Gas injection type slurry pipe-line transportation method and device

A technology for mud pipelines and gas supply devices, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as easy blockage of pipelines and sediment deposition, and achieve enhanced sand transport capacity and sand carrying capacity. , the effect of increasing the flow rate along the way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

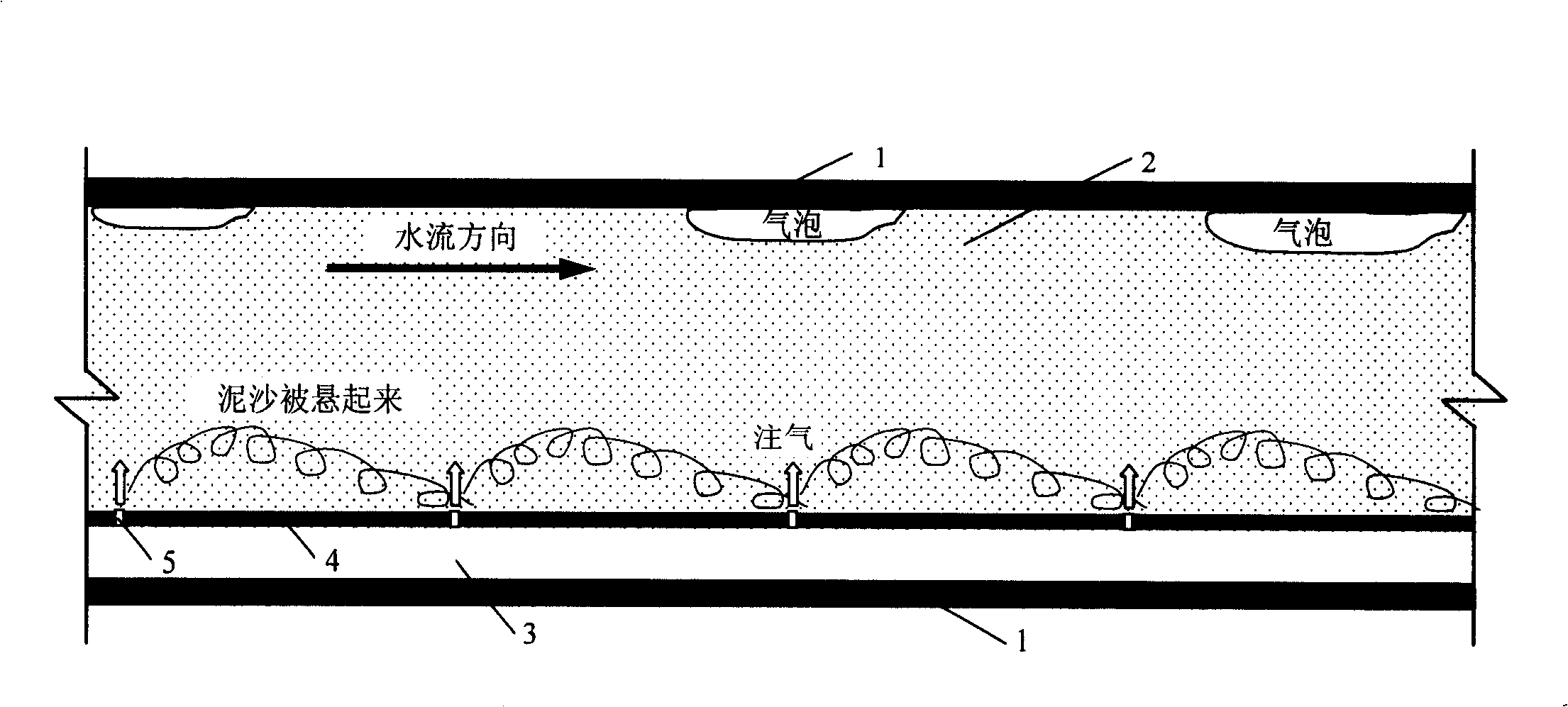

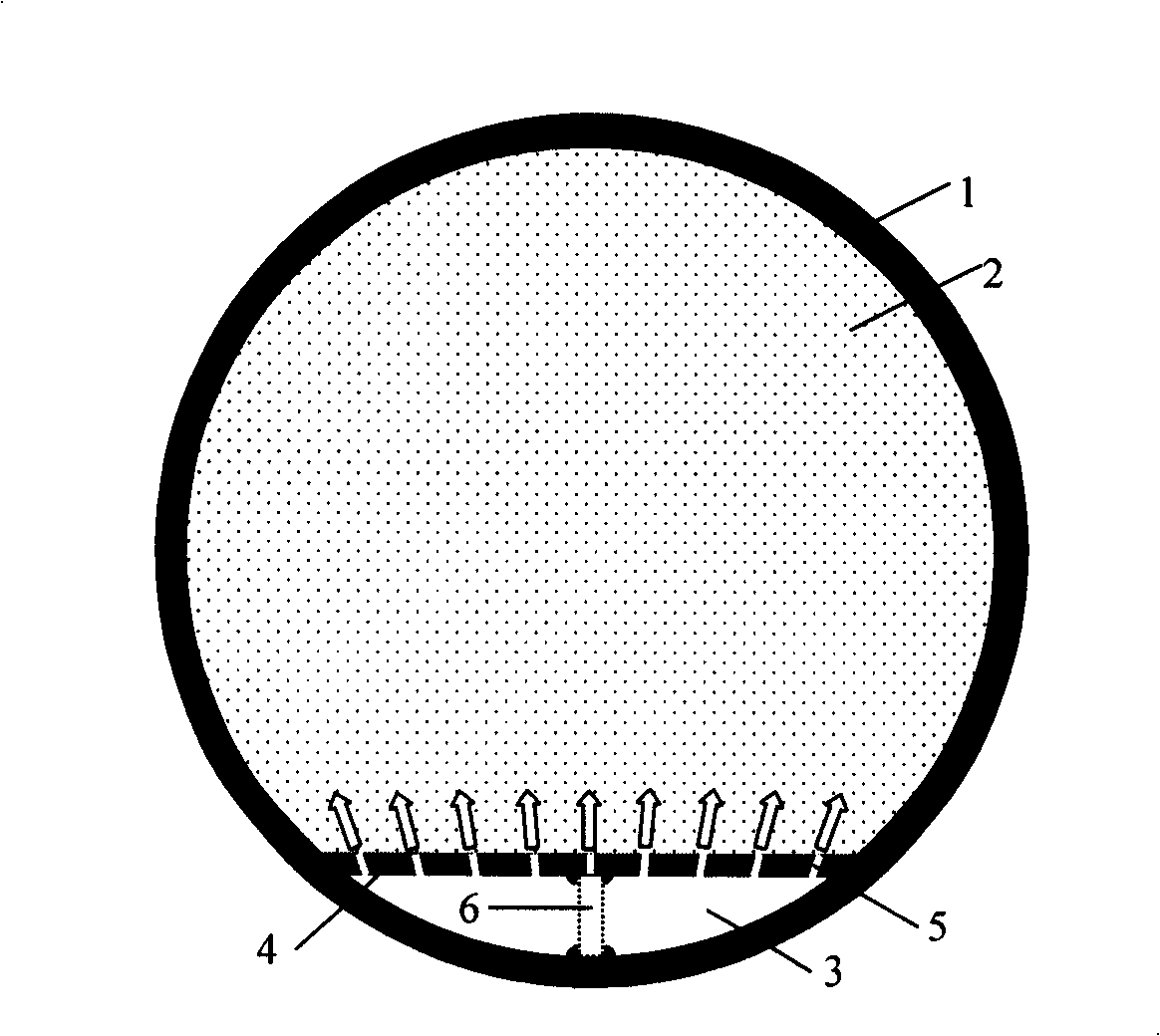

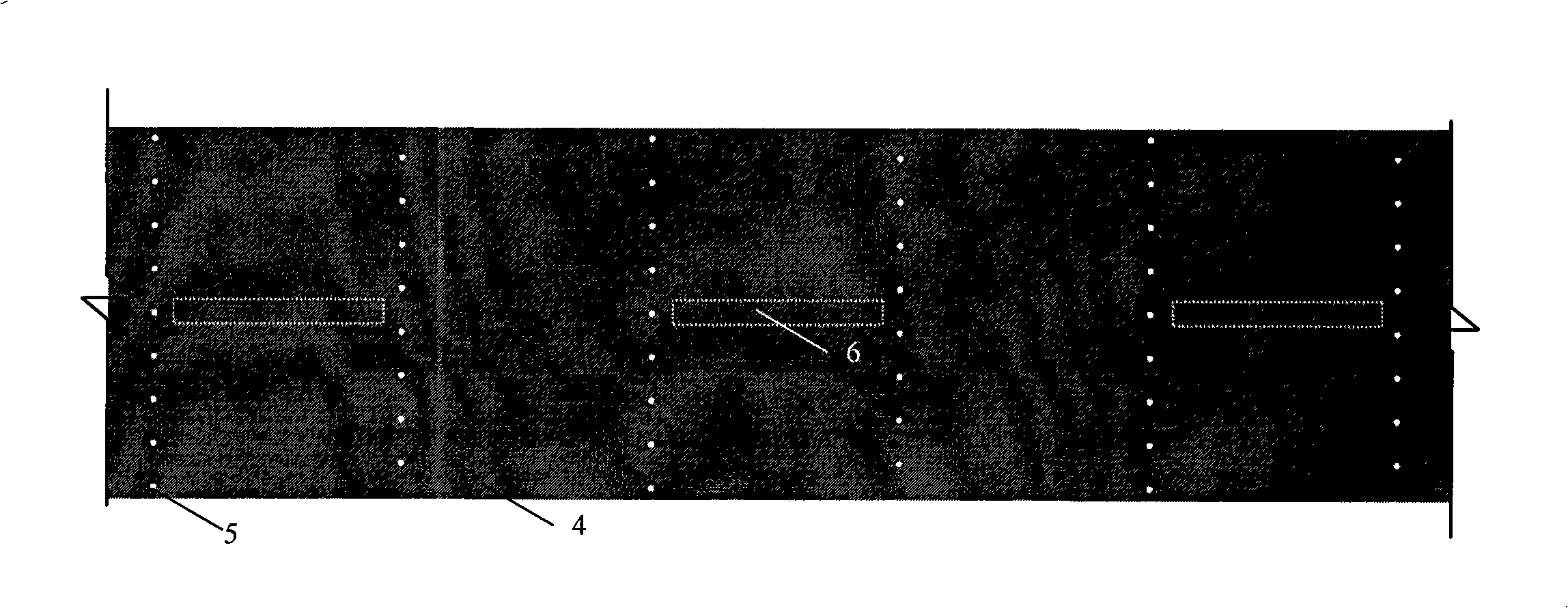

[0018] The air-injection type mud pipeline conveying device of the present invention is composed of two parts, i.e. the gas injection device and the traditional mud pipeline conveying device, the key of which is the refitting of the conveying pipeline. Such as Figure 1~3 As shown, there are: 1. Sediment conveying pipe; 2. Sediment fluid; 3. Air supply chamber; 4. Partition;

[0019] figure 1 The operating principle of the gas injection mud pipeline method is illustrated. For the traditional mud pipeline transportation method, the farther away from the mud pump, the water flow will gradually become stable, and the turbulence intensity will gradually decrease, and the relatively coarse-grained sediment will gradually drop to the bottom fluid. It moves in an approximate state of mass transfer, and even temporarily settles down, sometimes moving forward slightly. The higher the concentration of coarse-grained sediment at the bottom of the fluid in the pipe, the greater the fri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com