Patents

Literature

192 results about "Spray atomization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

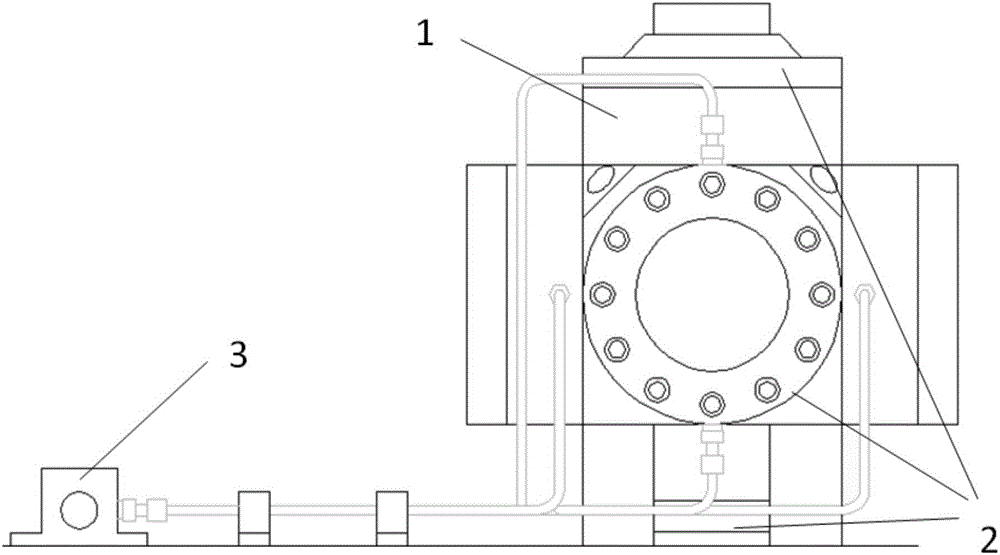

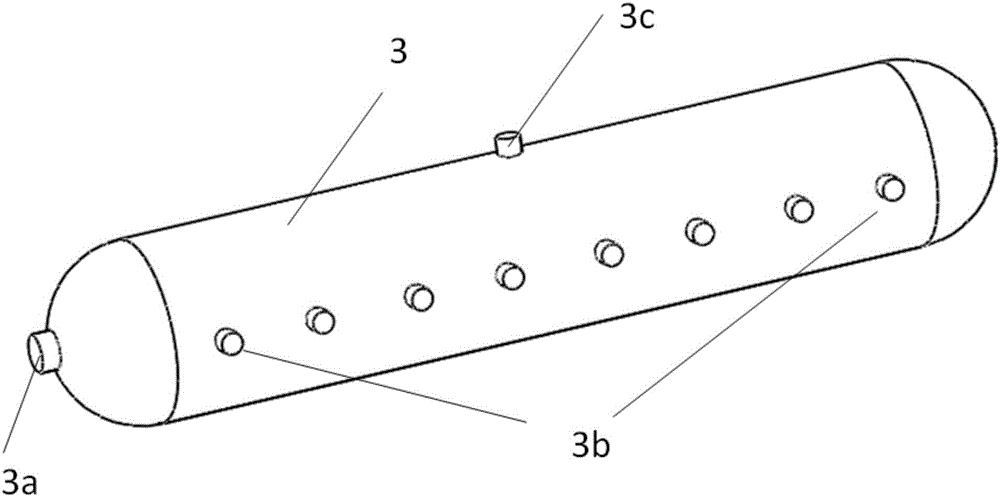

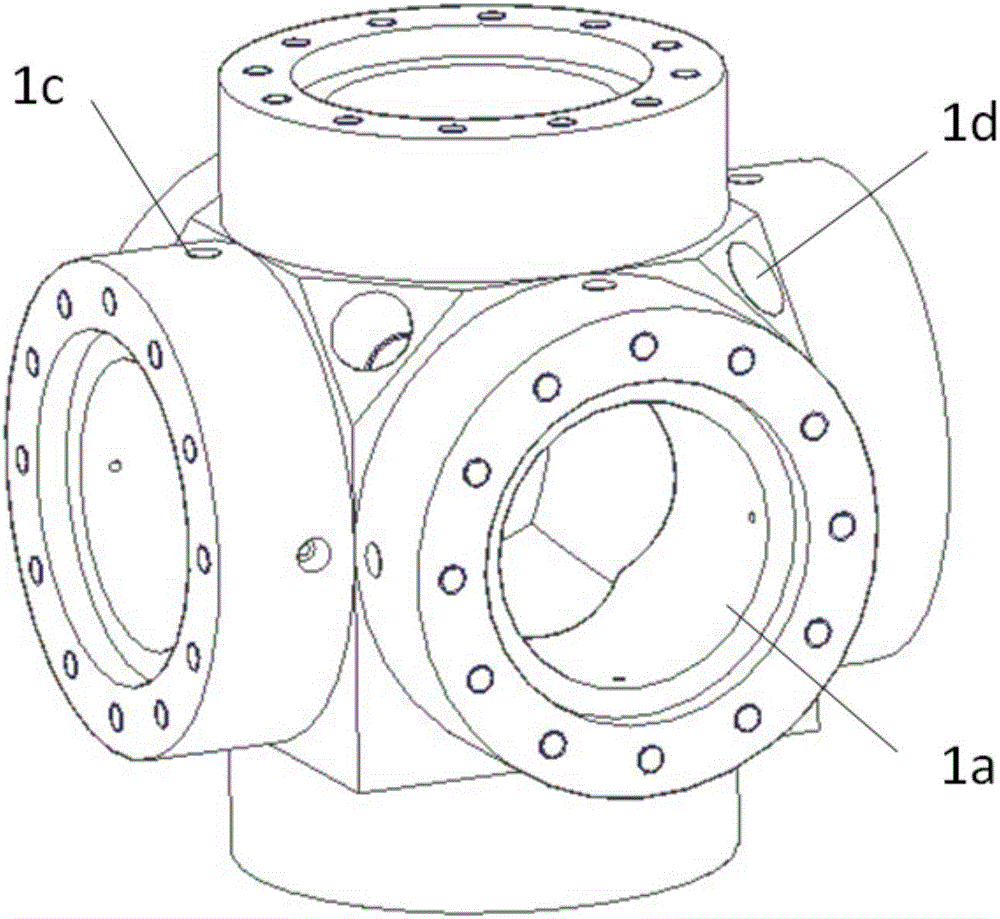

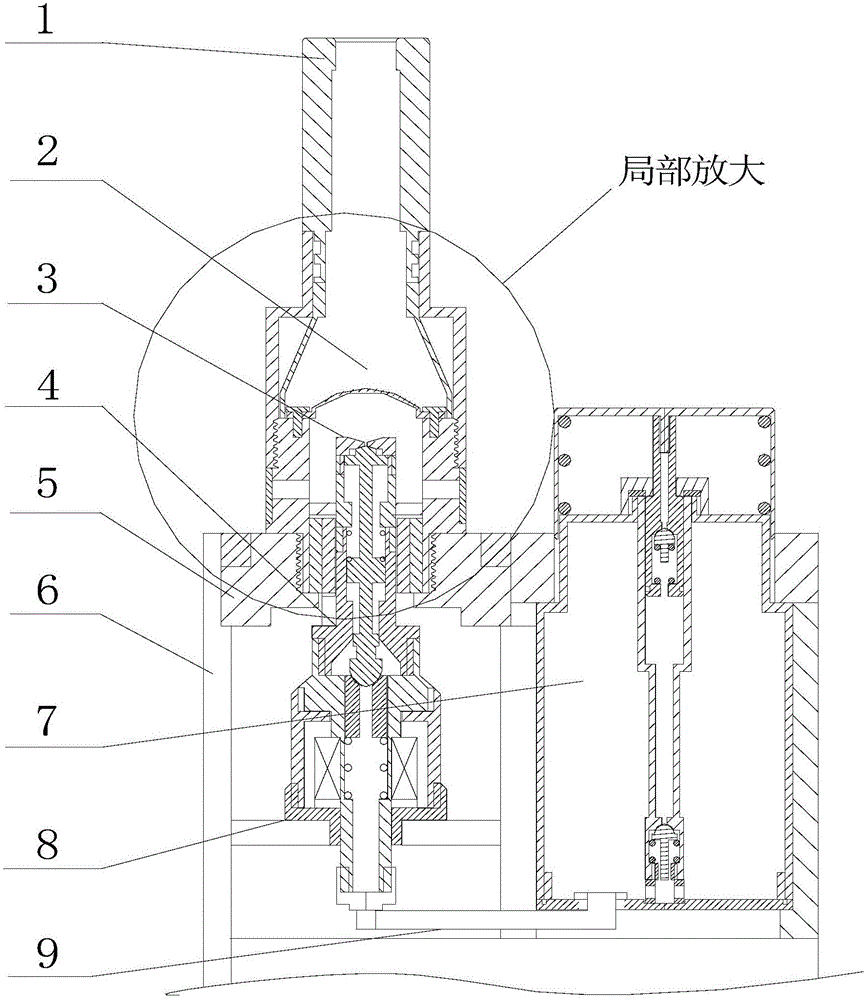

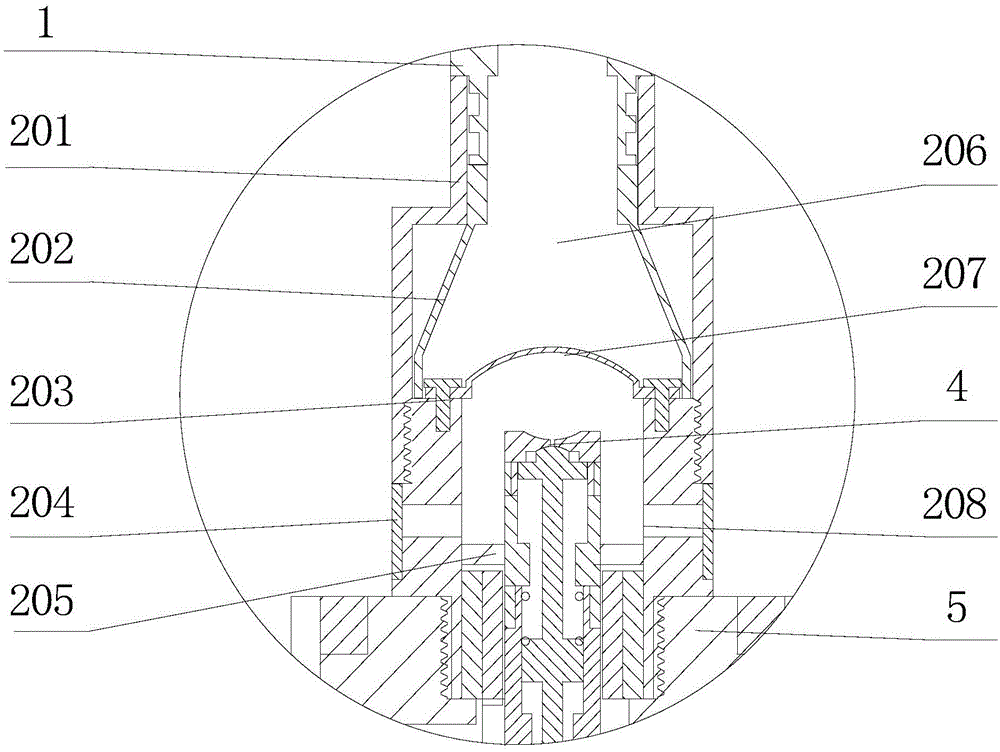

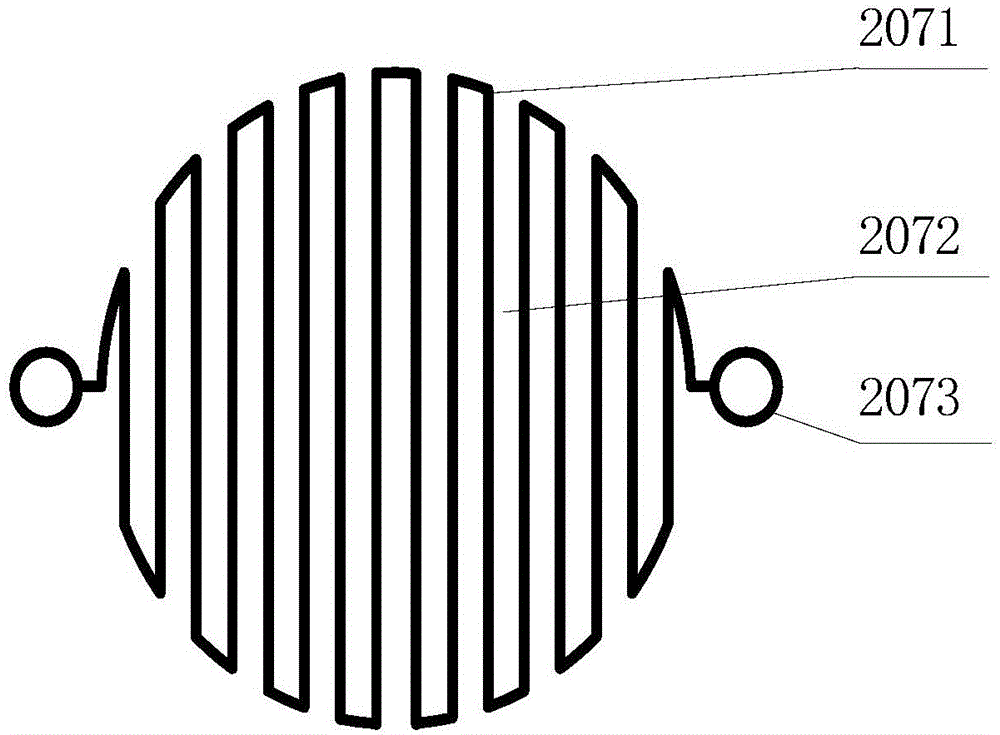

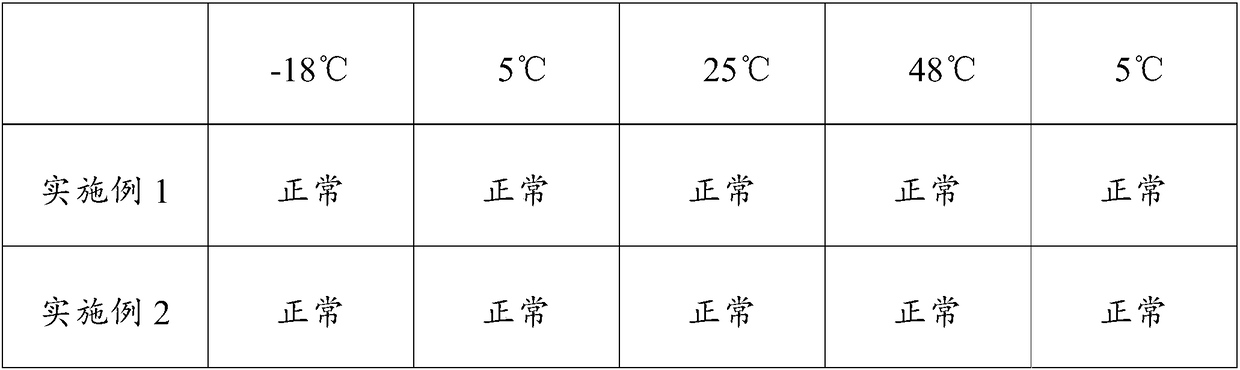

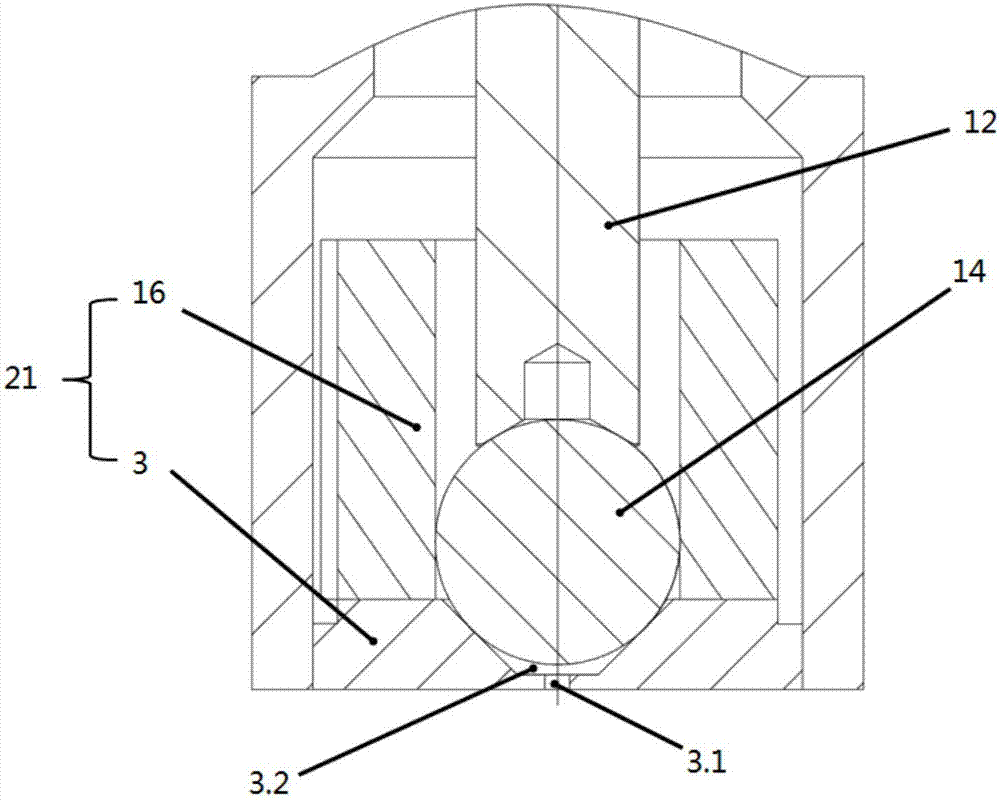

Functional spraying and combustion visualization measuring constant volume bomb

ActiveCN106441912AMeet the design requirementsCompact structureInternal-combustion engine testingEvaporationInlet pressure

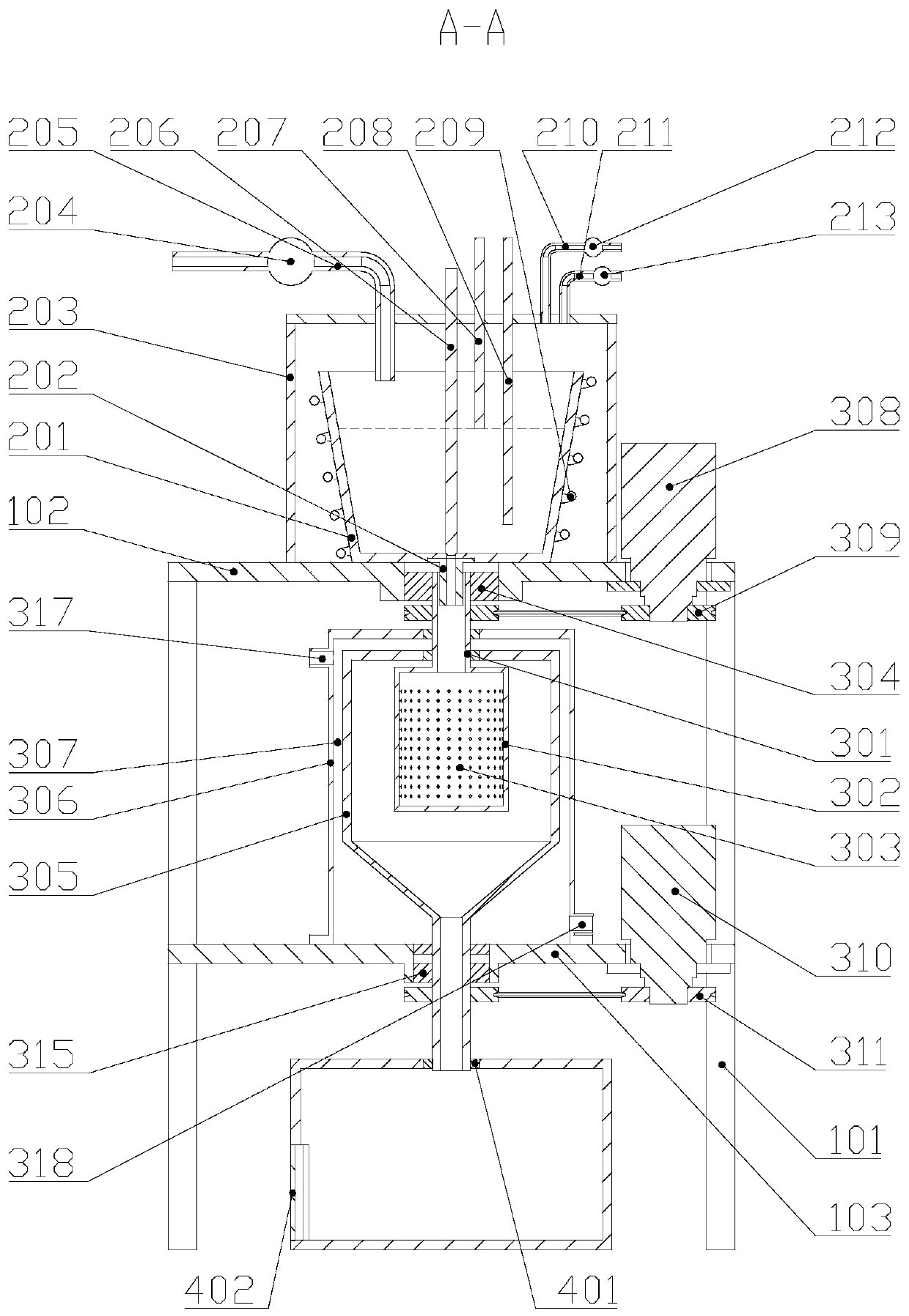

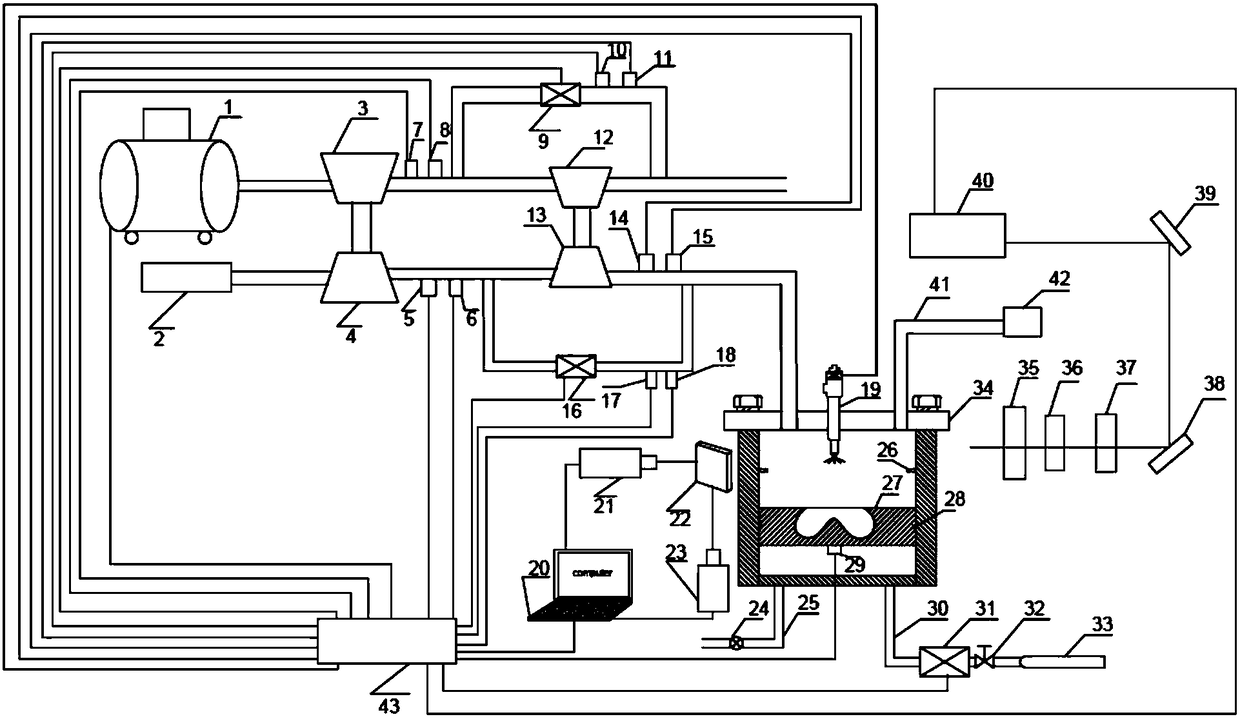

The invention provides a functional spraying and combustion visualization measuring constant volume bomb. The constant volume bomb includes a bomb body and 6 windows provided on the bomb body. The axes of all windows intersect at the center of the constant volume bomb so as to form a measurement region. The windows can be provided with adaptive covers having different functions. The constant volume bomb is designed to have multiple sealing, such that the constant volume bomb can withstand extreme pressure and temperature loads, and the large range of warm pressing can be adjusted. The constant volume bomb is designed to have adaptors which ensure the constant volume bomb can use various types of sensors. The bomb body is provided with a plurality of air inlet guide holes thereon, which can ensure stabilization of air inlet pressure and keep the measurement region unaffected, and also keep quartz windows from being polluted by oil mist and combustion products, thus achieving on-going measurement. According to the invention, the constant volume bomb can provide flexible light path arrangement for one or a group of multiple measurement technologies of shadow / schlieren, laser induced flourescense, particle imaging velocity measurement and spectrum temperature measurement, etc. The constant volume bomb has tight structure, can research spray atomization, evaporation, air blending, gas mixture distribution, combustion and process product characteristics, etc, has a wide range of measurement parameters, and has universality.

Owner:HARBIN ENG UNIV

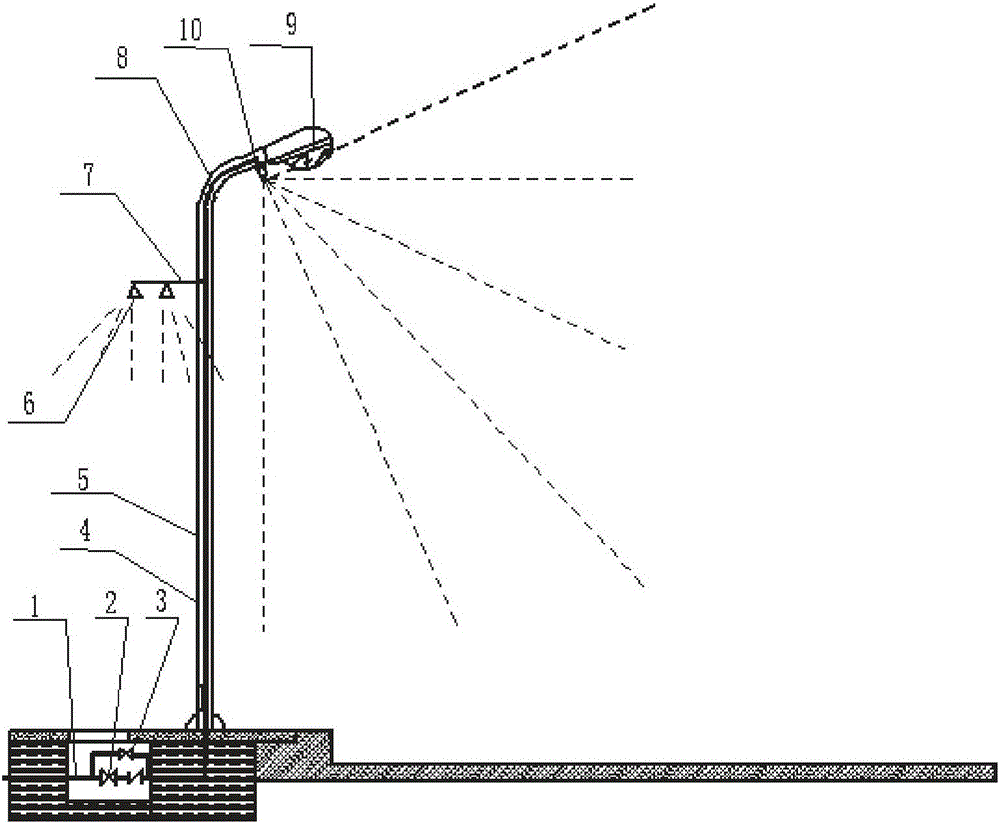

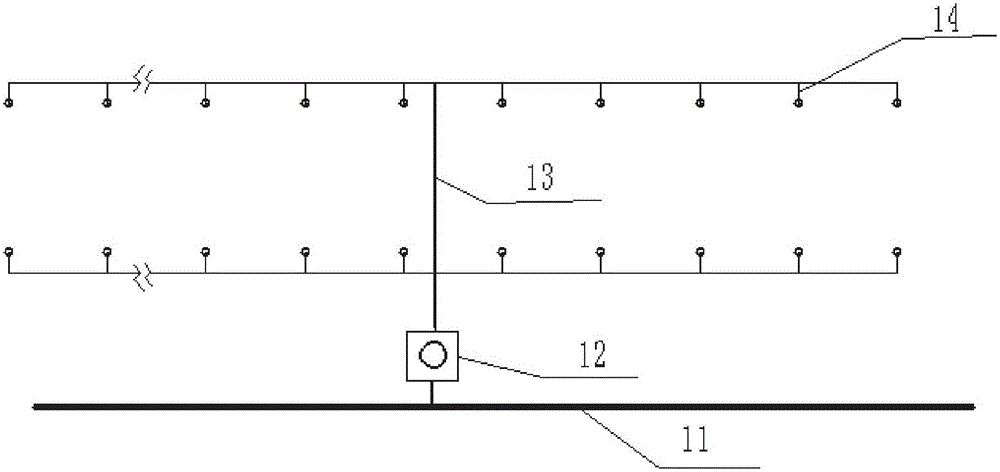

Urban intelligent high pole street lamp spraying system

InactiveCN105757562ASimple structureReduce construction costsMechanical apparatusGas treatmentParticulatesAutomatic control

The invention discloses an urban intelligent high pole street lamp spraying system.The urban intelligent high pole street lamp spraying system comprises a high pole street lamp, a spraying atomization device, a water supply pipeline system and an automatic control system.The spraying atomization device is used for producing atomized water and comprises at least one spray nozzles arranged on the upper portion of the high pole street lamp; the water supply pipeline system comprises a vertical water supply pipe, an underground water supply pipe and a water inlet pipe network; the automatic control system comprises a display device, a controller, a first signal input module, a second signal input module, a third signal input module and a pressure sensor set.The intelligent high pole street lamp spraying system is simple in principle structure, low in construction cost and high in automation degree.Corresponding spraying equipment is additionally installed on an existing urban street lamp to spray atomized water to urban roads, floating diffusion of particulate matter in air is effectively restrained, urban microclimate is improved, and the air quality is improved.Meanwhile, water sprays are mixed in the air, people feel cool and comfortable, the urban temperature can be decreased within a small range, and the urban heat island effect is relieved.

Owner:JIANGSU UNIV

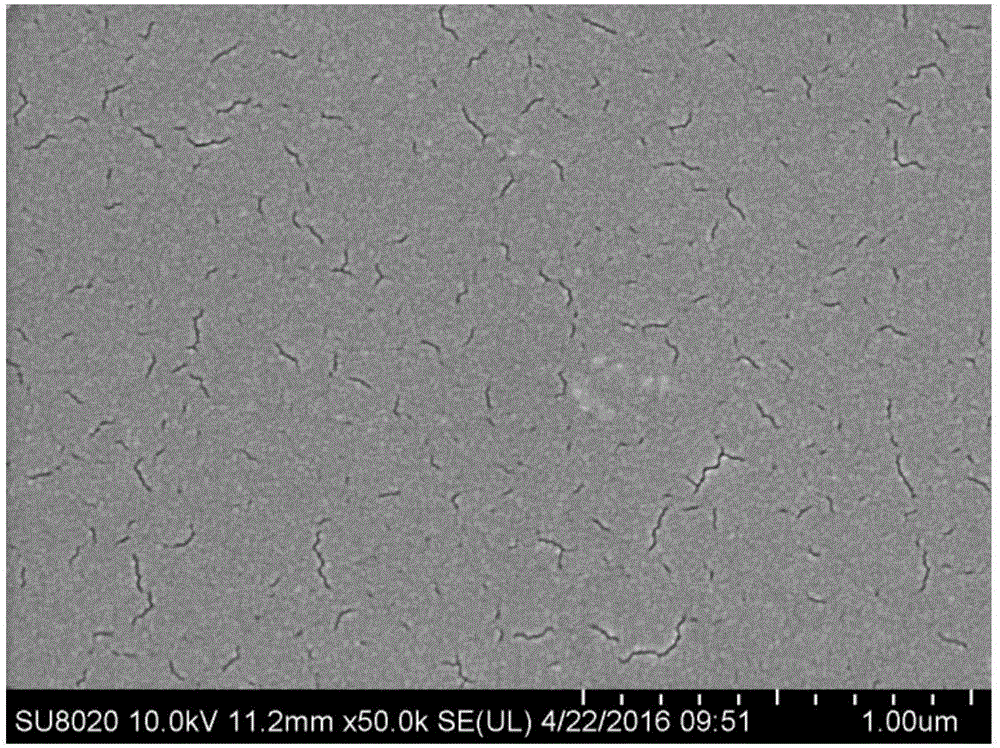

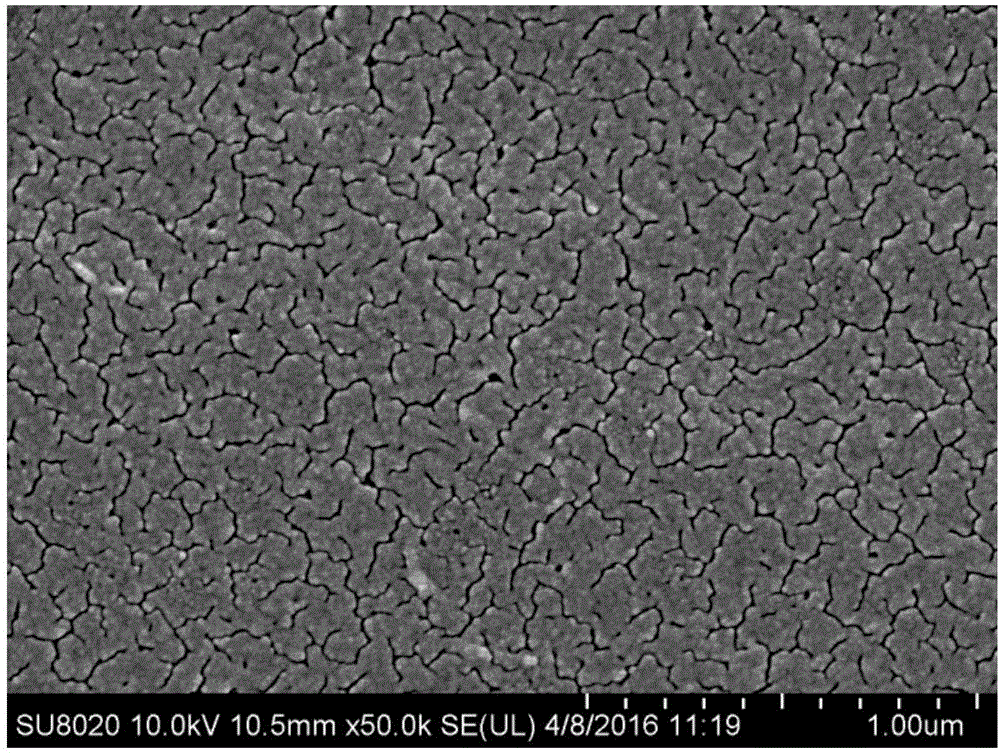

Method for preparing ultra-thin film through micro-phase diffusion control interface polymerization

InactiveCN107519769ASemi-permeable membranesWater/sewage treatment bu osmosis/dialysisCross-linkFiltration

The invention discloses a method for preparing an ultra-thin film through micro-phase diffusion control interface polymerization and belongs to the technical field of membrane separation. The method comprises the following steps: firstly, spraying a layer of an active amino monomer on a porous support, further spraying a layer of an active acyl chloride monomer, enabling the two components to react to generate a polyamide layer, and repeatedly spraying to generate multiple polyamide separation layers; soaking a prepared membrane into a glutaraldehyde solution, and performing a cross-linking reaction with unreacted amino to form an internal network structure, thereby improving the density grade and the structural stability of the membrane. The method is a novel interface polymerization method by dispersing a bulk phase reaction solution into micro droplets, converting bulk phase diffusion into micro phase diffusion and eliminating later diffusion process. Through a spraying atomization function, a reaction solution is dispersed into micron-order droplets, and the bulk phase diffusion is converted into micro phase diffusion. The sizes of the droplets are at a micron grade, and reaction monomers in the droplets can be completely reacted in the bulk phase diffusion process. When being applied to the field of nano filtration, the prepared membrane has super-high flux and a relatively high retention rate.

Owner:BEIJING UNIV OF TECH

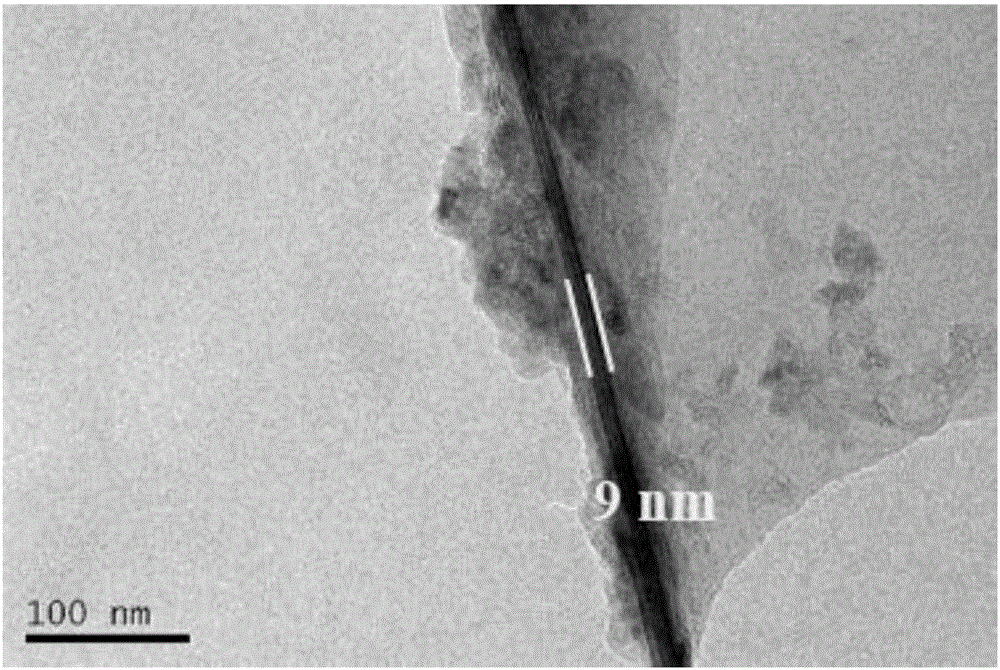

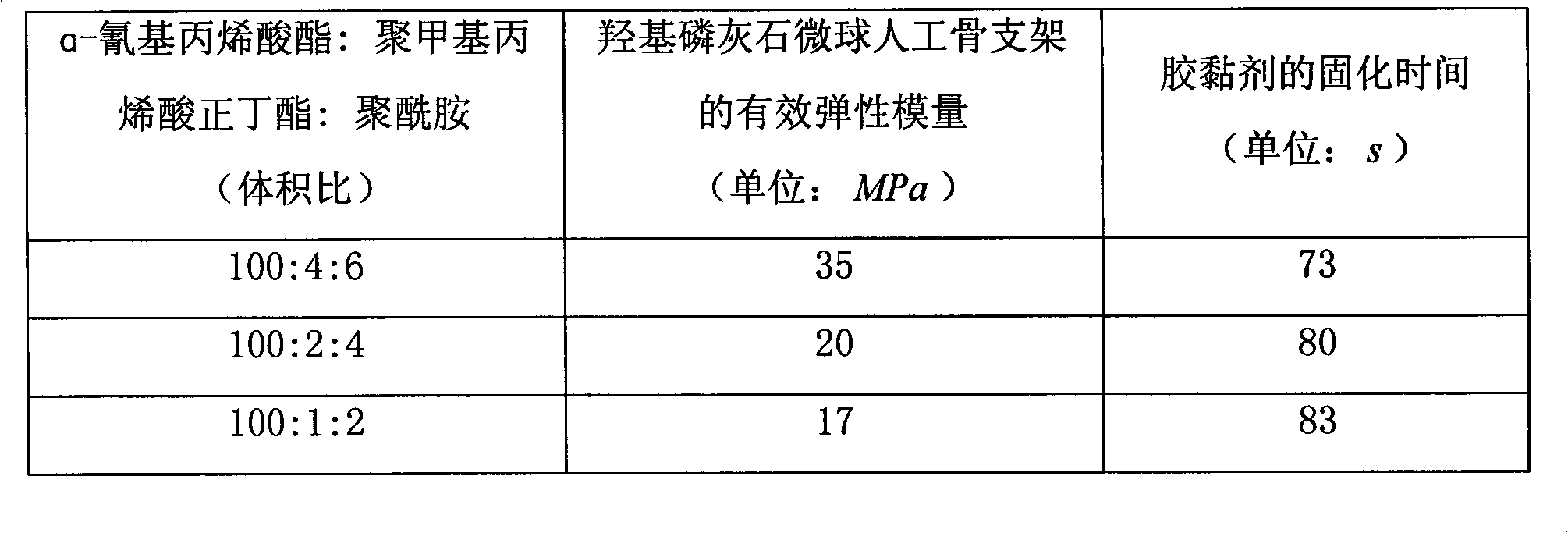

Preparation method of artificial bone scaffold of porous bioceramic microspheres

The invention discloses a method for preparing an artificial bone scaffold of porous bioceramic microspheres. A three-dimensional CAD model established according to individual characteristics is imported into a three-dimensional printer, and the three-dimensional printer sprays biological adhesives to realize the preparation of bioceramics. In order to overcome the disadvantages of pollution and poor mechanical properties due to sintering in the preparation process of the prior art porous ceramic stent, the present invention provides an improved bio-adhesive. By controlling the atomization and spraying parameters, different proportions of bio-adhesive, The curing accelerator and the thickening and toughening modifier are fully mixed to achieve the effect of controllable mechanical properties and controllable curing time. The improved adhesive has the advantages of high bonding strength, high toughness and good compatibility with human body fluids, and avoids sintering during the preparation process. The invention is made by a rapid prototyping method, which reduces the cost and time of making molds, improves the manufacturing efficiency and reduces the manufacturing cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

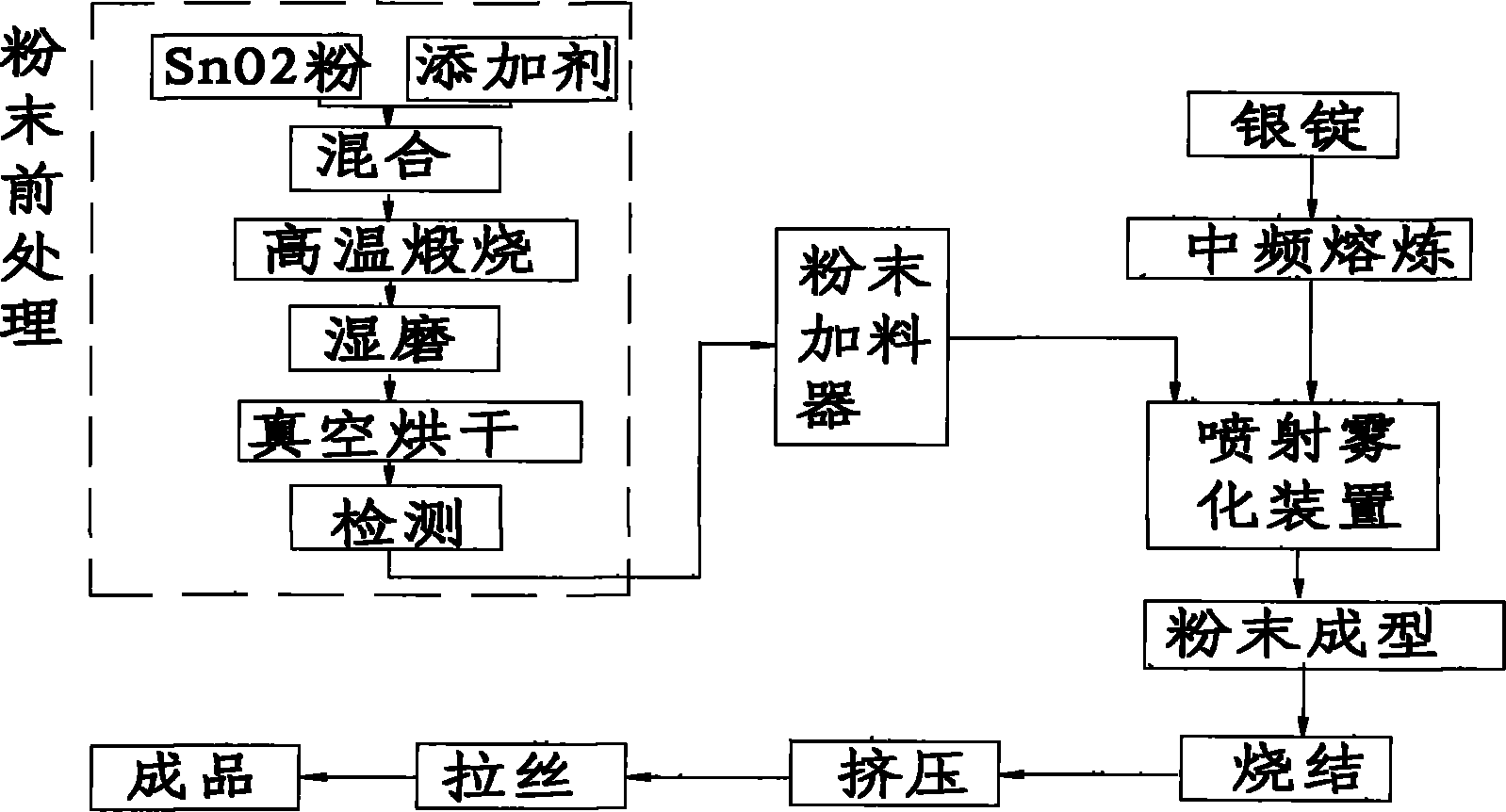

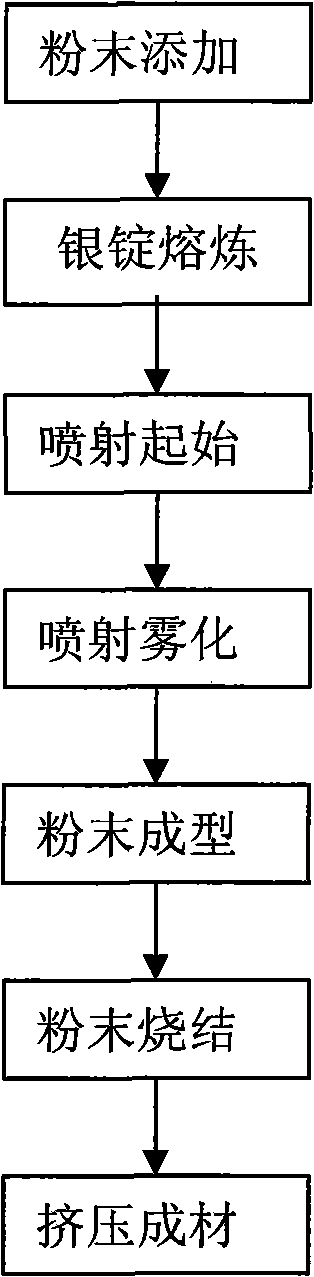

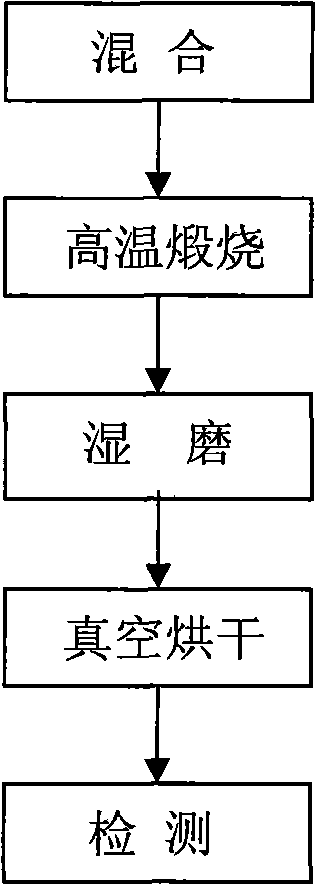

Spray atomization technology of silver tin oxide material

ActiveCN101798641AEvenly distributedExcellent electrical performanceElectric switchesLow voltageSpray atomization

The invention discloses a spray atomization technology of a silver tin oxide (SnO2) material, which comprises the following steps: a powder adding step, a silver ingot smelting step, a spray initiation step, a spray atomization step, a powder shaping step, a powder sintering step and an extrusion material forming step. In addition to the pretreatment process of an SnO2 powder, the production cycle of each batch is only 3 to 4 days, and therefore, the capital turnover speed of the production process is obviously increased, and meanwhile, precious metals are not used as additives, and therefore, the production cost is obviously reduced. After the SnO2 powder used by the invention is pretreated, the beneficial additives are dissolved in the SnO2 powder in a solid state instead of a silver matrix, and thus, the wettability of the SnO2 powder and silver is well improved, and therefore, the uniform distribution of the SnO2 powder in the silver matrix can be ensured, and meanwhile, the electrical property of low-voltage apparatus can be ensured; the silver tin oxide (SnO2) material can be easily processed into wires and sheets, and simultaneously, the cracking phenomenon can not be generated when the wires are processed into rivets, and therefore, the yield is obviously increased. All production processes of the invention are friendly to the environment and do not generate the harmful three wastes.

Owner:NINGBO HANBO PRECIOUS METAL ALLOY

Electronic cigarette device

ActiveCN105011379ANo leakageNo more problems with changing coilsTobacco devicesSpray nozzleEngineering

The invention discloses an electronic cigarette device. The electronic cigarette device comprises a cigarette liquid supplying device, a cigarette liquid atomizing device and an atomized cigarette mist sucking-out device. The cigarette liquid supplying device is a cigarette liquid pressurizing supplying device. The cigarette liquid atomizing device further comprises a cigarette liquid spraying atomization device body and a cigarette liquid heating atomization device body. The cigarette liquid pressurizing supplying device is communicated with the cigarette liquid spraying atomization device body. The cigarette liquid spraying atomization device body is provided with a spraying nozzle, and the spraying nozzle is arranged to face and be close to the cigarette liquid heating atomization device body. The cigarette liquid heating atomization device body is an electric heating plate. The atomized cigarette mist sucking-out device comprises a sucking-out channel and a sucking-out nozzle. According to the electronic cigarette device, due to the assisting effect of spraying atomization, the heating atomization temperature can be reduced in cooperation with the heating atomization effect, and the stability of an electronic cigarette can be kept to the maximum degree; meanwhile, liquid leakage can be prevented, and no atomization core is needed. The electronic cigarette device is an electronic cigarette product of a brand new structure.

Owner:INNOKIN TECH

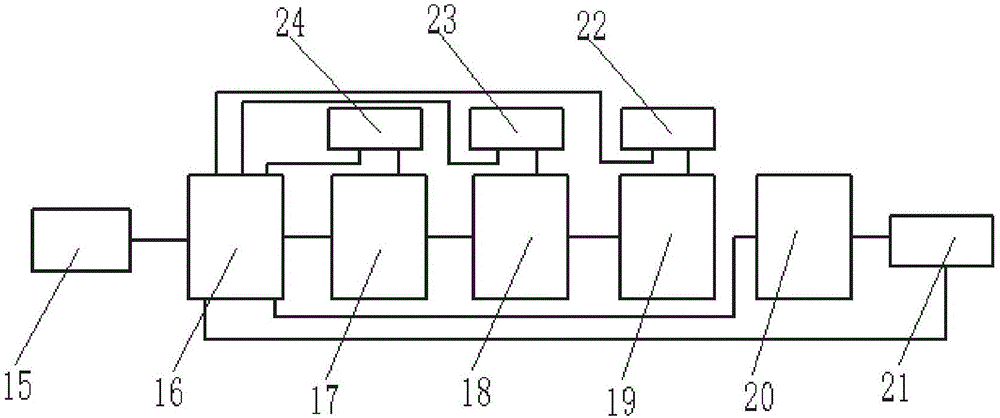

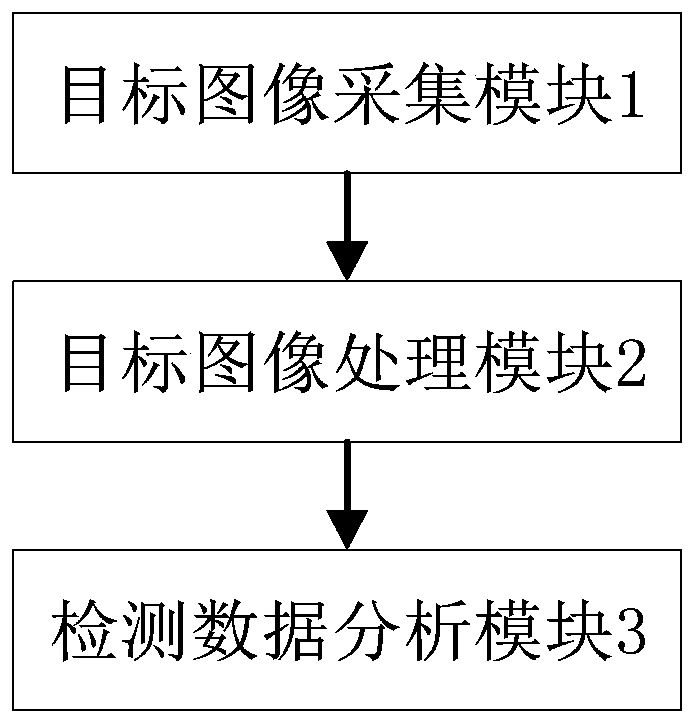

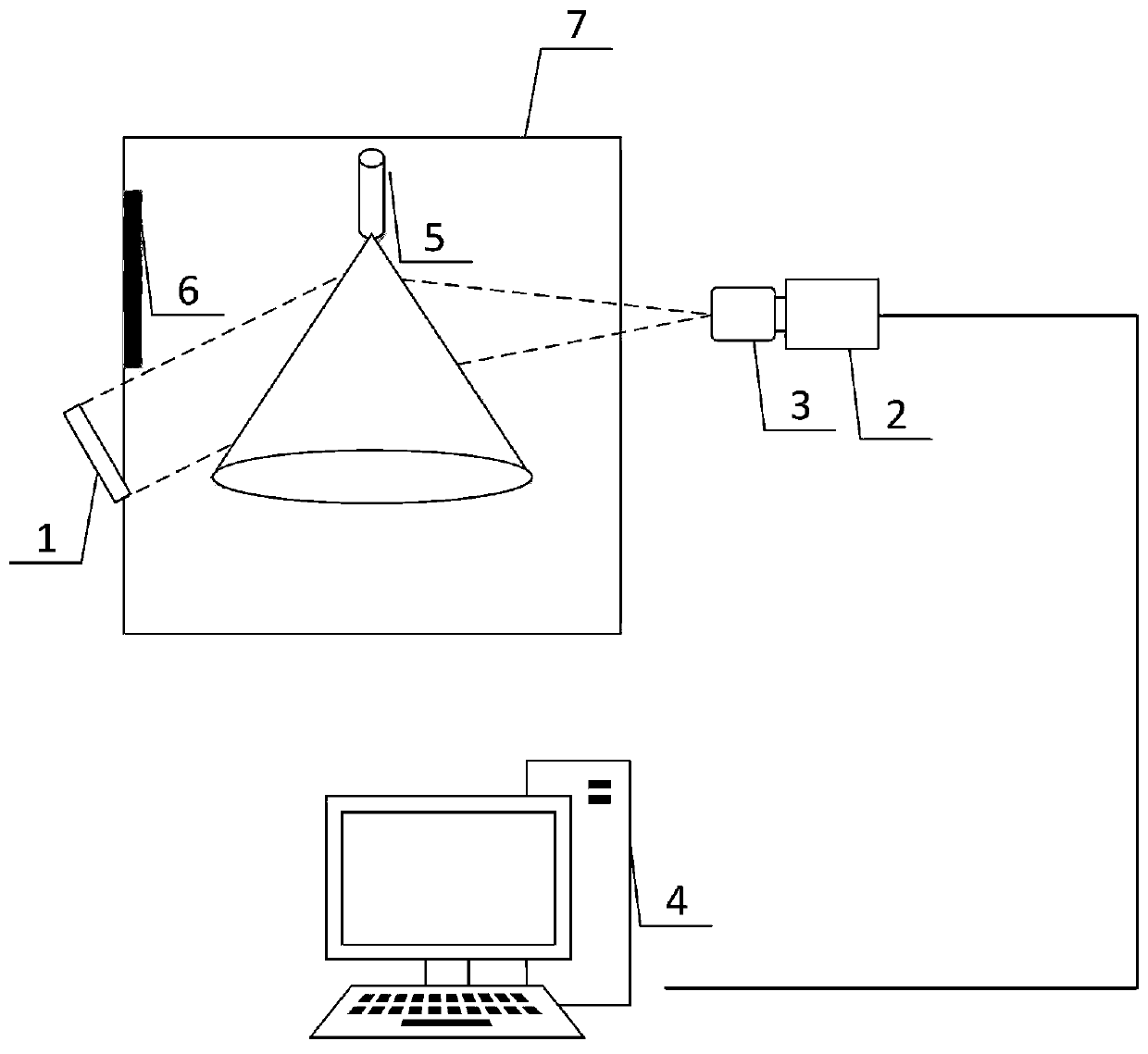

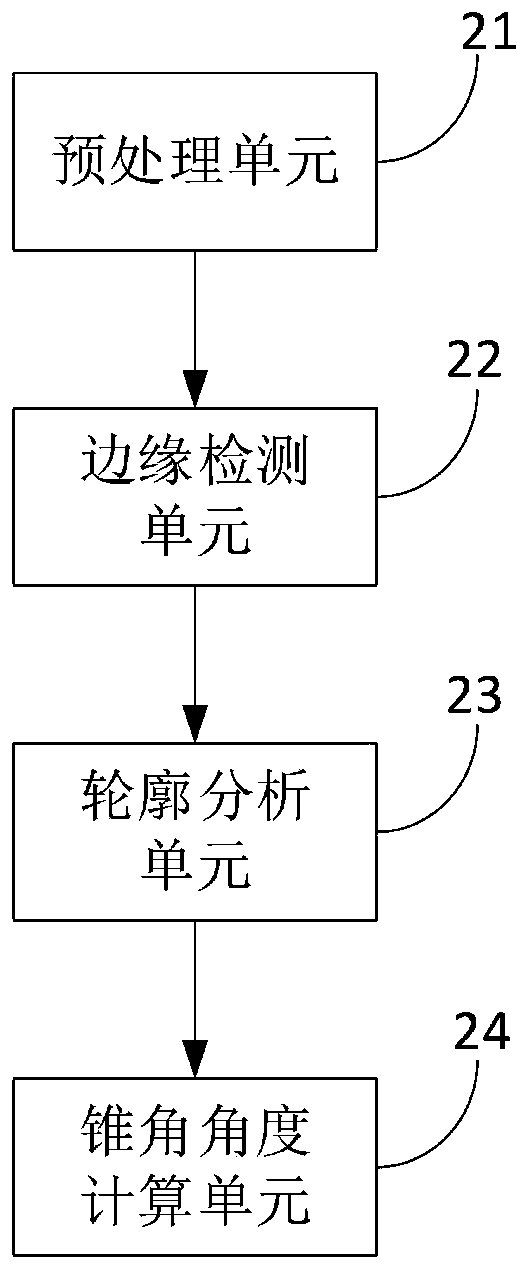

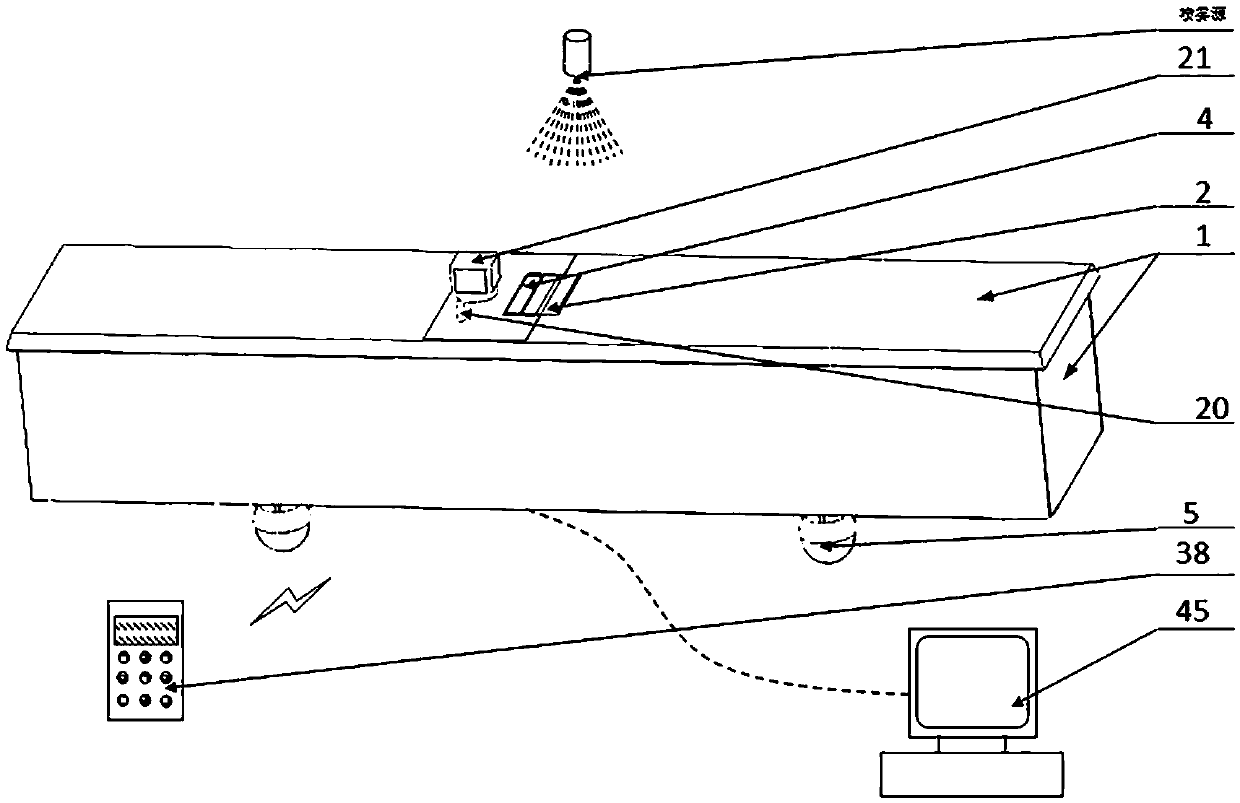

A nozzle atomization angle automatic detection system and method based on vision

The invention provides a nozzle atomization angle automatic detection system based on vision, and belongs to the technical field of image processing. The nozzle atomization angle automatic detection system based on vision comprises a target image acquisition module, a target image processing module and a detection data analysis module. The target image acquisition module is used for acquiring a spray image; the target image processing module is used for processing the collected spray image and calculating a spray atomization angle; and the detection data analysis module carries out data statistical analysis on the spray atomization angle to obtain a detection result. According to the nozzle atomization angle automatic detection system based on vision, the nozzle atomization angle can be rapidly, accurately and stably measured, and the randomness of manual measurement is solved. The invention further provides a nozzle atomization angle automatic detection method based on vision.

Owner:山东巍然智能科技有限公司

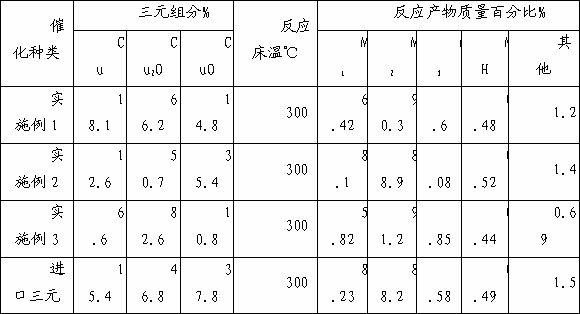

Catalyst produced through water atomization and manufacturing method thereof

InactiveCN102441382AImprove adsorption capacityHigh reactivityGroup 4/14 element organic compoundsCatalyst activation/preparationElectrolysisCompound (substance)

The invention discloses a catalyst produced through water atomization and a manufacturing method thereof. The catalyst is prepared by melting a cathode electrolytic copper plate serving as a primary raw material at high temperature, performing high water pressure spray atomization, precipitation, high-temperature drying oxidization, selection and ball milling oxidization on the copper plate. Besides the characteristics of multiple pores, and large specific surface area of a traditional elemental sheet copper powder catalyst, the catalyst also has the property of containing three element components, namely copper, cuprous oxide and copper oxide. Due to the characteristics of multiple pores, sheet shape and large specific surface area, absorption and contact area between the catalyst and silica powder are increased, more Si and Cu alloy and eta phase can be formed, and the reaction activity of a contact is improved. The disadvantages that the content of S in the three-element copper catalyst produced by a chemical method using CuSO4.5H2O as a raw material is relatively high and the S does harm to producers, users and environments are overcome. The catalyst is continuous in production way, good in controllability and stable in quality.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

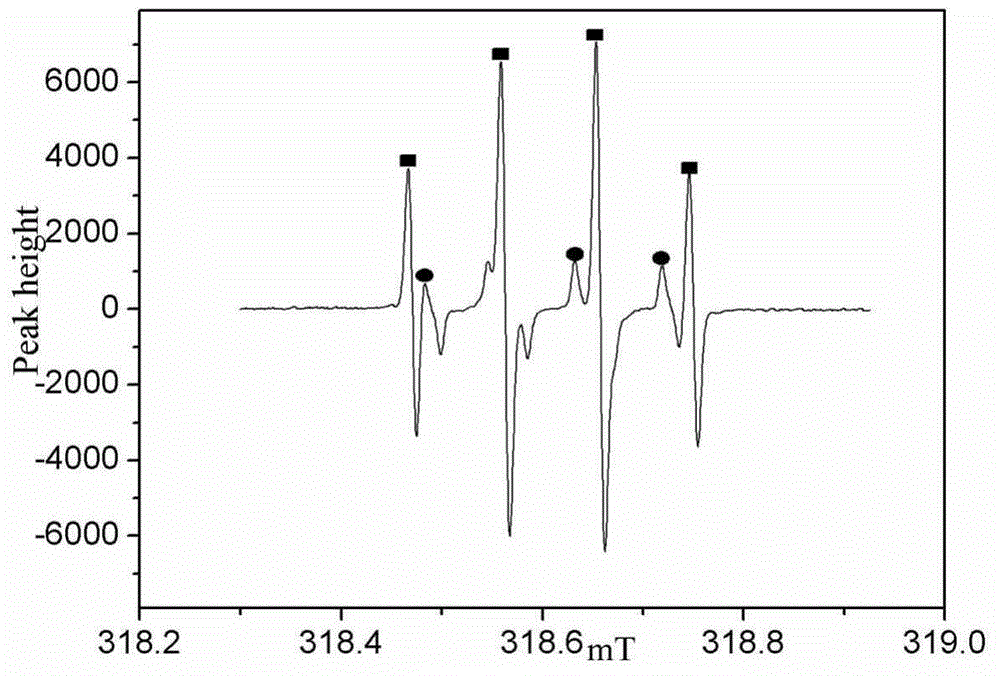

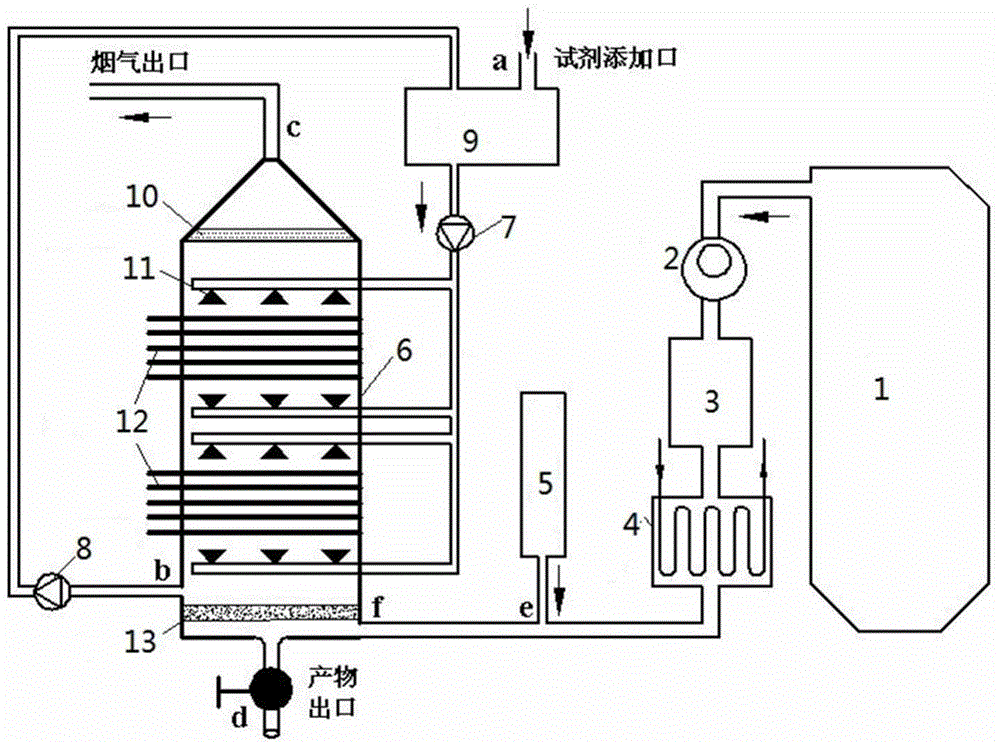

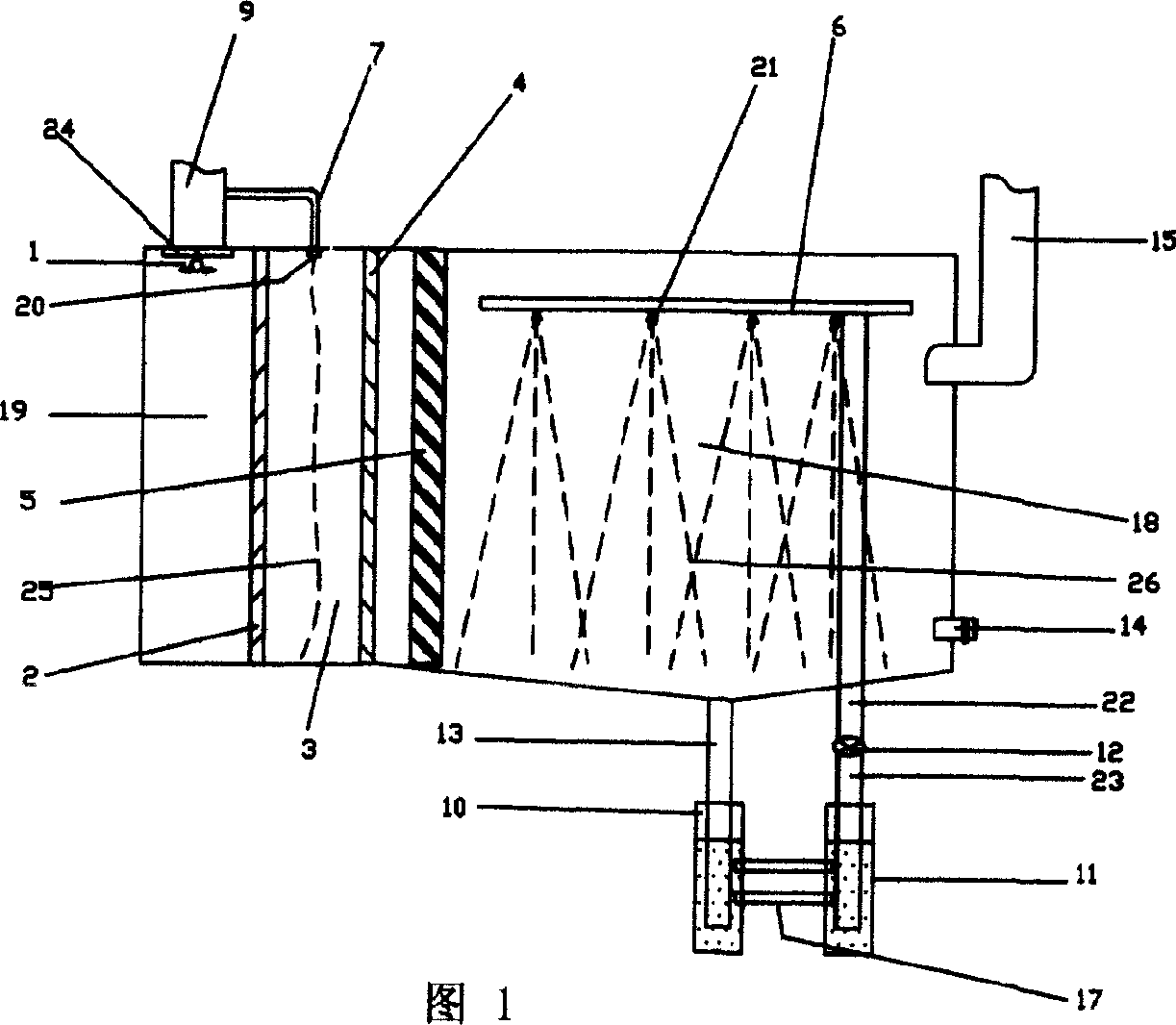

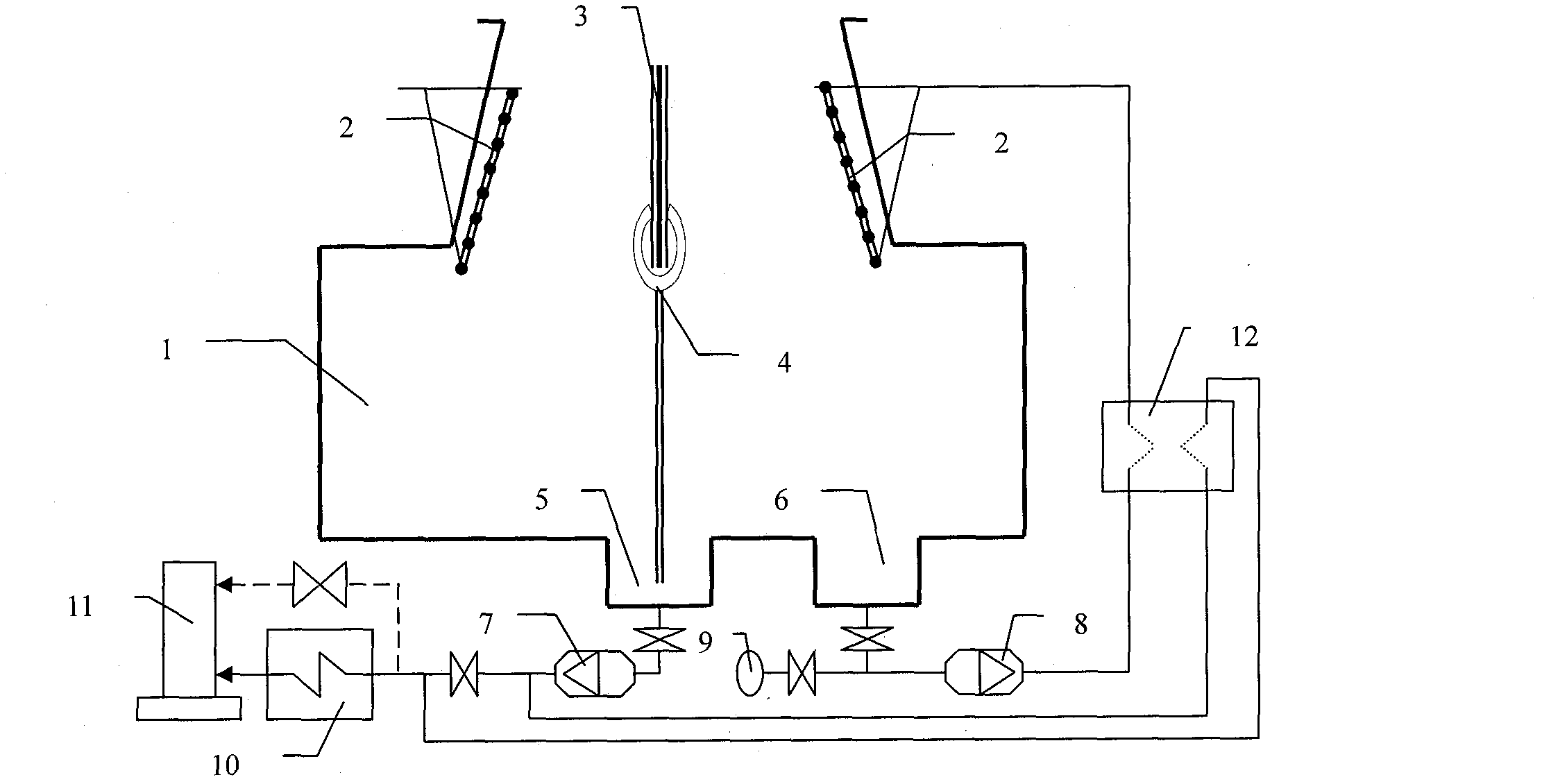

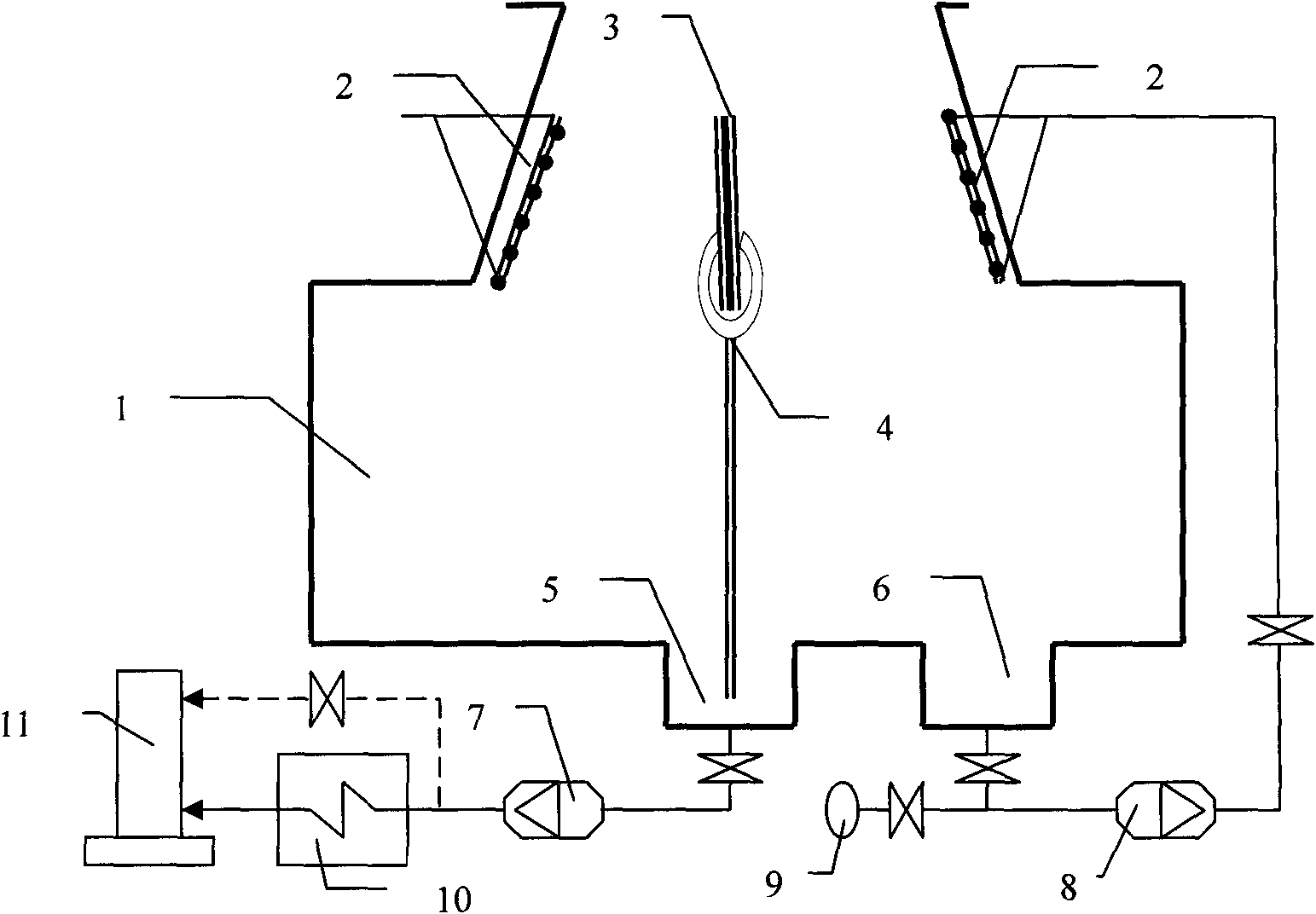

Method for realizing desulfuration, denitration and demercuration through combination of ozone and radiated peroxides

InactiveCN104785081AImprove removal efficiencyImprove oxidation capacityDispersed particle separationAir quality improvementSulfate radicalsUltraviolet lights

The invention relates to a method for realizing desulfuration, denitration and demercuration through the combination of ozone and radiated peroxides. The method comprises the following steps: SO2, NO and Hg<0> from a discharging source are pre-oxidized by ozone in a flue and are transformed into SO3, NO2 and Hg<2+>; ultraviolet lamps radiate ultraviolet light, the ultraviolet light stimulates peroxides to generate sulfate radicals and hydroxyl radicals so as to further oxidize SO2, NO and Hg<0>, and SO3 and NO2 which are generated through oxidation of ozone, wherein the reaction products are mainly sulfuric acid, nitric acid and divalent mercury ions, which can be used as resources. Devices for realizing the method mainly comprise the discharging source, a blower, a dust remover, a fume cooler, an ozone generator, a longitudinal opposite-spraying atomization bed, circulating pumps (I and II), a filler layer, ultraviolet lamp tubes, atomizing nozzles, a demister, a liquid tank and an after-treatment system of reaction products. A novel fume purifying system adopted by the method can efficiently remove the SO2, the NO and the Hg<0> in the fume, the process of removal does not generate secondary pollution, so that the novel fume purifying system has an extensive application prospect.

Owner:CHANGSHU CITY YUHENG KNITTING

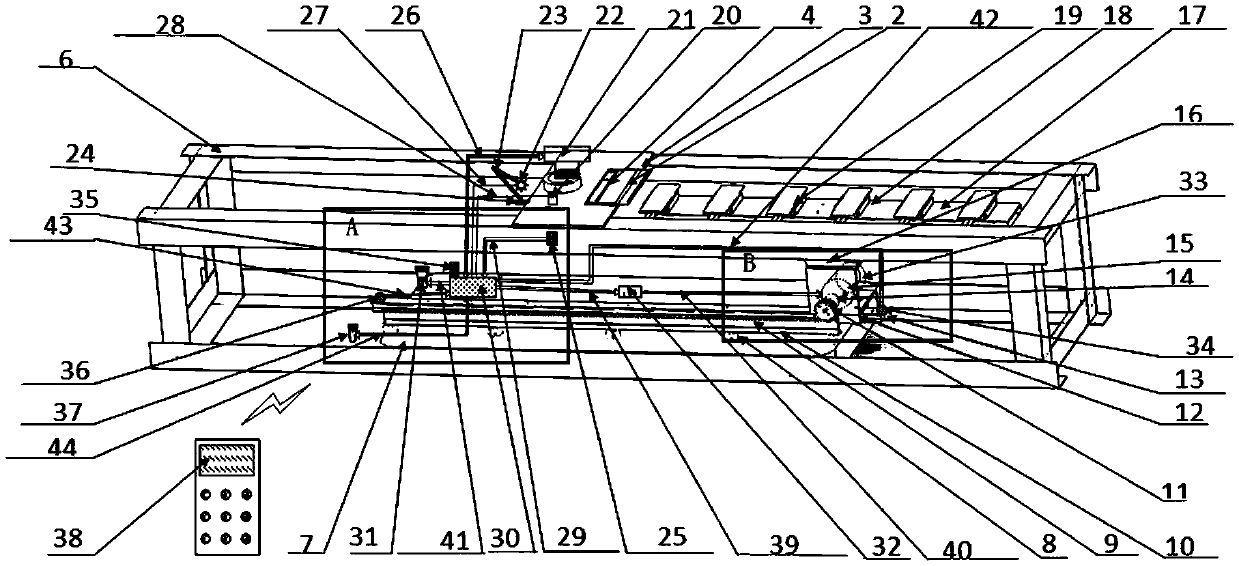

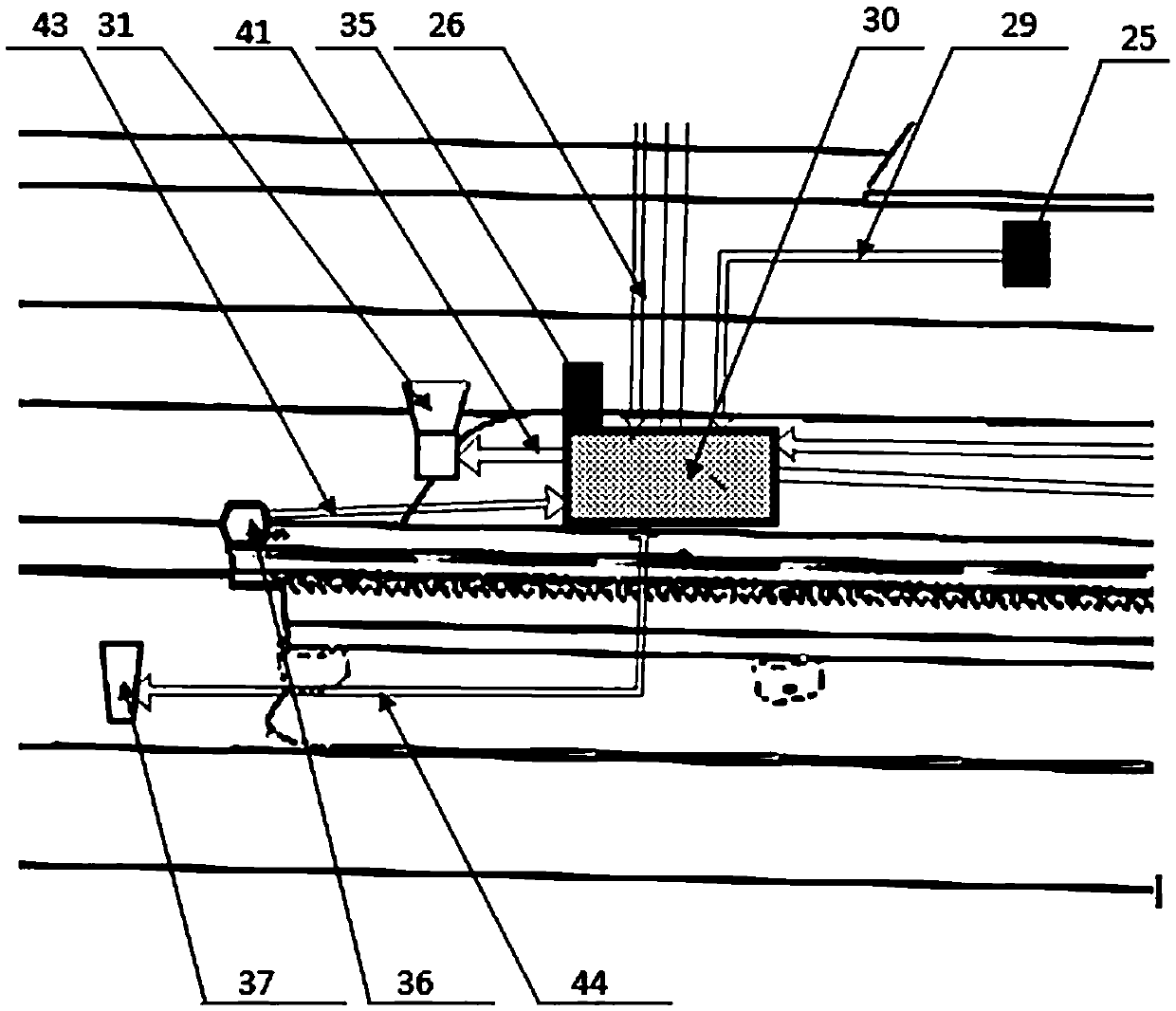

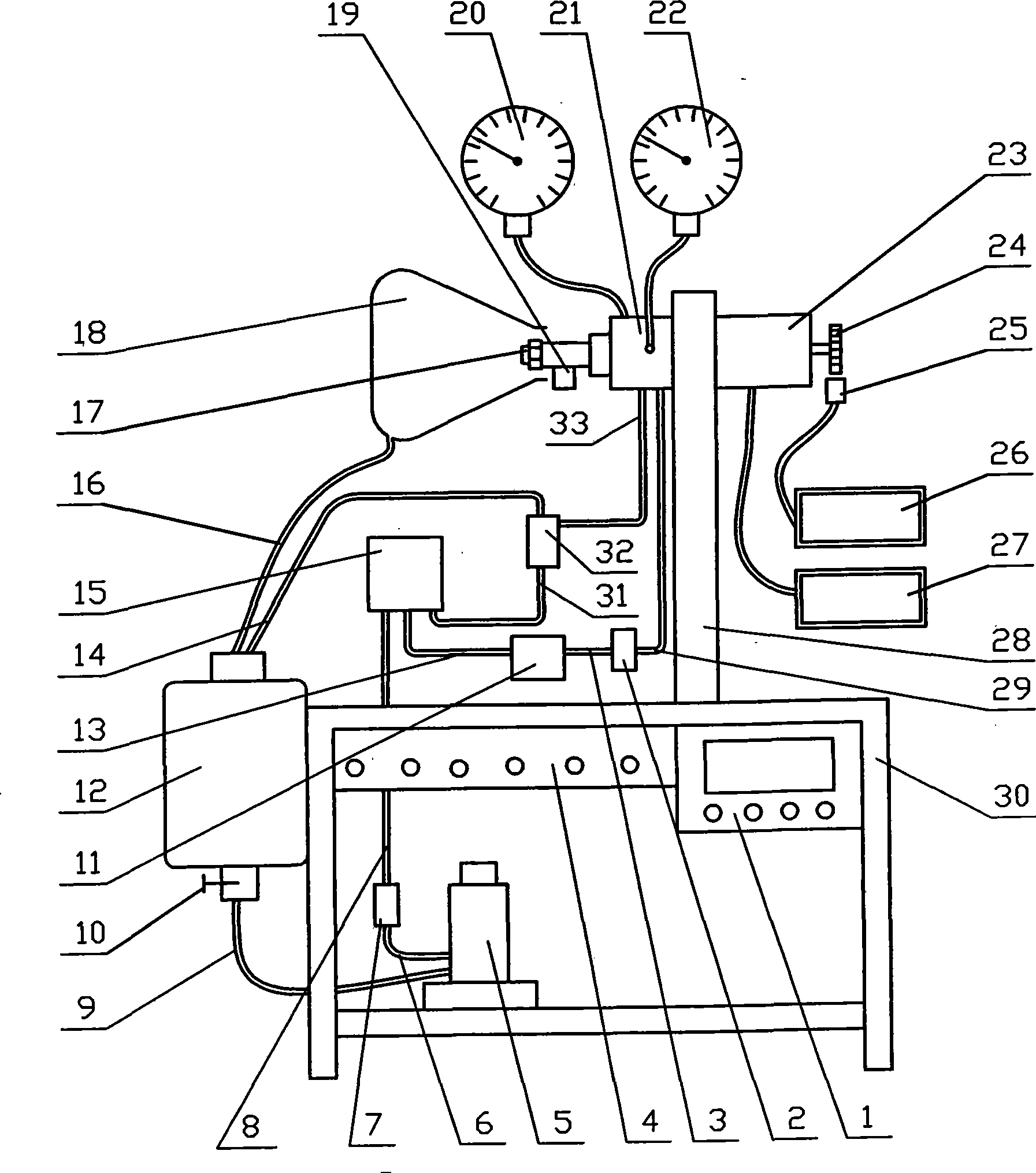

Apparatus and method for testing spray atomization performance

ActiveCN105372163ALarge particle sizeImprove distribution uniformityParticle size analysisParticle suspension analysisImaging processingImage processing software

The present invention discloses an apparatus and method for testing spray atomization performance. The apparatus consists of a mechanical part, a camera shooting part, a control part and an image processing part. The mechanical part is used for performing motion of a thin-layer chromatography silica gel plate driven by a stepper motor to achieve spray droplet collection; the camera shooting part is used for colleting the images of the spray droplets fallen to the thin-layer chromatography silica gel plate; the control part is used for controlling the entire apparatus in the testing process; the image processing part comprises a PC terminal and a piece of image processing software installed in the PC, and is used for processing and analyzing the images of the spray droplets on the thin-layer chromatography silica gel plate collected by the camera shooting part. The apparatus has the advantages of simpleness, low cost and easy operation; the image processing method can process the images to obtain particle size and distribution uniformity of the spray droplets, and achieve multiple real-time measurements; the test and analysis results are more reliable and credible; and measurement at multiple locations within the space at a time can analyze the spatial density distribution of the spray effect.

Owner:GUILIN UNIV OF ELECTRONIC TECH

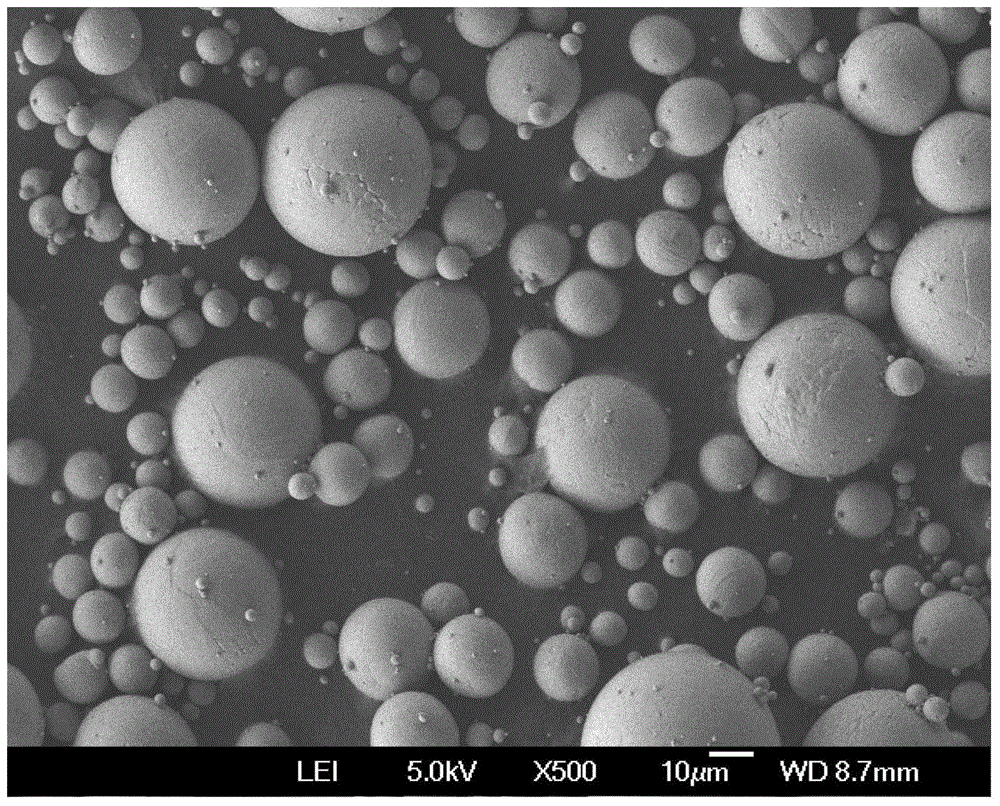

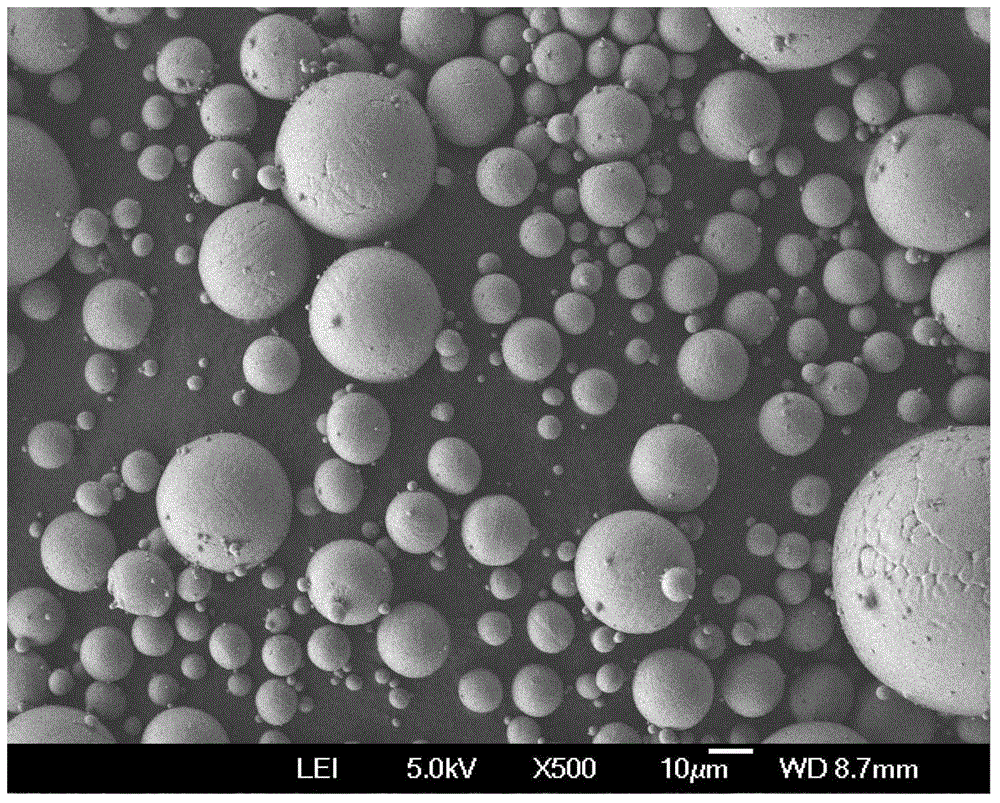

Spray atomization process used in process of preparing metal powder by water atomization

The invention discloses a spray atomization process used in the process of preparing metal powder by water atomization. The spray atomization process comprises primary atomization and secondary atomization, i.e. a spray nozzle is added below a spray nozzle for primary atomization to carry out secondary cold water atomization, a spray nozzle for secondary atomization is positioned below the spray nozzle for primary atomization at a distance of 0.5-2 cm and the cold water temperature of the spray nozzle for secondary atomization is 5-8 DEG C, wherein in the atomizing process, the aperture of a tundish is 5-8 mm, a spray vertex angle of primary atomization is 50-55 degrees, a spray vertex angle of secondary atomization is 40-45 degrees, the atomization pressure is 18-25 Mpa, the height of an atomization bucket is 3 m and the cooling water level is 0.2-0.4 m. According to the spray atomization process used in the process of preparing metal powder by water atomization, secondary atomization is added, parameters such as the spray vertex angles, the hole diameter of the tundish, the atomization pressure and cooling water level are comprehensively regulated, the degree of sphericity and the apparent density of the metal powder are effectively improved, granularity of the powder is finer and the high industry requirement on morphology can be met.

Owner:安徽旭晶粉体新材料科技有限公司

Preparation method of fine particle size and low oxygen spherical titanium and titanium alloy powder

The invention provides a preparation method of fine particle size and low oxygen spherical titanium and titanium alloy powder. The preparation method comprises the following steps: forming molten titanium and titanium alloy liquid drops by adopting arc melting wires, then crushing the metal liquid drops into superfine fog drops by using supersonic speed airflows, and condensing the metal fog drops into the spherical titanium and titanium alloy powder under the surface tension effect of the fog drops. By adopting the arc melting wires, the spherical titanium and titanium alloy powder is prepared in a high-purity argon or helium spray atomization technology, so that the preparation method is short in technological process and low in energy consumption; moreover, the powder preparation process of melting and atomizing raw materials is carried out under the protection of an inert atmosphere, so that the high-activity titanium and titanium alloy powder can be effectively prevented from being polluted, and low oxygen and high purity of the prepared powder are guaranteed; in addition, the molten titanium and titanium alloy liquid drops are sufficiently atomized through three paths of supersonic speed airflows, so that the prepared powder is fine in particle size and higher in yield and has a higher practical value.

Owner:陕西维克德科技开发有限公司

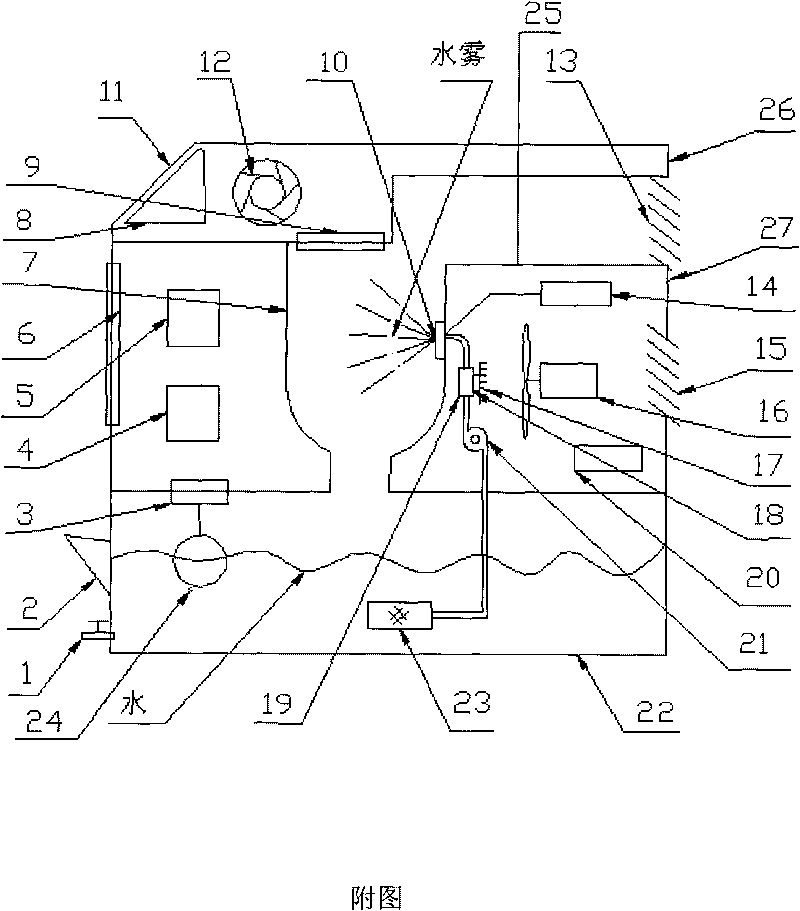

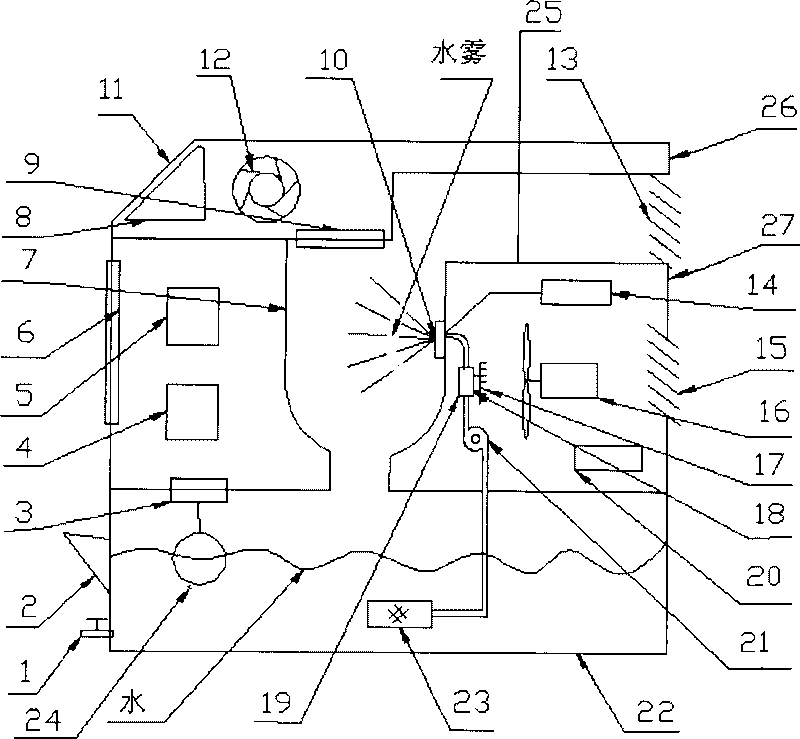

Novel negative ion refrigerating generator

InactiveCN101737884ASuitable for health care cooling needsMachines using electric/magnetic effectsDeodrantsCold airEngineering

The invention relates to a novel negative ion refrigerating generator which uses a semiconductor refrigerating device as a cold source and uses water as a substance for absorbing heat and dust and ionizing; by utilizing high-pressure water to generate air negative ions in the process of spray atomization, a domestic electric appliance product which integrates a refrigerating technology and a negative oxide ion generator is produced. The invention has the advantages of various negative ion generators and simultaneously can generate cold air to meet the demands on health care and temperature reduction.

Owner:洪旗

Emulsified fcc feetstock for improved spray atomization

InactiveCN1795255AIncrease productionReduce outputCatalytic crackingLiquid carbonaceous fuelsOil emulsionWater vapor

The present invention provides a feedstock composition for increasing atomization efficiency in hydrocarbon processing comprising a hydrocarbon water-in-oil emulsion containing a non-hydrocarbon oil capable of stabilizing the emulsion and having a hydrophilic-lipophilic balance greater than about 12. Ionic surfactant. The emulsion comprises water droplets having a diameter of about 5-10 microns substantially uniformly dispersed in the hydrocarbon oil phase. These surfactants are capable of stabilizing hydrocarbon water-in-oil emulsions under the temperature and pressure conditions associated with hydrocarbon processing, and the feedstock composition of the present invention provides metastable water-in-oil emulsions in which expanding water vapor is released in a spray state at system pressure The explosion destroys the large oil droplets and produces small oil droplets.

Owner:GENERAL ELECTRIC CO

Energy-saving water air-conditioning system

InactiveCN1677004AGrowth inhibitionGuaranteed unobstructedLighting and heating apparatusAir conditioning systemsEngineeringAir conditioning

The invention discloses a energy economizing water air-conditioner system which includes well water atomization room, drying air blow room ell and water pump; there are water shielding fins and at least a drying screen net; the water pump sends the well water through pipes to the atomization room to the spray pipe on which spray atomization nozzle is set. Water return tube is set at the bottom, one end of indoor air return tube is connected to the atomization room; drying blow room has got a air exit connected to indoor blowing tube and set at least one fan on the exit or the blowing tube; at the downstream of the fan on the indoor blowing tube a sub blowing tube is connected blowing air to the space between the water shielding fins and the drying blowing room forming at least a wind screen. The invention is of simple device, low energy needs, long service life, which saves energy with protects the environment.

Owner:徐跃华

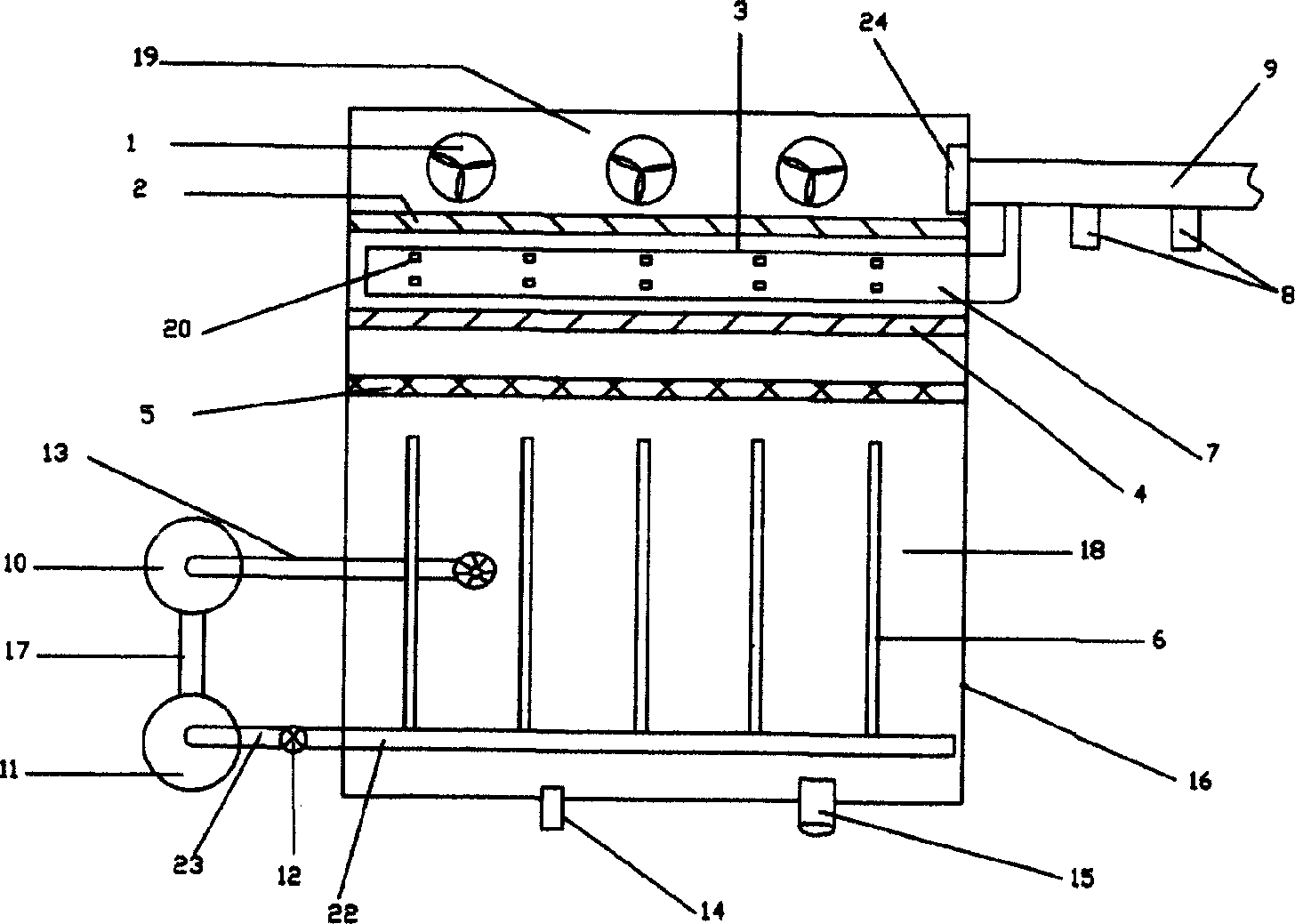

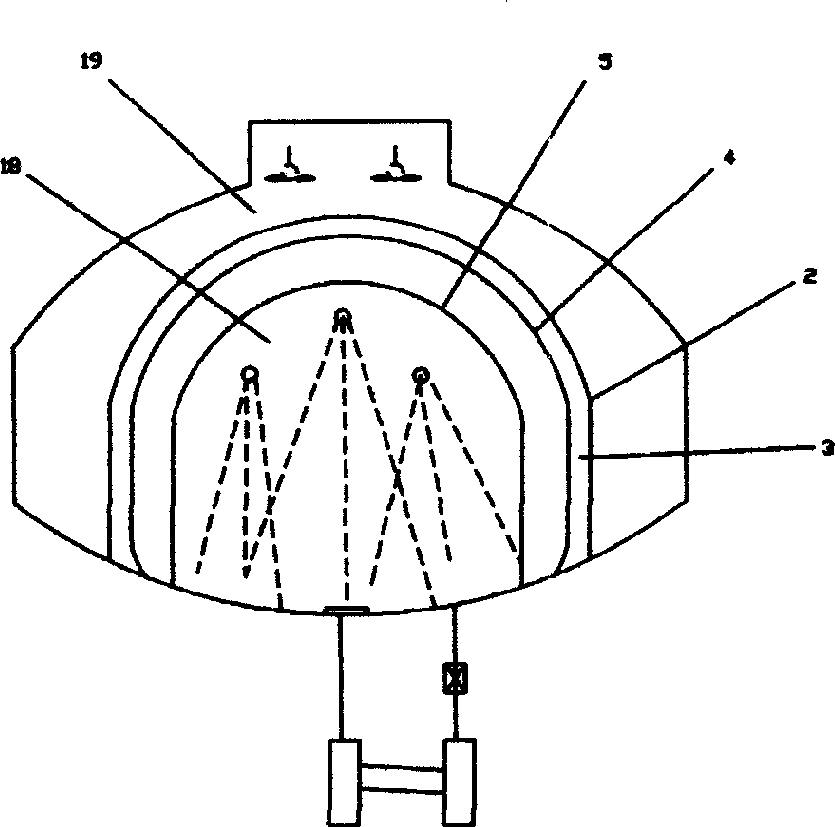

Multifunctional efficient greenhouse

InactiveCN103583273AEasy to manageSave human effortClimate change adaptationGreenhouse cultivationAir handlerThermal insulation

Disclosed is a multifunctional efficient greenhouse. An air conditioner host, an air supply device, an air treatment device and a water treatment device are arranged outside a greenhouse body. An air inlet is formed in the greenhouse body. A heating circulating tube system, a spraying atomization device and a temperature and humidity controller are arranged in the greenhouse body. A breeding or planting pond built by thermal insulation materials and waterproof materials is arranged below the ground or the water surface in the greenhouse body. The air conditioner host is connected with the heating circulating tube system, the temperature and humidity controller, the spraying atomization device, the air supply device and the air treatment device, and the water treatment device is connected with the spraying atomization device arranged in the greenhouse body. The air supply device is arranged on the air inlet in the greenhouse body to supply air treated by the air treatment device into the greenhouse body. Soil is placed in the planting pond, and the heating circulating tube system and a temperature sensor are arranged in the soil, wherein the heating circulating tube system and the temperature sensor are connected with the air conditioner host.

Owner:威海瑞冬空调有限公司

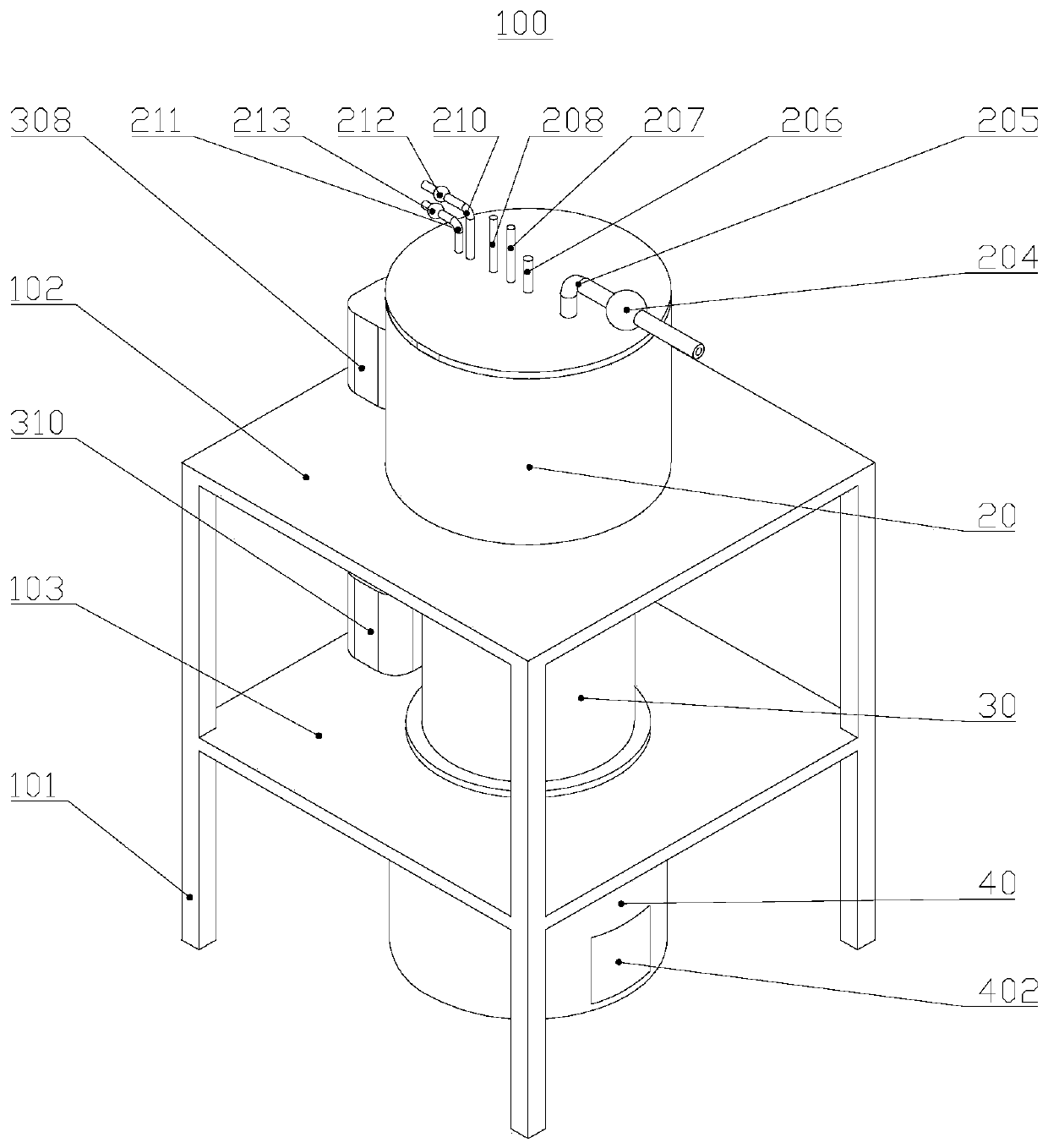

Production plant and production method of rapid setting metal powder

PendingCN111230133ARealize large-scale continuous productionEasy to makeIncreasing energy efficiencyMg alloysMetallurgy

The invention discloses a production plant and production method of rapid setting metal powder and belongs to the field of metal powder preparation. Molten metal enters a centrifugal atomizer rotatingat a high speed and is flung out through rotation liquid spray atomization holes in the centrifugal atomizer under the effect of centrifugal force, and small molten metal drops are flung to a quenching wall of a quenching chamber rotating at a high speed similarly to set rapidly. The obtained rapid setting metal powder is collected in a powder collection device at the bottom of the quenching chamber. The high-performance rapid setting metal powder is obtained in the mode of combination of high-speed centrifugal atomization and water cooling rotation metal barrel quenching, mass production canbe achieved, and the production plant and production method are suitable for preparing the high-strength metal powder of aluminum alloy, magnesium alloy and the like.

Owner:四川科匠轻金属材料科技有限公司

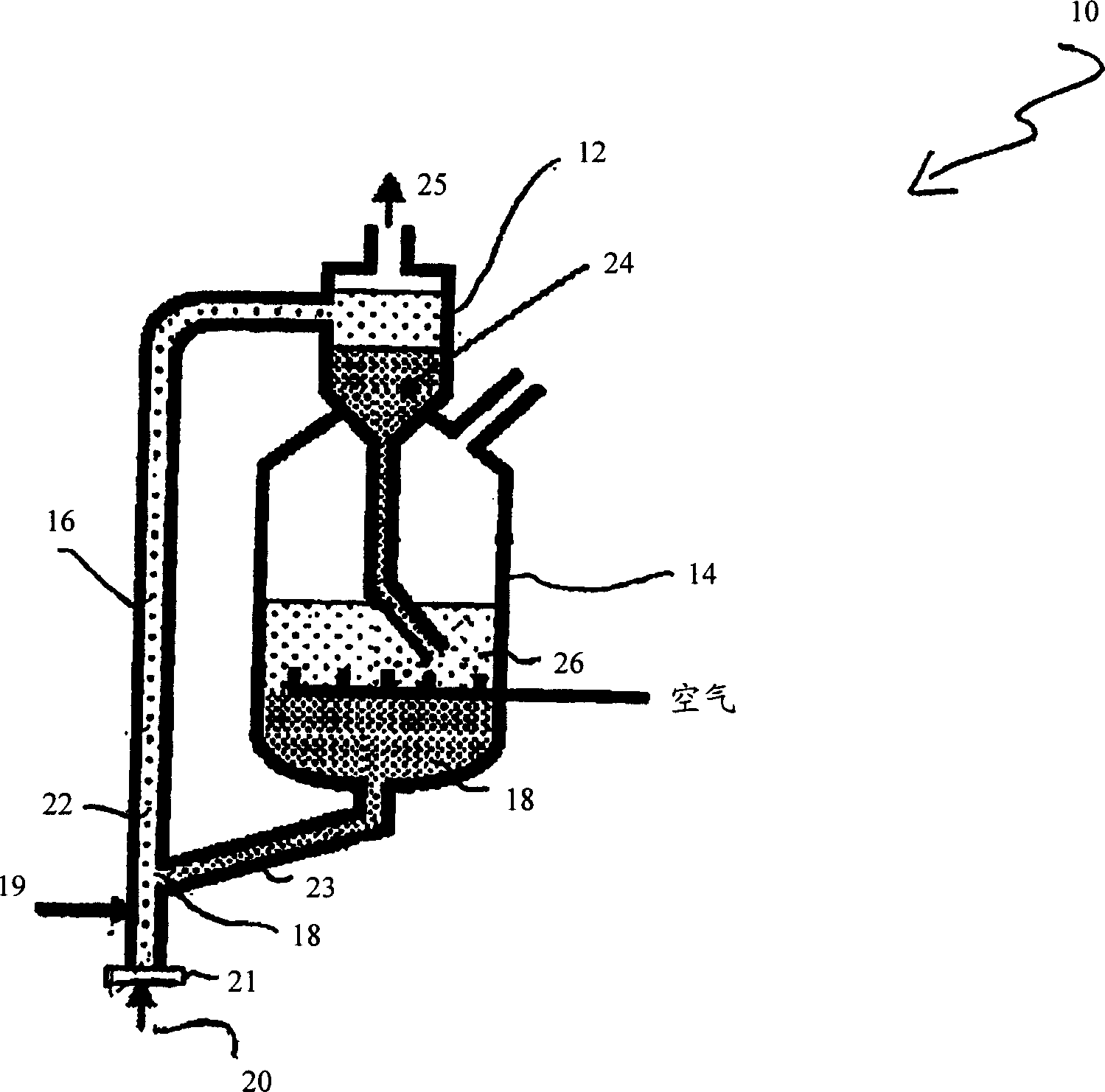

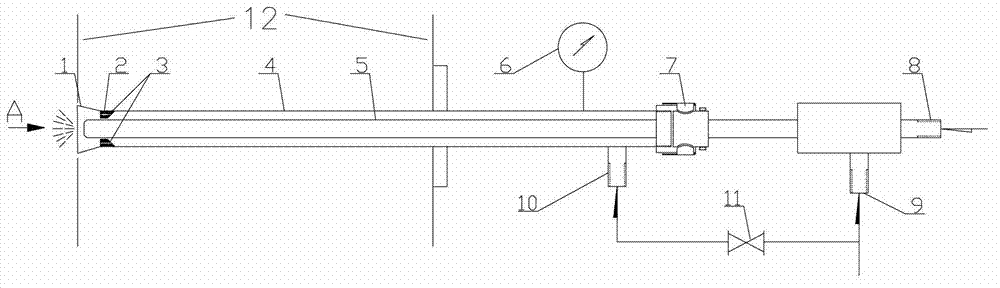

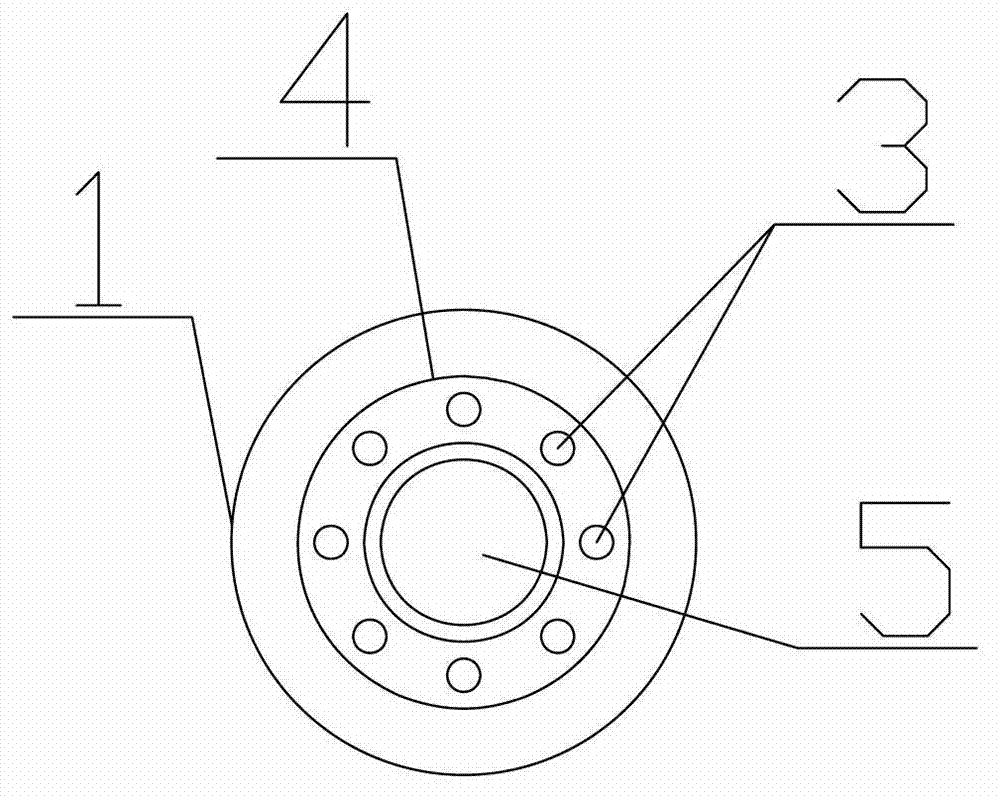

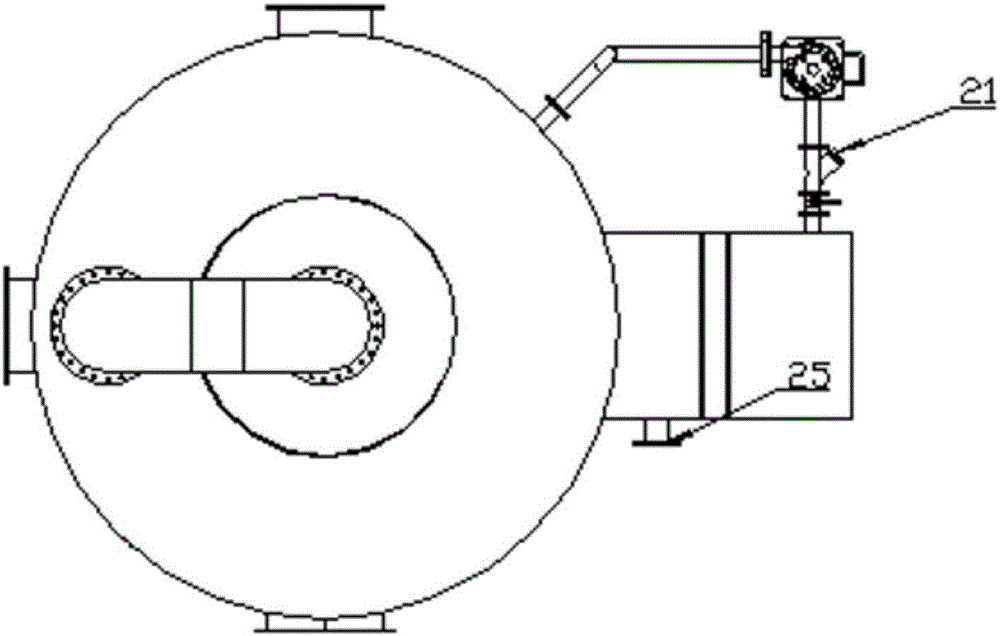

SNCR (Selective Non Catalytic Reduction) denitration automatic anti-blocking spray atomization spray gun device for smoke environment

ActiveCN102728208AAvoid cloggingAvoid enteringDispersed particle separationAgricultural engineeringSpray atomization

The invention discloses an SNCR (Selective Non Catalytic Reduction) denitration automatic anti-blocking spray atomization spray gun device for smoke environment, comprising a spray gun spray pipe, a sleeve which is sheathed on the spray gun spray pipe and a reducing agent inlet pipe, wherein the spray gun spray pipe is communicated with the reducing agent inlet pipe. The SNCR denitration automatic anti-blocking spray atomization spray gun device for smoke environment is characterized in that a ring-shaped dustproof plate is arranged between the sleeve and the spray gun spray pipe; the ring-shaped dustproof plate is located at a nozzle end of the spray gun spray pipe; a plurality of air holes are arranged on the ring-shaped dustproof plate; an air inlet pipe which is used for introducing compressed air from an air source is arranged on the sleeve; and the air holes are arranged on the ring-shaped dustproof plate in a circumferential equal manner. The SNCR denitration automatic anti-blocking spray atomization spray gun device for smoke environment is good in anti-blocking effect, simple in structure and easy for implementation.

Owner:湖南安普诺环保科技有限公司

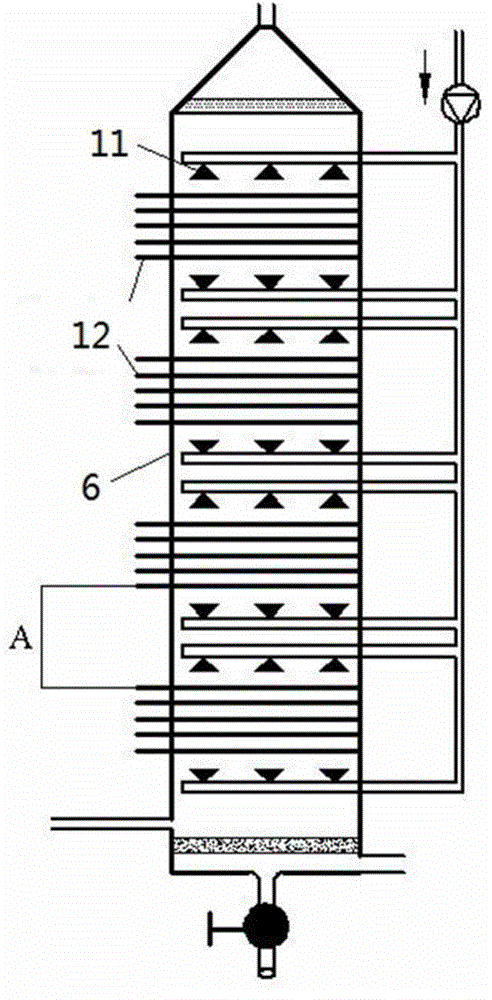

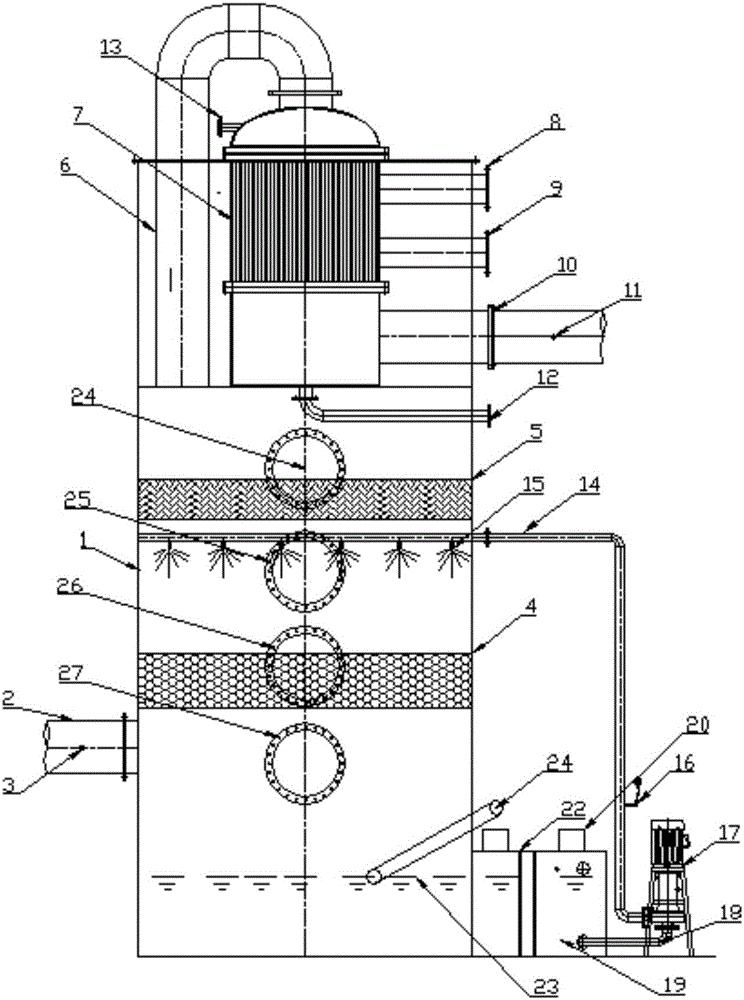

Deodorization tower device capable of realizing dusty and oily damp and hot gas temperature regulation

InactiveCN106310855AReduce the temperatureReal-time monitoring of temperature adjustment effectCombination devicesDirect contact heat exchangersEngineeringSewage

The invention discloses a deodorization tower device capable of realizing dusty and oily damp and hot gas temperature regulation. The deodorization tower device comprises a deodorization tower body, filler layers, a special-shaped tube type heat exchanger, an atomization spraying device, a circulation cooling device, a chemical dosing device and an intelligent control system, wherein the deodorization tower body comprises a gas inlet pipe arranged at the lower side of the tower body; the plurality of filler layers are sequentially arranged in the tower body from bottom to top; a liquid collecting tank is arranged at the lower part of the tower body, and a belt type oil removal machine is placed on the liquid collecting tank; the special-shaped tube type heat exchanger arranged at the upper end of the tower body comprises a cooling water inlet pipe, a hot water outlet pipe, a flushing pipe used for cleaning tubes, and a blow-off pipe used for discharging oil and sewage; a purified gas exhaust pipe is connected with the tube type heat exchanger and a subsequent device; the atomization spraying device comprises a circulating water channel, a circulating spray water pump, a Y-shaped filter, a spray atomization pipeline, and a circulation pipeline pressure gauge and a nozzle which are arranged at the outer side of the pipeline.

Owner:冯幼平

Process for repairing continuous casting crystal roller

ActiveCN101333637ASmall heat affected zoneImprove bindingMolten spray coatingMolten stateHigh pressure

The invention discloses a repairing method of a continuous casting crystallization roller, which relates to a repairing technique of the continuous casting crystallization roller, in particular to a technique utilizing a metal atomization spray and deposition process to repair the crystallization roller. The method is mainly characterized in that: the surface of the crystallization roller is cleaned, then the roller is positioned into a spraying atomization and deposition chamber and heated, then high pressure inert gases are input thereto for atomizing a metal repairing material in a molten state and making the material deposit on parts needing to be repaired of the crystallization roller, finally the redundant parts are removed through machining, thereby the repairing to the damaged parts or the whole surface of the crystallization roller is completed. The method can avoid the defects existing in the current crystallization roller repairing technique, and can improve the repairing efficiency and quality of the crystallization roller and extend the service life of the crystallization roller.

Owner:BAOSHAN IRON & STEEL CO LTD

SO2 and dust comprehensive treatment absorber

ActiveCN105413421AImprove bindingIncrease contact areaGas treatmentUsing liquid separation agentSufficient timeTrapping

The invention discloses an SO2 and dust comprehensive treatment absorber and belongs to the technical field of desulfurization and dust removal. The absorber is a mixed liquid 8-11 in pH comprising a protein ion membrane liquid and an alkaline liquid; the protein ion membrane liquid is a liquid membrane carrying negative and positive ions that is formed by adding an amphoteric surfactant and a foam stabilizer in a protein fermentation broth. The protein ion membrane liquid forms small-diameter bubbles during spray atomization, greatly increasing specific surface area (thousands of times in this increase), that is to say the area of contact between SO2 and an absorber liquid is increased, better facilitating the trapping of dust and SO2 in smoke; therefore, mass transfer contact residence time of an absorbed gas between gas and liquid phases is much longer than the retention time of the gas in the liquid phase to react with the alkaline liquid, and reaction is given sufficient time, that is to say the reaction time of SO2 with the absorber liquid is prolonged.

Owner:HEZE XINDING ENVIRONMENTAL ENG EQUIP

Energy-saving heat exchange system with direct vapor-water mixing

InactiveCN102878824AGreat effortImprove heat transfer effectFeed water supplySteam/vapor condensersWater storageWater vapor

The invention discloses an energy-saving heat exchange system with direct vapor-water mixing, namely, a spray atomization heat exchange water collection device is arranged in the high temperature end in the laryngeal portion of a condenser so as to perform high-low temperature condensed water shunting and further to achieve heat exchange cooling circulation and heating circulation of condensed water. The energy-saving heat exchange system is characterized in that cross-cooling circulation and heating circulation are utilized to solve the conflict between the vacuum degree of the unit and the too low temperature of the condensed water. Low-temperature condensed water vapor is directly mixed for heat exchange and cooling circulation to improve the vacuum degree. Condensed water heating circulation is utilized, which avoids the problem that the condensed water becomes too cold, so that backheating economy is improved. Water-water heat exchange and low-temperature water storage are used to improve the vacuum degree of the unit. Furthermore, a water collection device is used for separating the vapor discharging whirlpool at the laryngeal portion to improve the flowing effect. The energy-saving heat exchange system is remarkable in energy-saving effect and easy to implemente and can be massively and widely generalized.

Owner:张贵祥

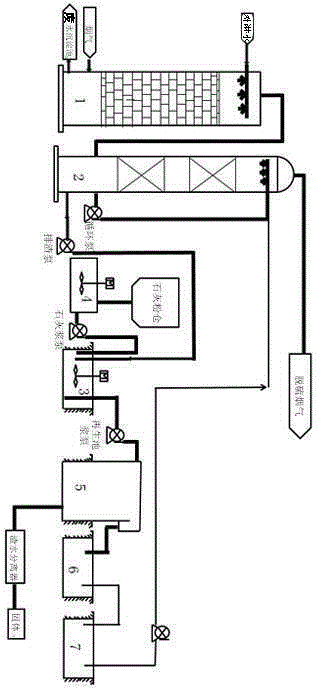

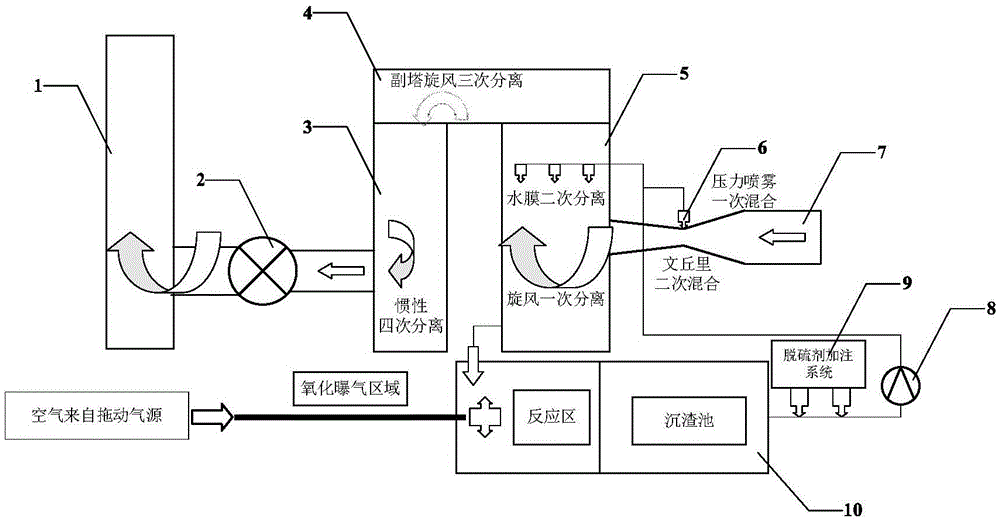

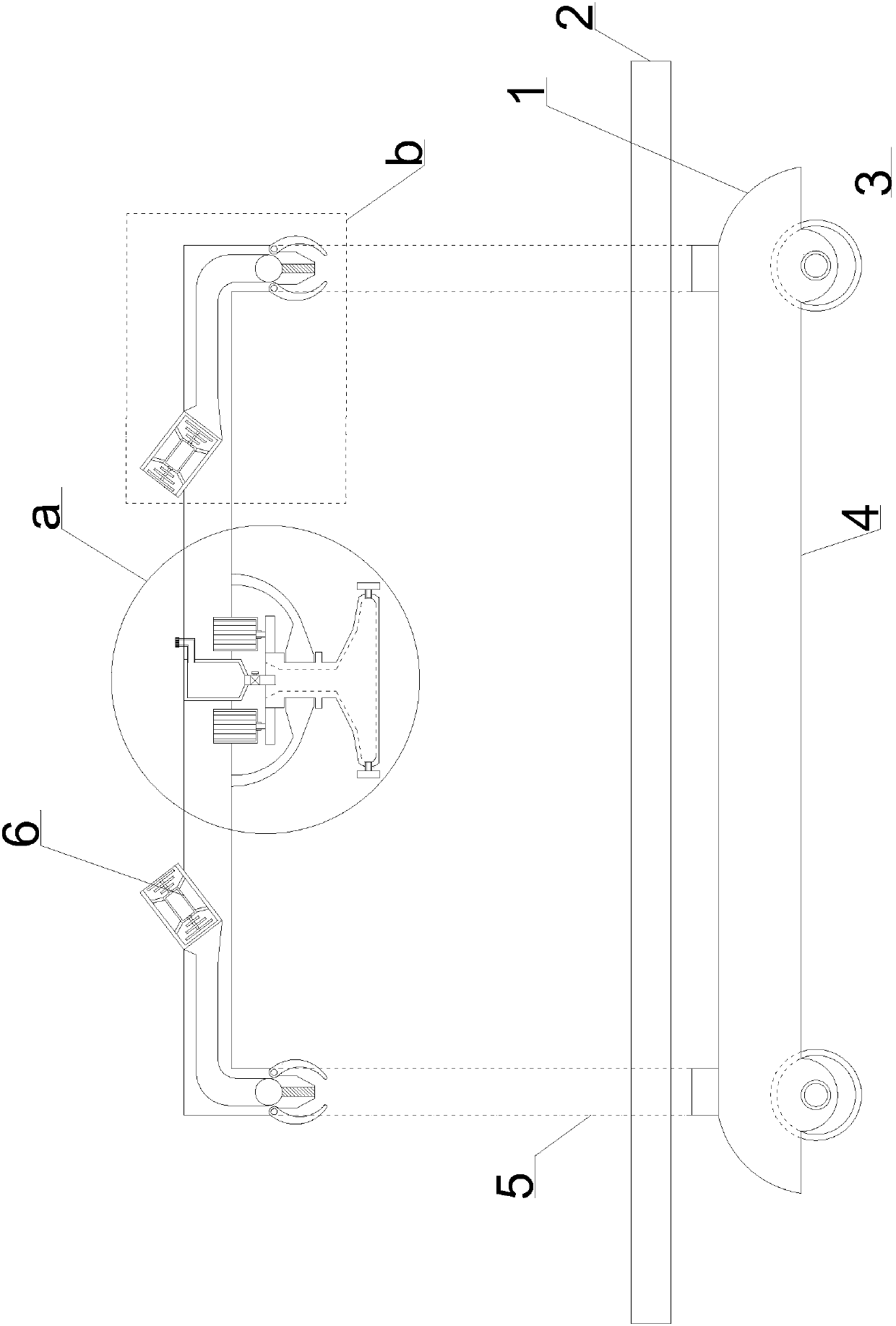

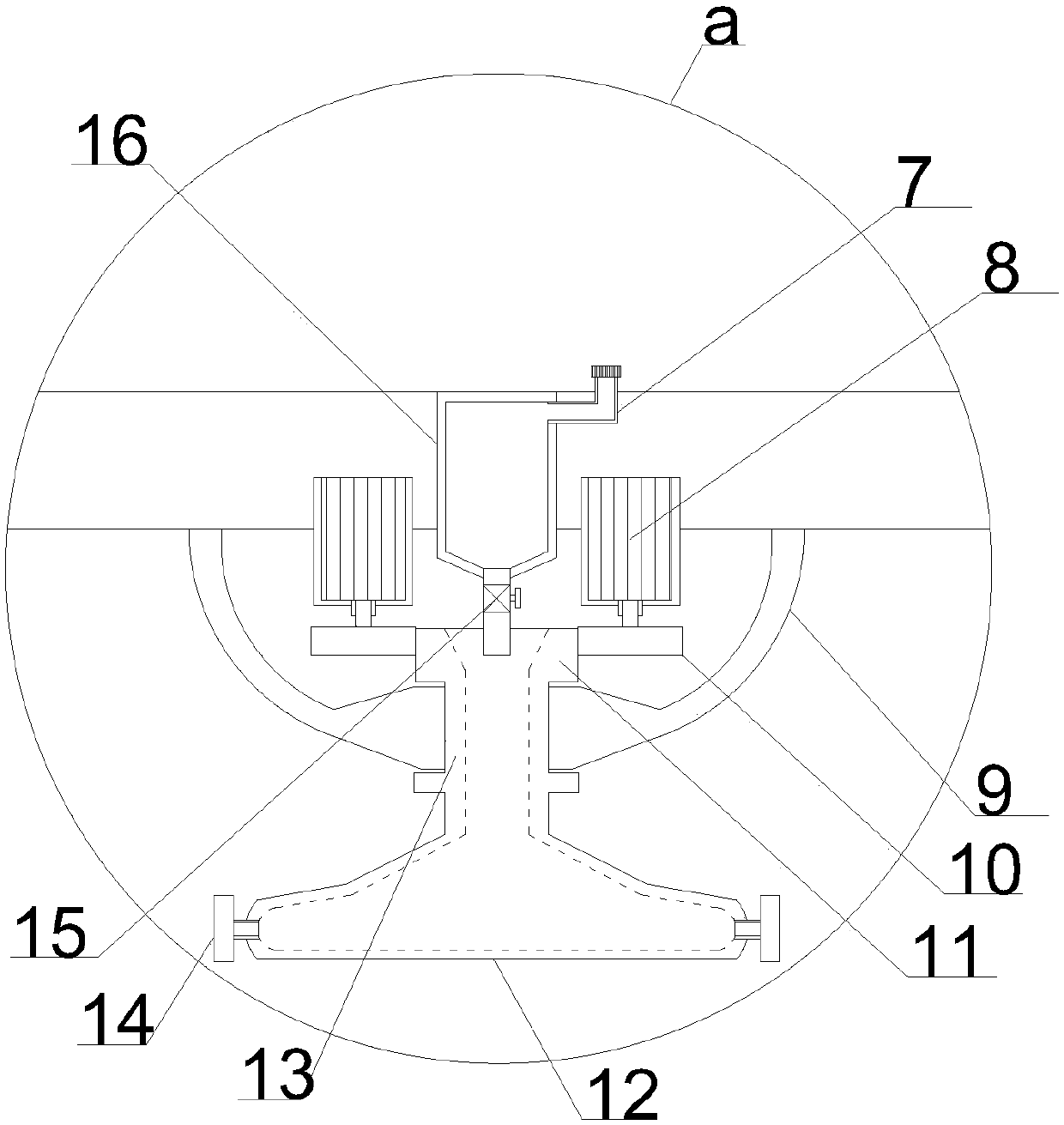

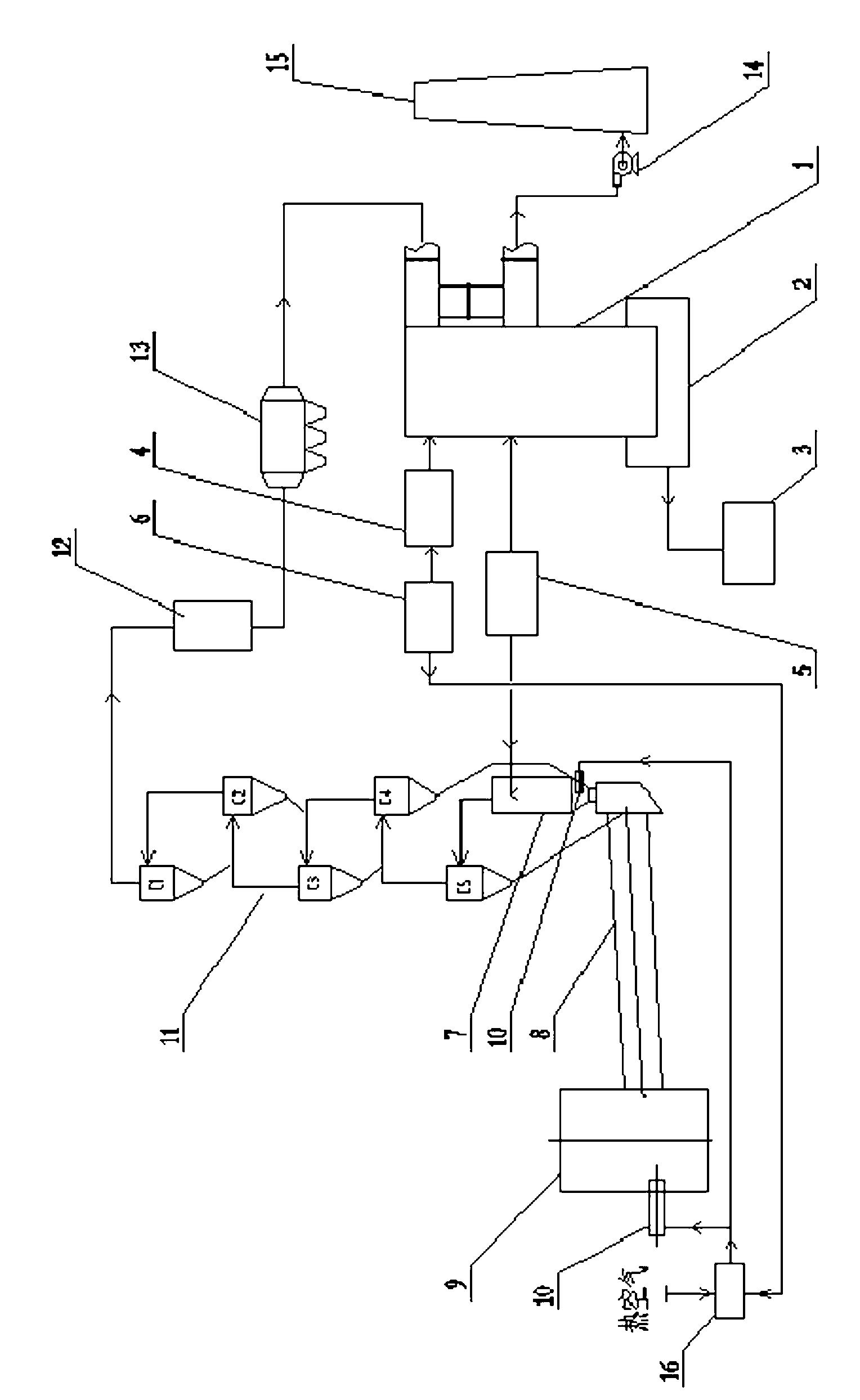

Coal-fired boiler flue gas environmentally-friendly deep treatment method and apparatus

InactiveCN105477963ALow running costLow costCombination devicesGas treatmentParticulatesCyclonic separation

The present invention provides a coal-fired boiler flue gas environmentally-friendly deep treatment method, dedusting, desulfurization and denitration deep treatment is performed on coal-fired boiler flue gas by a combined Venturi water film dedusting desulfurization and ammonia escape treatment technique, spray atomization mixing, venturi mixing, high-speed cyclone separation and water film absorption are combined, high salt wastewater comprising calcium ions and magnesium ions is used as a cleaning agent, after treatment with an oxidation sedimentation tank, a desulfurization agent is supplemented, and pH value is adjusted; and the treated coal-fired boiler flue gas is pumped back to a venturi pressure sprayer and a granite water film dust remover to form water film circular treatment; and after the treatment, boiler flue gas particulate matter emissions and sulfur dioxide emissions can be effectively reduced, the amount of used ammonia is reduced, and the liquid to gas ratio of the delivery amount of the cleaning agent can be reduced.

Owner:NINGXIA QIYUAN PHARMA

Bicycle frame paint even spraying device

The invention discloses a bicycle frame paint even spraying device comprising a supporting mounting plate. Supporting mounting columns are vertically and upwards arranged at the four corners of the upper end of the supporting mounting plate, a supporting mounting frame is arranged on the supporting mounting columns, an air curtain wall generation structure is arranged on the supporting mounting columns of the front end and the rear end on the same side, and each air curtain wall generation structure comprises a curtain wall generation cylinder matched with the upper ends of the supporting mounting columns on the front side and the rear side and arranged in a vertical penetrating mode. Flow equalizing cavities are embedded into the positions, at the upper ends of the curtain wall generationcylinders, of the supporting mounting columns. Pressurizing air draft cylinders are symmetrically and obliquely arranged at the left end and the right end of the supporting mounting frame in a semi-embedded mode, and air draft motors are arranged in the middles of the pressurizing air draft cylinders and are in parallel with the pressurizing air draft cylinders. The bicycle frame paint even spraying device has the advantages that the structure design is compact, paint spraying atomization is rapid and sufficient, the partition operation protection effect is good, environmental friendliness isachieved, and paint spraying is even, and the quality is high.

Owner:长沙双合盛企业管理有限公司

Device and method for simulating influence of two-stage supercharging pressure end/vortex end bypass on spray characteristics

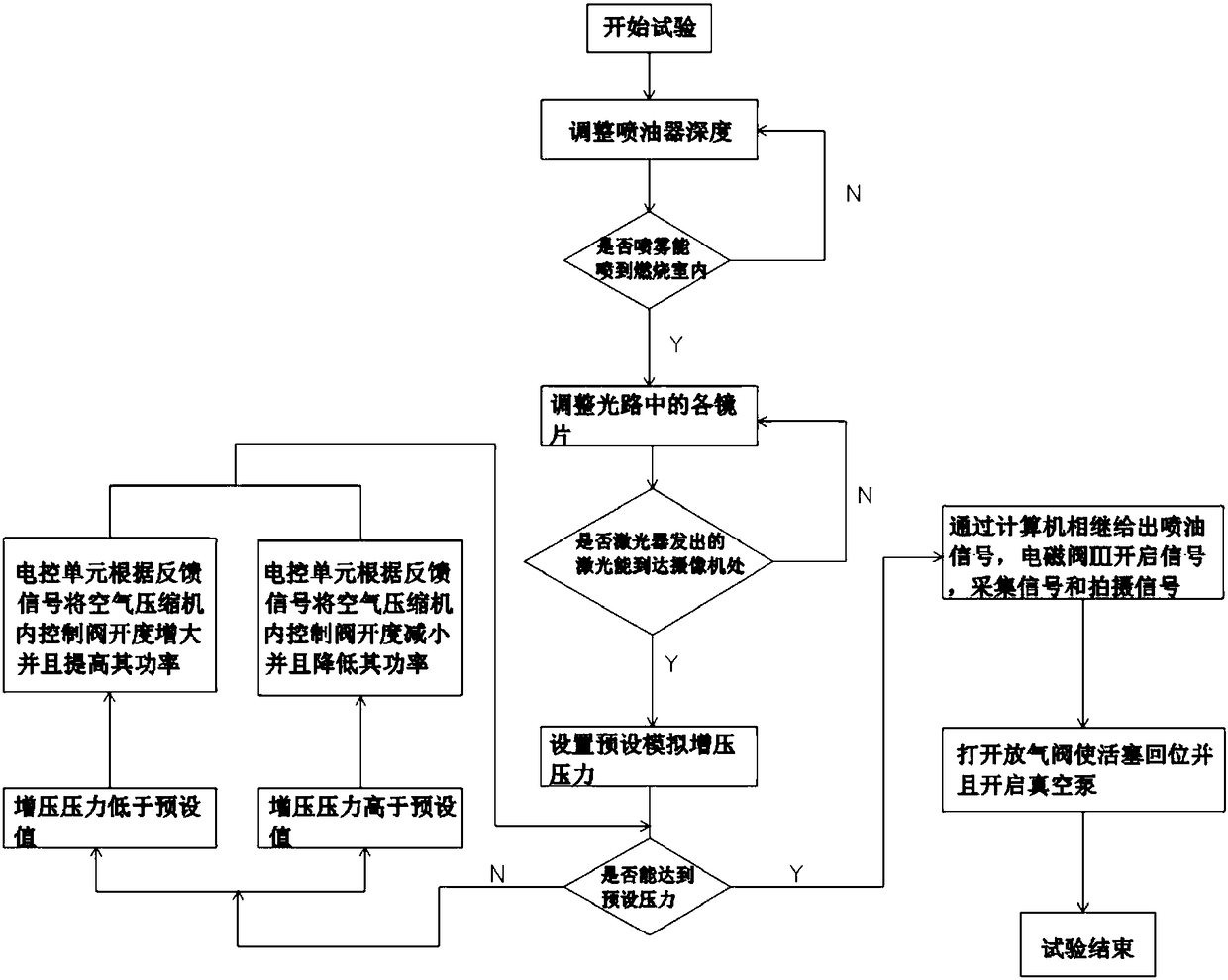

InactiveCN108152044AOptimize fuel injection strategyEasy to analyzeInternal-combustion engine testingCombustionTop dead center

The invention discloses a device and method for simulating the influence of a two-stage supercharging pressure end / vortex end bypass on spray characteristics. The device comprises a pressure end bypass simulation system, a variable volume combustion bomb device and a spray photographing system. The influence of the pressure end / vortex end bypass on atomization, mixing, development history, concentration distribution and microscopic properties can be studied in a variable volume combustion bomb by using a composite laser induced fluorescence technology. According to the device and method, the influence of the pressure end / vortex end bypass on the spray characteristics when a piston approaches a top dead center can be realistically simulated, and a theoretical data support is provided for anin-depth study that spray atomization and mixing are improved after the pressure end / vortex end bypass is adopted to achieve efficient clean combustion.

Owner:XIHUA UNIV

Vehicular oil heater spray atomization type oil fuel pump test device

The present invention provides a oil heater inject atomizing type oil fuel pump test device for automobile which includes D. C. motor, fuel tank, grease collector, fuel recovery tube, fuel consumption measuring apparatus, non-return electromagnetic valve, one-way bi-pass electromagnetic valves, three way electromagnetic valve and control circuit; D. C. motor with powermeter, electrical machine shaft with speedometer; Fuel tank, fuel consumption measuring apparatus, non-return electromagnetic valve, fuel circulate tank, fuel filter, one-way bi-pass electromagnetic valves are connected in sequence; Three way electromagnetic valve is communicated with fuel tank and is connected with fuel circulate tank; oil-out of grease collector is communicated with fuel tank; each electromagnetic valve and instrumentation is electrically connected with control circuit. The present invention can execute full experiment to pump oil mass of oil heater oil fuel pump for automobile , amount of fuel delivered, oil spout pressure, vacuum degree, oil pump rotary speed and elapsed power etc, and also can obtain various characteristic of oil fuel pump in different rotary speed.

Owner:SHANDONG UNIV

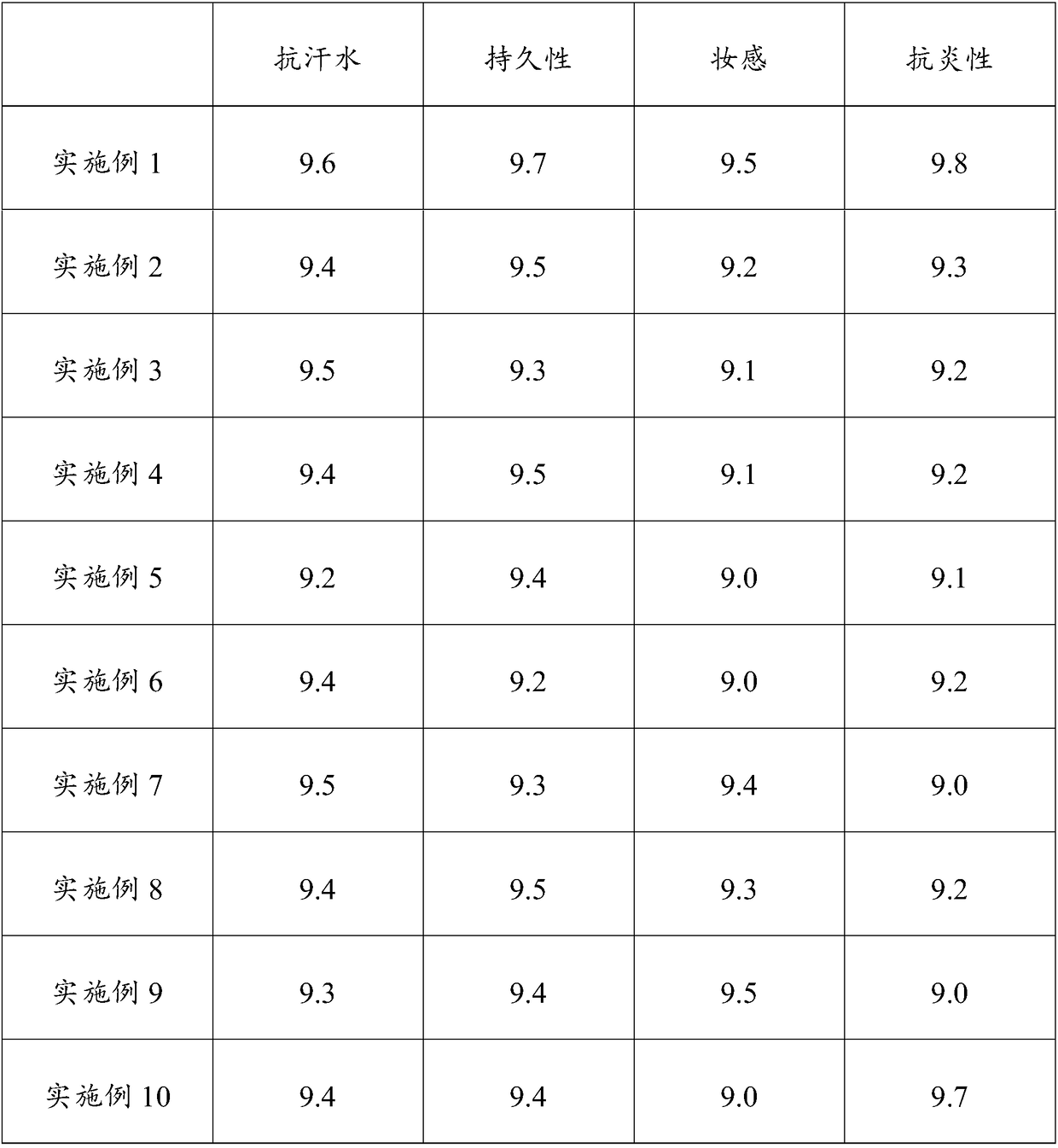

Fixed makeup spray with isolating and repairing functions and preparation method thereof

ActiveCN109260028AImprove functionalityImprove atomization effectCosmetic preparationsMake-upPreservativeAdditive ingredient

The invention discloses a fixed makeup spray with isolating and repairing functions and preparation method thereof, the fixed makeup spray comprises the following components in parts by weight: 0.2 to7 parts of spray, 0.8 to 11 parts of effective active ingredient, 81 to 100 parts of solvent, 0.3 to 11 parts of film forming agent, 0.1 to 1 part of preservative, 0.01 to 1.5 parts of pH regulator,0.05 to 1 part of chelating agent and 0.1 to 5 parts of moisturizing agent; the fixed makeup spray of the invention has good functionality, can meet the daily makeup-fixing requirements, and simultaneously overcomes the inconvenience of the makeup-fixing powder. The spray is simple and convenient, and can be fixed as long as the makeup is sprayed, and the makeup bag is not filled with the powder everywhere, and the functional active ingredient added by the invention can also play certain roles of isolation and repair, etc. A spray agent and other ingredients are added, so that the spray atomization effect is better, and the makeup feeling is better.

Owner:I&B GUANGZHOU BIOLOGICAL TECH CO LTD

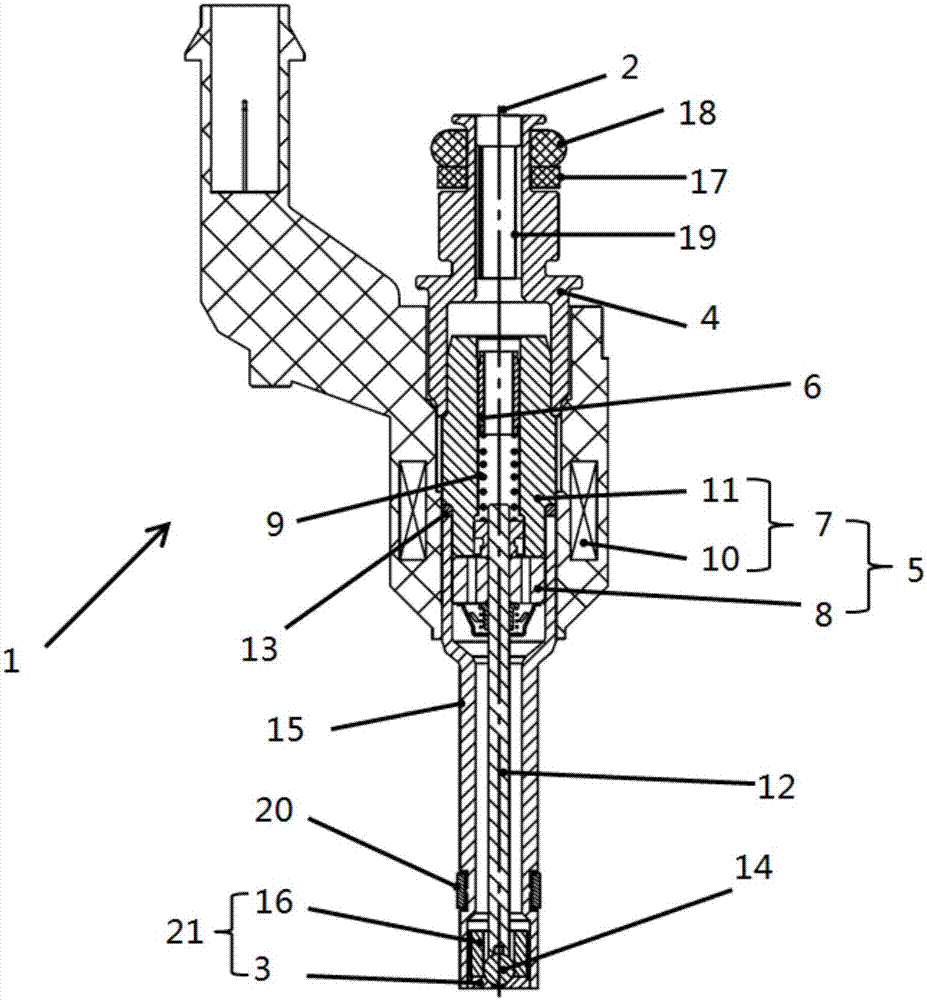

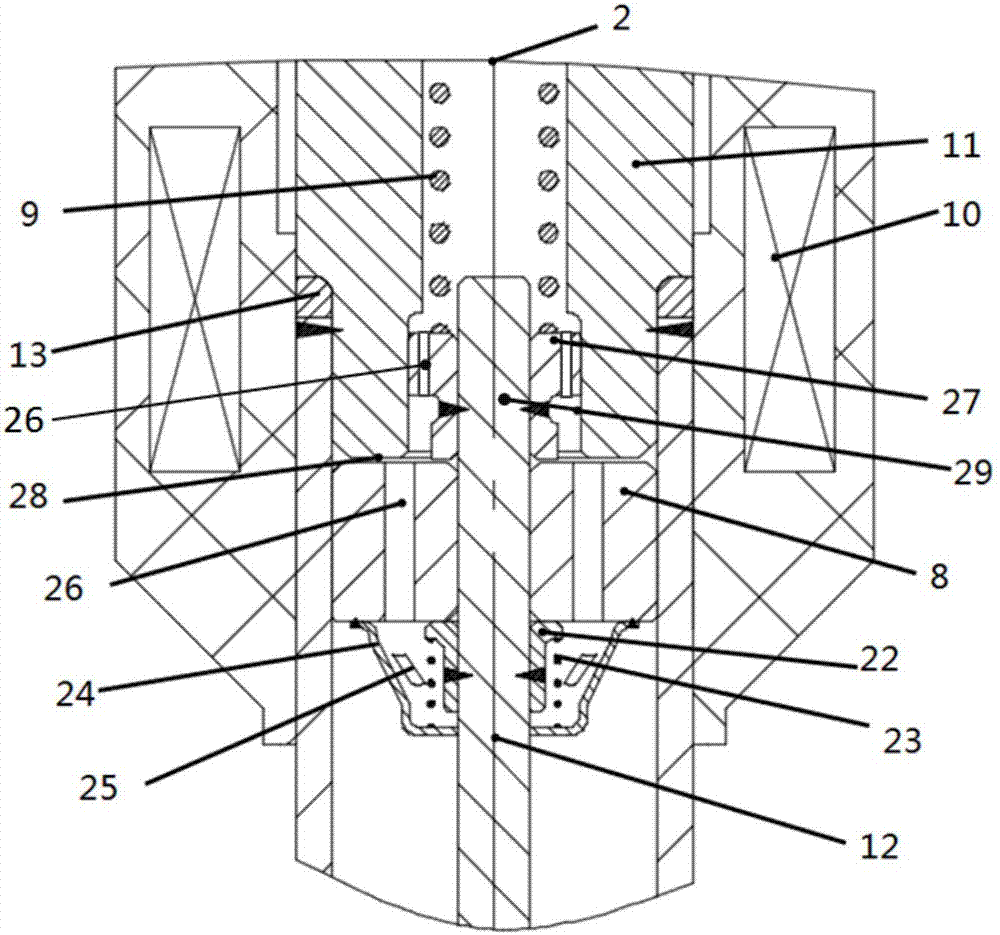

Vortex ejector

PendingCN106894930ALow priceSimple structureValve arrangementsExhaust apparatusInterference fitSpray atomization

The invention relates to a vortex ejector which comprises a tubular shell, an ejection switching valve, a ball valve, a valve rod, an electromagnetic valve assembly and a main spring. The shell is formed by welding a vortex ejector shell upper body, a fixed iron core, a vortex ejector shell lower body and an adjusting gasket. The ball valve, the valve rod, the main spring and a damping assembly are arranged in a tube. The ejection switching valve is composed of a valve seat and a guide part. The valve seat is matched with the ball valve, and the outer end face of the valve seat is integrally welded to the vortex ejector shell lower body. The guide part and the vortex ejector shell lower body are in interference fit, and a guide hole is formed in the guide part. The electromagnetic valve assembly can drive the ejection switching valve to control flowing and stopping of liquid flowing through the valve seat and comprises the fixed iron core, a winding coil and an armature, and the main spring is fixed in the fixed iron core. The valve rod can slide along the axis relative to the fixed iron core. The vortex ejector has the beneficial effects that the price is low, the structure is simple, the machining technology is simple, and the electromagnetic valve and the ejection valve are assembled in a split manner; and the vortex ejector is accurate in ejection and good in spray atomization quality.

Owner:CHINA FIRST AUTOMOBILE

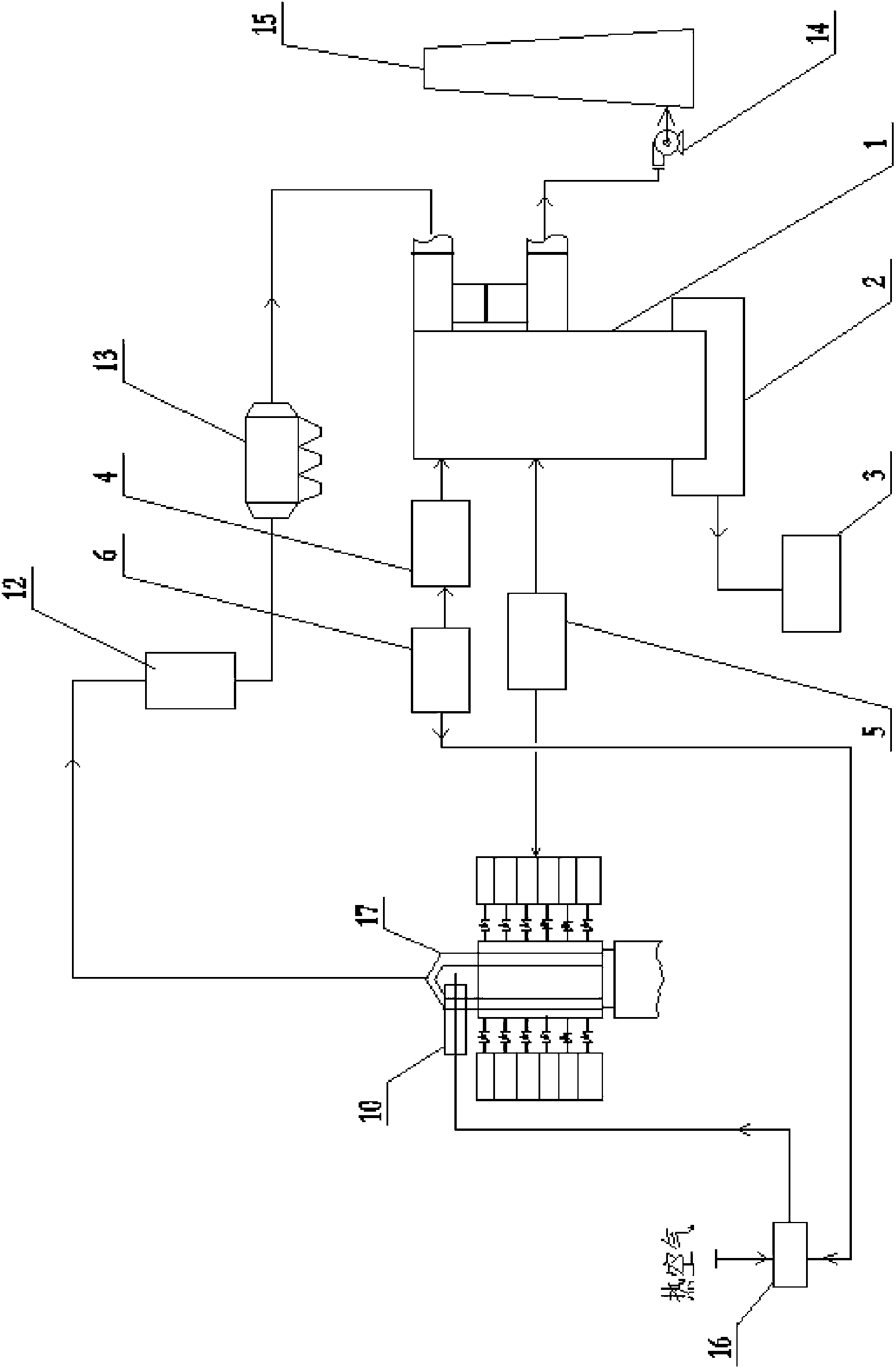

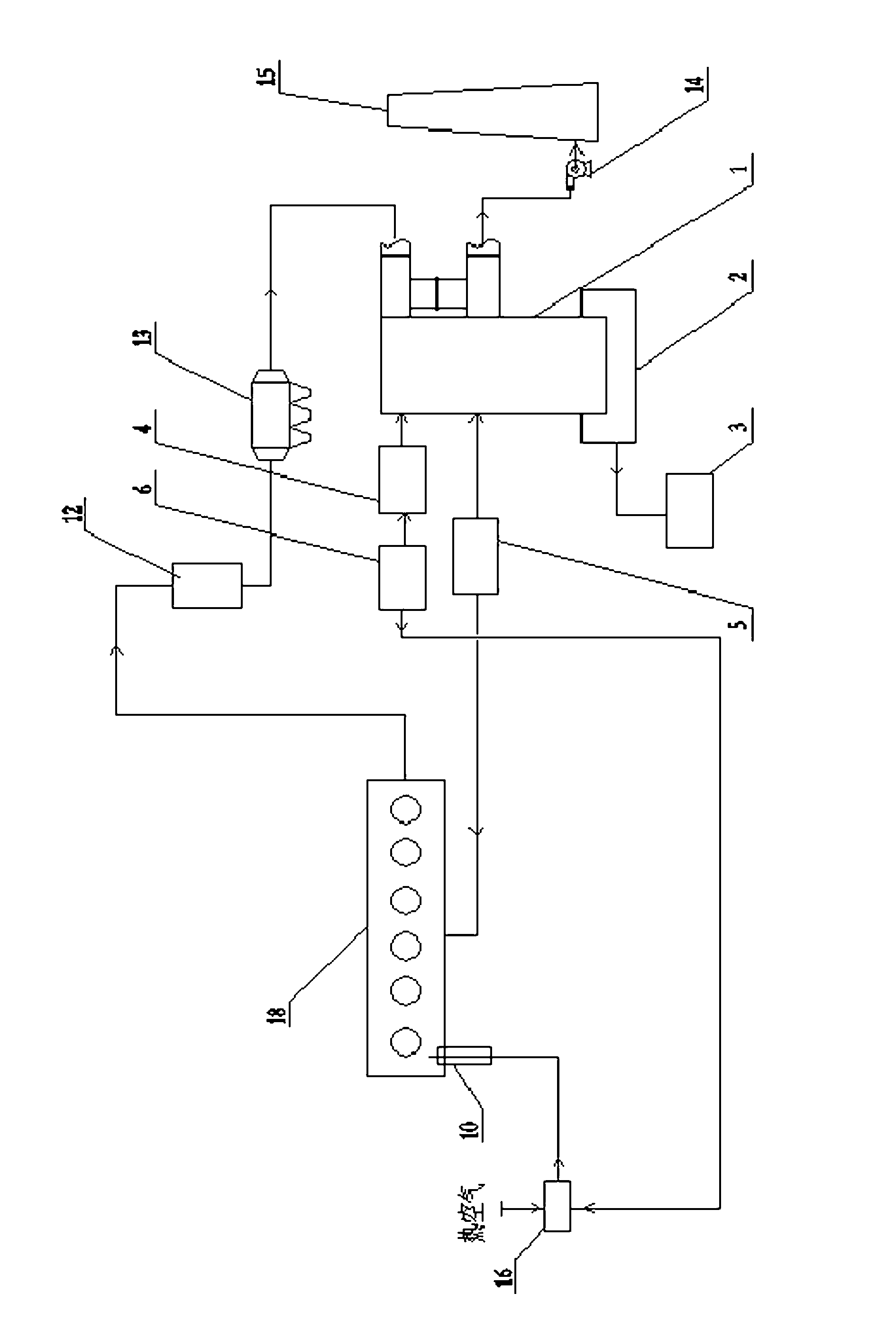

Industrial furnace comprehensive energy saving and emission reduction integrated system

InactiveCN103175408AImprove the combustion environmentReduce coal consumptionDispersed particle separationIndirect carbon-dioxide mitigationDust controlSpray atomization

An industrial furnace comprehensive energy saving and emission reduction integrated system is characterized in that the industrial furnace comprehensive energy saving and emission reduction integrated system is a comprehensive integration integrated system which compounds oxygen-enriched combustion-supporting technology, a selective non-catalytic reduction (SNCR) denitrification method and an oxidation neutralization desulfurization and denitrification dedusting method. The industrial furnace comprehensive energy saving and emission reduction integrated system comprises a waste heat boiler, a deduster, a reducing agent spray atomization device, an oxidation neutralization denitrification reaction tower, an ammonium salt pond, an oxygen-enriched generating device, a wind mixing device, an ozone generating device and an ammonium salt liquid-solid separation device, wherein the waste heat boiler, the deduster, the reducing agent spray atomization device, the oxidation neutralization denitrification reaction tower, the ammonium salt pond, the oxygen-enriched generating device, the wind mixing device, the ozone generating device and the ammonium salt liquid-solid separation device are sequentially connected. The industrial furnace comprehensive energy saving and emission reduction integrated system not only is reasonable in process route and high in desulfurization and denitrification efficiency and combustion efficiency; but also is high in use rates of desulfurization and denitrification absorbent, can effectively reduce consumption of fuel such as fire coal, and improves yield of a furnace. Besides, clinker combusted quality of a cement kiln in an industrial furnace can be effectively improved, and intensity of cement end products can be improved by 3 to 28 days.

Owner:DALIAN EAST NEW ENERGY DEV

Method for reproducing bamboo willow micro-implants

InactiveCN101849501AReproduce fastNeat emergenceCultivating equipmentsSoilless cultivationReproduction speedTwig

The invention discloses a method for reproducing bamboo willow micro-implants. The method comprises the following steps of: directly shearing micro-implants from bamboo willow twigs; dipping stem bases of the micro-implants into root-striking liquid for 30 seconds; and directly grafting the micro-implants on a seed bed prepared by mixing pearlite and peat soil and humidifying the seed bed by adopting a top-spraying atomization system so that the micro-implants take roots in 3 to 5 days. In the invention, seedling emergence is uniform and key points are easy to master; the method is low in cost and hardly influenced by external climate factors and can be carried out all the year round; the micro-implants are adopted, so a ratio of reproduction coefficient is increased by 8 to 10 times; and the method can quickly improve reproduction speed of the bamboo willow, is easy to operate in a standardized way and has high seedling quality and a short reproduction period.

Owner:江苏森茂生态科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com