Crossing spray orifice type injection nozzle of internal combustion engine

A technology of fuel injectors and internal combustion engines, applied in fuel injection devices, mechanical equipment, engine components, etc., to achieve the effects of improved emission performance and power performance, increased internal flow disturbance, and increased turbulence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

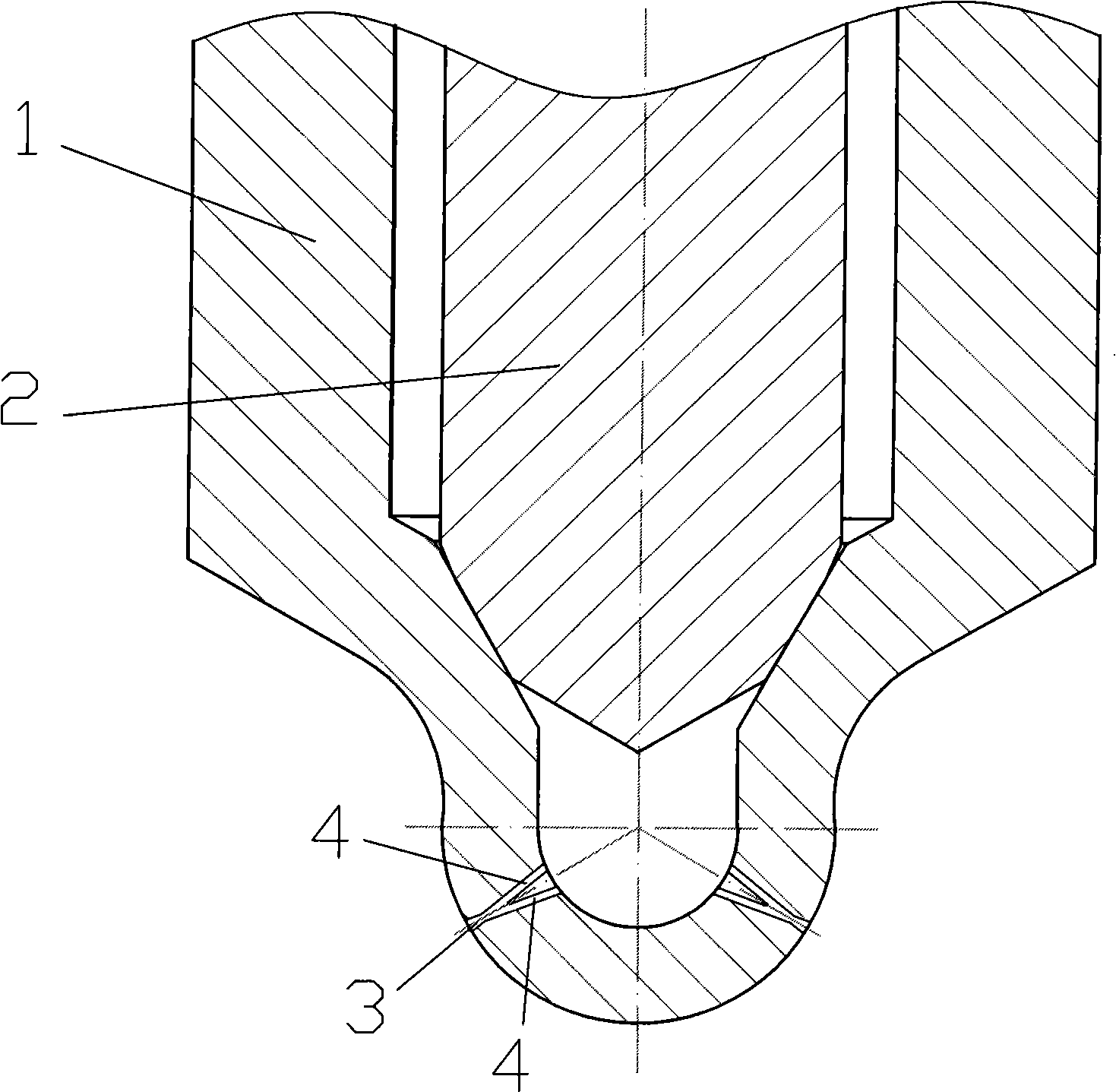

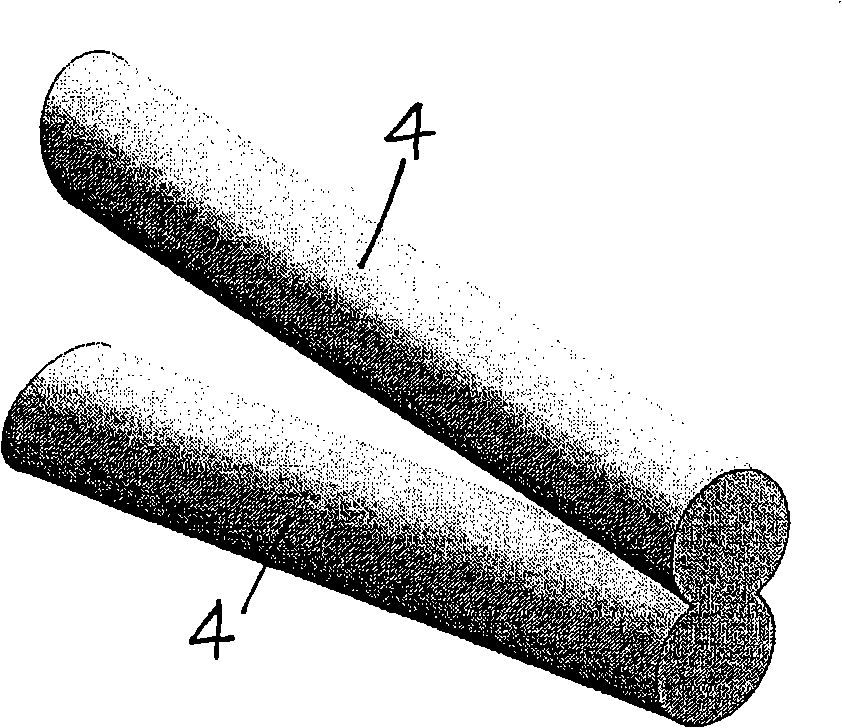

[0023] exist figure 1 In the example shown, the cross-spray nozzle is composed of a needle valve body 1 and a needle valve 2, and 4 to 6 cross-spray holes 3 are set on the head of the needle-valve body 1, and each cross-spray hole 3 is formed by crossing and converging 2 to 4 sub-nozzles 4 .

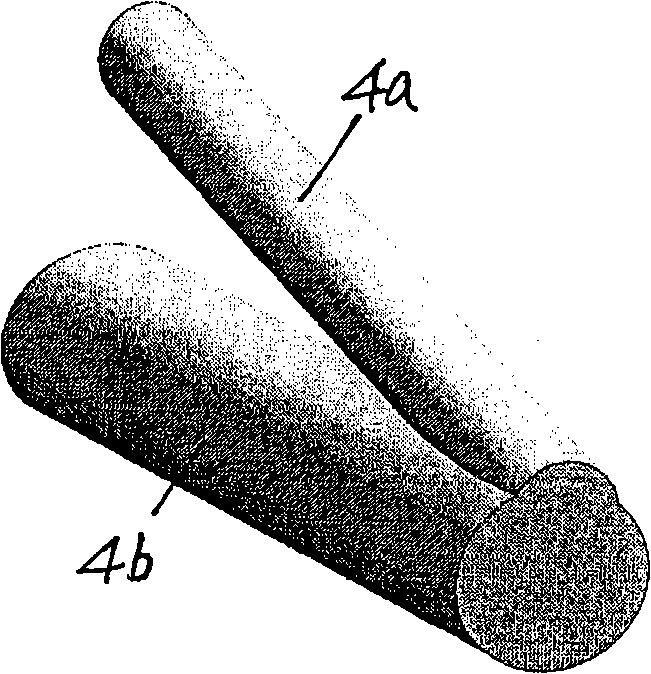

[0024] The cross nozzle hole 3 can have many different structural forms: the combination of the nozzle hole outlet shape factor nozzle hole 4 is different, and there may be many different shapes, such as Figure 2-12 as shown, Figure 2-10 A crossed orifice with a non-circular exit shape is shown in , Figure 11-12 Intersecting orifices with circular exit shapes are shown.

[0025] Figure 2-5 Four implementations of cross nozzle holes formed by the intersection of two sub nozzle holes are given, among which figure 2 The nozzle holes are equal in diameter, and the center lines are coplanar; image 3 Sub nozzle holes with different diameters, the center lines are coplanar; Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com