Coal-fired boiler flue gas environmentally-friendly deep treatment method and apparatus

A coal-fired boiler and flue gas technology, which is applied in the direction of combined devices, gas treatment, separation methods, etc., can solve the problems of high operating cost, large resource waste, and high operating cost, and achieve safe and stable operation of the economy, reduce coal-burning costs, Effect of running cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

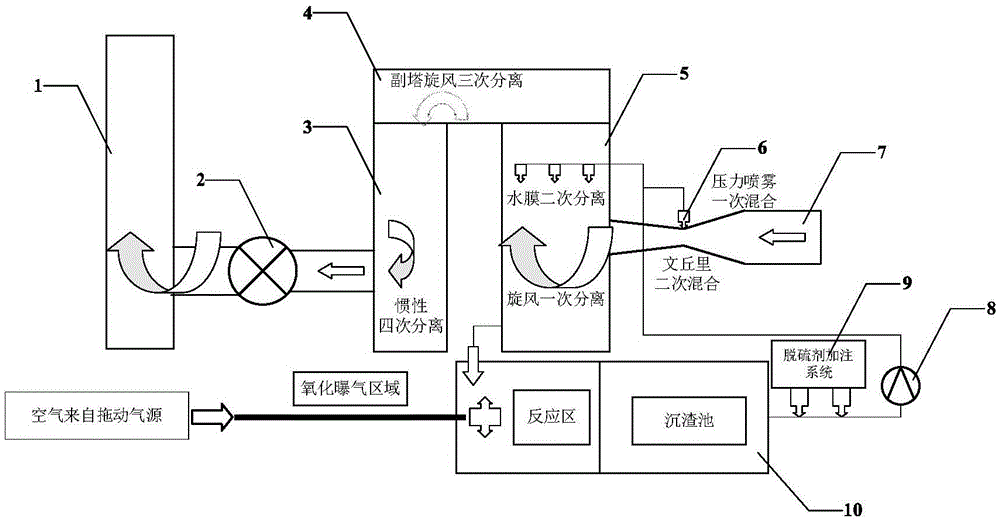

[0052] The method for environmental protection and deep treatment of coal-fired boiler flue gas, the specific steps are as follows: 1. The flue gas from the coal-fired boiler enters the Venturi tube after preliminary treatment, and the detergent passes through the pressure nozzle (6) at the front end of the Venturi tube throat Spray into the Venturi tube (7), and the detergent is sprayed and atomized by the pressure nozzle and fully mixed with the flue gas at one time; There is a speed difference between the flue gas, the ash particles and the detergent, and they undergo a second full mixing and absorption reaction through mutual shearing; 3. The flue gas discharged from the Venturi tube rotates at a high speed and tangentially enters the main tower of the stone water film dust collector (5) Carry out cyclone primary separation, ash, water phase and impurity are absorbed by water film for the second time along the wall; 4. The separated flue gas enters the sub-tower pipe (4) of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com