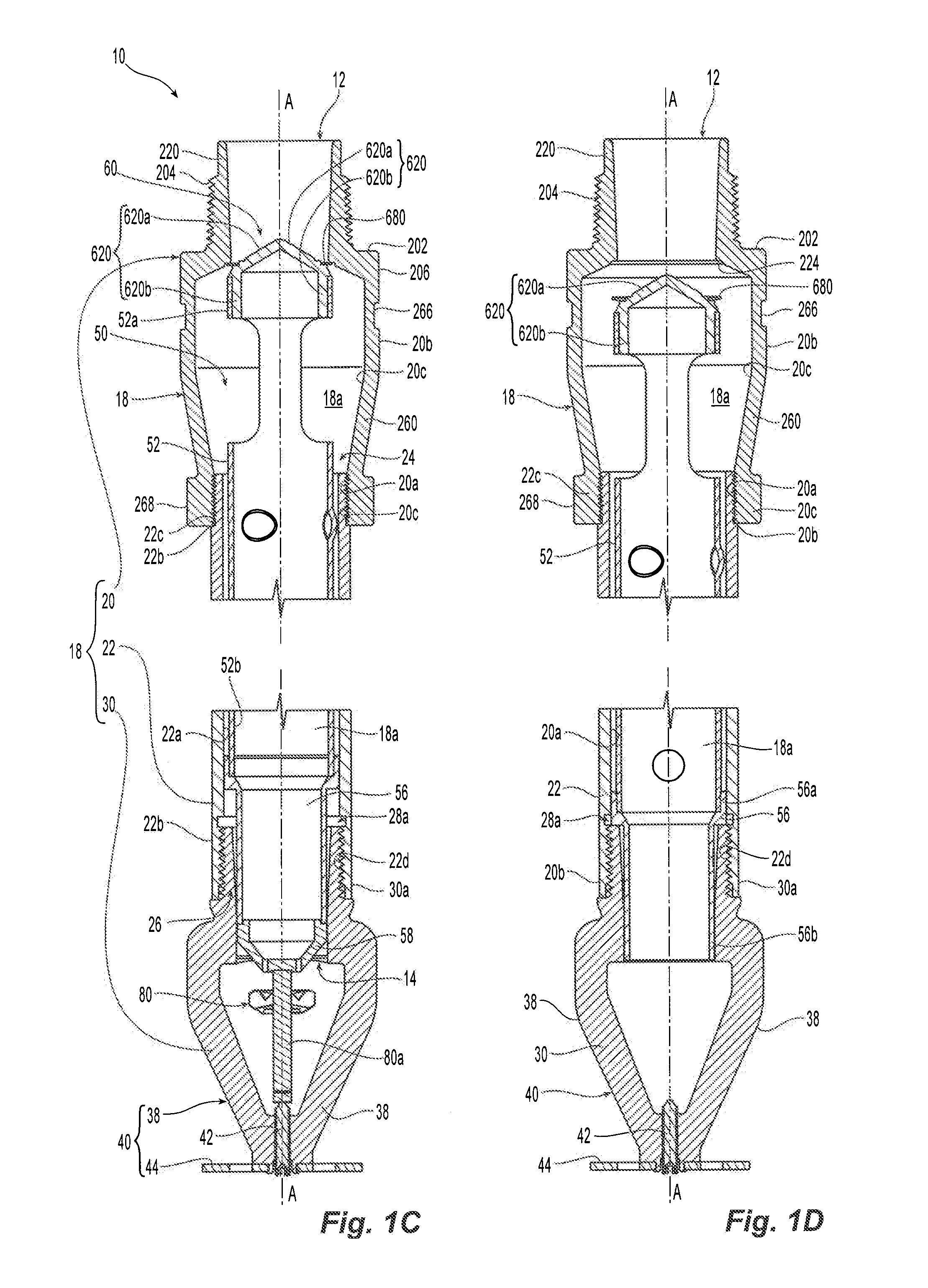

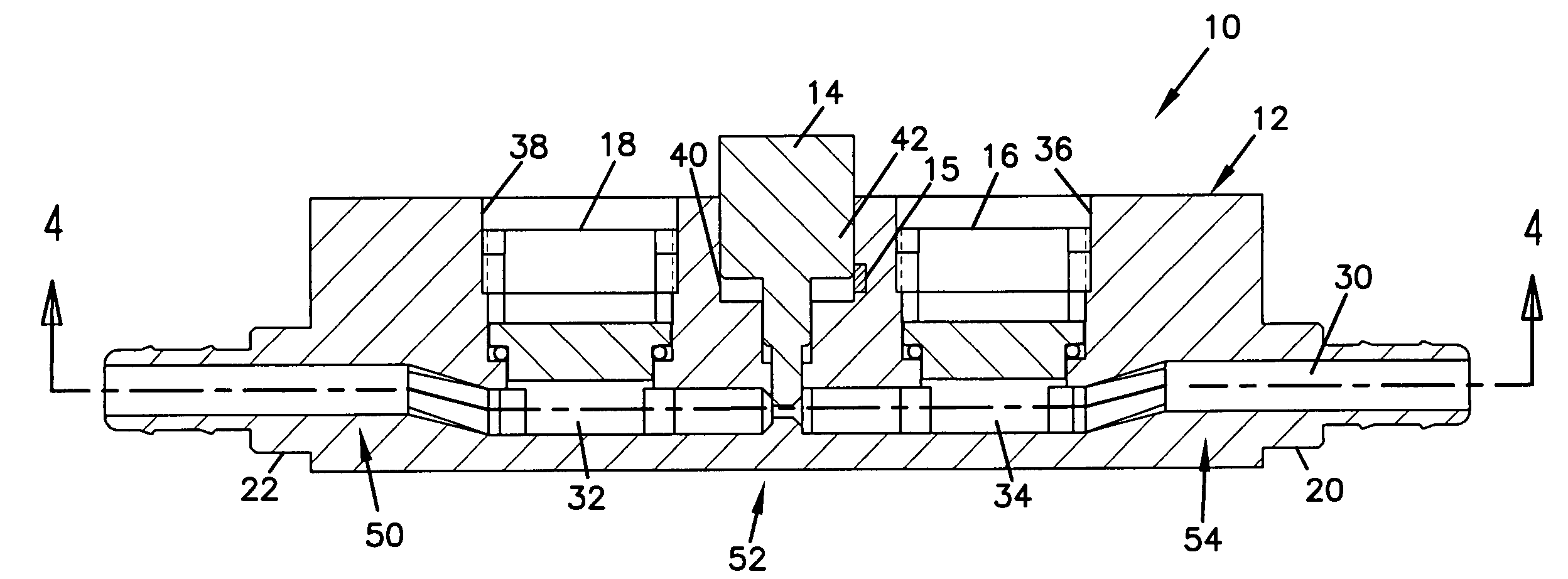

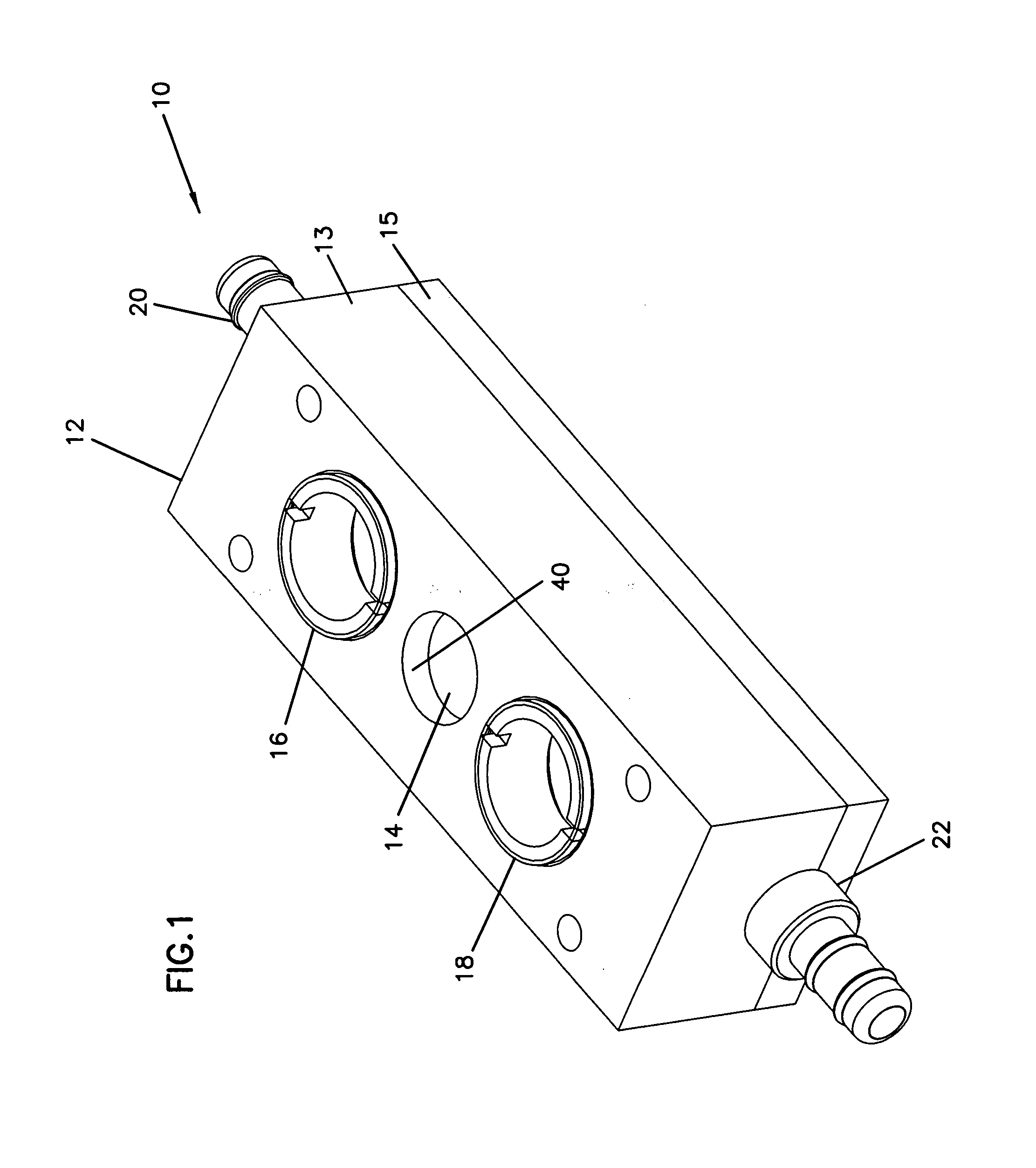

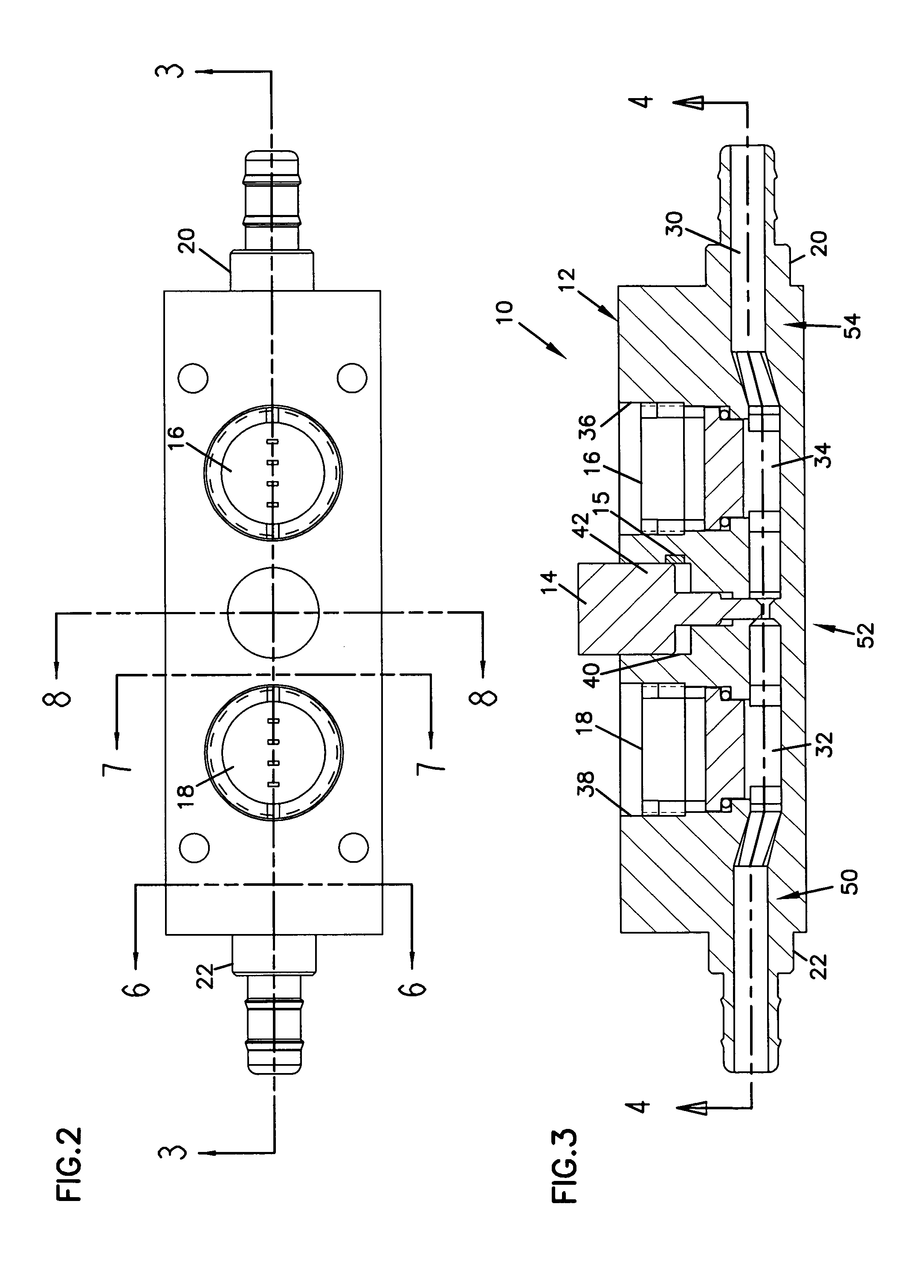

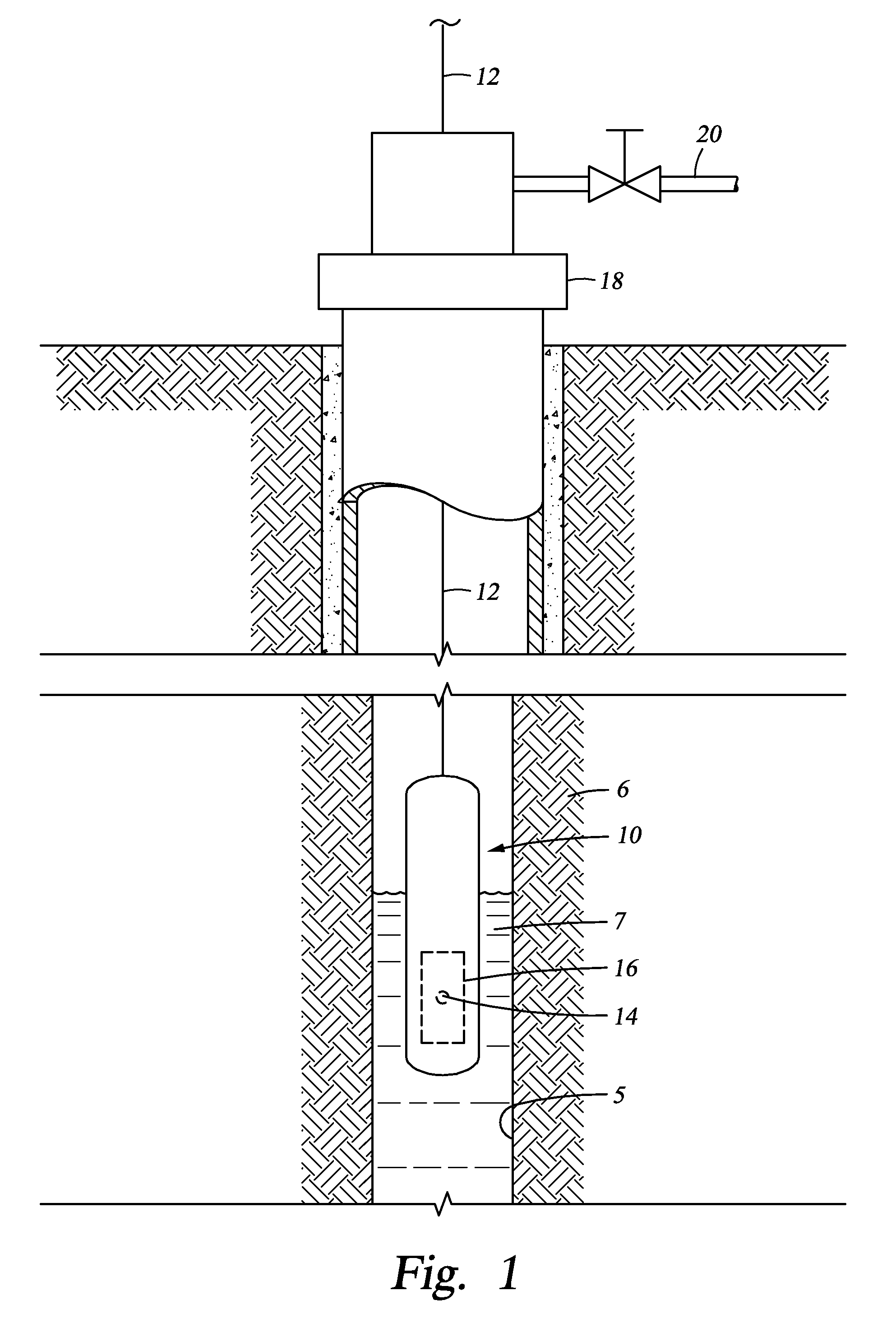

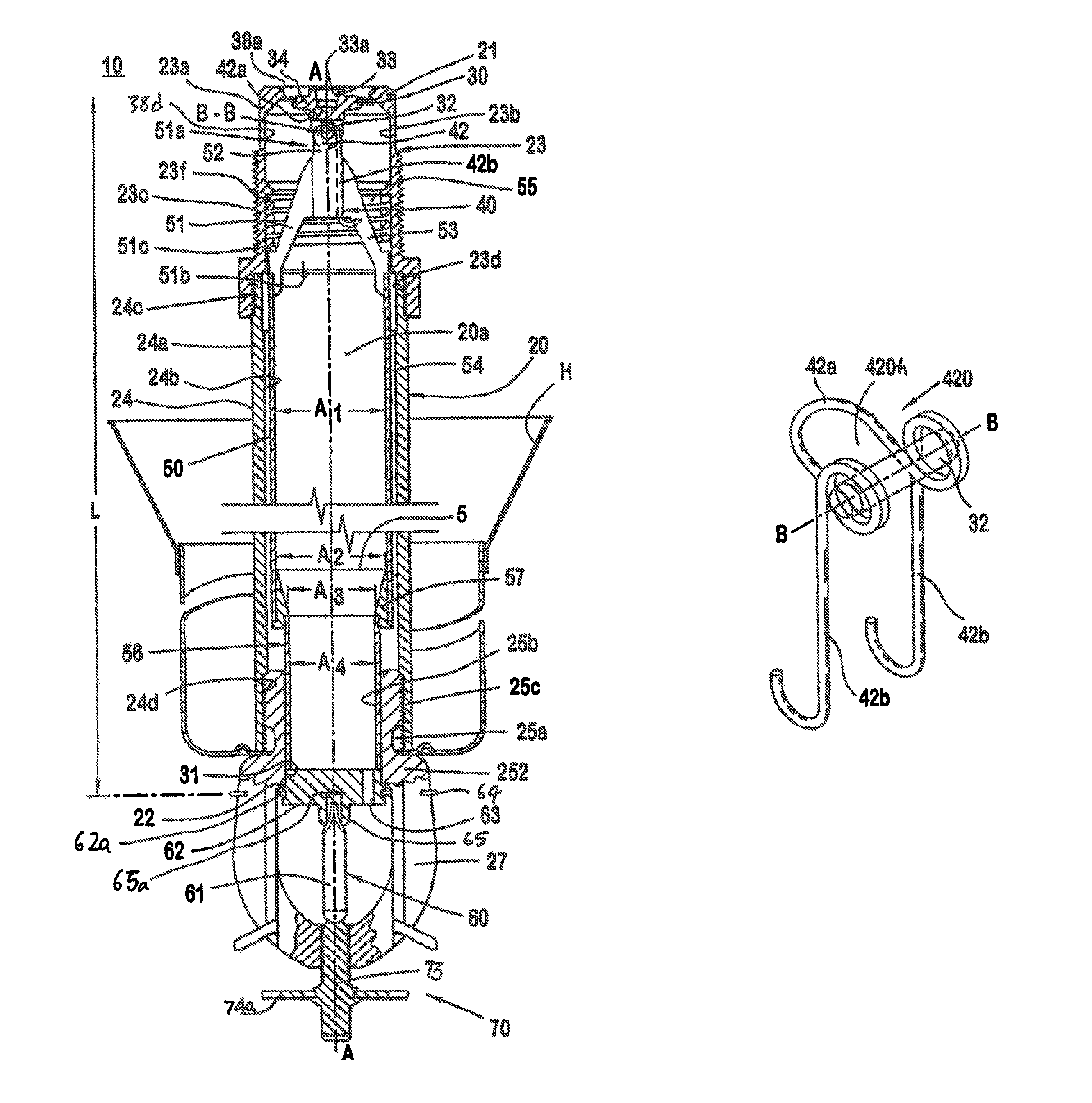

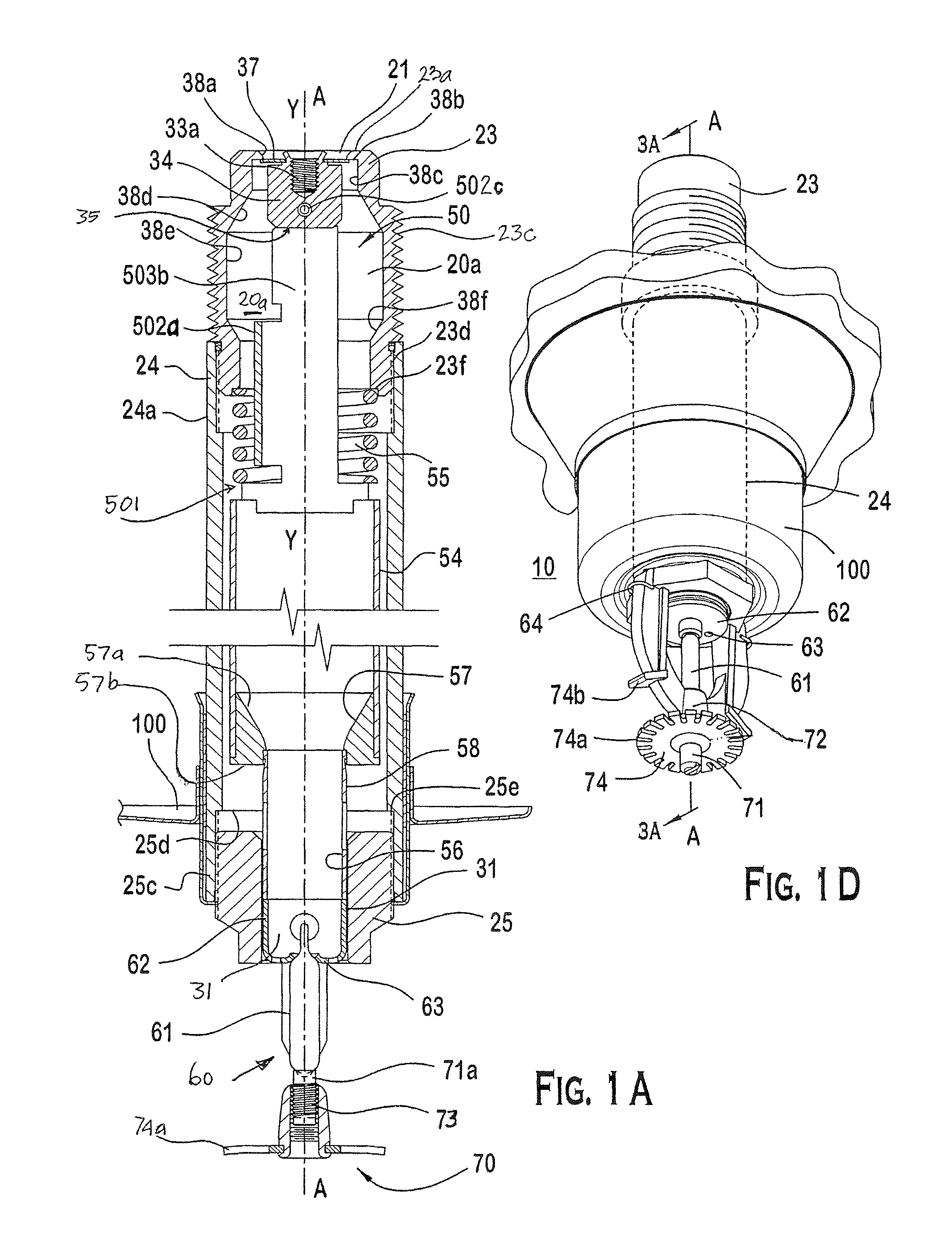

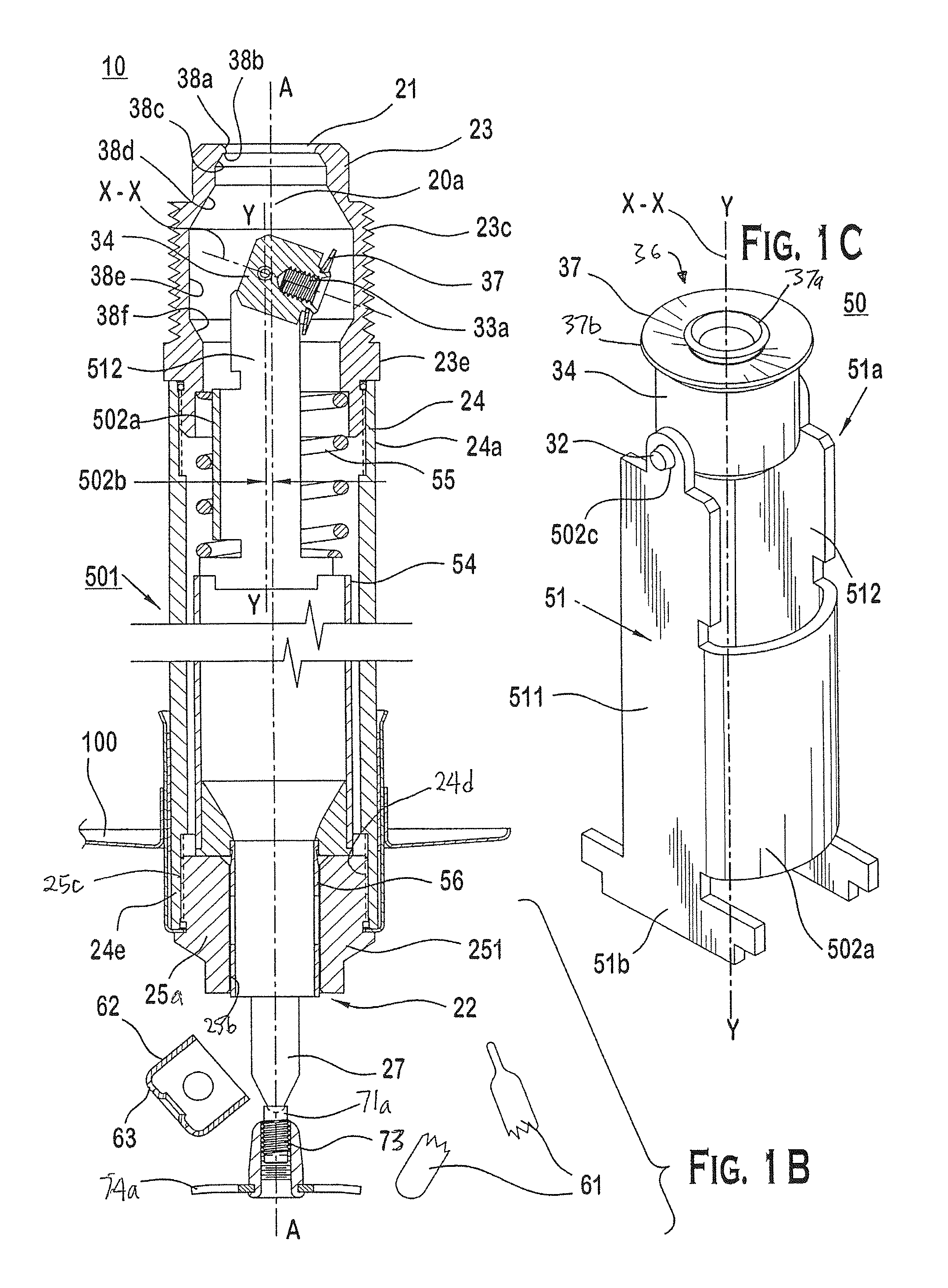

Dry sprinkler

A dry sprinkler for a fire protection system. The preferred dry sprinkler has a metallic disc annulus positionable within a passageway to skew a central axis of a face of the metallic disc annulus with respect to a longitudinal axis of the dry sprinkler so that an expected minimum flow rate based on a rated discharge coefficient is provided. The dry sprinkler operates to provide an expected flow rate over a range of start pressures. The expected flow rate is based on a K-factor rating. The dry sprinkler provides an acceptable level of fluid flow rate from the expected flow rate based on the K-factor for a range of start pressures.

Owner:TYCO FIRE PRODS LP

High performance flush valve assembly

Owner:AS IP HOLDCO LLC

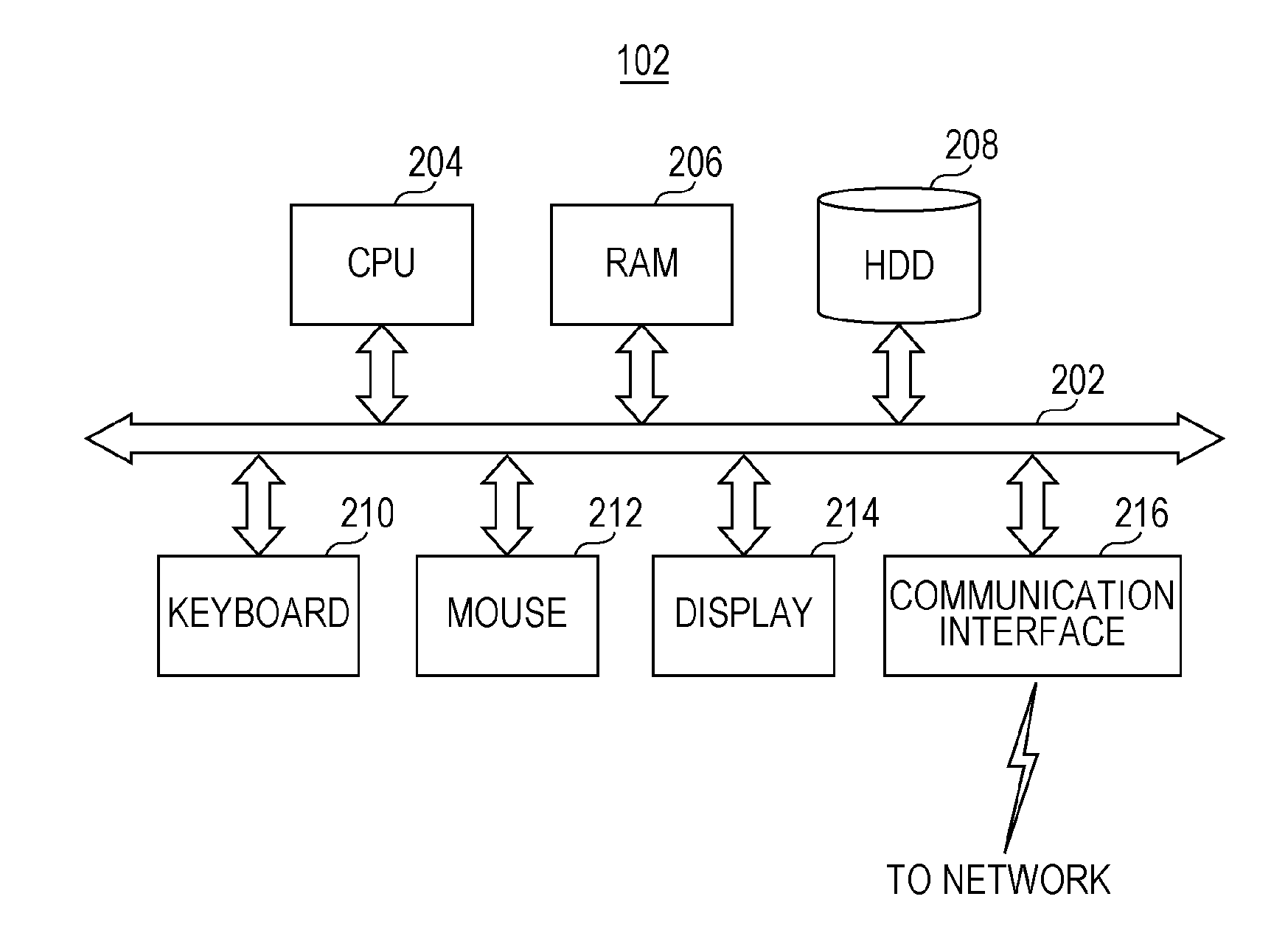

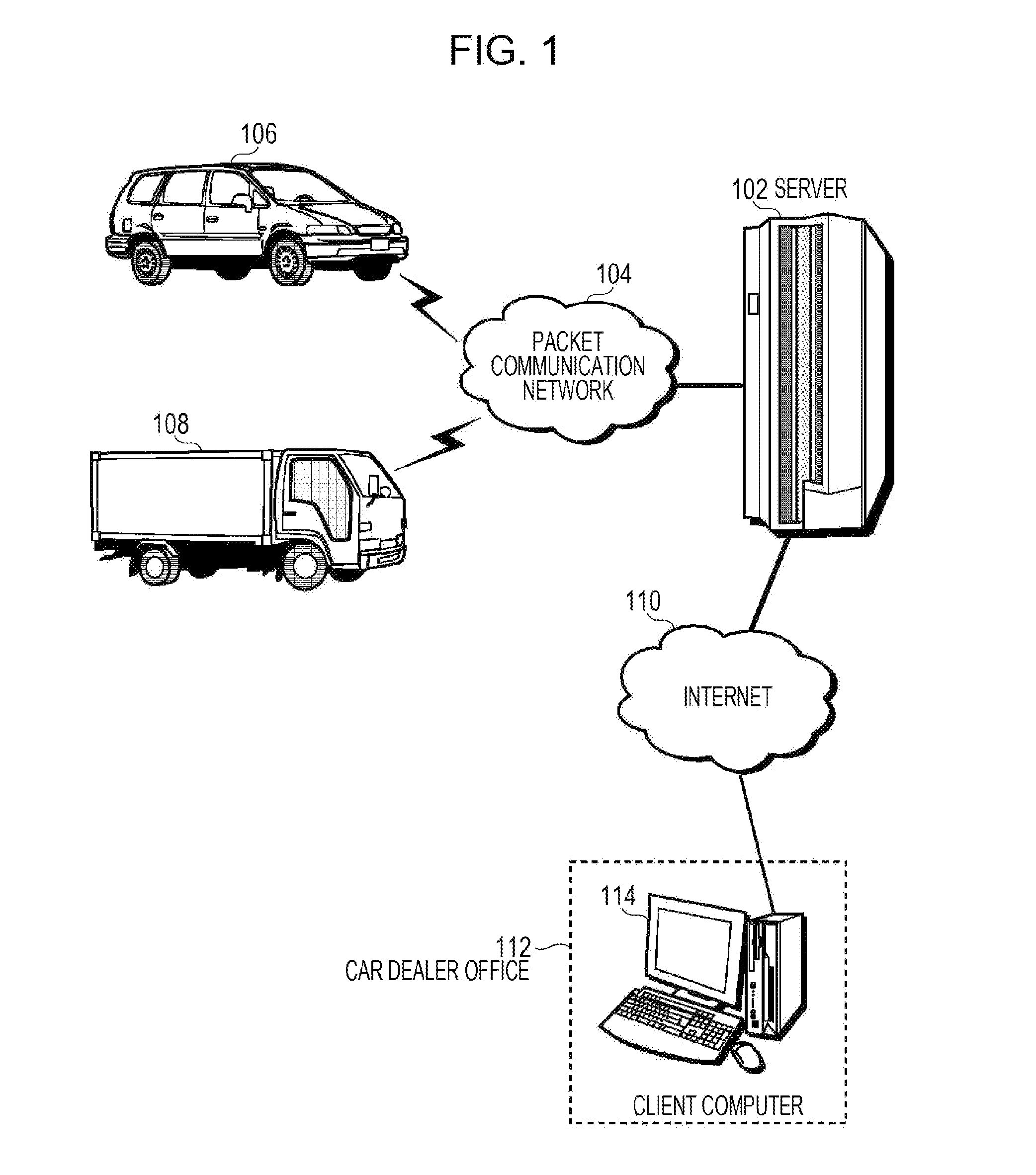

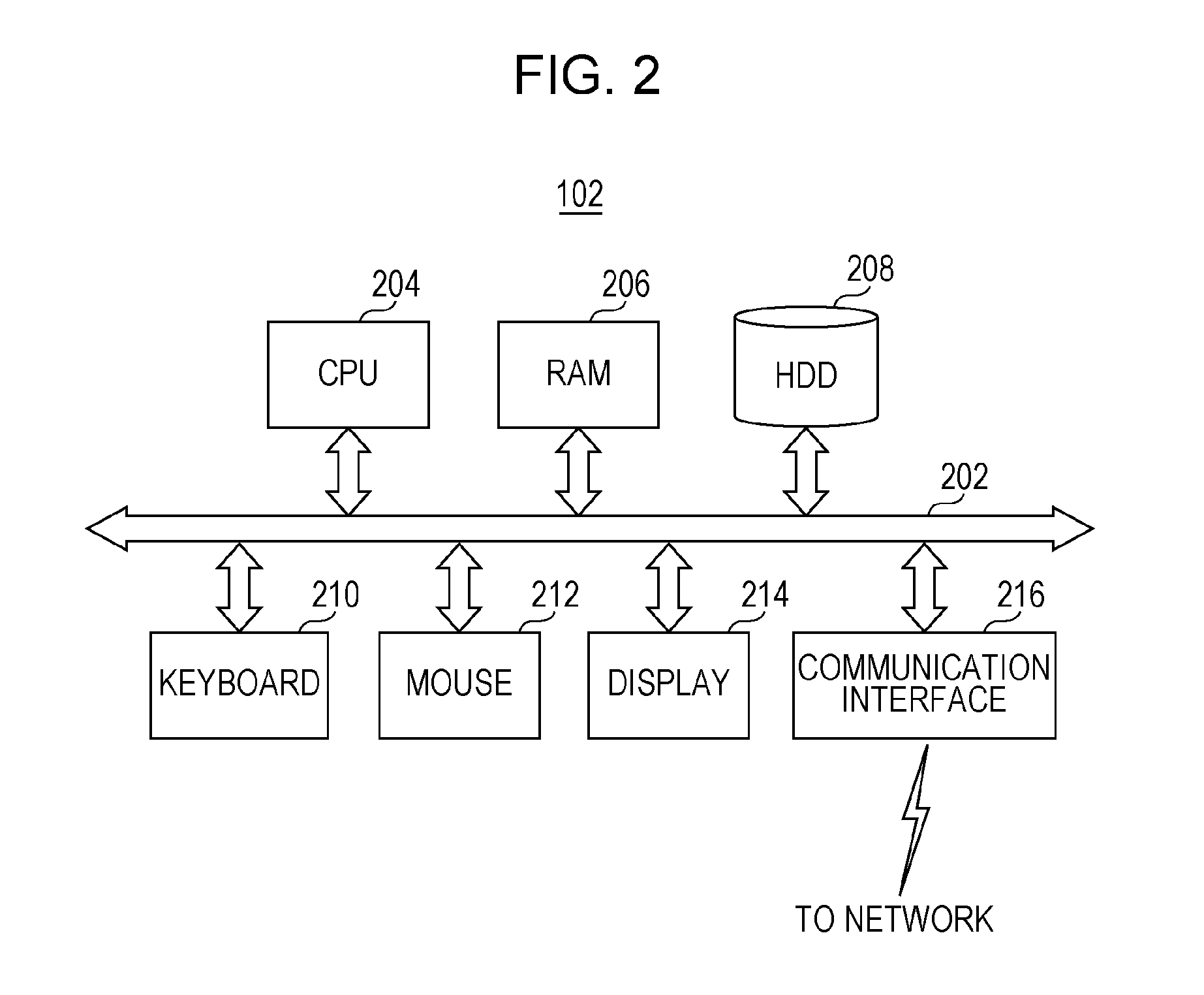

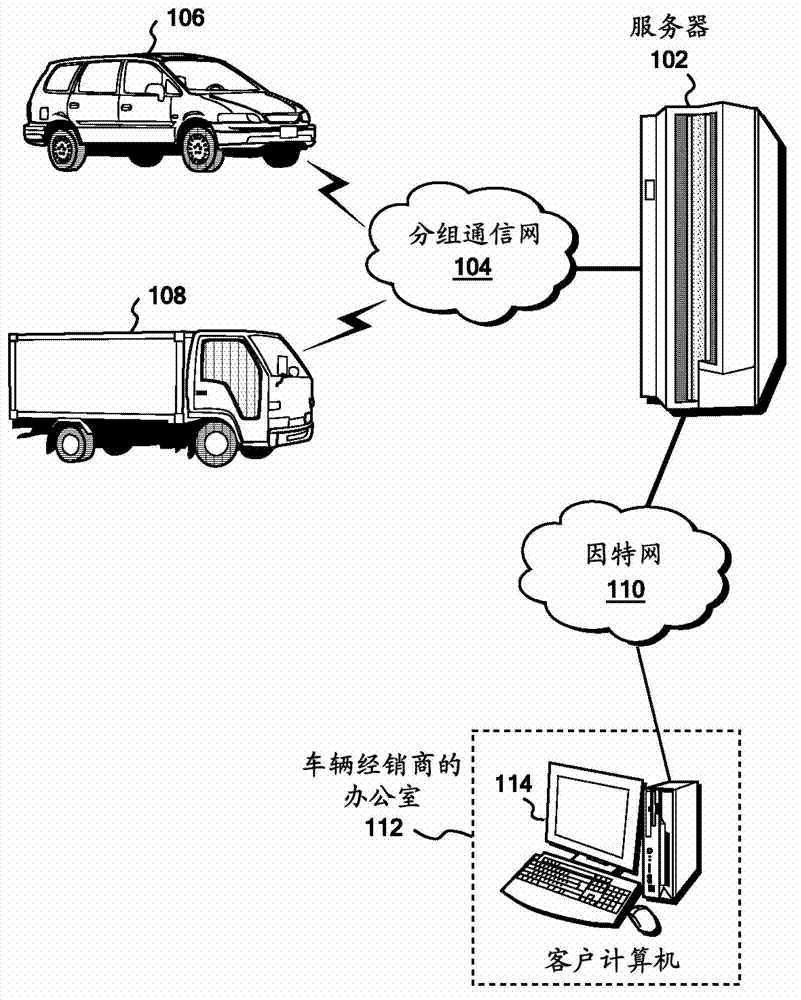

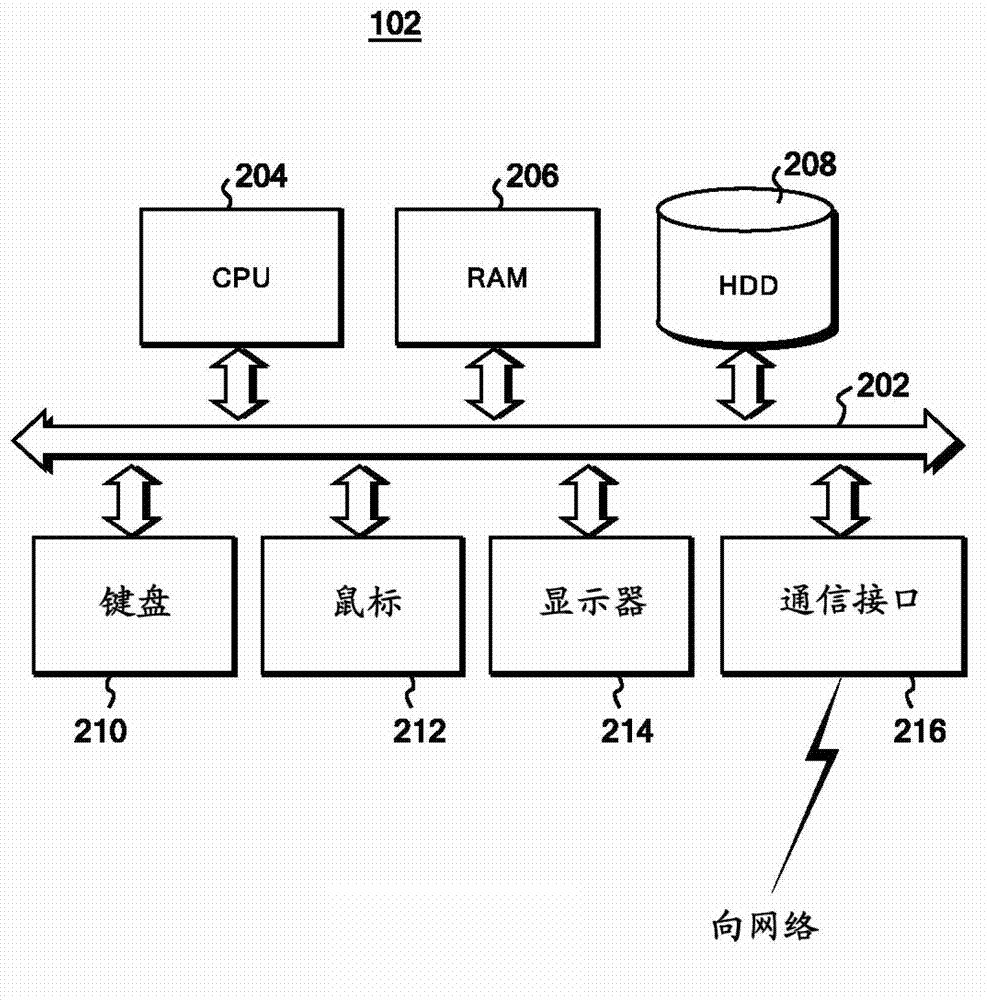

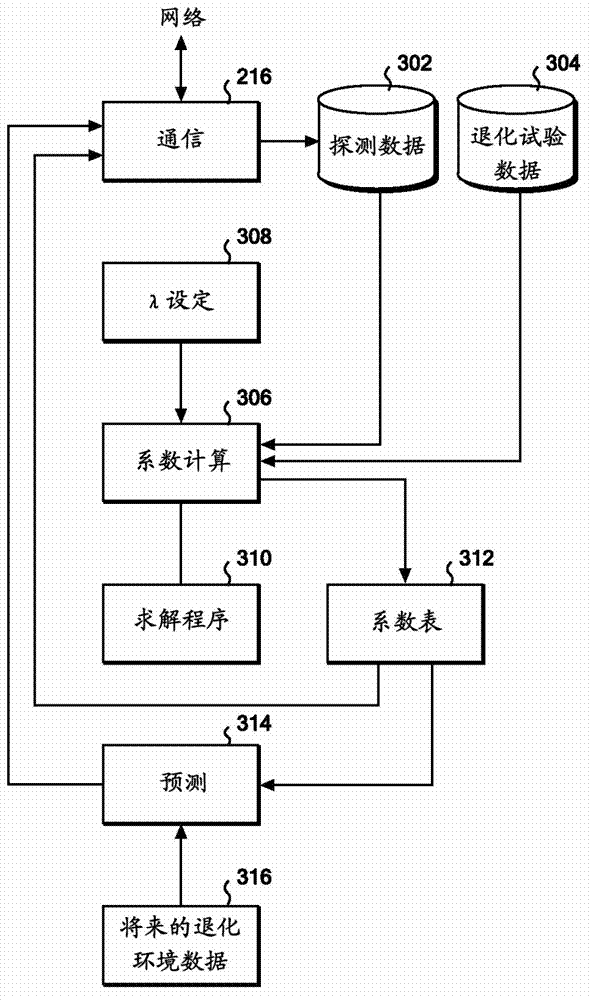

System, method, and program for predicting state of battery

InactiveUS20130096858A1Reduce the differenceElectrical testingComplex mathematical operationsComputational modelEngineering

A method and system for predicting degradation of a battery. Modeling of a battery is made to be separated into an aging section and a current-carrying section. The modeling is established such that the amount of degradation of a capacity retention ratio is determined by the linear sum of stay at each temperature and each SOC. The separation into degradation components at each temperature and each SOC enables predicting degradation under various degradation environments. A model for a battery separated into an aging section and a current-carrying section and a calculation model of a root law are combined into an objective function, and a table of discharge coefficients ah(T,S) and a table of current-carrying coefficients ac(T,S) are generated using a solver, where T indicates the temperature and S indicates SOC. Once tables are generated, degradation of the battery can be predicted by calculation using the tables.

Owner:IBM CORP

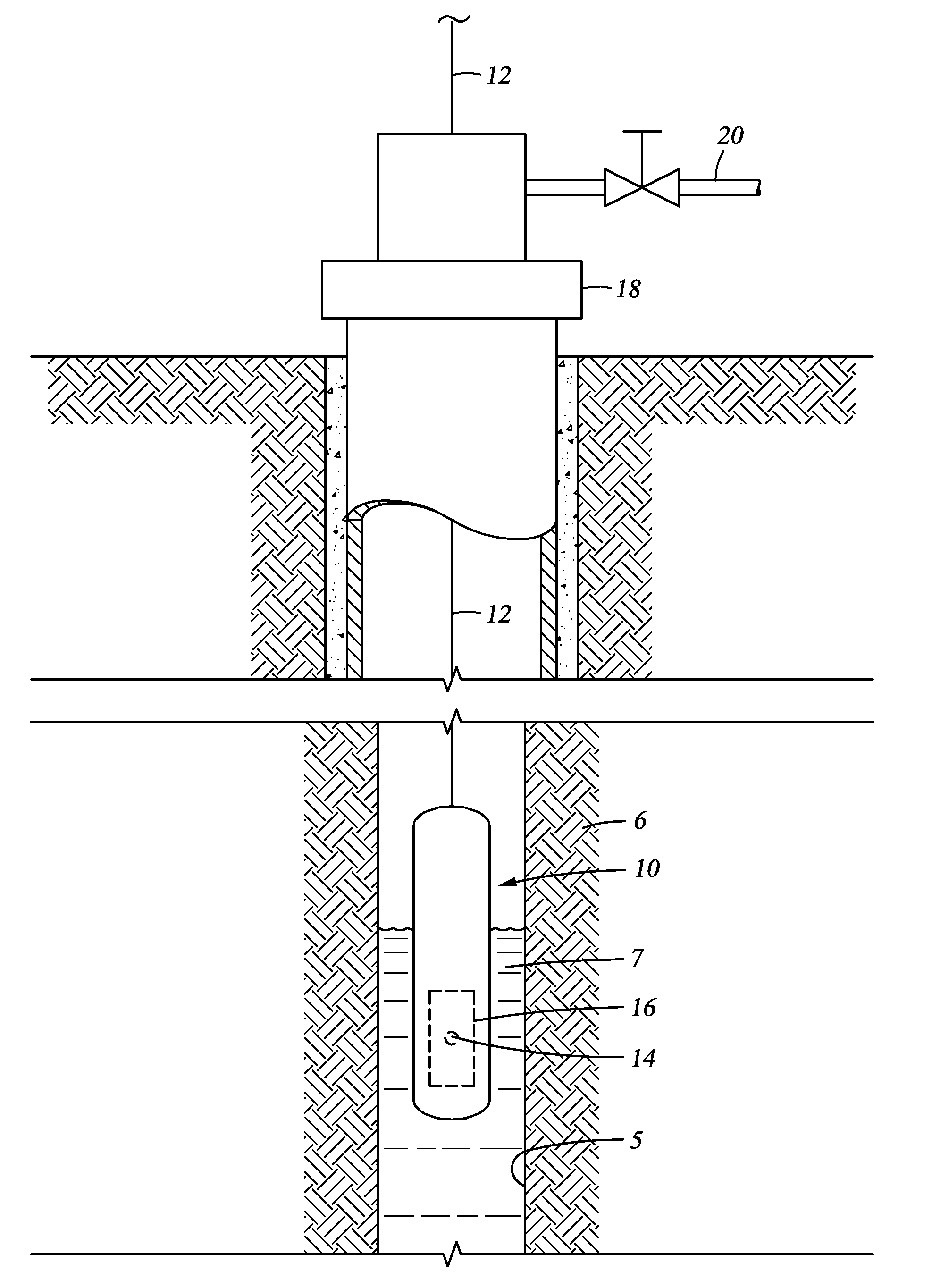

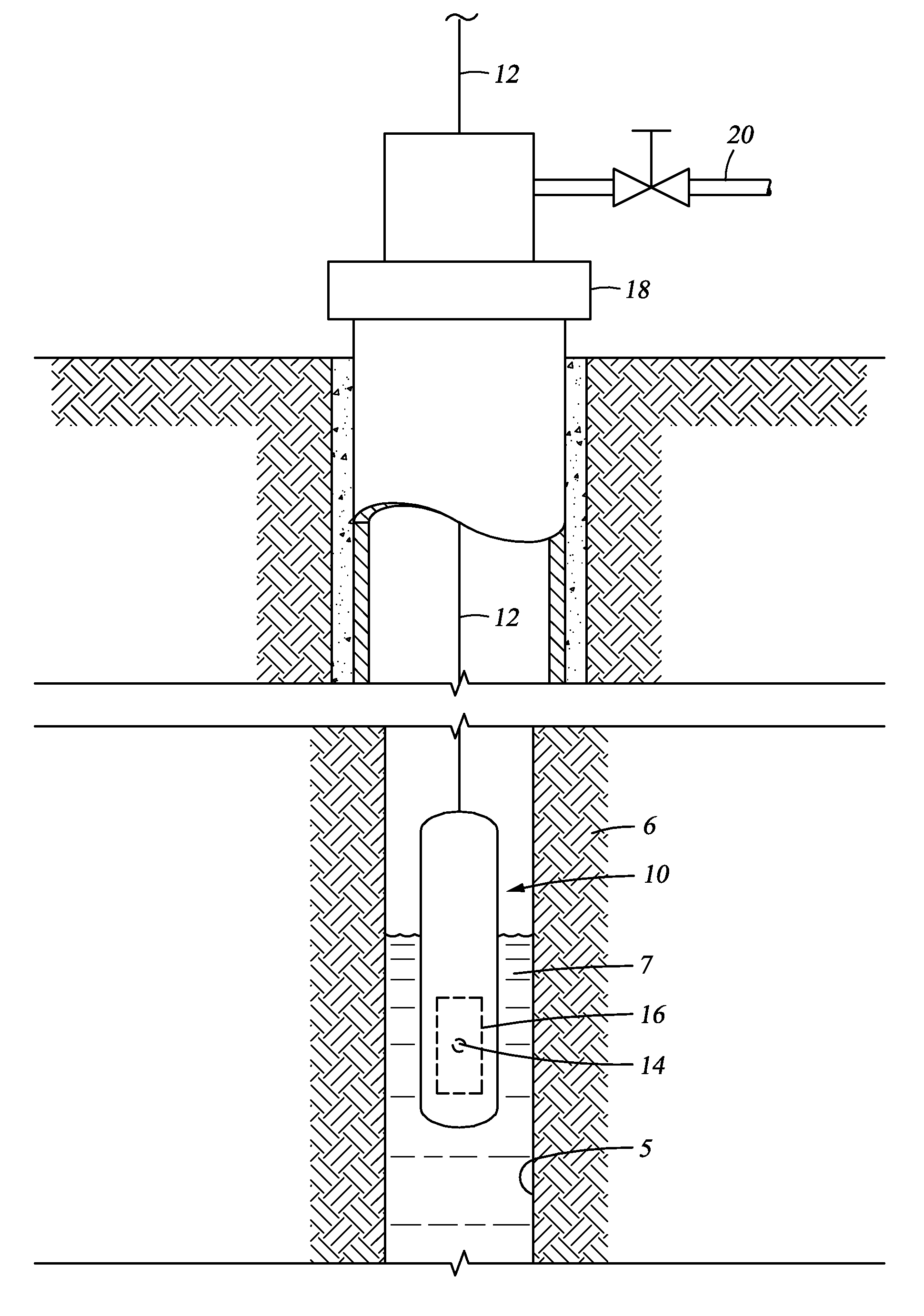

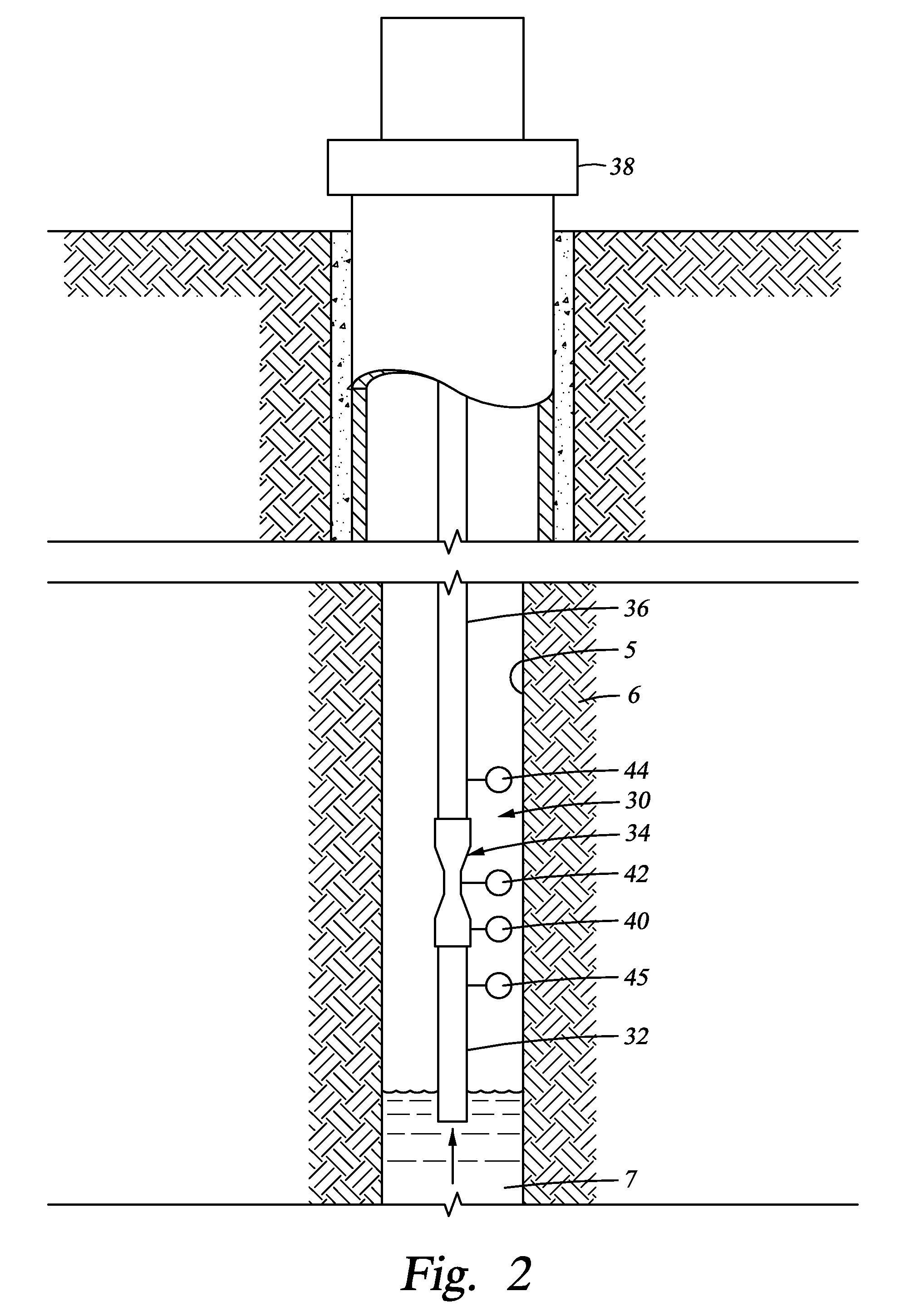

Method of measuring multi-phase fluid flow downhole

ActiveUS20110040485A1Electric/magnetic detection for well-loggingSurveyCorrection techniqueMulti phase

Multi-phase flow is estimated in a flow meter by measuring fluid pressure within the flow meter and using the measured pressure to calculate a density of the flow. A total flow rate through the flow meter is estimated based on the calculated density and a PVT analysis of the fluid. A corrected total mass flow rate is calculated using a liquid / gas slip correction technique. Fluid flow rates are further corrected with a discharge coefficient that varies with changes in the Reynolds number of the fluid. The gas and oil fractions can be determined from the corrected total mass flow rate and gas fraction.

Owner:BAKER HUGHES INC

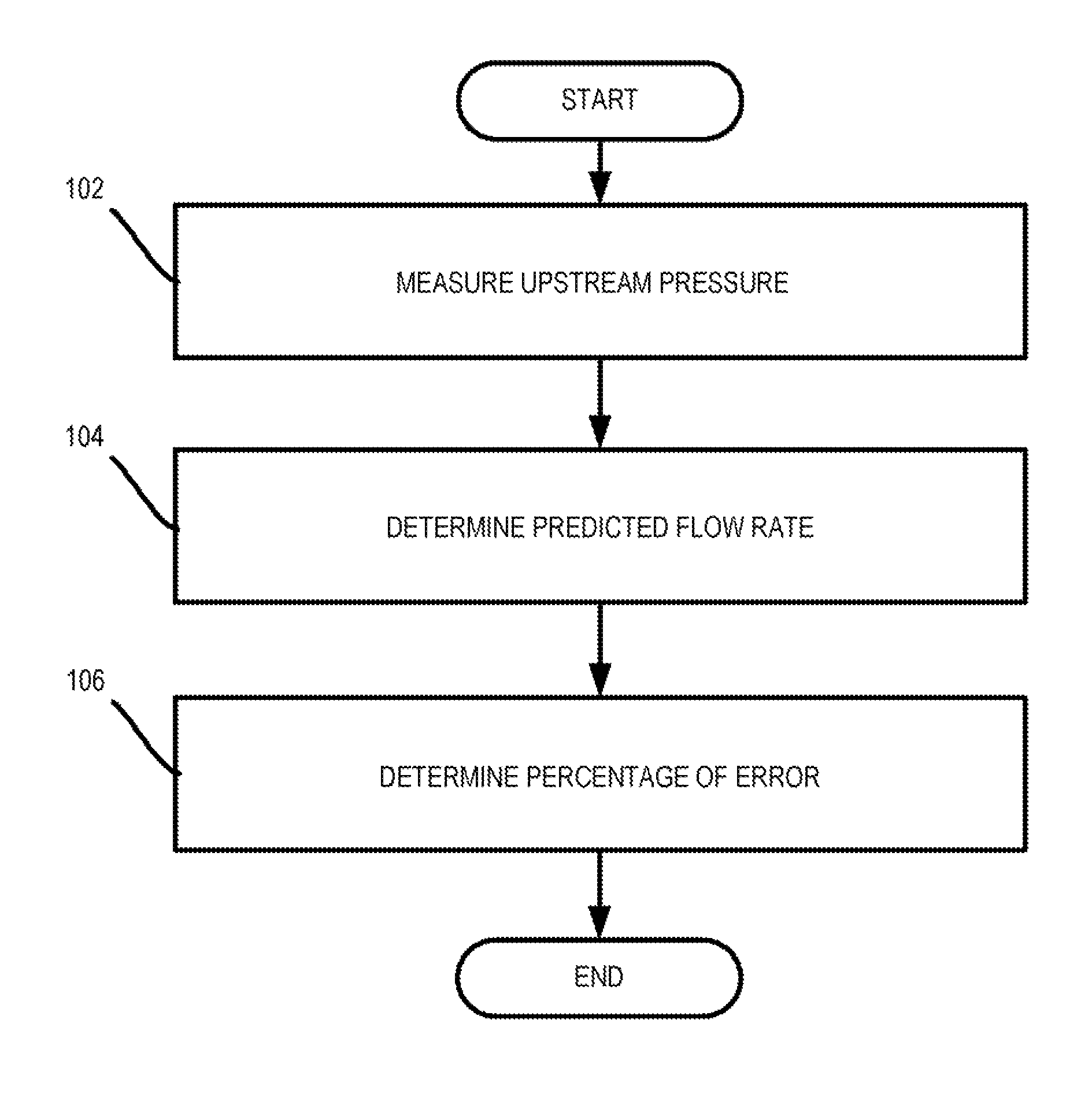

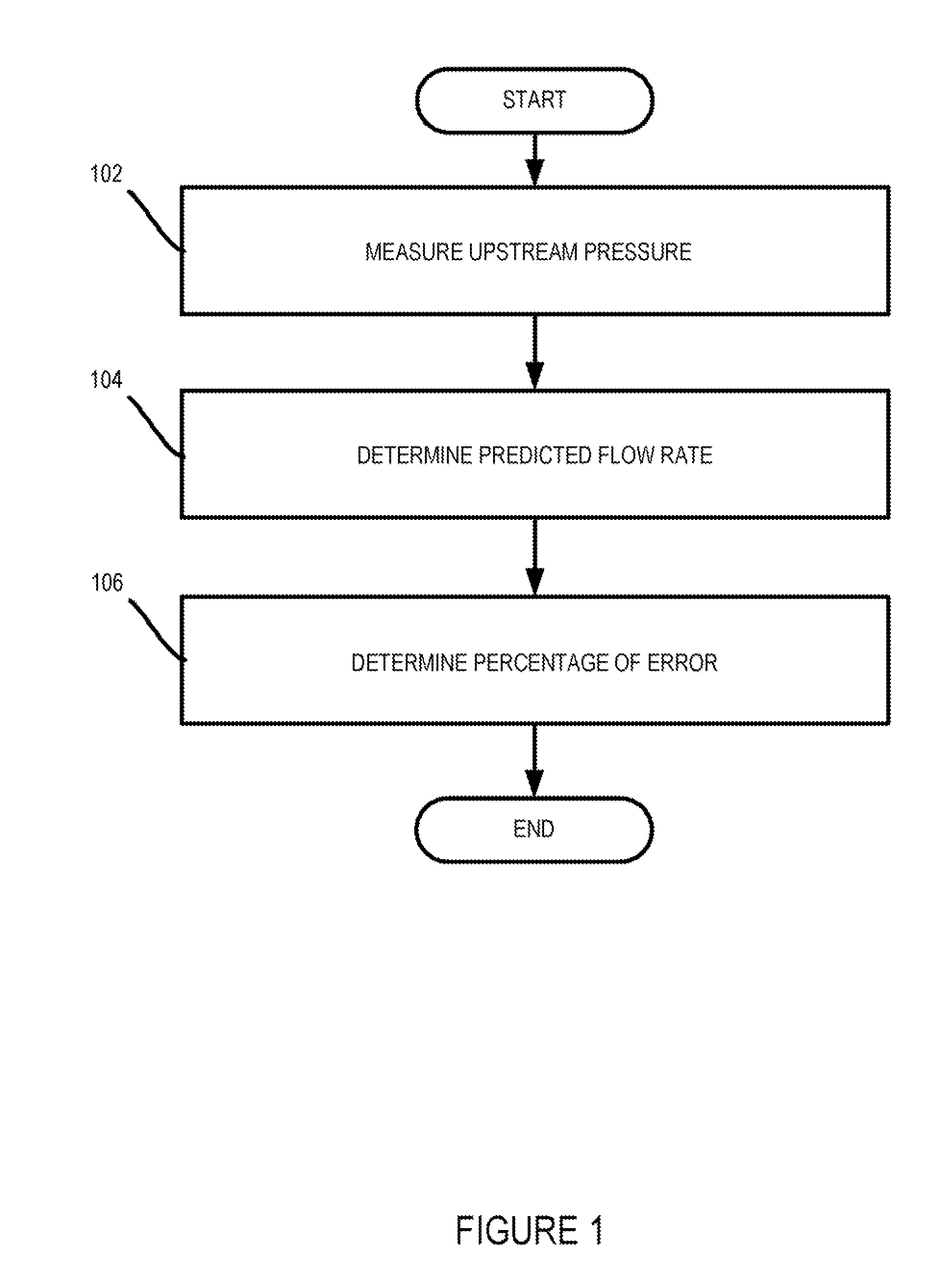

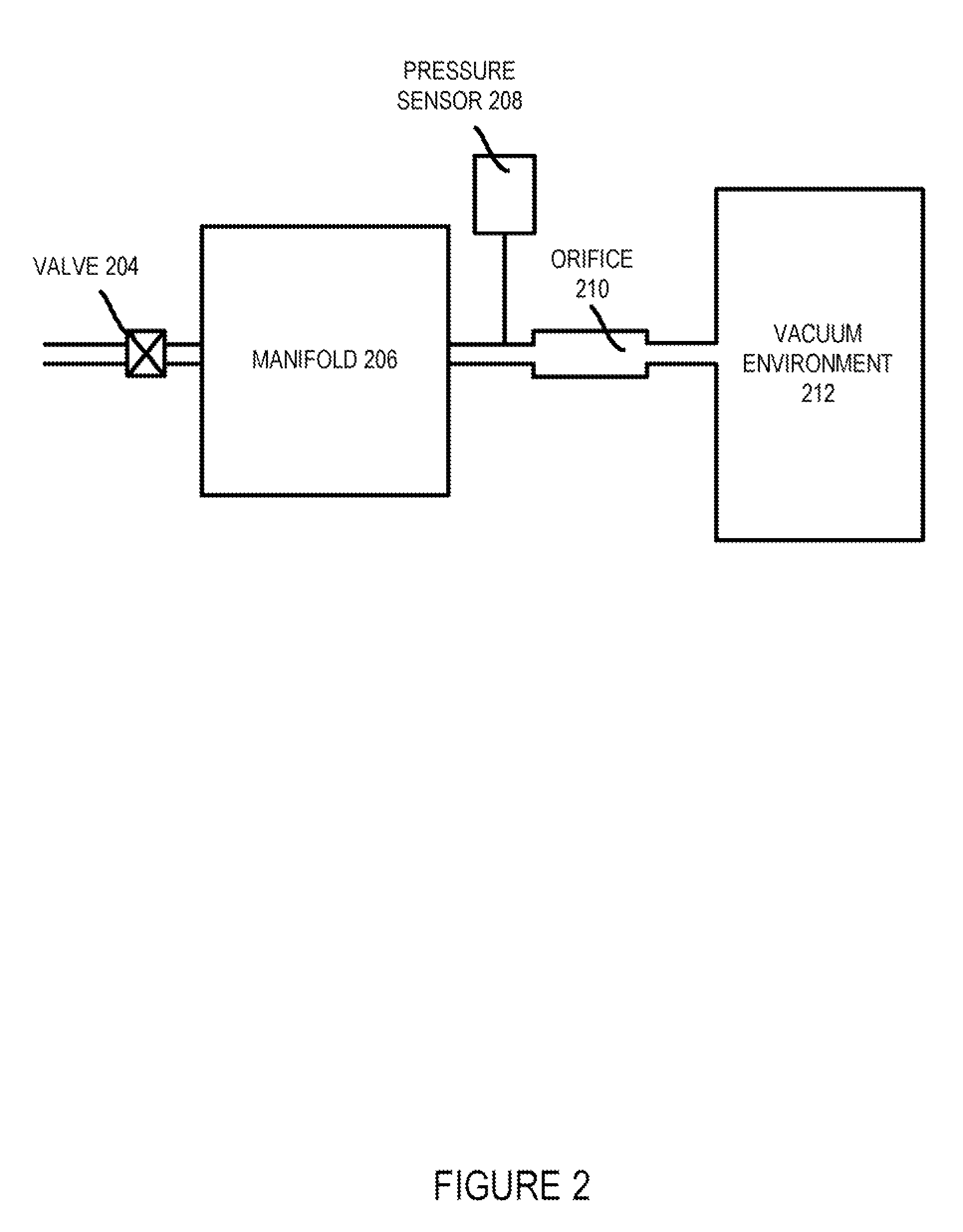

Methods for performing transient flow prediction and verification using discharge coefficients

ActiveUS7881886B1Testing/calibration apparatusFluid pressure measurementChoked flowProcess engineering

A method for determining an actual gas flow rate as gas flows through a gas flow delivery system is provided. The method includes sending the gas through the gas flow delivery system into a gas conduit, wherein a section of the gas conduit is widened to form an orifice. The method also includes pressurizing the gas to create a choked flow condition within the orifice of the gas conduit. The method further includes measuring upstream pressure of the gas via a set of pressure sensors. The method yet also includes calculating the actual flow rate based on the upstream pressure of the orifice of the gas conduit.

Owner:LAM RES CORP

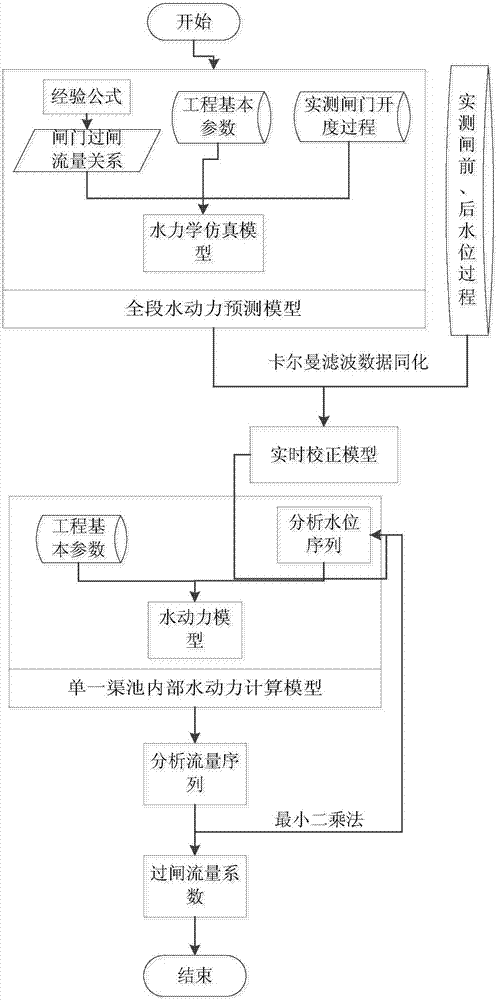

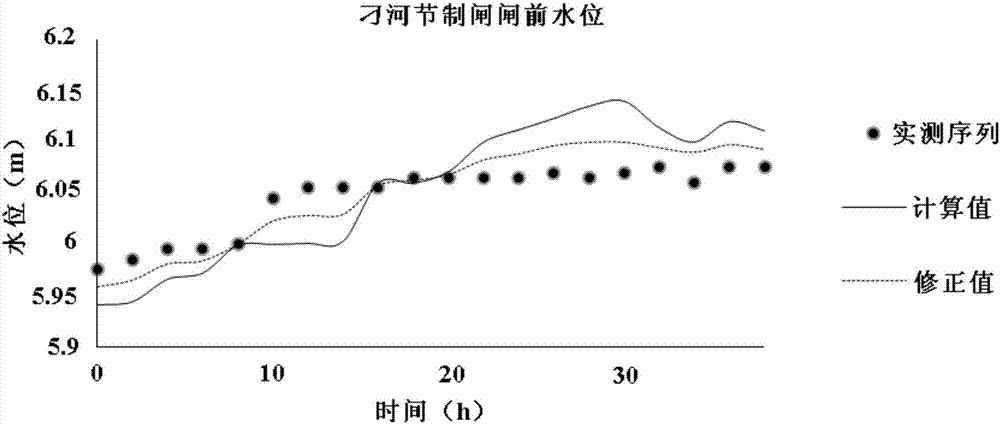

Cascaded multi-ditch gate lockage discharge coefficient calibration method

ActiveCN106874622AAccurate gate flow coefficientHigh precisionGeometric CADDesign optimisation/simulationReal time analysisEngineering

The invention discloses a cascaded multi-ditch gate lockage discharge coefficient calibration method, and relates to the field of hydrodynamic parameter identification. The method comprises the steps of building a hydrodynamic simulating and forecasting model of a researching channel section; combining flow measured values and water level measured values of all gates in the researching channel section, and using a Kalman filtering assimilation algorithm to obtain a real-time analysis water level sequence; utilizing a Saint-Venant equation to deduce and obtain an analysis flow sequence of a ditch gamma according to the real-time analysis water level sequence of the gates of any ditch gamma in the researching channel section; deducing and obtaining a ditch gamma lockage discharge coefficient by utilizing the real-time analysis water level sequence of the gates of the ditch gamma and the analysis flow sequence of the ditch gamma. By means of the cascaded multi-ditch gate lockage discharge coefficient calibration method, the precision of the hydrodynamic simulating and forecasting model is sharply improved, and the accuracy of a forecasting value is improved.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

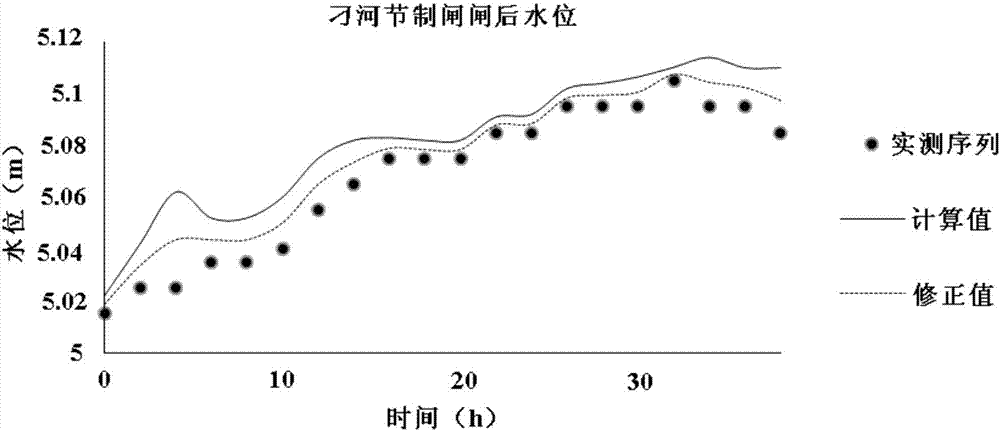

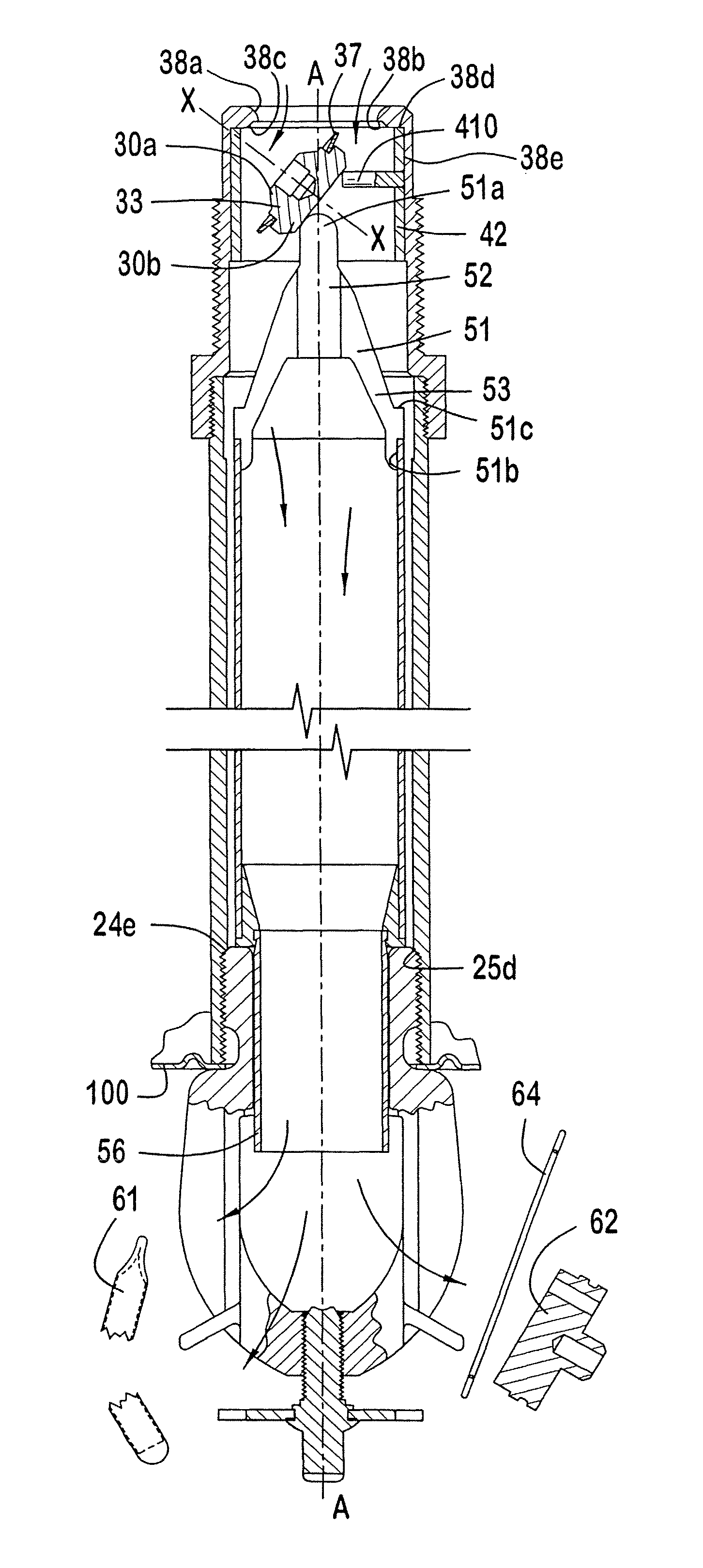

Dry sprinkler

A dry sprinkler for a fire protection system. The preferred dry sprinkler has a metallic disc annulus positionable within a passageway to skew a central axis of a face of the metallic disc annulus with respect to a longitudinal axis of the dry sprinkler so that an expected minimum flow rate based on a rated discharge coefficient is provided. The dry sprinkler operates to provide an expected flow rate over a range of start pressures. The expected flow rate is based on a K-factor rating. The dry sprinkler provides an acceptable level of fluid flow rate from the expected flow rate based on the K-factor for a range of start pressures.

Owner:TYCO FIRE PRODS LP

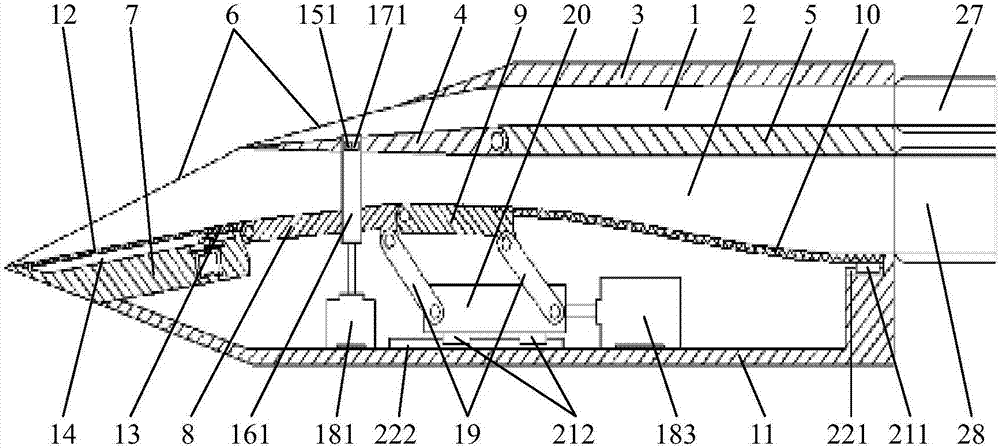

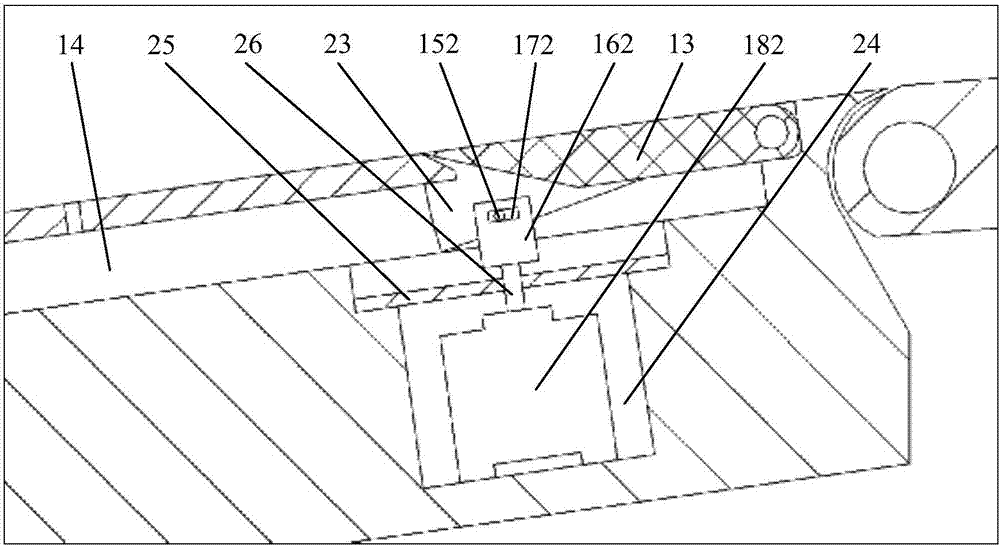

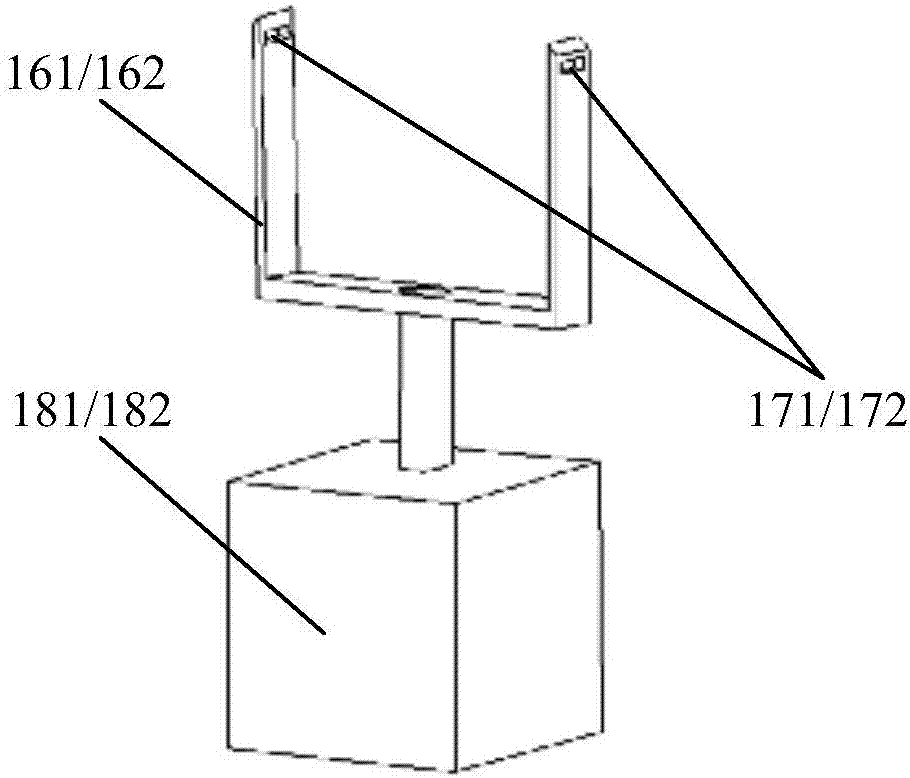

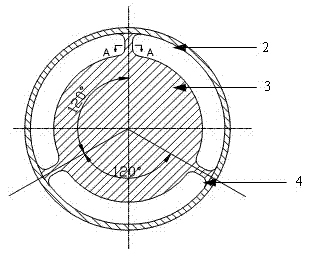

Pneumatic type/mechanical type combined adjustment mach number 0-7 stage combined engine air inlet

ActiveCN107448296AGuaranteed low Mach number starting performanceGuaranteed high Mach number compression performanceGas turbine plantsJet propulsion plantsShock waveWork performance

The invention discloses a pneumatic type / mechanical type combined adjustment mach number 0-7 stage combined engine air inlet. The pneumatic type / mechanical type combined adjustment mach number 0-7 stage combined engine air inlet is mainly composed of a high-speed channel, a low-speed channel, a mechanical type variable geometry assembly and a pneumatic type shock wave adjusting assembly. Under the low-speed mode, the mechanical type variable geometry assembly is adopted for adjusting the throat area and the internal shrinkage ratio of the air inlet, and the low mach number starting performance and the high mach number compression performance of the air inlet are guaranteed; and under the high-speed mode, the pneumatic type shock wave adjusting assembly is used for adjusting the precursor shock wave position, the precursor shock wave sealing state is kept, and the discharge coefficient and the working performance of the air inlet are obviously improved within the wide mach number scope. According to the pneumatic type / mechanical type combined adjustment scheme, the compression amount and the precursor shock wave position of the air inlet can be continuously adjusted, it is guaranteed that the combined engine air inlet can effectively work within the wide mach number scope, and the good pneumatic performance is obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

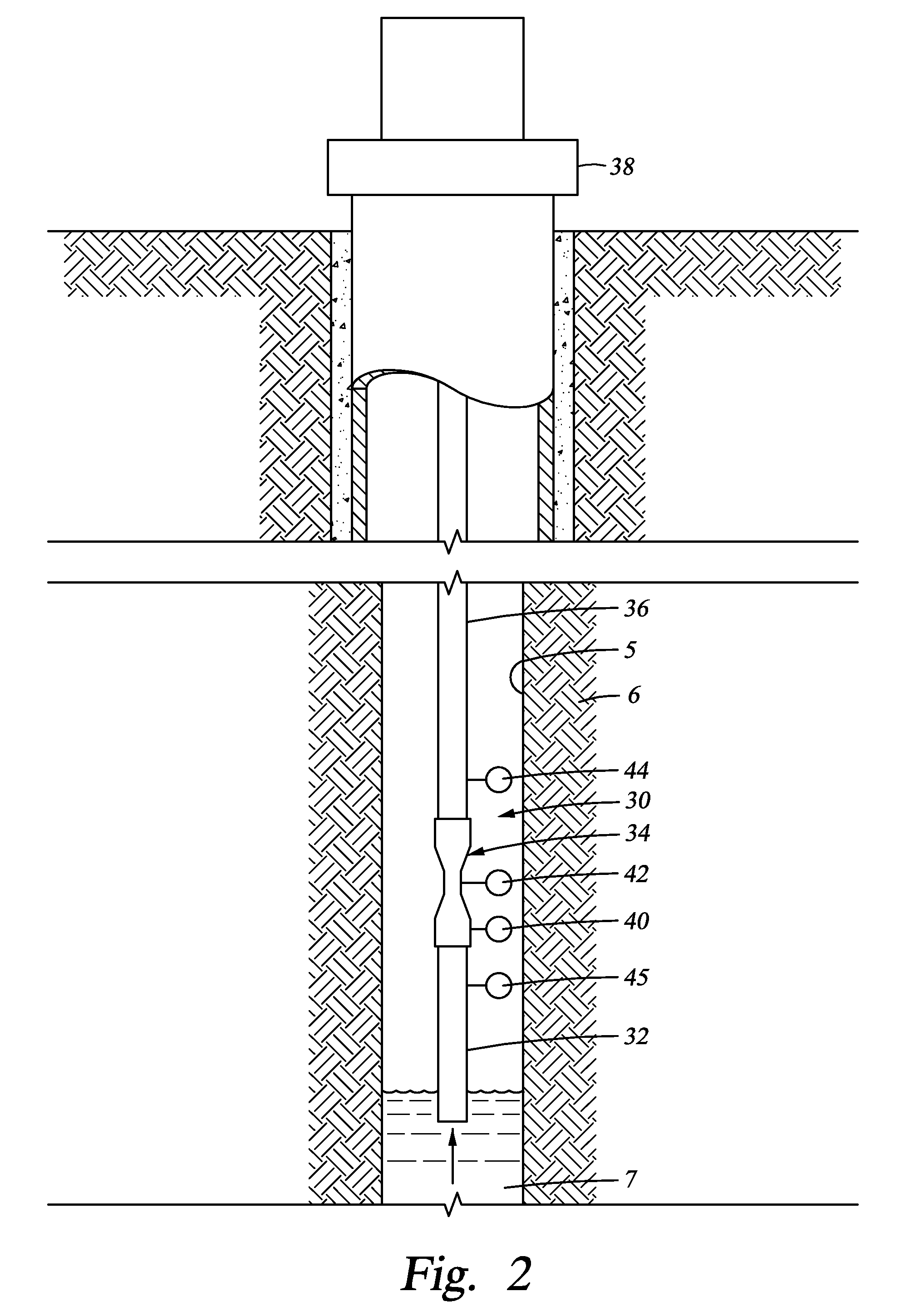

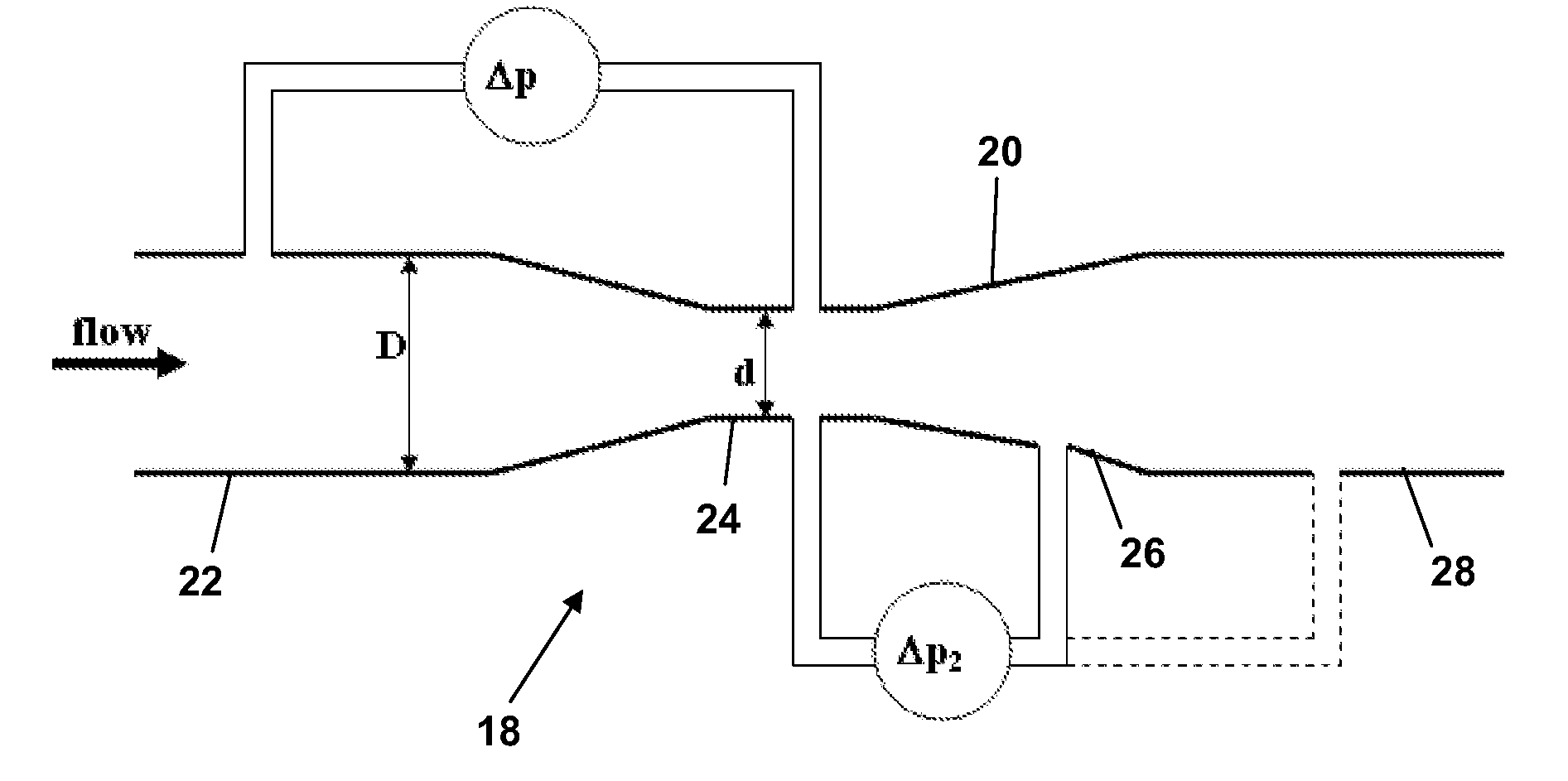

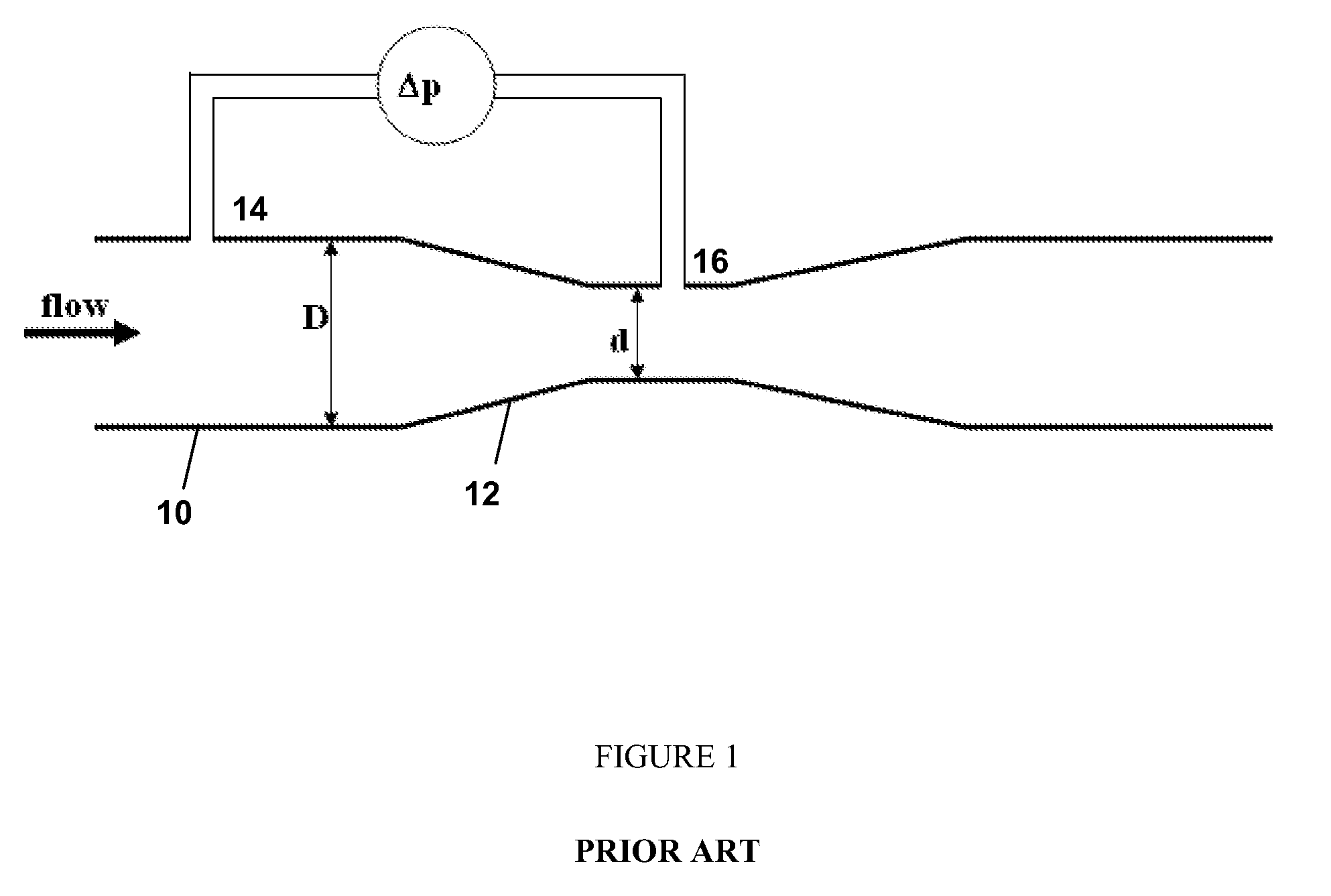

Apparatus and a method of measuring the flow of a fluid

InactiveUS20100138168A1Improve accuracyMeasure the mass flow rate sufficiently accuratelyVolume flow measuring devicesVolume/mass flow by differential pressureMeasurement deviceDifferential pressure

An apparatus and method for measuring a mass flow rate of a multi-phase fluid flowing through a conduit. The apparatus includes a differential pressure element located in the conduit, wherein a first differential pressure measurement device is in communication with the multi-phase fluid between a first and second position across the differential pressure element and is able to measure a first fluid differential pressure. A second differential pressure measurement device is in communication with the multi-phase fluid between a third and fourth position across the differential pressure element and is able to measure a second fluid differential pressure. A processor is in communication with the first and second differential pressure measurement devices, and is able to calculate the Reynolds number and discharge coefficient using the first and second fluid differential pressures. The processor is also capable of calculating the mass flow rate by using the Reynolds number and discharge coefficient.

Owner:SCHLUMBERGER TECH CORP

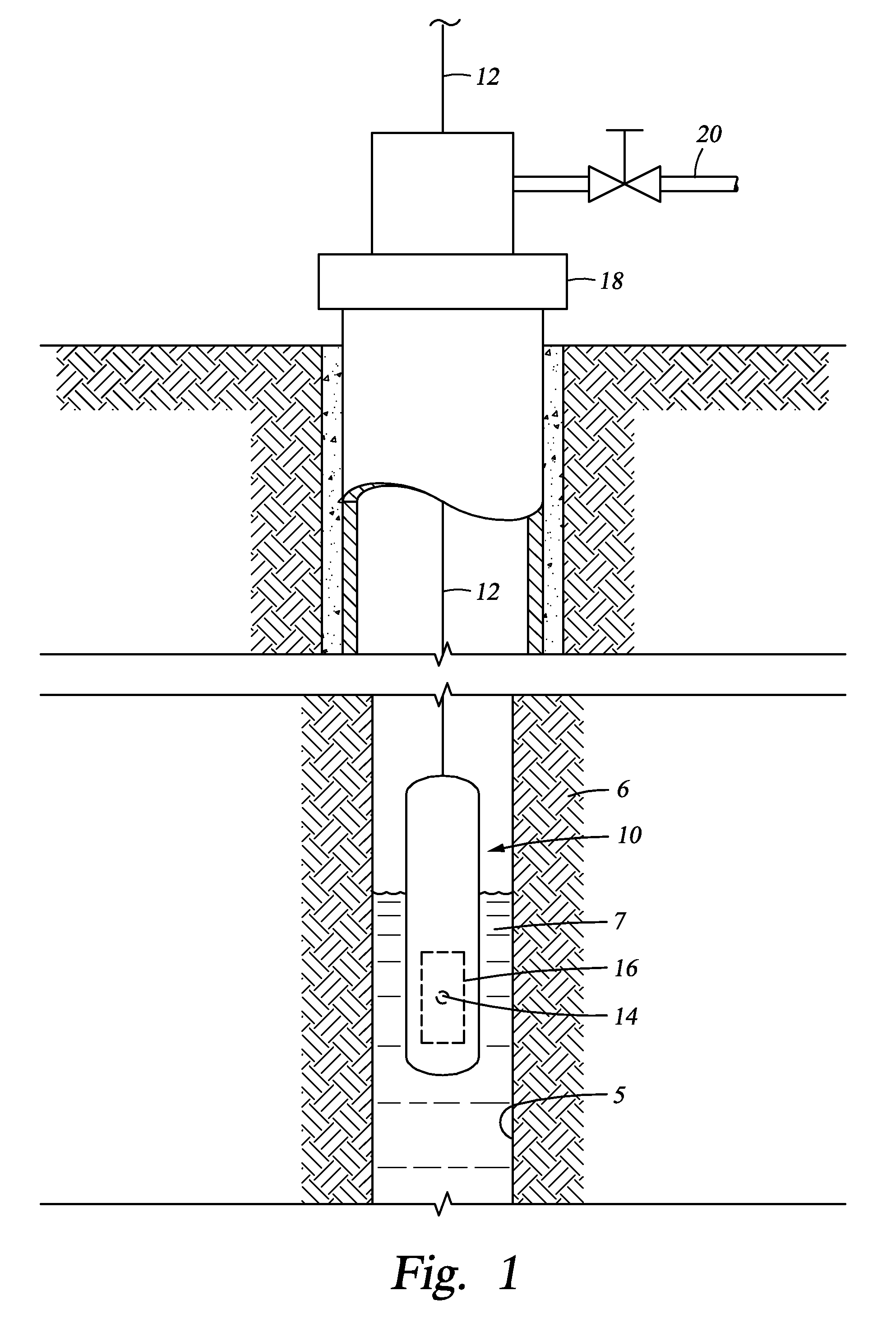

Dry sprinkler assemblies

A dry sprinkler for a fire protection system having a configuration with one or more coupling arrangements for connection to a fluid supply piping of the system. The dry sprinkler structure further includes an inner surface and inner assembly to provide a preferred discharge performance. The dry sprinkler provides for a flow rate from the outlet of the sprinkler in accordance with the start pressure at the inlet of the sprinkler and the rated discharge coefficient, K factor, ranging between 16.8 GPM / PSI½ and 33.6 GPM / PSI½

Owner:TYCO FIRE PRODS LP

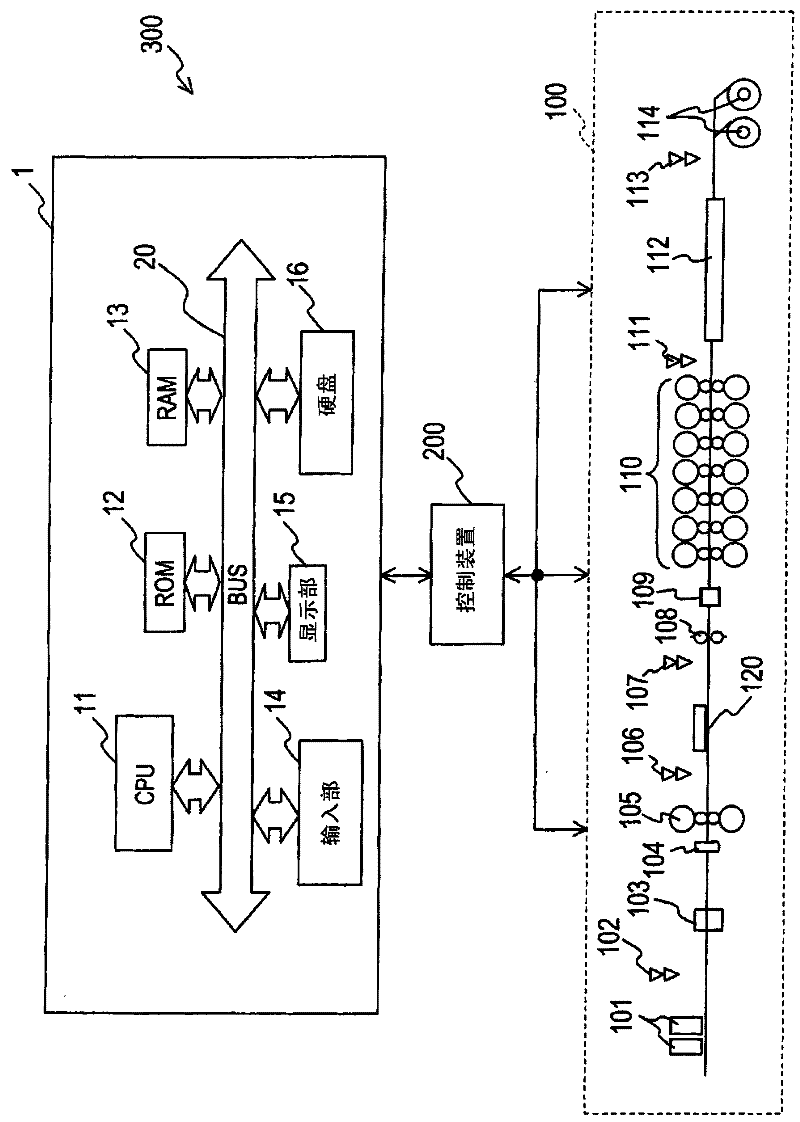

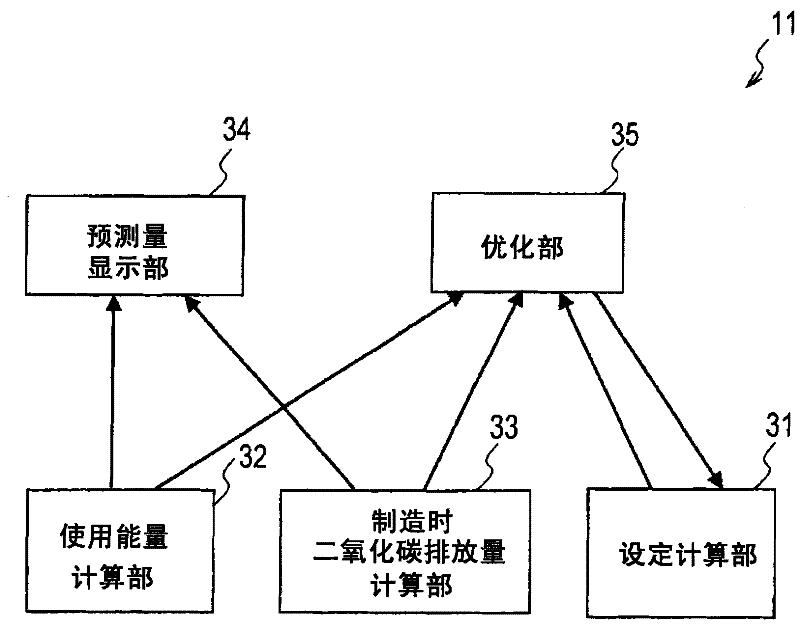

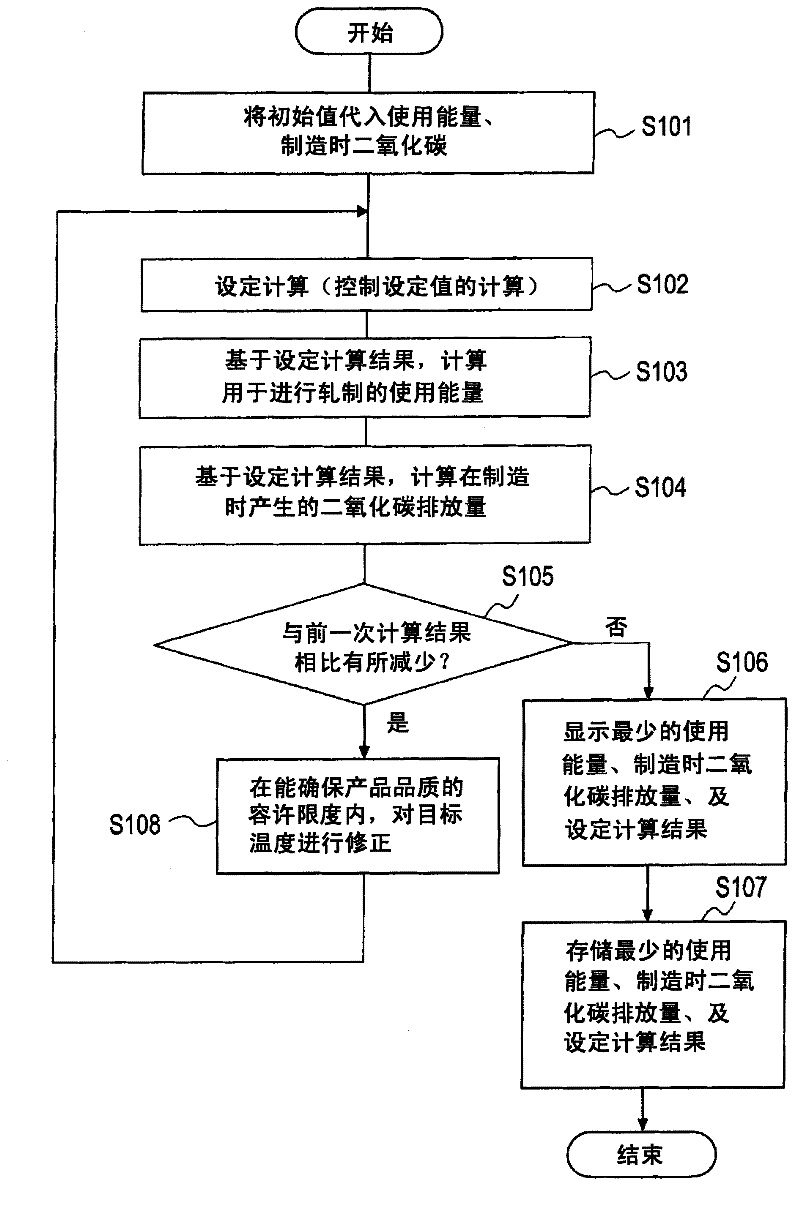

Optimizing apparatus

ActiveCN102348516AGuaranteed qualityTemperature control deviceMetal rolling arrangementsControl setMaterials science

Provided an optimizing apparatus comprising a setting calculation unit (31) for calculating a control setting value for a hot rolling apparatus (100) to roll a rolling material (120), on the basis of the initial sizes, the initial temperature and the target temperature of the rolling material (120), a working energy calculation unit (32) for calculating a working energy necessary for the hot rolling apparatus (100) to roll the rolling material (120), on the basis of the control setting value, a during-manufacture carbon dioxide discharge calculating unit (33) for calculating the quantity of carbon dioxide to be discharged in the hot rolling apparatus (100), on the basis of the working energy and the carbon dioxide discharge coefficient, and an optimizing unit (35); for calculating the target temperature both as the temperature at or higher than the value necessary for retaining the quality of the rolling material (120) to be rolled, and as a temperature for minimizing at least one of the working energy or the carbon dioxide discharge.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

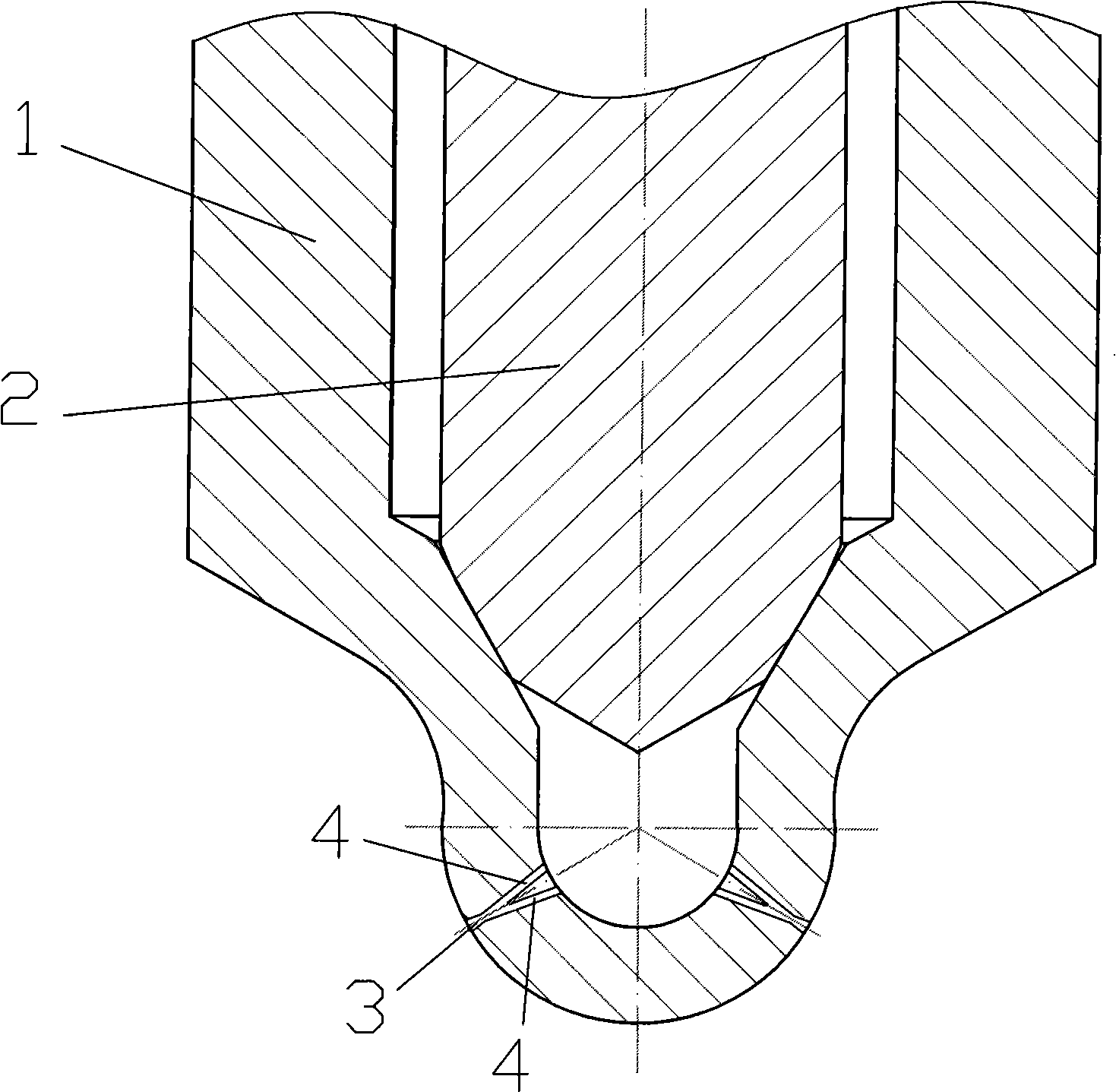

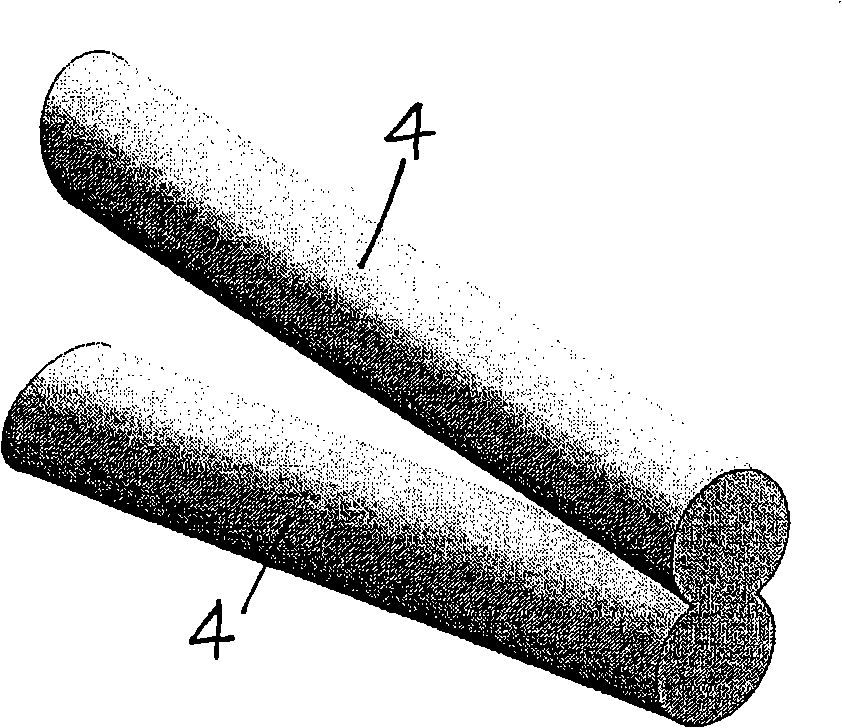

Crossing spray orifice type injection nozzle of internal combustion engine

InactiveCN101294533AIncreased turbulence intensityPromote atomizationFuel injection apparatusMachines/enginesCombustionExternal combustion engine

The invention relates to a cross orifice typed injection nozzle for an internal-combustion engine and belongs to an oil injection device of a fuel system of the internal-combustion engine. The nozzle is a precision coupling formed by an injector valve body and an injector valve. The head of the injector valve body is provided with at least one cross sub-orifice and each cross orifice is formed by crossing and collecting of at least two sub-orifices. As the collection of fuel in the sub-orifices of the cross orifice can form intense disturbance, the turbulent kinetic energy is increased and the atomization is improved; as an outlet of the cross orifice is formed by the collection of the sub-orifices, the flow area of the outlet is less than the sum of the outlet areas of all the sub-orifices, the injection nozzle is characterized by improving discharge coefficient like an analogous V-shaped gradually shrinking orifice. In brief, the crossing of the sub-orifices increases the internal flow, improves the turbulent intensity, causes the cross orifice to improve atomization, improves the quality of the mixed gas and leads to rapid, sufficient and perfect combustion, thus being beneficial to the further improvement of the economic performance, discharging performance and kinetic performance of the motor.

Owner:DALIAN UNIV OF TECH

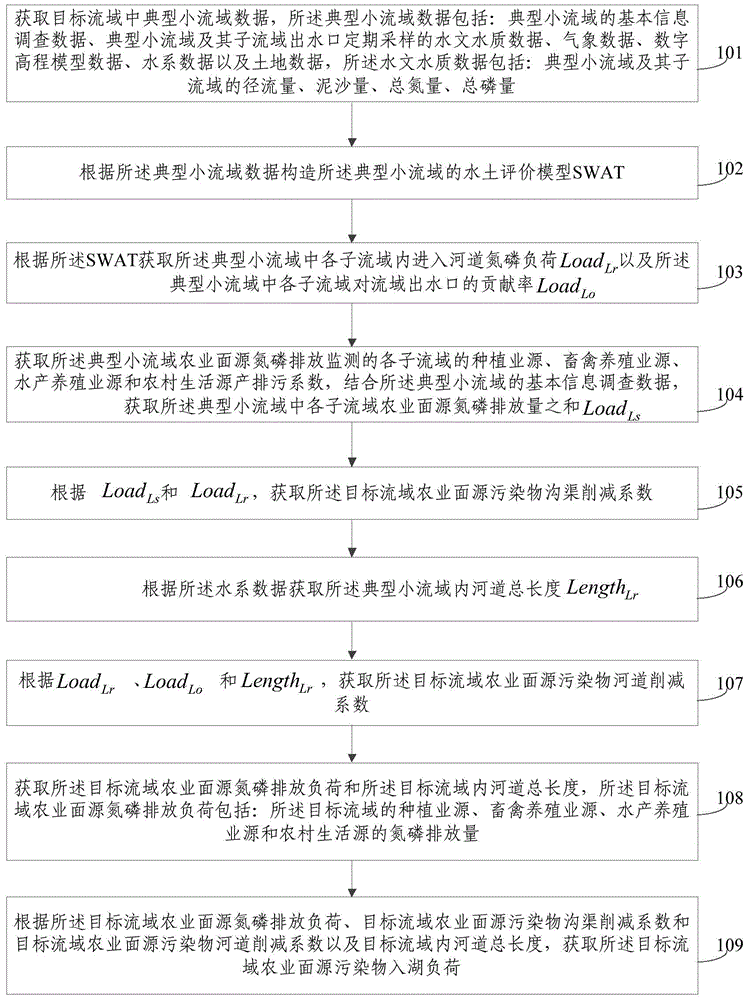

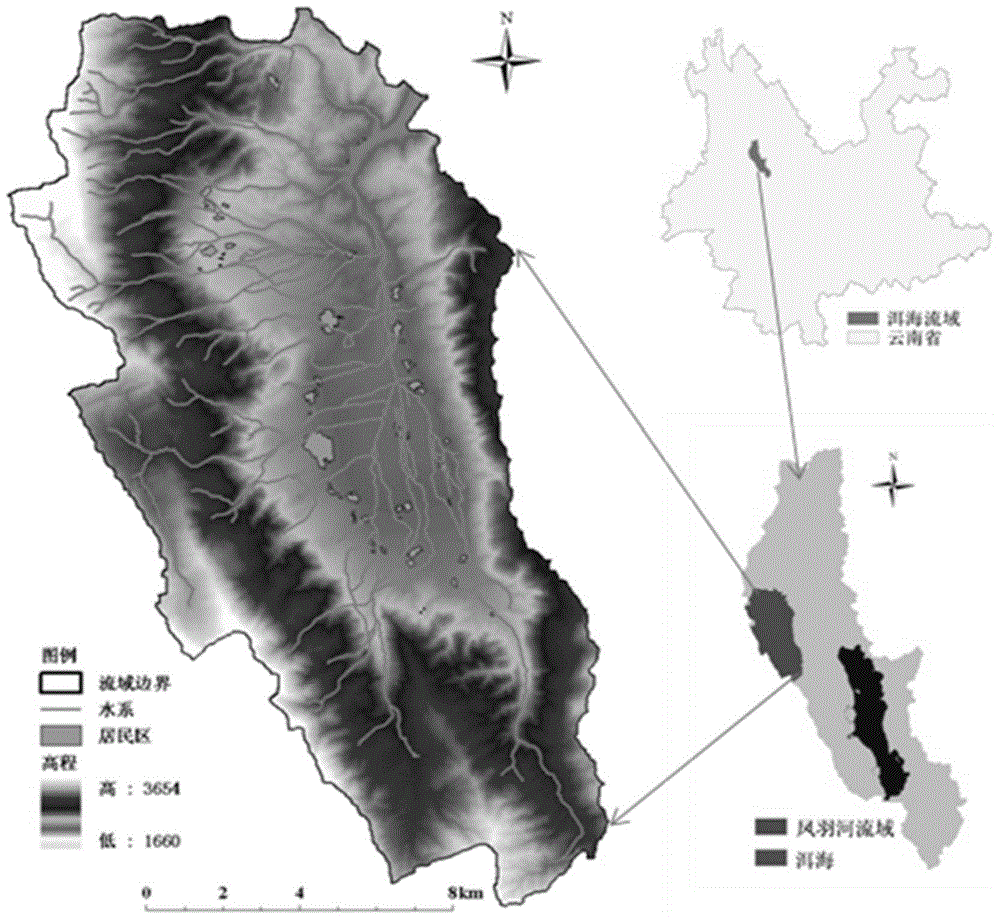

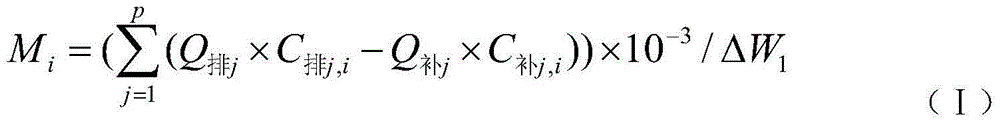

Estimation method for load of watershed agricultural non-point source pollutants into lake

ActiveCN104951986AEasy accessAccurate acquisitionData processing applicationsAquaculture industryDitch

The invention provides an estimation method for load of watershed agricultural non-point source pollutants into a lake. The estimation method includes acquiring data of a typical small watershed in a target watershed, creating a SWAT (soil and water assessment tool) of the typical small watershed, and acquiring LoadLr and LoadLo in the typical small watershed according to the SWAT; acquiring planting industry source, livestock and poultry industry source, aquaculture industry source and rural life source pollutant producing and discharging coefficients of each sub watershed of the typical small watershed, and combining basic information survey data to acquire LoadLs in the typical small watershed; acquiring target watershed agricultural non-point source pollutant ditch reduction factor Factorcr according to the LoadLs and the LoadLr; acquiring LengthLr according to water system data; acquiring target watershed agricultural non-point source pollutant riverway reduction factor Factorrr according to the LoadLr, the LoadLo and the LengthLr; acquiring target watershed agricultural non-point source nitrogen and phosphorus discharge load and the total length LengthBr of an inner riverway of the target watershed; acquiring the load of the target watershed agricultural non-point source pollutants into the lake according to the target watershed agricultural non-point source nitrogen and phosphorus discharge load, the Factorcr, the Factorrr and the LengthBr. By the method, the total load of the watershed agricultural non-point source pollutants into the lake can be acquired simply, accurately and rapidly, cost is low and large-scale comprehensive implementation is achieved.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

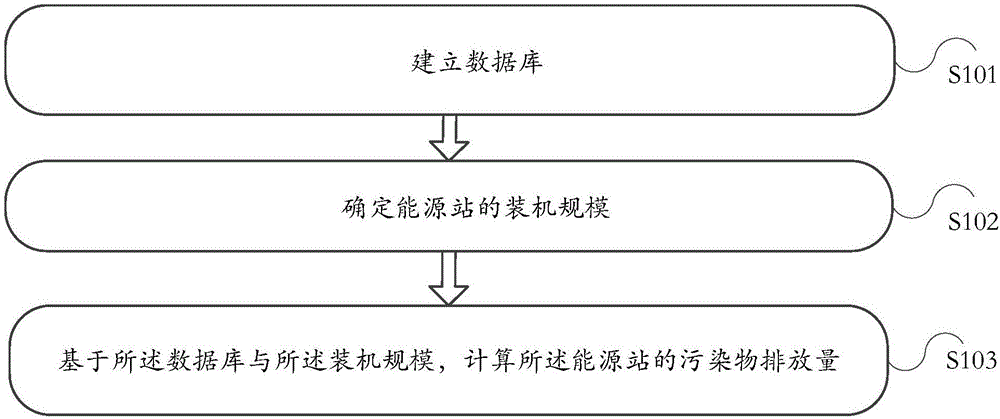

Pollutant discharge amount computing method and electronic equipment

ActiveCN106295145AImprove work efficiencyGood reproducibilitySpecial data processing applicationsInformaticsTime ratioPollutant emissions

The invention discloses a pollutant discharge amount computing method and electronic equipment. The pollutant discharge amount computing method comprises the steps that a database is built; the database comprises hourly cooling load coefficients, hourly heating load coefficients, cooling season time, heating season time, first time proportions of different temperature intervals corresponding to different cooling daily loads in the cooling season time, second time proportions of different temperature intervals under different heating daily loads in the heating season time and pollutant discharge coefficients of different cities in different operating modes; the scale of installation capacity of an energy station is determined; based on the database and the scale of installation capacity, the pollutant discharge amount of the energy station is computed. According to the method, the technical problems that the pollutant discharge amount computing mode in the prior art is complex in computing process and is not intelligent enough are solved.

Owner:ENN ENERGY SERVICE

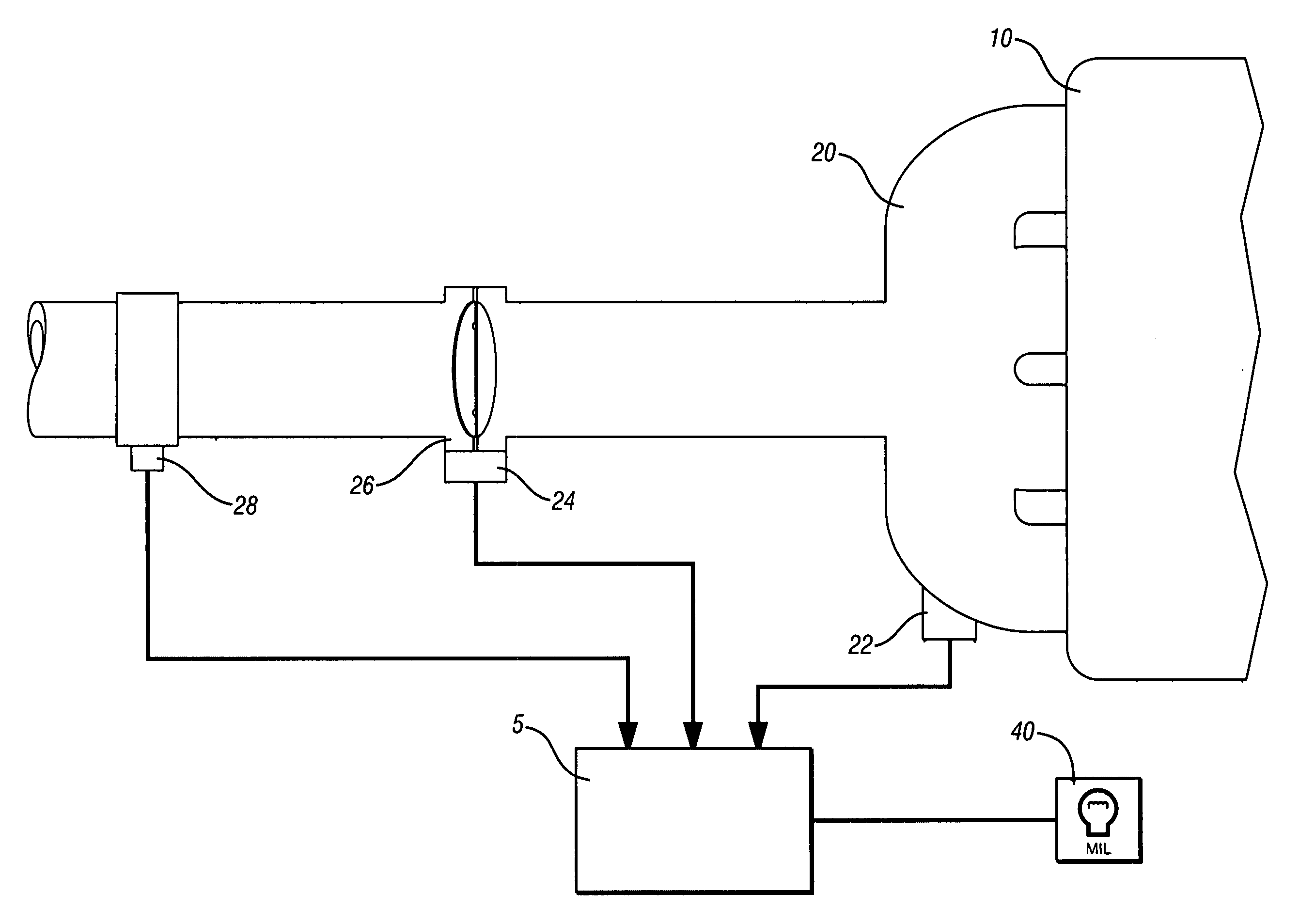

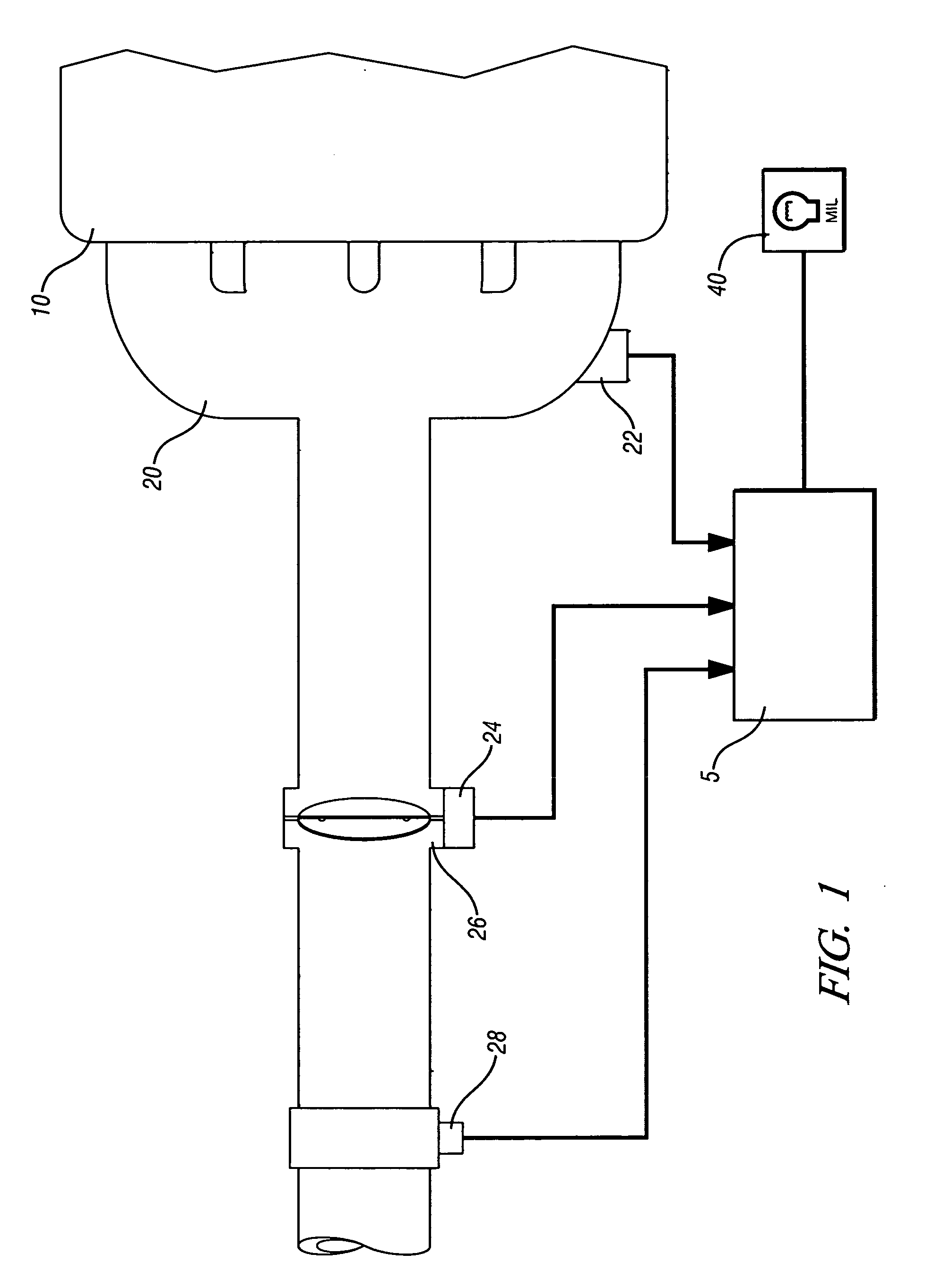

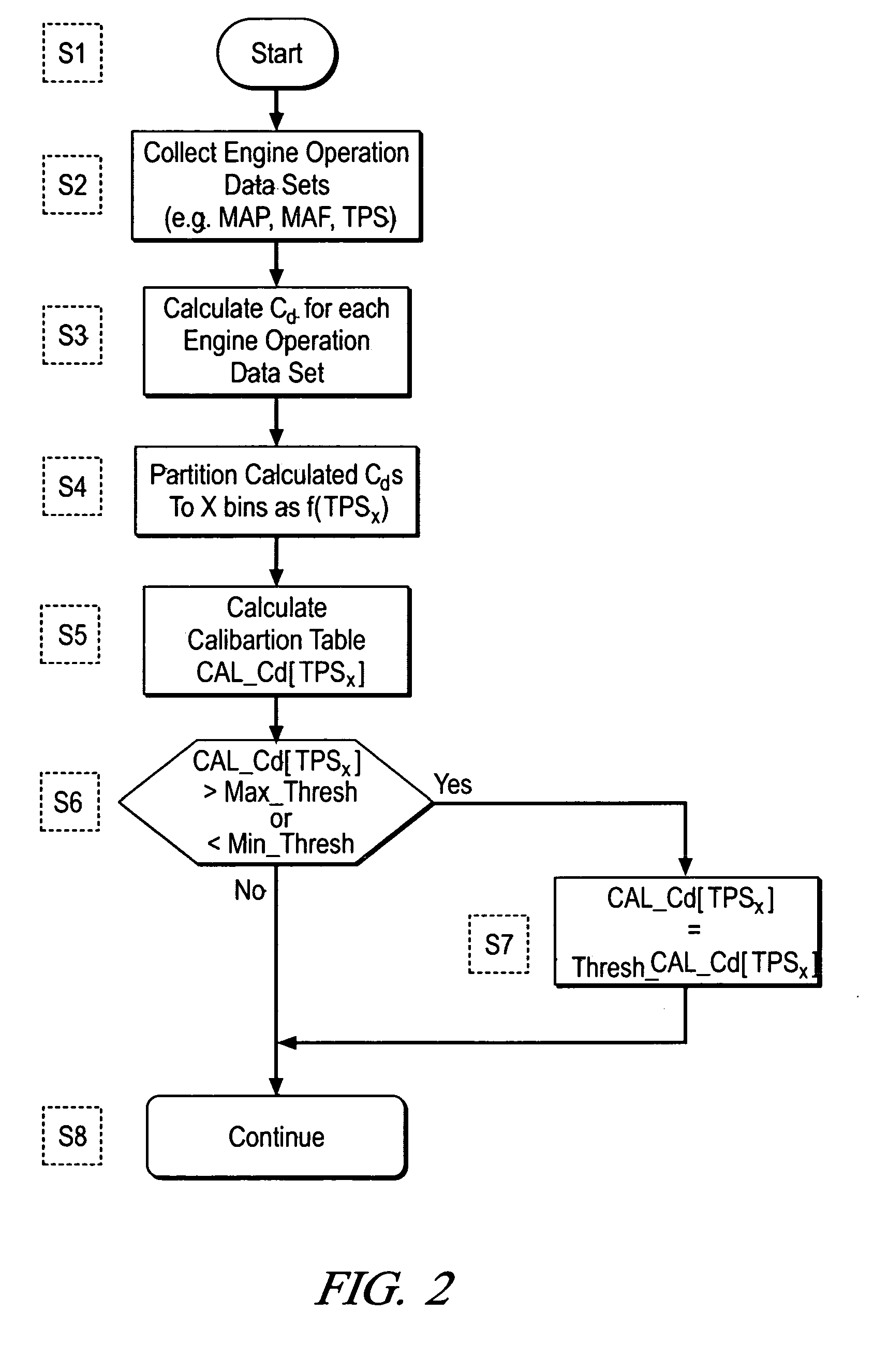

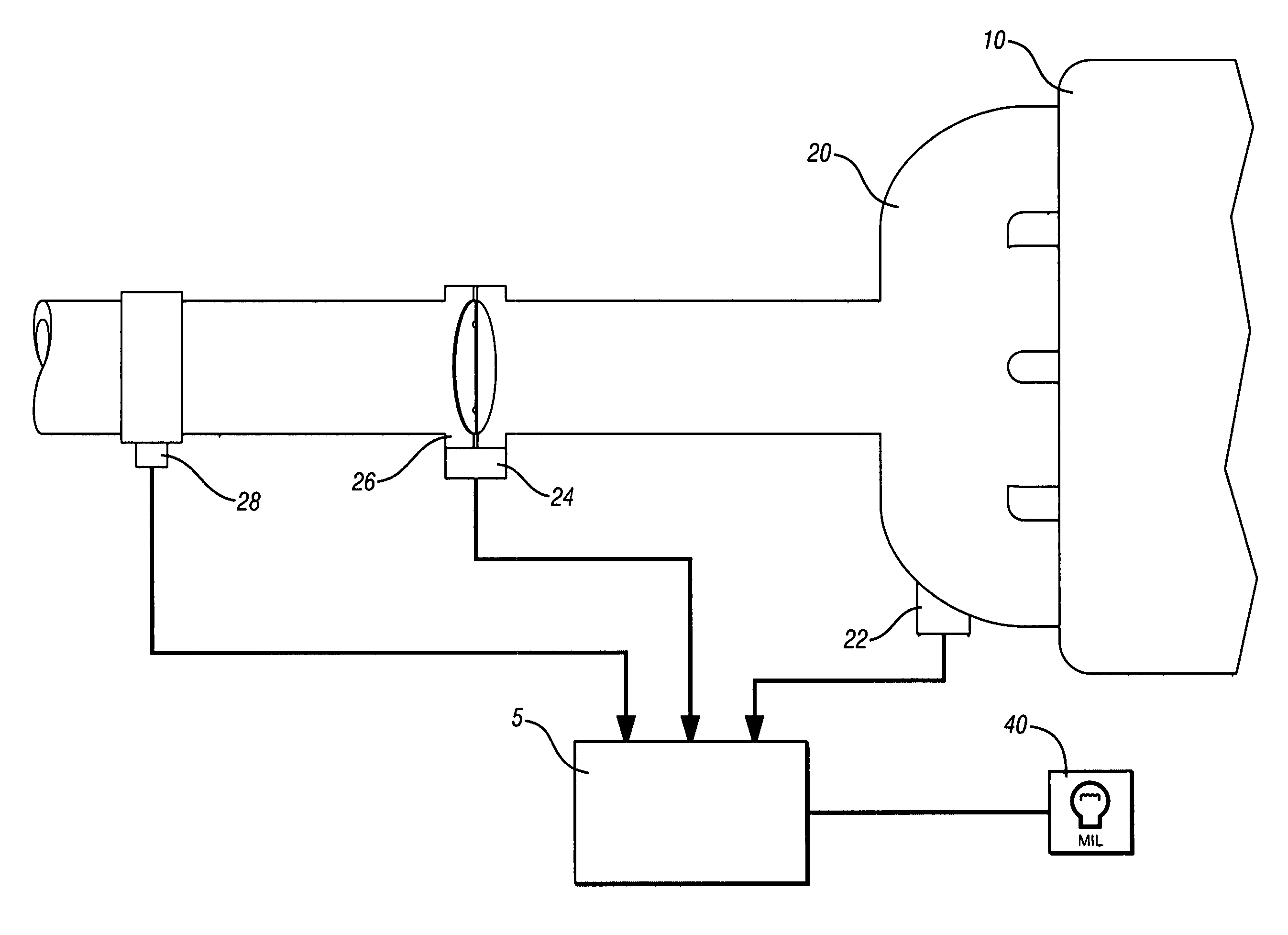

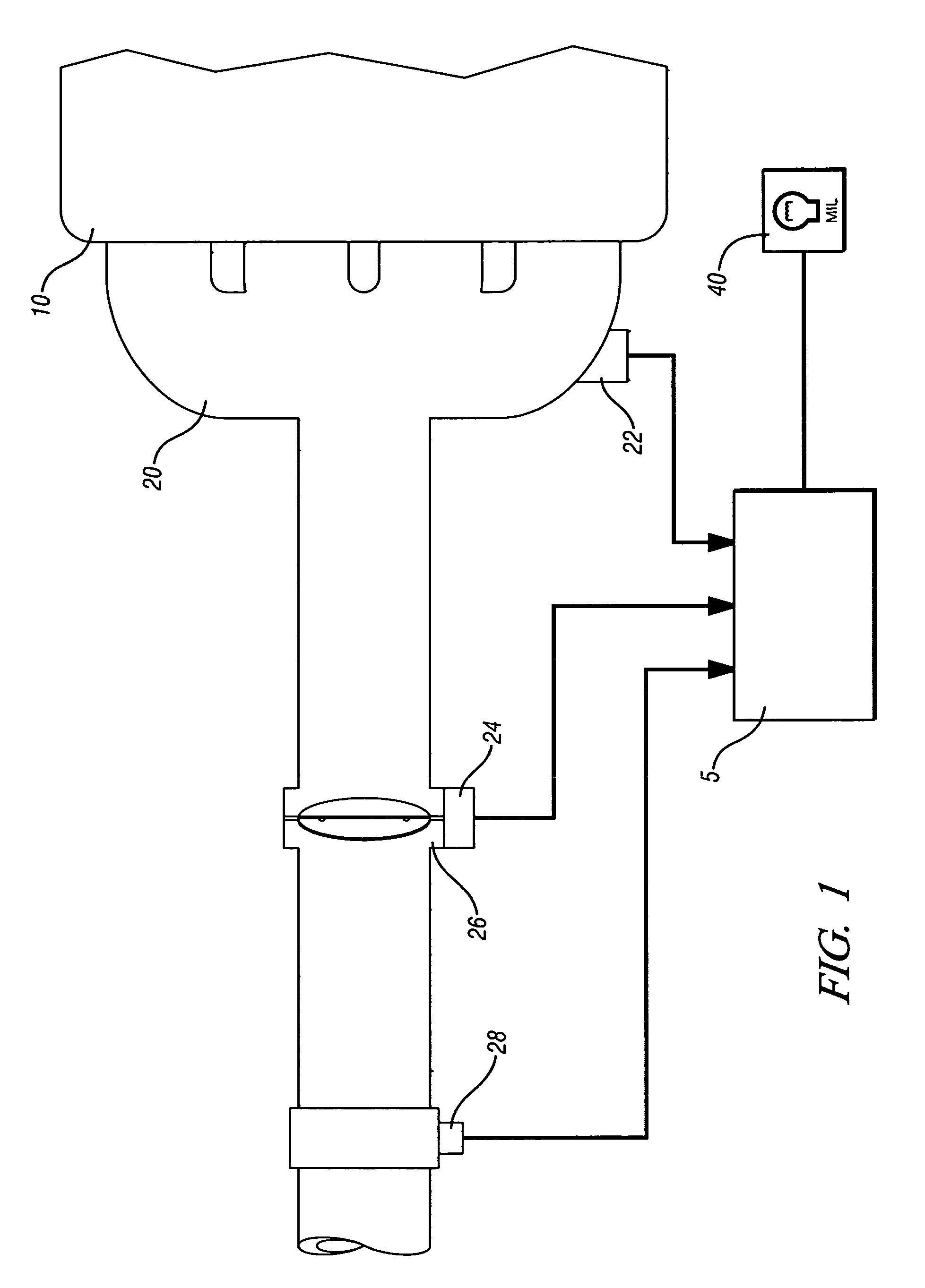

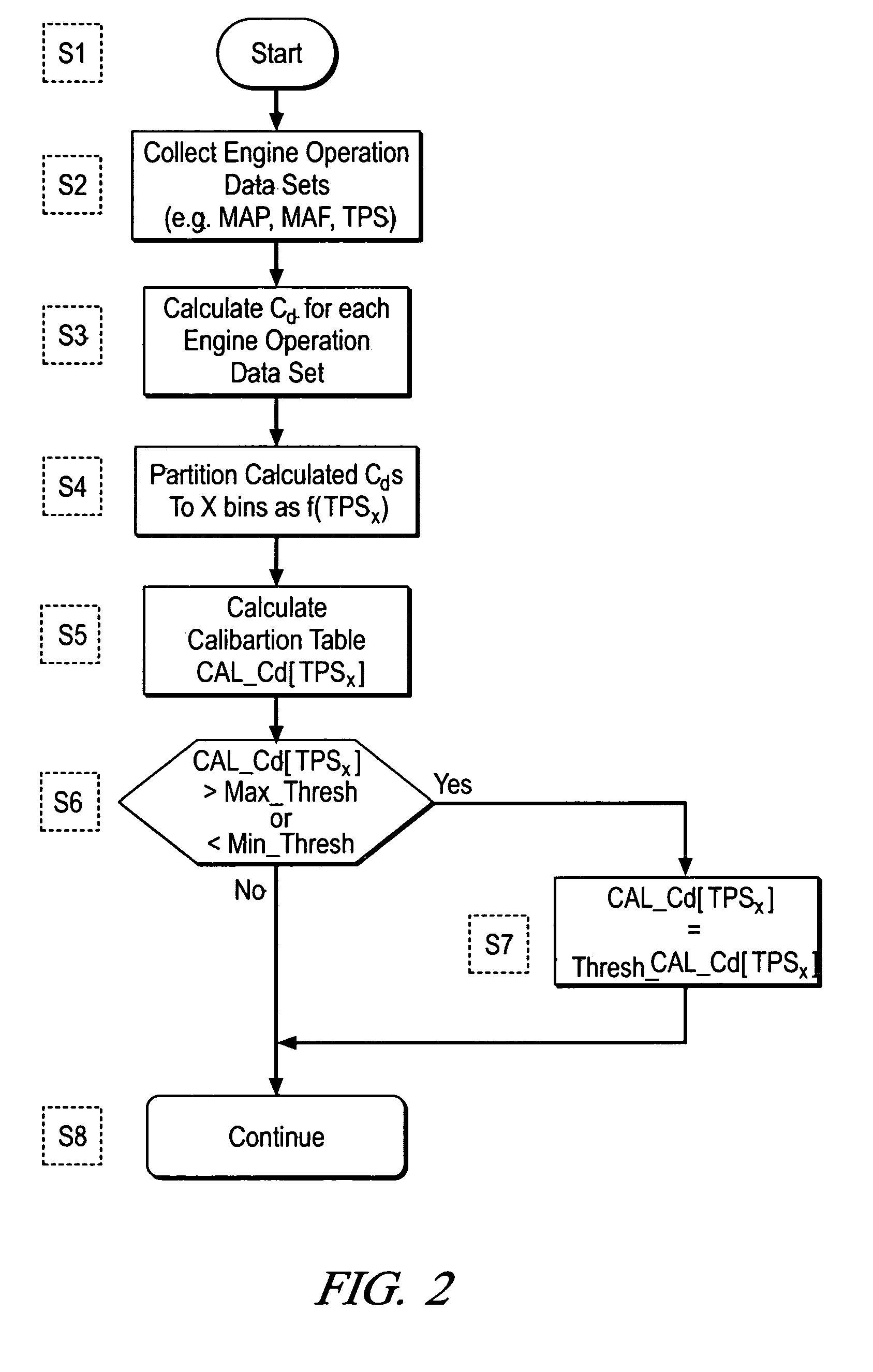

Adaptive throttle model for air intake system diagnostic

InactiveUS20070061062A1Analogue computers for vehiclesElectrical controlStream flowAtmospheric pressure

A method and system to optimize values of a plurality of calibration discharge coefficients useable in a computer program operable to estimate mass air flow into an internal combustion engine having an air intake system comprising a throttle body and a plurality of sensors is presented. This includes collecting engine operation data points, including throttle position. Discharge coefficients are calculated, one for each engine operation data point. The discharge coefficients are partitioned based upon throttle position. Calibration discharge coefficients are calculated for each partitioned plurality of discharge coefficients. This includes circumscribing each calibration discharge coefficient based upon predetermined thresholds. This further includes monitoring and collecting input signals correlatable to airflow from the sensors during ongoing engine operation, preferably comprising throttle position, manifold pressure, intake air temperature, and, atmospheric pressure.

Owner:GM GLOBAL TECH OPERATIONS LLC

Software correction method and apparatus for a variable orifice flow meter

InactiveUS7082842B2Volume/mass flow by dynamic fluid flow effectVolume/mass flow by differential pressureDifferential pressureEngineering

Owner:RIVATEK

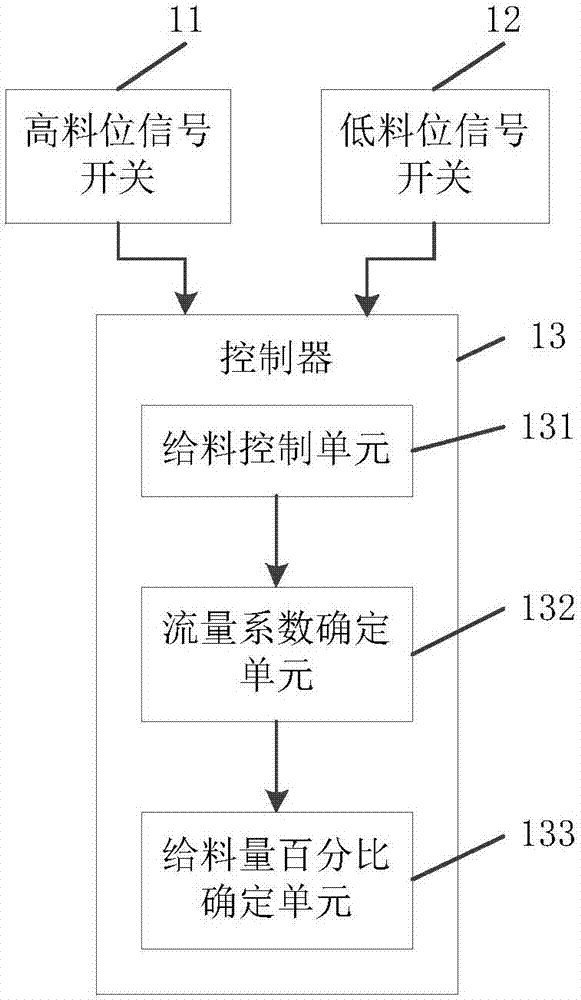

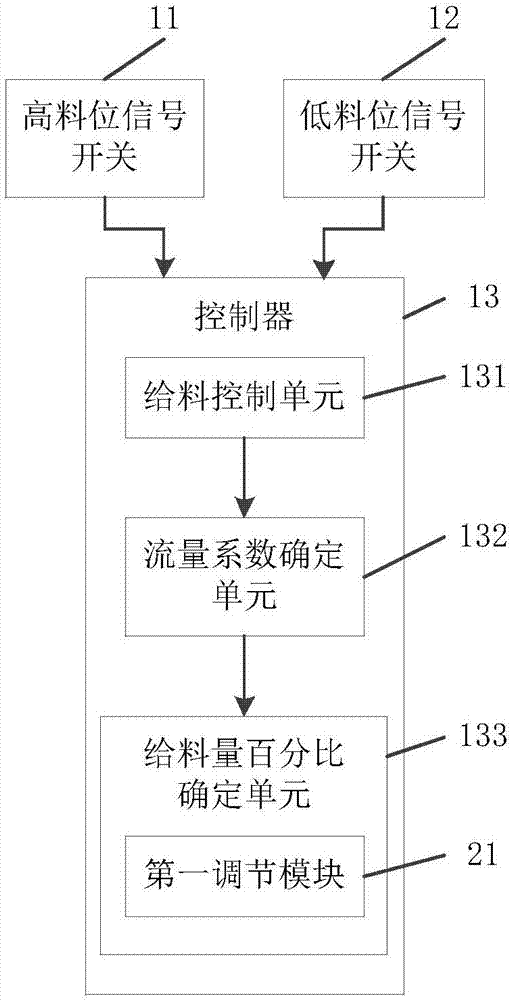

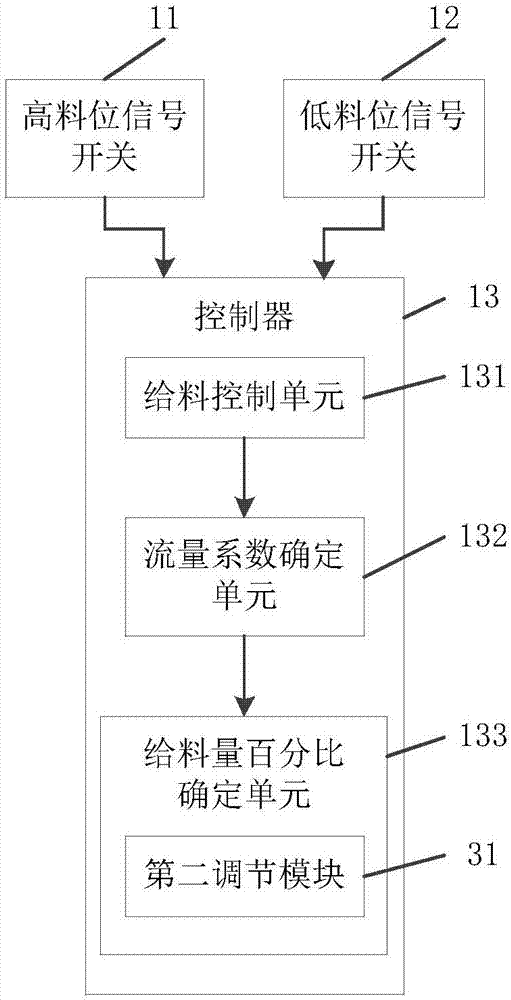

Car dumper hopper feeding control system and method

ActiveCN106865276AEasy to adjustImprove work efficiencyLoading/unloadingConveyor partsAutomatic controlControl system

The invention relates to the technical field of automatic control, and discloses a car dumper hopper feeding control system and a car dumper hopper feeding control method which solve the problem that the working capacity of an operation driver is too high. The car dumper hopper feeding control system comprises a high material level signal switch, a low material level signal switch and a controller; the controller comprises a feeding control unit, a discharge coefficient determination unit and a feeding quantity percentage determination unit; the feeding control unit is used for starting a plurality of hopper activation feeding machines at a predetermined time interval sequentially and controlling the feeding of the hopper activation feeding machines according to the predetermined feeding quantity percentage; the discharge coefficient determination unit is used for determining a discharge coefficient of each hopper activation feeding machine according to the starting sequence of the hopper activation feeding machines, readings of a belt weigher and the predetermined feeding quantity percentage; and the feeding quantity percentage determination unit is used for determining the actual feeding quantity percentage of each hopper activation feeding machine according to the readings of the belt weigher, a high material level signal, a low material level signal, a predetermined adjustment factor and the discharge coefficient. The car dumper hopper feeding control system and a car dumper hopper feeding control method are applicable to a feeding process of a car dumper.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Adaptive throttle model for air intake system diagnostic

InactiveUS7266442B2Analogue computers for vehiclesElectrical controlRam-air intakeInternal combustion engine

A method and system to optimize values of a plurality of calibration discharge coefficients useable in a computer program operable to estimate mass air flow into an internal combustion engine having an air intake system comprising a throttle body and a plurality of sensors is presented. This includes collecting engine operation data points, including throttle position. Discharge coefficients are calculated, one for each engine operation data point. The discharge coefficients are partitioned based upon throttle position. Calibration discharge coefficients are calculated for each partitioned plurality of discharge coefficients. This includes circumscribing each calibration discharge coefficient based upon predetermined thresholds. This further includes monitoring and collecting input signals correlatable to airflow from the sensors during ongoing engine operation, preferably comprising throttle position, manifold pressure, intake air temperature, and, atmospheric pressure.

Owner:GM GLOBAL TECH OPERATIONS LLC

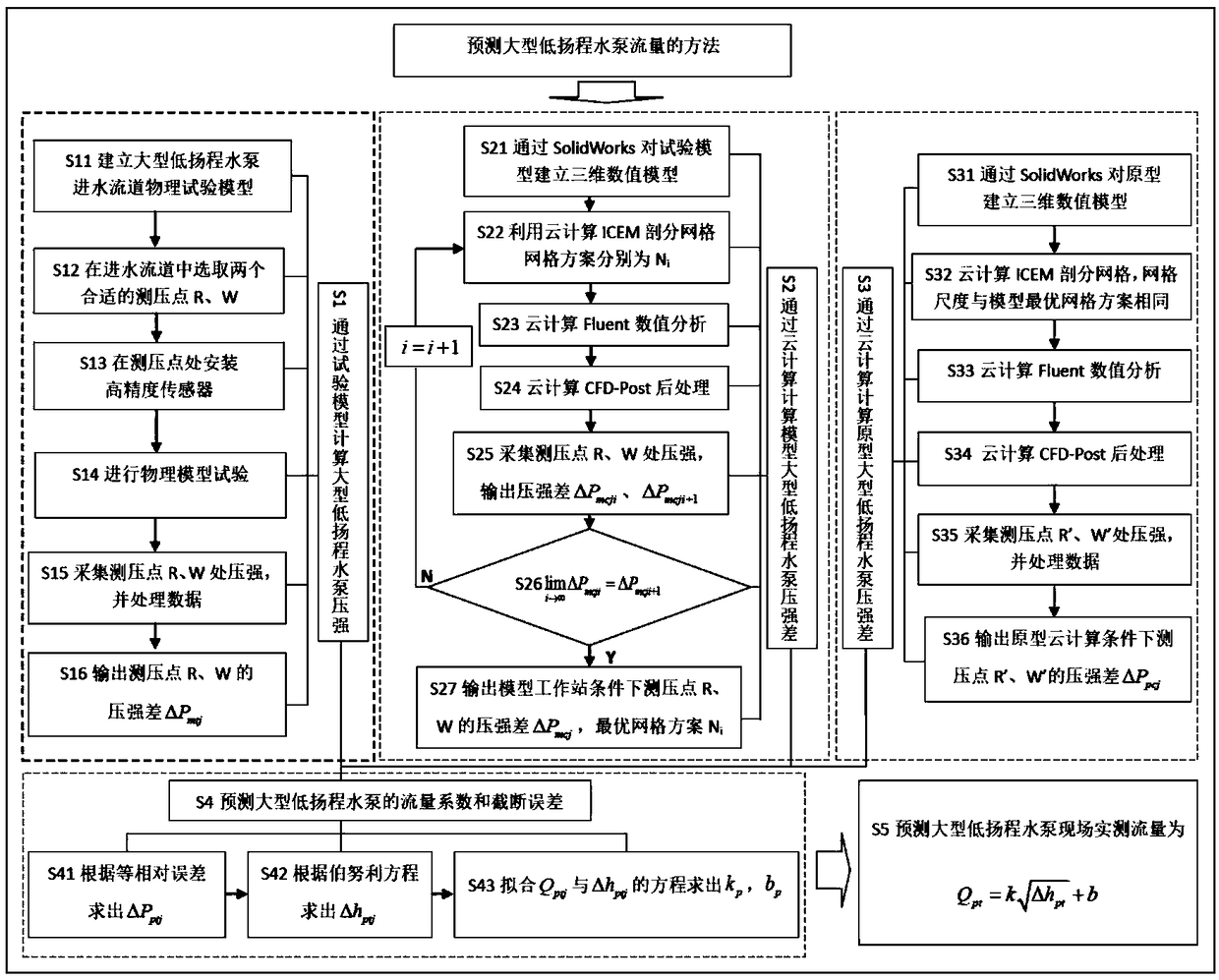

A method for predicting the flow of large low-head pumps

ActiveCN109460605APrediction of field measured flowScientifically Accurate Performance TestingGeometric CADSpecial data processing applicationsPressure differenceWorkstation

The invention discloses a method for predicting the flow rate of a large-scale low-head pump, which comprises the following steps: S1, calculating the pressure difference of the large-scale low-head pump through a test model; S2, calculating the pressure difference of large-scale low-head pump by cloud computing model; S3, calculating the pressure difference of the prototype large-scale low-head pump by cloud computing; S4, predicting discharge coefficient and truncation error of large-scale low-head pump; S5 predicts the field measured discharge of large-scale low-lift pumps. Cloud computingis introduced into the method of predicting the flow of large-scale low-head pumps, The numerical method of cloud computing solves the problem that the workstation can not compute because the model mesh size is used to generate huge mesh in the prototype numerical computation, and avoids the problem that the simulation results are not accurate due to the hardware problem which will increase the grid spacing. The invention can accurately predict the field measured flow rate of the large-scale low-lift pump, thereby determining the efficiency of the pump device and the unit energy consumption inthe pump station engineering, and scientifically and accurately completing the performance test of the pump device.

Owner:HOHAI UNIV

Method of measuring multi-phase fluid flow downhole

Owner:BAKER HUGHES HLDG LLC

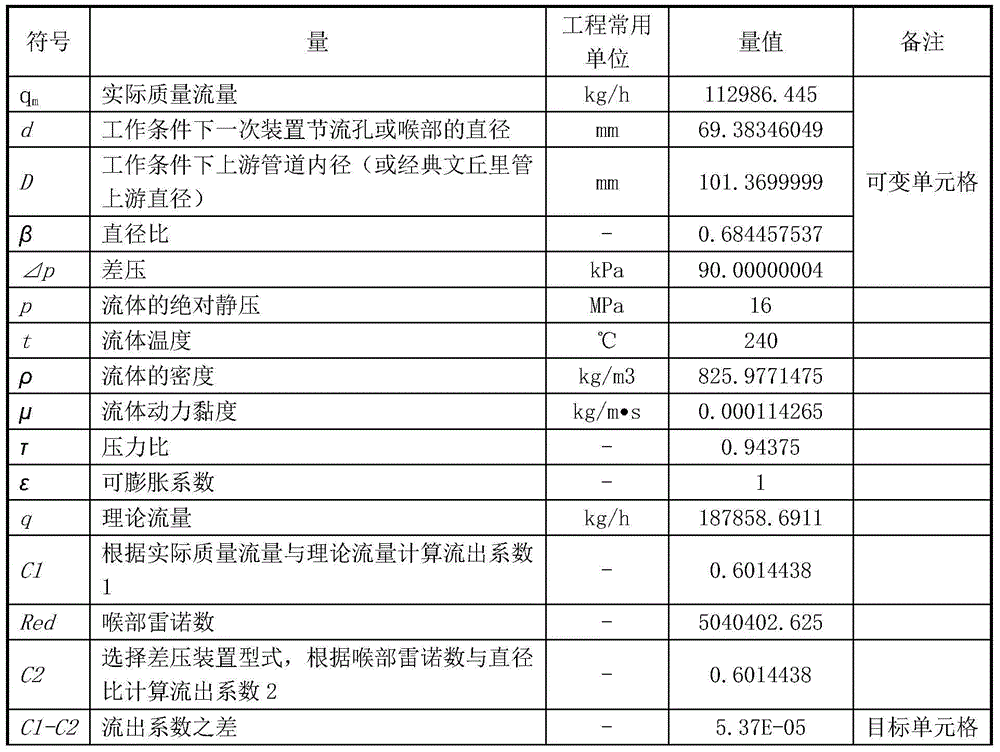

Simple detection method of differential pressure device

ActiveCN104458107AEasy qualityImprove efficiencyTesting/calibration apparatusVolume/mass flow by differential pressureMeasurement deviceDifferential pressure

The invention discloses a simple detection method of a differential pressure device. The simple detection method includes the steps that EXCEL table cells are filled with the practical mass flow q<m> of the differential pressure device, the inner diameter D of an upstream pipe under the working condition, the diameter d of a throttle hole or a throat part of a primary device under the working condition, the differential pressure deltap and the diameter ratio beta from top to bottom; initial values are assigned to quantities required to be solved, and other quantities are obtained through measurement by a measurement device; the fluid density and the dynamic viscosity are determined according to characteristic parameters, namely the pressure and the temperature, of fluid of the differential pressure device; the discharge coefficient C1 and the discharge coefficient C2 are calculated; the difference value between the discharge coefficient C1 and the discharge coefficient C2 is calculated to serve as a target table cell, a target value is zero, when a certain value is needed to be solved, the table cell where the certain value is located is selected to be a variable table cell, a determining button is clicked, and a value in the variable table cell is the result of the quantity needing to be solved after calculation is completed. The simple detection method is rapid, simple and convenient to detect.

Owner:STATE GRID CORP OF CHINA +1

System, method, and program for predicting state of battery

A method and system for predicting degradation of a battery. Modeling of a battery is made to be separated into an aging section and a current-carrying section. The modeling is established such that the amount of degradation of a capacity retention ratio is determined by the linear sum of stay at each temperature and each SOC. The separation into degradation components at each temperature and each SOC enables predicting degradation under various degradation environments. A model for a battery separated into an aging section and a current-carrying section and a calculation model of a root law are combined into an objective function, and a table of discharge coefficients ah(T,S) and a table of current-carrying coefficients ac(T,S) are generated using a solver, where T indicates the temperature and S indicates SOC. Once tables are generated, degradation of the battery can be predicted by calculation using the tables.

Owner:INT BUSINESS MASCH CORP

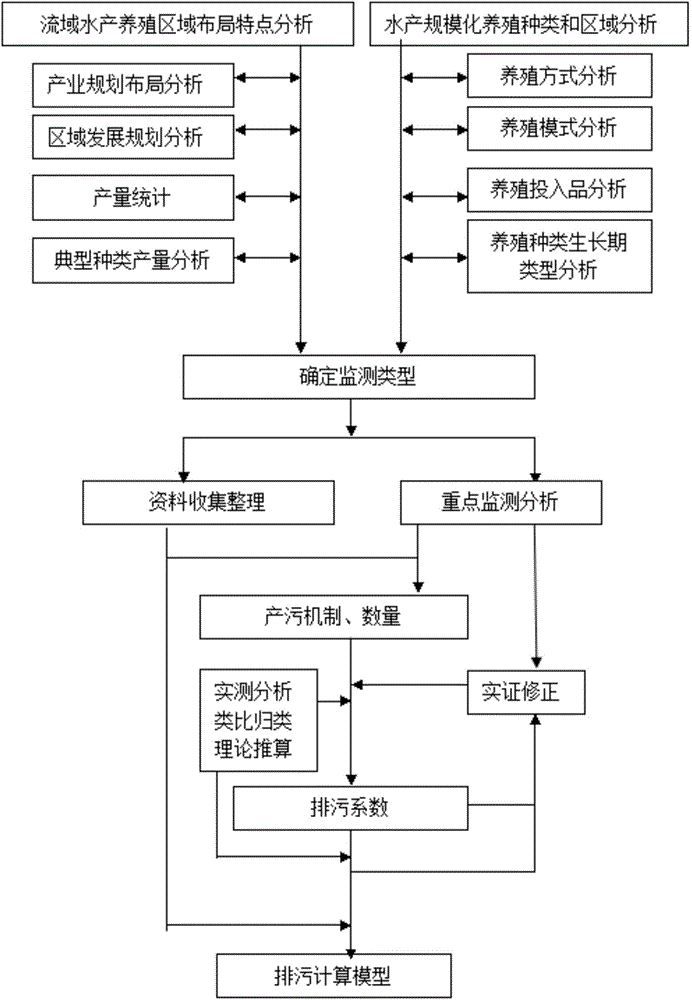

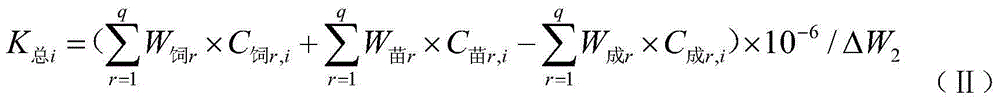

Method for determining discharge capacity of drainage basin fresh water aquiculture pollution

ActiveCN104463689AEfficient determinationIncrease productivityData processing applicationsGeomorphologyMaterial balance

The invention relates to a method for determining the discharge capacity of drainage basin fresh water aquiculture pollution. The method comprises the steps that drainage basin aquiculture modes, aquiculture types and corresponding yields are inquired and confirmed; investigation and survey are carried out according to the basic situation of aquiculture, and basic calculation models of various pollutant discharge coefficients under the different aquiculture types and the different aquiculture modes are studied and determined based on the field measurement method and the material balance method. According to the method, on one hand, the basic search is carried out, the features of drainage basin aquiculture are combined, and the effect of aquiculture on the water environment is reasonably evaluated; on the other hand, the basic calculation models of various pollutant discharge coefficients under the different aquiculture types and the different aquiculture modes are studied and determined based on the field measurement method and the material balance method, and reducing of the production efficiency and increasing of aquiculture cost are avoided.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

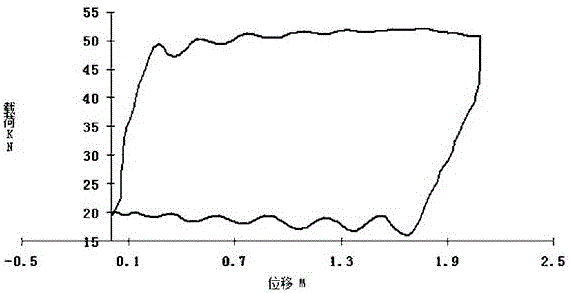

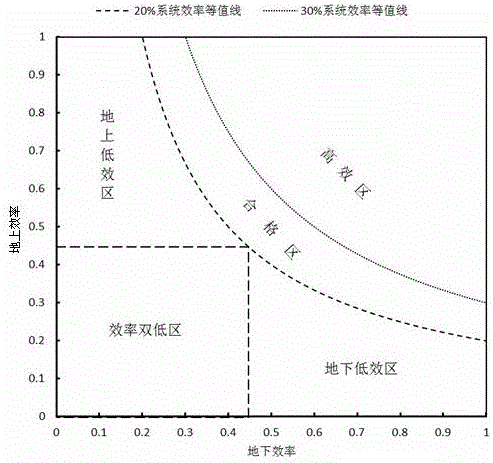

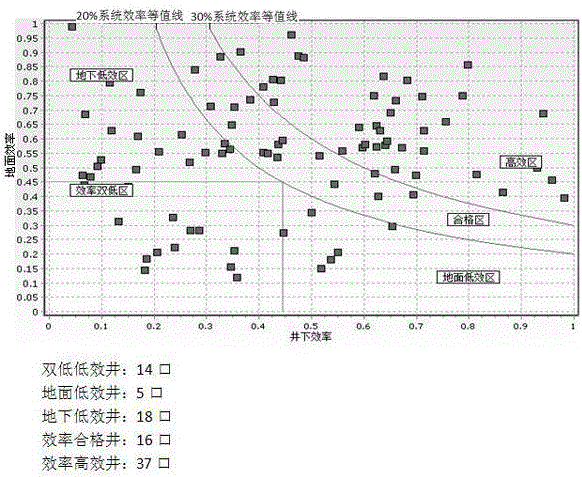

Evaluation and rectification method based on operation conditions of rod-pumped wells in whole block

ActiveCN105863607AImprove production management levelTo achieve the effect of economic intensificationSurveyConstructionsParallel computingIndicator diagram

The invention relates to an evaluation and rectification method based on operation conditions of rod-pumped wells in a whole block. Relevant data in an A2 database are extracted; the load rate, the torque load rate and the power load rate are worked out, and ground efficiency, underground efficiency and system efficiency are worked out through indicator diagram data; and evaluation criterions of key nodes such as the rod-pumped well system efficiency, the motor load rate, the reduction gearbox load rate, the polished rod load rate, the pump discharge coefficient and the submergence depth, and corresponding rectification measures are established. The operation conditions of the rod-pumped wells in the whole block are considered, the wells to be rectified are screened out according to the evaluation criterions, the numbers of the wells are listed, the specific rectification measures are proposed for the wells according to specific problems, and the reliable technological method is provided for efficient and economical management of the wells in the whole block.

Owner:NORTHEAST GASOLINEEUM UNIV

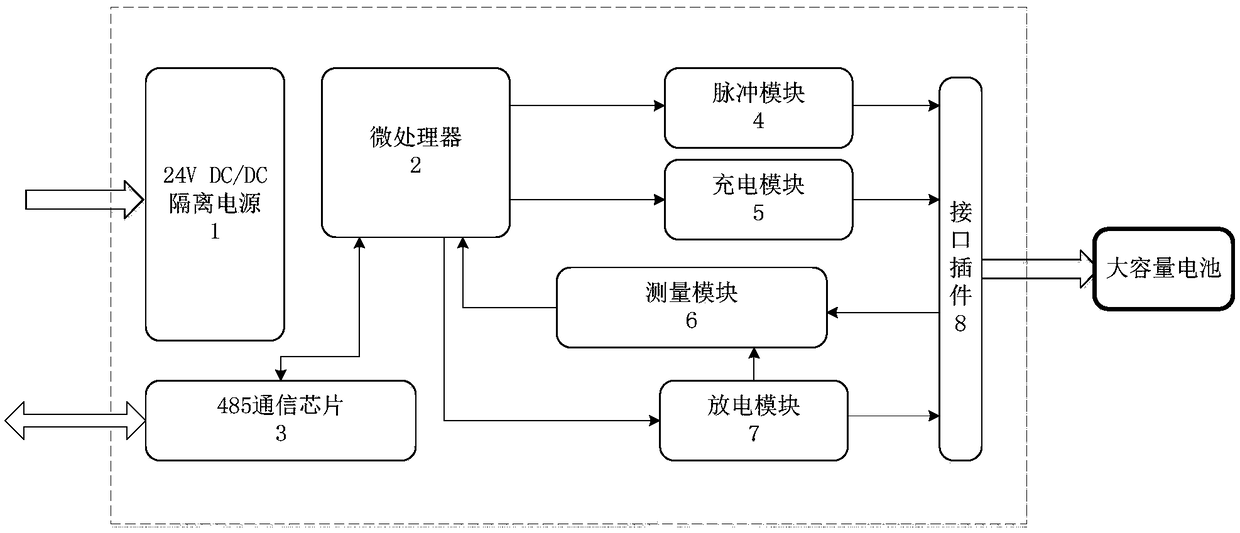

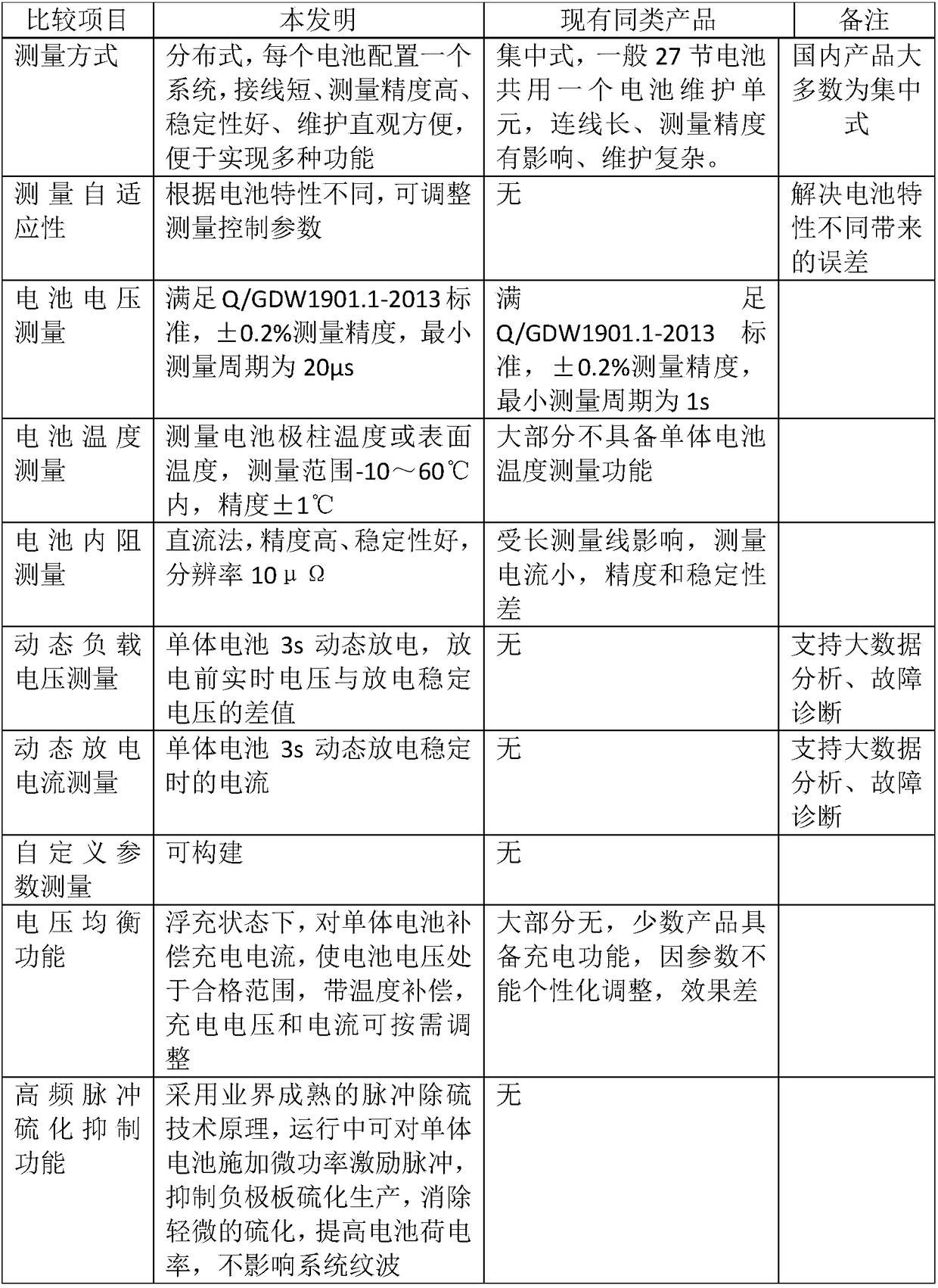

Battery online monitoring and maintenance system

InactiveCN108767335AImprove adaptabilityEasy to troubleshootCells structural combinationSecondary cells testingVulcanizationInternal resistance

The invention discloses a battery online monitoring and maintenance system. The system comprises an isolated power source, a microprocessor, a communication chip, a pulse module, a charging module, ameasuring module and a discharging module. The isolated power source is used for eliminating voltage clutter. The pulse module, the charging module and the discharging module are respectively connected to the microprocessor and are controlled by the microprocessor. Output ends of the pulse module, the charging module and the discharging module are respectively connected to a battery. A first dataacquisition end of the measuring module is connected to the battery. A second data acquisition end of the measuring module is connected to the discharging module. An output end of the measuring moduleis connected to the microprocessor. The microprocessor acquires the voltage, temperature, internal resistance, dynamic load voltage, dynamic discharge current and a dynamic discharge coefficient or dynamic discharge power or dynamic discharge energy of the battery. The microprocessor is connected to the communication chip. The system can monitor many kinds of parameters on line, is installed in adistributed installation way and realizes the online voltage equalization and the online high-frequency pulse anti-vulcanization maintenance.

Owner:NINGBO POWER SUPPLY COMPANY STATE GRID ZHEJIANG ELECTRIC POWER

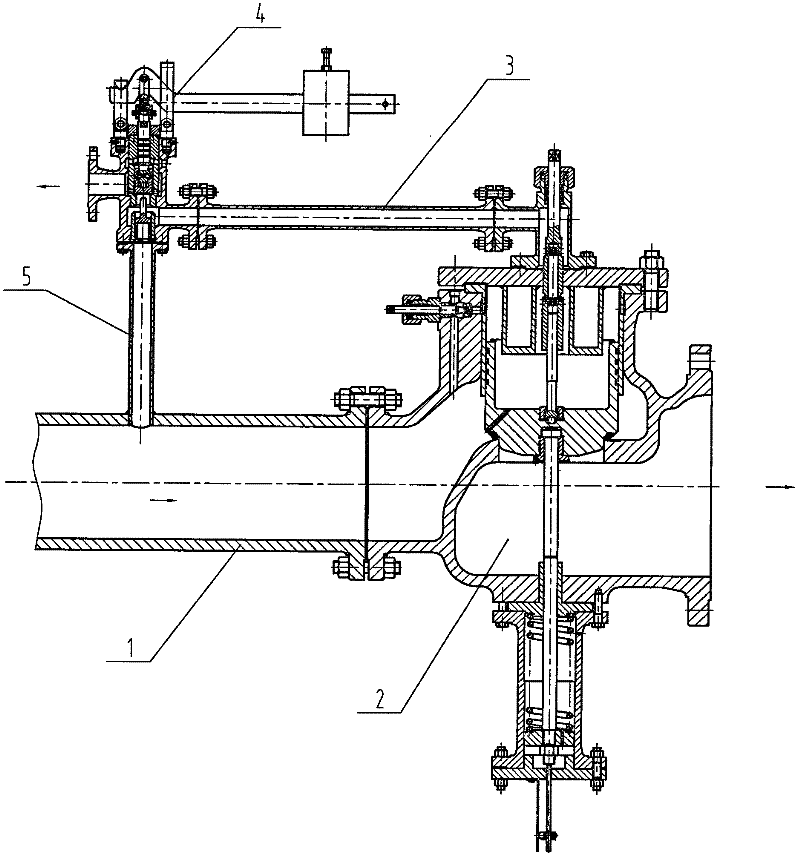

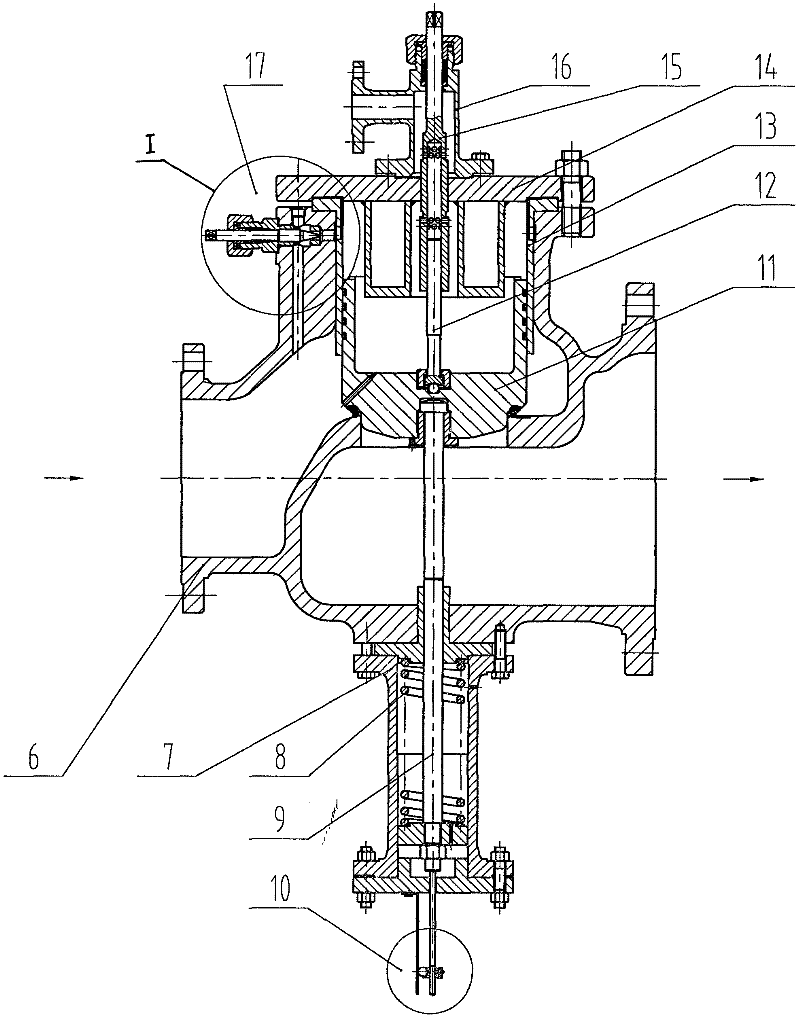

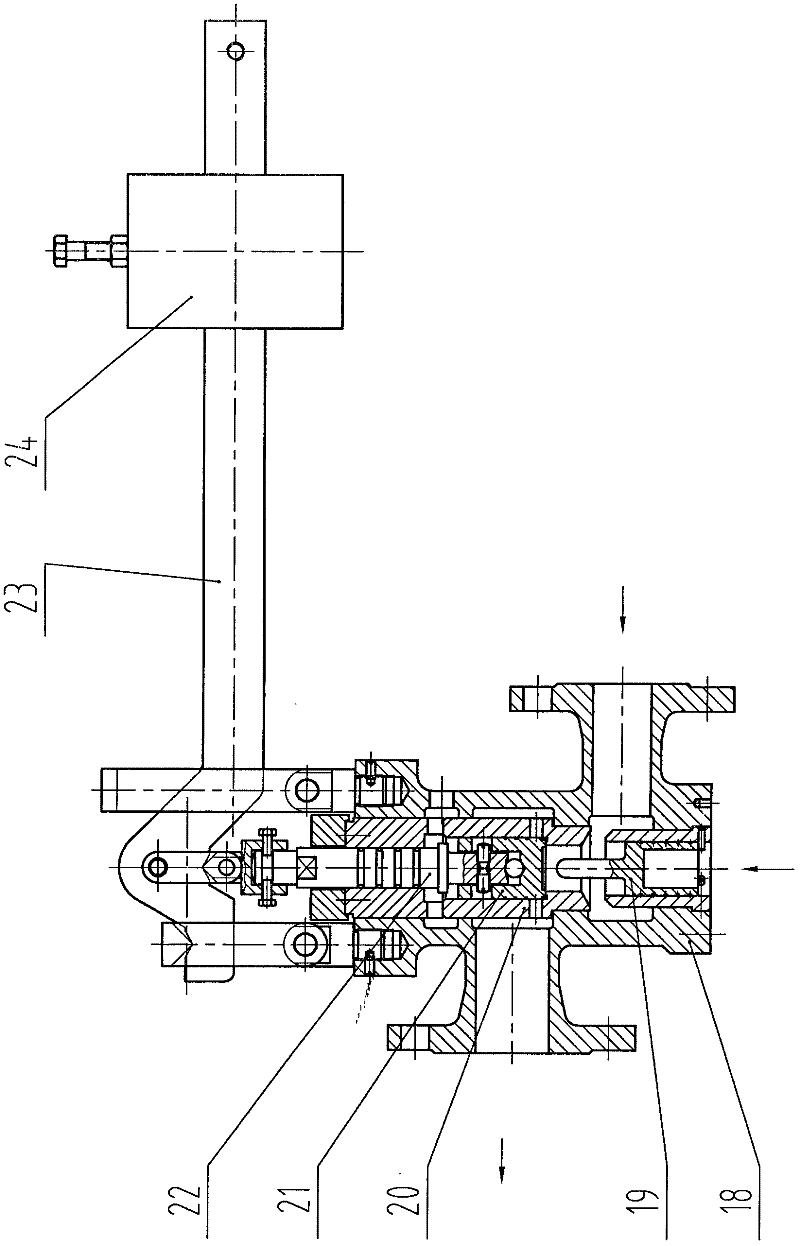

Air suction type safety valve

ActiveCN102313053AAdjust flow coefficientControl closing speedEqualizing valvesSafety valvesEngineeringPressure difference

The invention relates to an air suction type safety valve, which comprises a main valve and a pilot valve. Primarily, a piston chamber is formed between a valve flap of the main valve and a valve cavity as well as a valve cover on the side of a valve body inlet; the valve flap is provided with a small hole for communicating a valve body inlet passage with the piston chamber; the valve body is provided with a through hole for communicating the inlet passage thereof with the piston chamber; a flow adjuster is arranged on the through hole; an opening height adjusting thread sleeve is arranged between the valve cover and the piston chamber; a seal chamber which is communicated with a transverse inlet of the pilot valve is formed between the opening height adjusting thread sleeve and the valvecover; the center of the opening height adjusting thread sleeve is provided with an inner hole for communicating the piston chamber with the seal chamber; and opening height of the valve flap and main valve flow coefficient are adjusted by adjusting relative position of the opening height adjusting thread sleeve and an upper valve rod; and closing speed of the main valve and the opening and closing pressure difference are controlled by adjusting an adjusting needle of the flow adjuster. The valve has the advantages that the opening height, discharge coefficient, discharge time and opening andclosing pressure difference can be adjusted and the opening height can be observed at any time and the like, and the safety valve is suitable to be used for various medium pipelines and vessels.

Owner:YONGYI VALVE

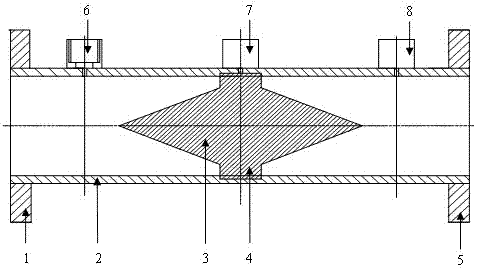

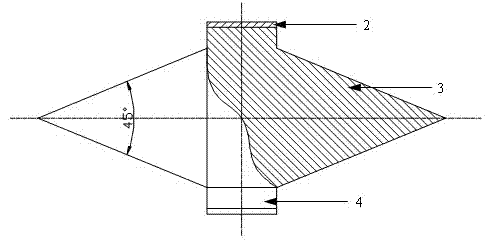

Full-symmetry double-cone flowmeter

InactiveCN102928028AShock resistanceHigh sensitivityVolume/mass flow by differential pressureDifferential pressureEngineering

The invention discloses a full-symmetry double-cone flowmeter. The full-symmetry double-cone flowmeter comprises a straight measurement pipe and a double-cone body, wherein an upstream pressure-taking port, a throat pressure-taking port and a downstream pressure-taking port are sequentially formed in the same axial section of the straight measurement pipe; the double-cone body consists of cone bodies at two ends and a middle cylinder body; three support column plates with the same thickness are arranged on the middle cylinder body at equal intervals along the circumference direction, and the length of each support column plate is equal to that of the middle cylinder; the double-cone body is coaxially arranged in the straight measurement pipe; the throat pressure-taking port is positioned between the two support column plates of the double-cone body and also positioned in the middle of the length of the double-cone body; and the cylinder part of the double-cone body is closely matched with the straight measurement pipe. The full-symmetry double-cone flowmeter can acquire a stable discharge coefficient under high Reynolds number, and has the characteristics of causing small pressure loss, being good in repeatability, requiring a short straight pipe section and the like. Double-differential pressure signals obtained by the three pressure-taking ports also can be applied to two-phase flow parameter measurement.

Owner:ZHEJIANG MEASUREMENT SCI RES INST

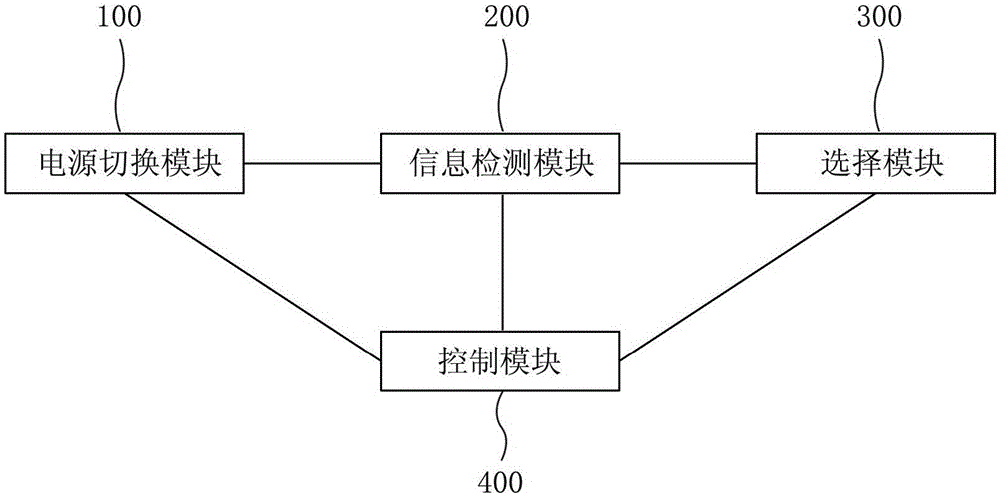

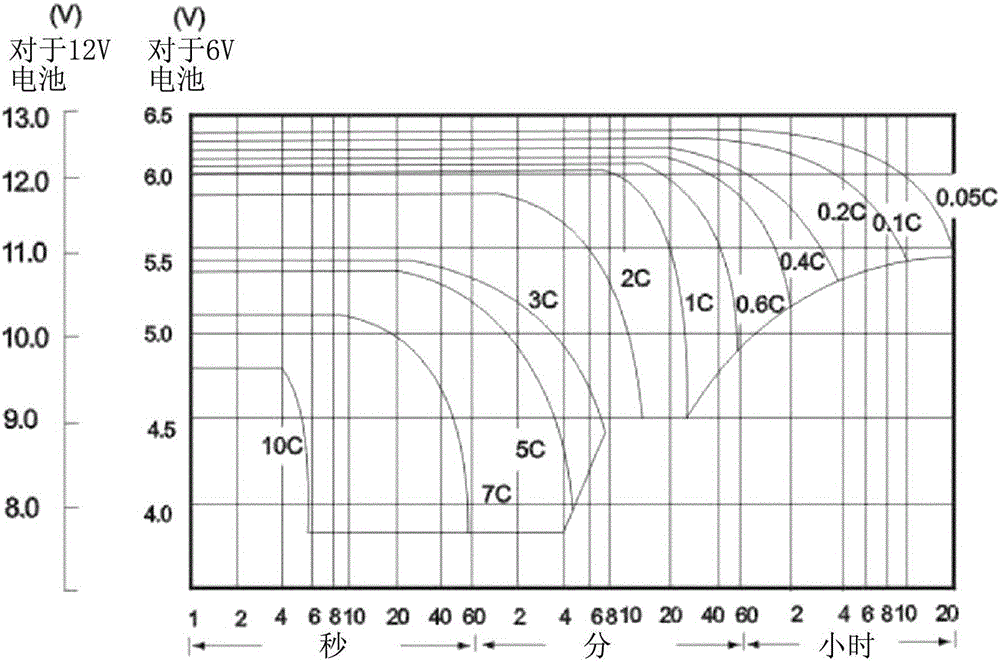

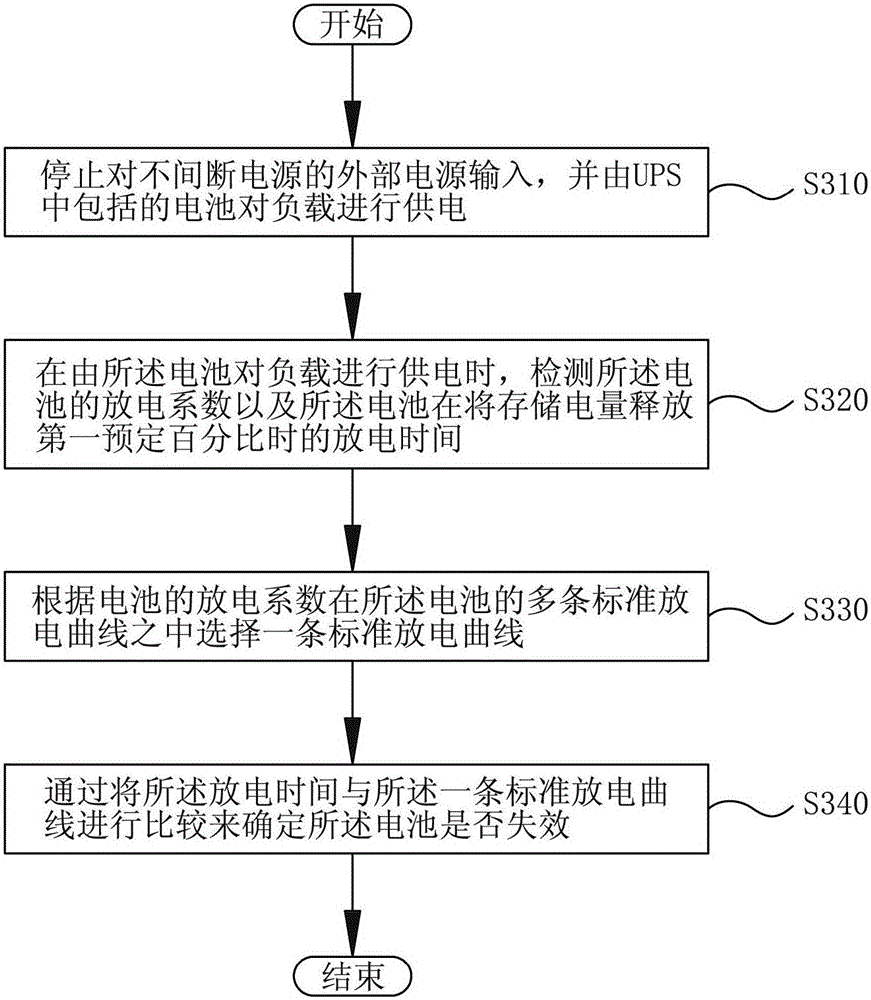

Method and apparatus for monitoring battery in uninterruptible power supply

ActiveCN106501735AAvoid downtimeLow failure rateProgramme controlComputer controlElectricityElectrical battery

The invention provides a method and apparatus for monitoring a battery in an uninterruptible power supply. The method comprises: external power inputting to an uninterruptible power supply is stopped and a battery in the uninterruptible power supply provides power for a load; when the battery provides power for the load, a discharge coefficient of the battery and discharge time of the battery for releasing the stored electricity by a first predetermined percentage are detected; according to the discharge coefficient of the battery, one standard discharge curve is selected from a plurality of standard discharge curves of the battery; and the discharge time and the standard discharge curve are compared to determine whether the battery fails to work.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Dry sprinkler

A dry sprinkler for a fire protection system. The preferred dry sprinkler has a metallic disc annulus positionable within a passageway to skew a central axis of a face of the metallic disc annulus with respect to a longitudinal axis of the dry sprinkler so that an expected minimum flow rate based on a rated discharge coefficient is provided. The dry sprinkler operates to provide an expected flow rate over a range of start pressures. The expected flow rate is based on a K-factor rating. The dry sprinkler provides an acceptable level of fluid flow rate from the expected flow rate based on the K-factor for a range of start pressures.

Owner:TYCO FIRE PRODS LP

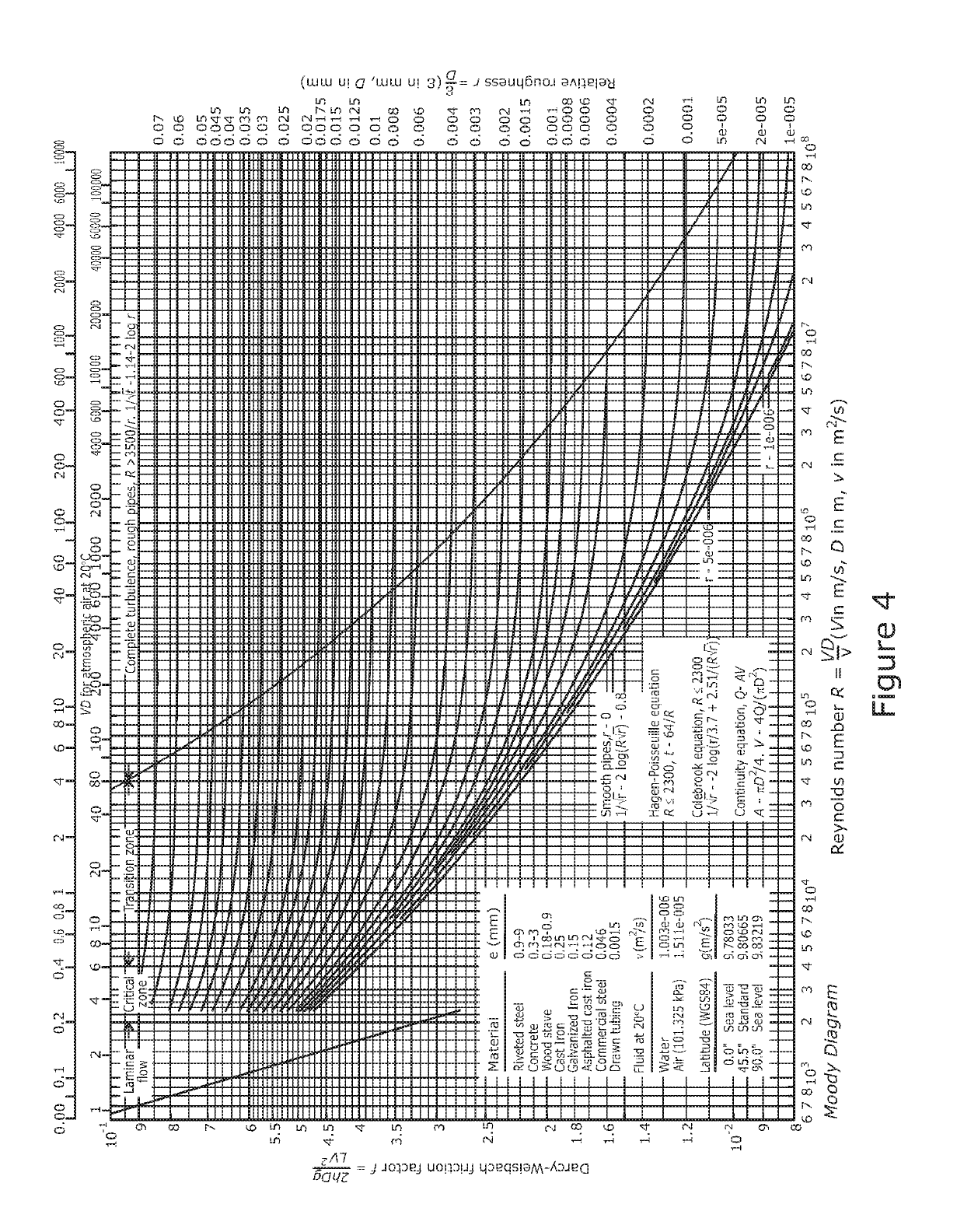

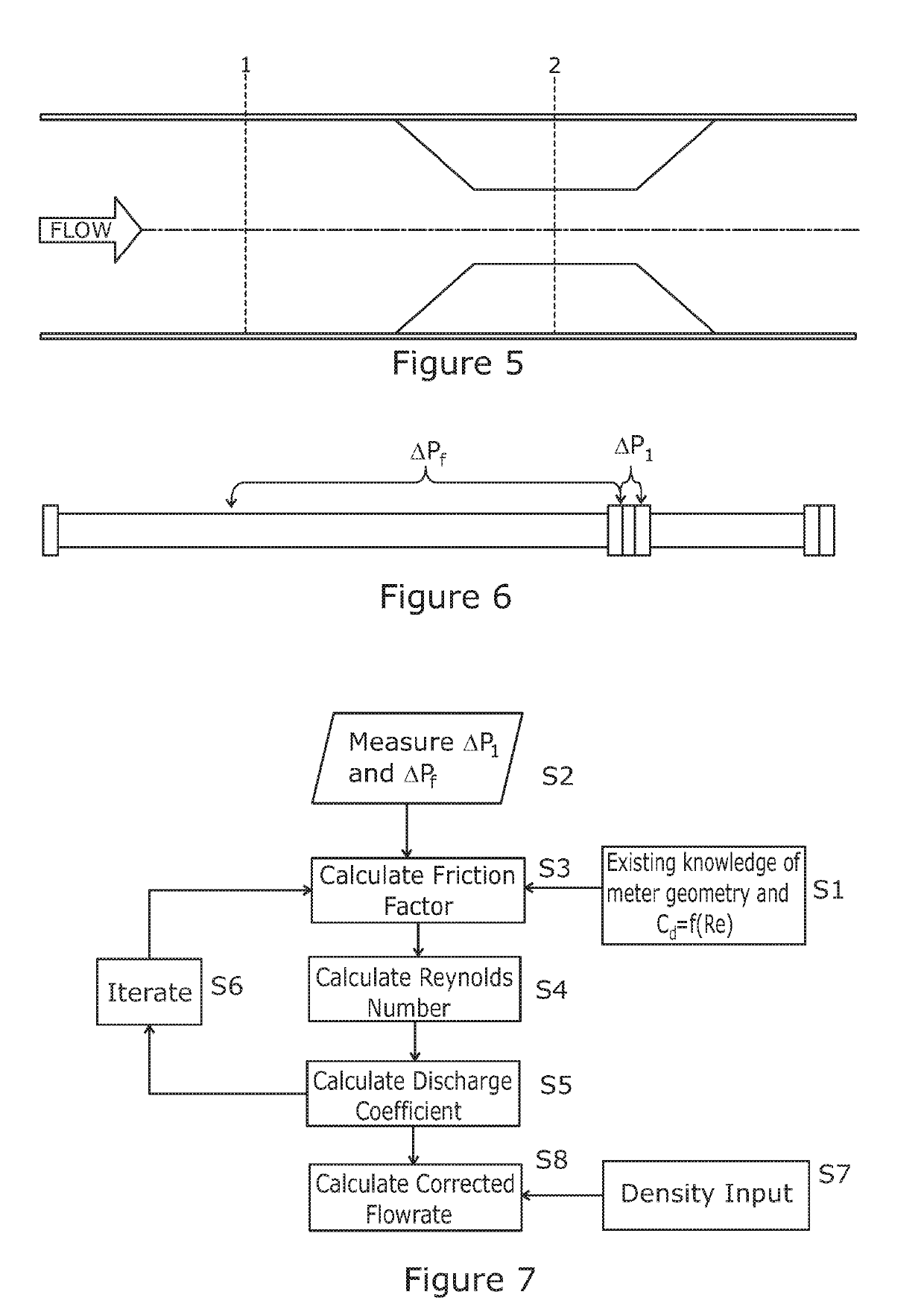

Improvements in or relating to the monitoring of fluid flow

ActiveUS20190310122A1Easy to calculateEnabling useVolume variation compensation/correction apparatusTesting/calibration for volume flowDifferential pressureVolumetric Mass Density

The present invention provides a method and apparatus for the measurement of a pressure differential across a differential pressure flow meter ΔP1 and the line pressure drop due to friction ΔPf along a length L of pipe. Subsequently, the quantity (formula) is calculated, enabling the inline calculation of multiple properties of the flow. Calculated flow properties include friction factor, Reynolds number, discharge coefficient, density, viscosity, and corrected flowrate. The present invention further relates to a method of calibration of a differential flow meter and a calibration apparatus for a differential flow meter utilising the same principles.

Owner:COVENTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com