Vehicular oil heater spray atomization type oil fuel pump test device

A fuel heater, spray atomization technology, applied in the direction of fuel injection device, measurement device, testing of machine/structural components, etc., can solve problems such as unfavorable development of fuel heater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

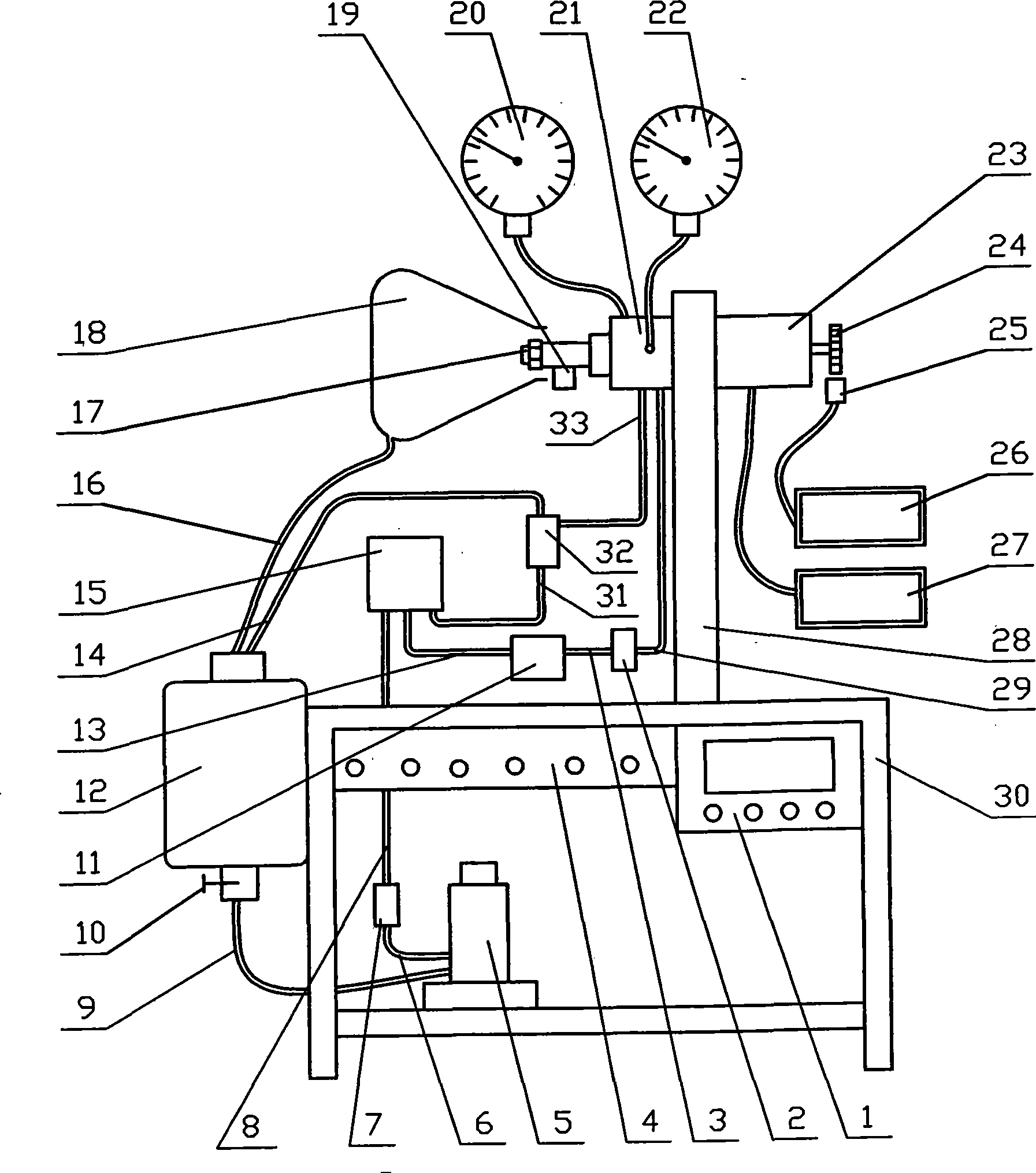

[0010] Accompanying drawing has provided the structural representation of the present invention. The present invention mainly includes a DC motor 23, a fuel tank 12, a fuel circulation tank 15, an oil collector 18 made of transparent glass, a fuel recovery pipe 16, a fuel consumption measuring instrument 5, a check solenoid valve 7, and a one-way two-way solenoid valve 2 and three-way solenoid valve 32. In addition, it also includes a fixed platform 30 for installing various parts, the DC motor 23 is installed on the bracket 28 on the fixed platform 30, the fuel consumption measuring instrument 5, the fuel circulation tank 15 and the fuel tank 12 are all installed on the fixed platform 30, An adjustable DC stabilized power supply 1 and a control circuit board 4 for supplying power to the DC motor 23 are also installed on the fixed platform 30 . During the test, the fuel pump 21 was connected to the motor shaft of the DC motor 23 through a sleeve coupling. The DC motor 23 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com