Functional spraying and combustion visualization measuring constant volume bomb

A constant-volume bomb and multi-functional technology, applied in the field of internal combustion engine research, can solve problems such as damaged sensor threads, different mounting threads, and unusable sensors, and achieve the effects of improving the sealing effect, uniform force in all directions, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

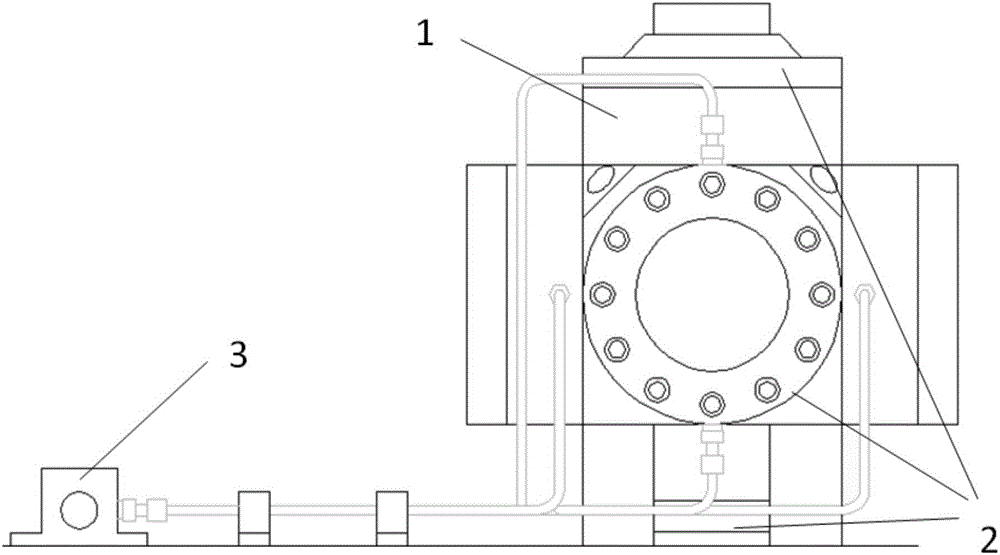

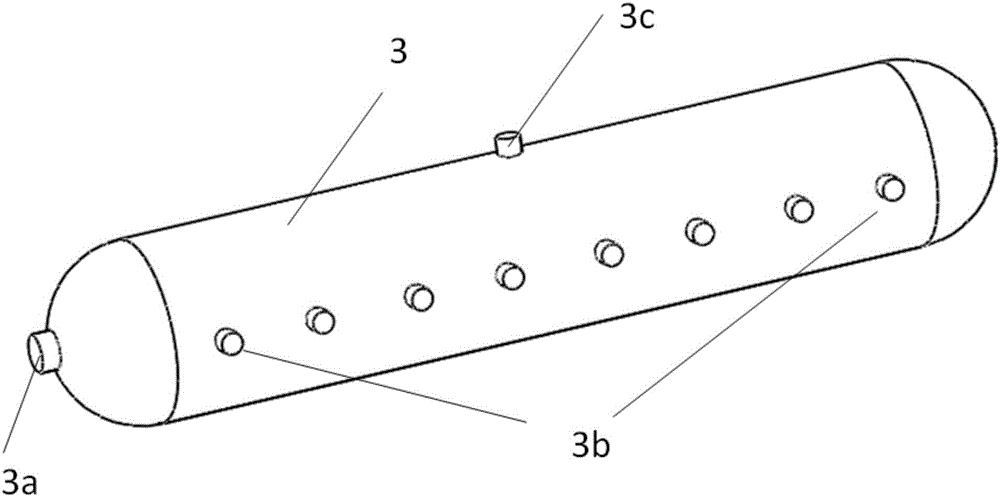

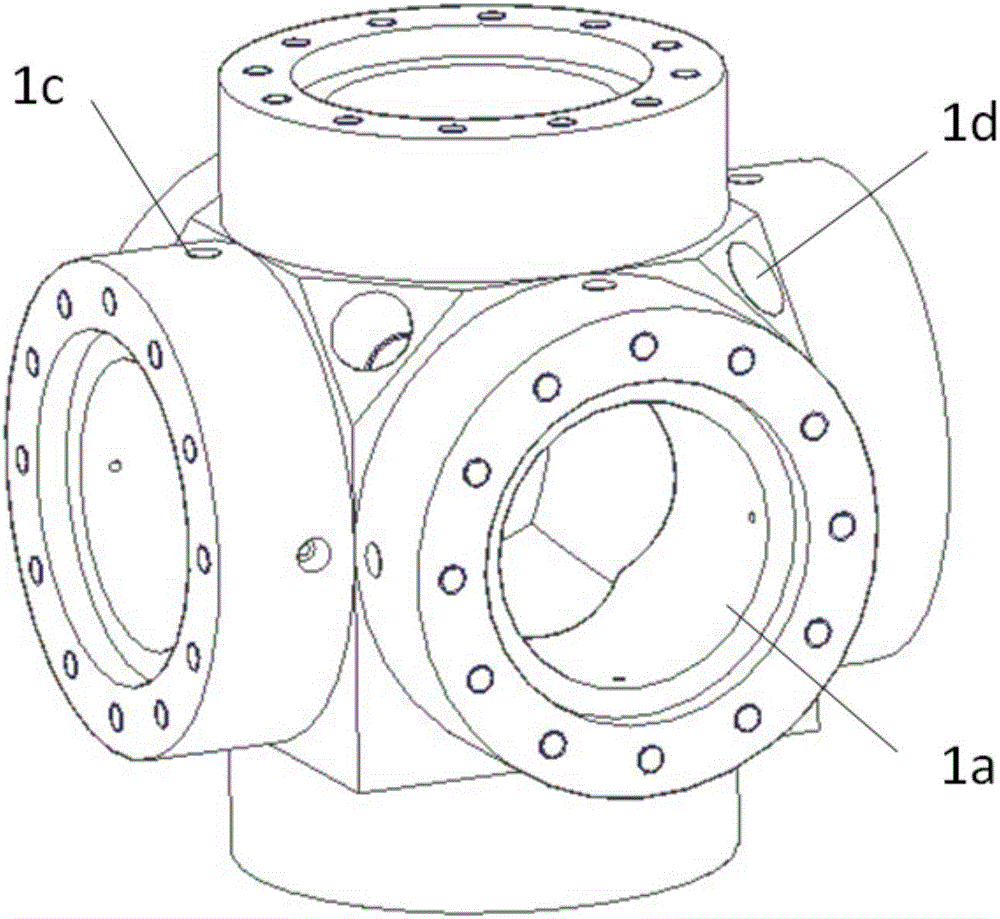

[0042] The present invention provides a multi-functional spray and combustion visual measurement constant volume bomb, the schematic diagram of its appearance is as follows figure 1 As shown, it mainly includes: whether the volume-constant projectile body 1, the adapter cover plate 2 and the air-mixing and stabilizing chamber 3 should be included. The fixed-volume projectile can realize different optical paths and functions by installing different functional adapter covers to fix fuel injectors, electric heaters, quartz glass and other equipment. There is one air inlet 3a, eight air outlets 3b and one pressure gauge installation port 3c on the mixed air pressure stabilizing chamber, which are used to ensure the stability of the inlet pressure, such as figure 2 shown.

[0043] The structure diagram of the constant volume projectile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com